Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

848results about "Sublimation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

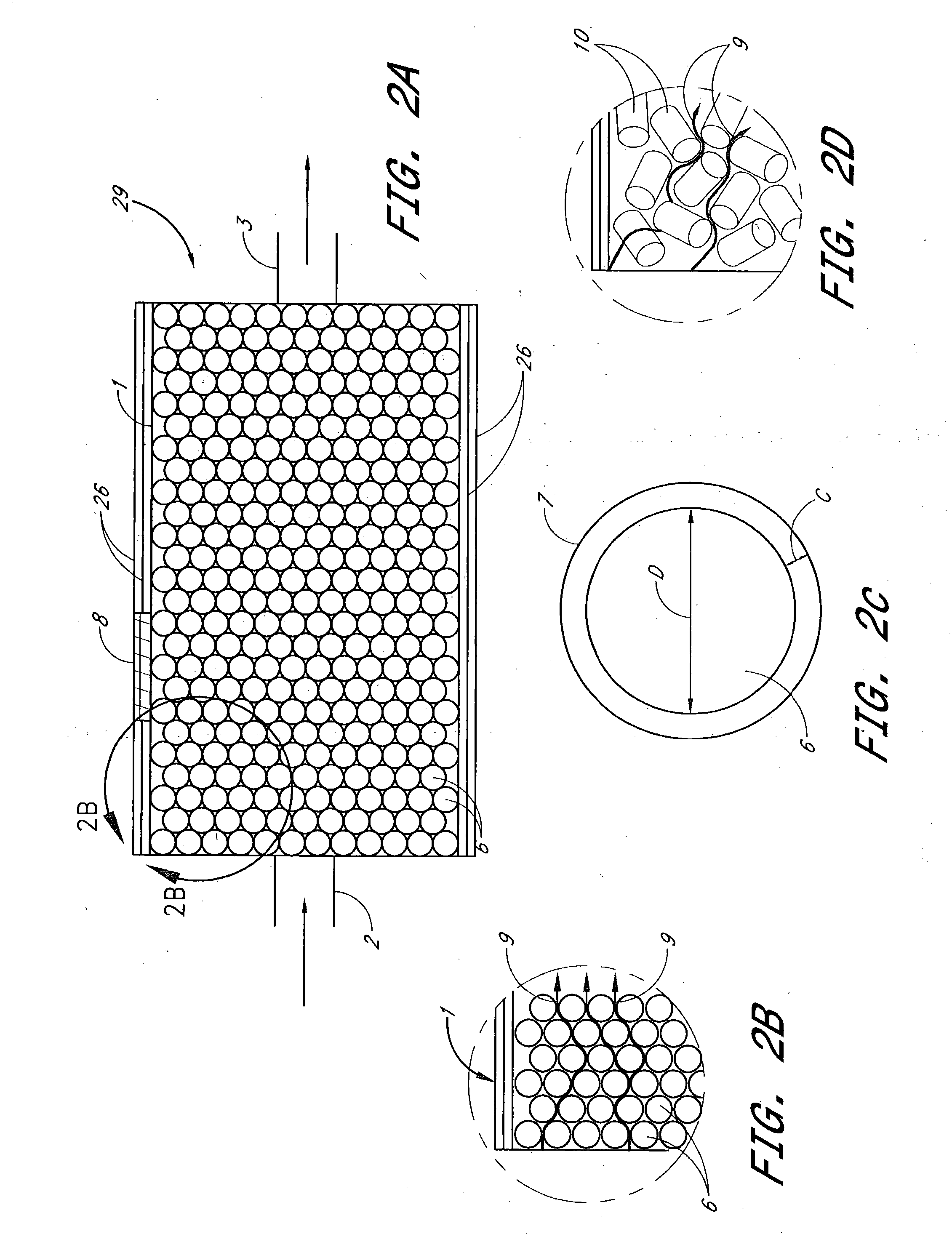

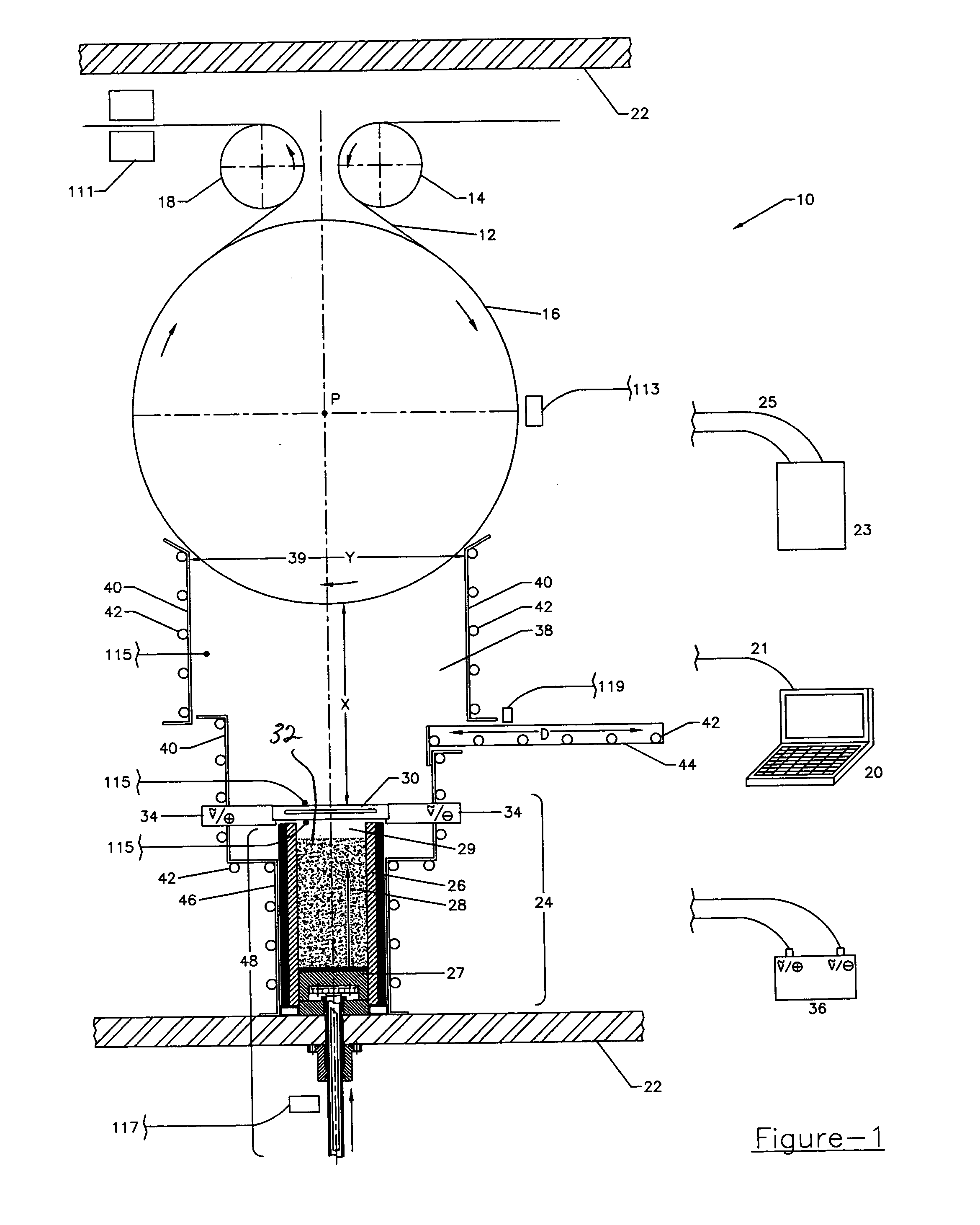

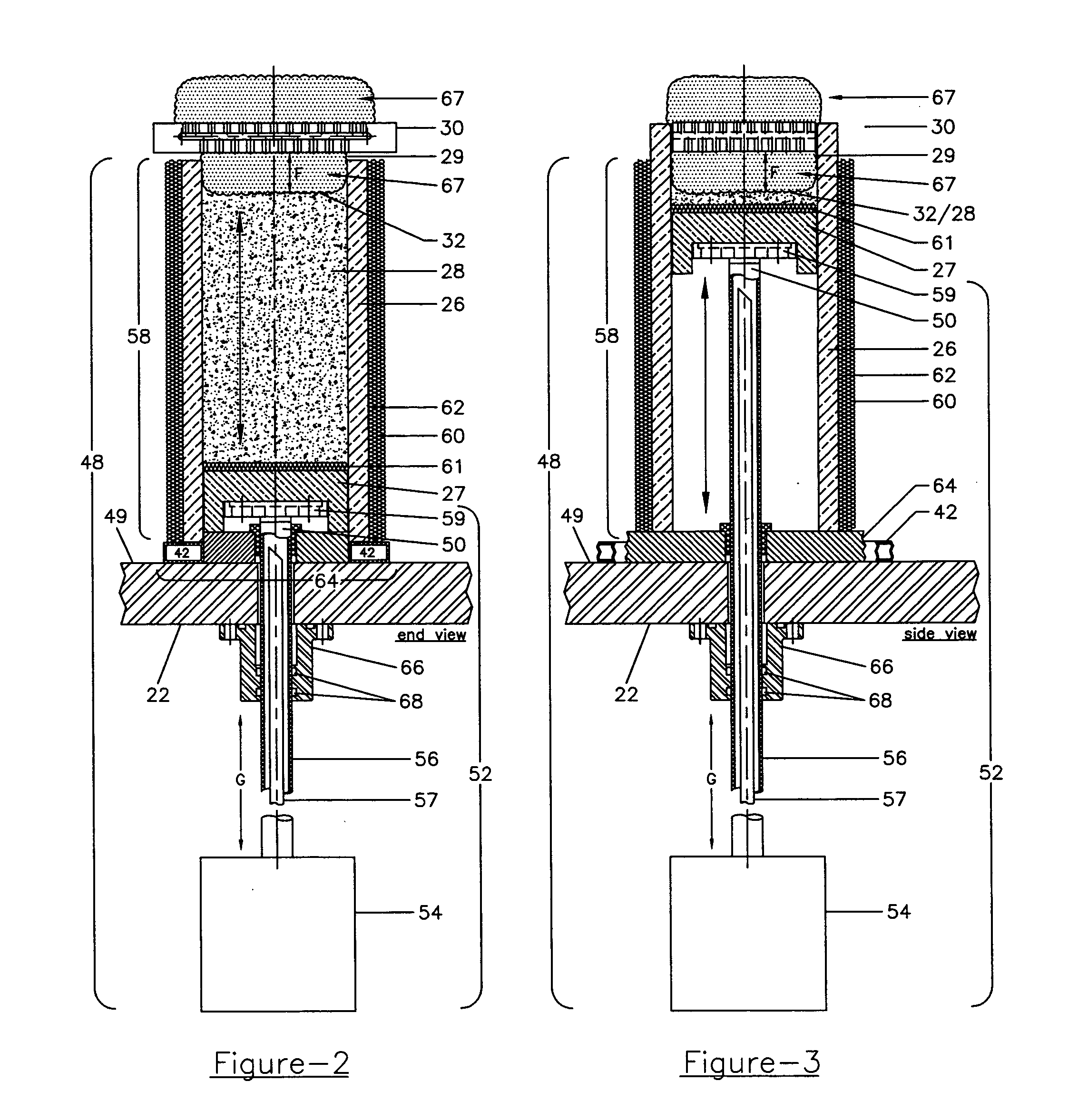

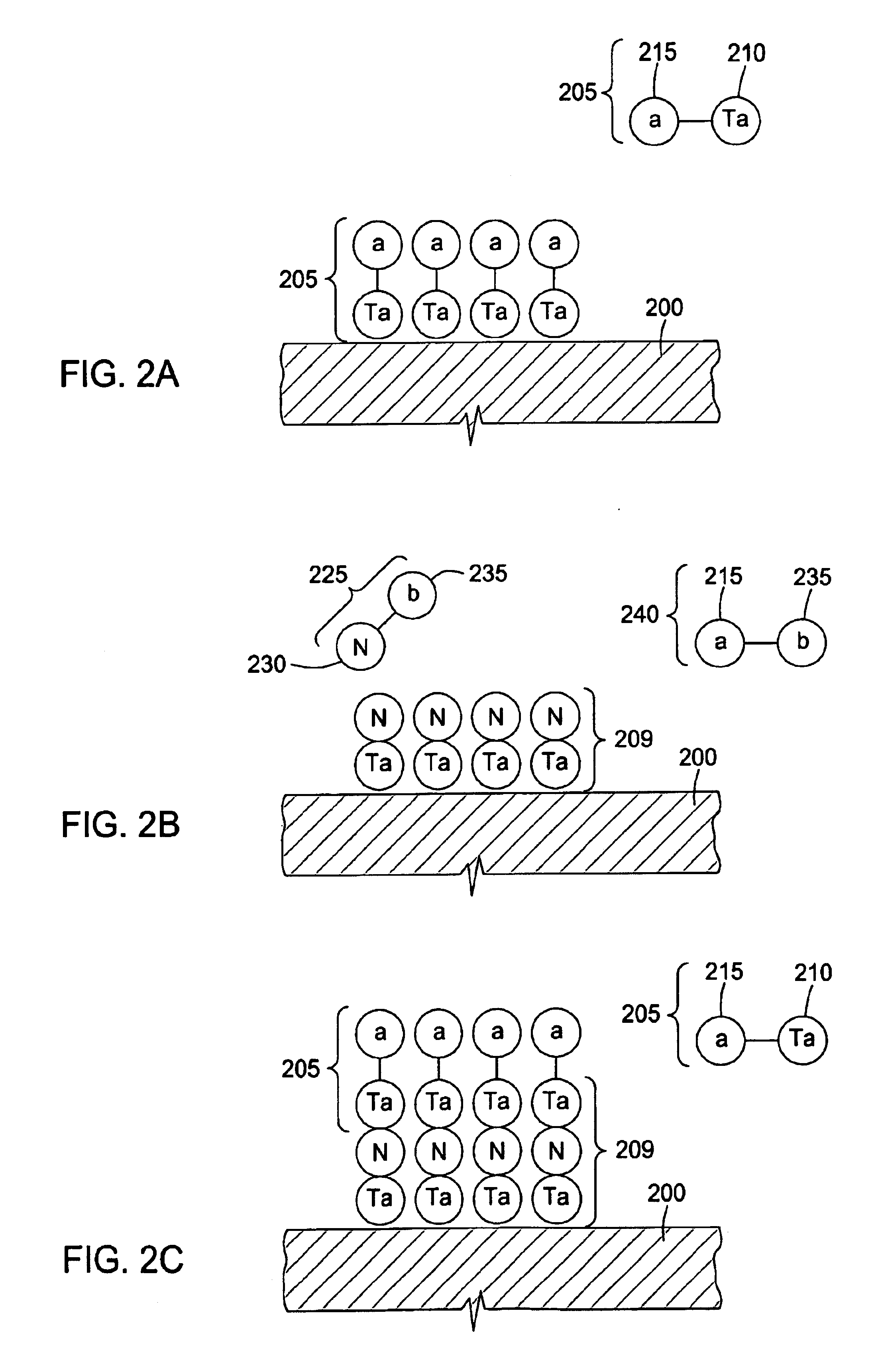

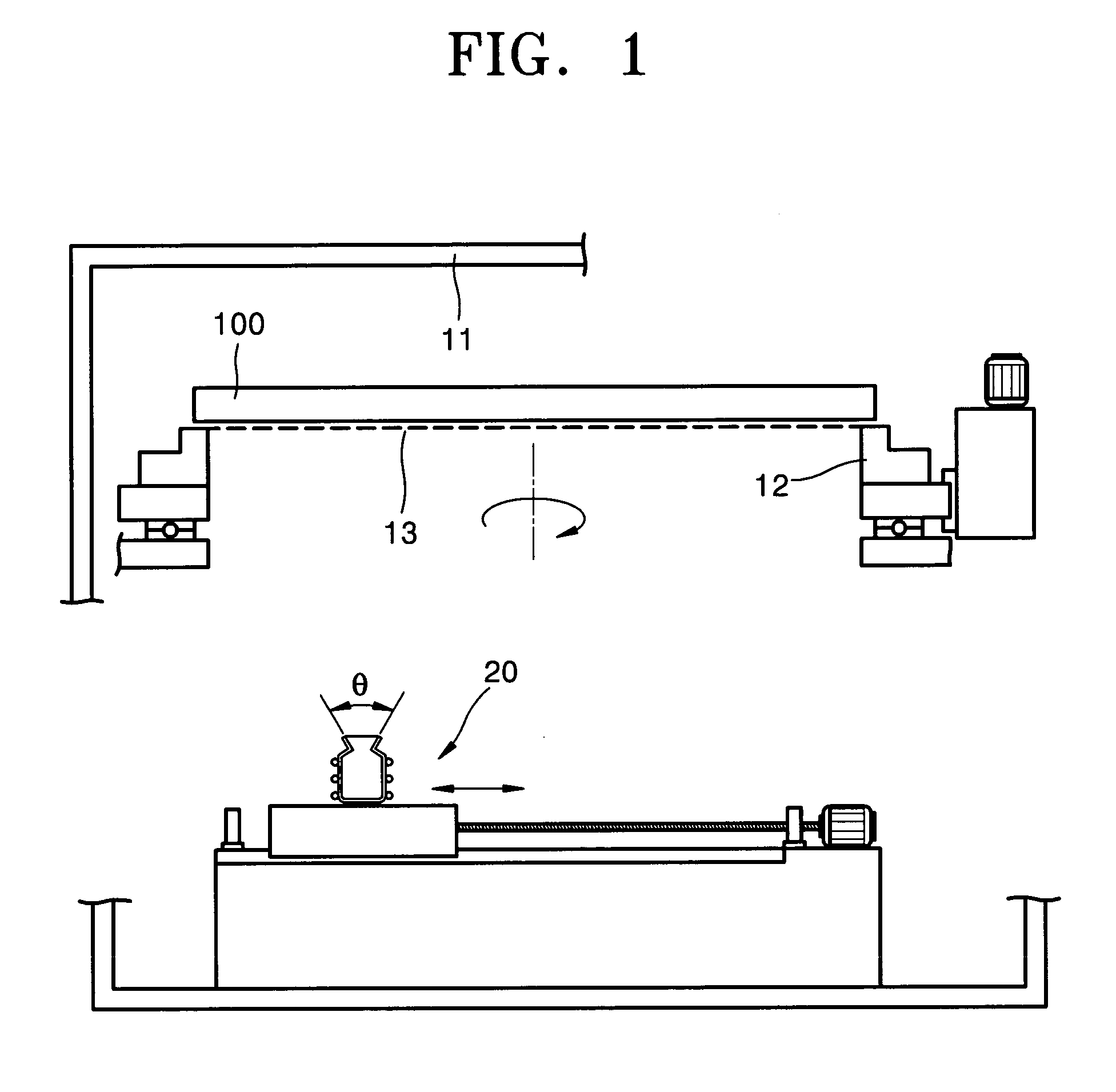

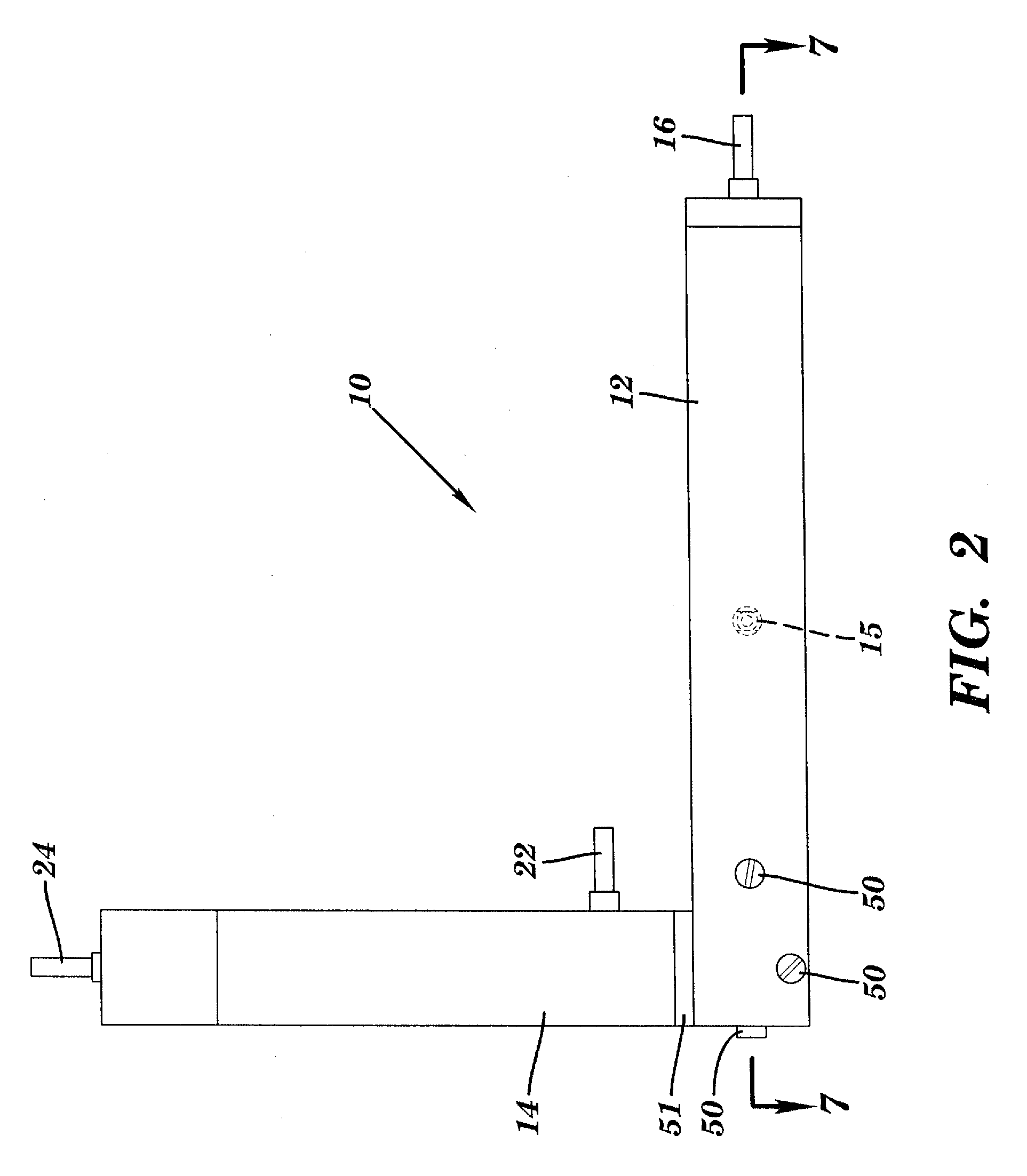

Sublimation bed employing carrier gas guidance structures

ActiveUS20050072357A1Raise the ratioIncrease contact timeLiquid spraying plantsLiquid surface applicatorsSource materialEngineering

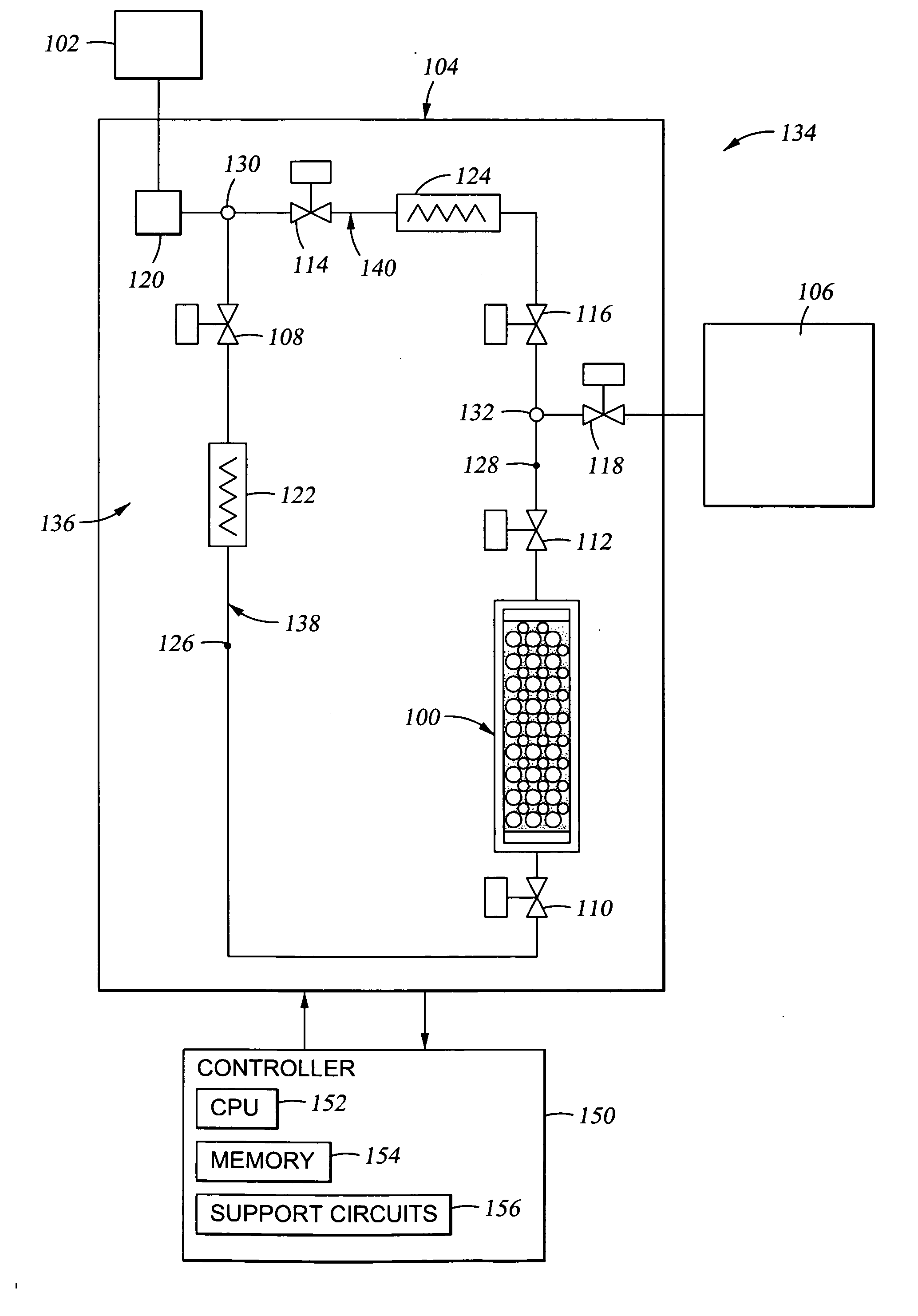

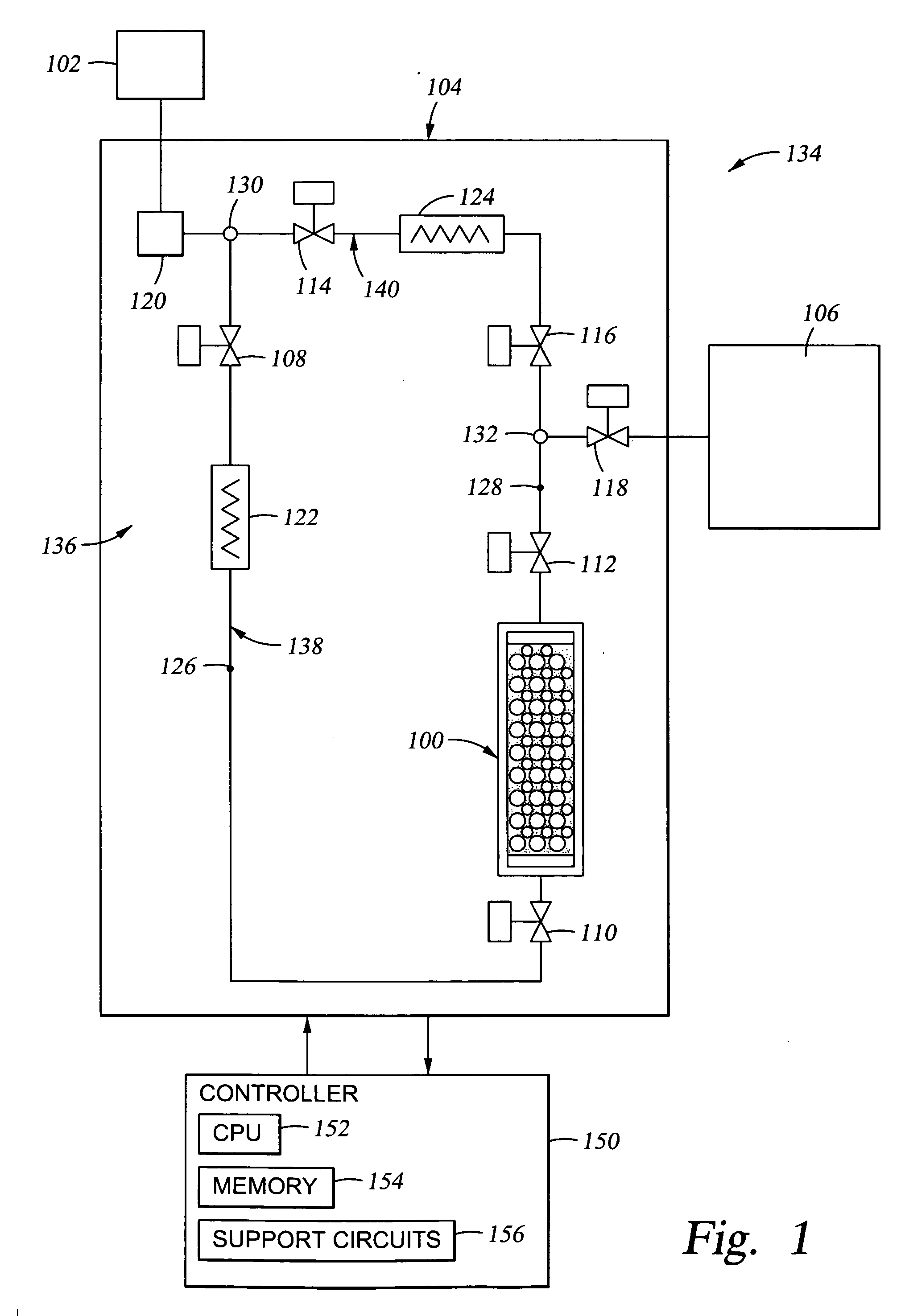

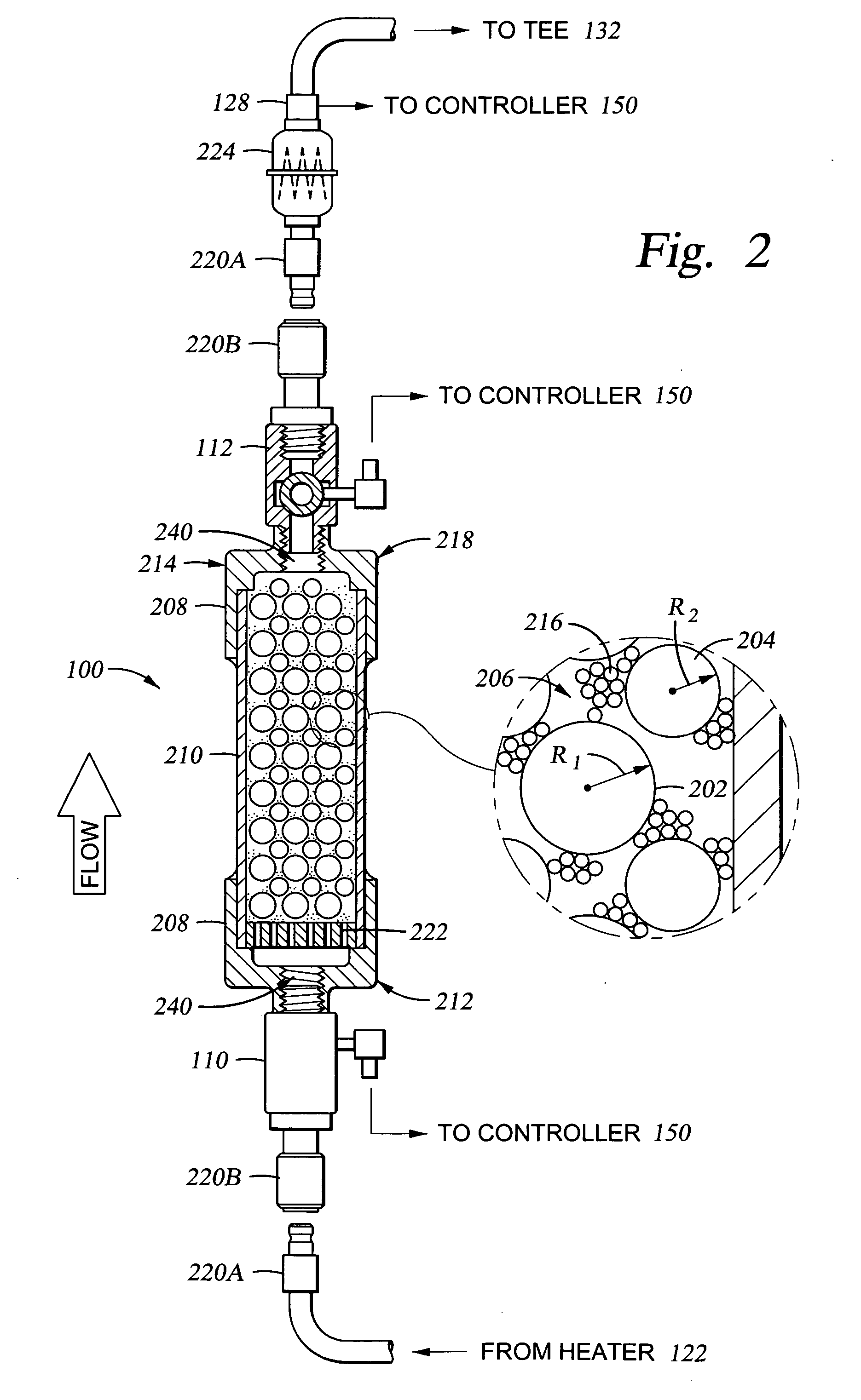

Preferred embodiments of the present invention provides a sublimation system employing guidance structures including certain preferred embodiments having a high surface area support medium onto which a solid source material for vapor reactant is coated. Preferably, a guidance structure is configured to facilitate the repeated saturation of the carrier gas with the solid source for a vapor reactant. Methods of saturating a carrier gas using guidance structures are also provided.

