High arsenicum gold ore roasting smoke gas treatment system and method for recovering arsenicum and desulfurating

A technology for recovering arsenic and flue gas, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of arsenic-containing hazardous waste polluting the environment, waste of arsenic resources, etc., achieving easy control of process conditions, low environmental pollution, The effect of solving the problem of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

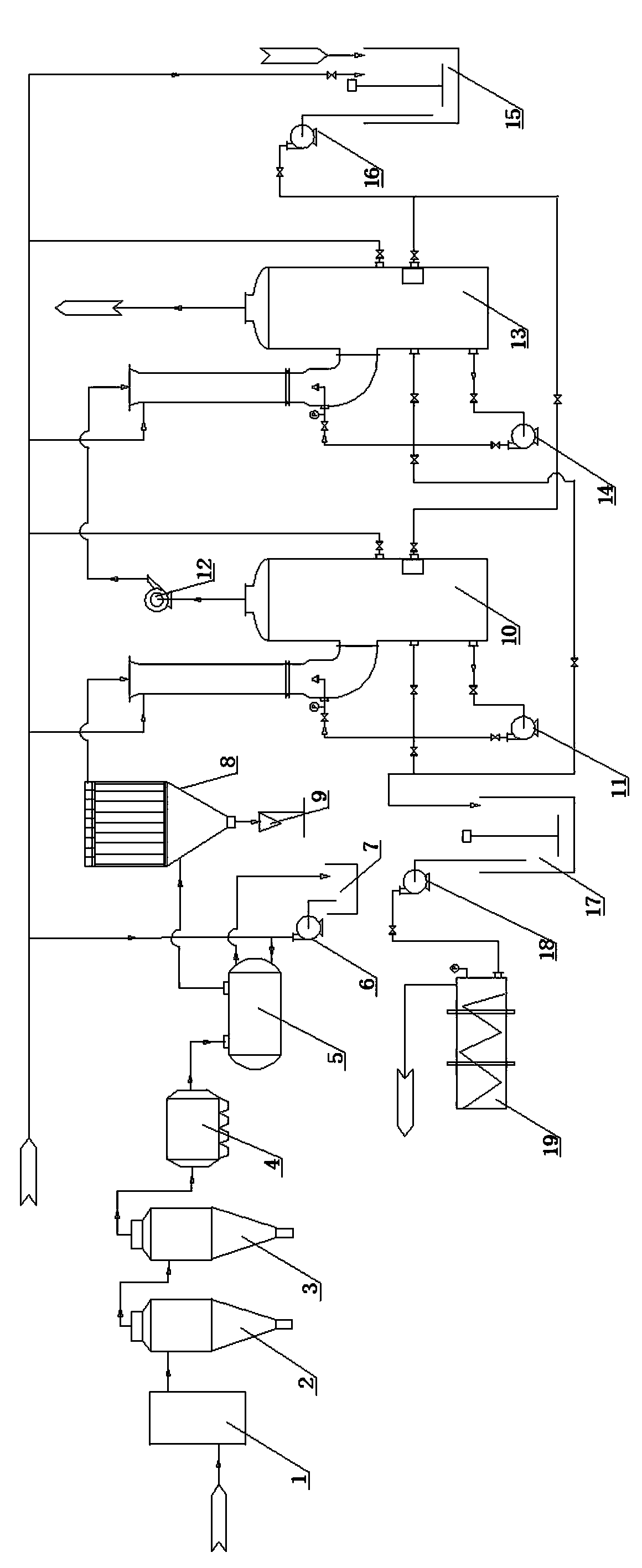

[0030] Embodiment 1 The method for recovering arsenic in the high-arsenic gold ore roasting flue gas treatment system of the present invention comprises the following steps:

[0031] a. Roasting flue gas dedusting

[0032] When the high-temperature roasting flue gas is at a temperature of about 380-500°C, the dust concentration is 23437.5mg / m 3 、As 2 o 3 Concentration 1367.5 mg / m 3 , SO 2 Concentration 8325 mg / m 3 (Take the roasting flue gas of gold ore containing 0.39% arsenic and 1.21% sulfur as an example), the flue gas first passes through the settling chamber 1 and the secondary cyclone dust collector 2 to remove large dust particles, and then passes through the electrostatic precipitator 4 to remove fine dust particles. At this time, the temperature of the flue gas at the outlet of the electrostatic precipitator 4 is controlled at 380-470°C; the dust concentration after the dust removal by the electrostatic precipitator 4 is 187.5 mg / m 3 、As 2 o 3 Concentration 1...

Embodiment 2

[0039] Embodiment 2 The method for desulfurization of the high-arsenic gold ore roasting flue gas treatment system of the present invention,

[0040] Including the turbulence washing step, the outlet temperature of the flue gas from the bag arsenic collector 8 in Example 1 is about 120°C, the flue gas enters the first-stage turbulent scrubber 10 for desulfurization, and then is introduced by the fan 12 into the second-level turbulent scrubber 13 The flue gas can be discharged up to standard after further desulfurization treatment.

Embodiment 3

[0041] Example 3 The method for desulfurization of the high-arsenic gold ore roasting flue gas treatment system. In order to achieve better results, lime powder with a mass content > 80% is used. The mass ratio of Ca and S in the lime powder is 1.5-2. The lime powder Pour it into the milk of lime preparation tank 15, start the agitator installed in the milk of lime preparation tank 15, and dilute it with water into 10% lime emulsion; The liquid accumulation tank in the liquid accumulation tank and the secondary turbulent scrubber 13 is used as a desulfurization absorbent, and is sprayed from the primary turbulent scrubber 10 and the secondary turbulent scrubber through the primary circulation pump 11 and the secondary circulation pump 14 respectively. The upper part of 13 enters the exhaust gas to form a turbulent zone, and the SO in the exhaust gas 2 to absorb.

[0042] The washing liquid discharged from the primary turbulent scrubber 10 and the secondary turbulent scrubber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com