Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Achieve automatic ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ignition control system of tube furnace

ActiveCN101576314AEnsure reliabilityMake sure to installFuel supply regulationElectric spark ignitersCapacitanceHigh energy

The invention relates to an ignition control system of a tube furnace. The system comprises a high-energy ignition device, a burner, an automatic ignition control system and a burning control system, wherein the high-energy ignition device adopts a capacitive discharge type igniter capable of providing the safe and reliable ignition performance; the burner is provided with a flame detection device and can realize the regulation of burning-supporting air and fuel in certain proportion; and the automatic ignition control system has the functions of flame detection, safety protection of the furnace and self diagnosis. The invention has the advantages of high heat efficiency, safety and reliability, stable and controllable burning, energy saving and emission reduction.

Owner:ACRE AUTOMATION CO LTD MCC

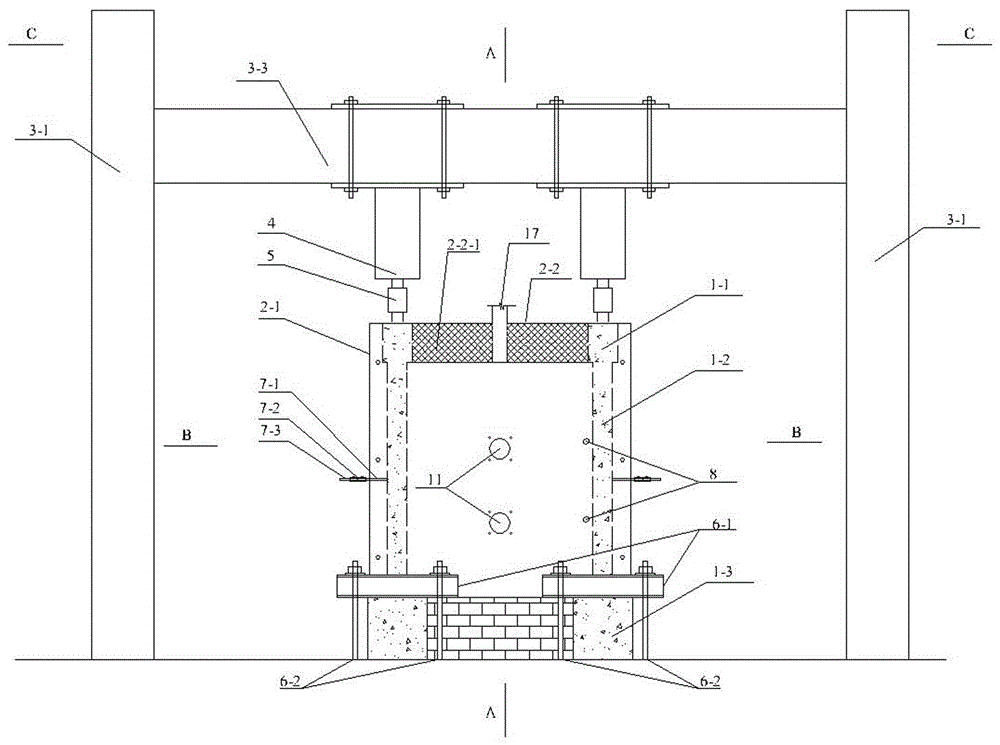

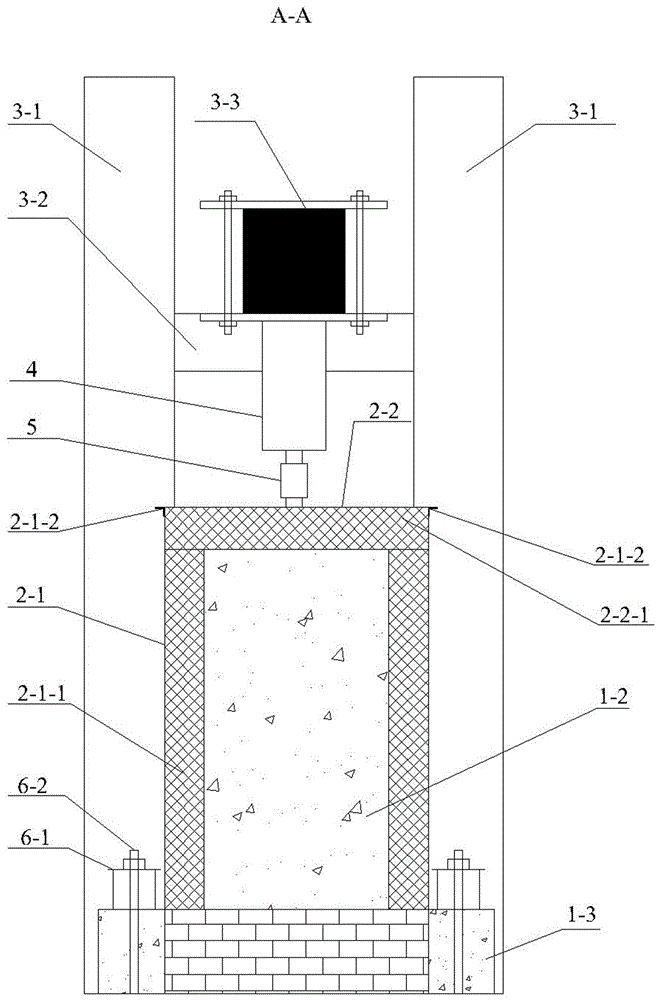

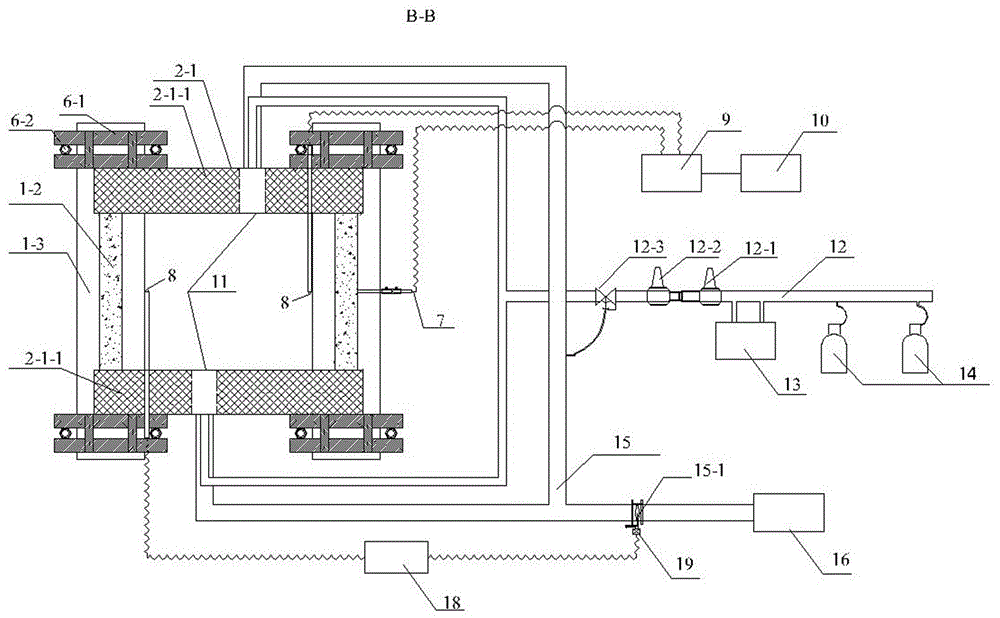

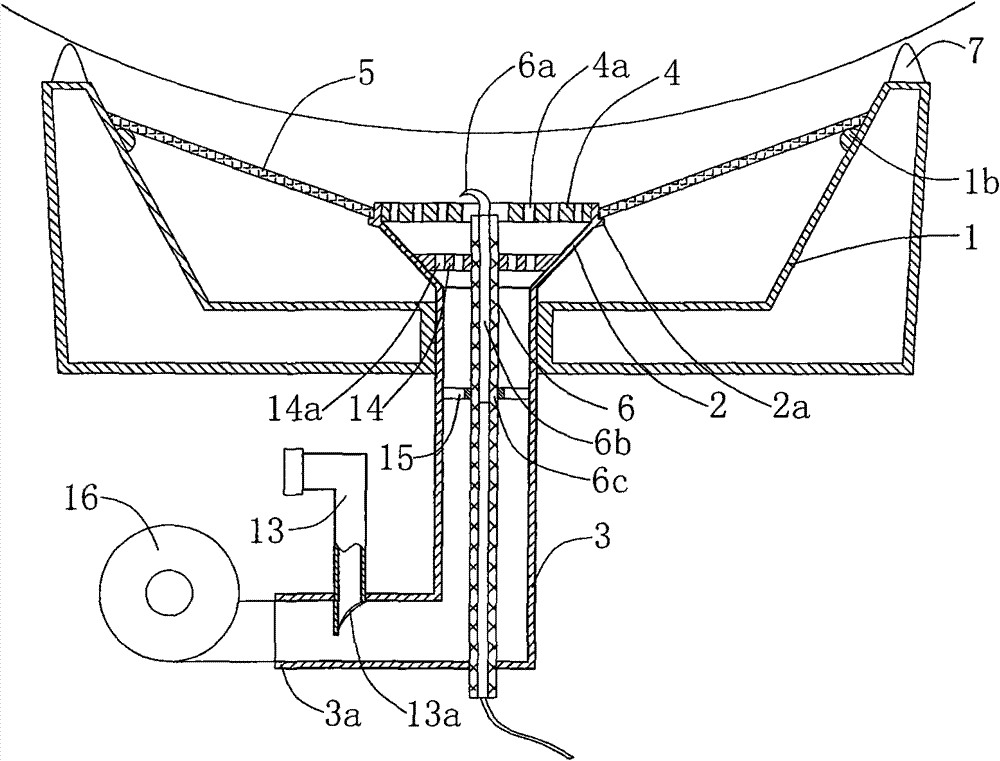

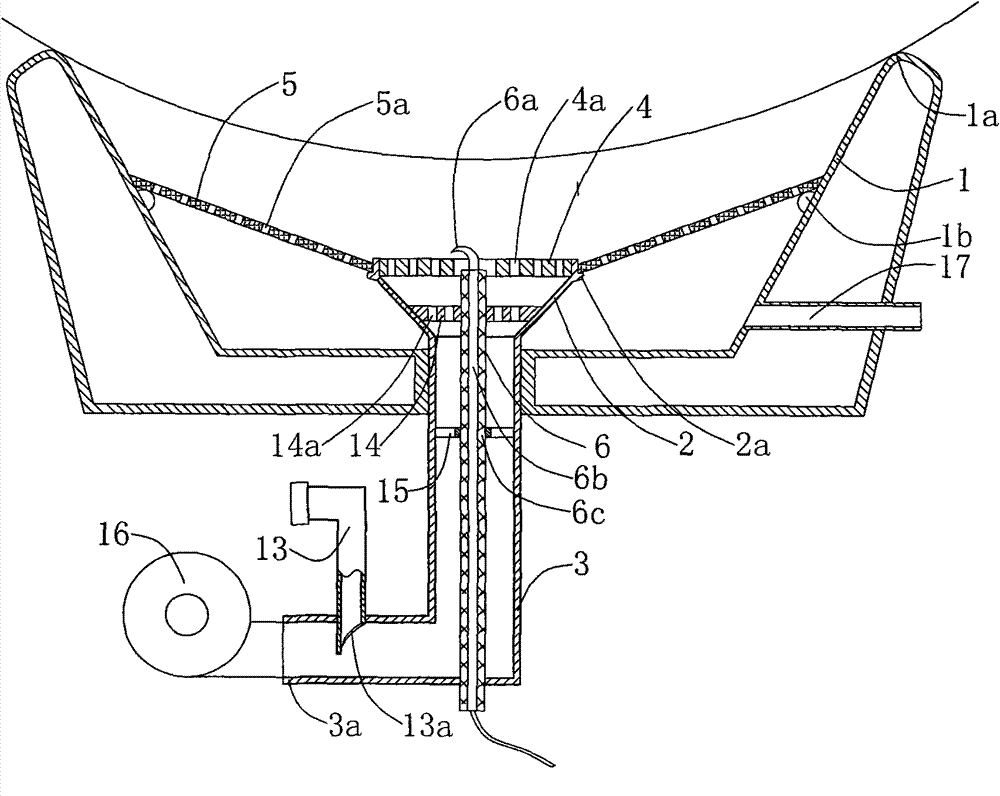

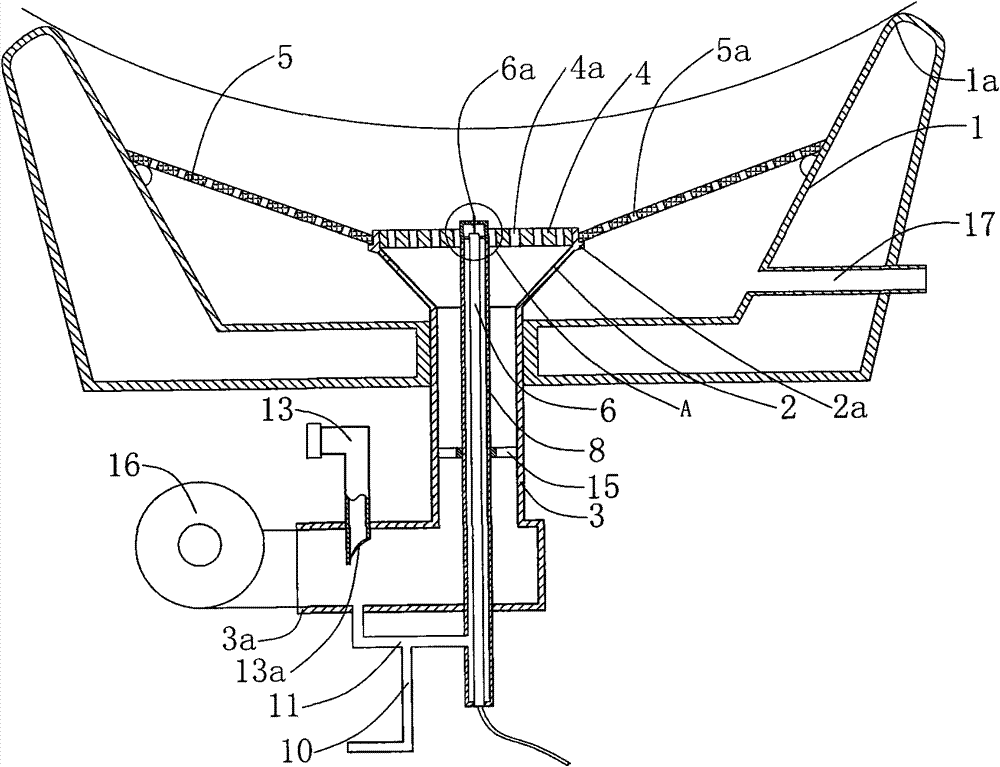

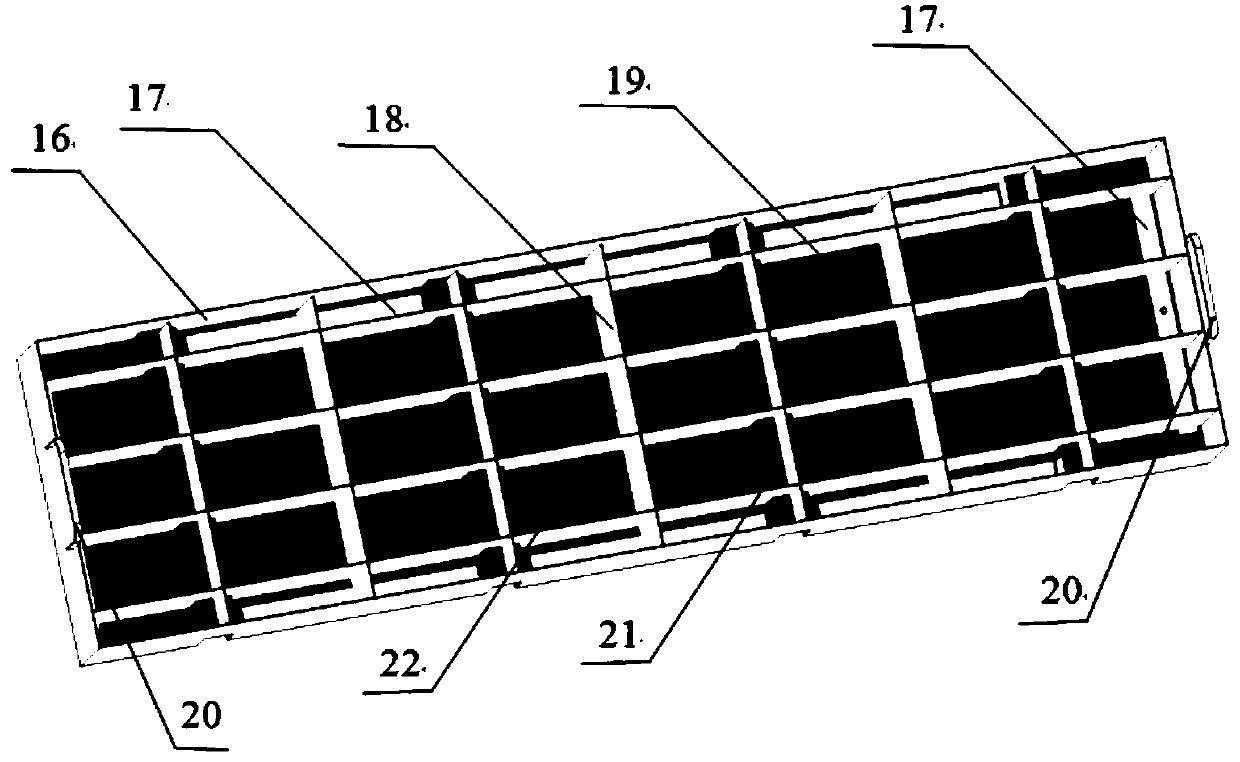

Shear wall fire exposure testing device under vertical load effect

InactiveCN105910940ARealize automatic monitoringSmall discreteTemperatue controlMaterial strength using tensile/compressive forcesFurnace temperatureFiber