Owner:ASM IP HLDG BV

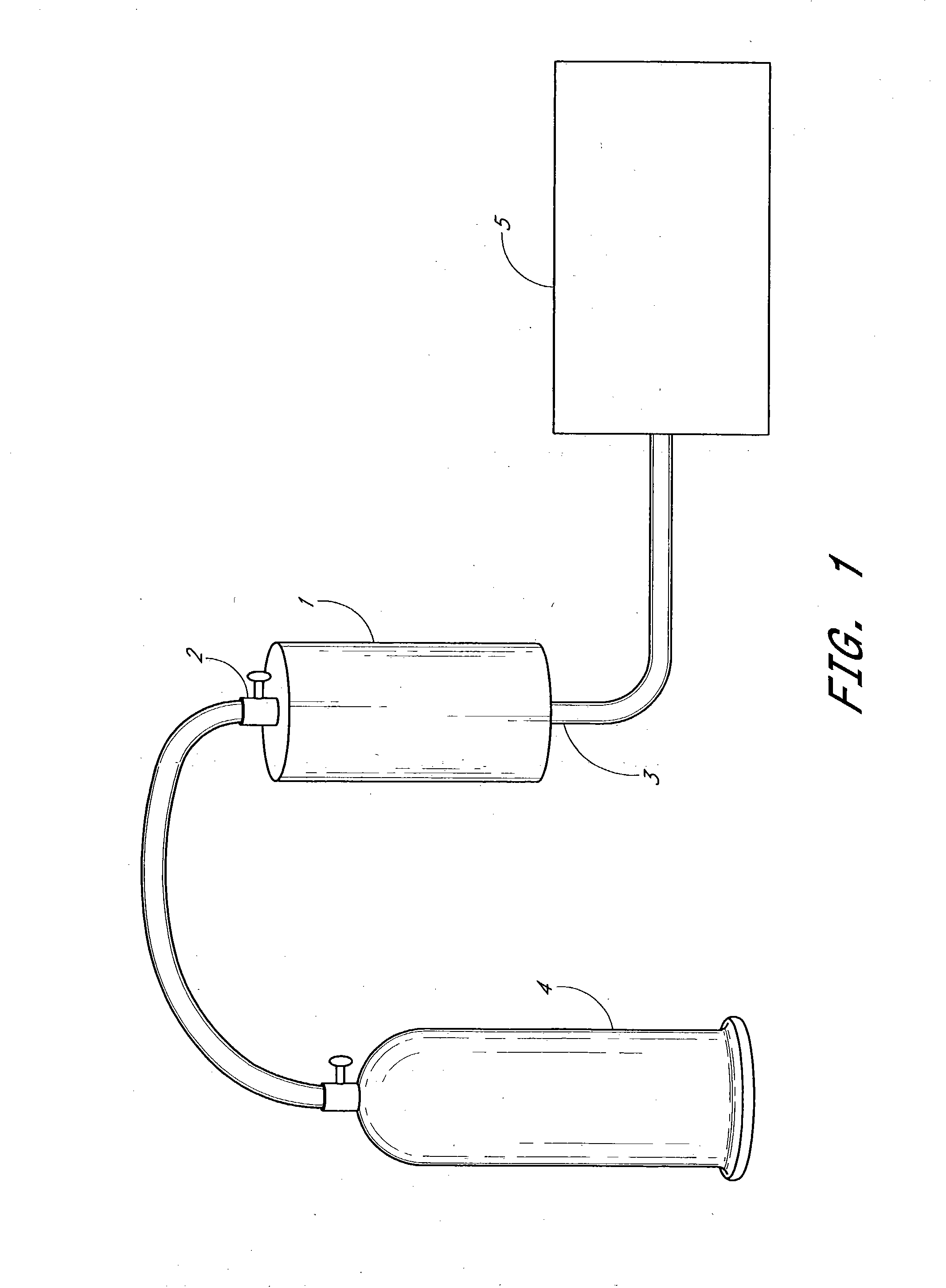

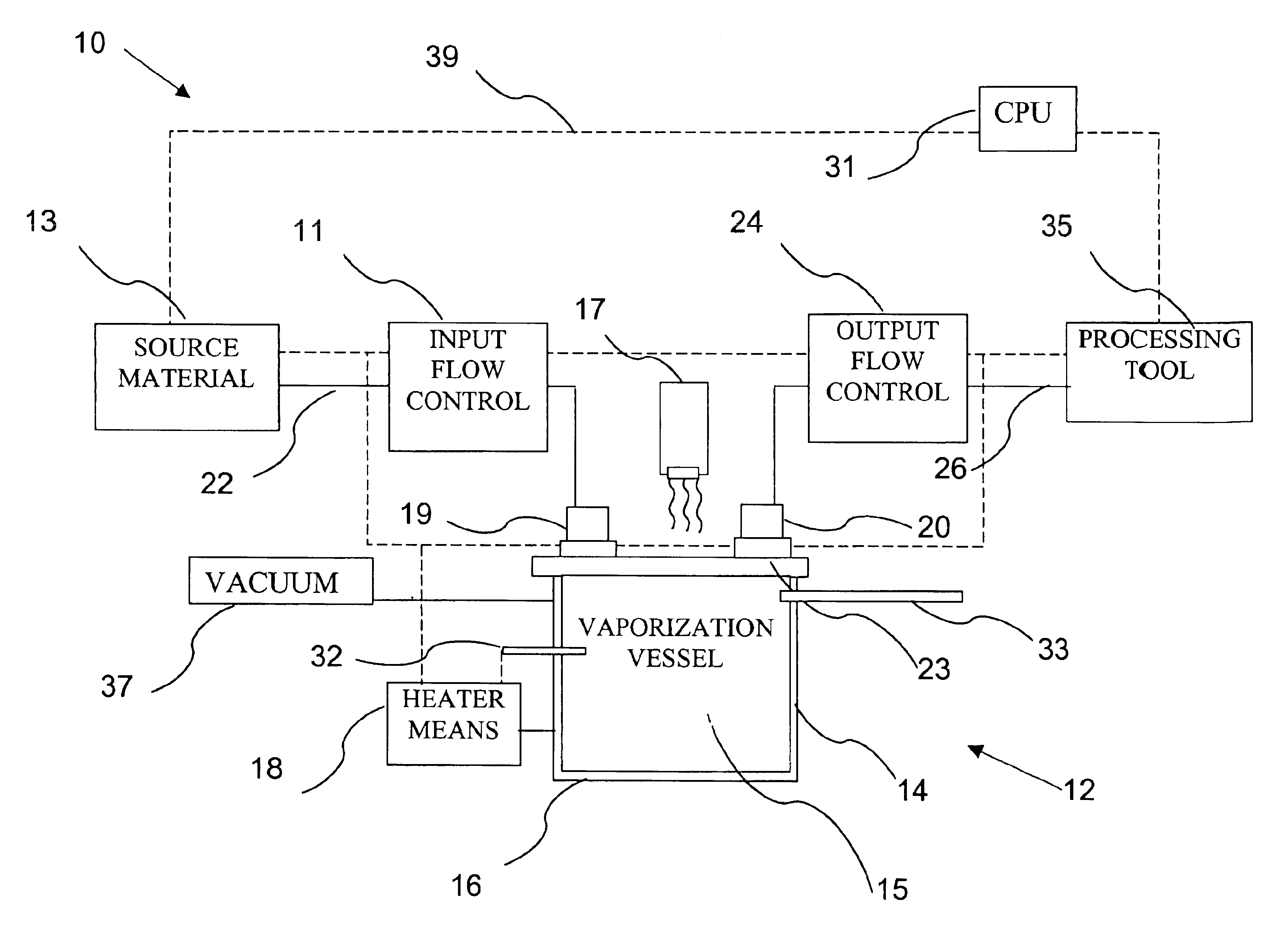

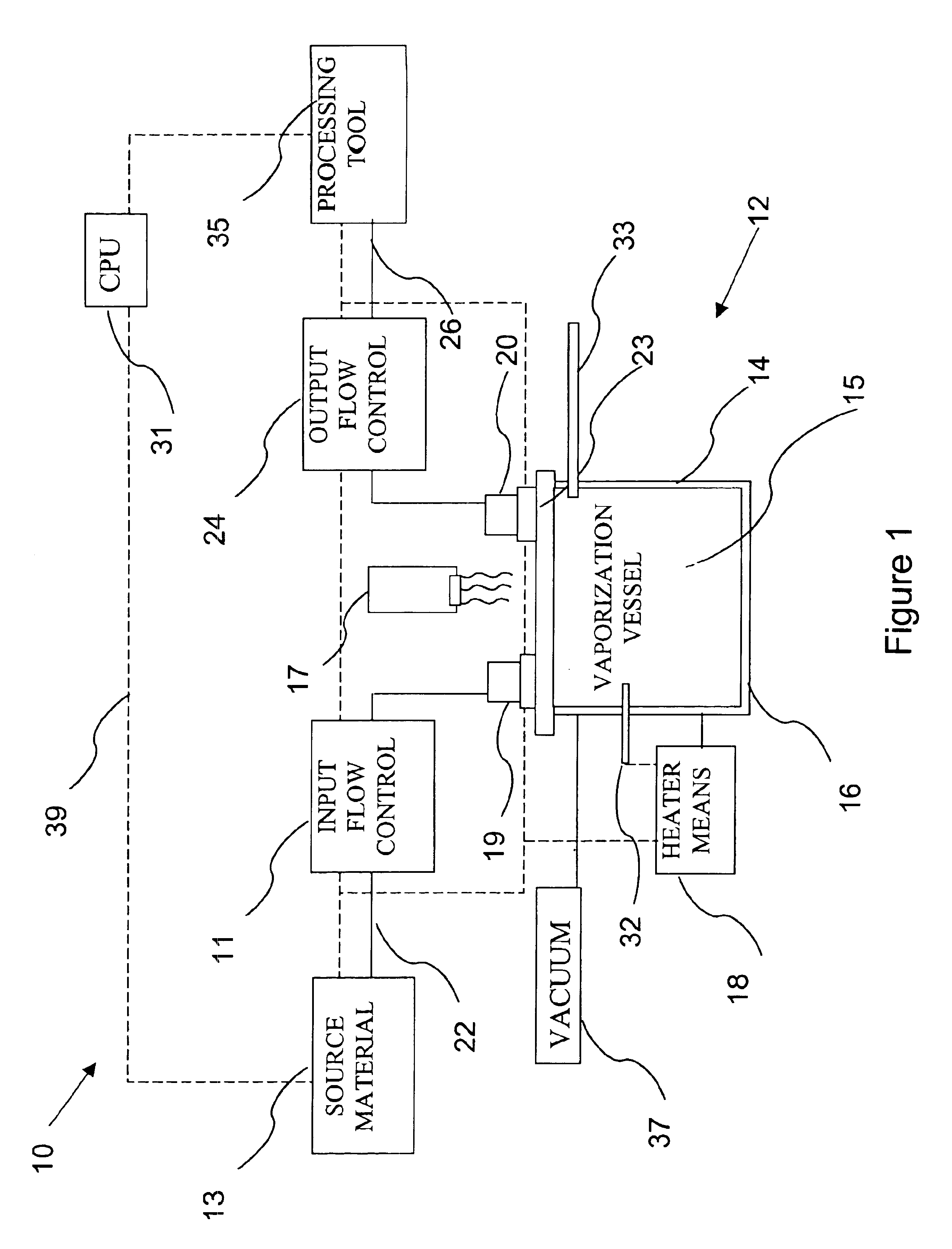

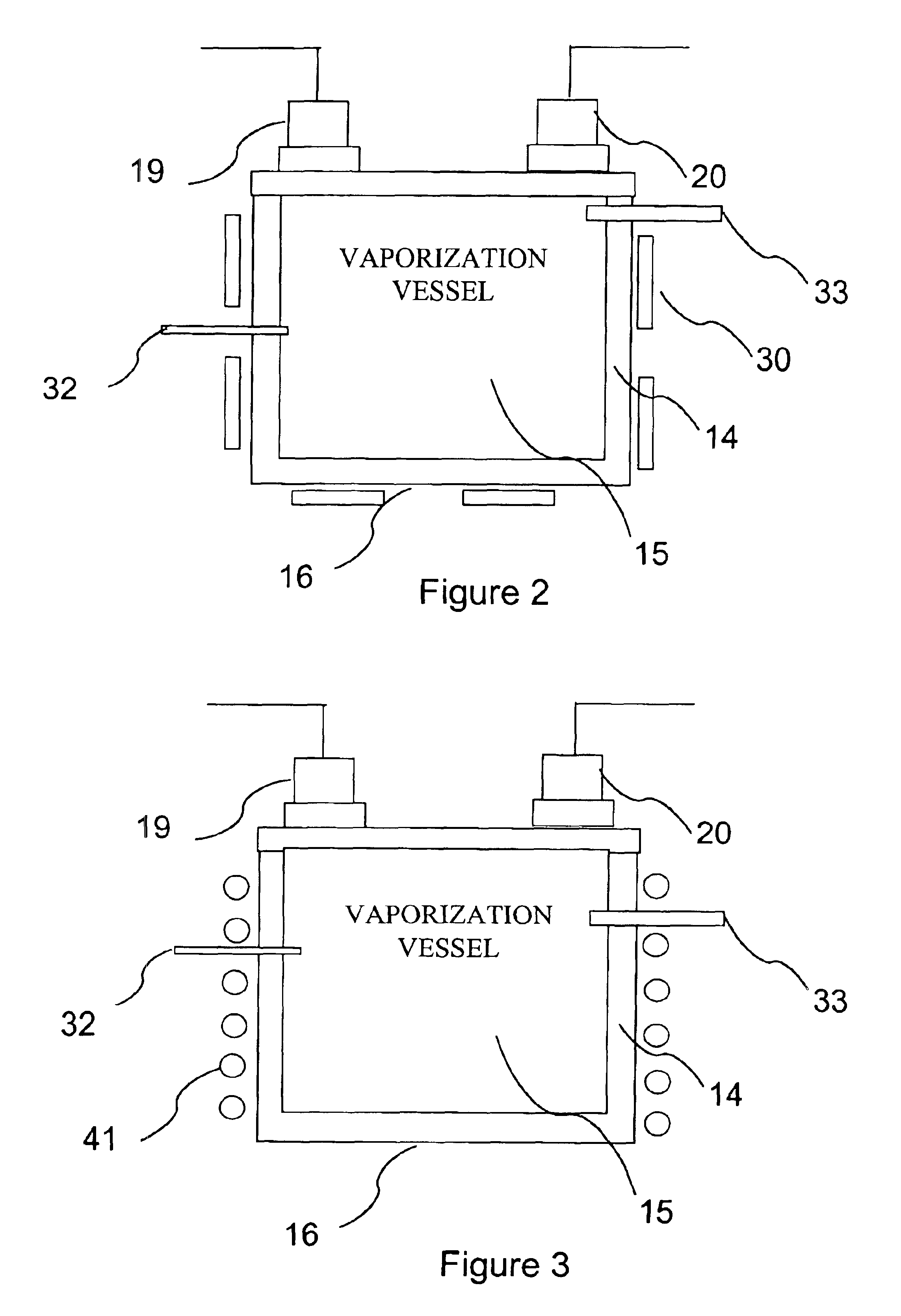

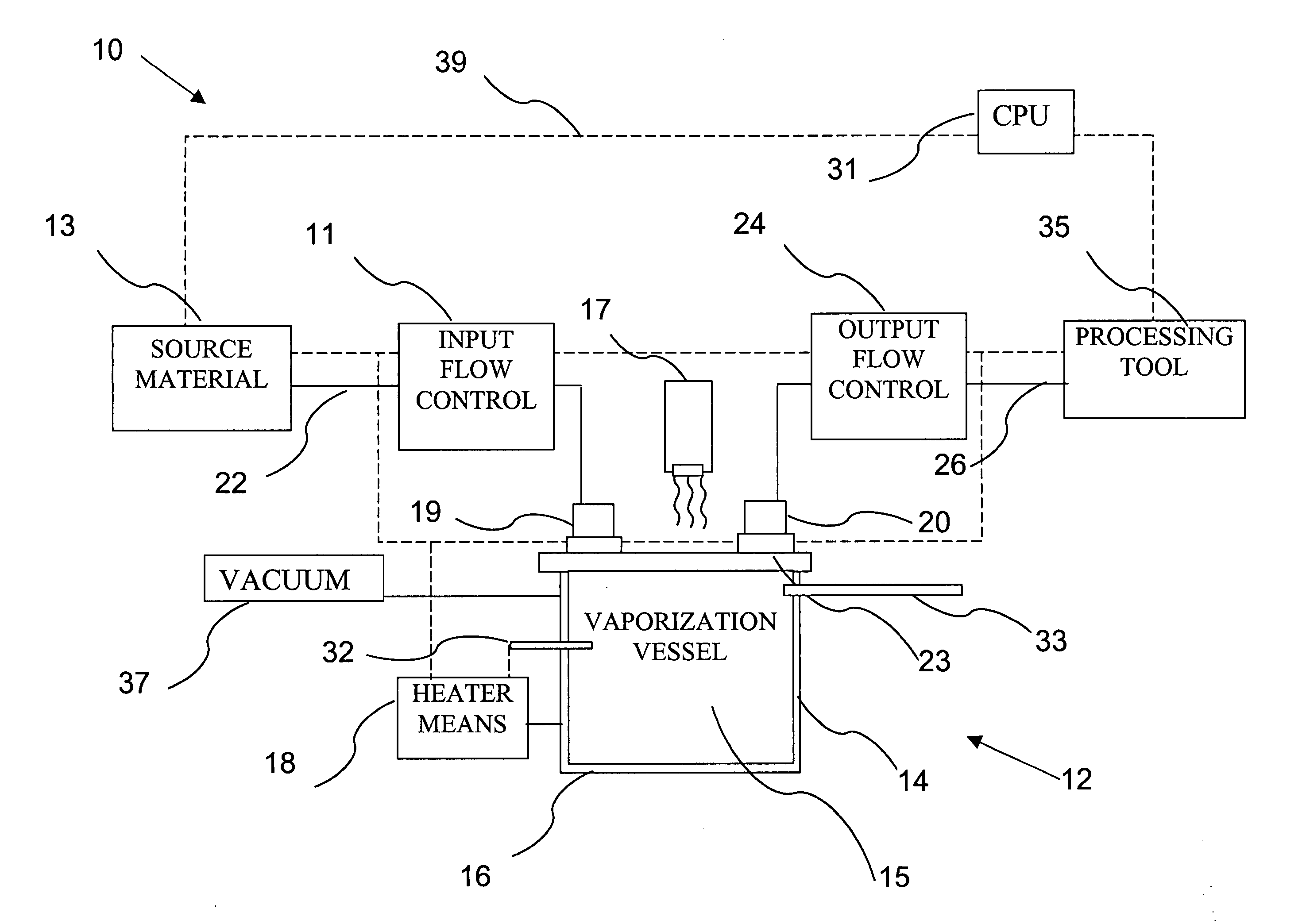

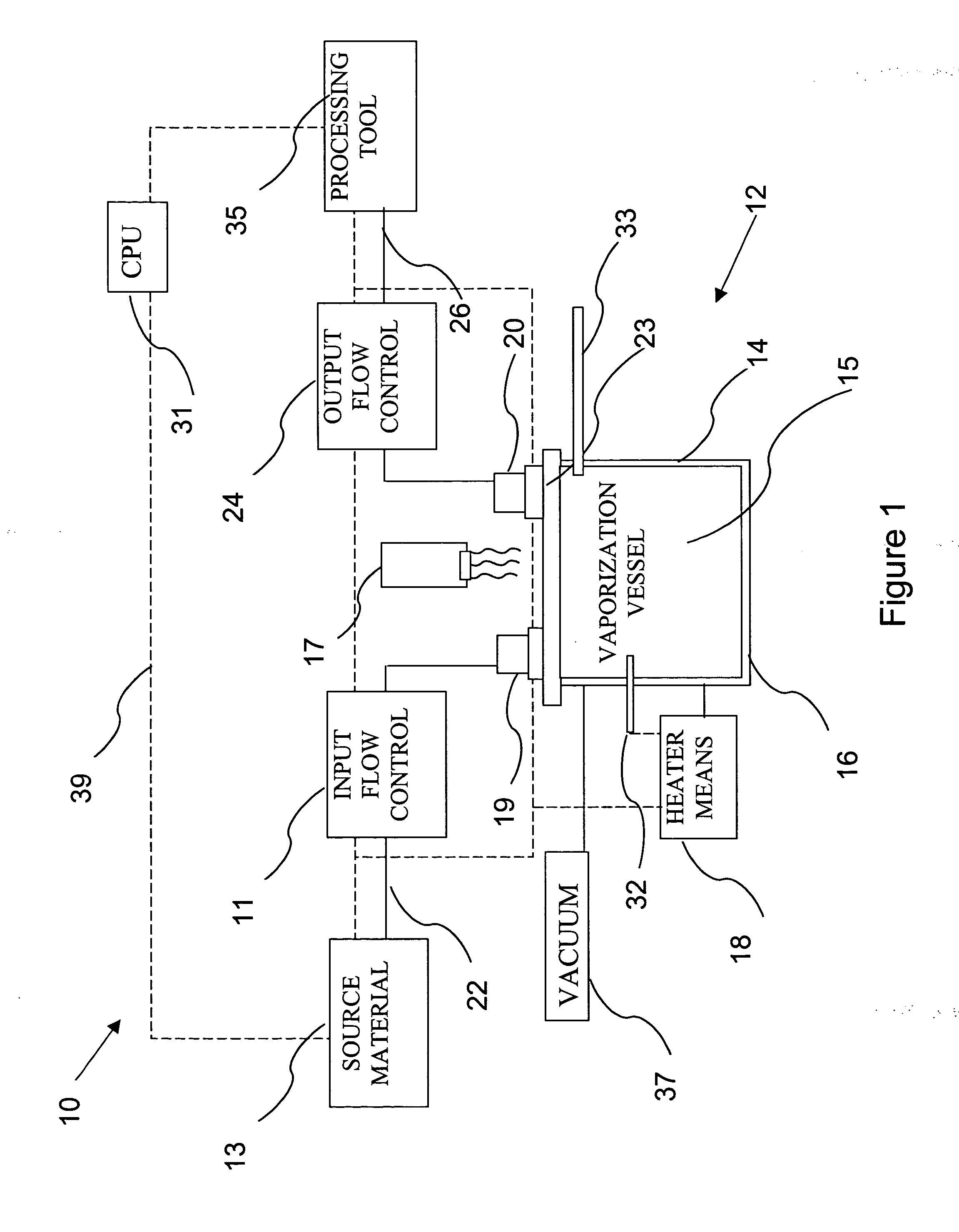

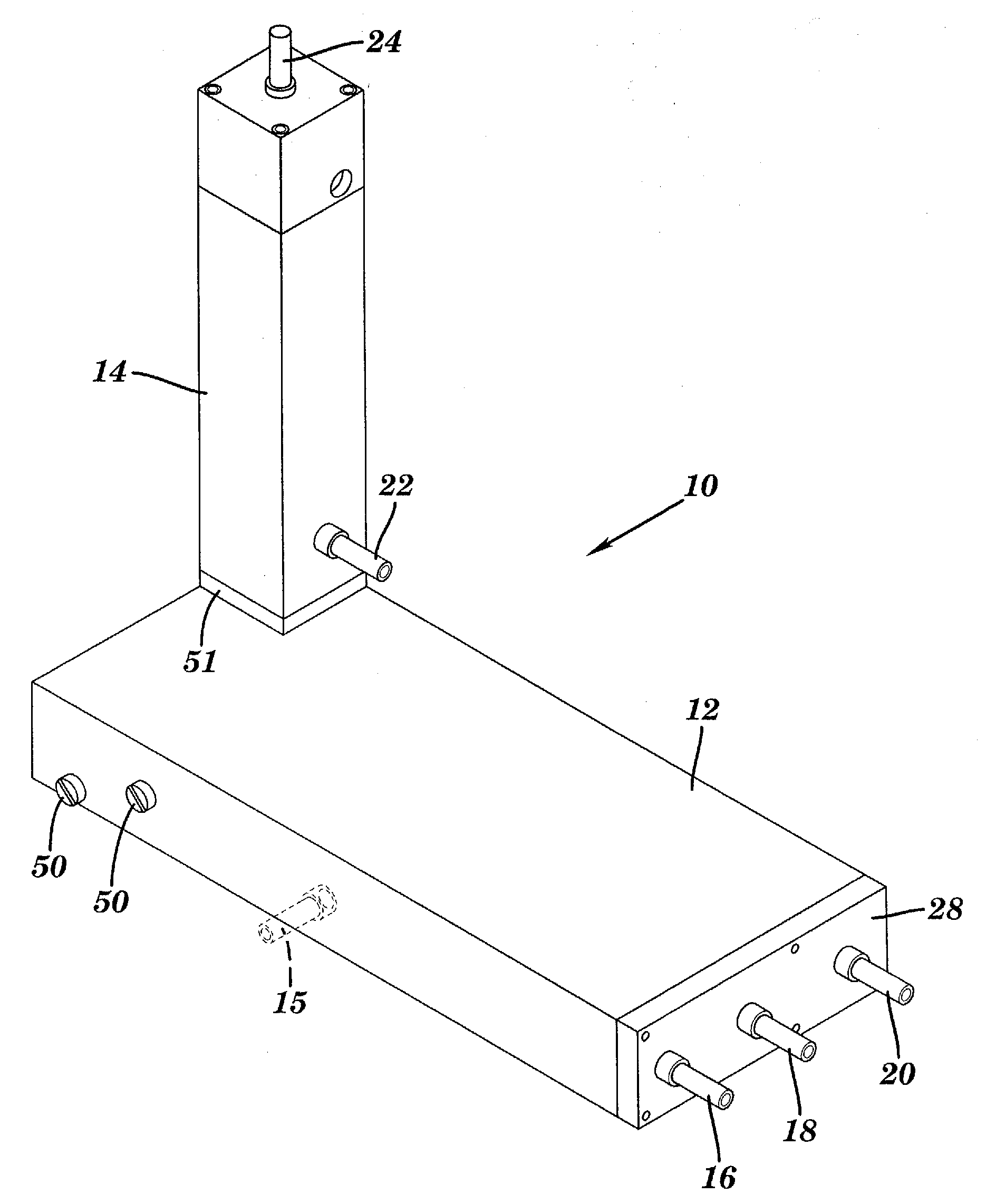

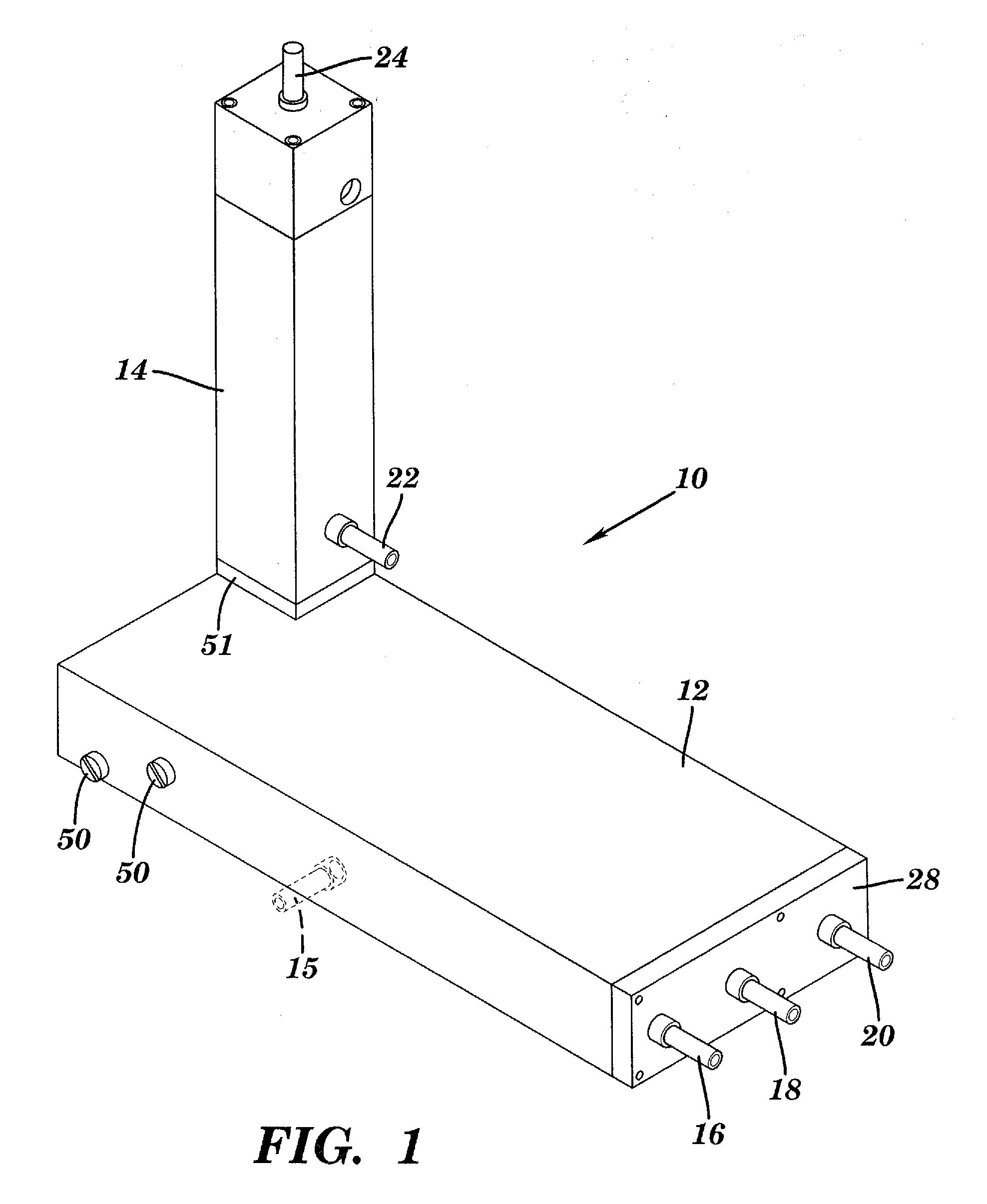

Delivery systems for efficient vaporization of precursor source material

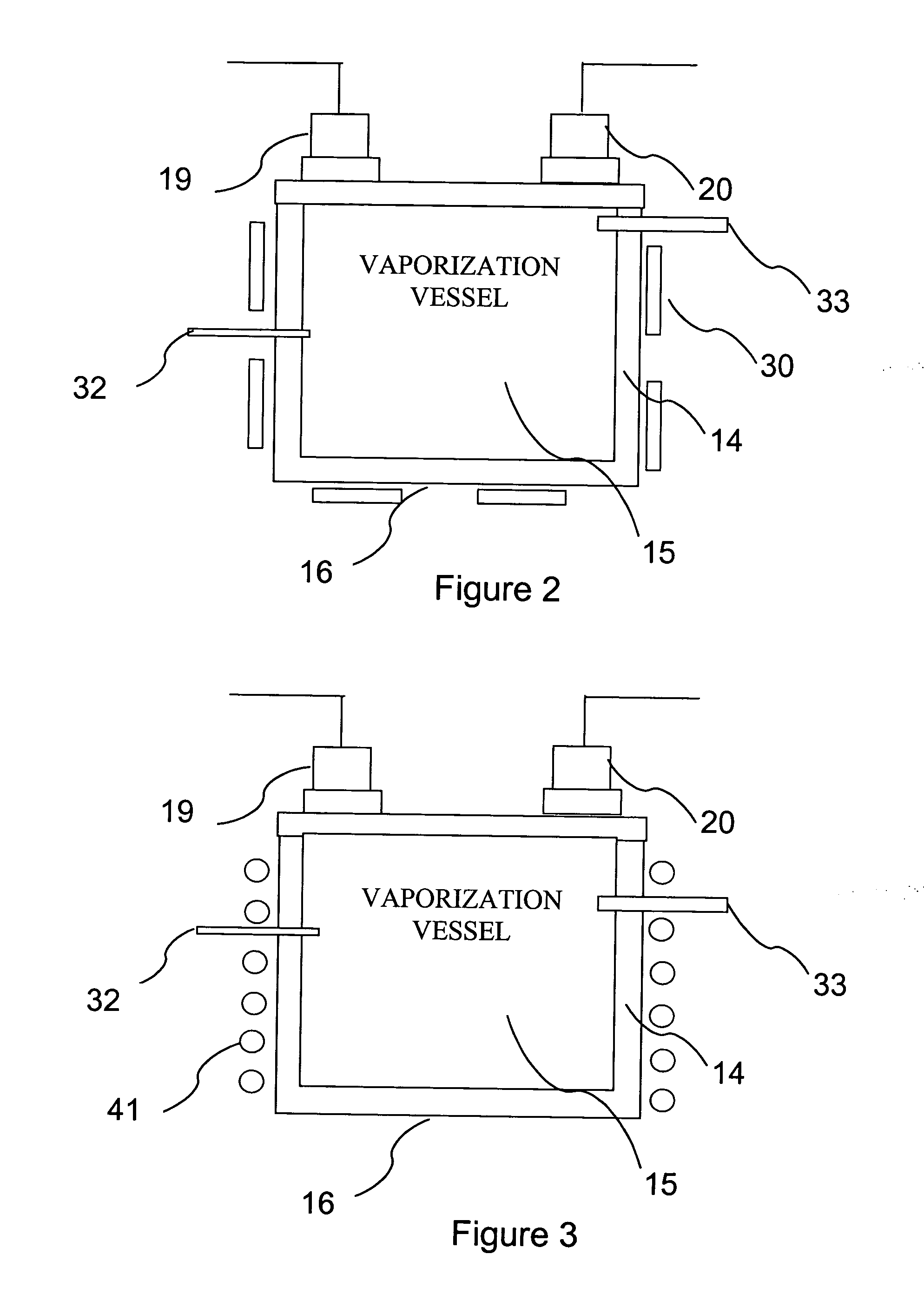

InactiveUS6909839B2Precise deliveryVacuum evaporation coatingSputtering coatingControl flowSource material

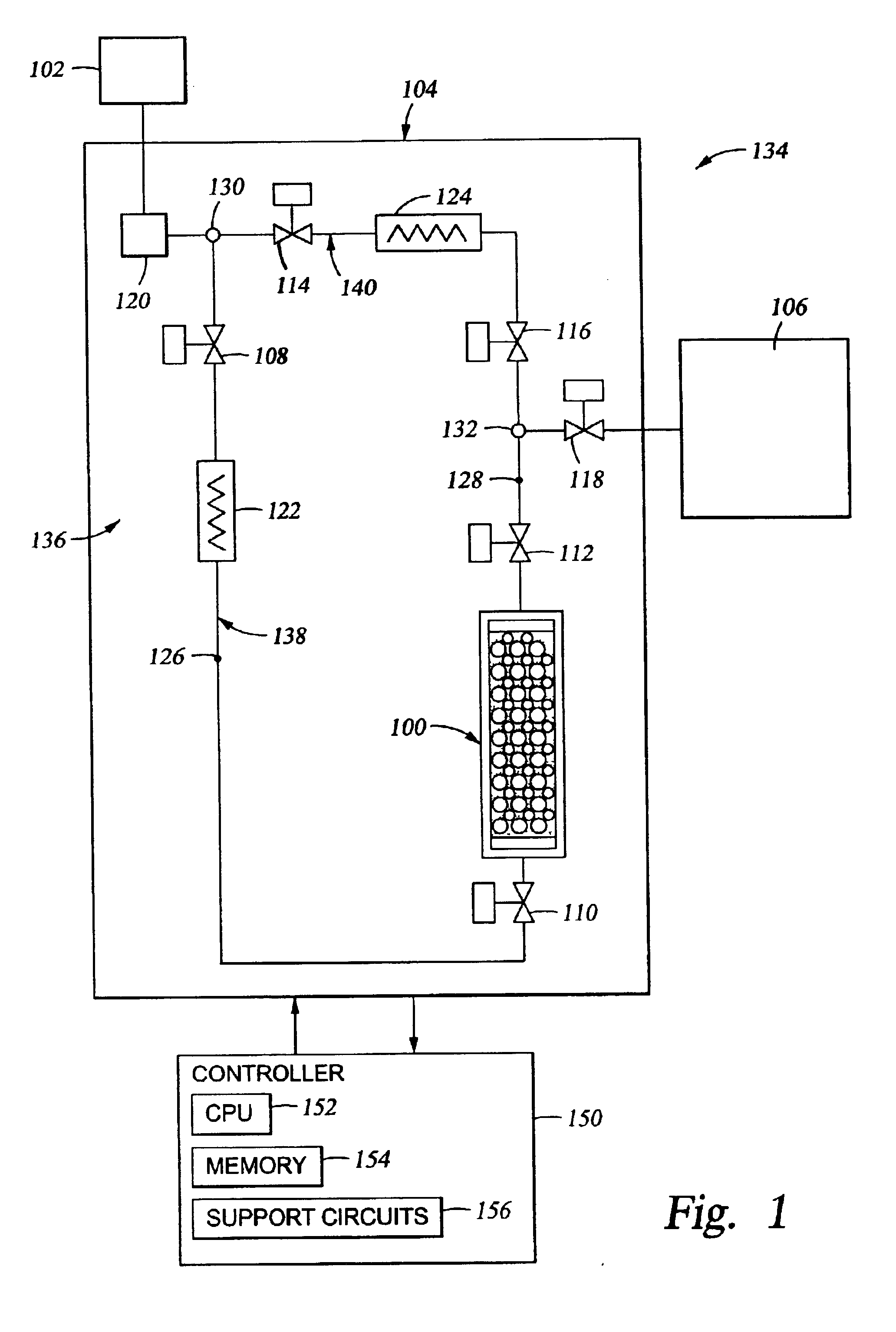

The present invention relates to a delivery system for vaporizing and delivering vaporized solid and liquid precursor materials at a controlled rate having particular utility for semiconductor manufacturing applications. The system includes a vaporization vessel, a processing tool and a connecting vapor line therebetween, where the system further includes an input flow controller and / or an output flow controller to provide a controlled delivery of a vaporizable source material to the vaporization vessel and a controlled flow rate of vaporized source material to the processing tool.

Owner:ENTEGRIS INC

Delivery systems for efficient vaporization of precursor source material

InactiveUS20050019026A1Precise deliveryVacuum evaporation coatingSemiconductor/solid-state device manufacturingControl flowSource material

The present invention relates to a delivery system for vaporizing and delivering vaporized solid and liquid precursor materials at a controlled rate having particular utility for semiconductor manufacturing applications. The system includes a vaporization vessel, a processing tool and a connecting vapor line therebetween, where the system further includes an input flow controller and / or an output flow controller to provide a controlled delivery of a vaporizable source material to the vaporization vessel and a controlled flow rate of vaporized source material to the processing tool.

Owner:ENTEGRIS INC

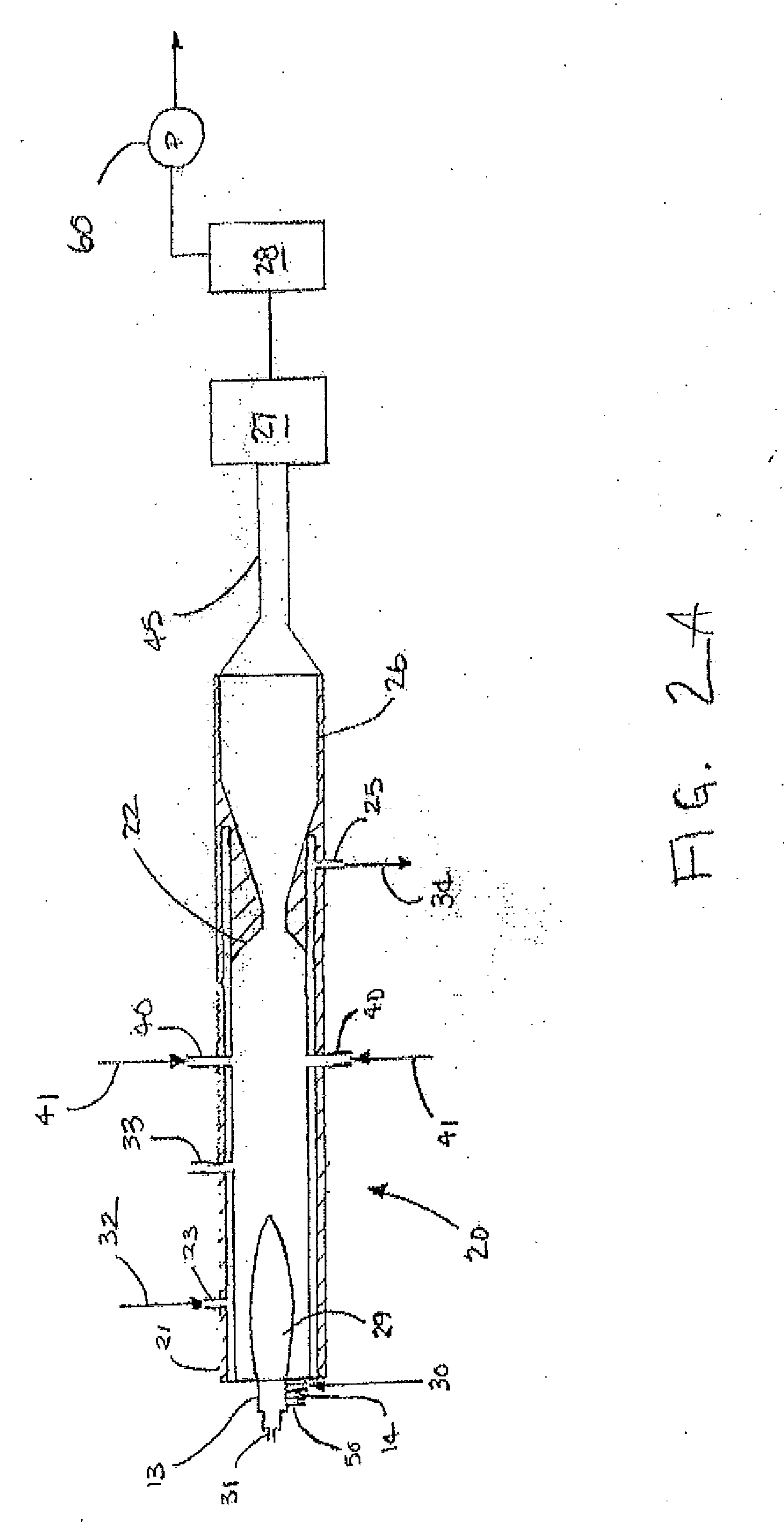

Nozzle-based, vapor-phase, plume delivery structure for use in production of thin-film deposition layer

Owner:UD TECH CORP +2

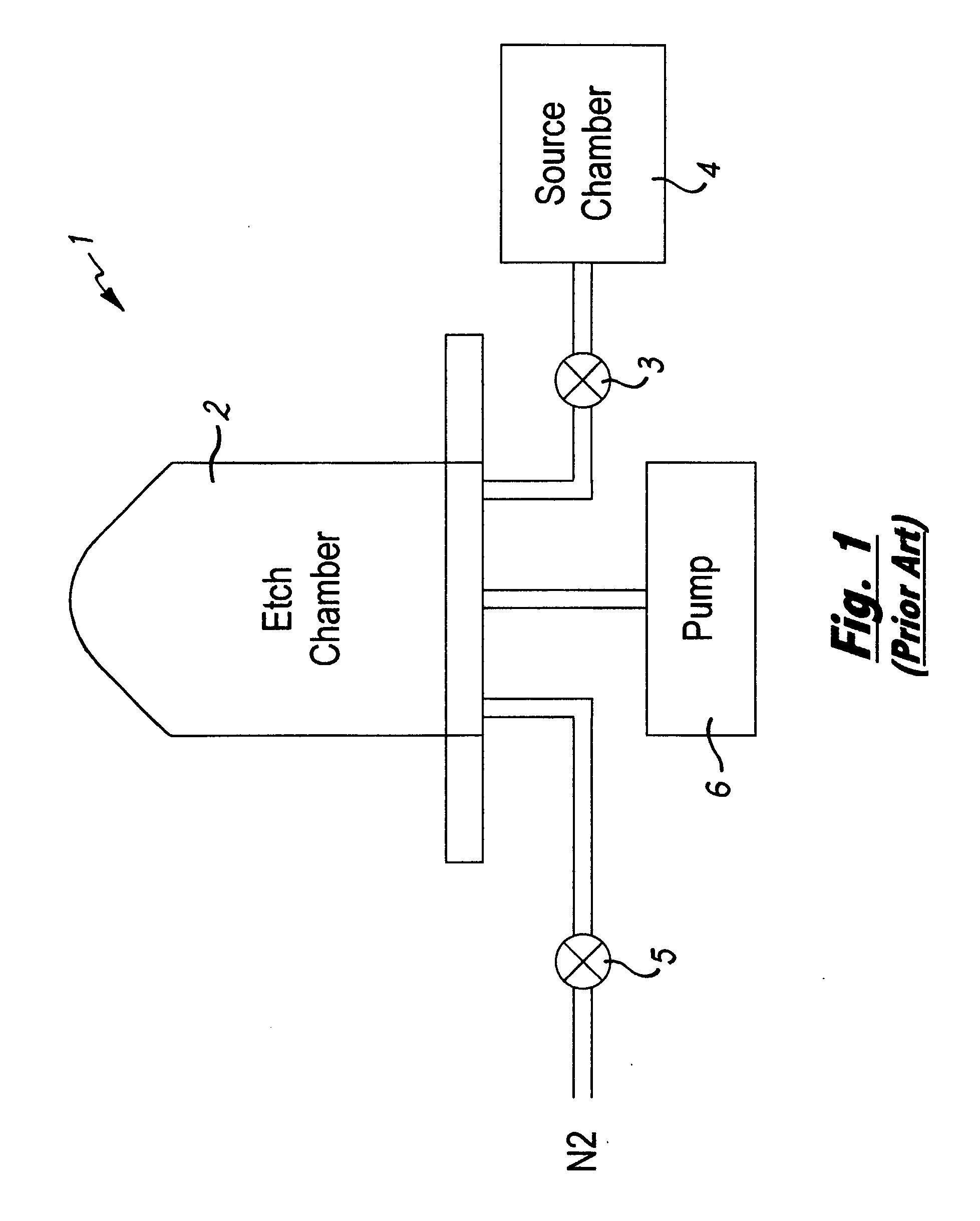

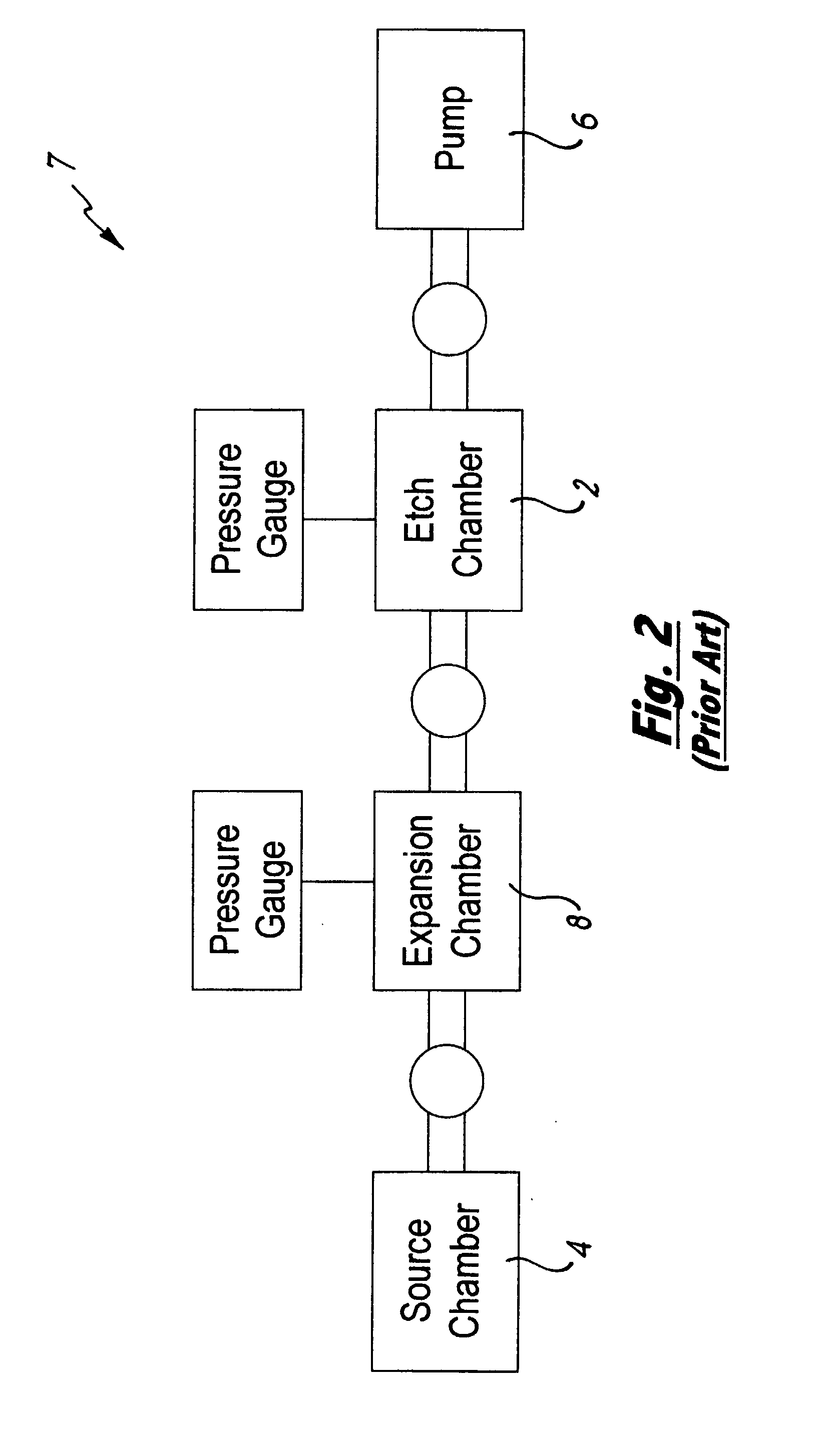

Method and Apparatus for the Etching of Microstructures

InactiveUS20080035607A1Increase partial pressureIncrease ratingsElectric discharge tubesDecorative surface effectsEtchingContinuous flow

An apparatus and method for providing an etching gas source for etching one or more microstructures located within a process chamber. the apparatus has a gas source supply line attached to a gas source and one or more chambers for containing an etching material. In use, the etching material is transformed into an etching material vapor within one or more of the chamber and the gas supply line provides a supply of carrier gas to the etching material vapor and also supplies the etching material vapor transported by the carrier gas to the process chamber. Advantageously, the apparatus of the invention does not require the incorporation of any expansion chambers or other complicated mechanical features in order to achieve a continuous flow of etching gas.

Owner:MEMSSTAR

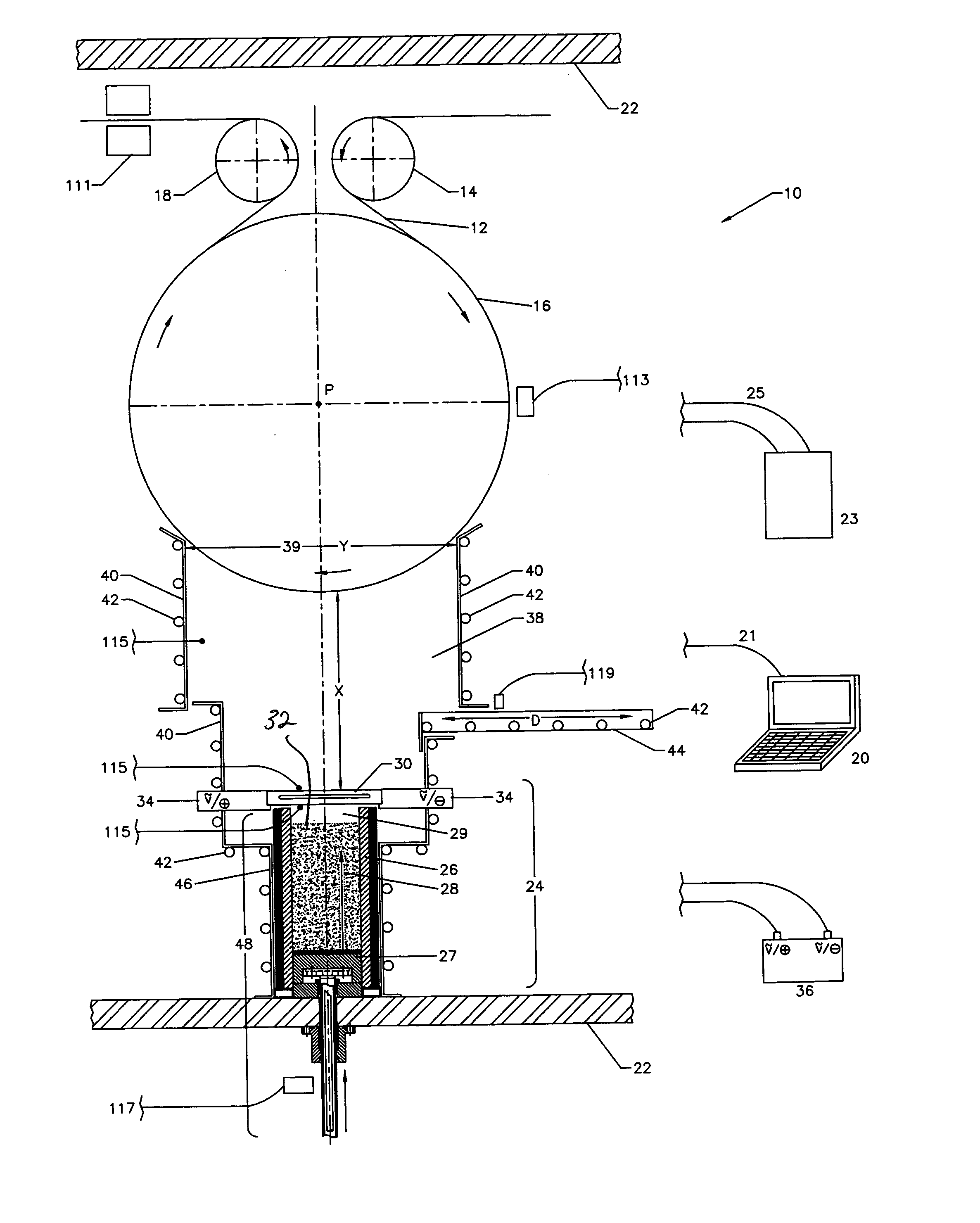

Multi-layered radiant thermal evaporator and method of use

InactiveUS20050072361A1Stable and reliableHigh quality usefulnessVacuum evaporation coatingSputtering coatingCrucibleVacuum chamber

The present invention provides a system and method for uniform coating of a substrate at high deposition rates by evaporating a coating material in a vacuum chamber. The system includes an evaporator having a heating crucible for containing a coating material to be evaporated and a generally planar heat source disposed so as to heat a surface of a coating material contained in the heating crucible. Preferably, the heat source is manufactured from a ceramic or intermetallic material and includes a first layer defining a first set of openings and a second layer defining a second set of openings wherein the second layer overlies the first layer and is spaced apart therefrom. The first and second sets of openings allow the evaporated coating material to pass therethrough for dispersion of the coating material in a deposition zone defined by a containment shield disposed above the heat source.

Owner:DARLY CUSTOM TECH

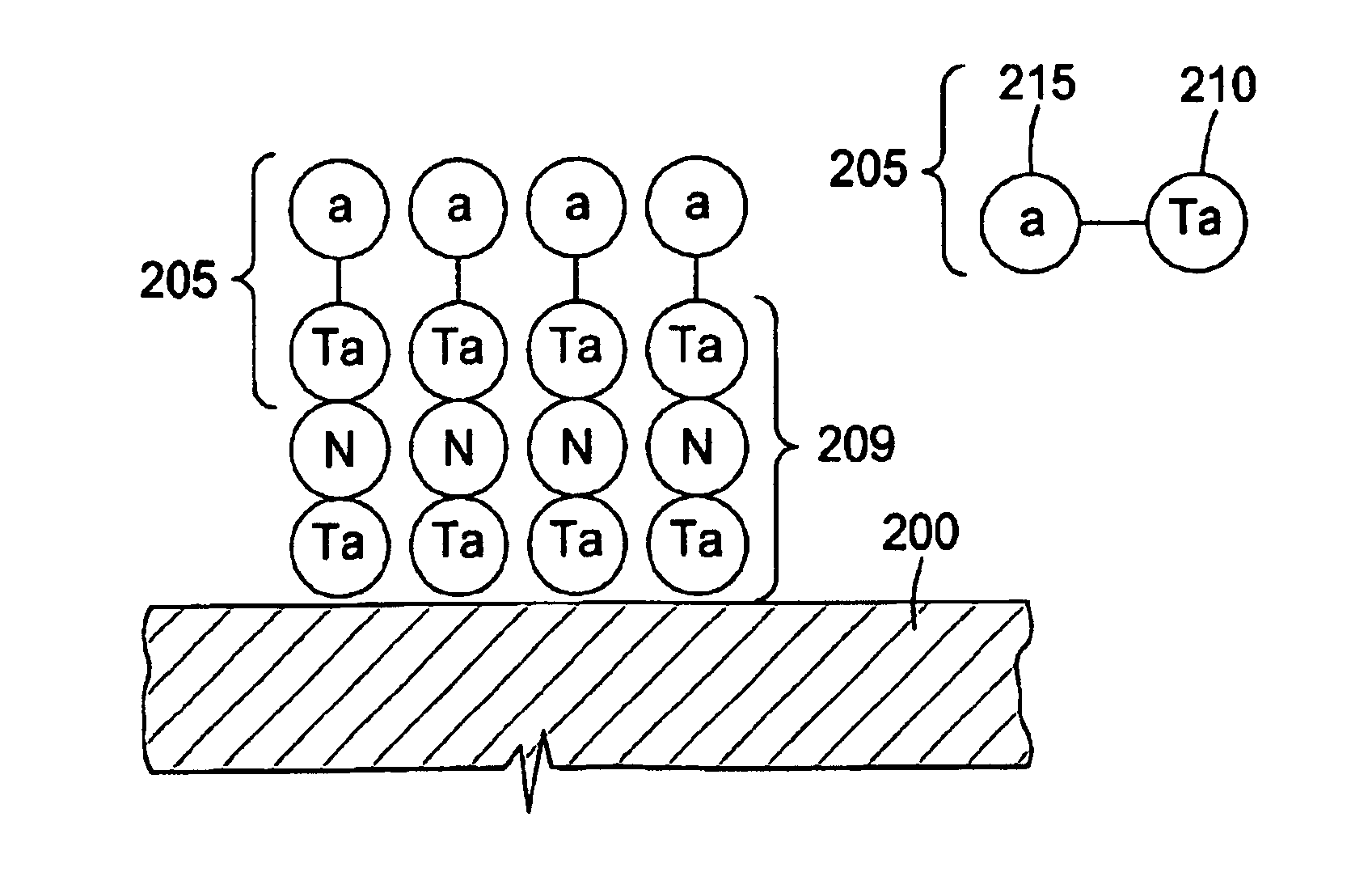

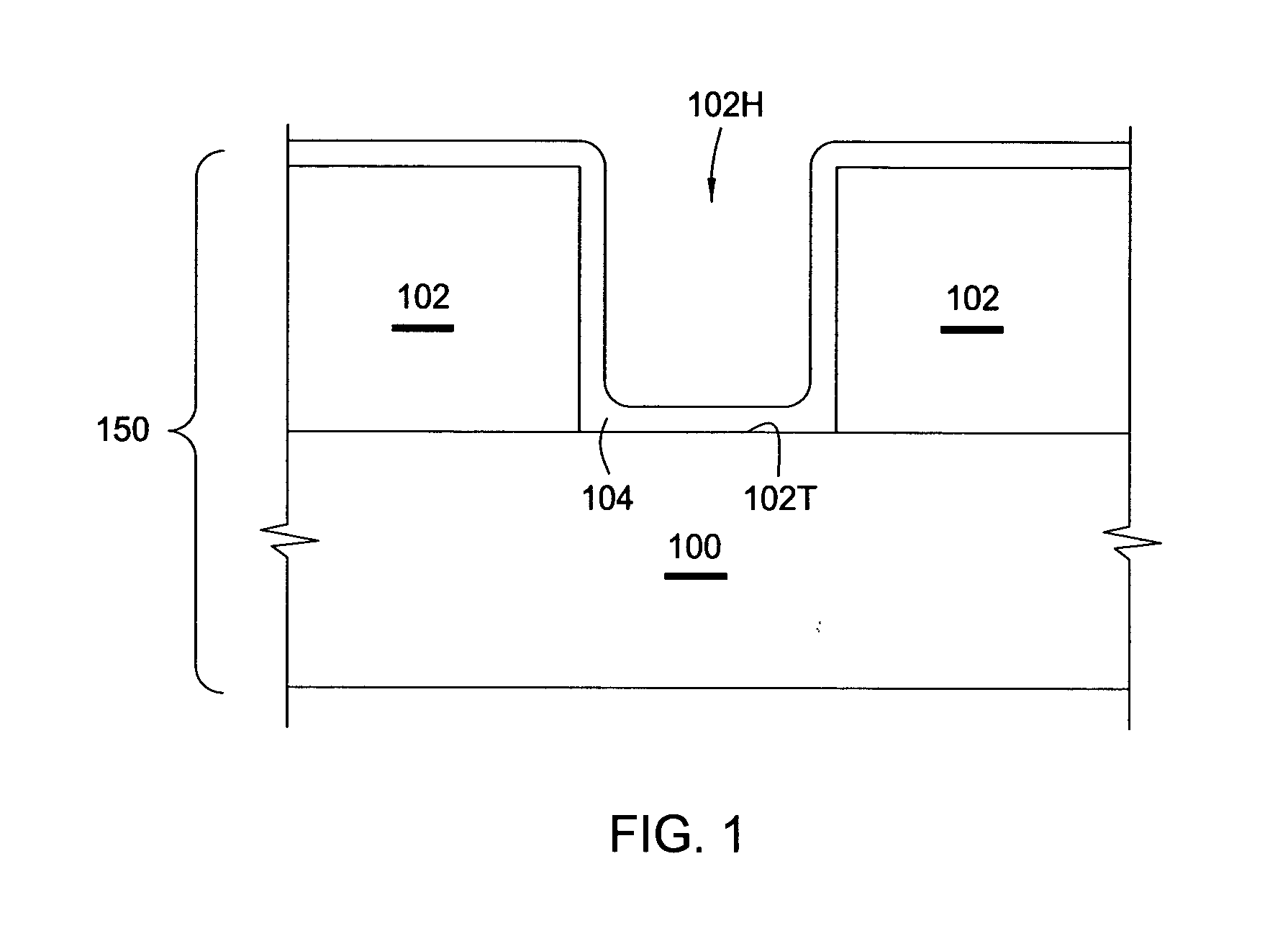

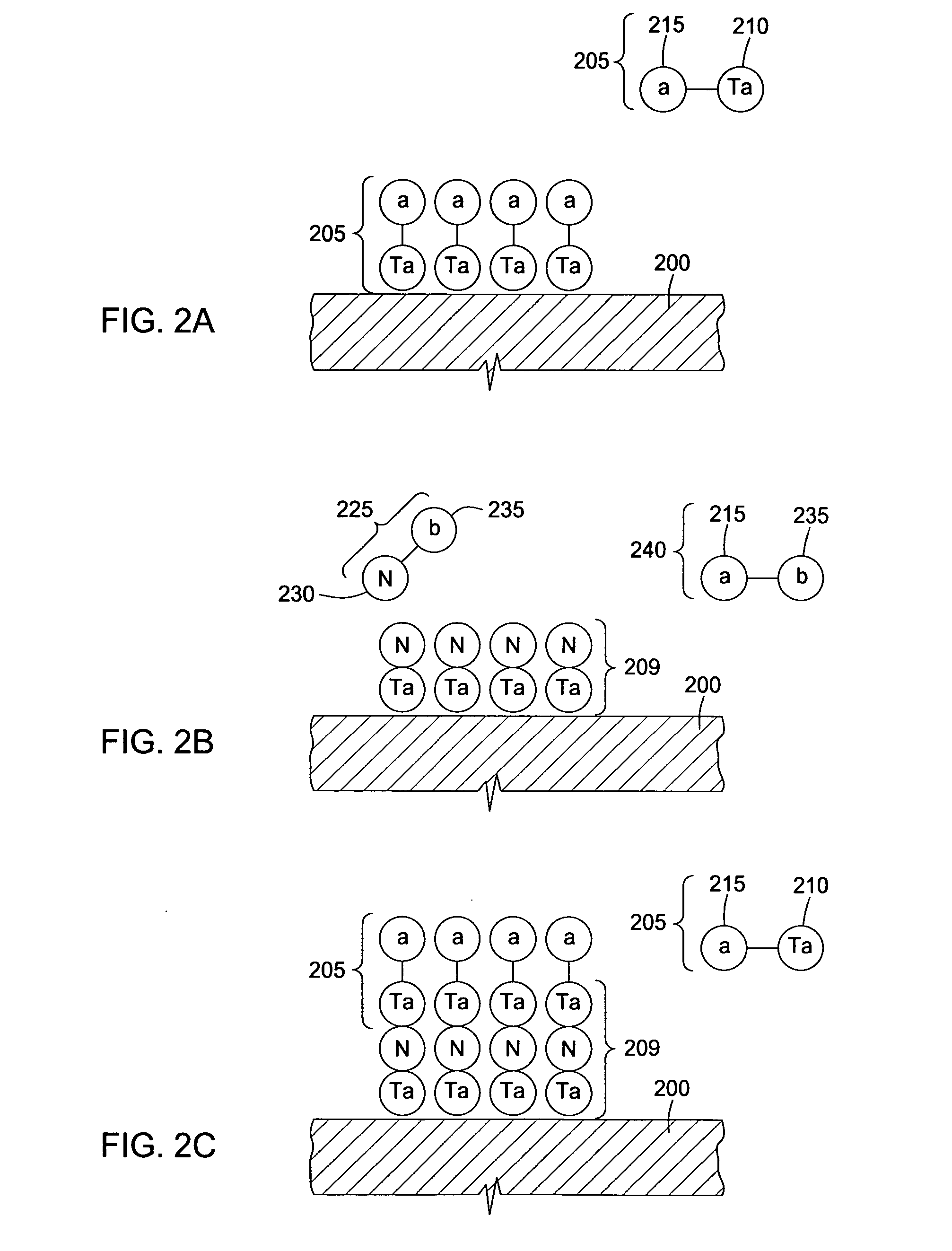

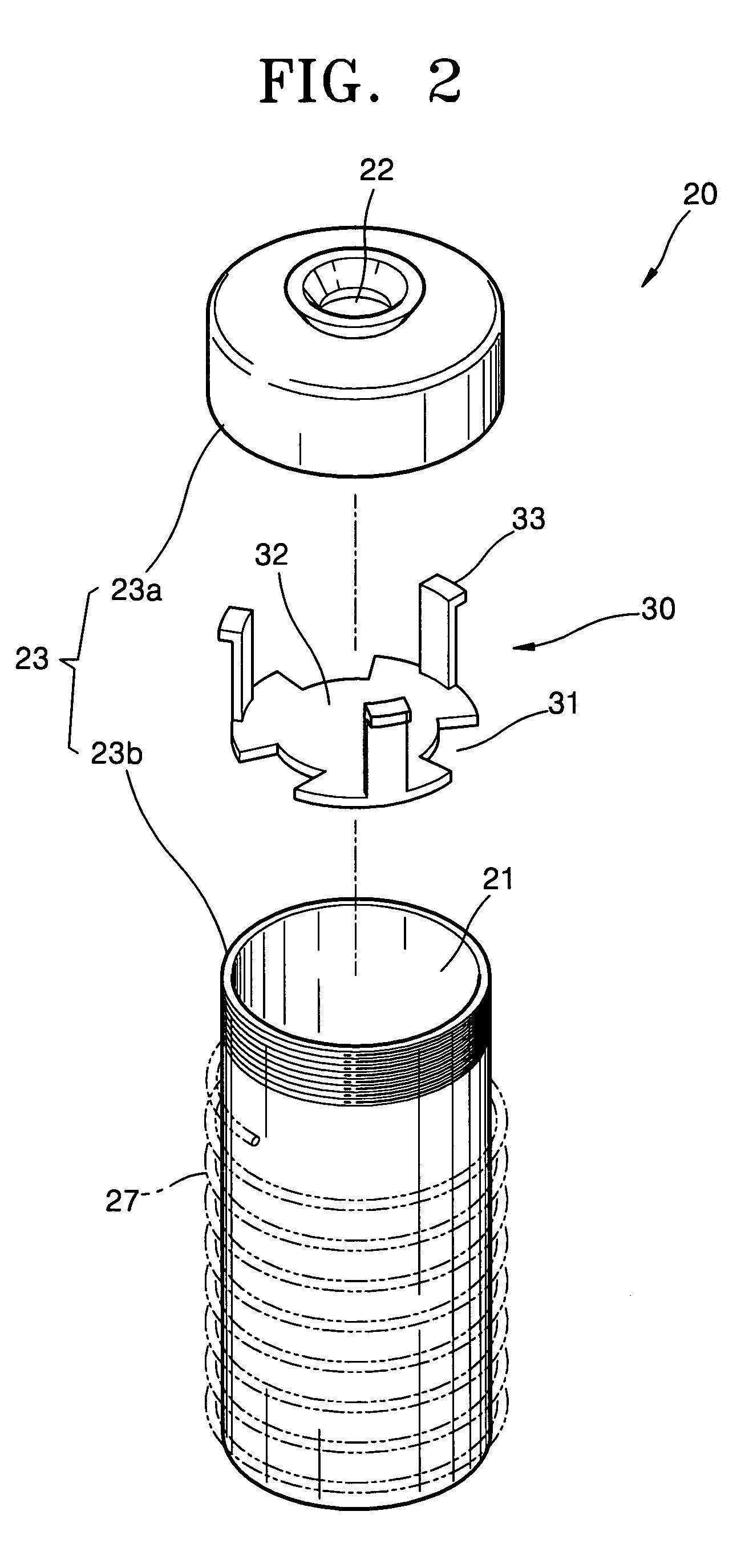

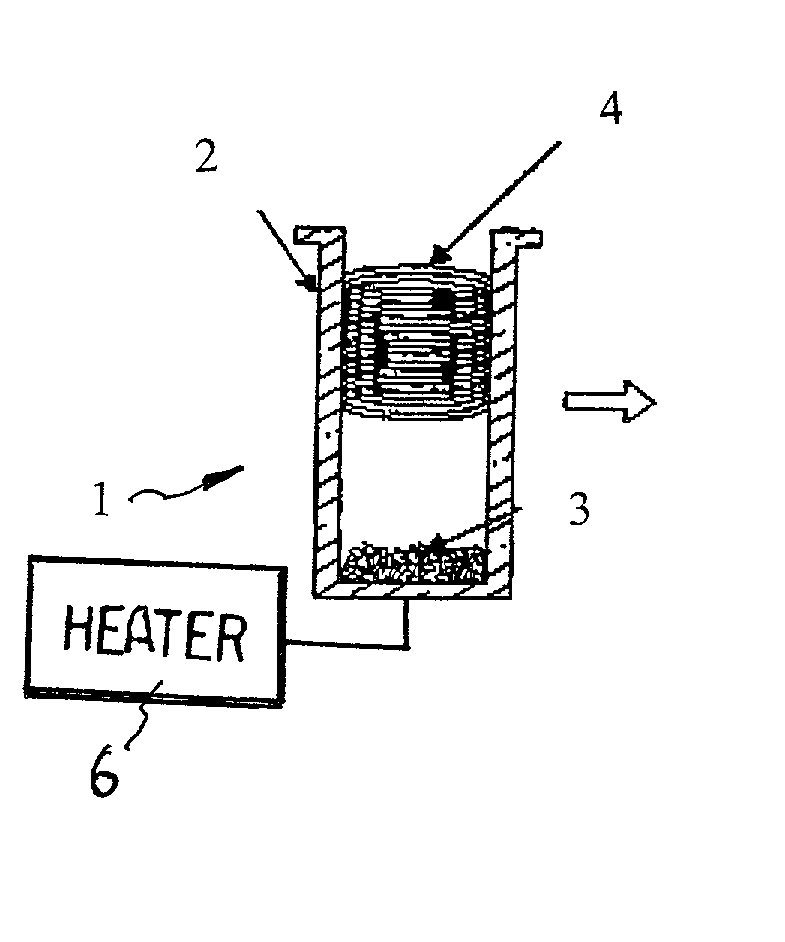

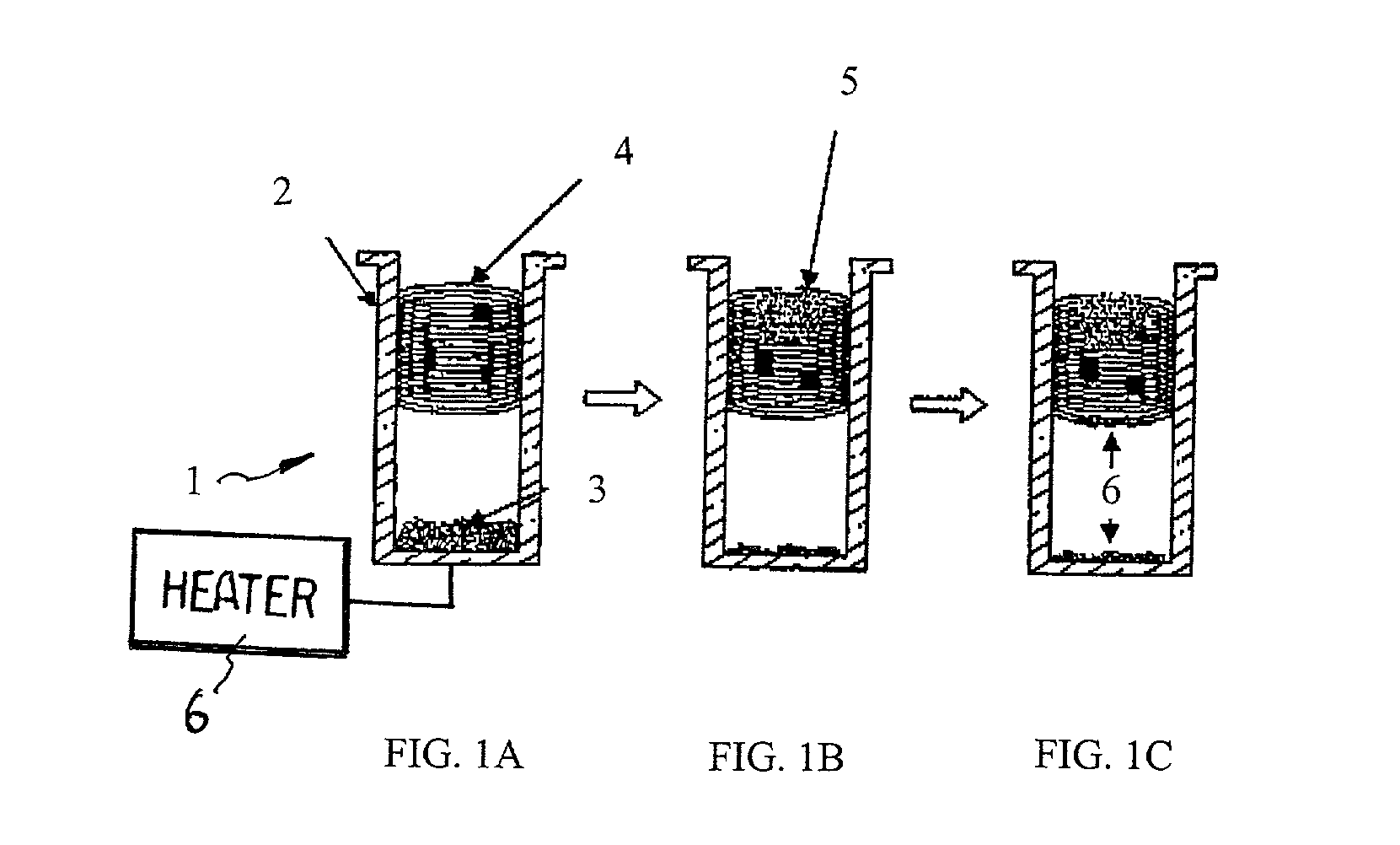

Method and apparatus of generating PDMAT precursor

InactiveUS6905541B2Polycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringImpurity

A precursor and method for filling a feature in a substrate. The method generally includes depositing a barrier layer, the barrier layer being formed from pentakis(dimethylamido)tantalum having less than about 5 ppm of chlorine. The method additionally may include depositing a seed layer over the barrier layer and depositing a conductive layer over the seed layer. The precursor generally includes pentakis(dimethylamido)tantalum having less than about 5 ppm of chlorine. The precursor is generated in a canister having a surrounding heating element configured to reduce formation of impurities.