The invention discloses a shear wall fire exposure testing device under the vertical load effect, relates to a fire resistance testing device, and belongs to the technical field of building structure disaster prevention and reduction. The shear wall fire exposure testing device comprises a furnace body, a loading system, an information collection system and a combustion control system. The furnace body is formed by assembling a shear wall component, a furnace side wall and a furnace top cover through bolts and screws. The furnace side wall and the furnace top cover fix zirconium-containing refractory fiber modules to a steel plate by means of stainless steel anchoring parts. The assembling efficiency is high, the modifiability is good, the containment furnace wall can be modified according to different test piece sizes, the repeated utilization factor is high, waste is reduced, a vertical placement shear wall fire resistance test under the axial pressure is achieved, and real working conditions of test pieces can be simulated; an intelligent ratio adjuster and an electric actuator are used for achieving automatic control over the furnace temperature; the shear wall test piece and the furnace wall are combined into the furnace body, one or more shear walls can be synchronously tested, the test data discreteness is lowered, and the purpose of saving energy is achieved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

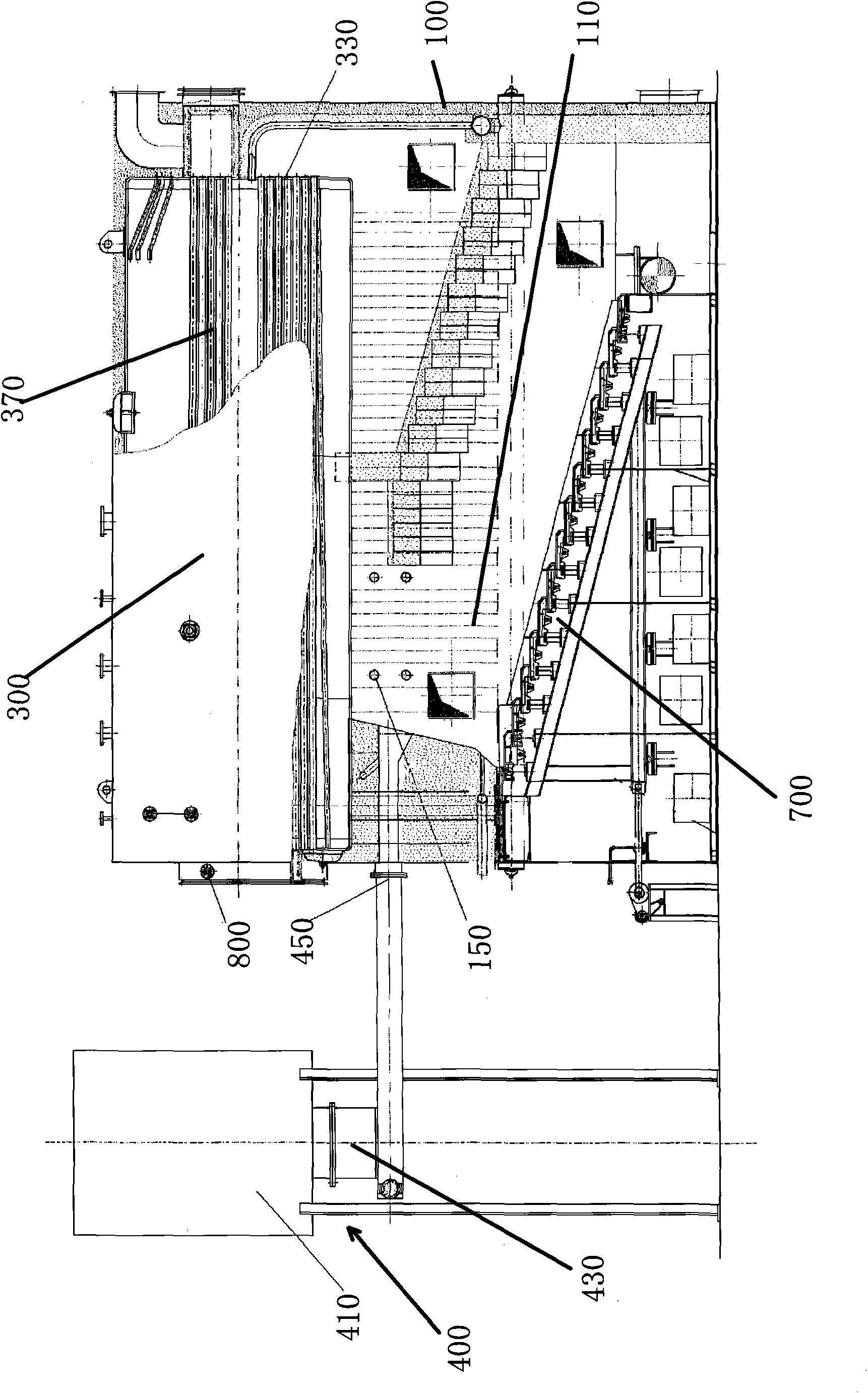

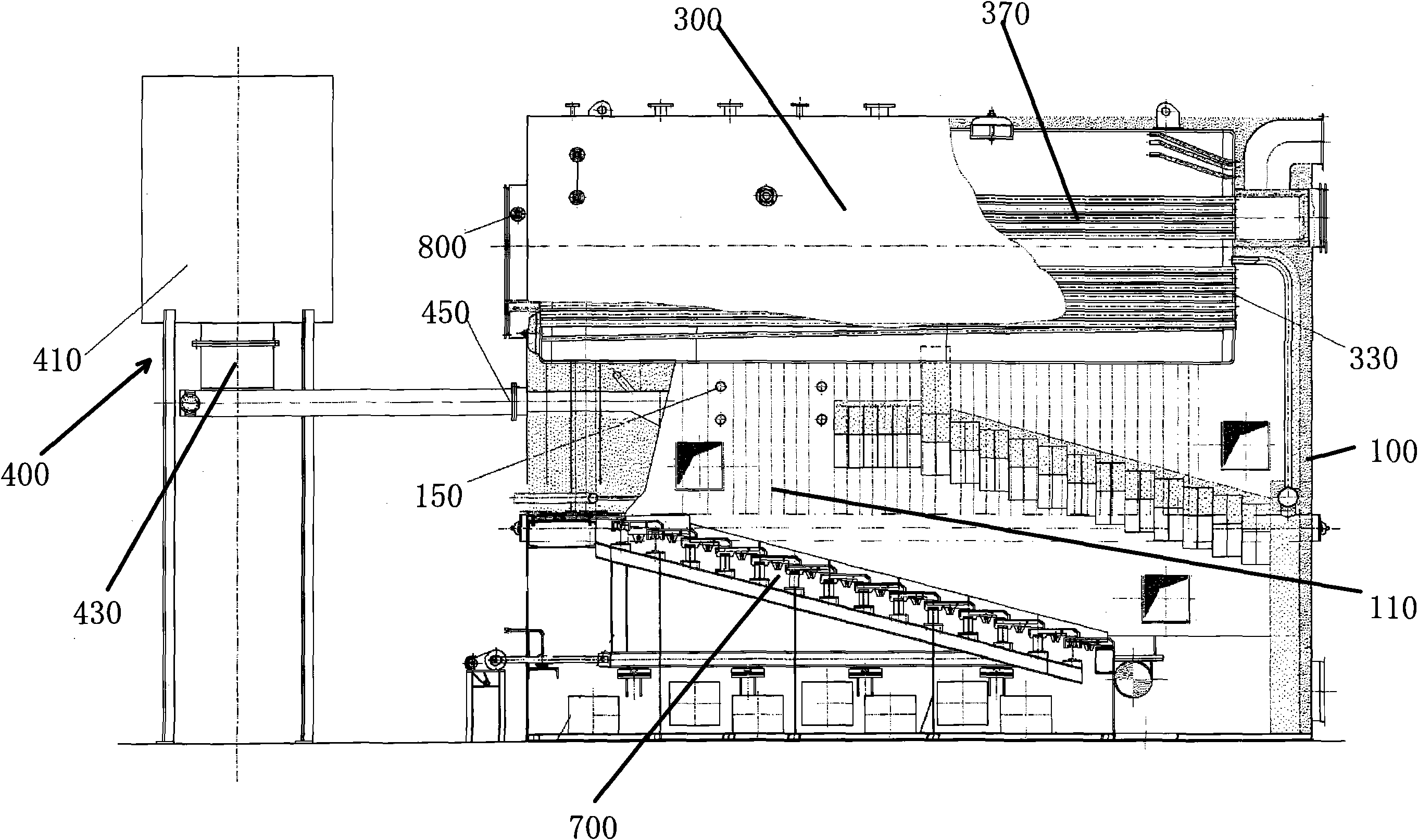

Steam boiler capable of burning biomass

InactiveCN101881433AHigh heat resistanceBig spaceTravelling grateAir/fuel supply for combustionCombustionHearth

The invention discloses a steam boiler capable of burning biomass, comprising a boiler body, a loading system and a vapour-water pipe system, wherein the boiler body is provided with a hearth in which the biomass fuel burns so as to release heat and a heat exchange device positioned above the hearth; the loading system is connected with the boiler body so as to convey the biomass fuel to the hearth for burning; the vapour-water pipe system is connected with the heat exchange device so as to exchange heat generated by the burning of the biomass; the hearth is internally provided with a reciprocal grate which downward slopes relatively to the level in an angle of inclination of 5-25 degrees from the end of the hearth close to the loading system to the far end far away from the loading system so as to enable the biomass fuel falling on the fire grate to be pushed and extruded and to roll relatively to the fire grate. In the invention, the fire grate moves relatively to fuel, the fuel is constantly extruded in the process of being pushed so as to damage coke and ash shells; and the fuel rolls slowly, thereby enabling the material layer to be loosened and facilitating full combustion.

Owner:GUANGZHOU DEVOTION THERMAL TECH

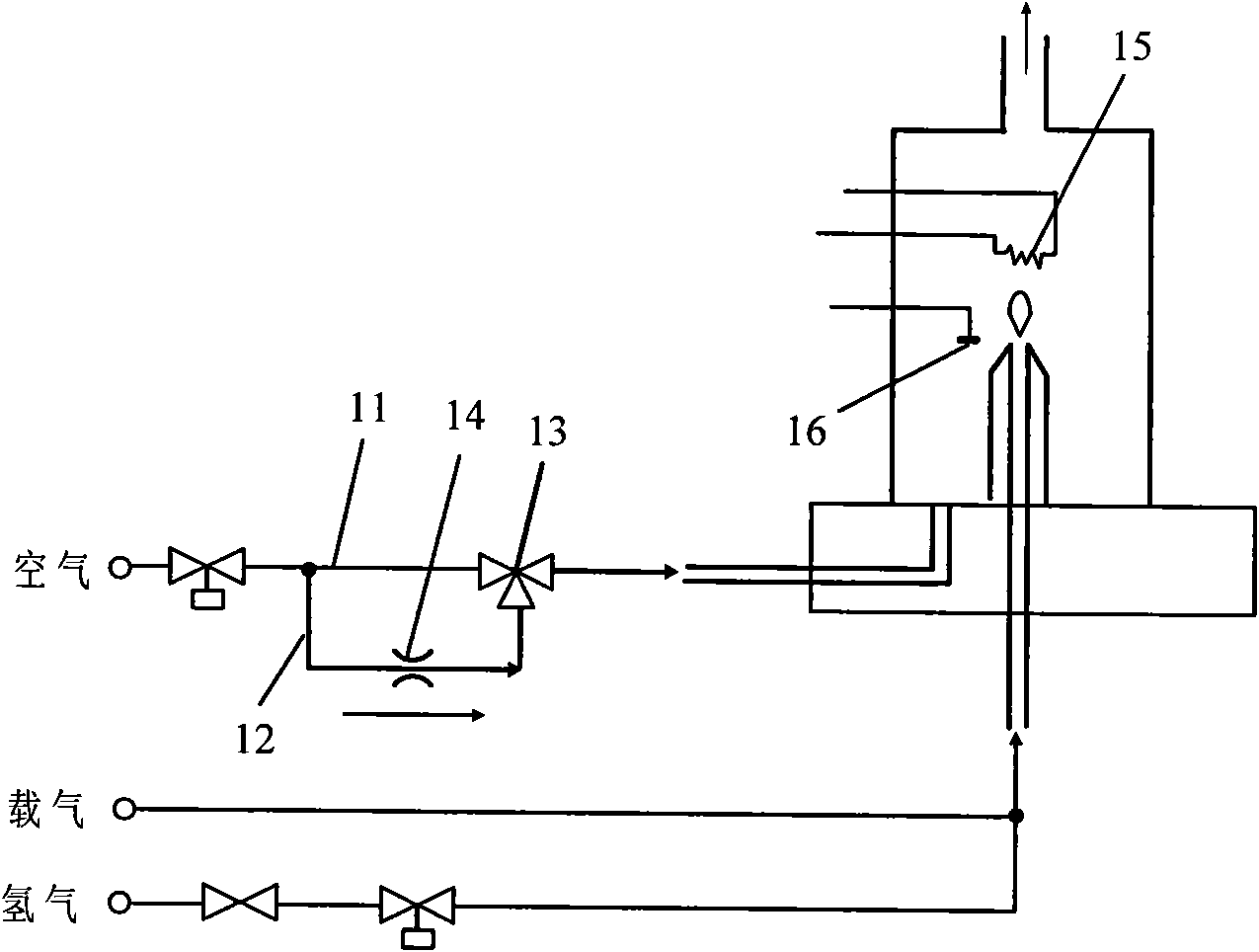

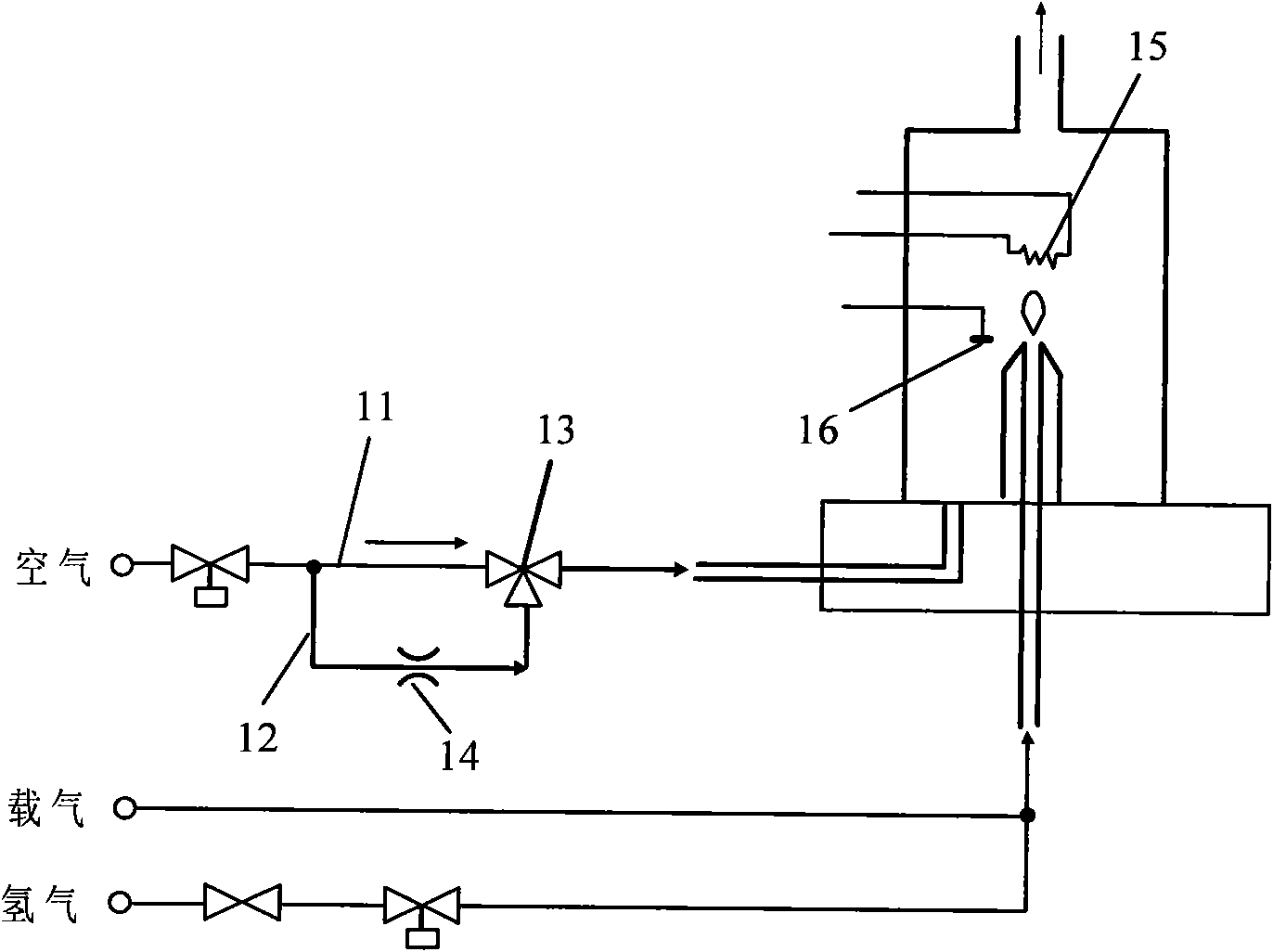

FID ignition method and device for chromatographic analysis

InactiveCN101975836ARapid auto-ignitionReal-time monitoring of combustionComponent separationHydrogenCombustion

The invention relates to a flame ionization detector (FID) ignition method for chromatographic analysis. The method comprises the following steps of: a, ignition, namely regulating a flow ratio of hydrogen to air so as to make the ratio greater than a flow ratio during the normal analysis, and igniting the hydrogen by using an igniter; b, monitoring and judging, namely monitoring physical information generated by combustion, and judging whether the hydrogen is in a combustion state or not according to the information; if so, performing analysis operation; and otherwise returning to the step a, or entering a protection state, namely shutting the hydrogen off. The invention also provides an FID ignition device for the chromatographic analysis.

Owner:FOCUSED PHOTONICS

Ignition burner

ActiveCN103672892AStable ignitionStable flame detection signalGaseous fuel burnerControl systemIgnition coil

The invention discloses an ignition burner. The ignition burner comprises a fuel gas sleeve, an air sleeve, a burner nozzle, an ignition rod and a swirler, wherein a fuel gas inlet is formed in the fuel gas sleeve, the fuel gas sleeve is sleeved with the air sleeve, an air inlet is formed in the air sleeve, the burner nozzle is connected to one end of the air sleeve and is communicated with the fuel gas sleeve and the air sleeve, an electrode tip is arranged on the ignition rod and extends into the burner nozzle, and the swirler is arranged between the fuel gas sleeve and the air sleeve and is close to the burner nozzle. According to the ignition burner, due to the arrangement of the swirler, air entering the ignition burner from the air inlet can enter the burner nozzle under the action of the swirler, burning is stable, backfire and blow-off cannot be caused, and the stiffness of a flame is high; due to the arrangement of the ignition rod, a flame detection signal is stable (a flame detection current is large and is over 15 microamperes on average); due to the fact that an ignition control cabinet is in linkage with a burning control system, automatic ignition can be achieved.