Owner:APPLIED MATERIALS INC

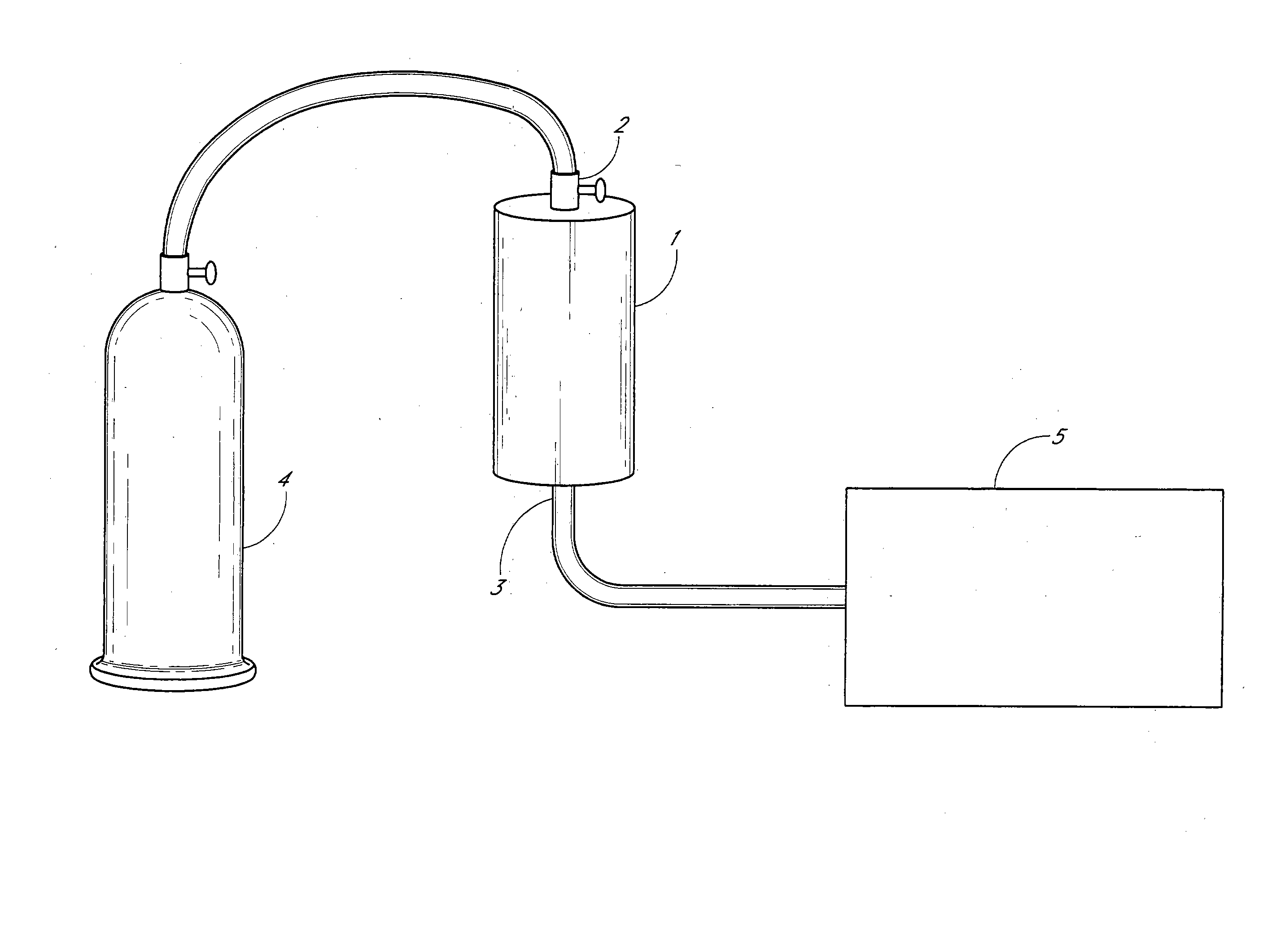

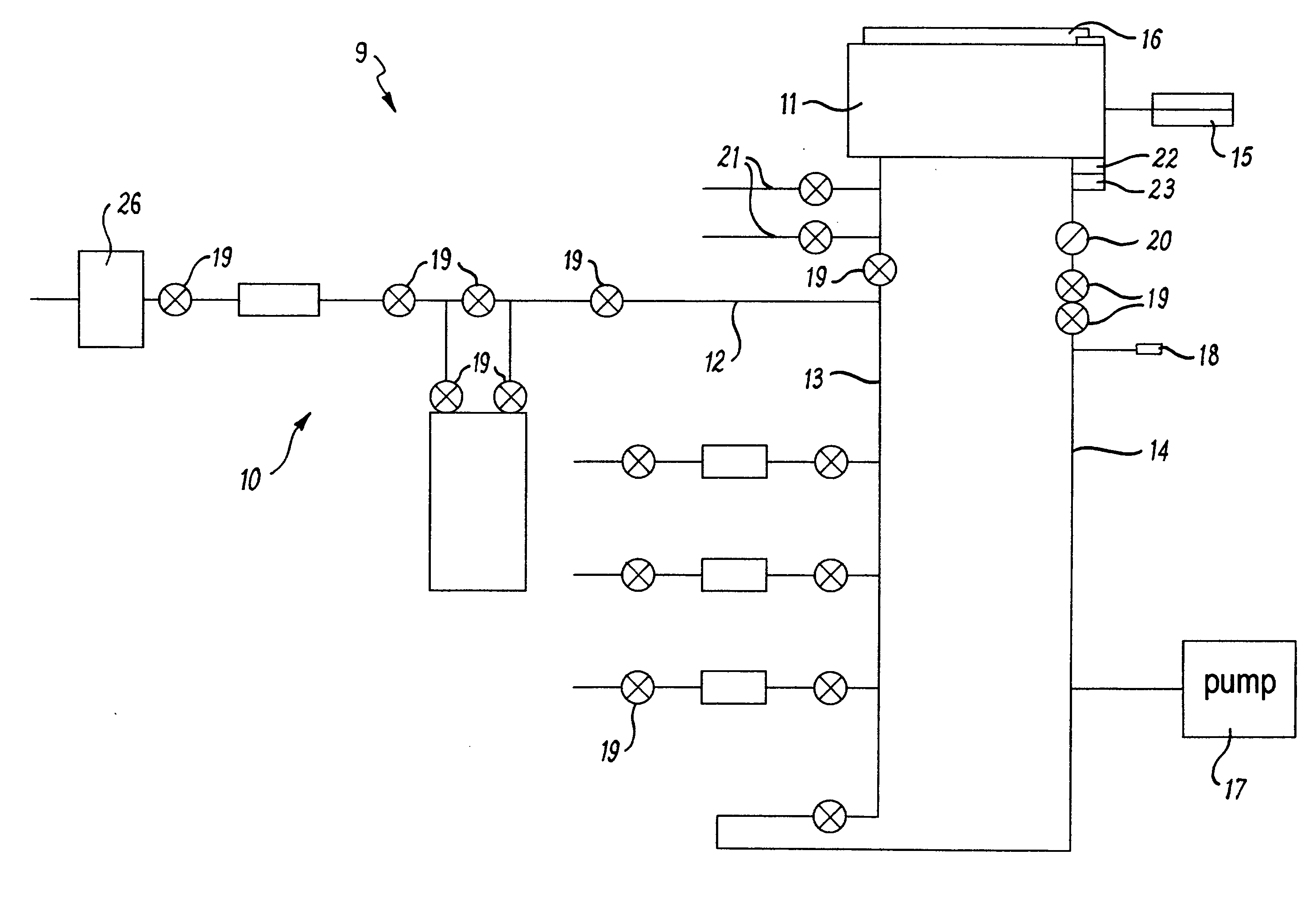

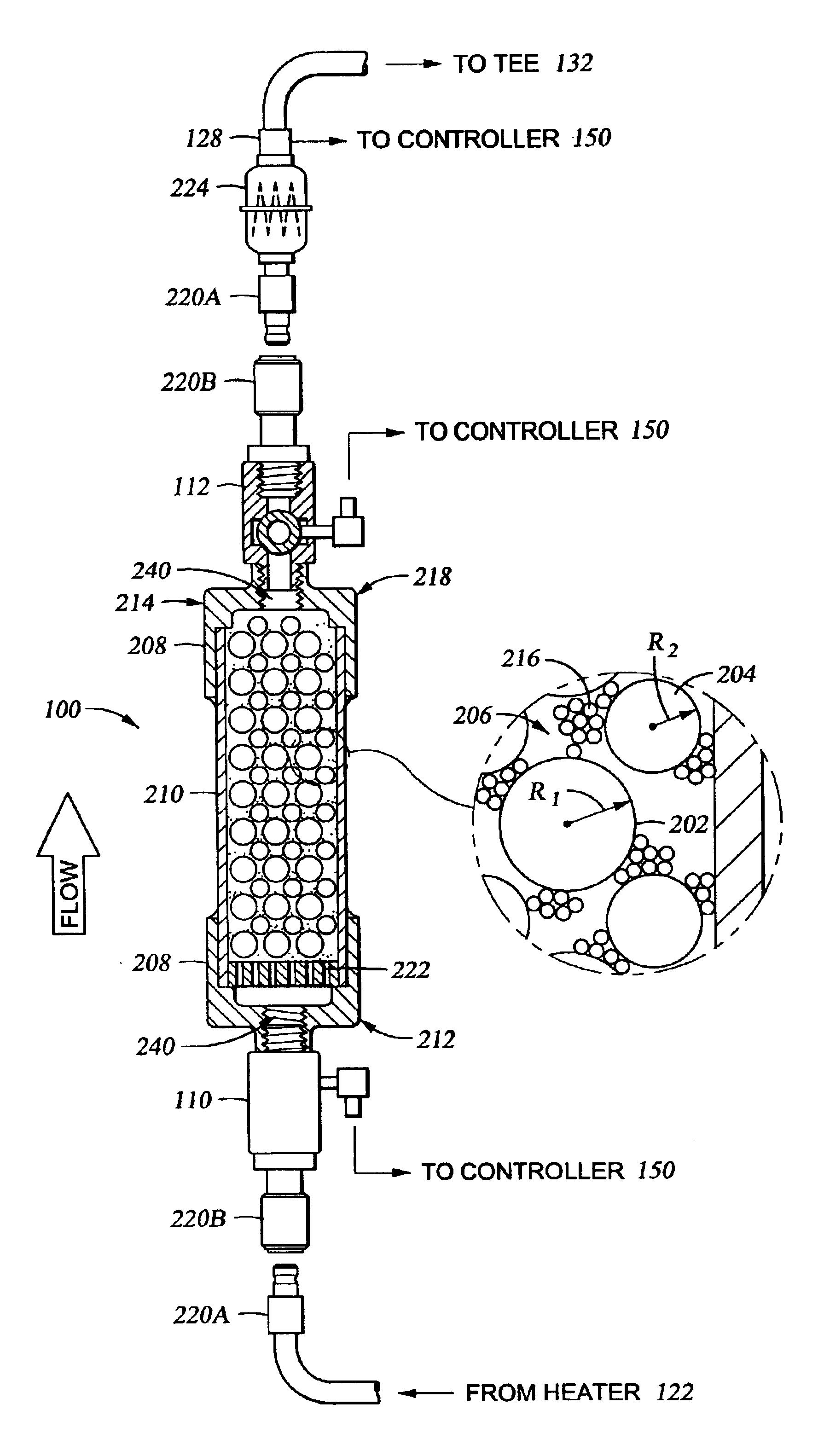

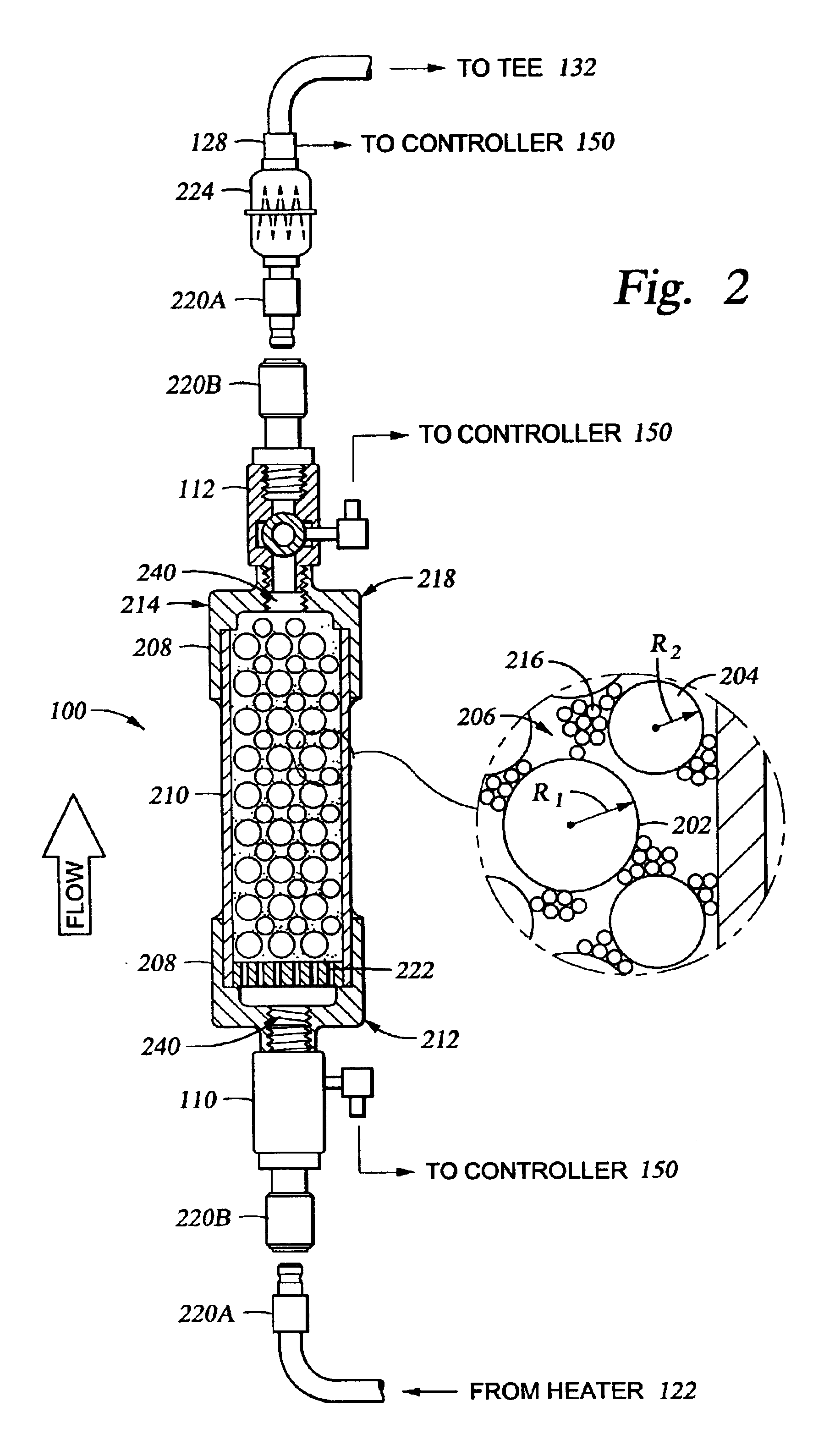

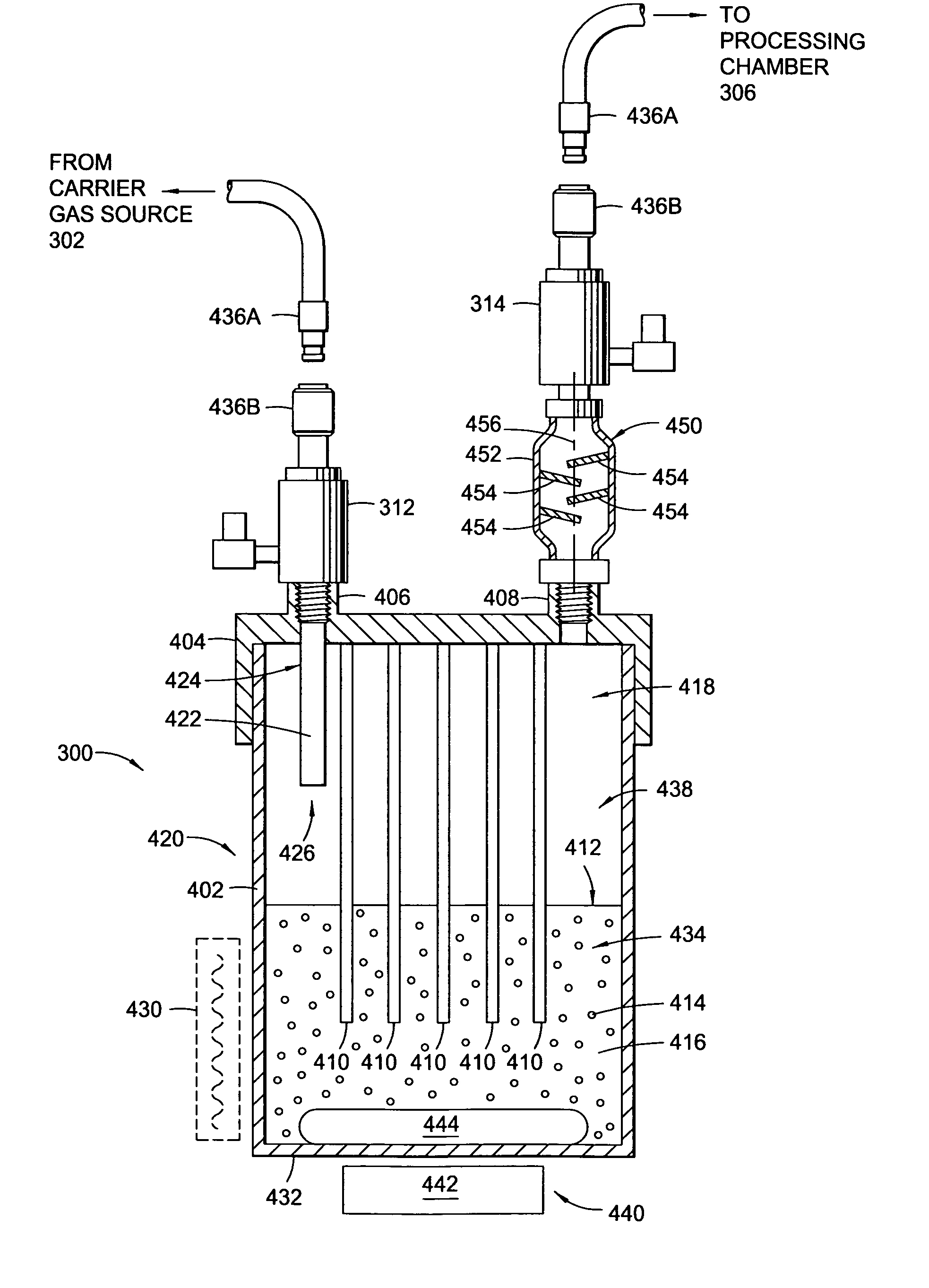

Method and apparatus for generating gas to a processing chamber

A method and apparatus for generating gas for a processing system is provided. In one embodiment, an apparatus for generating gas for a processing system includes an unitary, isolatable, transportable canister having a plurality of first spacing elements, a plurality of second spacing elements and a solid material disposed within the canister. The spacing elements have different mean diameters. The solid material is adapted to produce a gas vapor when exposed to a temperature above a predetermined level at a predetermined pressure. In another embodiment, an apparatus for generating gas includes a gas source coupled to a processing chamber by a first gas line. A canister is coupled in-line with the first gas line and contains a solid material that produces a process gas when heated. A heater is disposed between the gas source and the canister to heat gas flowing into the canister.

Owner:APPLIED MATERIALS INC

Fixing member for evaporation apparatus

InactiveUS6881271B2Uniform dischargeEfficient heatingSnap fastenersElectric lighting sourcesCrucibleEvaporation

An electric heater is placed so as to cover an upper opening of a crucible. Then, a plurality of angle members are disposed along the side portions of the electric heater and are pressed and fixed by clamps. The clamp includes, at its bottom, a curved portion formed by bending a plate-like spring member into a convex shape, and generates pressing force between the curved portion and corresponding claw portions at the upper edge, thereby clamping the crucible.

Owner:SANYO ELECTRIC CO LTD

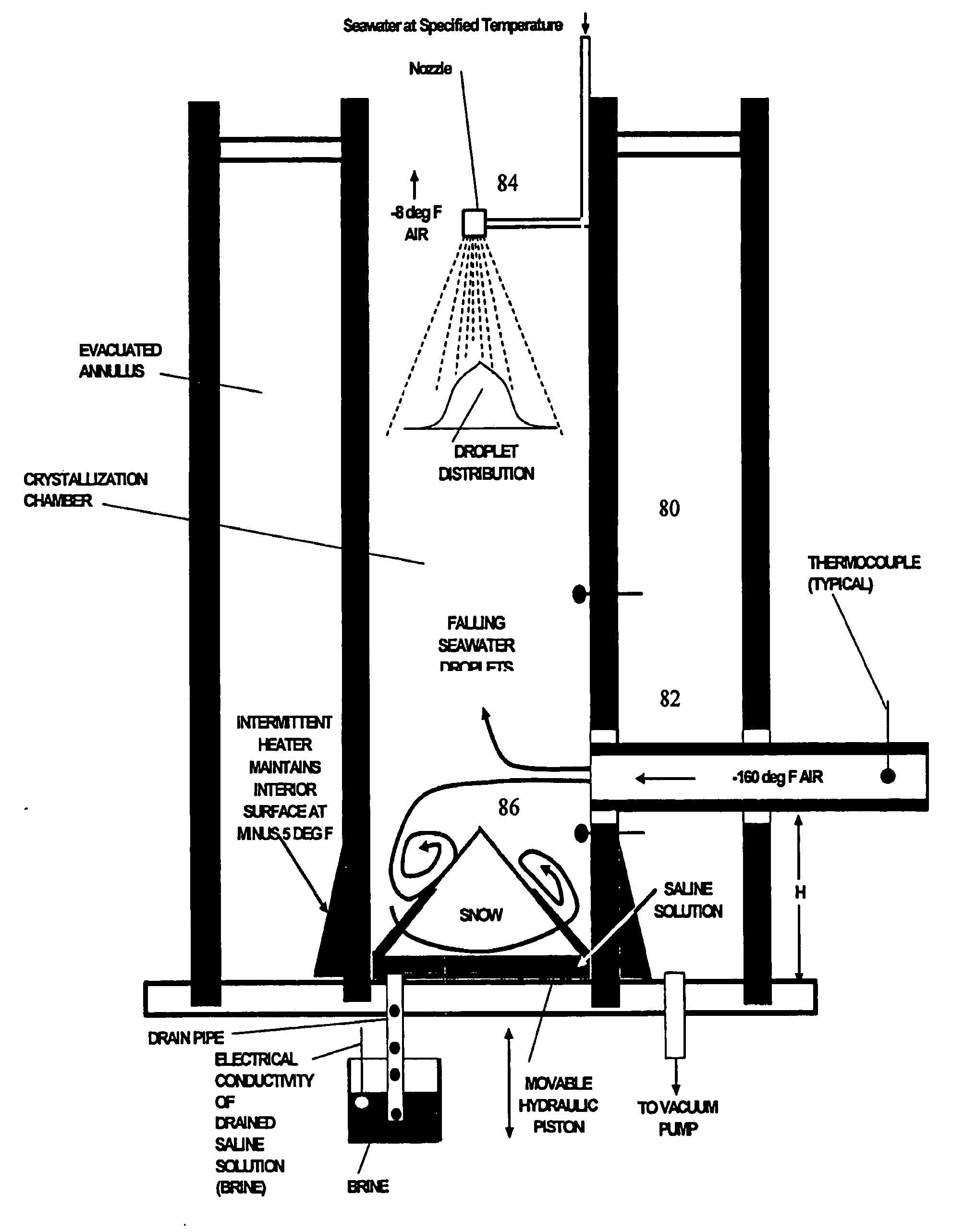

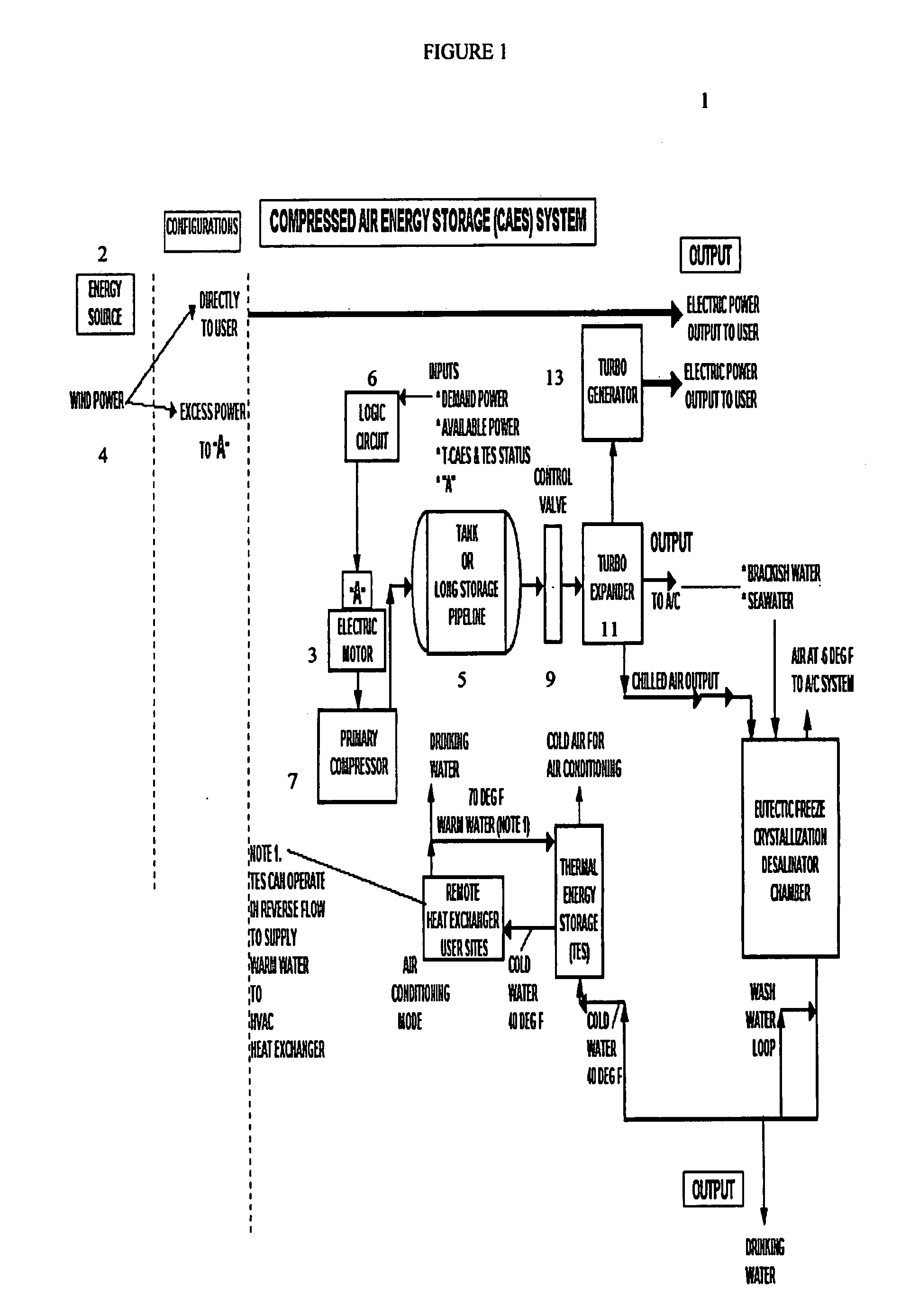

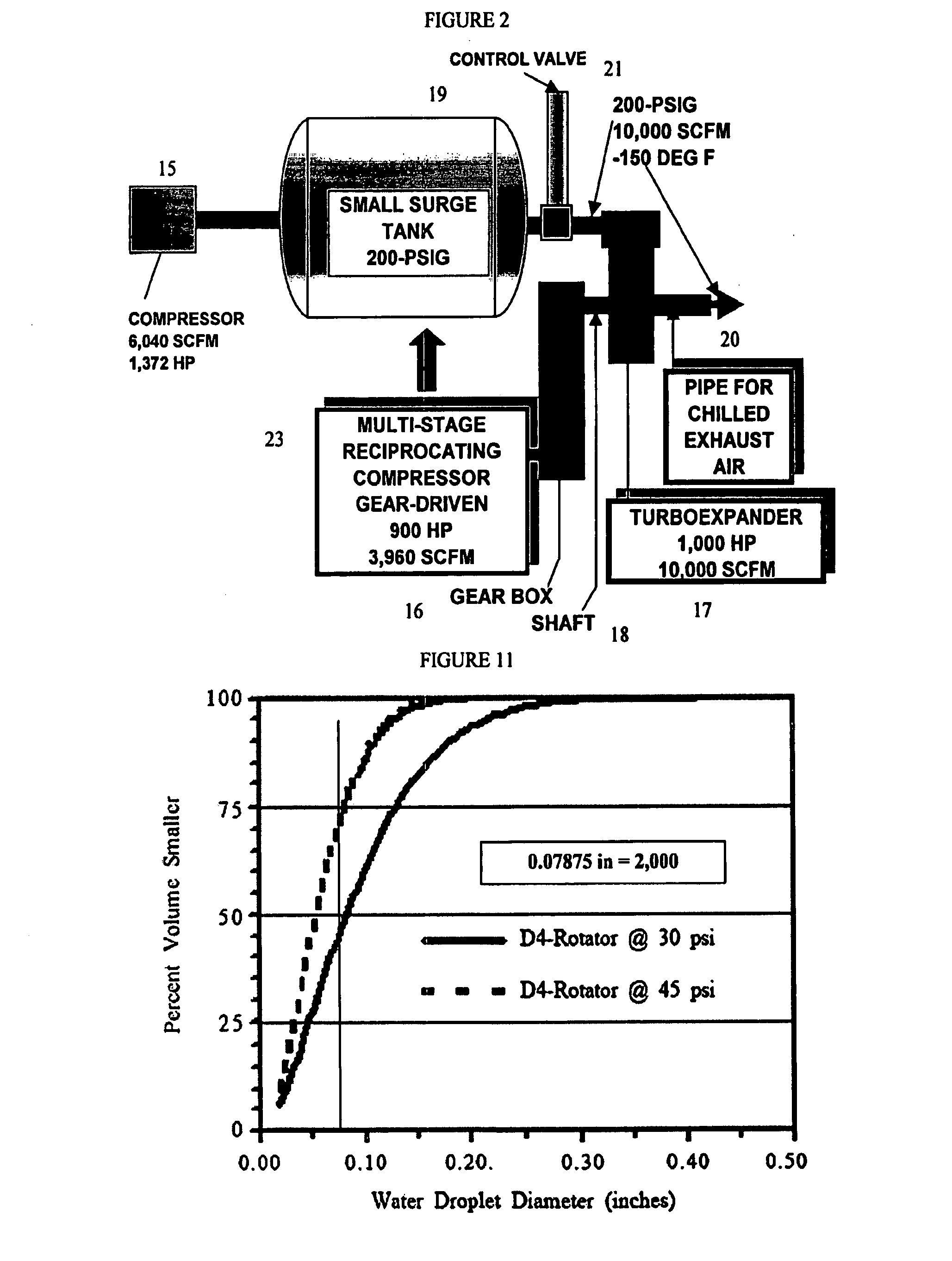

Desalination Method and System Using Compressed Air Energy Systems

InactiveUS20100037653A1Facilitate runoffClean the ice massGeneral water supply conservationSeawater treatmentDesalinationSalt water

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

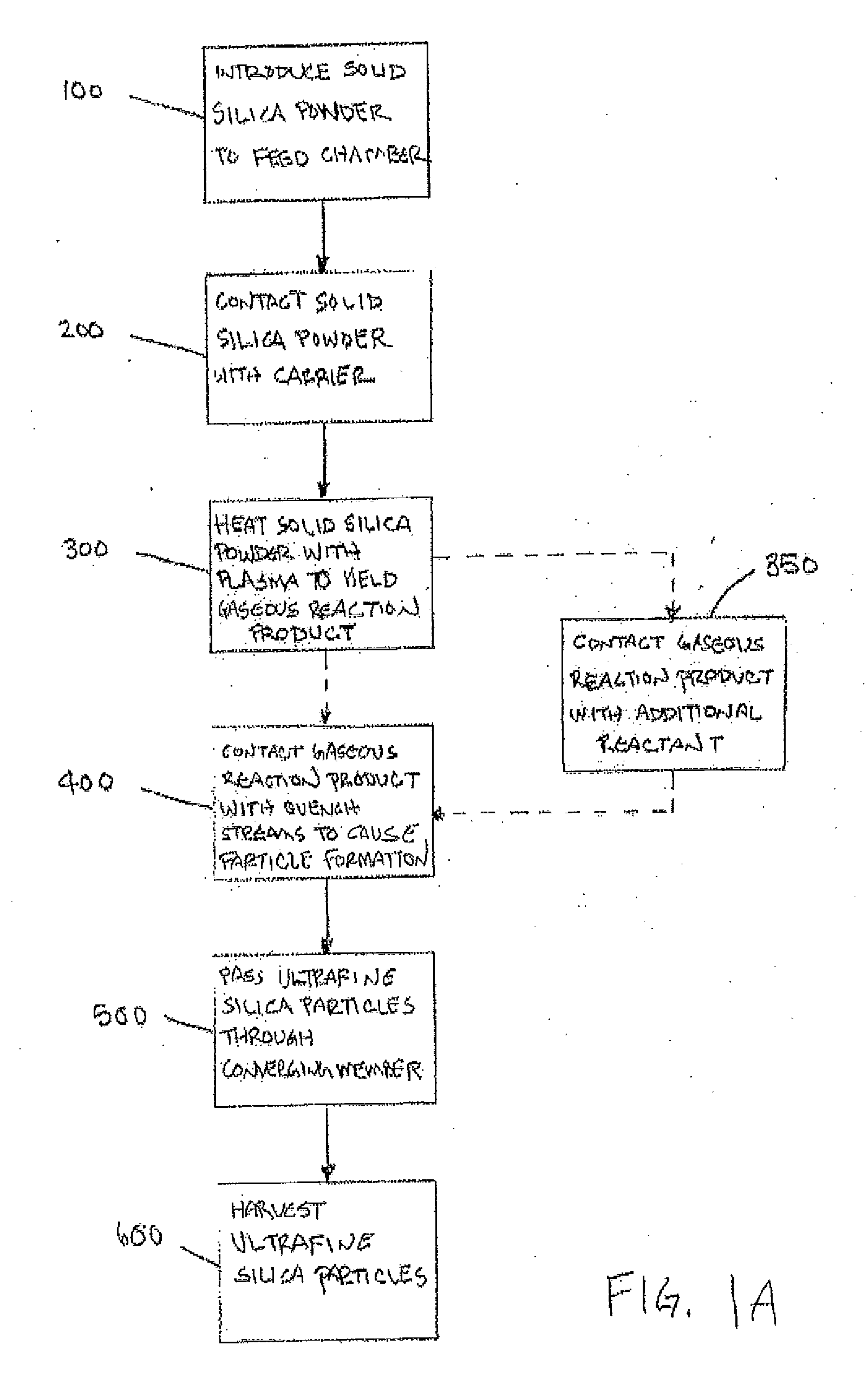

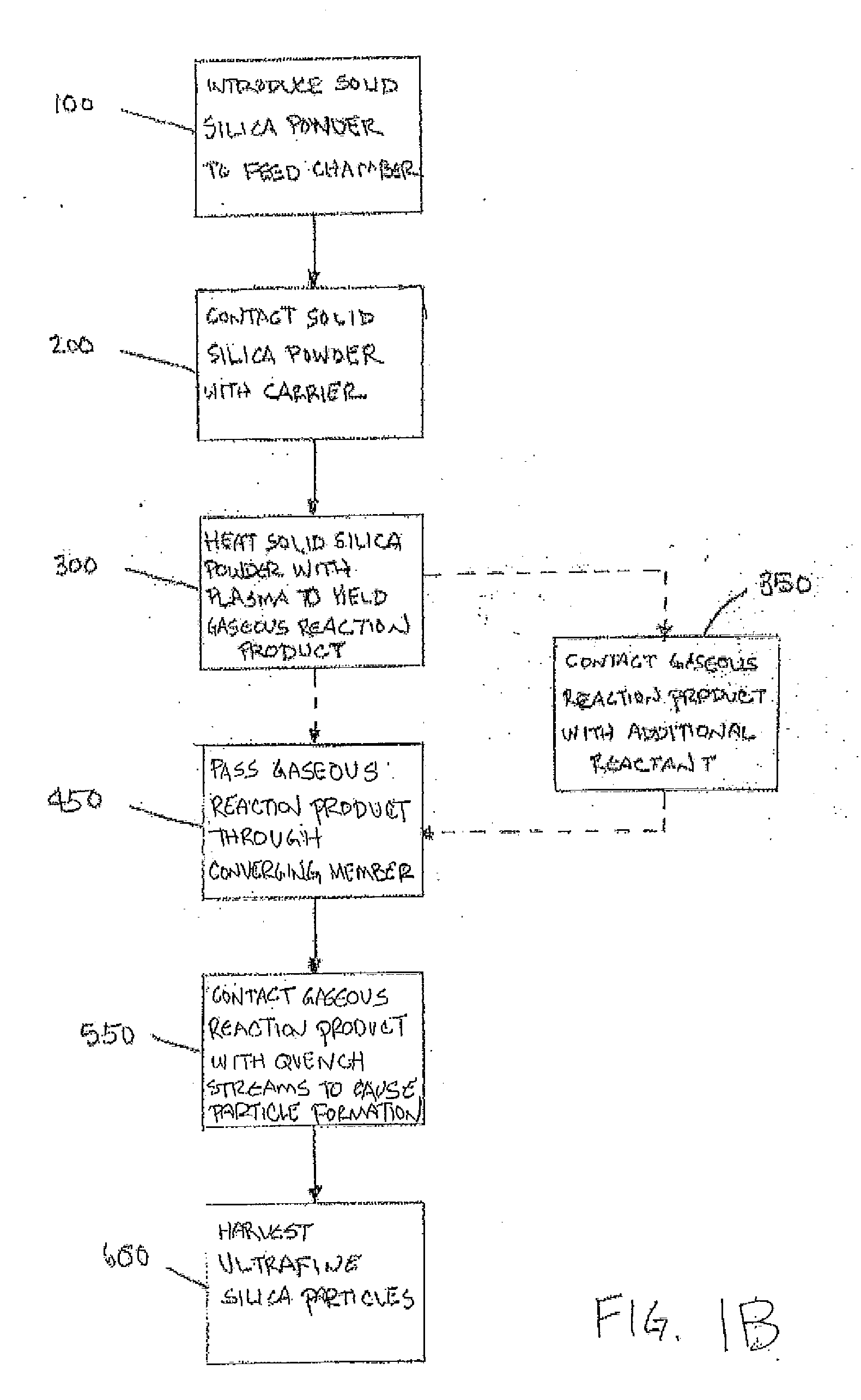

Method and apparatus for the production of ultrafine silica particles from solid silica powder and related coating compositions

Owner:PPG IND OHIO INC

Method and apparatus of generating PDMAT precursor

Owner:APPLIED MATERIALS INC

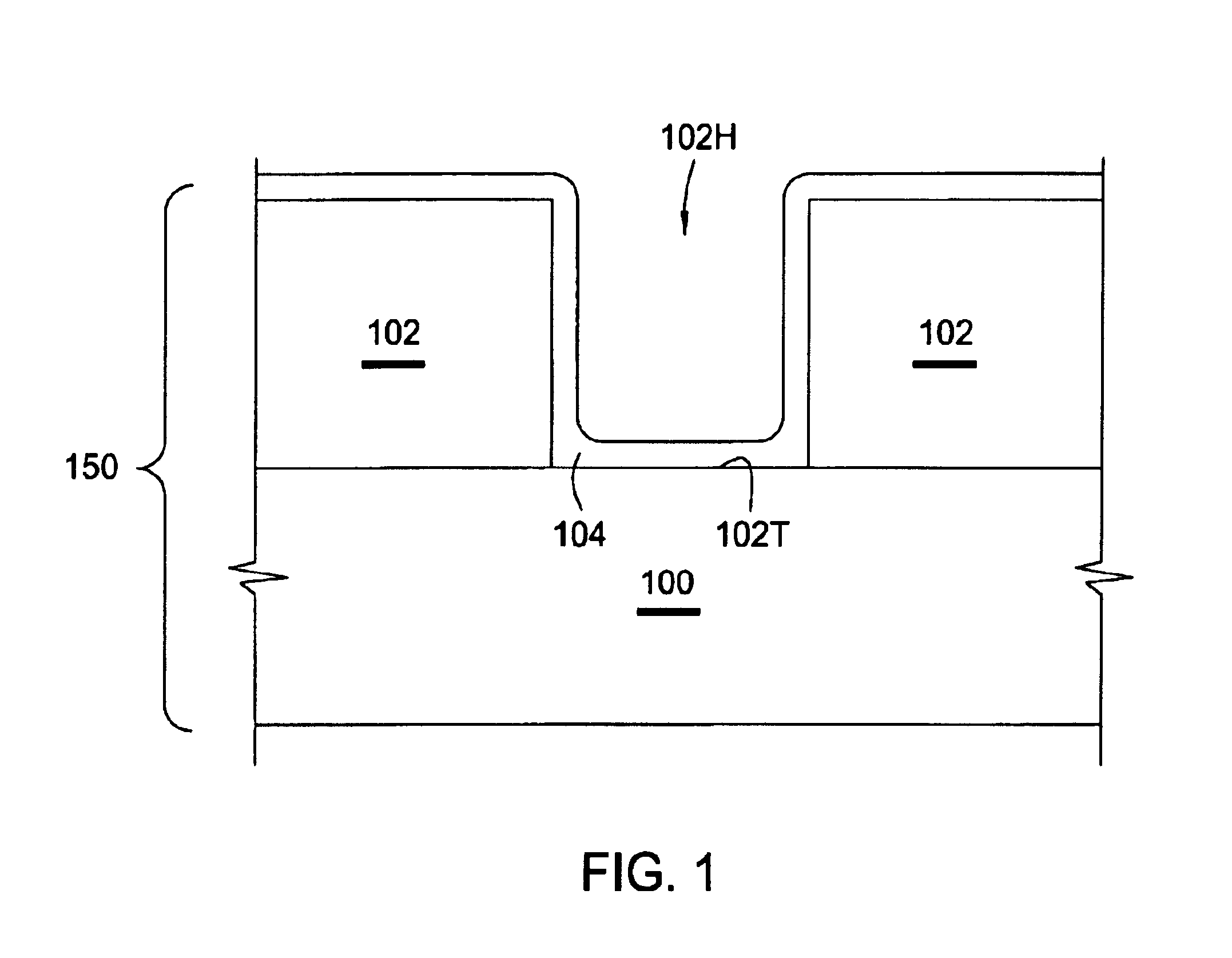

Method and apparatus for providing gas to a processing chamber

InactiveUS20050257735A1Polycrystalline material growthFrom chemically reactive gasesMean diameterProcess engineering

A method and apparatus for generating gas for a processing system is provided. In one embodiment, an apparatus for generating gas for a processing system includes a unitary, isolatable, transportable canister having a plurality of first spacing elements, a plurality of second spacing elements and a solid material disposed within the canister. The spacing elements have different mean diameters. The solid material is adapted to produce a gas vapor when exposed to a temperature above a predetermined level at a predetermined pressure. In another embodiment, an apparatus for generating gas includes a gas source coupled to a processing chamber by a first gas line. A canister is coupled in-line with the first gas line and contains a solid material that produces a process gas when heated. A heater is disposed between the gas source and the canister to heat gas flowing into the canister.

Owner:APPLIED MATERIALS INC

Heating crucible and deposition apparatus using the same

A deposition apparatus includes a vacuum chamber and a heating crucible. A substrate, on which deposition films are formed, is installed in the vacuum chamber. The heating crucible is installed opposite to the substrate so as to vaporize an organic compound. The heating crucible includes a main body and an inner plate. The main body includes a space which contains the organic compound and a nozzle through which the organic compound that is vaporized is discharged. The inner plate is installed within the main body and includes at least one opening formed around an edge of an area facing the nozzle, so as to transmit the vaporized organic compound.

Owner:SAMSUNG DISPLAY CO LTD

Method to obtain microparticles

InactiveUS6753014B1Reduce brittlenessEasily controllable density and strengthPowder deliveryDrying solid materials without heatMicroparticleFreeze Technique

Method of obtaining microparticles.A method for the preparation of homogeneous microparticles containing a pharmaceutically active substance by a spray freezing technique wherein the medium to be atomized into droplets has a high dry content and comprises besides the active substance a polymer and a liquid (in which the polymer may be soluble) in which the active substance and polymer are suspended, dissolved or emulsified.

Owner:ASTRAZENECA AB

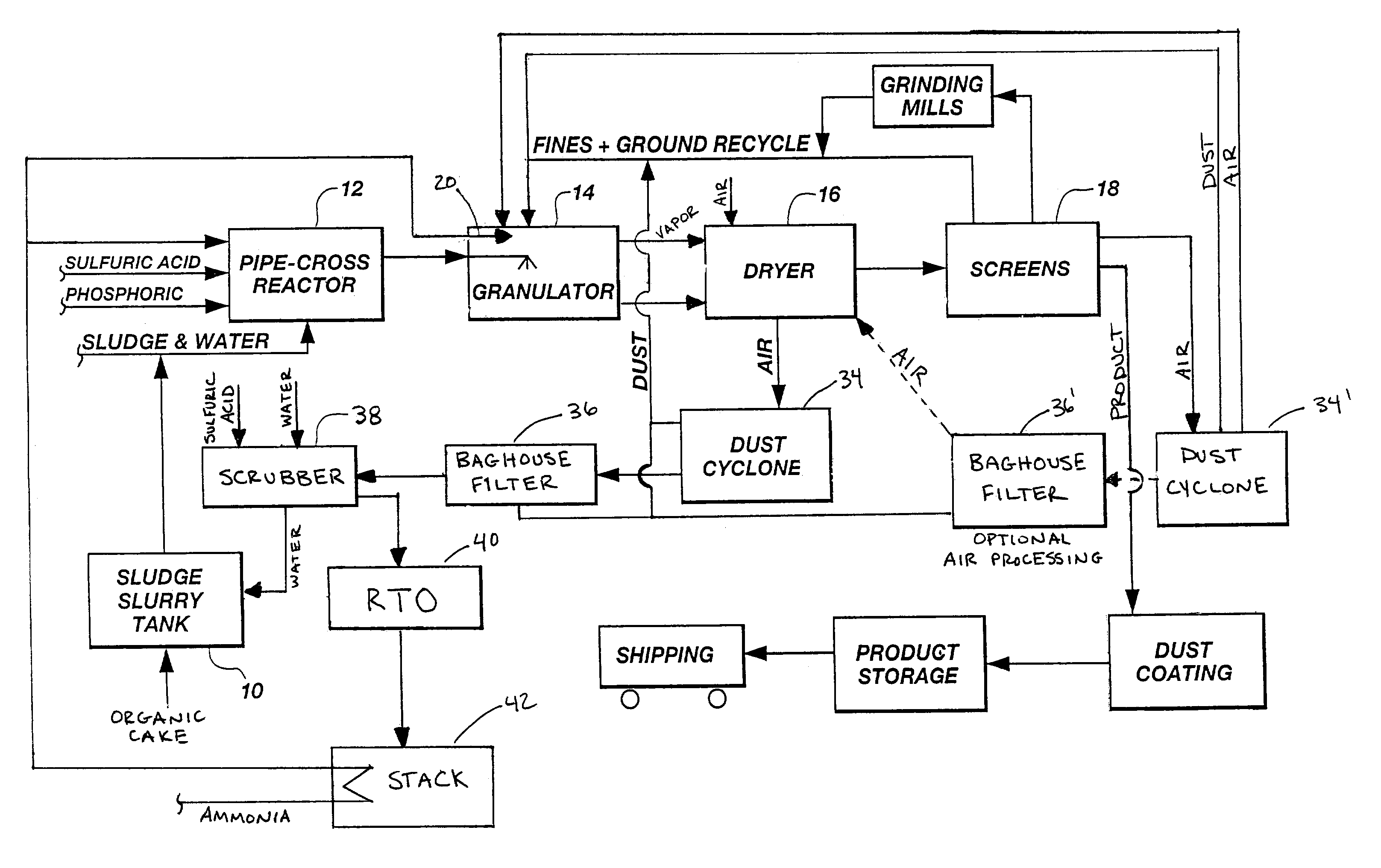

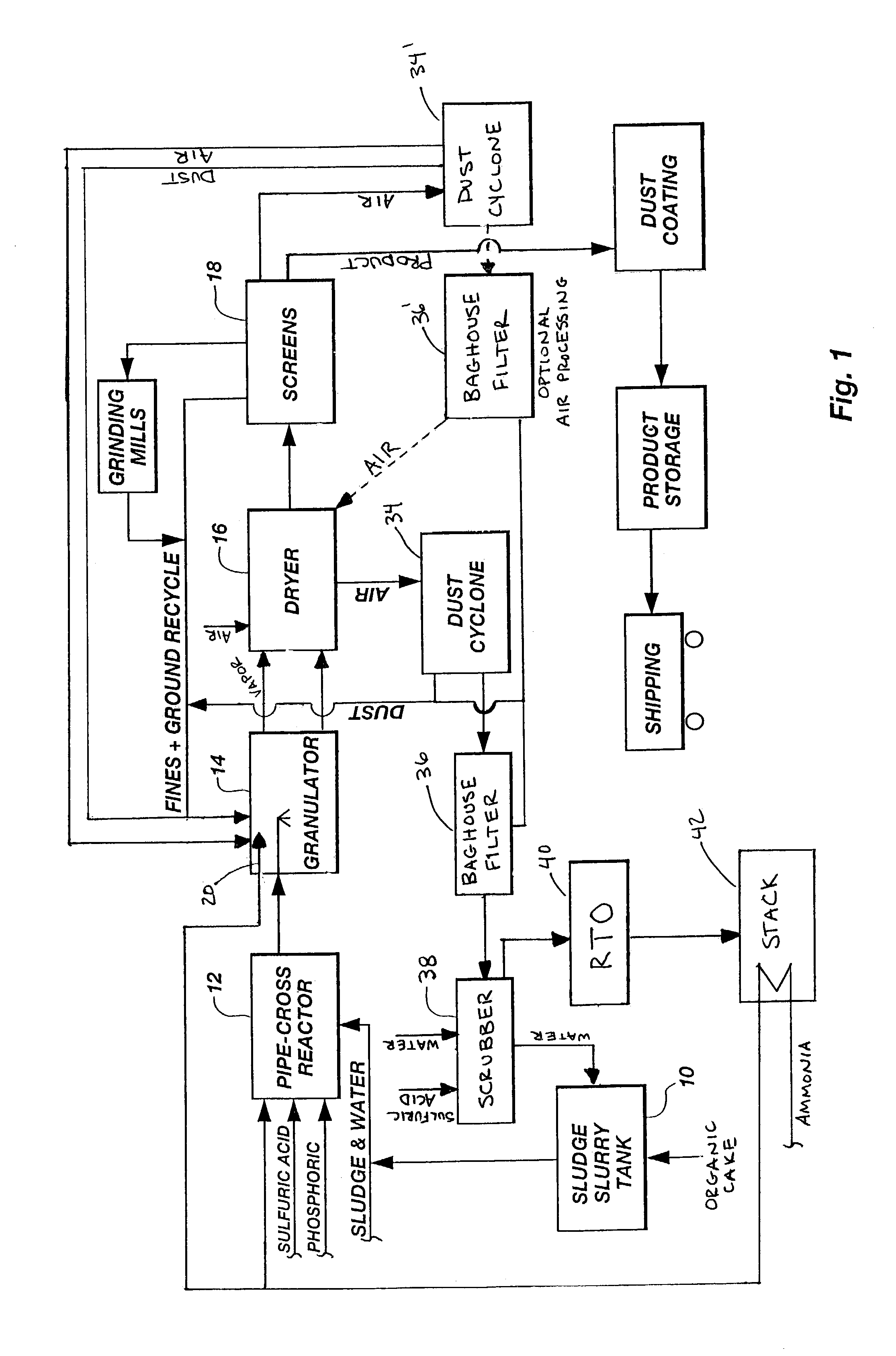

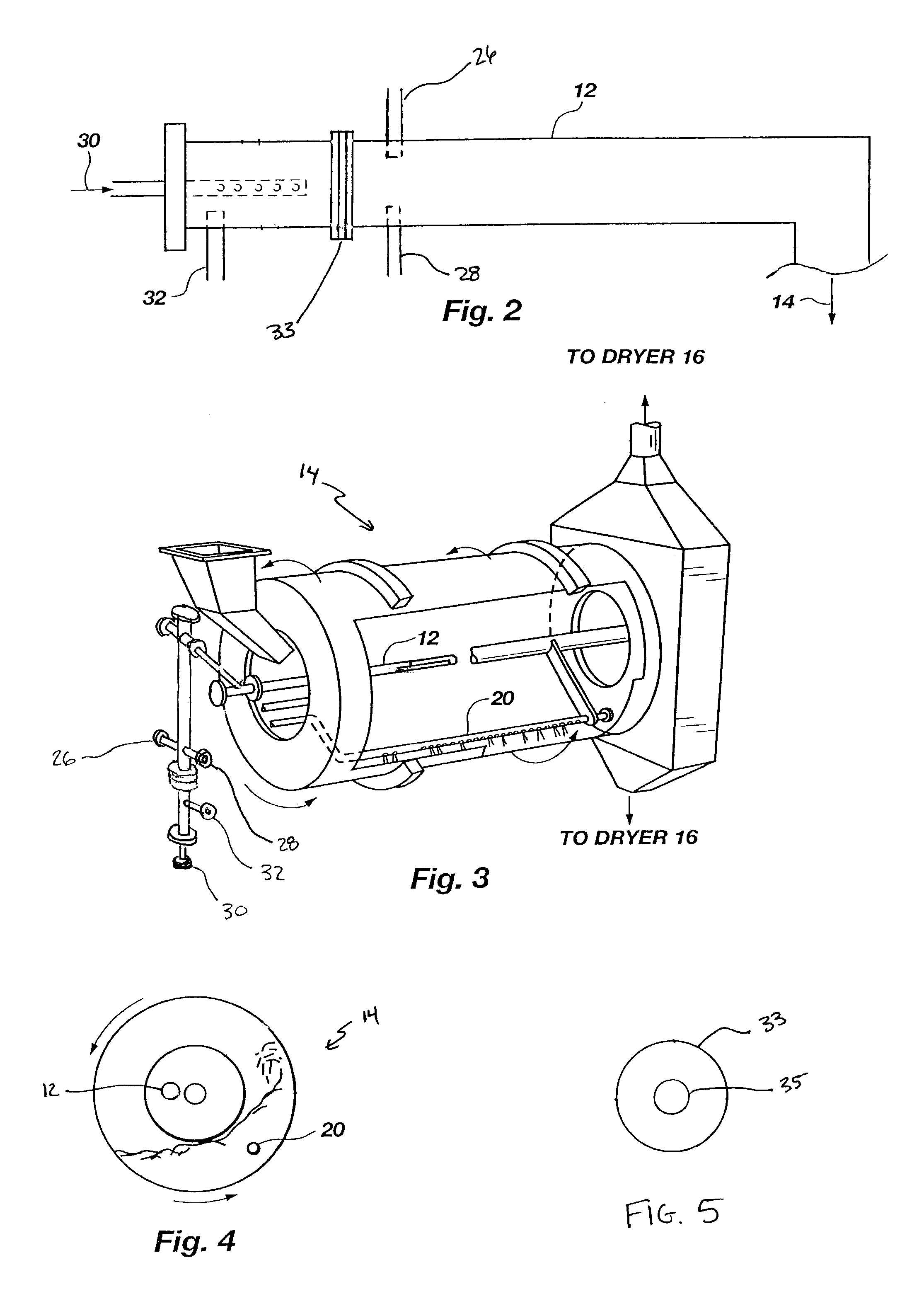

Organic recycling with a pipe-cross or tubular reactor

ActiveUS7128880B2Reduce moisture contentSimple compositionPhosphatesAnimal corpse fertilisersWater vaporSludge

The invention is directed to a process for enhancing the plant nutrient value of relatively low analysis organic waste material (e.g. sewage sludge) involves treating the waste material with an acid and base in a pipe-cross reactor or tubular to form a melt; spraying the melt onto a recycling bed of fines in a granulator and flashing off the water contained in the melt as steam; rolling the melt onto recycled fine particles in a granulator to form granulated particles; and drying these granulated particles to form an enhanced plant nutrient value composition (e.g. a fertilizer or soil conditioner having a greater NPK value than the original relatively low analysis organic waste material). The process further includes drawing off the fumes from the granulator, passing them through a dryer with the granulated particles, and subsequently oxidizing the fumes to eliminate volatile organic compounds and / or gaseous hydrocarbon pollutants be converting such into carbon dioxide and water vapor.

Owner:UNITY FERTILIZER LLC

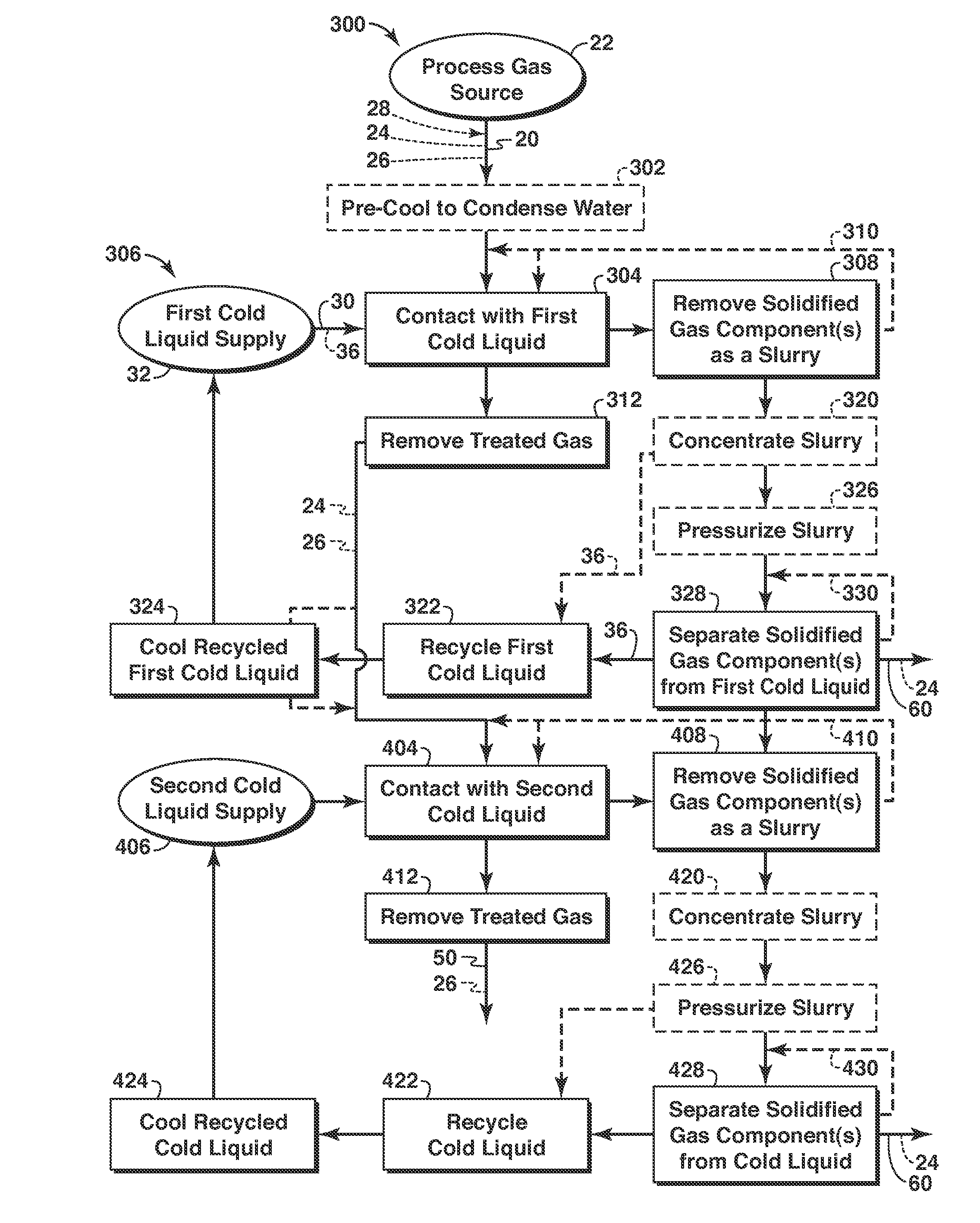

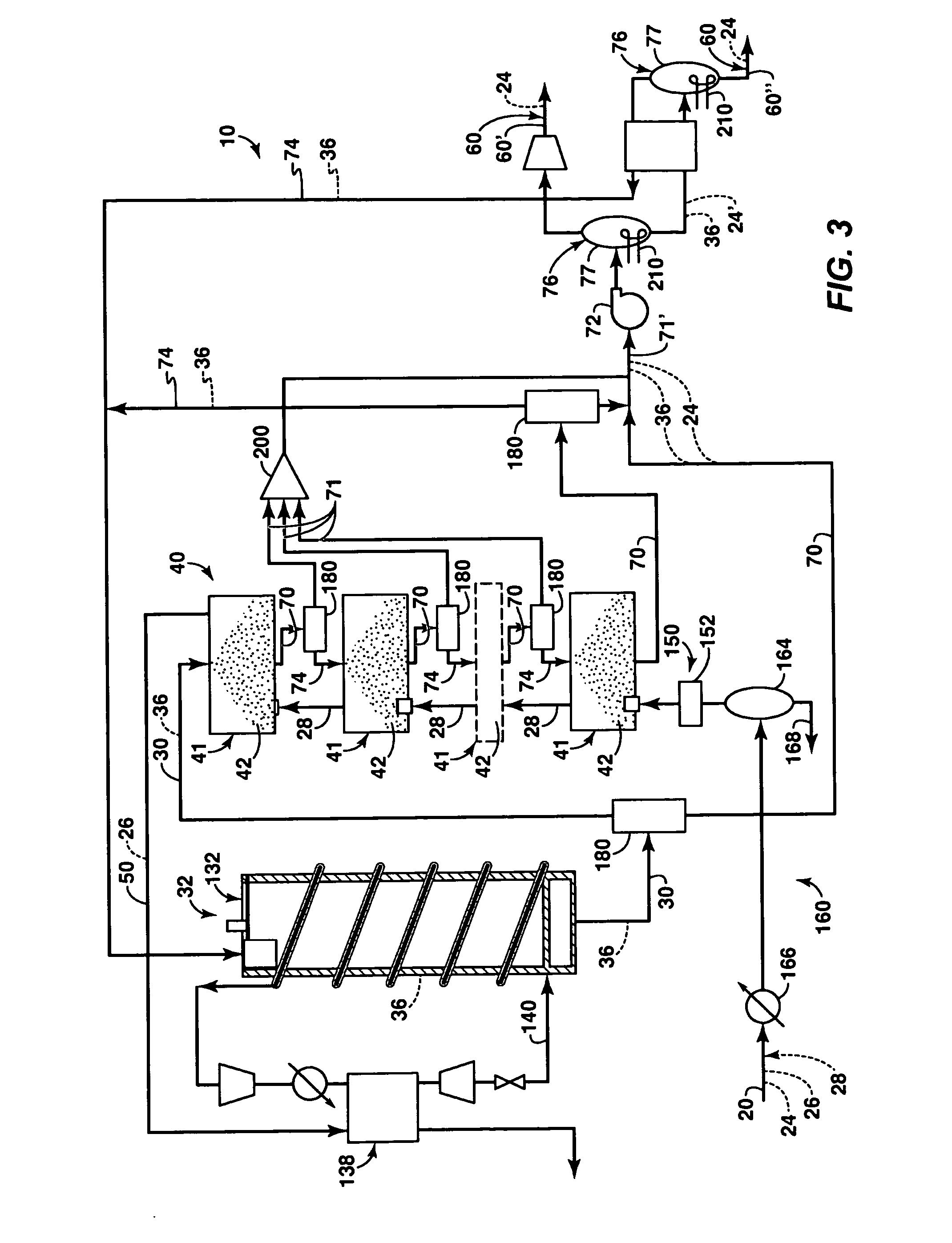

Systems and Methods For Using Cold Liquid To Remove Solidifiable Gas Components From Process Gas Streams

ActiveUS20130074541A1Increase pressureImprove concentrationSolidificationLiquefactionSlurryChemistry

Systems and methods are described for re-moving solidifiable gas from a process gas stream by direct contact with a cold liquid. The process gas stream includes at least gas that is frozen by the cold liquid while one or more other gases of the process gas stream remain in a gaseous state. The process gas stream may include water, and will have a different composition than the cold liquid. The contacting of the cold liquid with the process gas stream may be at a pressure that is less than 200 psia, and optionally less than 100 psia, 50 psia, or even 30 psia, and the solidified gas may be removed from the contacting assembly as a slurry with cold liquid.

Owner:EXXONMOBIL UPSTREAM RES CO

Nozzle-based, vapor-phase, plume delivery structure for use in production of thin-film deposition layer

Owner:UNIVERSITY OF DELAWARE +1

Devices, methods, and systems for detecting particles in aerosol gas streams

Turbulent mixing condensation devices, methods, and systems adapted to condense a working fluid on particles from a sample gas to enlarge the particles for subsequent detection are provided. The device includes a vapor generator adapted to produce a working-fluid saturated carrier gas and a condensation chamber. The working-fluid saturated carrier gas is mixed with a sample gas containing particles to be detected and is then introduced to the condensation chamber. The operating conditions are controlled to enhance the condensation of the working fluid on the particles. The particles are typically forwarded to a particle detection device to detect at least one characteristic, for example, the size, of the particles. The flow of carrier gas to the vapor generator may be regulated to vary the degree of saturation of the carrier gas with working fluid.

Owner:THERMO FISHER SCIENTIFIC INC

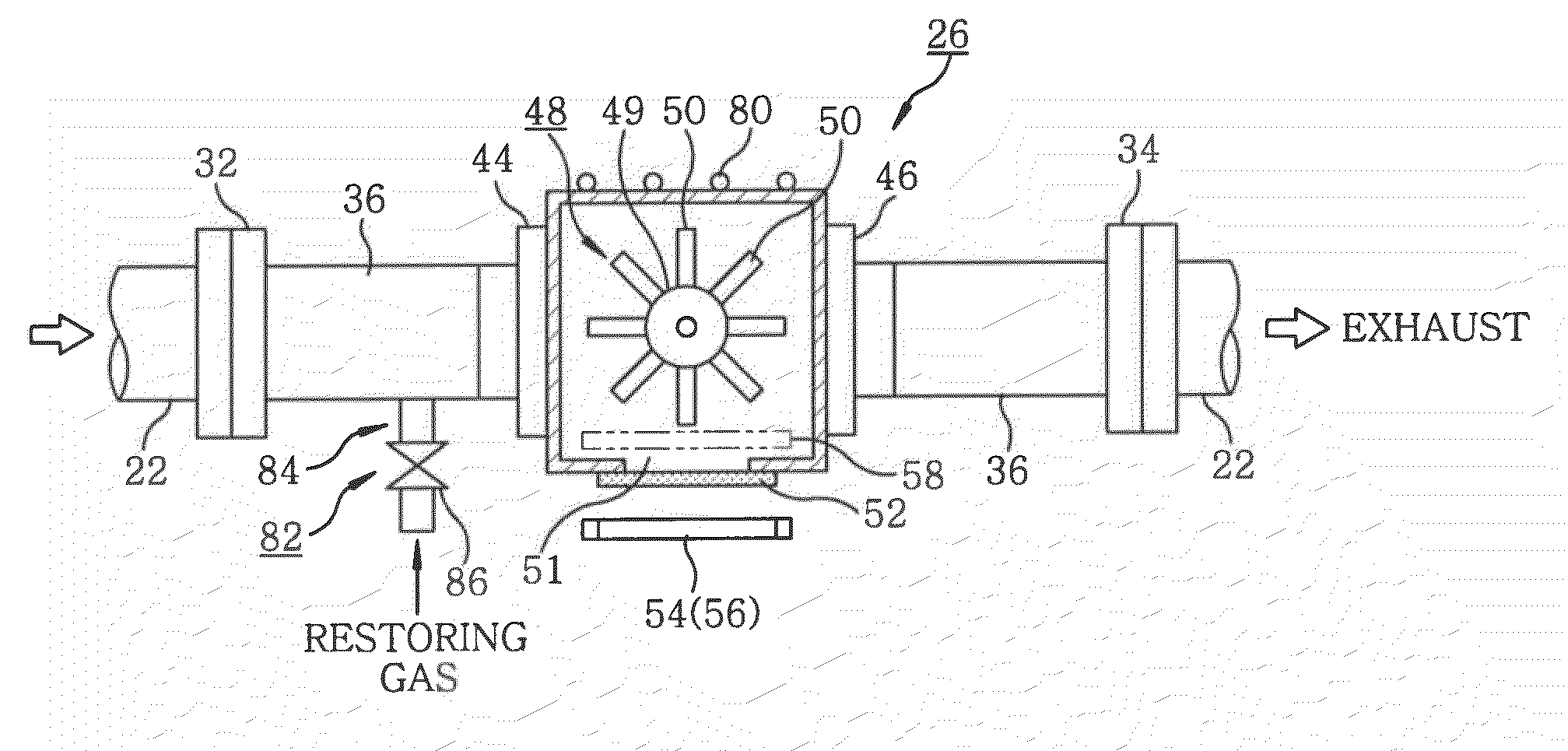

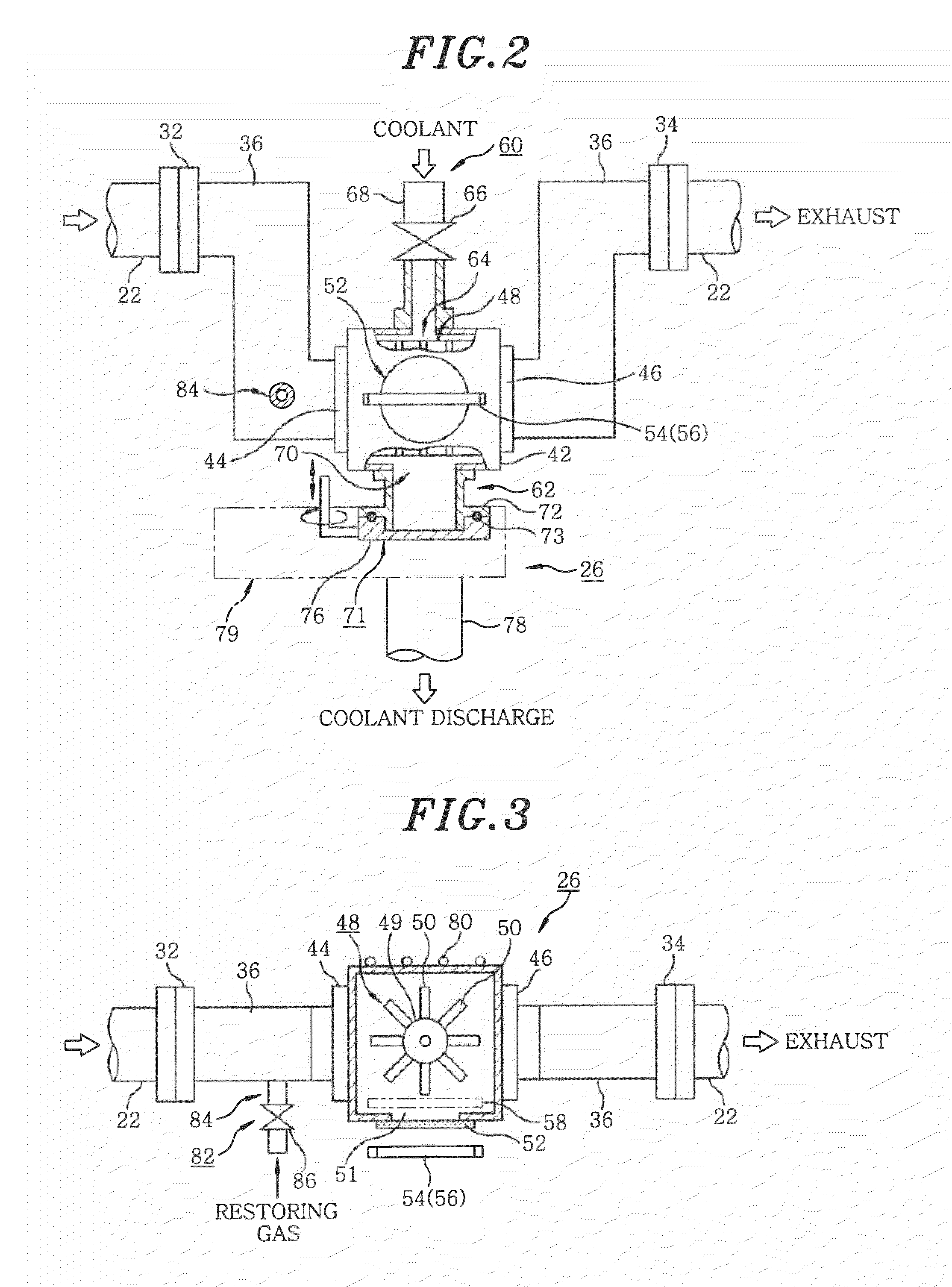

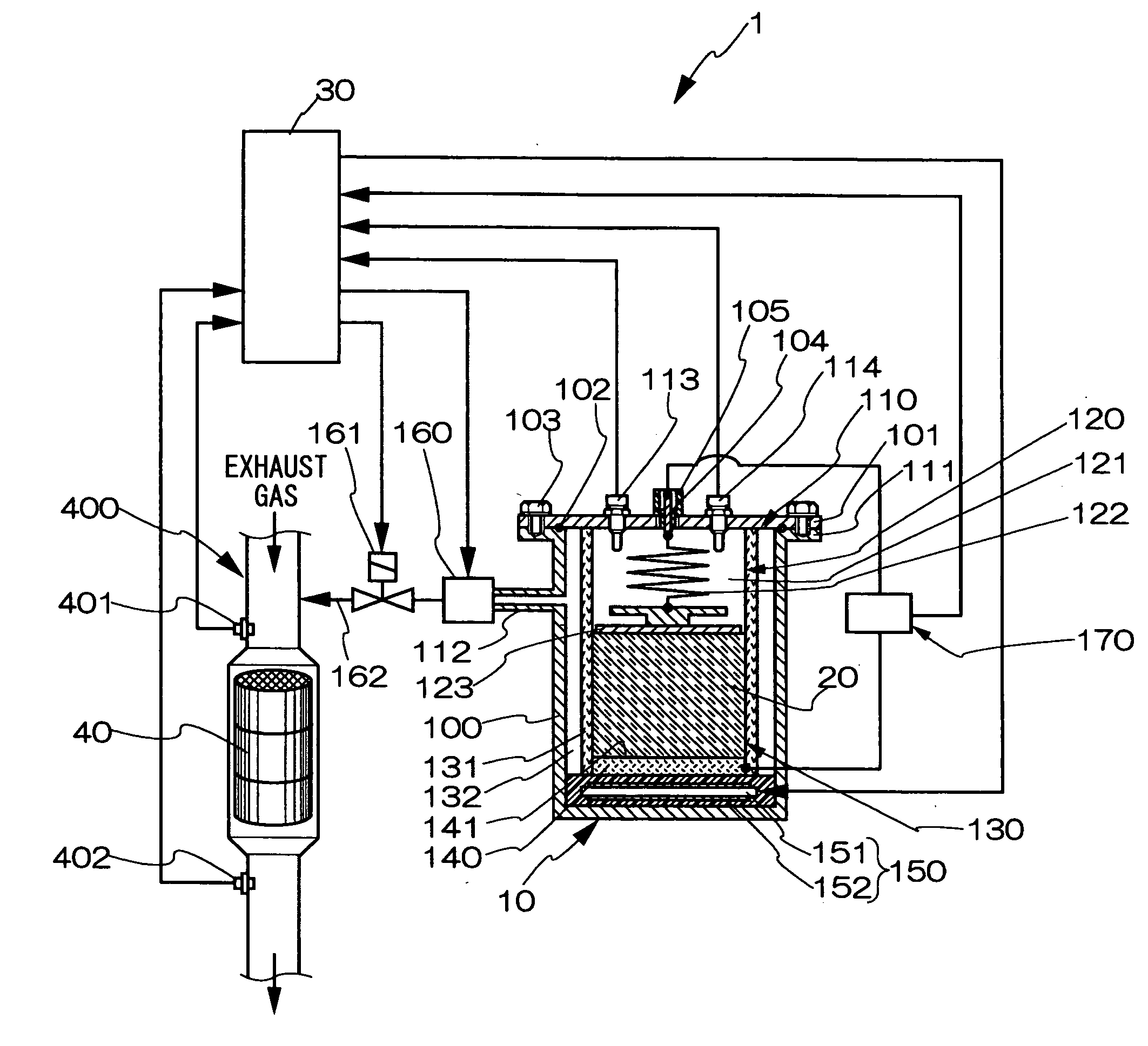

Trap apparatus, exhaust system and processing system using same

InactiveUS20100012292A1Fully removedPrevent leakageCombination devicesSolidificationEnvironmental engineeringHandling system

Provided is a trap apparatus, disposed in an exhaust passage 22 for discharging an exhaust gas from a processing chamber 10 for processing a wafer W, thereby to trap exhaust from the exhaust gas, so that the exhaust trapped by a trap element can be efficiently removed to regenerate the trap element. The trap apparatus includes a housing 42 disposed in the exhaust passage, a trap element 48 disposed in the housing for trapping the exhaust, a trap heating unit 54 for heating the trap element, a coolant introducing unit 60 for introducing a coolant into the housing, a coolant discharging unit 62 for discharging the coolant from the housing, and a controller 88 which performs a control to introduce the coolant from the coolant introducing unit into the housing, while the trap element being heated by the trap heating unit, to remove the exhaust trapped by the trap element.

Owner:TOKYO ELECTRON LTD

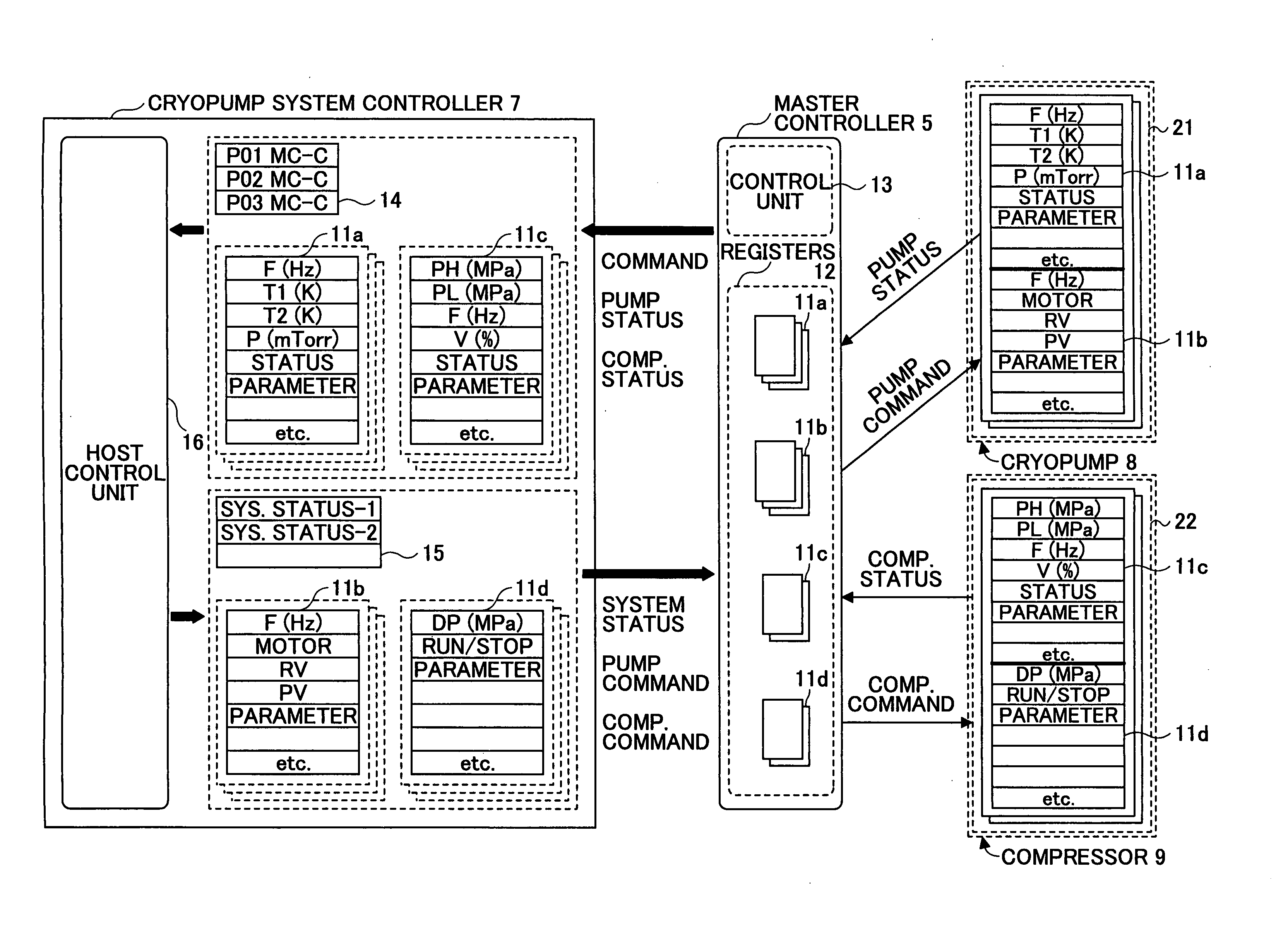

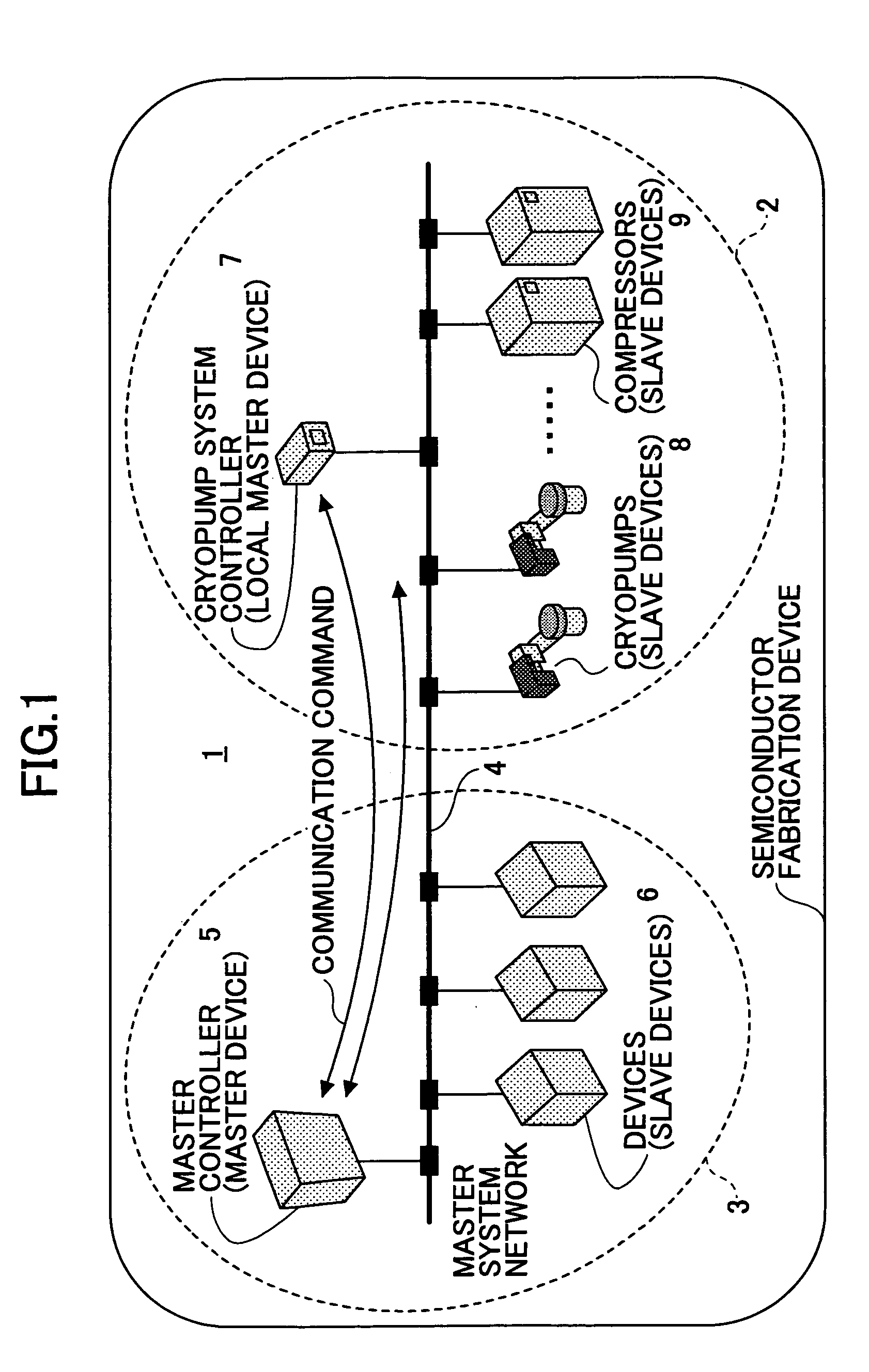

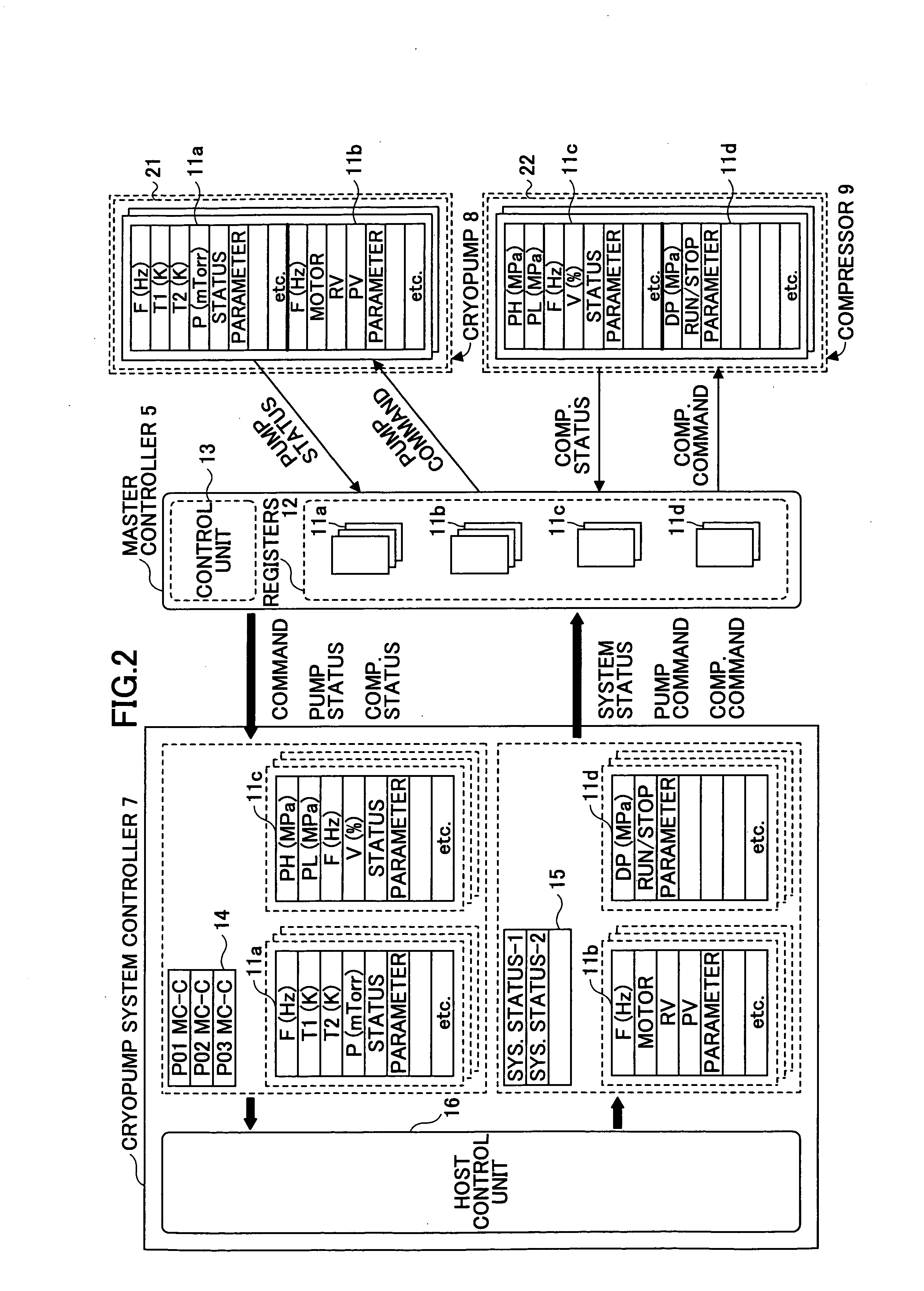

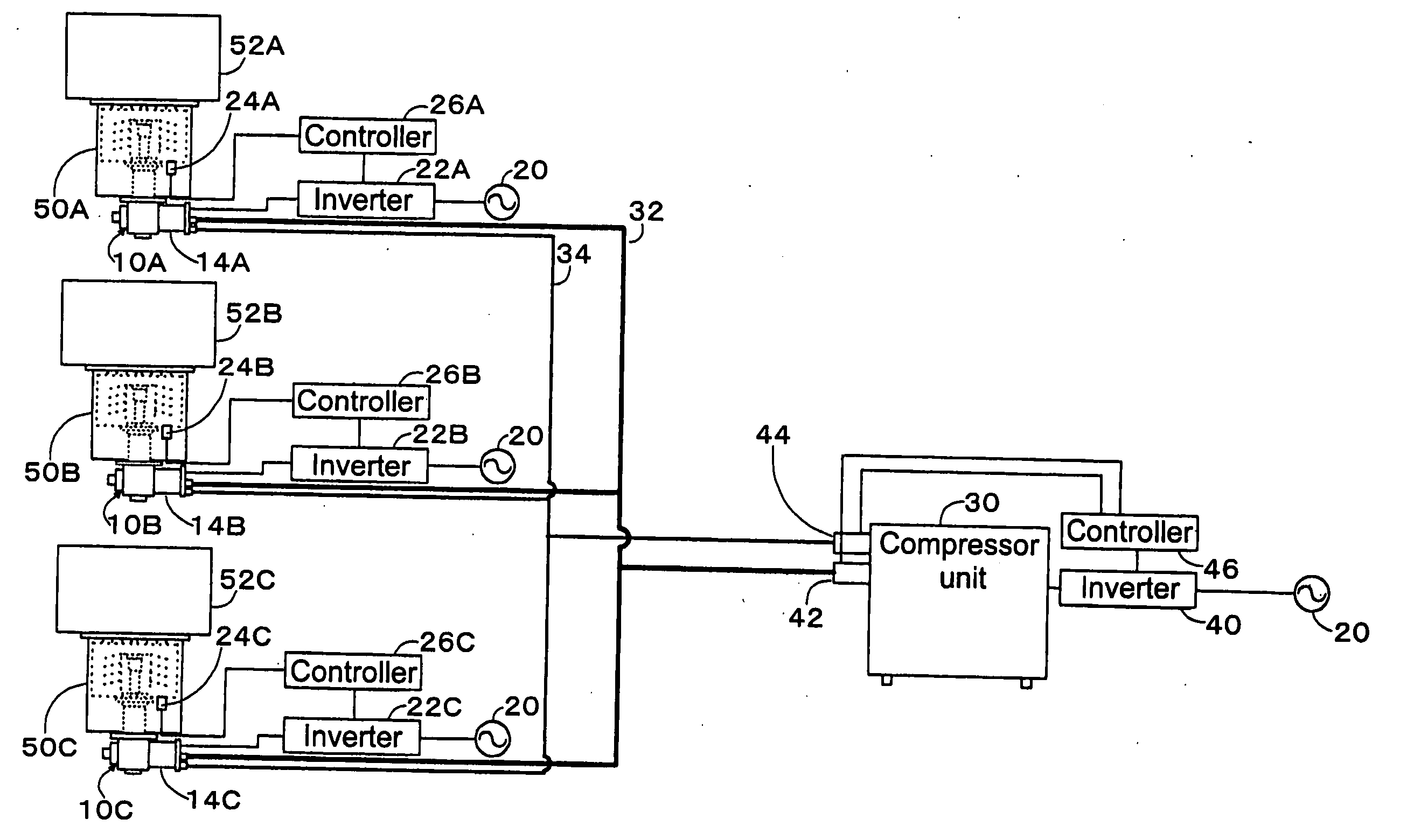

Communication network system

InactiveUS20080078189A1Ensure reliabilityReduce wiringProgramme controlSolidificationNetworked systemControl data