Owner:SHENWU TECH GRP CO LTD

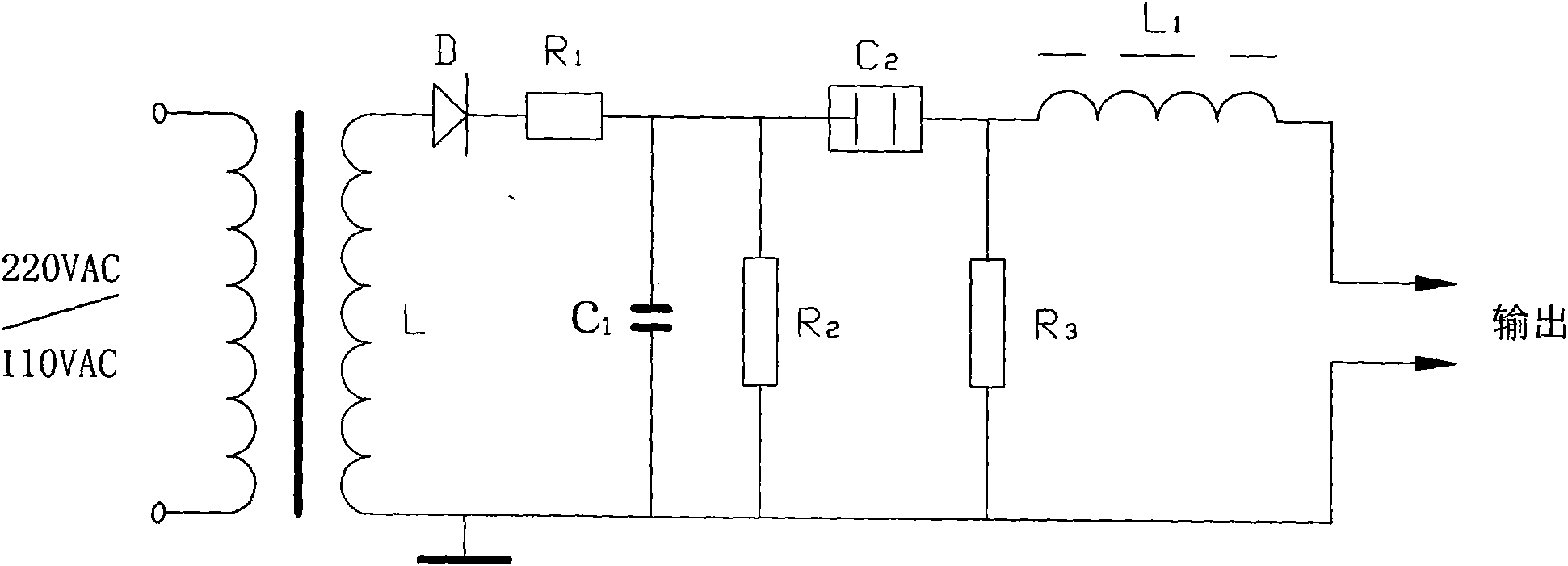

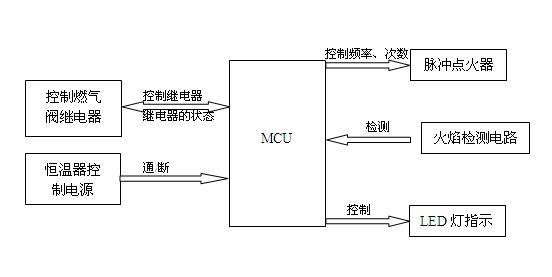

Intelligent ignition controller for gas wall-mounted furnaces and gas water heaters and intelligent ignition control method thereof

The invention discloses an intelligent ignition controller for gas wall-mounted furnaces and gas water heaters and an intelligent ignition control method thereof. The intelligent ignition controller for gas wall-mounted furnaces comprises an MCU, a gas control valve relay, a thermostat control power supply, a pulse igniter, a flame detection circuit and an LED indication lamp, wherein the gas control valve relay, thermostat control power supply, pulse igniter, flame detection circuit and LED indication lamp are connected with the MCU through the respective circuit; the gas control valve relay is used for controlling the gas supply; the thermostat control power supply is used for supplying power for the intelligent ignition controller; the pulse igniter is used for igniting gas wall-mounted furnaces and gas water heaters; the flame detection circuit is used for detecting flame; and the LED indication lamp is used for indicating working state and giving an alarm. The intelligent ignition controller for gas wall-mounted furnaces and gas water heaters is controlled by a microcomputer to detect the flame state at any time. Once the flame is out, the intelligent ignition controller can close the valve to carry out the corresponding security protection. Thus, the intelligent ignition controller can realize the functions of automatic ignition, flameout, valve closing and flame state detection, thereby ensuring the security of gas wall-mounted furnaces and gas water heaters. The invention has the advantages of simple structure and easy production.

Owner:扬州嘉华电气股份有限公司

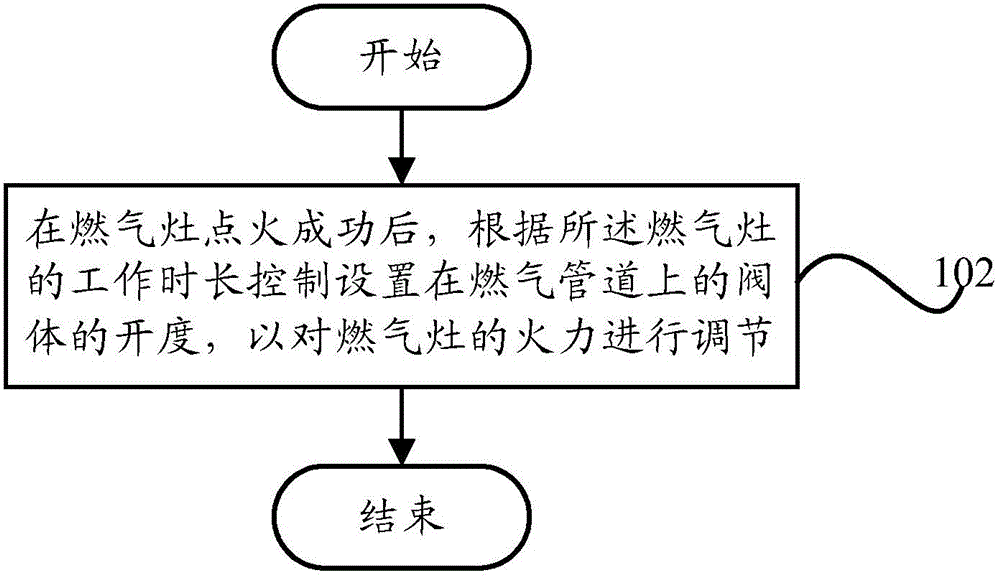

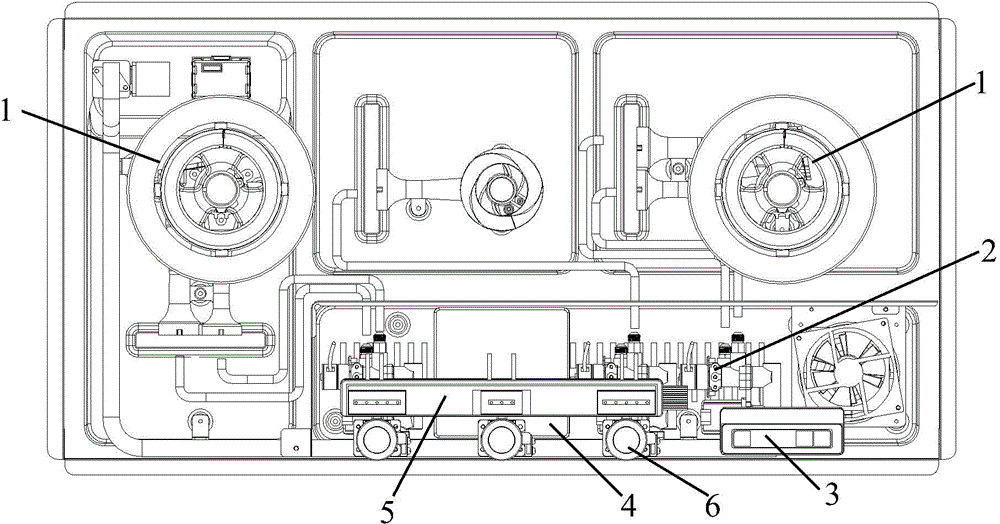

Control method and control system for gas stove and gas stove

InactiveCN105333462ARealize the function of automatic adjustment of firepowerSolve the problem of manual operation to adjust the firepowerDomestic stoves or rangesLighting and heating apparatusAuto regulationControl system

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

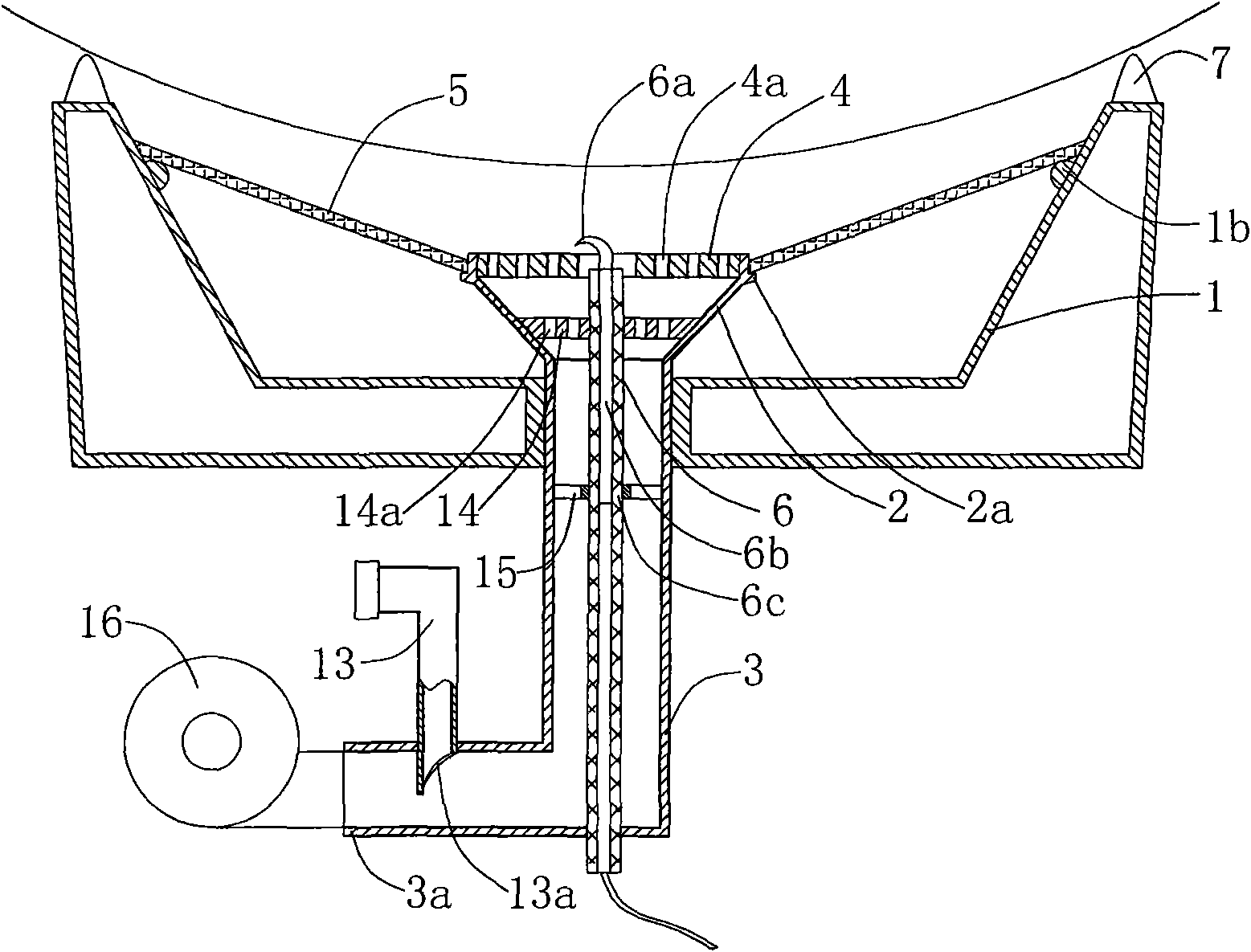

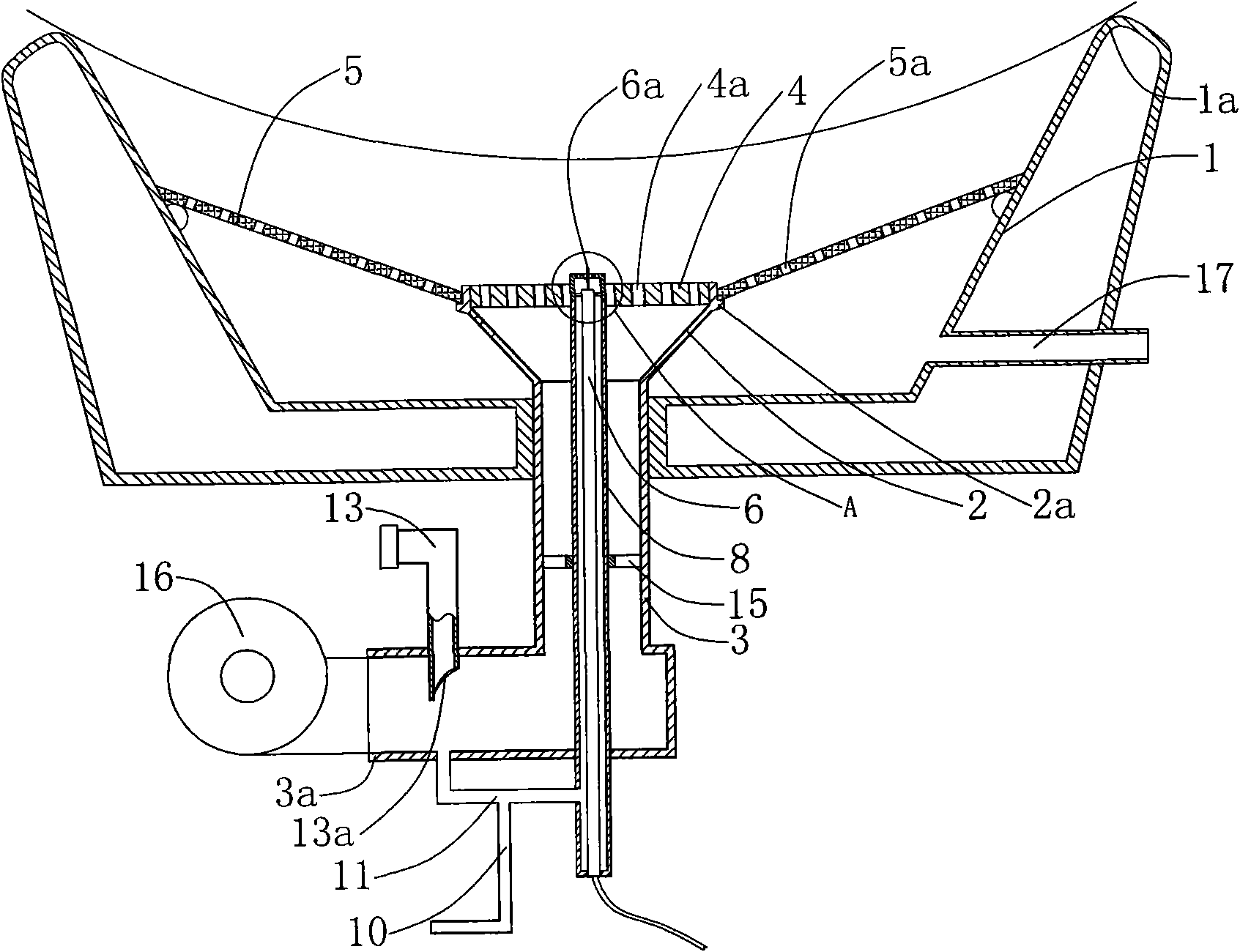

Energy-saving stove with ignition needle arranged at flame critical point

ActiveCN101793413AAchieve automatic ignitionImprove heat utilizationDomestic stoves or rangesLighting and heating apparatusCold airEngineering

The invention discloses an energy-saving stove with an ignition needle arranged at a flame critical point. The energy-saving stove comprises a stove body, a stove head and a gas pipe, wherein the stove head is arranged in the center of the inner chamber of the stove body and the gas pipe is communicated with the head. A stove plate with a gas hole is installed at the upper part of the stove head. A ring tapered platform mask body made of ceramic material is fixedly installed between the outer wall of the stove head and the inner wall of the stove body. The ignition needle is fixed in the gas pipe. The discharge tip of the ignition needle is arranged in the gas hole of the stove plate, or penetrates through the gas hole of the stove plate and is arranged between the upper surface of the stove plate and the erupted flame. The invention realizes the automatic ignition of the energy-saving stove. Since the ignition needle is arranged in the stove head and in the gas pipe and the discharge tip of the ignition needle is arranged above the gas hole of the stove plate and is lower than the critical point at the bottom of the flame, the ignition needle is prevented from being directly burnt by the flame and is continuously cooled by cold air sprayed by the gas pipe, and the service life of the ignition needle is effectively prolonged.