In a communication network system which unifies a system communication network and a master system communication network, each of a plurality of controlled devices is configured to transmit status data to a master controller and receive control data from the master controller so that the controlled device is operated based on the control data. The master controller comprises a control unit configured to receive status data of the controlled devices and transmit control data to the controlled devices, the control unit being configured to transmit the status data to a system controller and receive the control data from the system controller. The system controller comprises a second control unit configured to receive the status data of the controlled devices from the master controller, perform a processing operation based on the status data, and transmit a result of the processing operation to the master controller as the control data.

Owner:SUMITOMO HEAVY IND LTD

Multiple-nozzle thermal evaporation source

InactiveUS6982005B2Simple structureImprove balanceVacuum evaporation coatingSputtering coatingLow emissivityEvaporation

A multiple nozzle thermal evaporation source includes a plurality of nozzles having a tapered shape. The nozzles may comprise a thermally conductive material having a low emissivity material.

Owner:UNIVERSITY OF DELAWARE

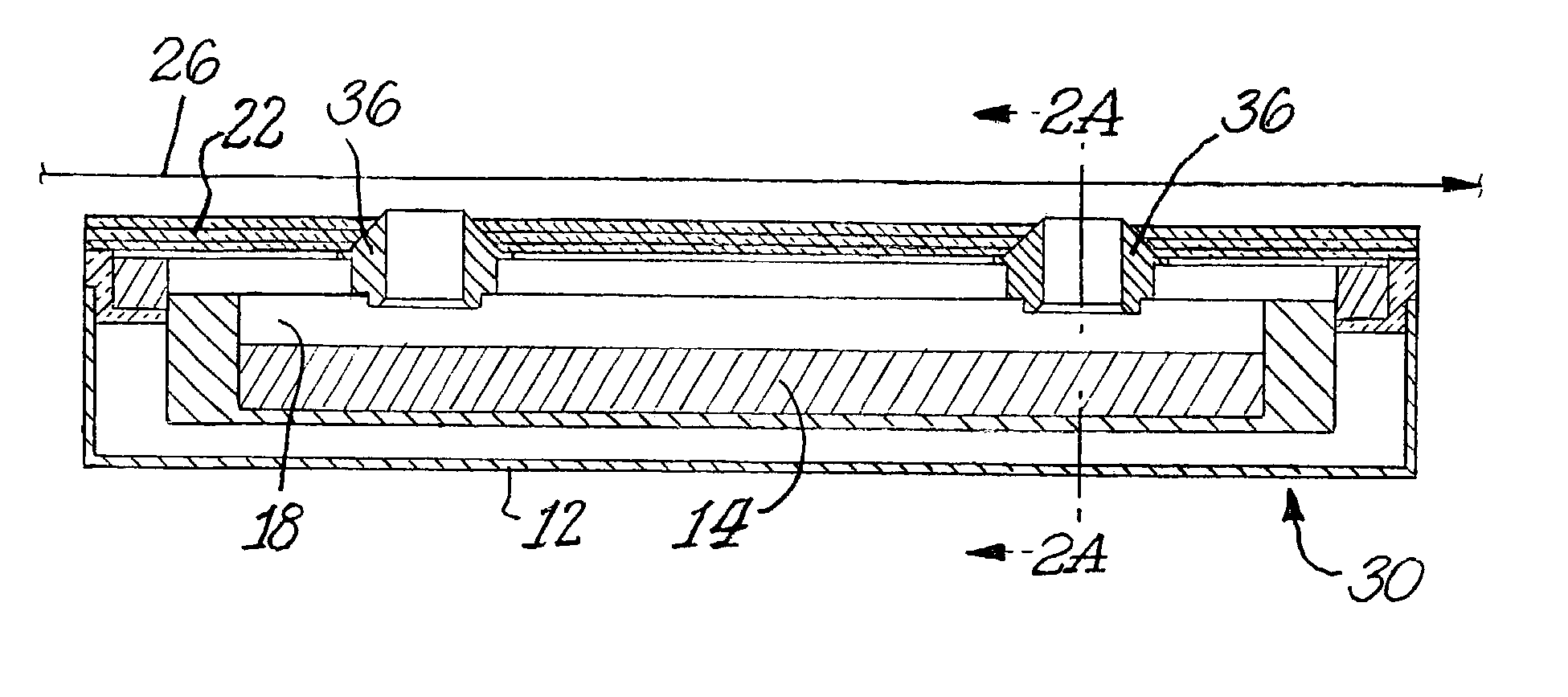

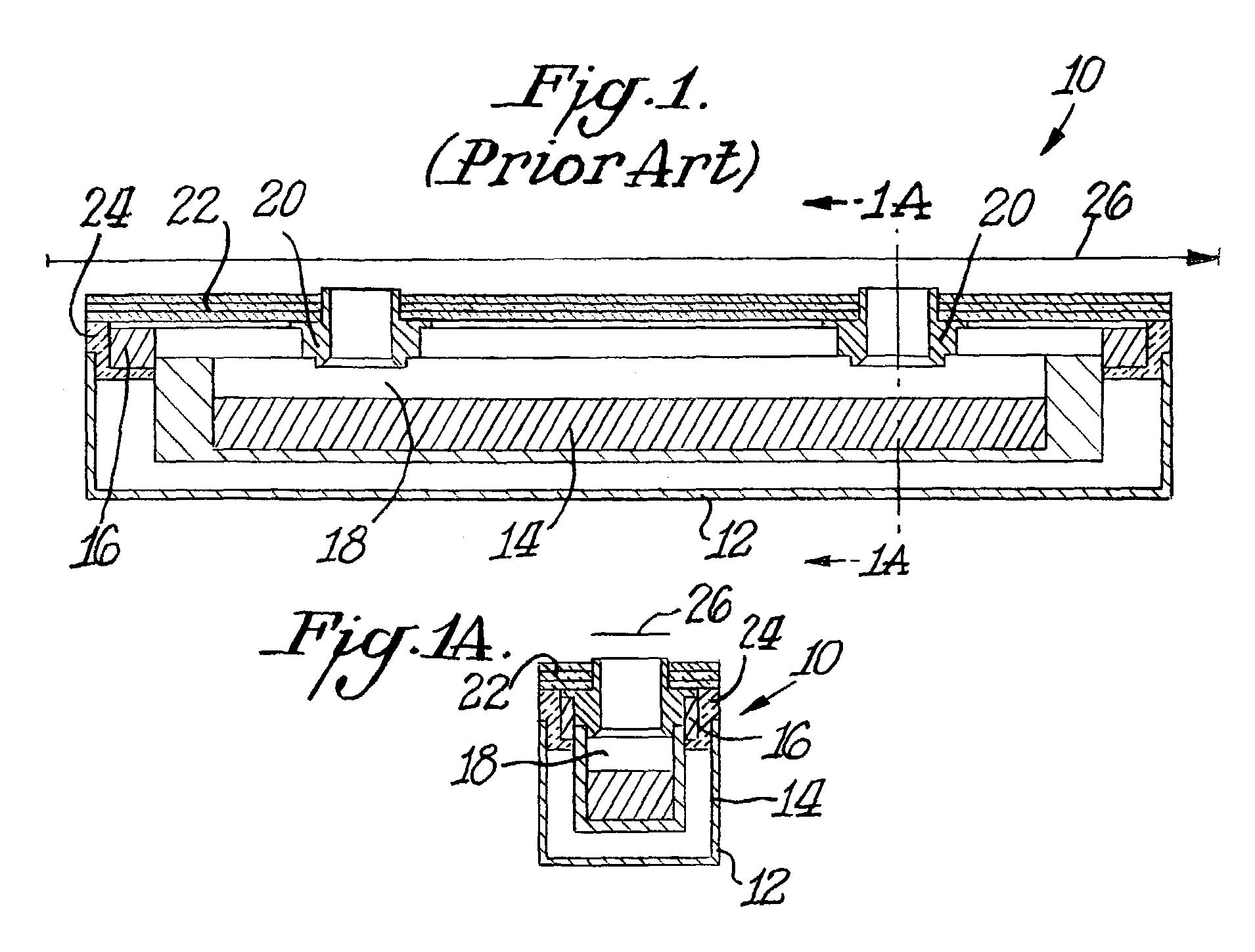

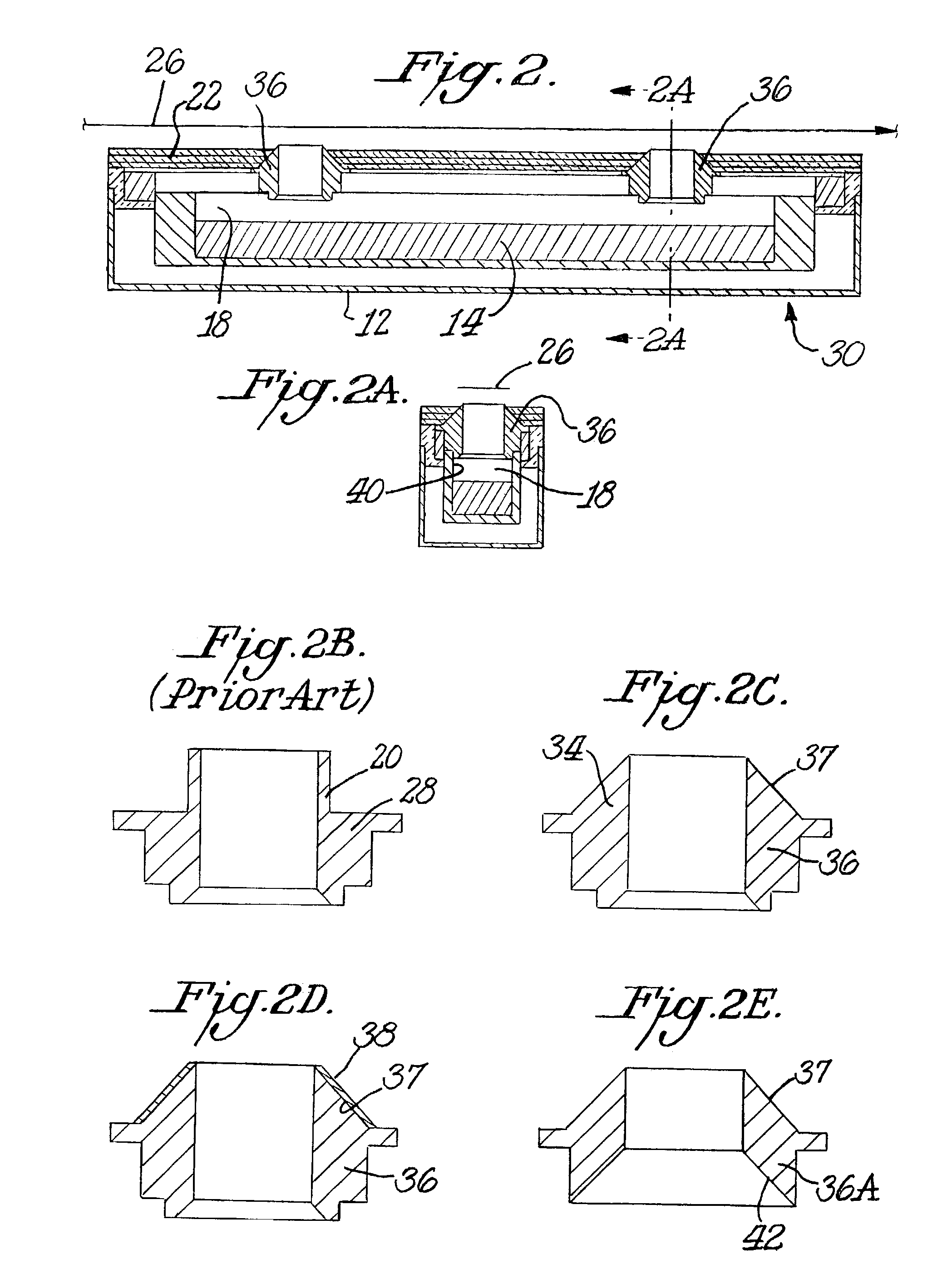

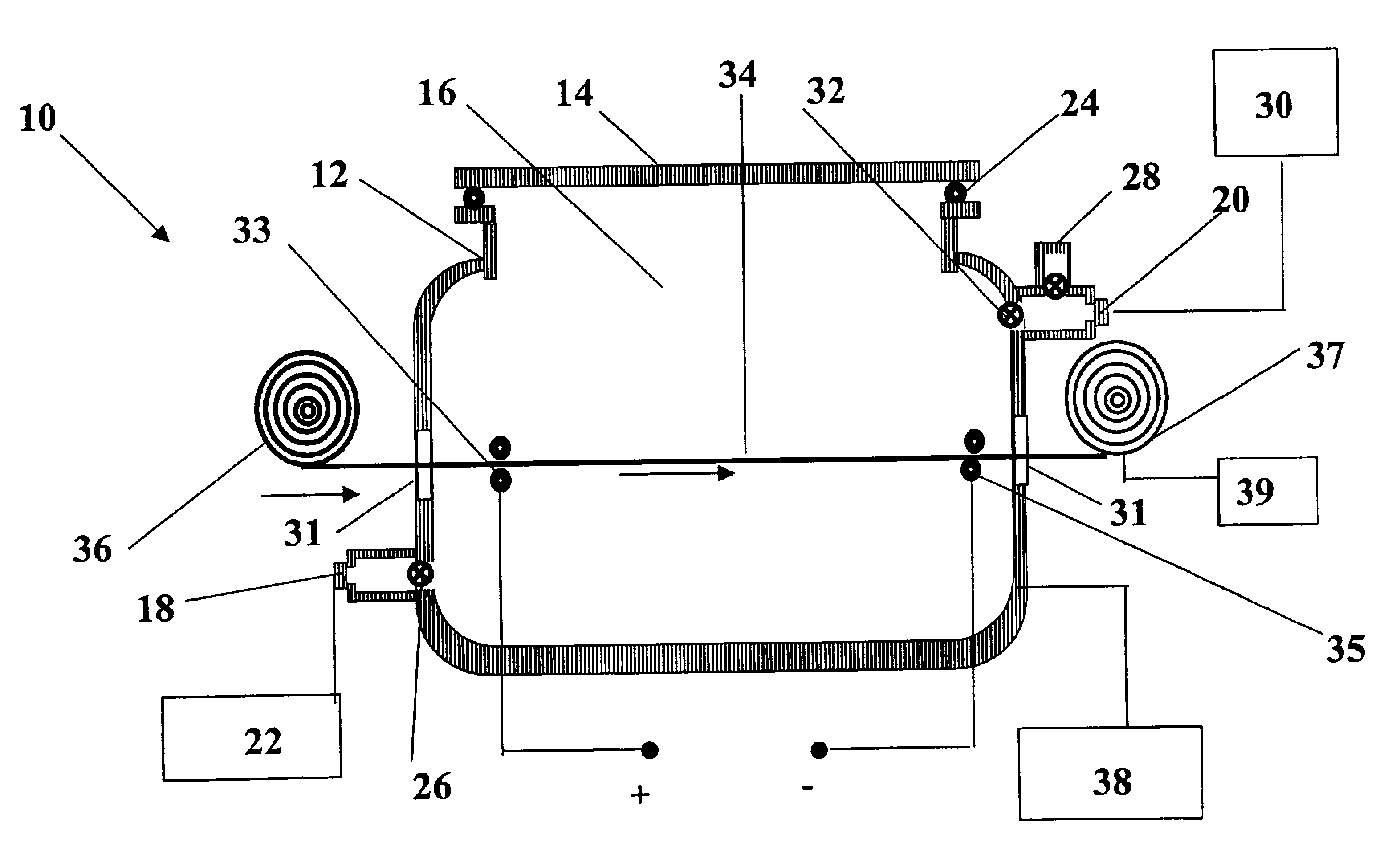

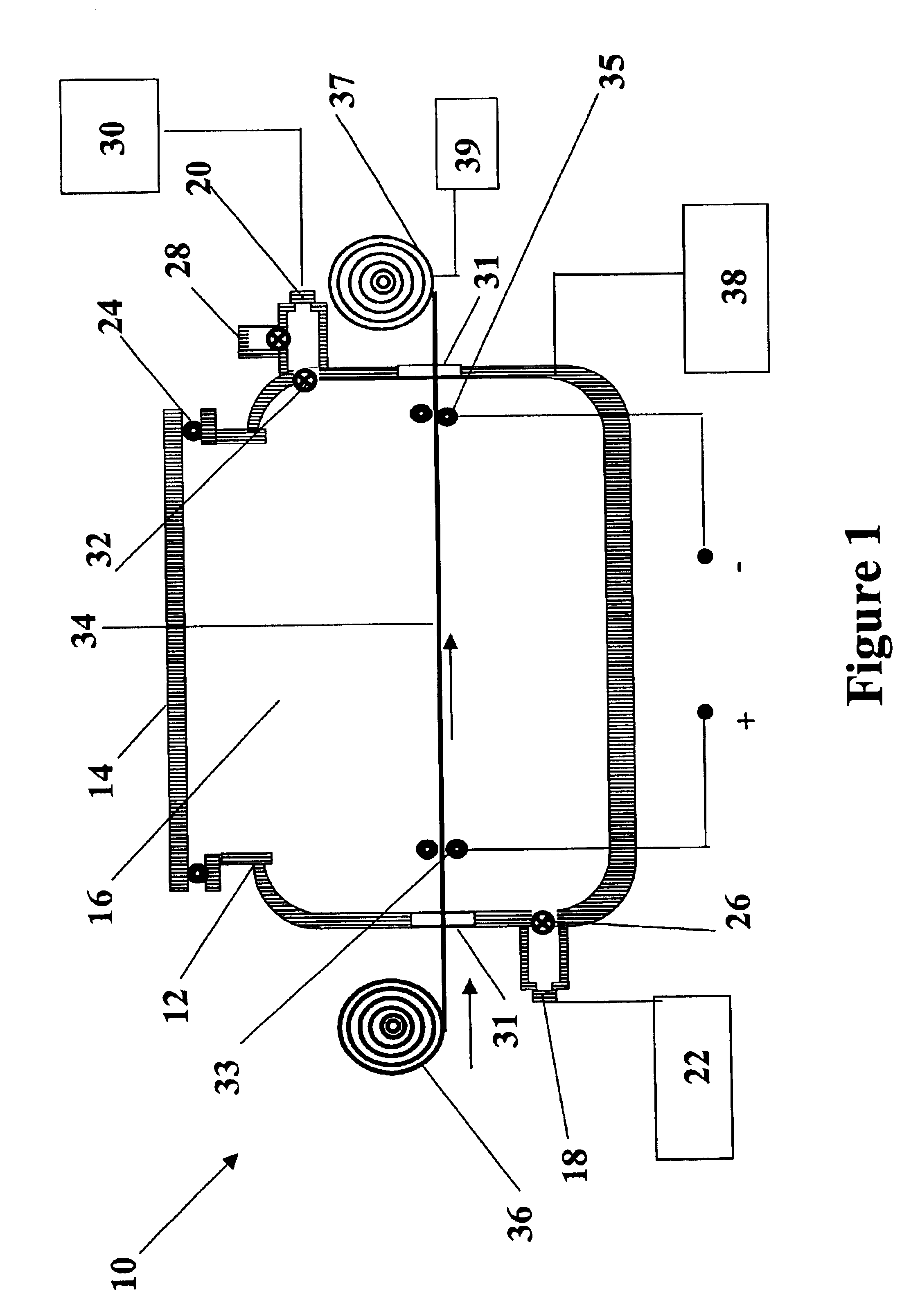

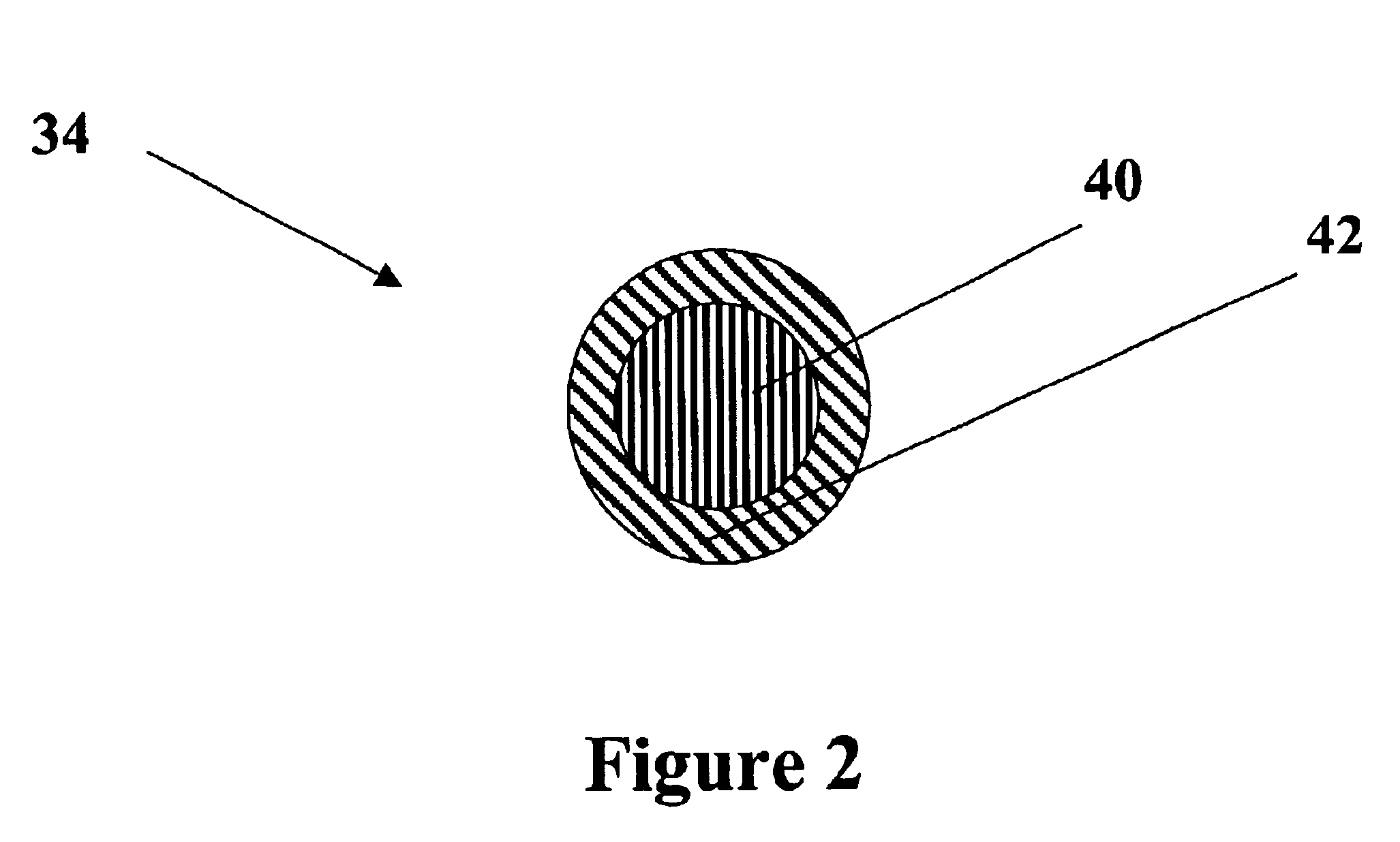

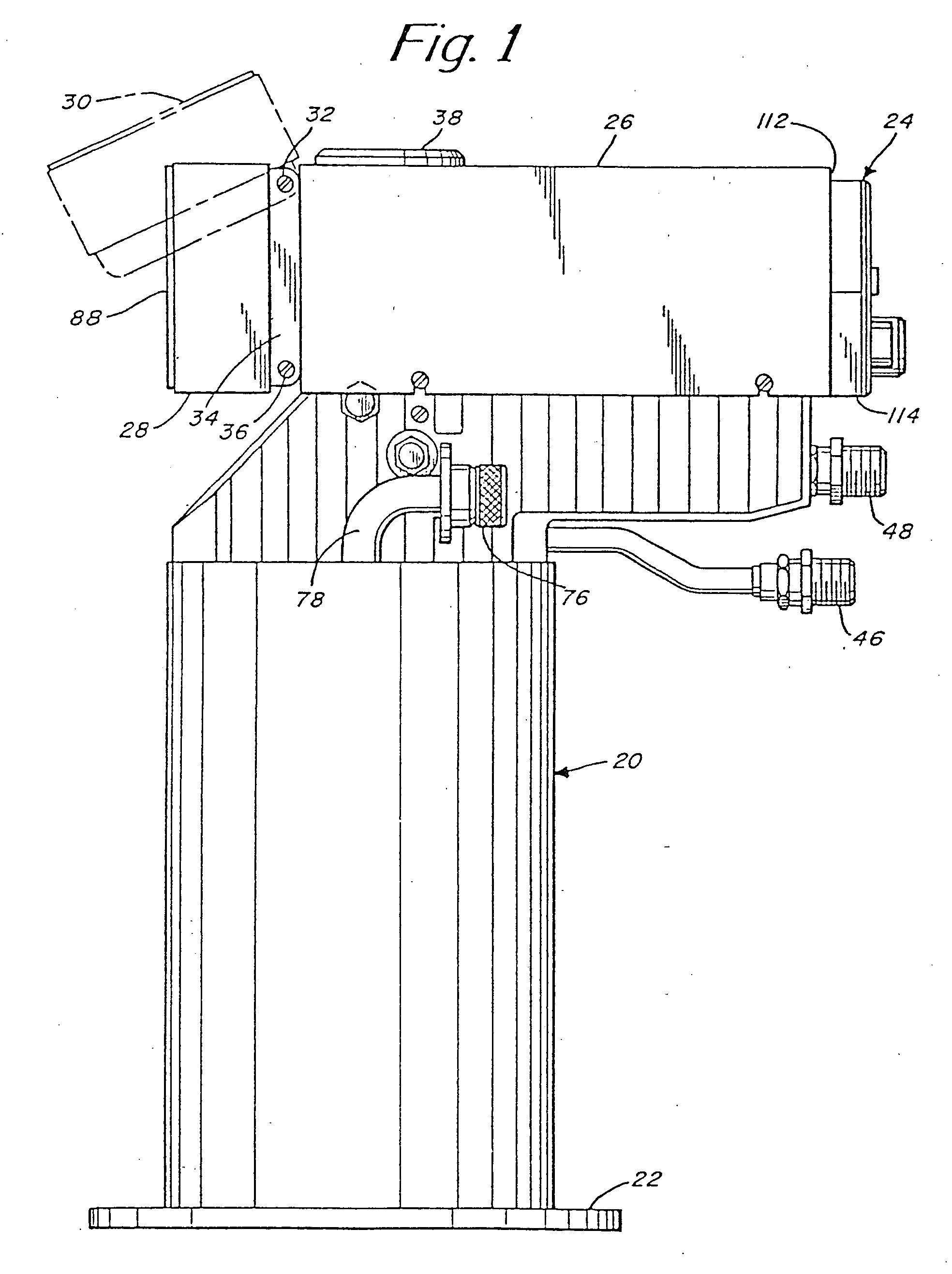

Vapor delivery system for solid precursors and method of using same

InactiveUS6740586B1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingEngineeringDelivery system

A vaporizer delivery system including a sublimatable solid precursor material applied to a wire substrate for vaporizing and achieving a continuous uninterrupted delivery of a vaporized precursor to a downstream semiconductor process chamber. The coated wire substrate is drawn past a heat source at a predetermined speed to rapidly heat and vaporize the sublimatable solid precursor.