Owner:宁波科莱尔节能科技股份有限公司

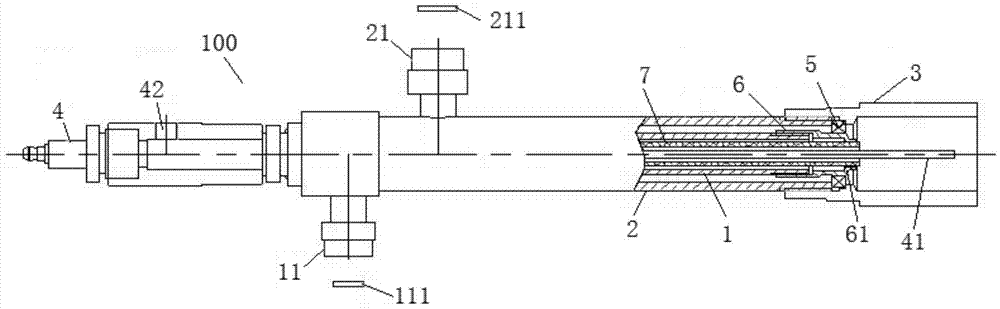

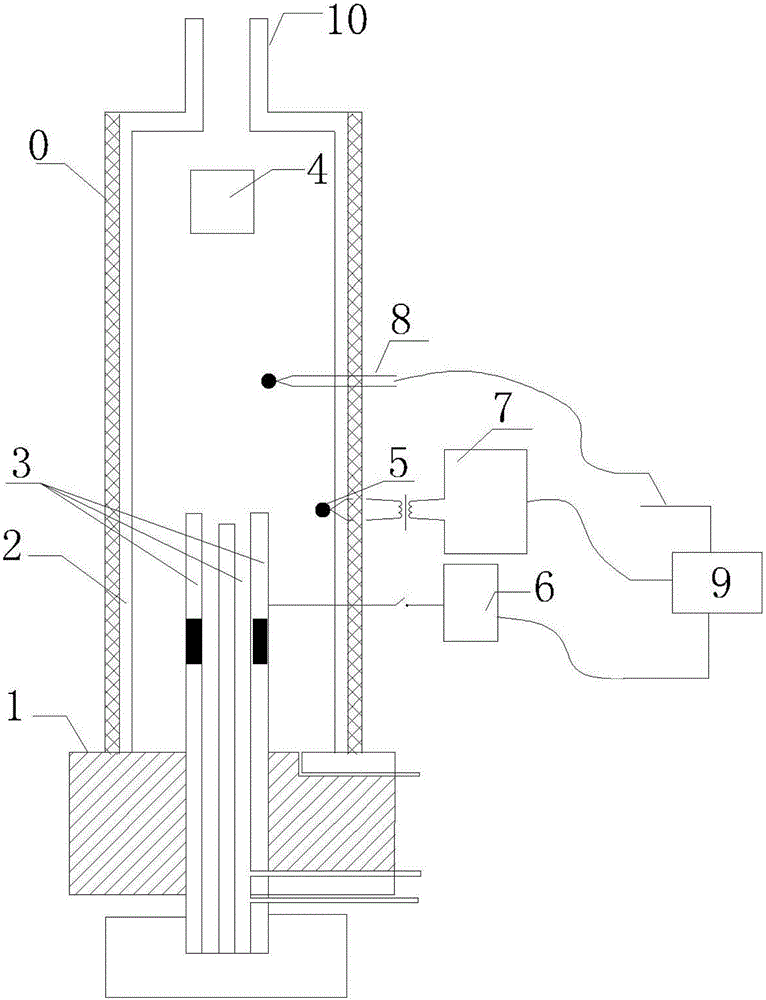

Ignition control device and method for flame ionization detector

InactiveCN106645525AExtended service lifeAchieve automatic ignitionProgramme controlComponent separationFlame ionization detectorIgnition control

The invention provides an ignition control device and method for a flame ionization detector. The ignition control device comprises a detector fixing base, a shell, a polarization electrode, a collector, an ignition head, a polarization electrode control circuit and an igniter high-voltage control circuit, wherein the polarization electrode, the collector and the ignition head are arranged in the shell, the polarization electrode and the collector are arranged on the same axis, a spare space exists between the polarization electrode and the collector, the detector fixing base is arranged at the lower end of the shell, the polarization electrode is arranged on the detector fixing base, an outlet is formed in the upper portion of the shell, the polarization electrode control circuit is connected with the polarization electrode and provides high voltage for the same, and the igniter high-voltage control circuit is connected with the ignition head and provides high voltage for the same.

Owner:浙江宜蓝环保科技有限公司

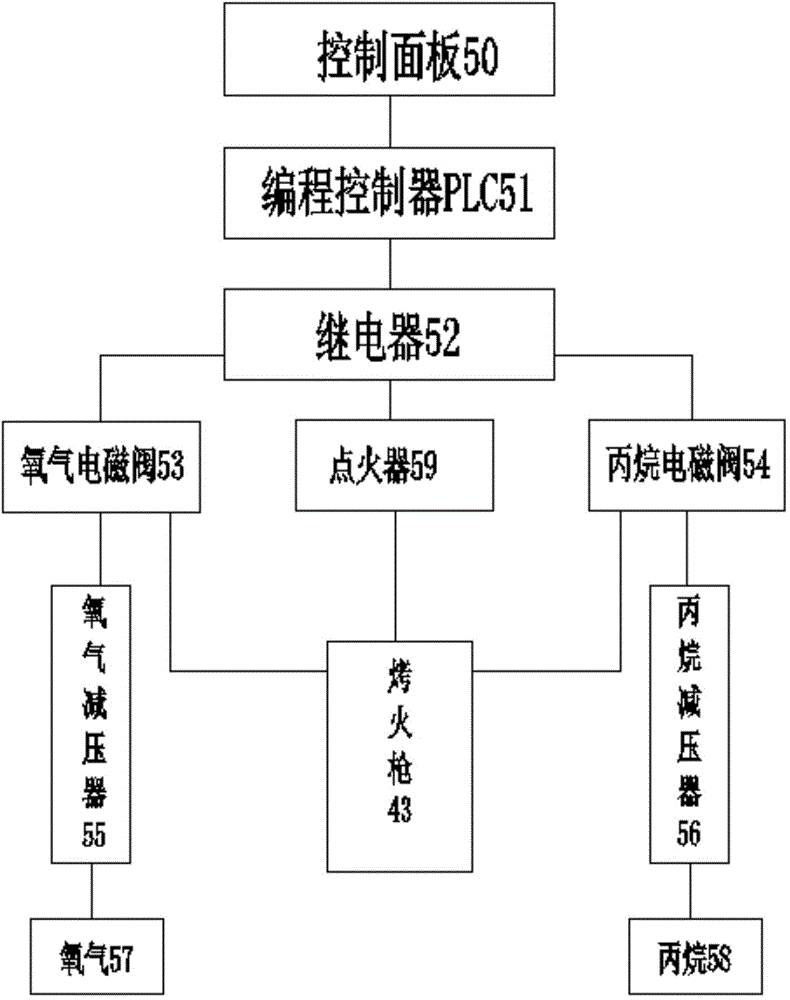

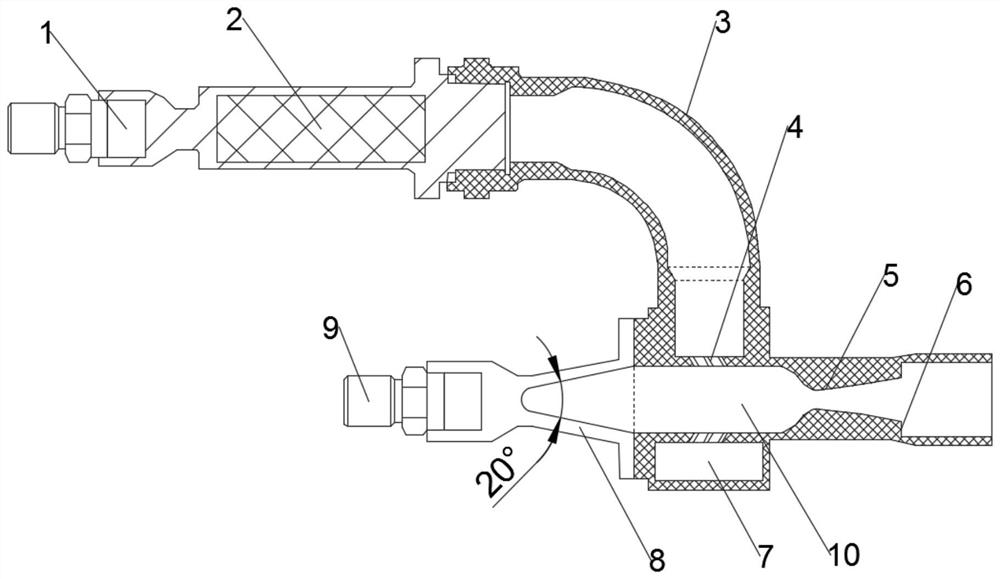

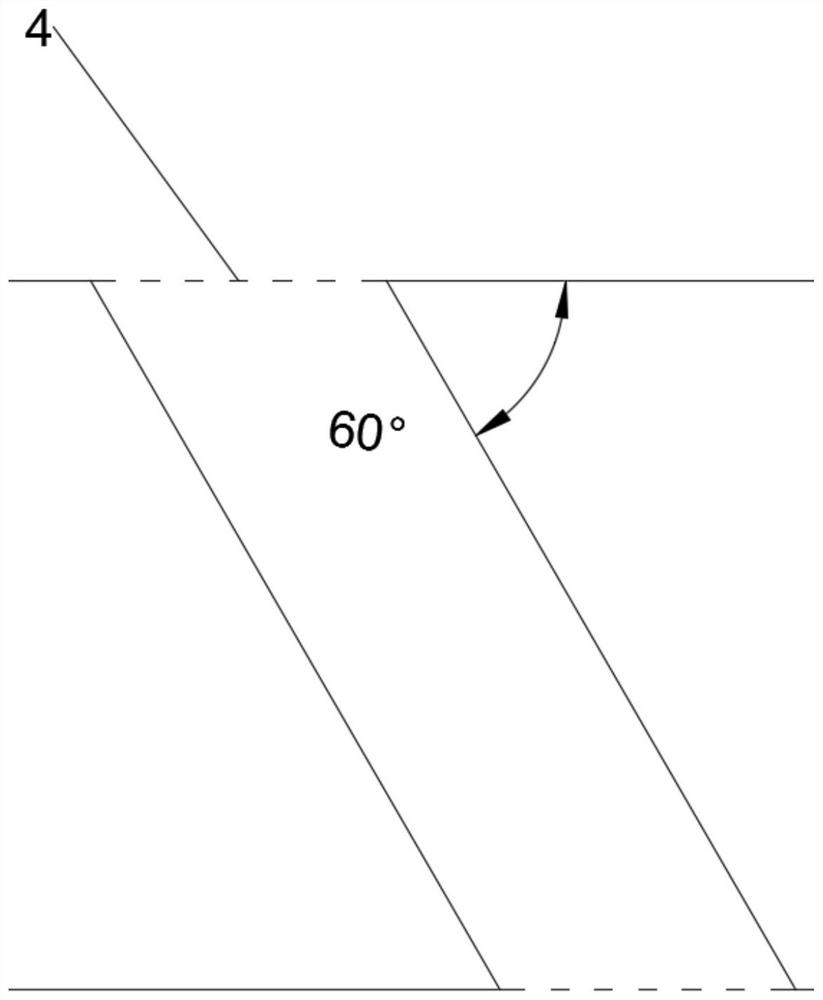

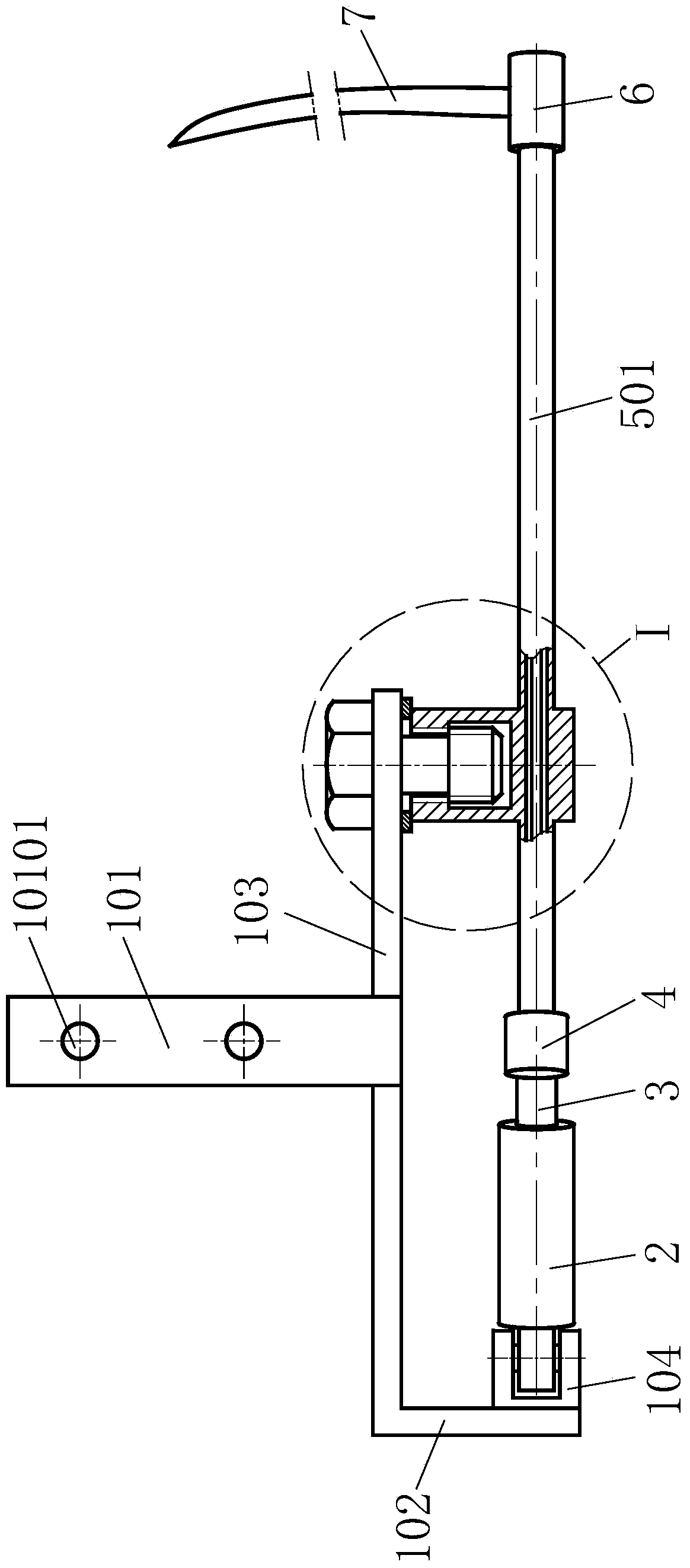

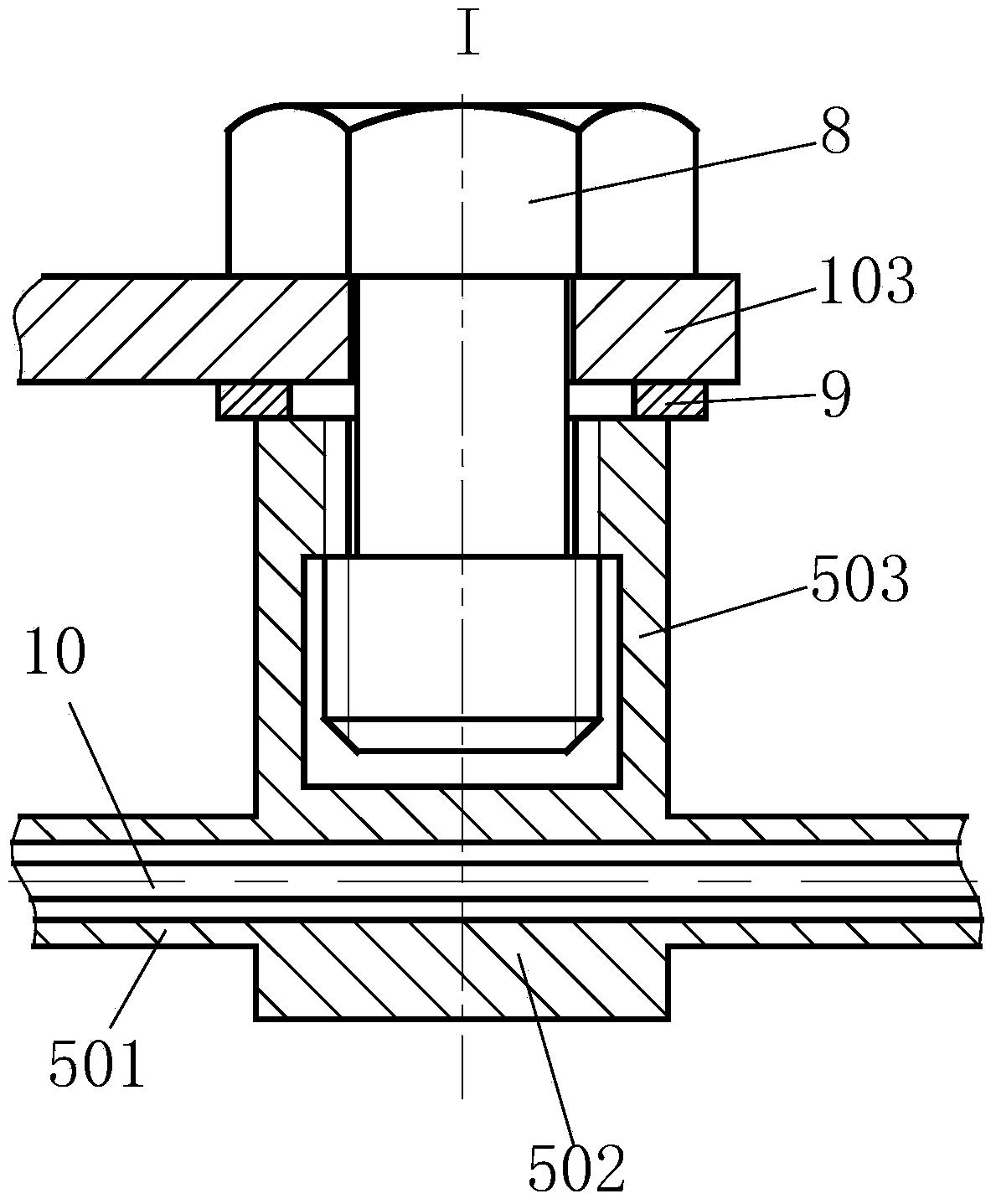

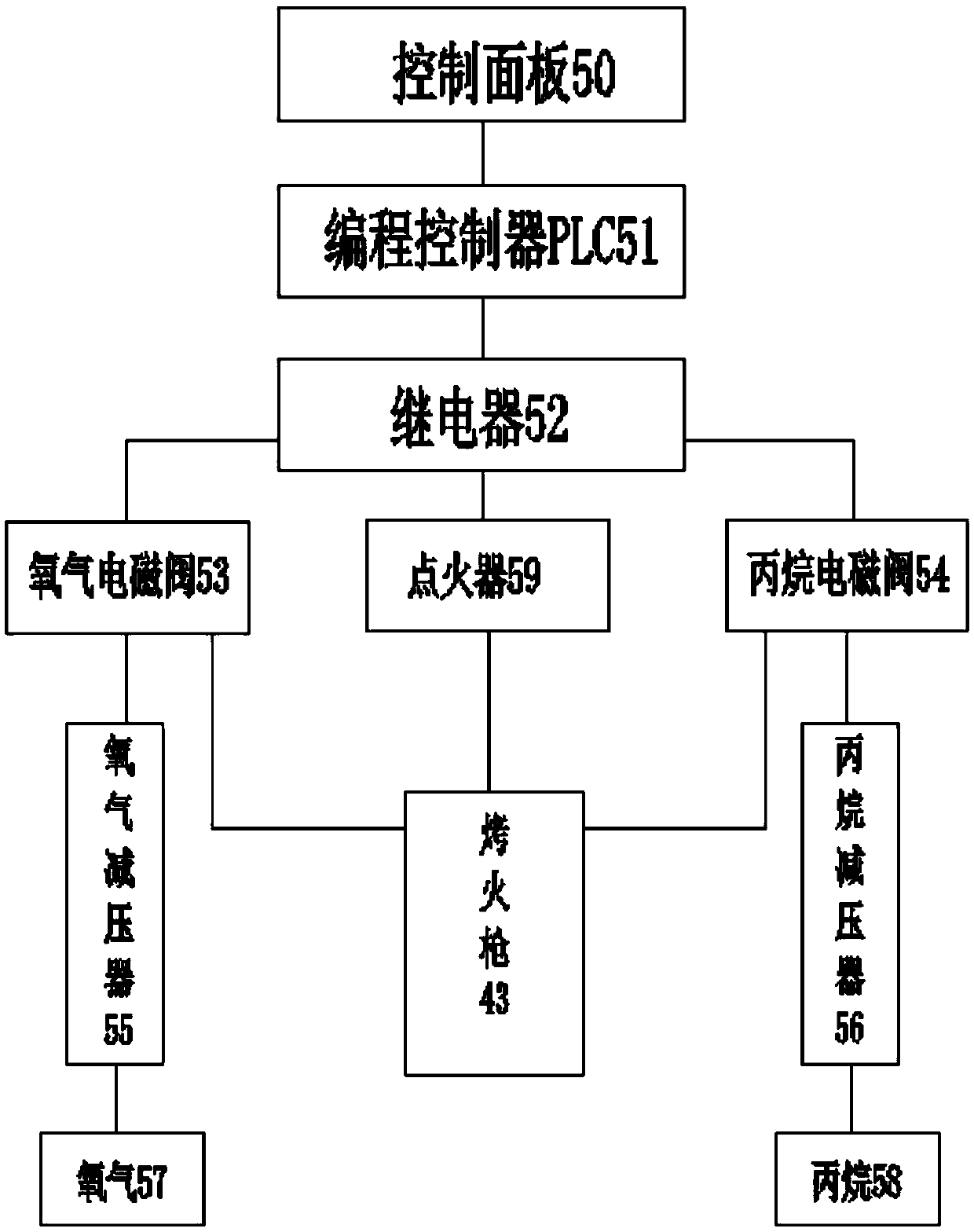

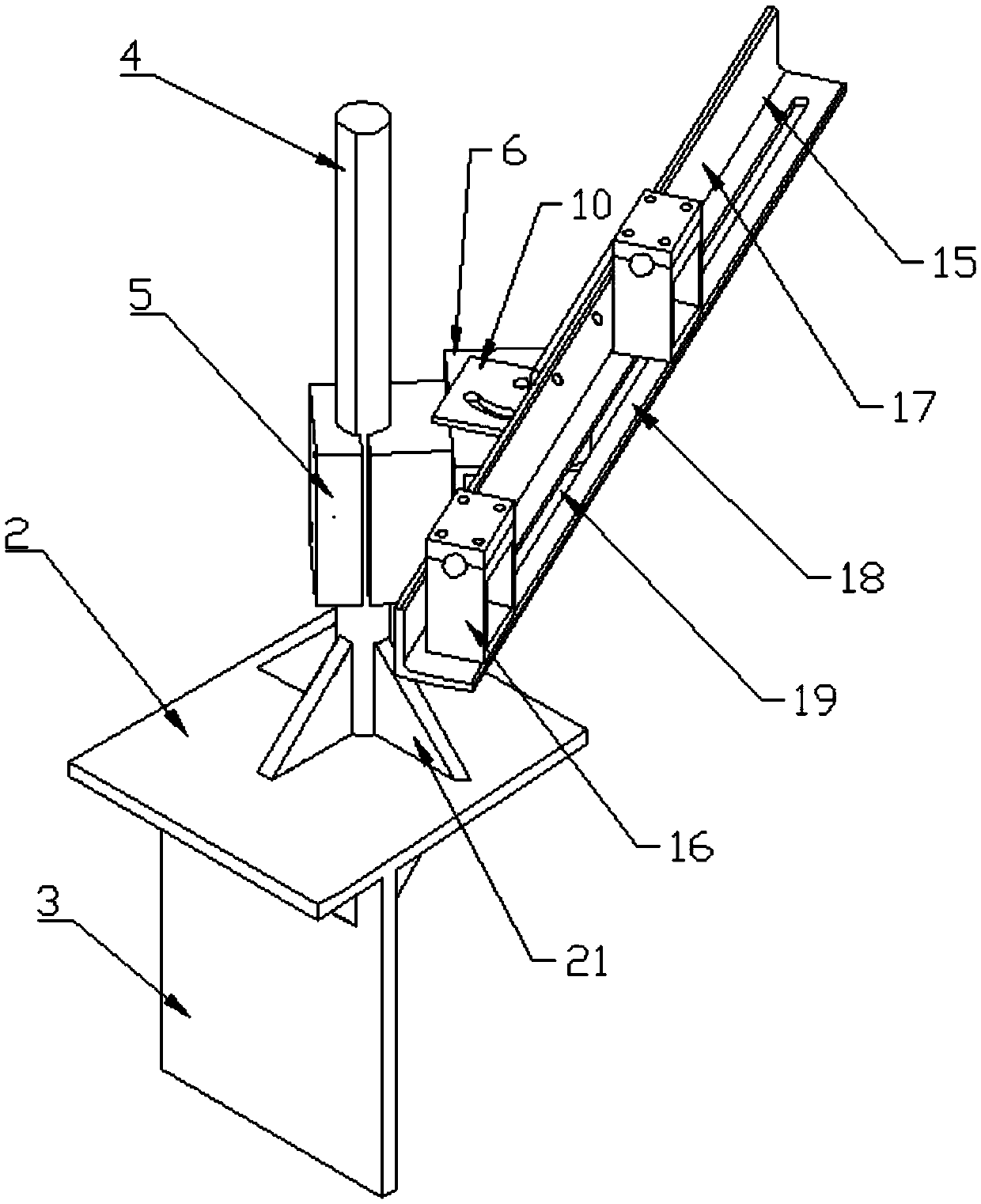

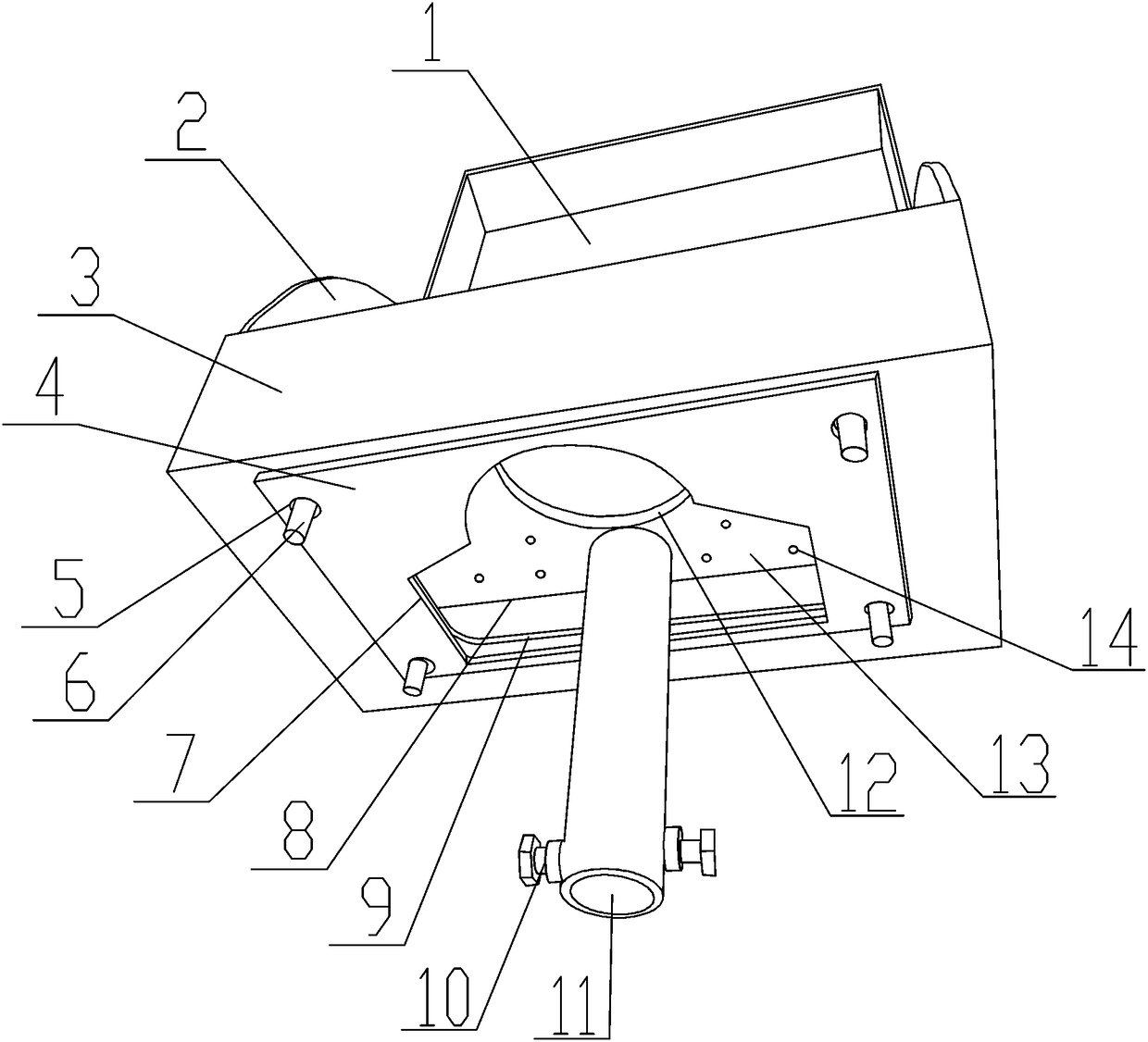

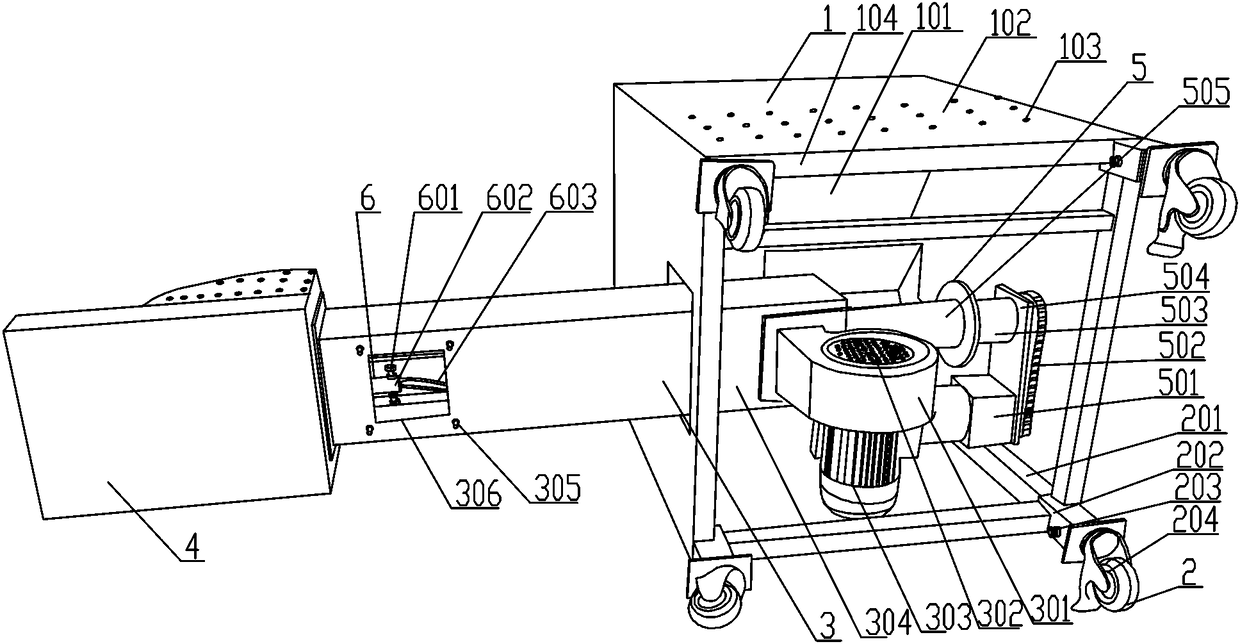

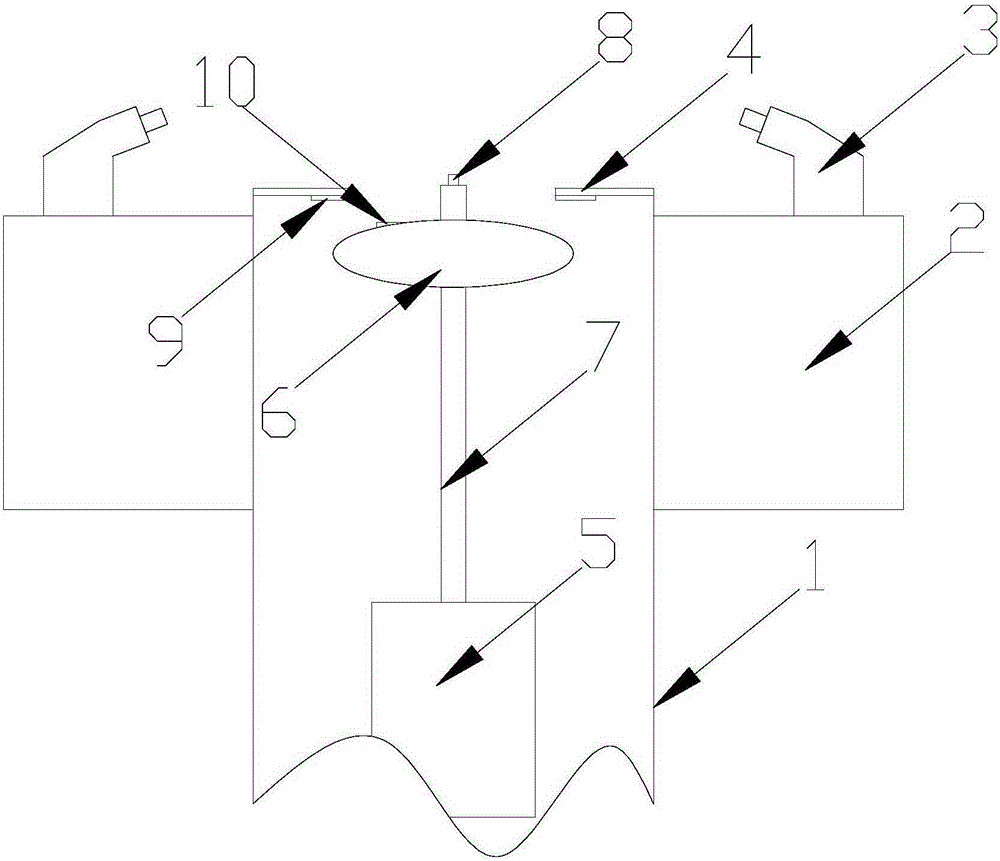

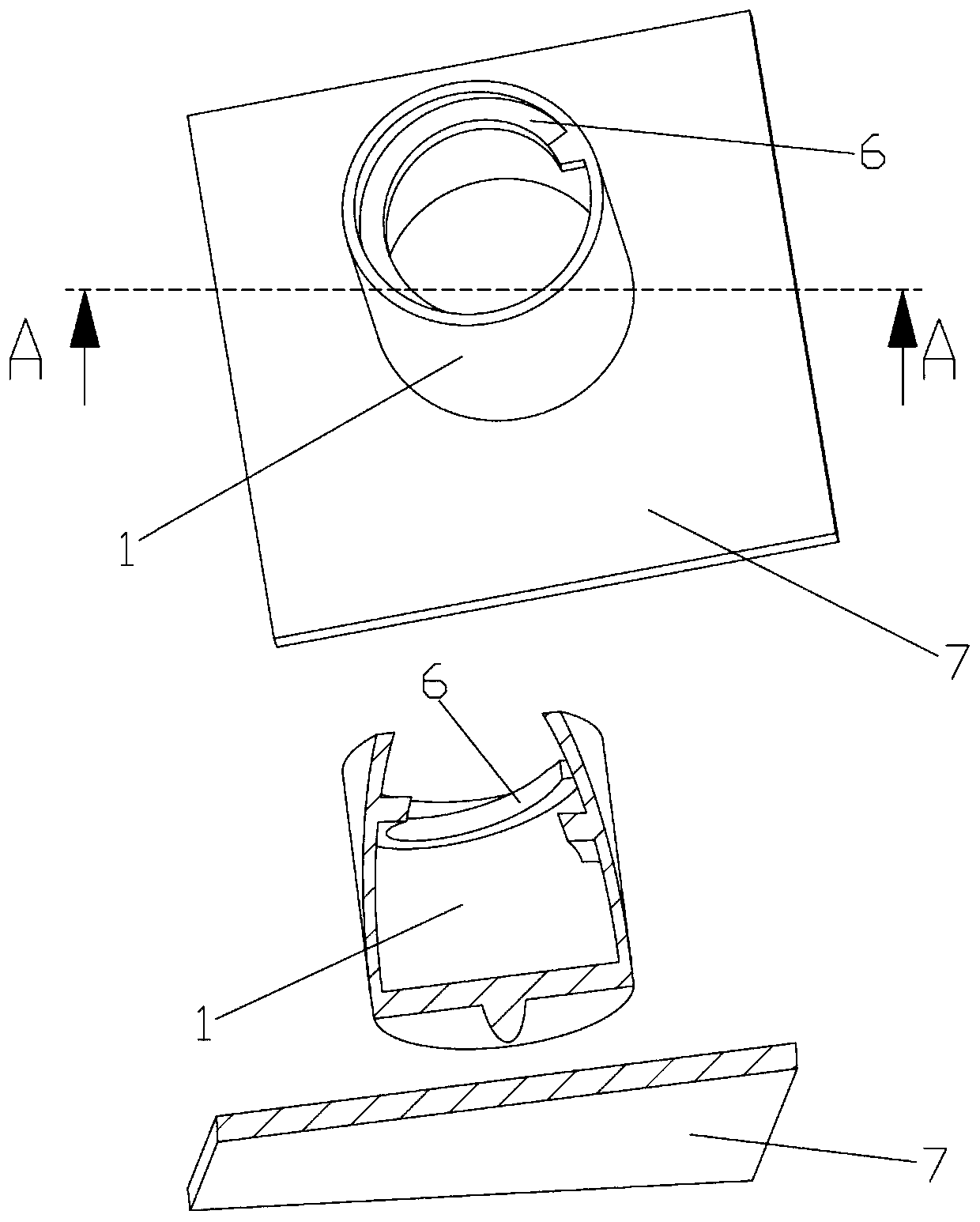

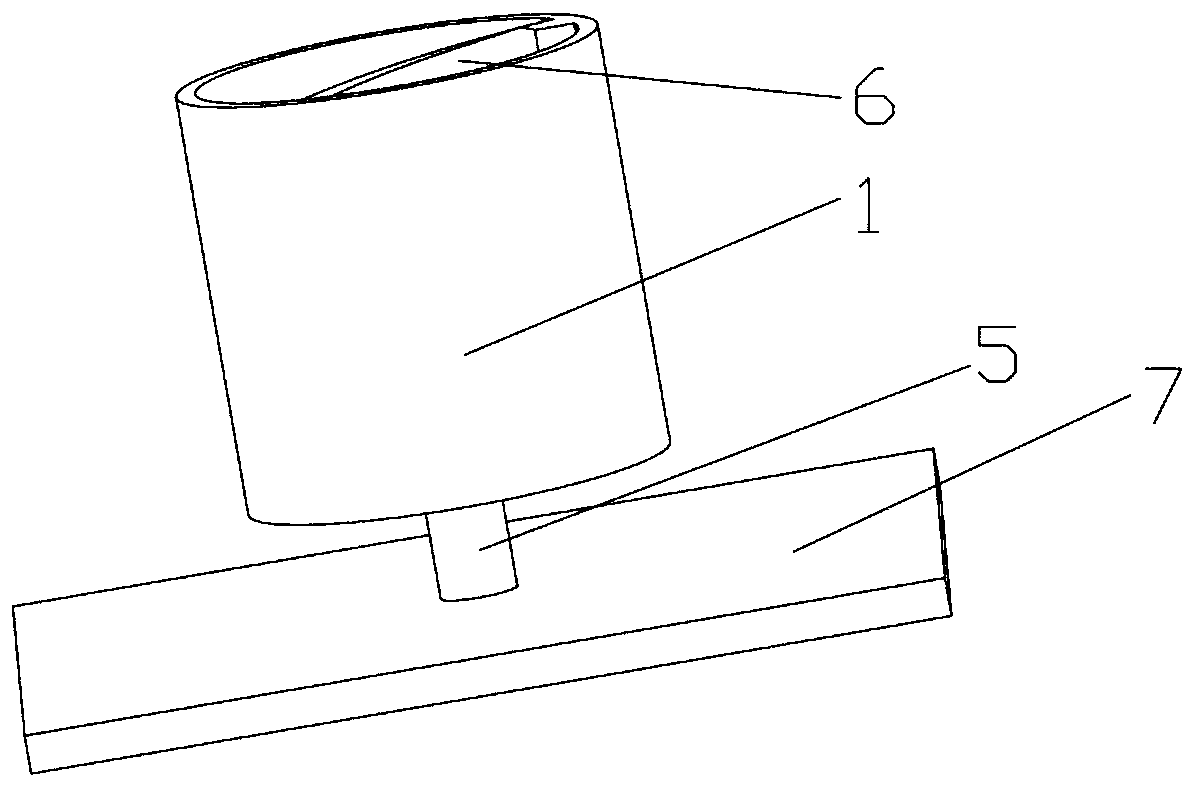

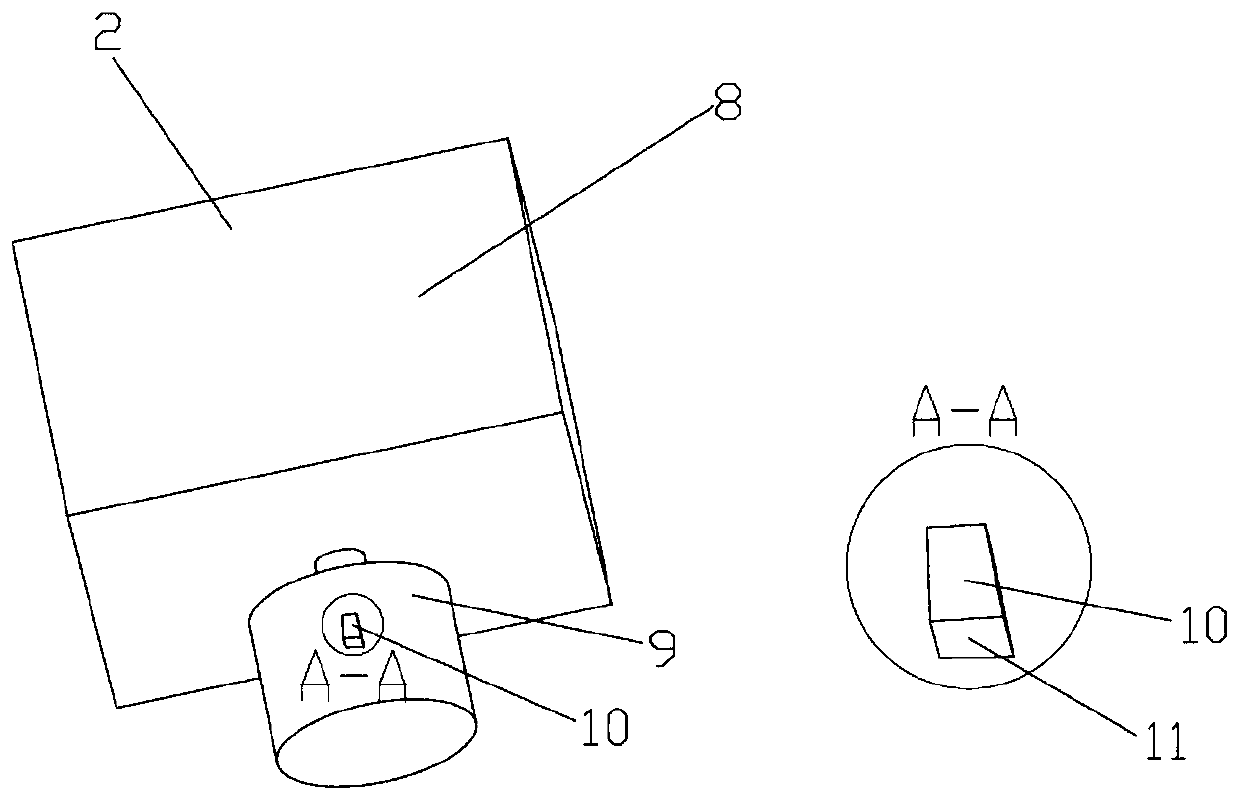

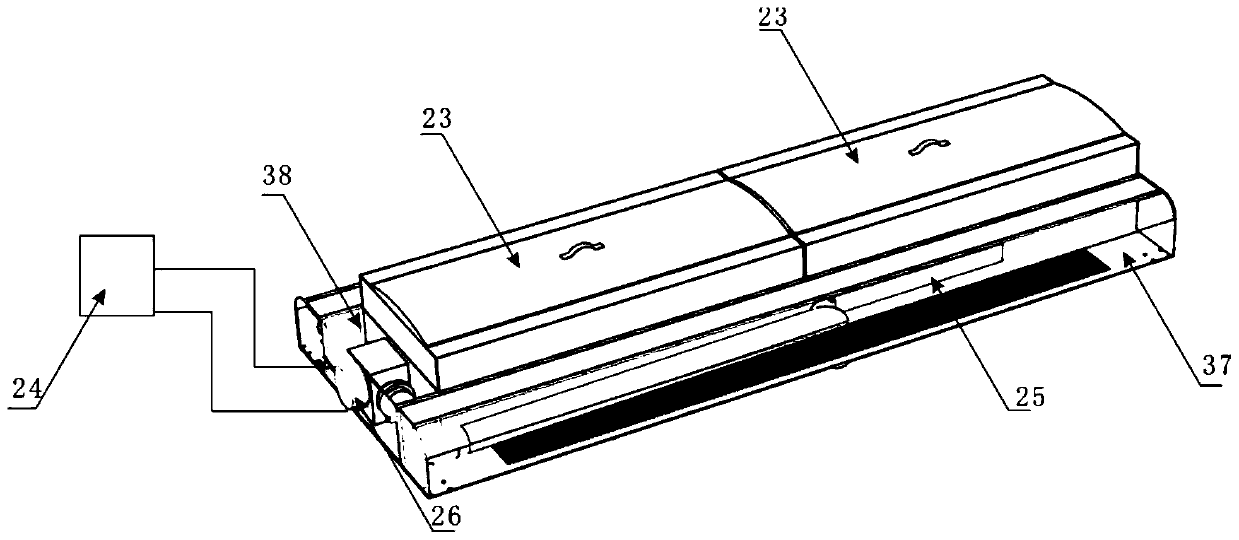

Automatic firing system for spinning hot necking machine

ActiveCN104525764AImprove stability and consistencyGuaranteed stabilityMake-and-break ignitionHollow articlesSpray nozzleGas pipeline

The invention relates to an automatic firing system for a spinning hot necking machine. The automatic firing system comprises a supporting device arranged on the necking machine, a firing gun mounted on the supporting device and a firing control system connected with the firing gun. The firing gun comprises a gun head base, a spray nozzle arranged on the gun head base, an ignition rack located on the side edge of the gun head base, an ignition electrode arranged on the ignition rack, and a gas pipeline connected with the gun head base. The firing control system comprises a control panel, a PLC connected with the control panel through a wire, a relay connected with the PLC through a wire, a gas electromagnetic valve and an igniter, wherein the gas electromagnetic valve and the igniter are both connected with the relay through wires. The gas electromagnetic valve is connected with a gas pipeline placed on the top of the gun head base and a gas cylinder pipeline containing gas, and the igniter is connected with the ignition electrode through a wire. The automatic firing system can guarantee the personal safety of technical personnel, further lower the labor intensity of the technical personnel, and improve the production rate, the product quality and the processing precision.

Owner:SHENYANG OUSHIDUN NEW MATERIAL TECH

Igniter capable of being ignited repeatedly and ignition method

PendingCN111720241AControl injection timeAchieve repetitive ignitionRocket engine plantsCombustion chamberPtru catalyst