Owner:ADVANCED TECH MATERIALS INCL

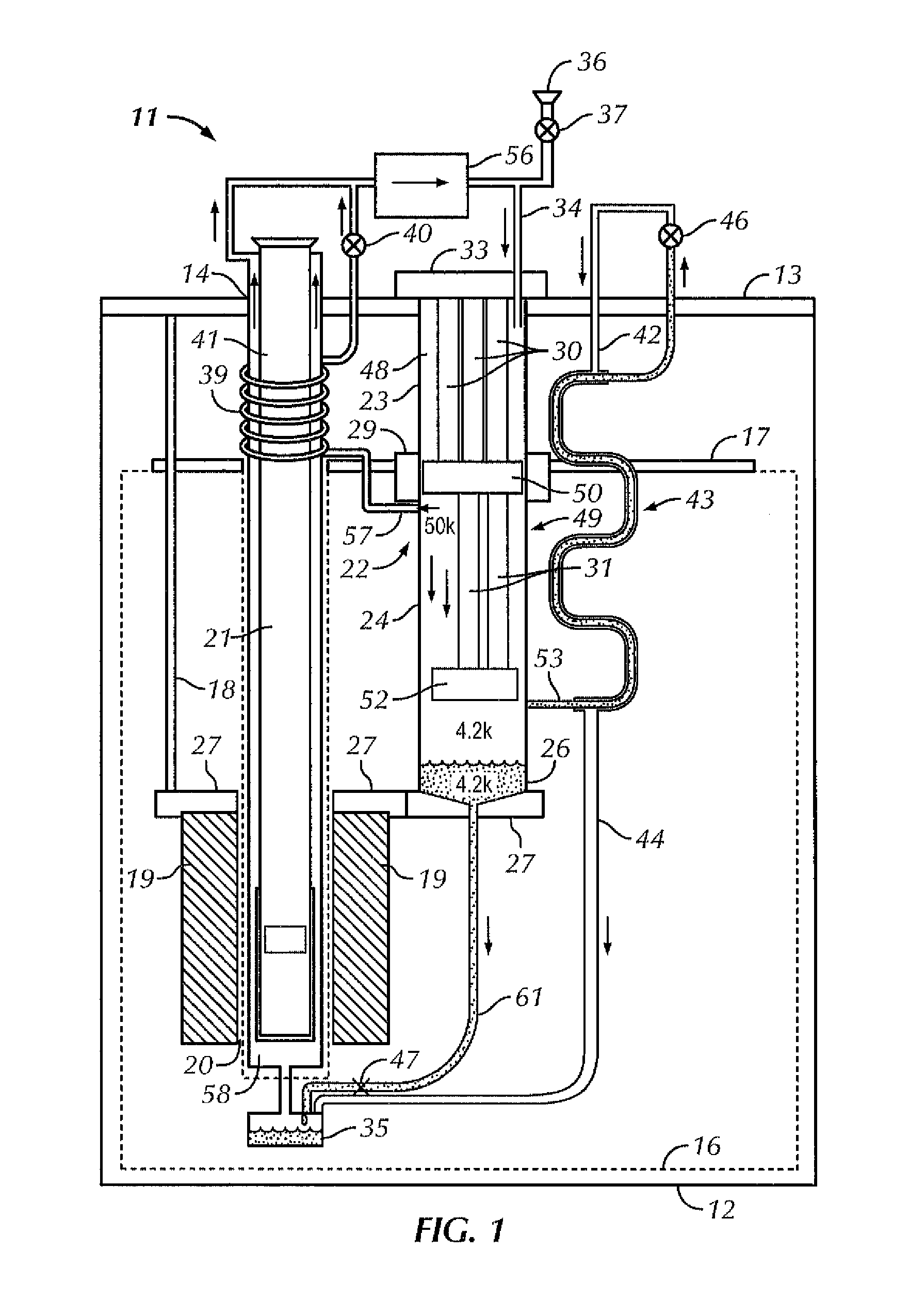

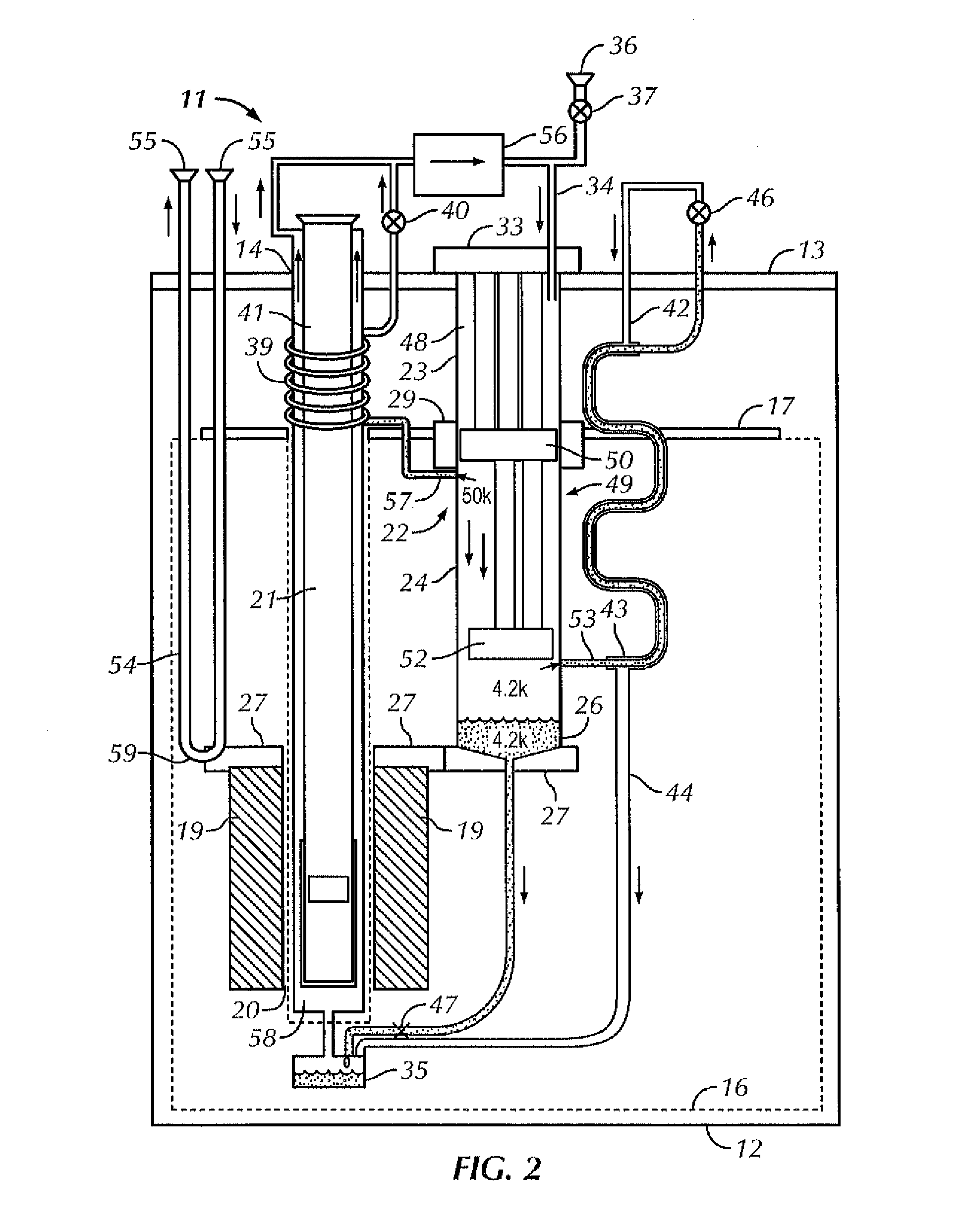

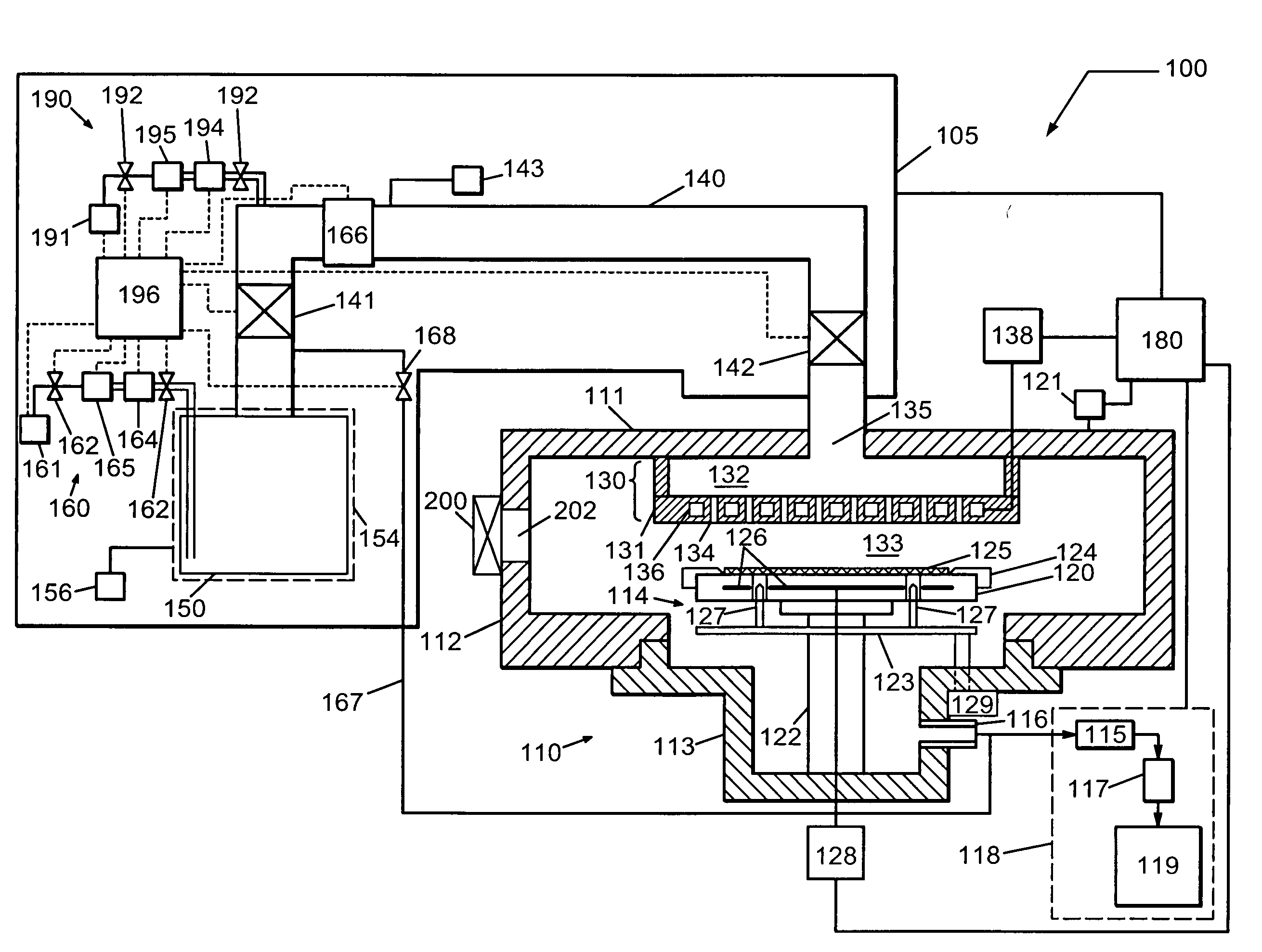

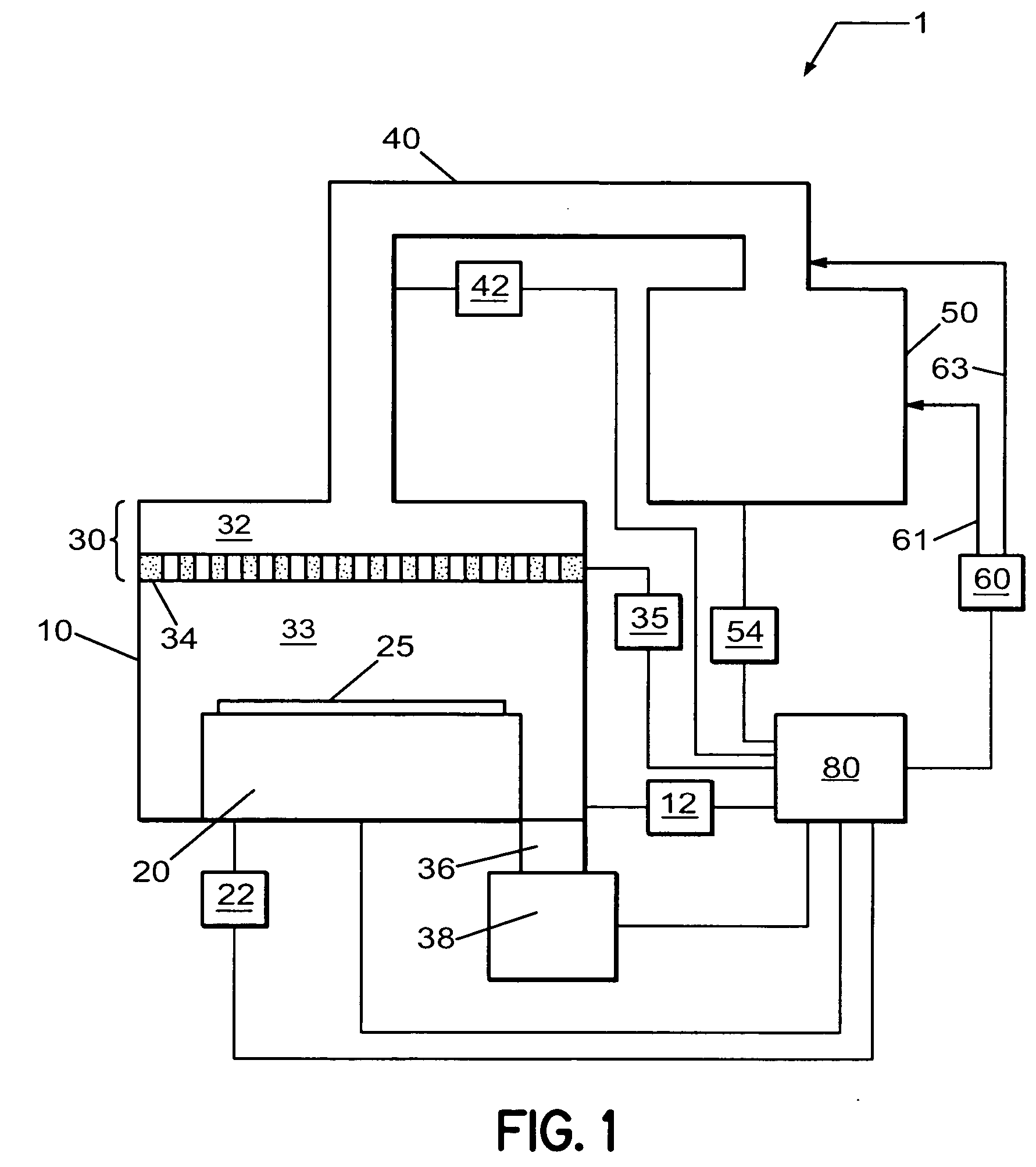

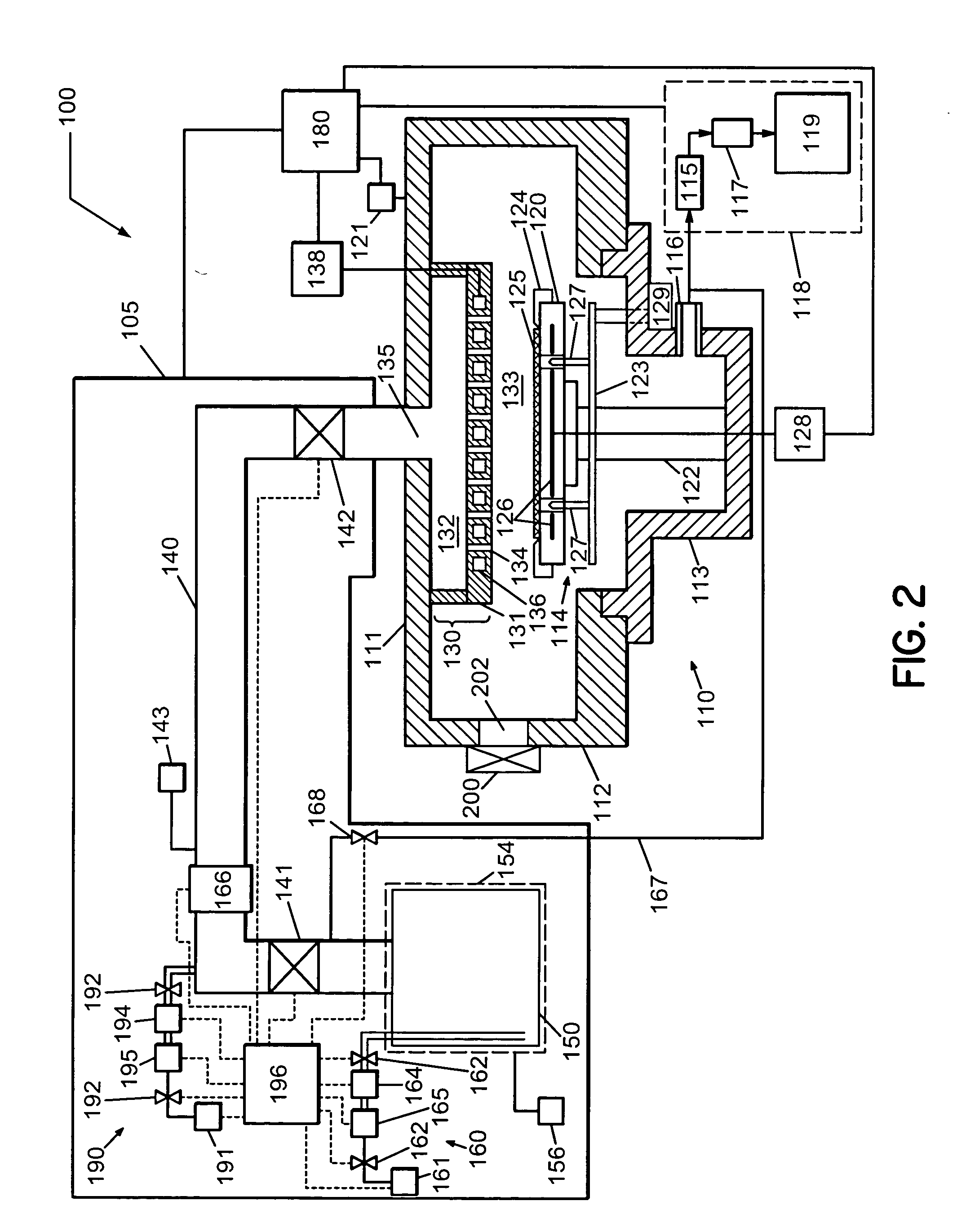

Method and apparatus for controlling temperature in a cryocooled cryostat using static and moving gas

ActiveUS20110219785A1Rapid initial cool-downMinimal, if any, helium replenishmentSolidificationLiquefactionCounter flowTemperature conditioning

A cryostat for providing temperature regulation, one purpose being measuring physical properties of materials, the cryostat employing a superconducting magnet assembly for generating variable magnetic field in the sample space and a cryogenic cooler for cooling the sample space. The cryogenic cooler chamber configuration provides for efficient heat exchange between different stages of the cryogenic cooler without the need for physical heat links. This construction enables selective delivery of cooling power from the cryogenic cooler to the desired areas within the cryostat without using flexible physical thermal links. A counter flow exchanger and ambient temperature valves facilitate efficient use of the cryogenic cooler stages. The removal of large heat load generated by the superconducting magnet while operating in the sweeping mode is achieved, in part, by employing a solid plate thermal coupling element between the cryogenic cooler chamber and the magnet assembly.

Owner:QUANTUM DESIGN

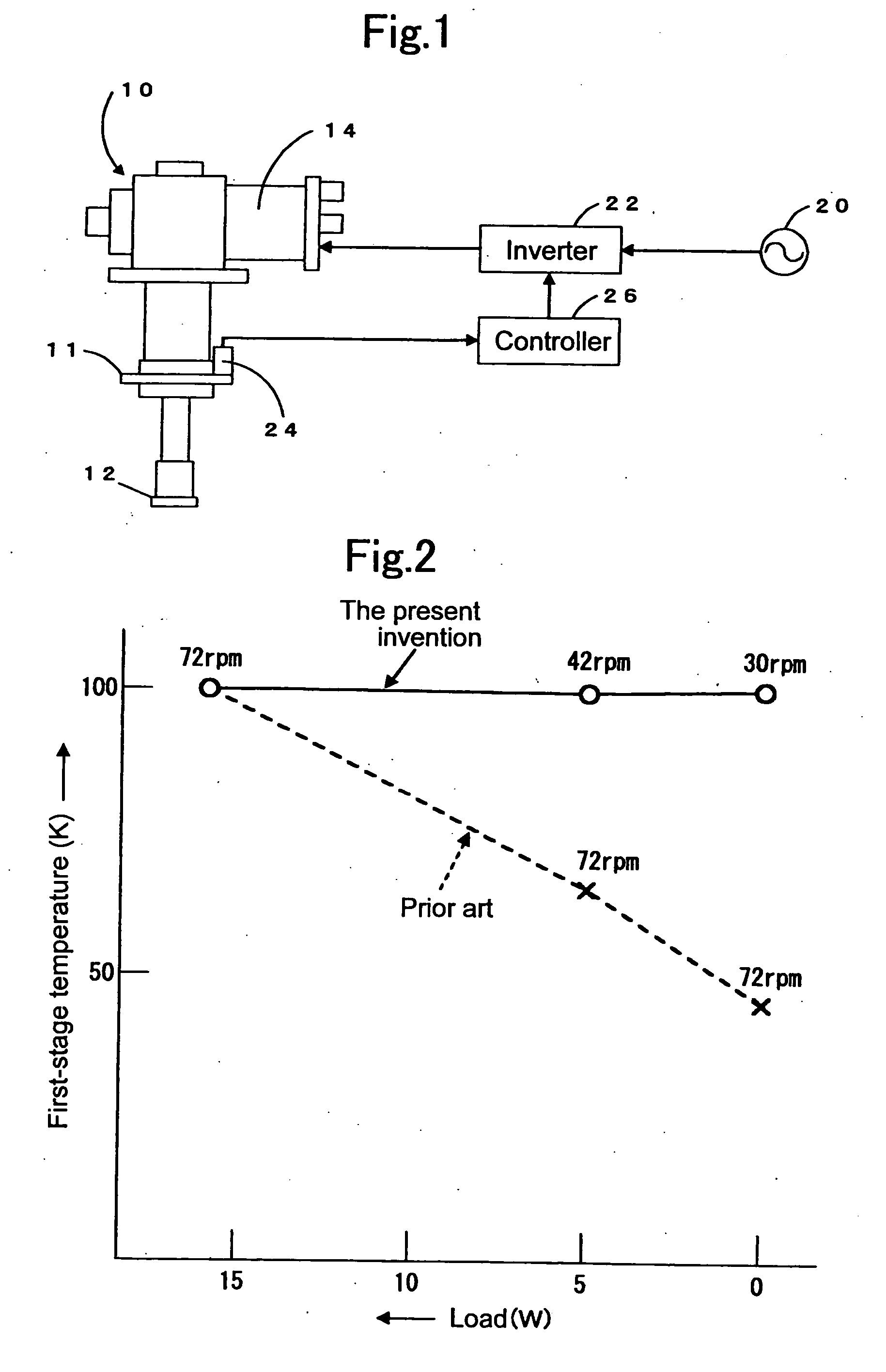

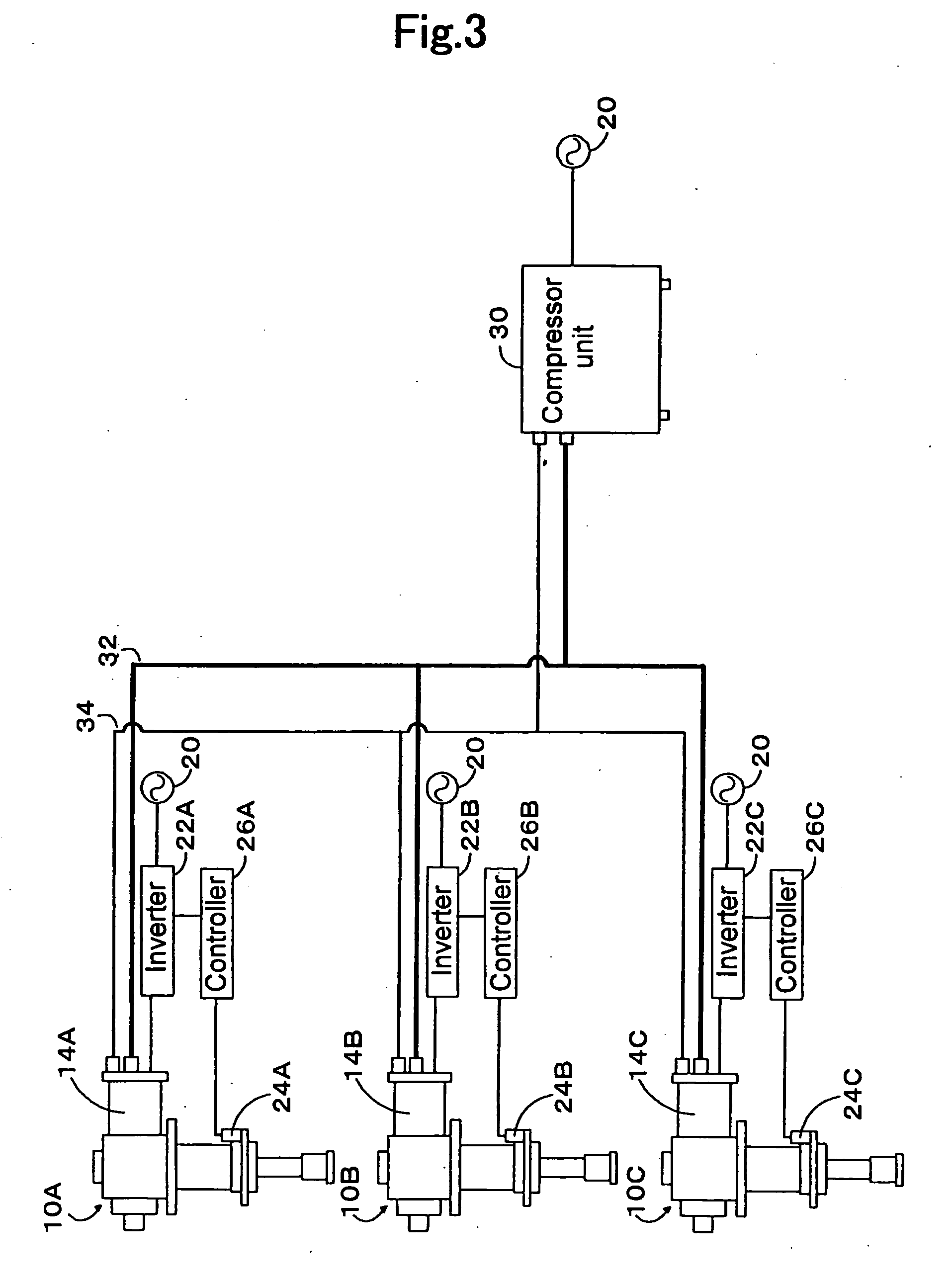

Very low temperature refrigerator

An inverter (22) is provided between a power source (20) and a suction / discharge valve driving motor (14) that controls cycle time of suction and discharge of a refrigerator unit (10). An output frequency of the inverter (22) is controlled in accordance with output of a sensor (24) that detects temperature of a thermal load portion (11) of the refrigerator unit (10). This enables temperature adjustment of individual refrigerators with a highly reliable method without using an electric heater.