The embodiment of the invention discloses an igniter capable of being ignited repeatedly and an ignition method. The igniter comprises a hydrogen peroxide catalyst bed, wherein a hydrogen peroxide nozzle is installed at one end of the hydrogen peroxide catalyst bed, a transition section is installed at the other end of the hydrogen peroxide catalyst bed, the bottom end of the transition section communicates with a collecting distribution cavity, and the connecting surfaces of a premixing chamber and the collecting distribution cavity are provided with oxygen-enriched gas nozzles; and a fuel nozzle is installed on one side of the premixing chamber through a tapered structure section, a premixing chamber outlet throat is installed on the other side of the premixing chamber, and a step structure is installed on the outer side of the premixing chamber outlet throat. Hydrogen peroxide with a concentration of no less than 82% is decomposed by catalysts to produce high-temperature oxygen-enriched gas, then the high-temperature oxygen-enriched gas is mixed with hydrocarbon fuel in the premixing chamber, the temperature of fuel is improved, the ignition delay time is shortened, automatic ignition and initial reaction are realized, and then flames are jetted into a combustion chamber to ignite an engine.

Owner:合肥中科重明科技有限公司 +1

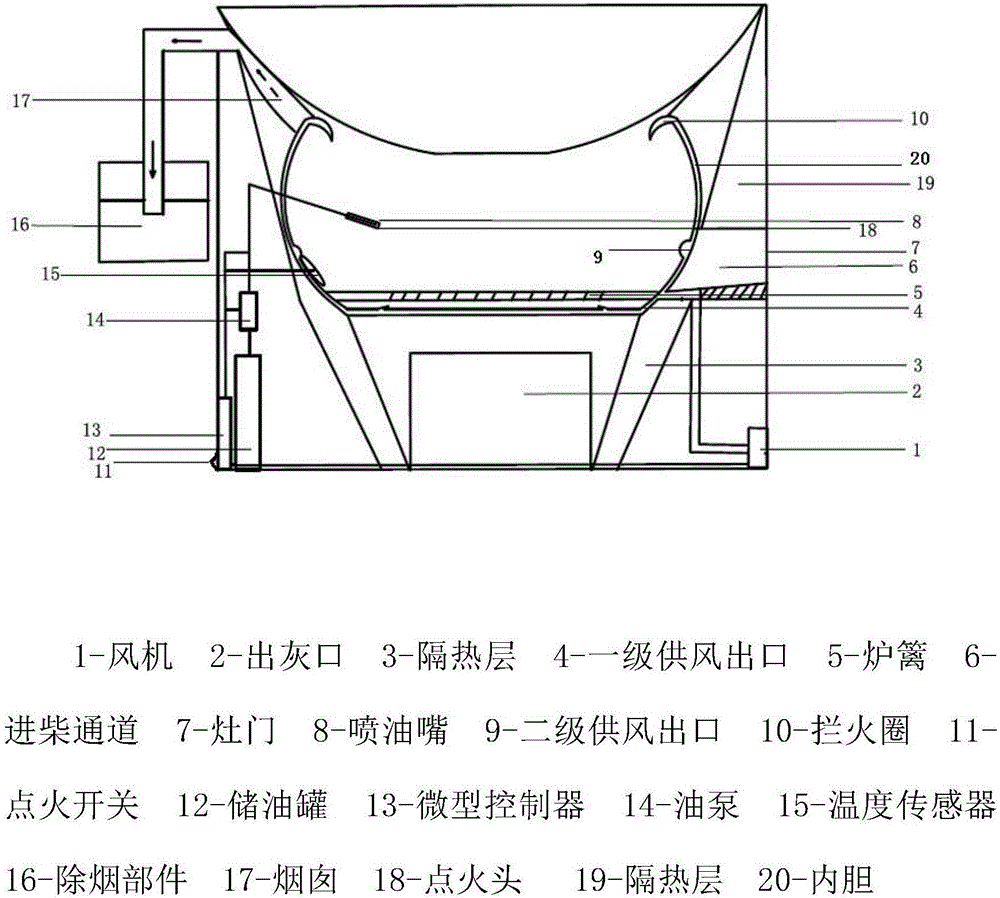

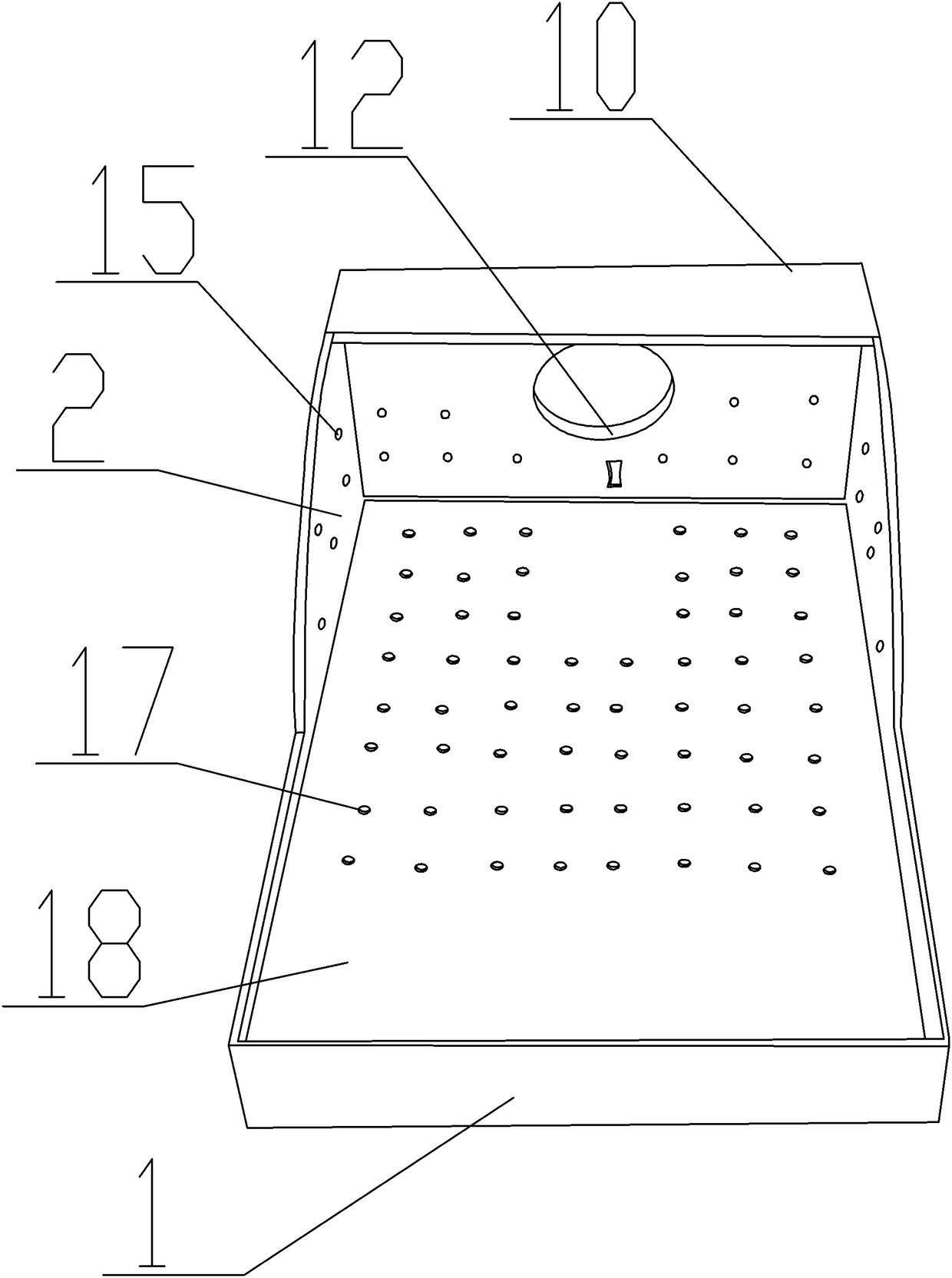

Automatic ignition firewood-fired stove and ignition method thereof

InactiveCN106642211AAchieve automatic ignitionRealize automatic air supplyDomestic stoves or rangesFuel lightersFirewoodCombustion

The invention belongs to the technical field of firewood-fired stoves and particularly relates to an automatic ignition firewood-fired stove and an ignition method thereof. The firewood-fired stove achieves automatic ignition and automatic air feeding and air control by means of the design of an automatic ignition system and an automatic air supply system, the ignition mode that fuel is directly sprayed on firewood is used so that ignition of the firewood-fired stove can be easier, the technical problems that in the prior art, a firewood-fired stove is difficult to ignite and the combustion rate is low are solved, the whole firewood-fired stove is easier to ignite, combustion efficiency is higher, and the firewood-fired stove is more environmentally friendly and can also be used in densely populated and densely built areas.