Owner:SUMITOMO HEAVY IND LTD

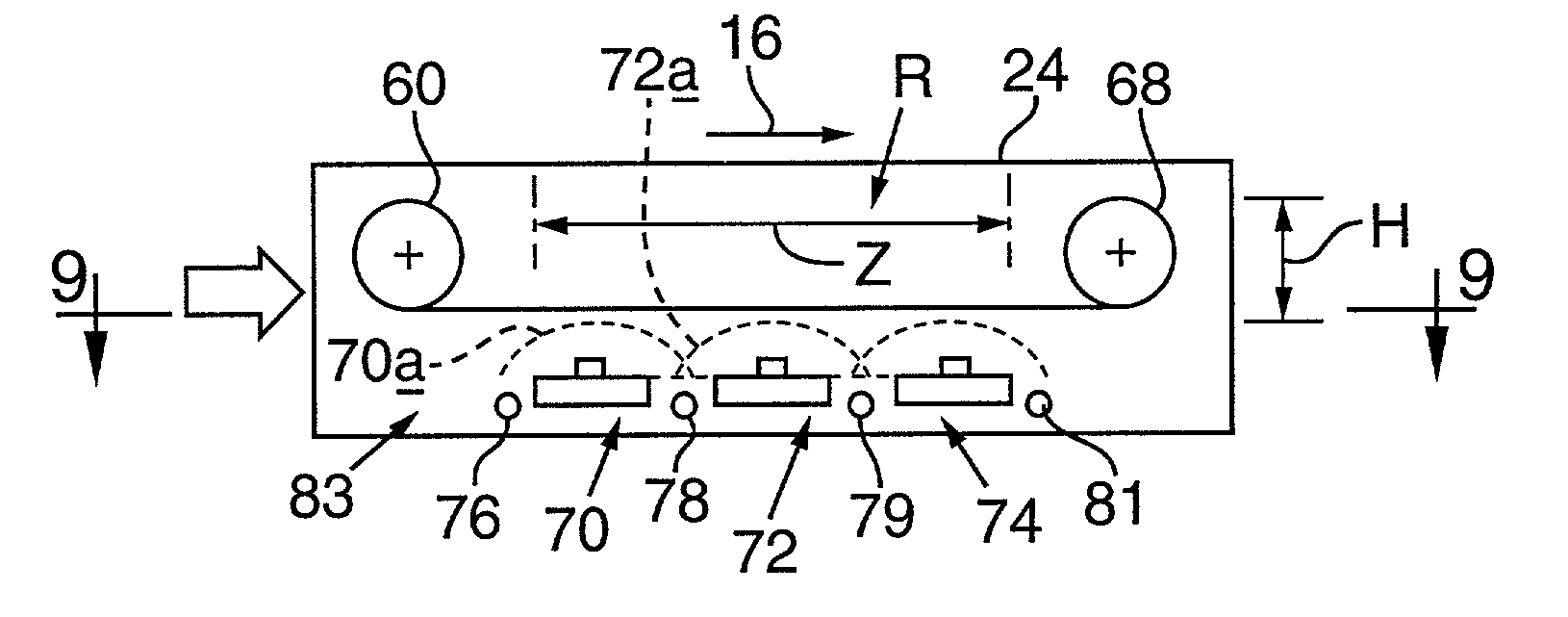

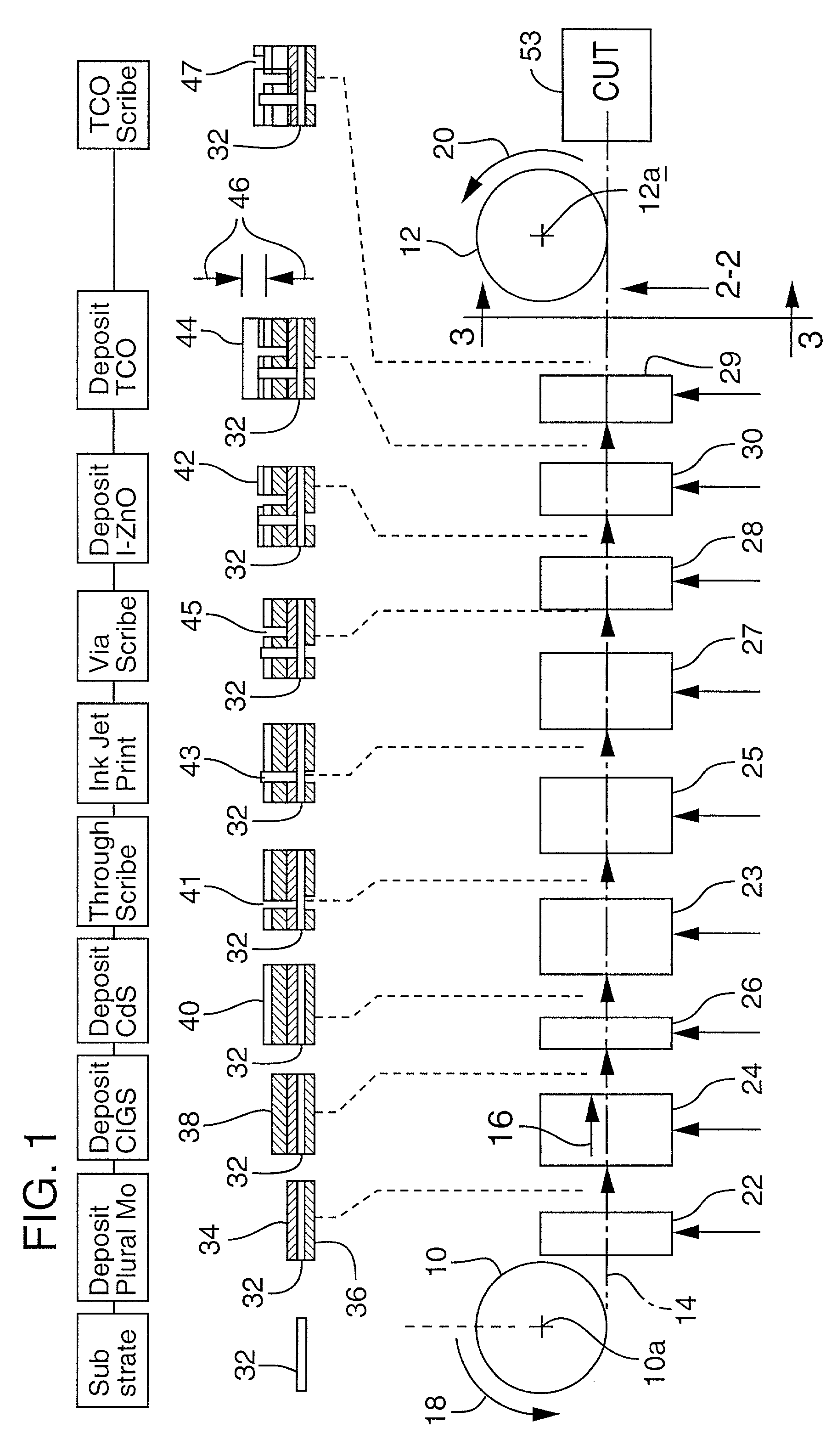

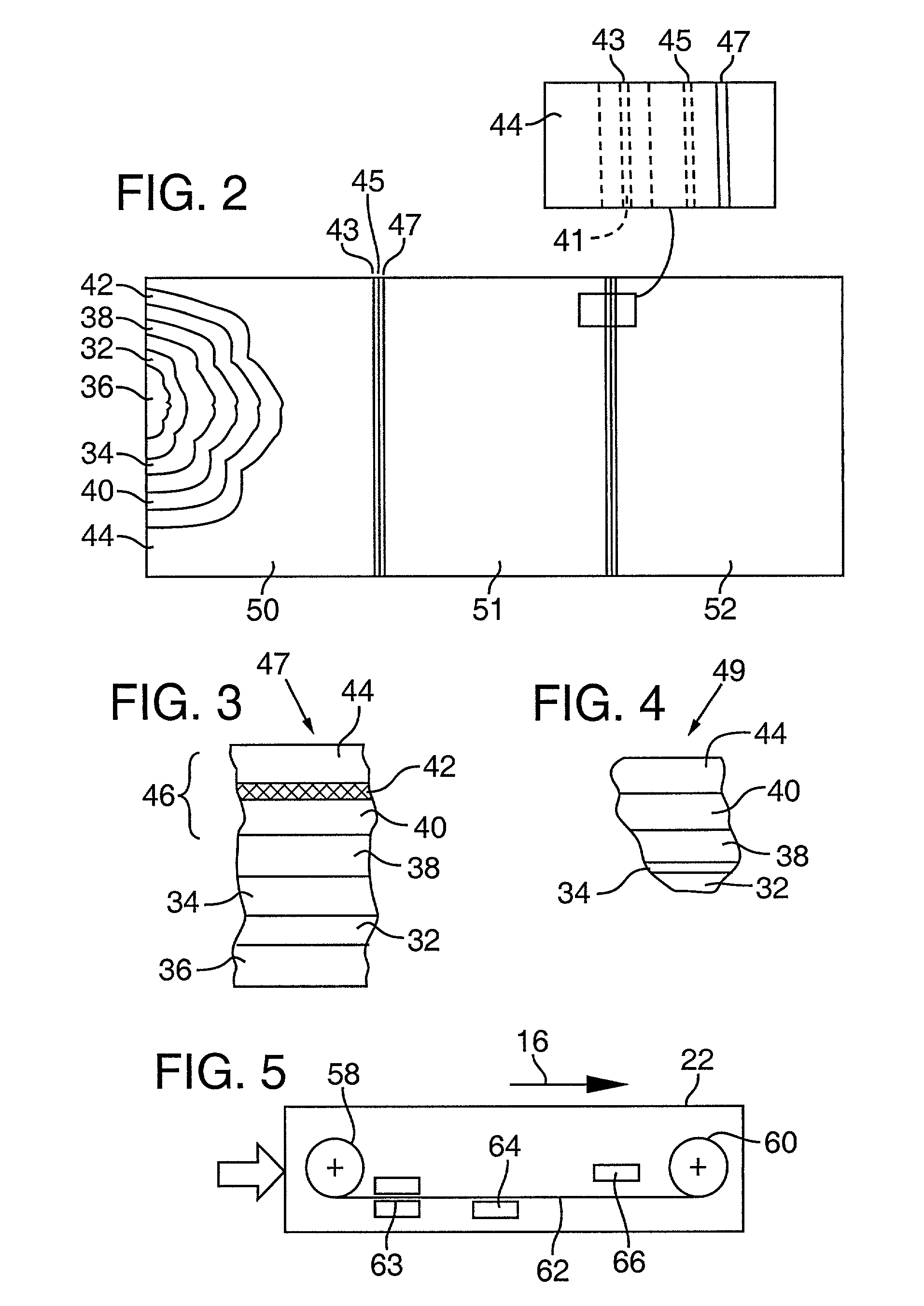

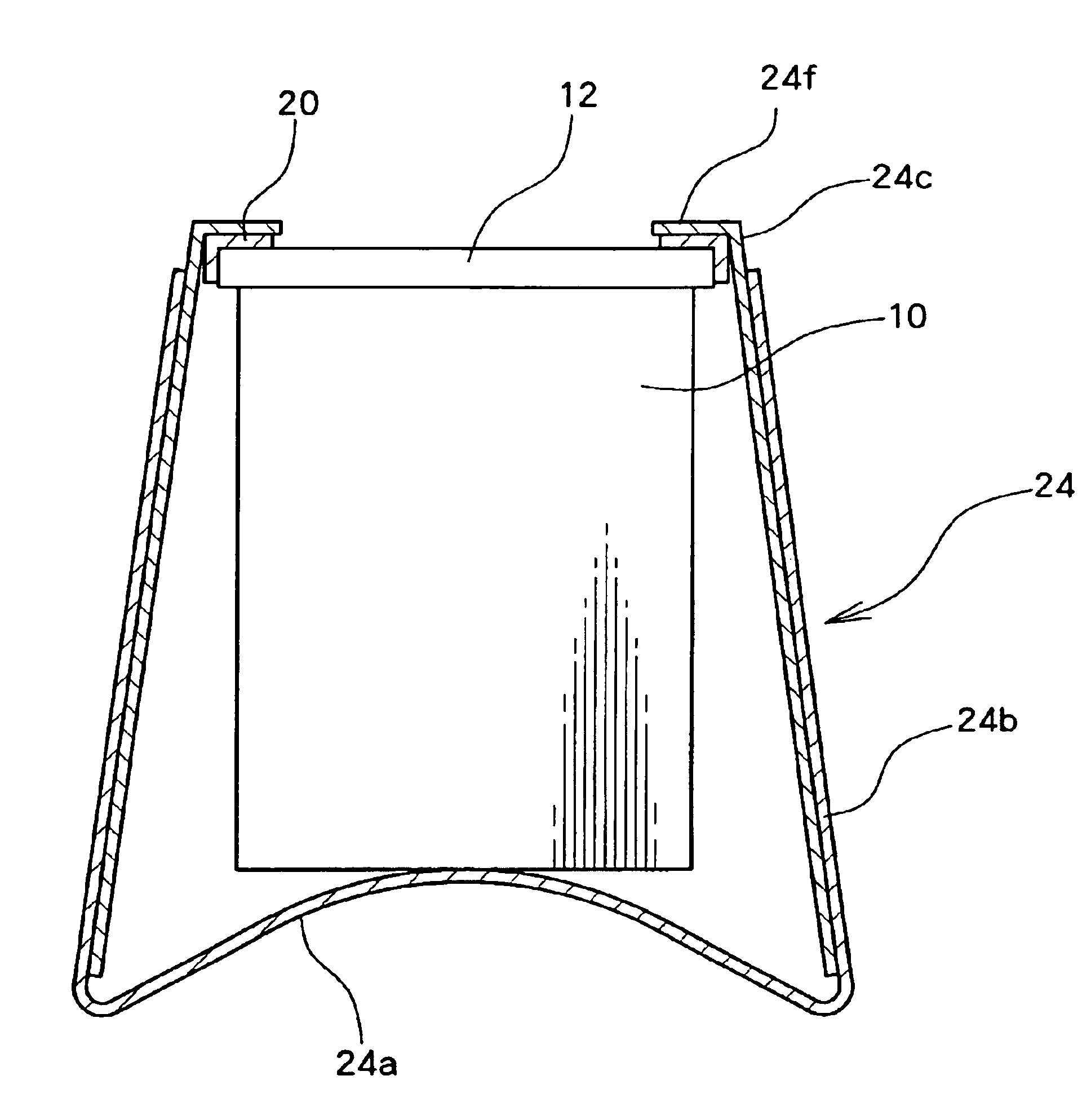

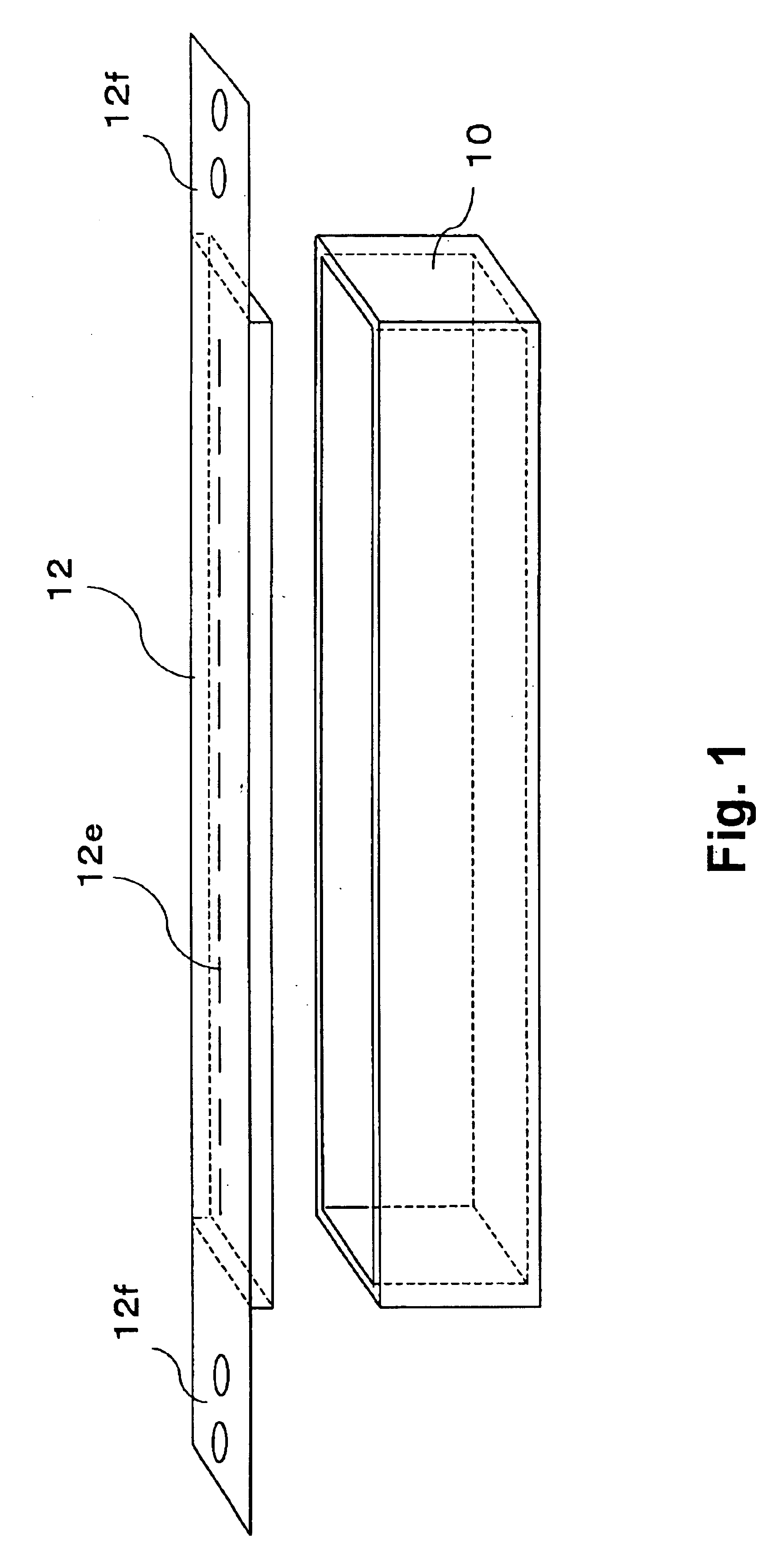

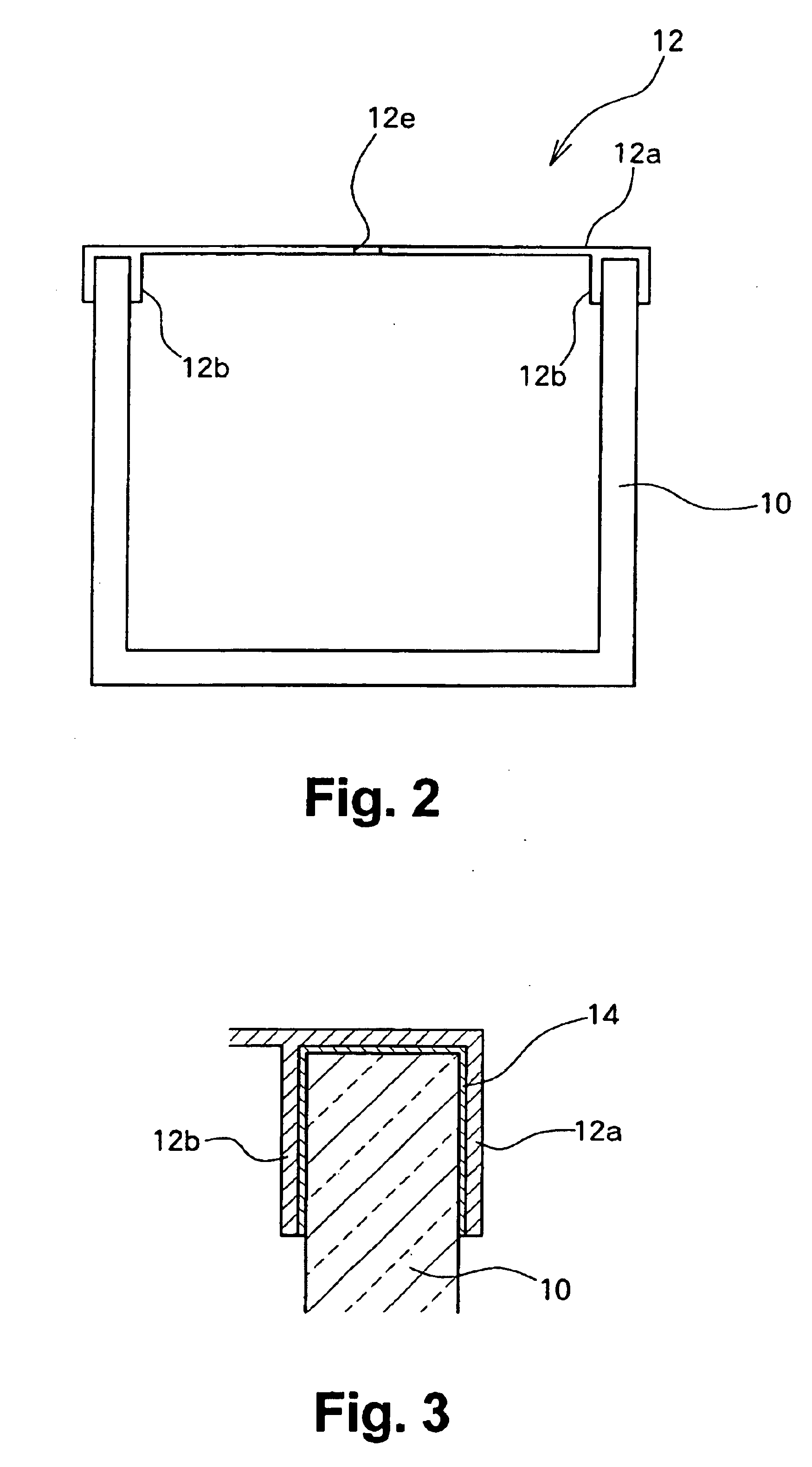

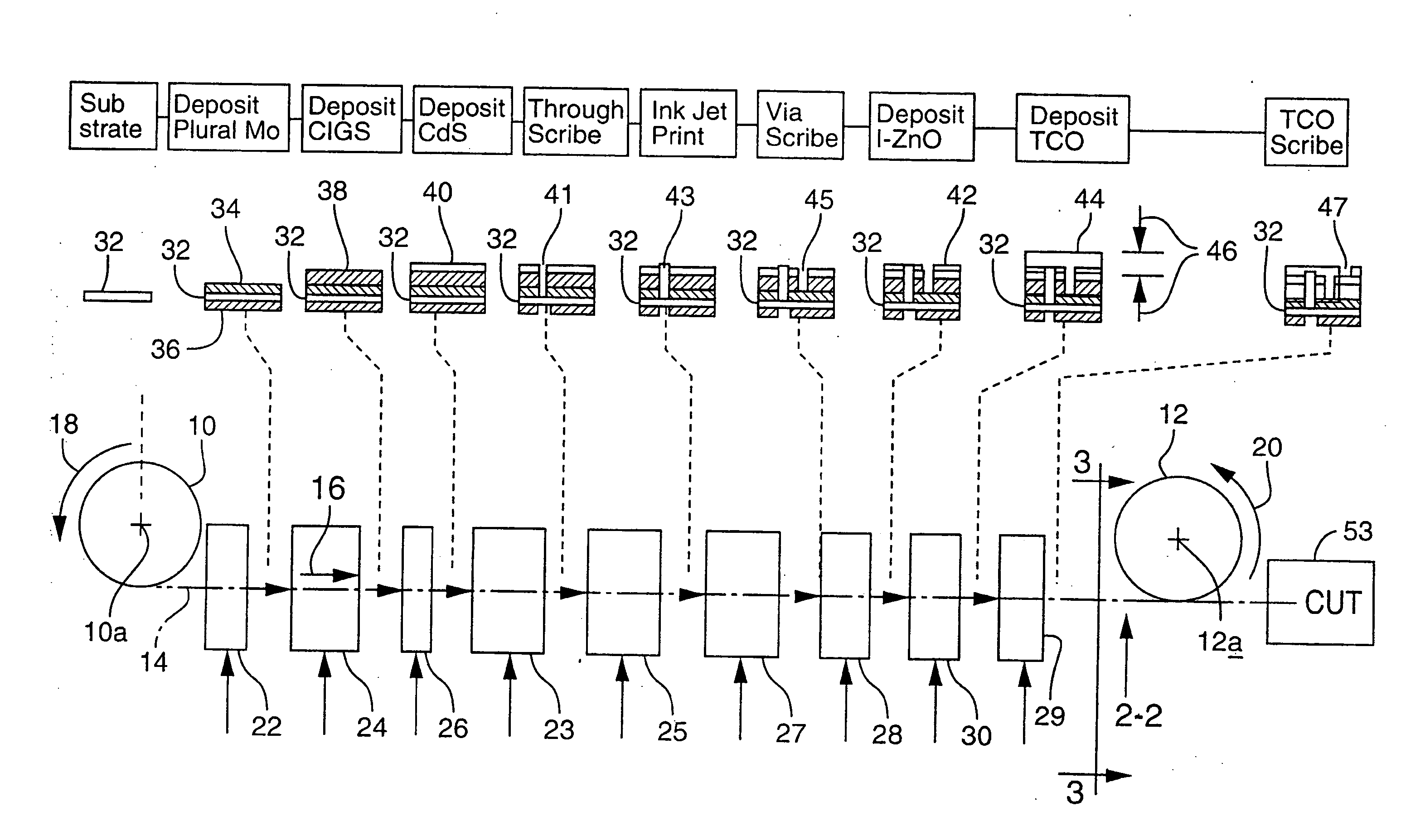

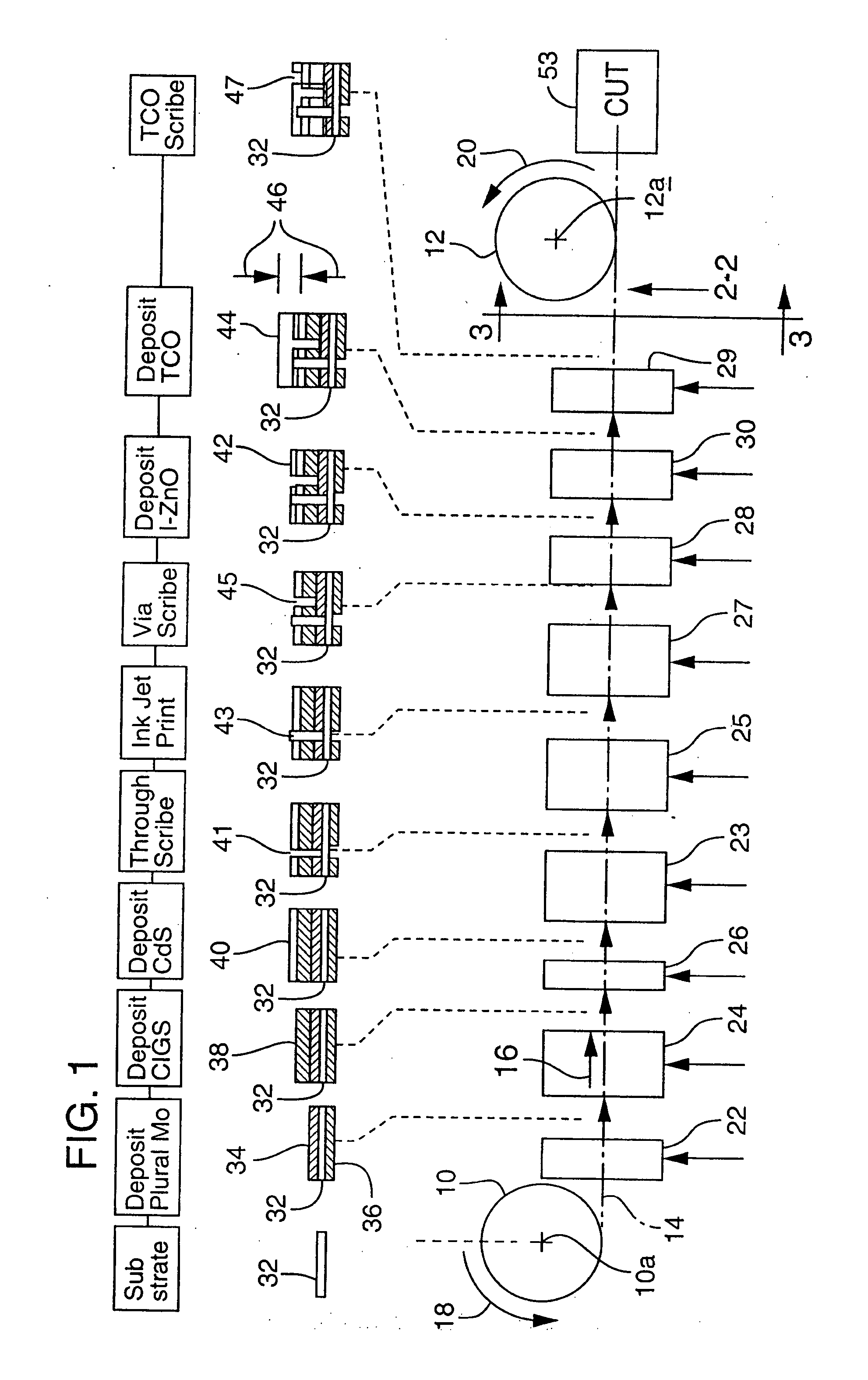

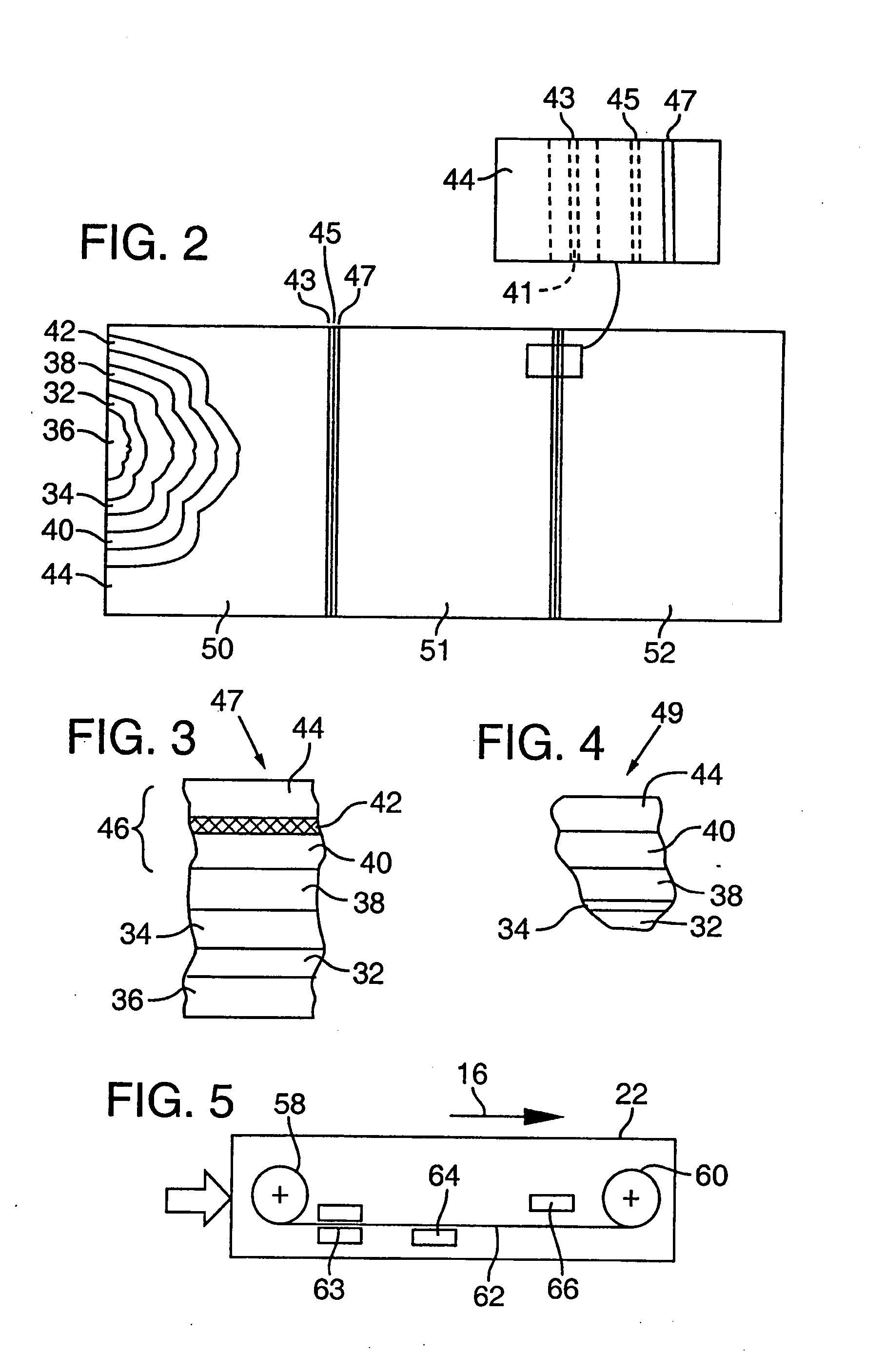

Multi-tray film precursor evaporation system and thin film deposition system incorporating same

ActiveUS20060112882A1Increase chanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingEvaporation (deposition)Thin membrane

A high conductance, multi-tray solid precursor evaporation system coupled with a high conductance vapor delivery system is described for increasing deposition rate by increasing exposed surface area of solid precursor. The multi-tray solid precursor evaporation system includes a base tray with one or more upper trays. Each tray is configured to support and retain film precursor in, for example, solid powder form or solid tablet form. Additionally, each tray is configured to provide for a high conductance flow of carrier gas over the film precursor while the film precursor is heated. For example, the carrier gas flows inward over the film precursor, and vertically upward through a flow channel within the stackable trays and through an outlet in the solid precursor evaporation system.

Owner:TOKYO ELECTRON LTD

Vapor deposition and in-situ purification of organic molecules

A process for in-situ purification of organic molecules and vapor deposition of the purified molecules involves vaporizing the organic molecules from a crude material, condensing the organic molecules on a glass wool baffle, re-vaporizing the condensed organic molecules, and depositing the re-vaporized organic molecules on a substrate. An apparatus adapted for practicing the process includes a crucible, a glass wool baffle in the crucible above the bottom of the crucible, and a heater configured to heat the crucible and glass wool baffle.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

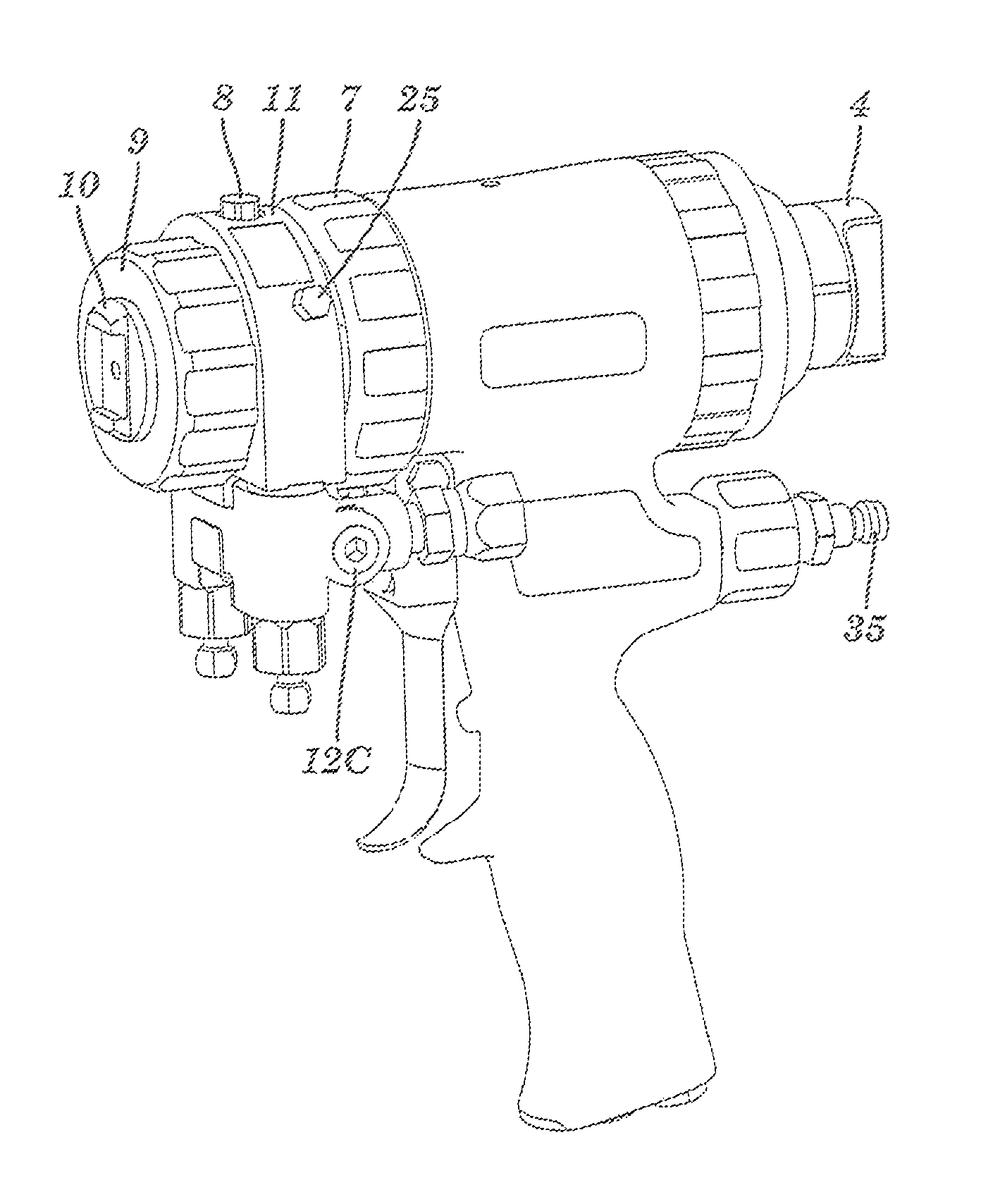

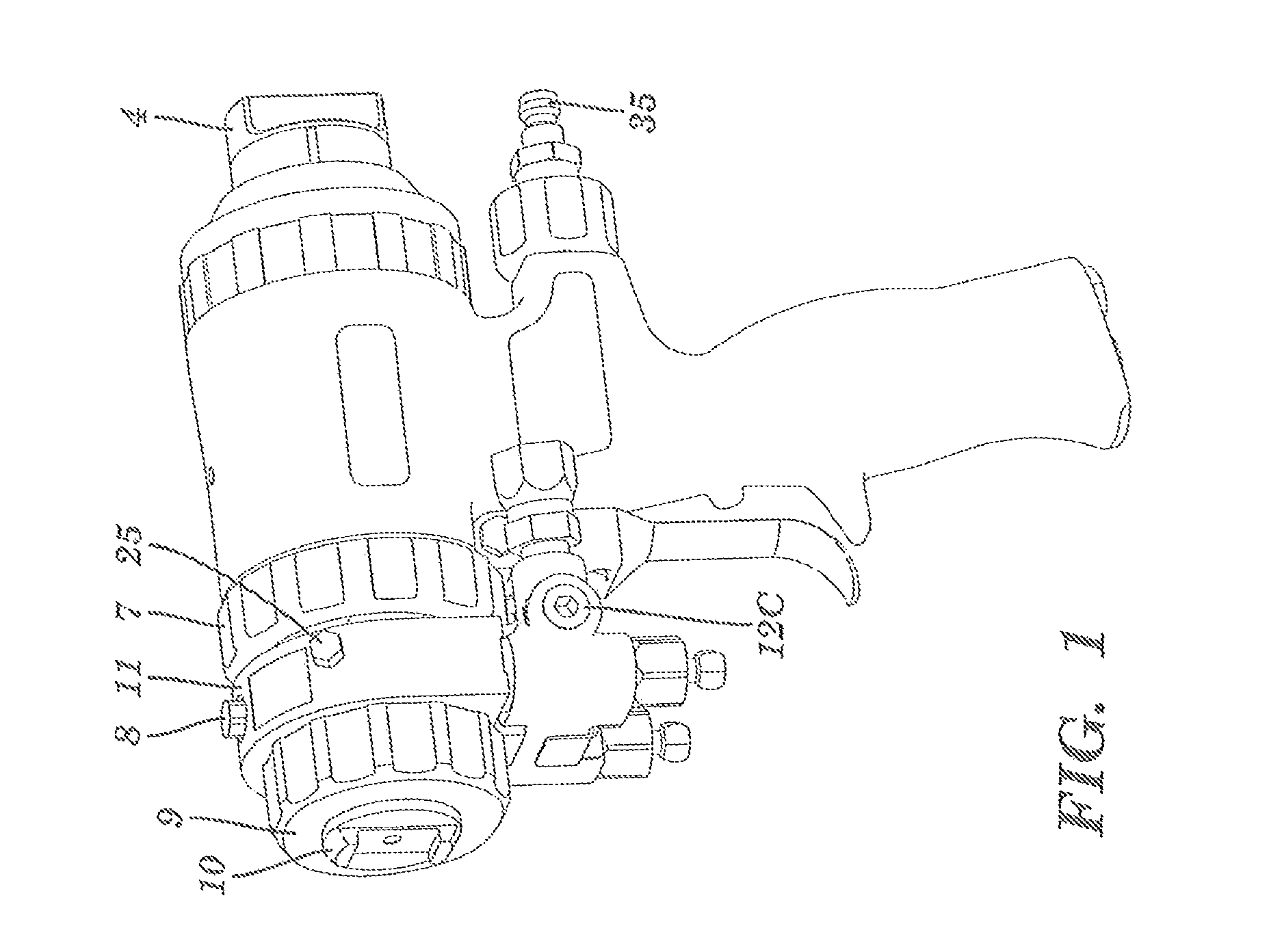

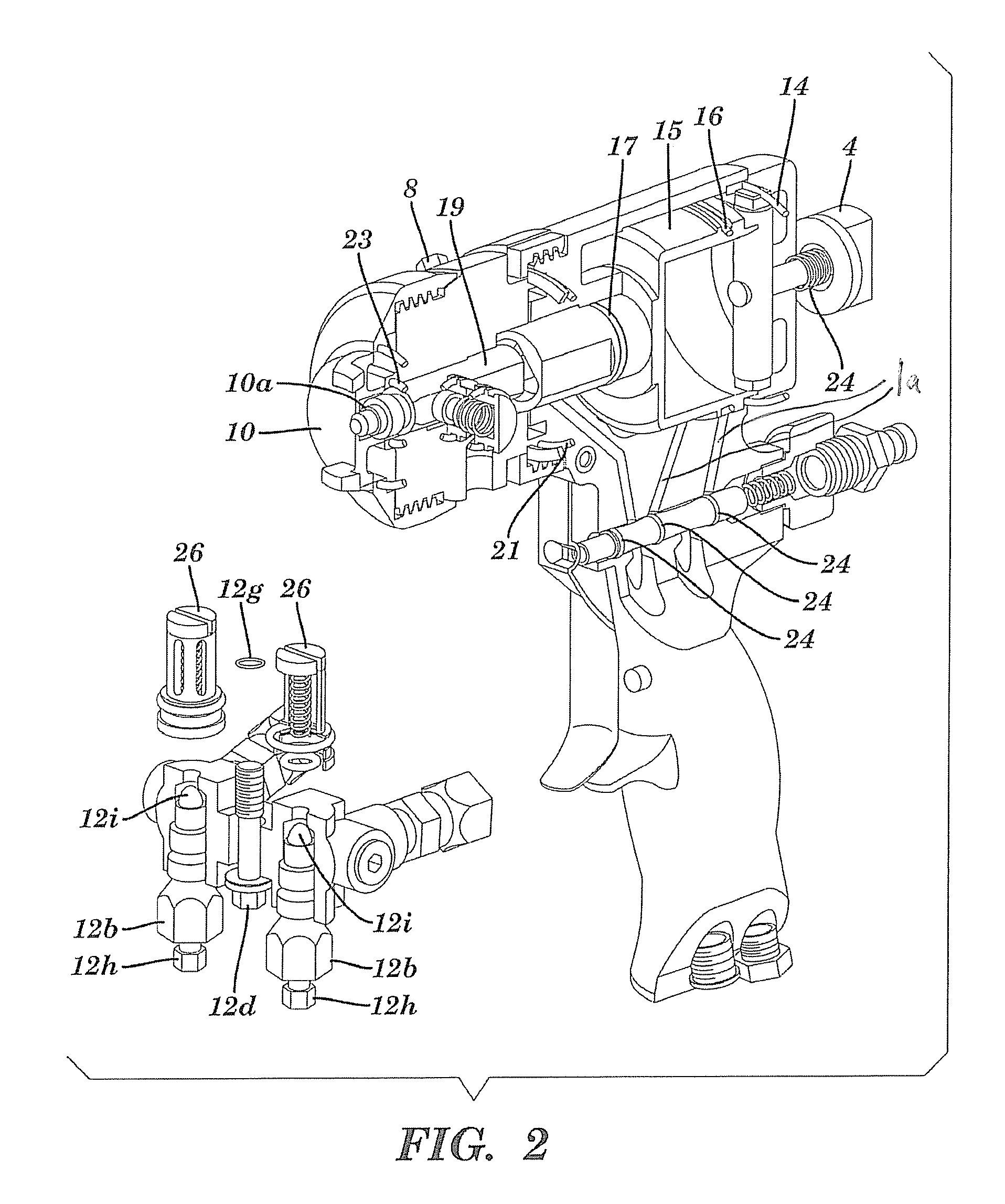

Plural component spray gun for fast setting materials

InactiveUS7694893B2Easy maintenanceEasy to cleanFlow mixersTransportation and packagingEngineeringPolyurea

Owner:GRACO INC

Electronically controlled vacuum pump

InactiveUS20050196284A1Potential damage to the bearings with the prompt pressure change is avoidedImprove scalabilitySolidificationLiquefactionDriving currentCurrent load

A vacuum system comprises, as an integral assembly, a vacuum pump with drive motor, a purge valve, a roughing valve and an electronic control module. A cryogenic vacuum pump and a turbomolecular vacuum pump are disclosed. The control module has a programmed processor for controlling the motor and valves and is user programmable for establishing specific control sequences. The integral electronic control module is removable from the assembly and is connected to the other devices through a common connector assembly. In the turbomolecular pump system proper introduction of a purge gas through the purge valve is detected by detecting the current load on the pump drive or by detecting foreline pressure. To test the purge gas status, the purge valve may be closed and then opened as drive current or pressure is monitored. After power failure, the controller will continue normal drive of the turbomolecular pump so long as the speed of the pump has remained above a threshold value. Otherwise the vent valve will have been opened, and a start-up sequence must be initiated. During shutdown, power to the pump drive motor is discontinued and the vent valve is opened before the roughing valve is closed.

Owner:BROOKS AUTOMATION INC

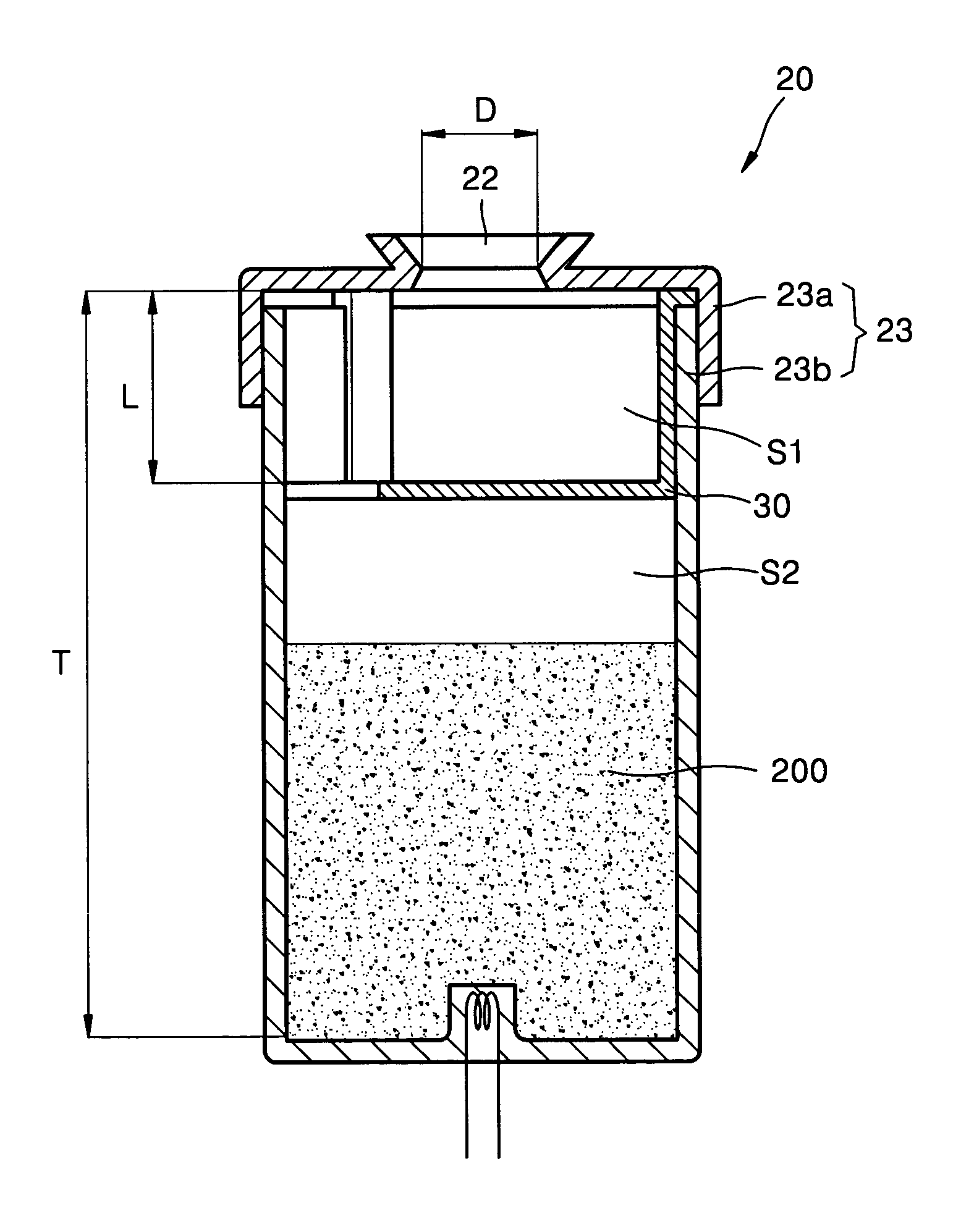

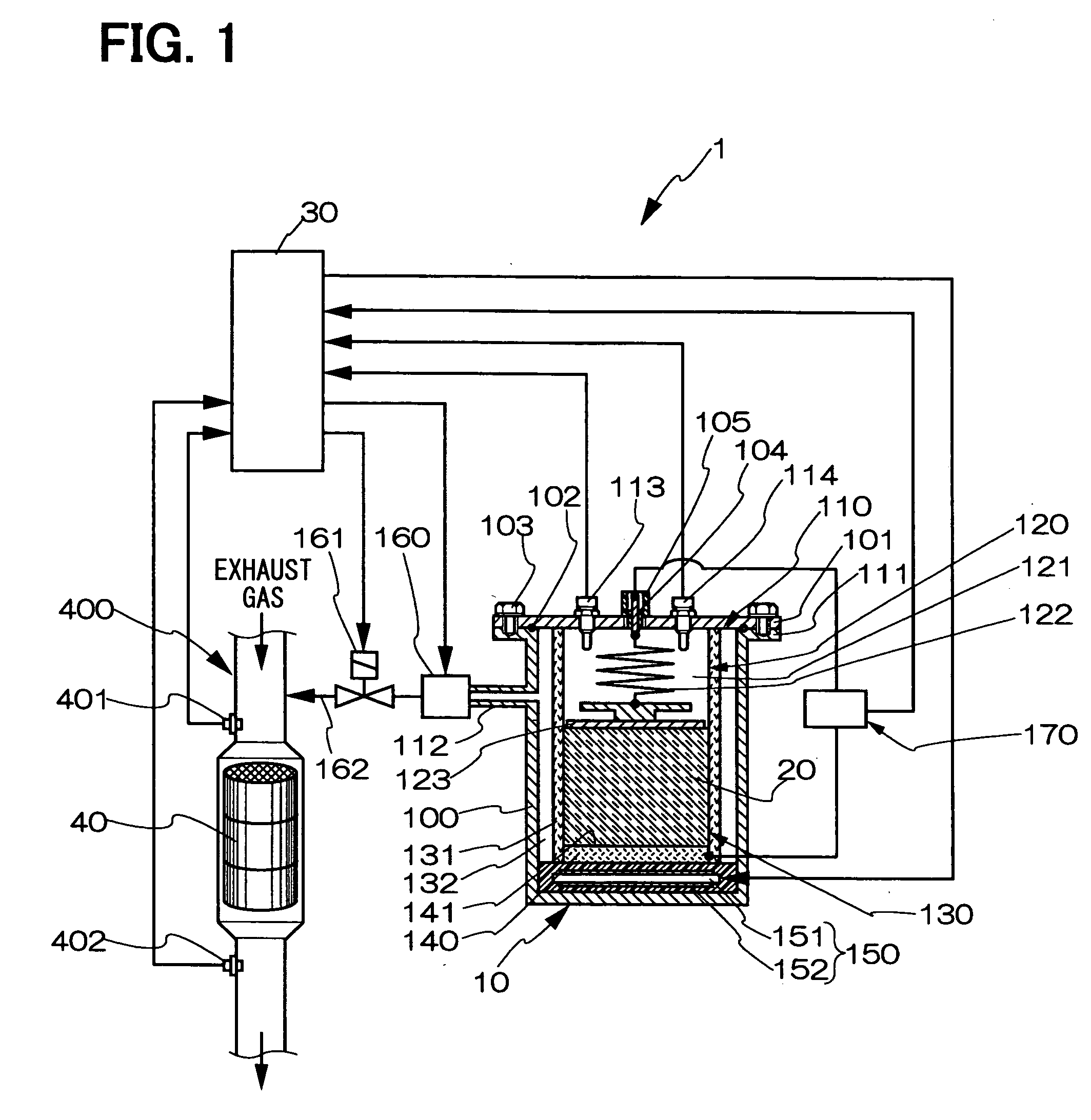

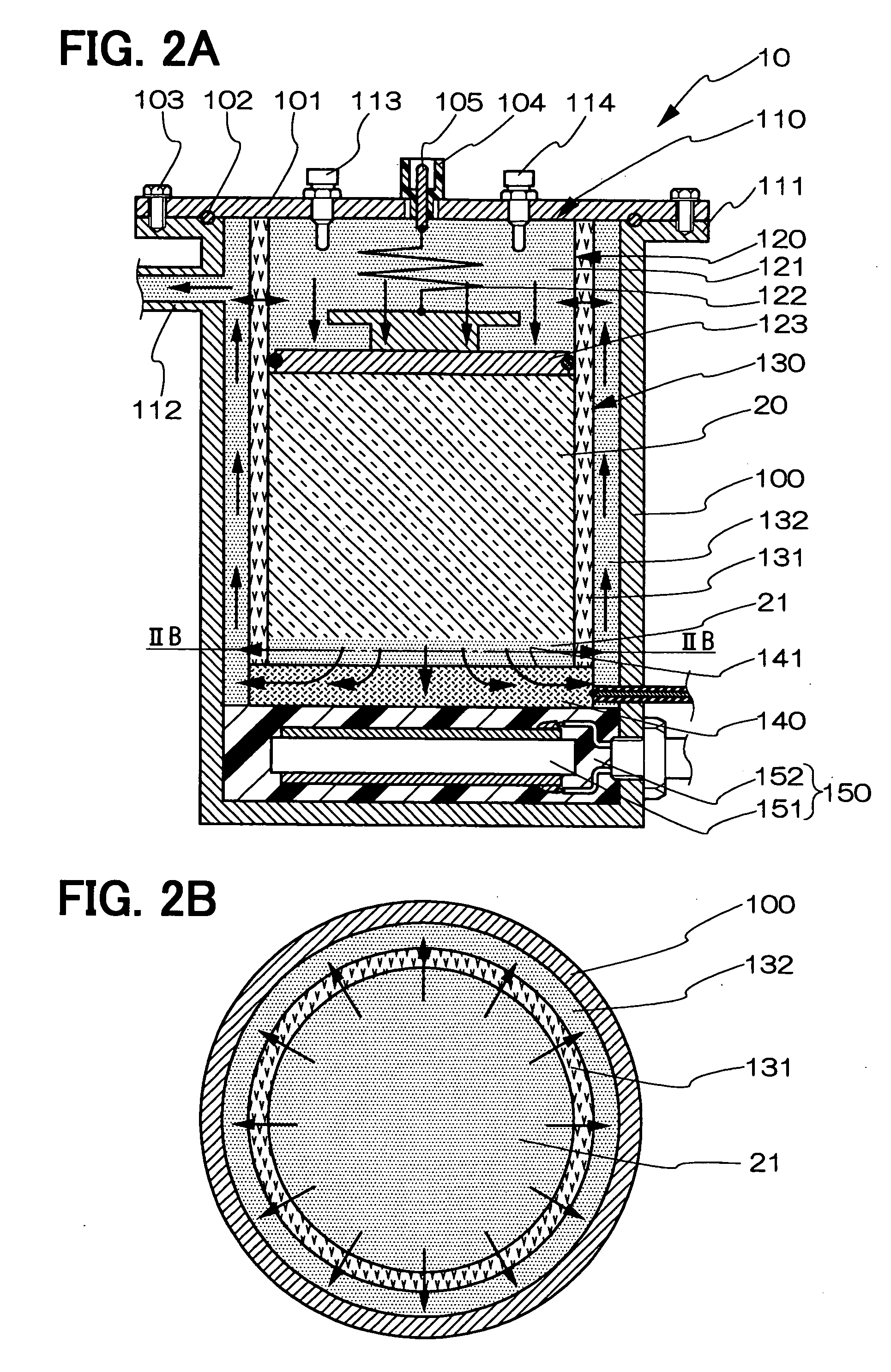

Reducing gas generator and solid reductant SCR system having the generator

ActiveUS20080260597A1Simple configurationImprove volume efficiencyCombination devicesPressurized chemical processEngineeringWood gas generator

A reducing gas generator generates reducing gas including ammonia. The generator includes a solid reductant and a heat-generating portion. The solid reductant is formed in a columnar shape. A cross-sectional surface of the solid reductant has a constant shape and is perpendicular to a central axis of the solid reductant. The heat-generating portion includes a heat-generating surface opposed to a lower surface of the solid reductant in a vertical direction thereof and in contact with an entire region of the lower surface, and a heating element that heats the heat-generating surface when energized, so that the solid reductant is heated and decomposed to generate the reducing gas.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com