Owner:张小平

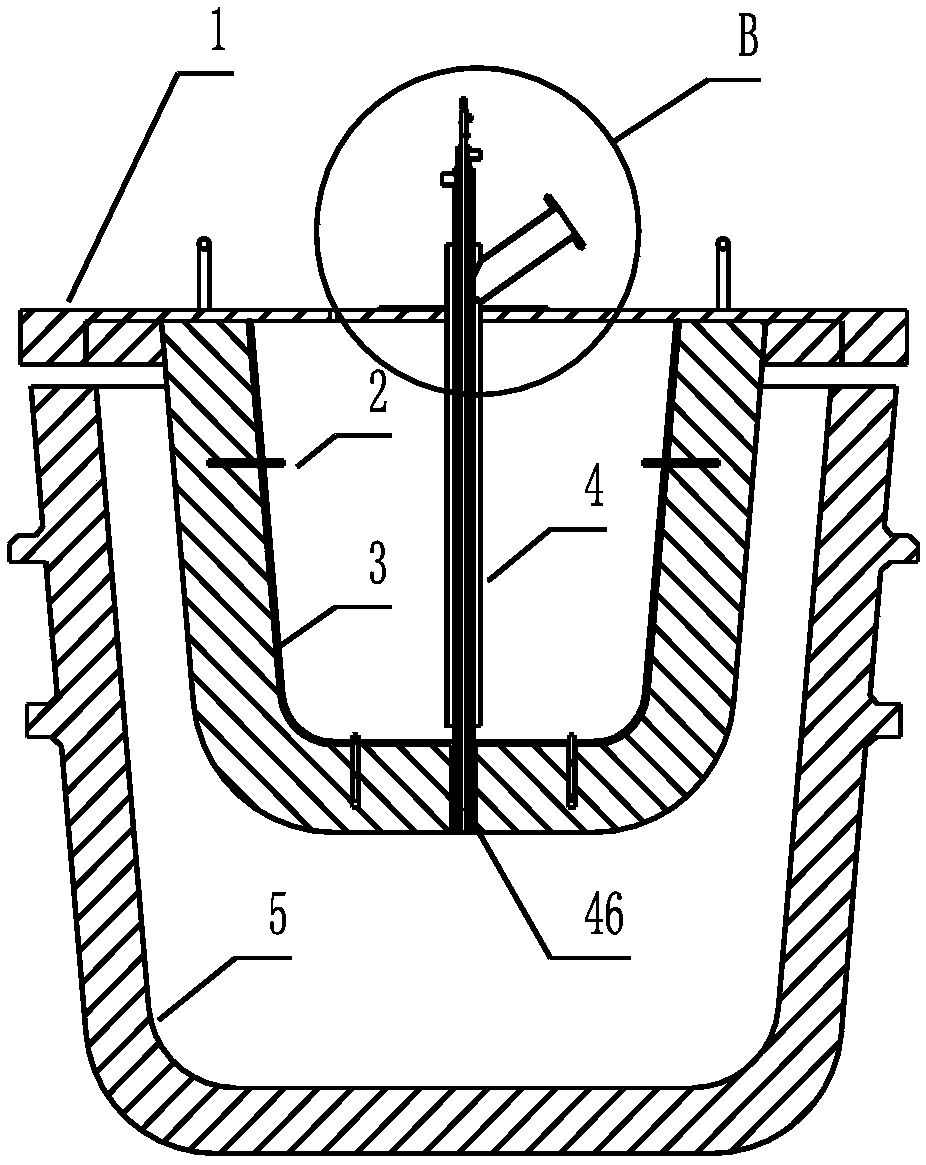

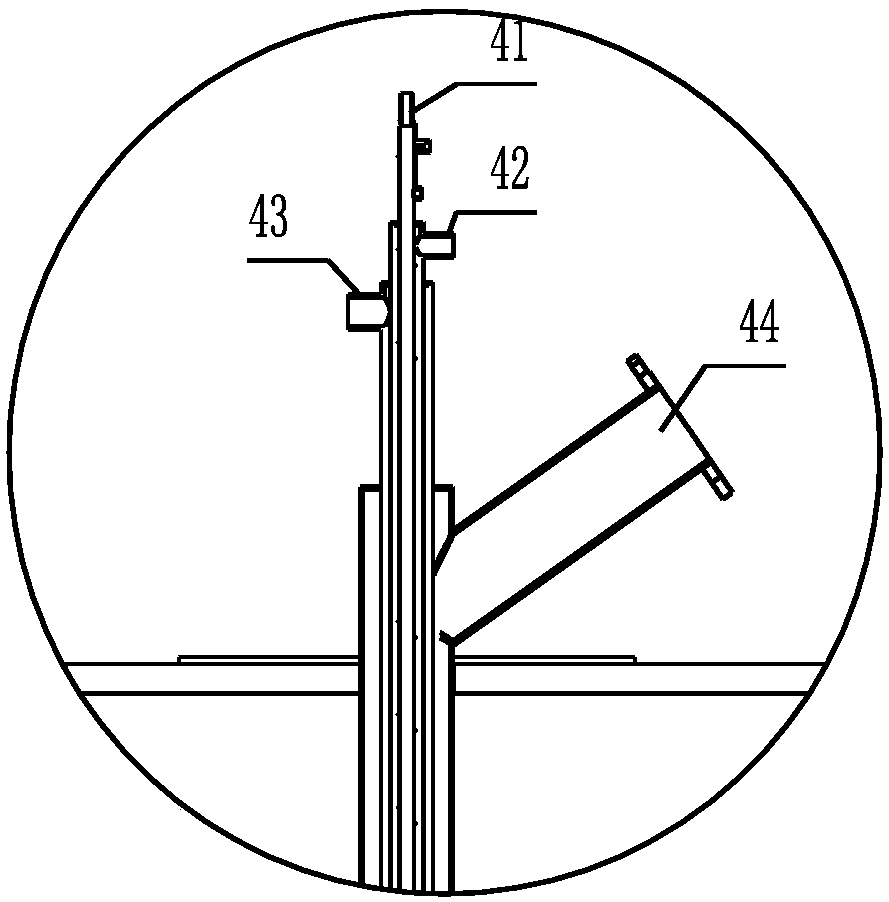

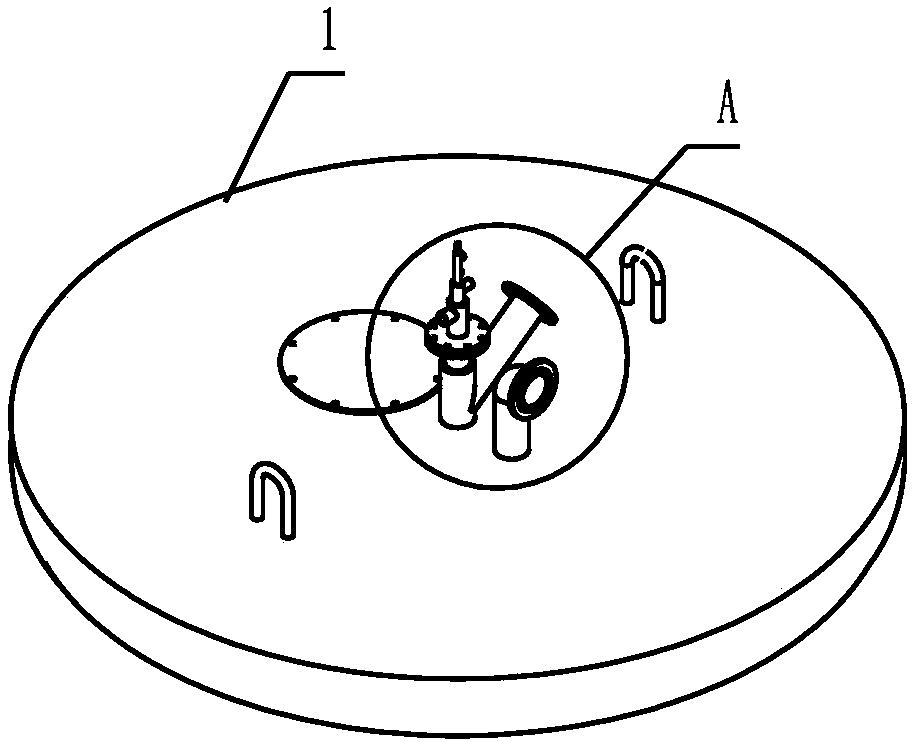

Oxygen-rich intelligent temperature-control ladle baking device and using method thereof

ActiveCN108393475AUniform heating temperatureIncrease the baking temperatureMelt-holding vesselsTemperature controlCombustor

The invention relates to an oxygen-rich intelligent temperature-control ladle baking device and a using method thereof. The ladle baking device is provided with a ladle cover, a ladle liner and a burner assembly, a space is reserved between the outer periphery of the ladle liner and the inner wall of a steel ladle, and a gap is further reserved between the periphery of the ladle cover and the edgeof the upper opening of the steel ladle; a plurality of temperature sensors capable of testing the temperature of the outer wall of the ladle liner are arranged on the wall of the ladle liner; the burner assembly is provided with an igniter, a fuel gas pipe, a combustion-supporting gas pipe and a combustion head, the combustion head extends out of the bottom of the ladle liner, the upper end of the burner assembly extends out of the ladle cover, the burner assembly is fixed in the middle of the ladler cover, and a self-control switch of the igniter, a gas inlet of the fuel gas pipe and a gasinlet of the combustion-supporting gas pipe are arranged at the upper end of the burner assembly; and the ladle baking device is further provided with a PLC, and the PLC is in signal and control connection with the temperature sensors and the self-control switch. The ladle baking device has the advantages that the structural design is reasonable, running is safe and reliable, the automation degreeis high, the operation and the use are convenient, the steel ladle is uniformly baked, the baking time is effectively shortened, the baking efficiency is improved, and the pollution to the environment is relatively low.

Owner:王研

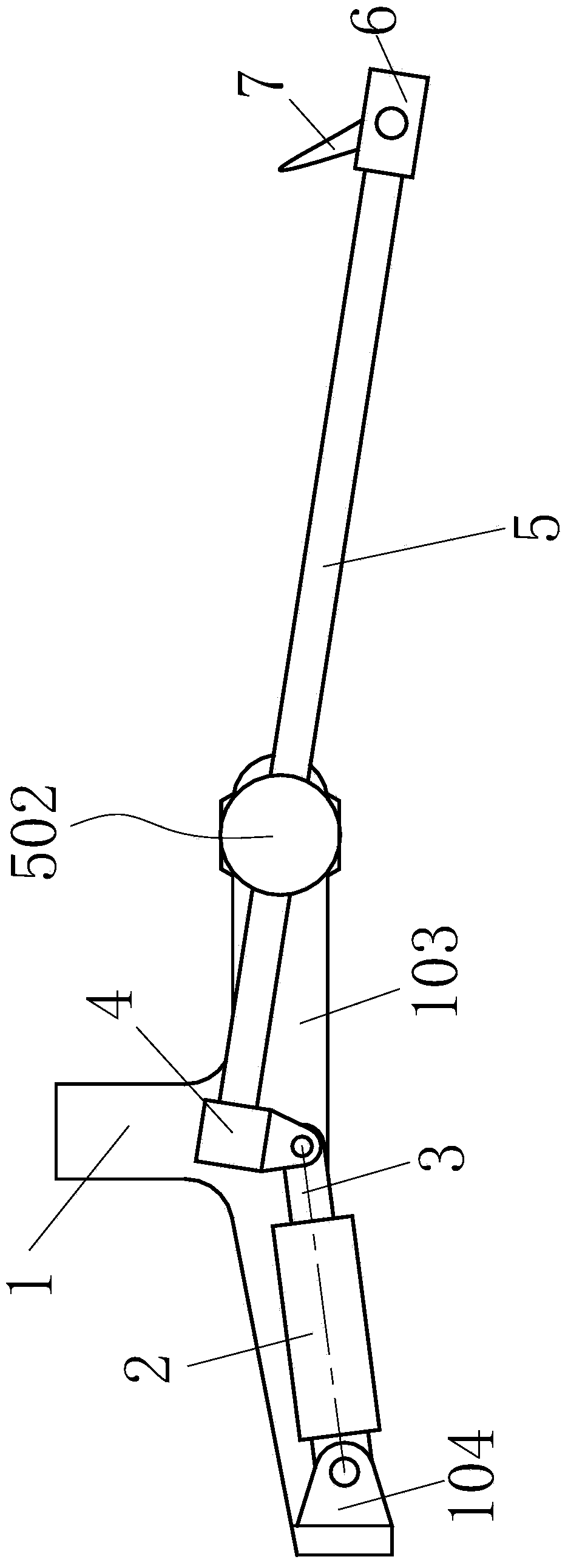

Translocation ignition device of plasma gun

ActiveCN103556101AGuarantee personal safetyReasonable structural designMolten spray coatingPush pullEngineering

The invention relates to a translocation ignition device of a plasma gun. The translocation ignition device comprises a bending board, wherein the bending board comprises a first bending part, a second bending part, a third bending part and a hinge seat; the first bending part is symmetrically provided with bolt holes; the second bending part is located at the left of the first bending part; the third bending part is located at the right of the first bending part; the right end of the third bending part is provided with a mounting hole; the hinge seat is fixedly arranged on the second bending part and is connected with a push-pull air cylinder in a hinged way; the push-pull air cylinder is connected with an adapter through a push rod; the mounting hole of the third bending part is internally provided with a translocation ignition mechanism; the left end of the translocation ignition mechanism is connected with the adapter. The translocation ignition device has the advantages of reasonable structural design, convenience in control, high degree of automation and the like and is capable of realizing automatic ignition, so that the efficiency is increased, potential safety hazards existing in artificial ignition are avoided, and the guarantee is provided for the safety of workers.

Owner:WUHU DINGHAN REMFR TECH

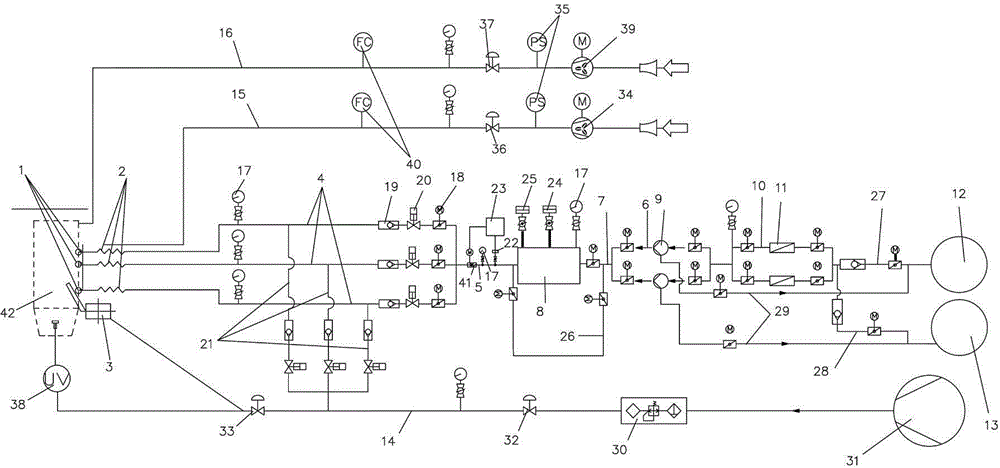

Combustion system with coal water slurry fired boiler

InactiveCN102997228AAvoid heavy polluting processes with insufficient combustion at low temperaturesThe furnace heats up rapidlyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemFuel tank

The invention relates to a combustion system with a coal water slurry fired boiler. The combustion system comprises a coal water slurry storage tank, a stirrer, a slurry supply pump, a filter, a combustor and the boiler which are sequentially connected with one another, wherein the combustor is respectively provided with an air-blast system and an ignition oil way which are used for atomizing coal water slurry, the air-blast system comprises an air storage tank and an air compressor acting on the air storage tank, the air storage tank is connected with the combustor, and the ignition oil way comprises a daily oil tank and an ignition oil tank which are sequentially connected with the combustor. The combustion system totally adopts flow conveying and atomization of pipelines, can implement automatic ignition of oil in a short time, is simple and convenient to operate and high in safety, and requires labor intensity which is much less than that required by a coal-fired boiler.

Owner:CHANGZHOU OLYMSPAN THERMAL ENERGY EQUIP

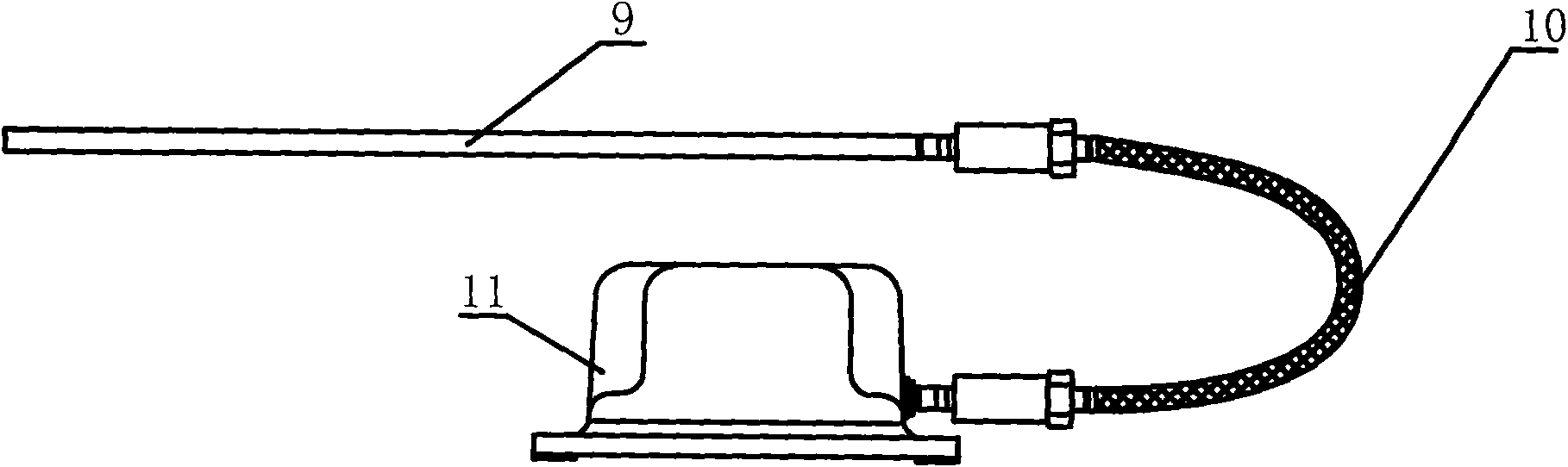

Portable plasma ignition device

PendingCN107366927AIncrease powerIncrease output powerIncandescent ignitionThermodynamicsStandby power

The invention relates to a portable plasma ignition device. The portable plasma ignition device comprises an ignition control box, a storage battery, a power line, a power source, a cable, a socket, an ignition rod, an ignition gun and a flame detection probe; the storage battery used for providing a standby application power source is arranged in the ignition control box, the ignition control box is connected with the 220V power source through the power line, the ignition control box is connected with the socket through the cable, the socket is connected with the ignition gun through the ignition rod, the flame detection probe is mounted on the ignition gun, and the ignition gun and the flame detection probe are connected with the ignition control box through the cable in the ignition rod. The technical problems that a traditional ignition device is small in energy, low in ignition success rate, heavy in structure and the like are solved. The functions of long-time flame monitoring and on-time remote ignition control are achieved, under the condition that on the scene, no 220V power source exists, the device can be used for a long time, and the ignition device can be widely applied to ignition of oil and gas well open flow drained liquid and ignition of low-heat-value fuel.

Owner:沈成东

Energy-saving stove with ignition needle arranged at flame critical point

ActiveCN101793413BAchieve automatic ignitionImprove heat utilizationDomestic stoves or rangesLighting and heating apparatusCold airEngineering

The invention discloses an energy-saving stove with an ignition needle arranged at a flame critical point. The energy-saving stove comprises a stove body, a stove head and a gas pipe, wherein the stove head is arranged in the center of the inner chamber of the stove body and the gas pipe is communicated with the head. A stove plate with a gas hole is installed at the upper part of the stove head.A ring tapered platform mask body made of ceramic material is fixedly installed between the outer wall of the stove head and the inner wall of the stove body. The ignition needle is fixed in the gas pipe. The discharge tip of the ignition needle is arranged in the gas hole of the stove plate, or penetrates through the gas hole of the stove plate and is arranged between the upper surface of the stove plate and the erupted flame. The invention realizes the automatic ignition of the energy-saving stove. Since the ignition needle is arranged in the stove head and in the gas pipe and the dischargetip of the ignition needle is arranged above the gas hole of the stove plate and is lower than the critical point at the bottom of the flame, the ignition needle is prevented from being directly burnt by the flame and is continuously cooled by cold air sprayed by the gas pipe, and the service life of the ignition needle is effectively prolonged.

Owner:宁波科莱尔节能科技股份有限公司

An automatic heating system for spinning heat closing machine

ActiveCN104525764BImprove stabilityImprove consistencyMake-and-break ignitionHollow articlesProduction rateControl system

The invention relates to an automatic firing system for a spinning hot necking machine. The automatic firing system comprises a supporting device arranged on the necking machine, a firing gun mounted on the supporting device and a firing control system connected with the firing gun. The firing gun comprises a gun head base, a spray nozzle arranged on the gun head base, an ignition rack located on the side edge of the gun head base, an ignition electrode arranged on the ignition rack, and a gas pipeline connected with the gun head base. The firing control system comprises a control panel, a PLC connected with the control panel through a wire, a relay connected with the PLC through a wire, a gas electromagnetic valve and an igniter, wherein the gas electromagnetic valve and the igniter are both connected with the relay through wires. The gas electromagnetic valve is connected with a gas pipeline placed on the top of the gun head base and a gas cylinder pipeline containing gas, and the igniter is connected with the ignition electrode through a wire. The automatic firing system can guarantee the personal safety of technical personnel, further lower the labor intensity of the technical personnel, and improve the production rate, the product quality and the processing precision.

Owner:SHENYANG OUSHIDUN NEW MATERIAL TECH

Control system of heavy oil burner of carbon rotary kiln

The invention relates to a control system of a heavy oil burner of a carbon rotary kiln, three oil nozzles are formed in a kiln head of a rotary kiln, each oil nozzle is arranged at the end of an oil injection gun, the oil nozzle is provided with an igniter; a shaping wind pipeline is formed in the kiln head, a combustion-supporting wind pipeline is arranged on the circumference of the outer side of the oil nozzle; each oil injection gun is connected with one oil supplying pipeline, three oil supplying pipelines are connected with the oil outlet pipe of the heavy oil burner, the oil inlet pipe of the heavy oil burner is connected with one end of the supercharging oil pipe, a heavy oil heater is formed between the oil outlet pipe of the heavy oil burner and the oil inlet pipe of the heavy oil burner, a supercharging pump is formed on the supercharging oil pipe, the other end of the supercharging oil pipe is connected with one end of a filtering oil pipe, a filter is formed on the filtering oil pipe, the other end of the filtering oil pipe is connected with a diesel tank and a heavy oil tank; the igniter is connected with the first compressed air pipeline. The control system of the heavy oil burner of the carbon rotary kiln has the advantages as follows: three oil injection guns are formed for increasing the regulating ratio of the oil amount and having good atomization effect, and thereby the supercharging pump can be matched with the oil nozzle better.

Owner:辽宁实创新能源有限公司

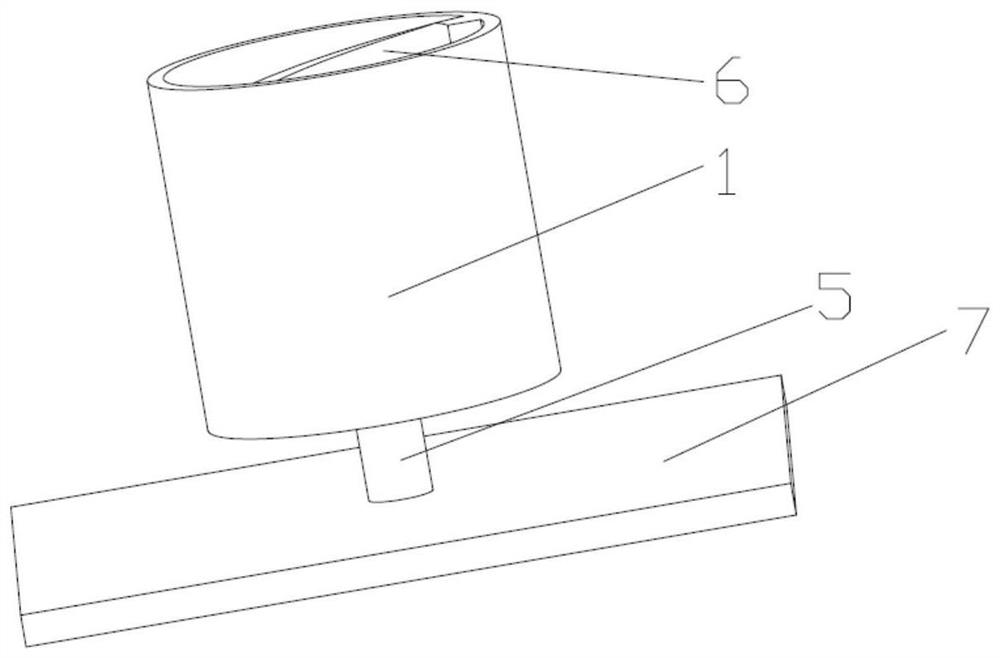

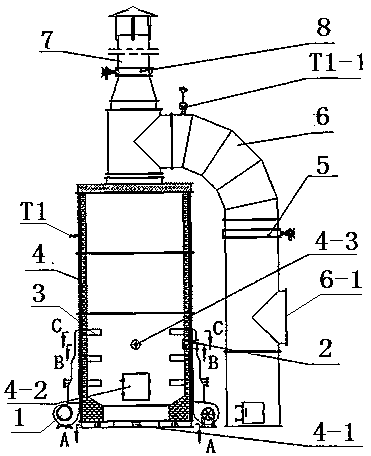

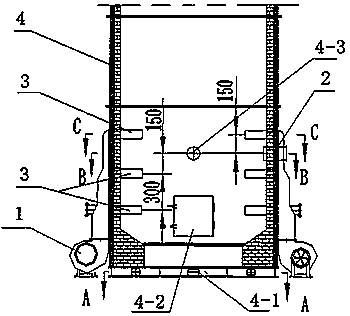

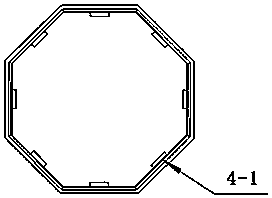

Combustion furnace structure used for biomass fuel combustor and operation method

PendingCN109268818AGuaranteed working environmentReduce labor intensitySolid fuel combustionAir/fuel supply for combustionEngineeringBiomass fuels

The invention provides a combustion furnace structure used for a biomass fuel combustor and an operator method. The combustion furnace structure comprises a bearing box, a box body is arranged at thetail of the bearing box, side baffles are arranged on the two sides of the tops of the box body and the bearing box, a center through hole is machined in the center of the box body, a windward plate is arranged at the position, at a certain distance from the side wall where the center through hole is formed, inside the box body, a gap is formed between the windward plate and the bottom of the bearing box, and a ventilating groove is formed. The combustion furnace structure can be used for killing-out equipment, drying equipment, tea frying equipment and other sets of equipment needing a heat source in a tea factory, wherein the equipment needs to combust firewood, a traditional firewood burning mode is replaced, in this way, the working efficiency is improved greatly, and the labor intensity of operation workers is lowered.

Owner:WUFENG TANMU AGRI MACHINERY

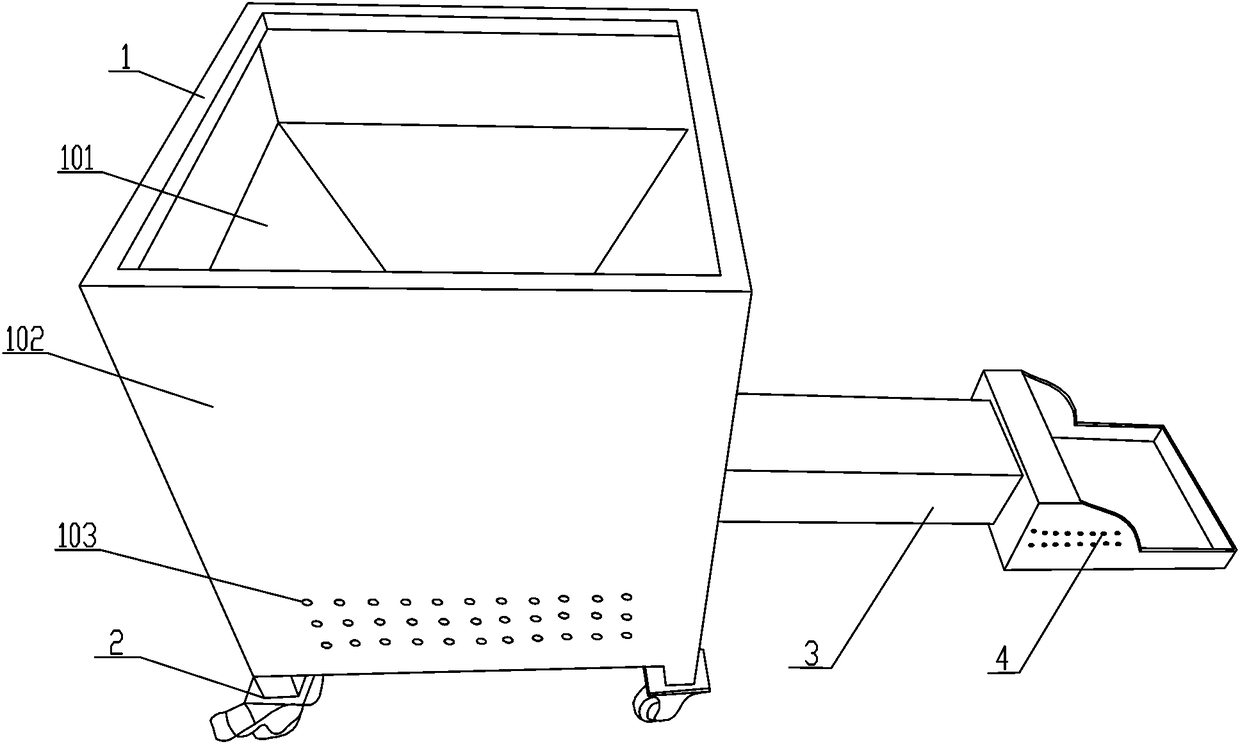

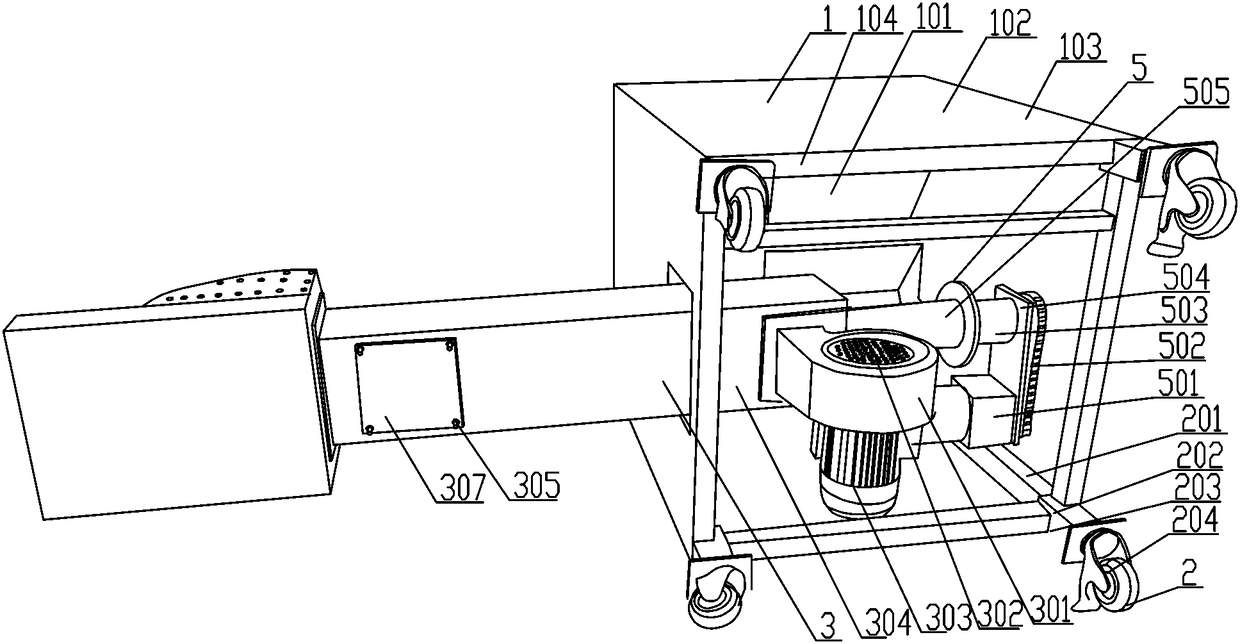

Biomass fuel combustion machine and operation method thereof

PendingCN109268816AGuaranteed working environmentGuarantee processing qualitySolid fuel combustionAir/fuel supply for combustionFirewoodPellet fuel

The invention provides a biomass fuel combustion machine and an operation method thereof, which comprises a rack box body component used for storing granular fuel, wherein four corners of the bottom of the rack box body component are provided with lifting adjusting mechanisms used for adjusting the height of the rack box body component, a blanking funnel of the rack box body component is connectedwith a material conveying device for conveying granular fuel, the material conveying device is matched with an air supply device, a combustion furnace component for burning the granular fuel is arranged at the tail end of the material conveying device, and an ignition device for ignition is arranged on the combustion furnace component. The combustion machine can be used for de-enzyming equipment,drying equipment, tea frying equipment and other equipment which need heat sources and need to burn firewood in a tea factory to replace the traditional firewood burning mode, so that the working efficiency is greatly improved, and the labor intensity of operating personnel is reduced.

Owner:WUFENG TANMU AGRI MACHINERY

An automatic start-stop and firepower adjustment device based on a gas stove

ActiveCN110425580BAchieve automatic ignitionImprove practicalityDomestic stoves or rangesLighting and heating apparatusDrive shaftElectric machinery

The invention discloses an automatic start-stop and firepower adjustment device based on a gas stove, which comprises a firepower adjustment button connection sleeve, a motor drive device, a spring and a casing; the bottom of the firepower adjustment button connection sleeve is connected with the gas stove firepower adjustment button, The main body of the adjustment button connecting sleeve is a cylindrical cavity, and the upper part of the cavity is provided with a thread guide protrusion; the motor drive device includes a stepping motor and a drive shaft; the drive shaft is provided with a thread surface push protrusion; one end of the spring is connected The fire power adjustment button is connected to the bottom of the inner wall of the sleeve, and the other end is connected to the top of the drive shaft of the motor drive device; the thread surface push protrusion of the motor drive device cooperates with the thread guide protrusion of the fire power adjustment button connecting sleeve, the motor drive device and the fire power The adjustment button connecting sleeve is connected by a spring. The problem that the existing gas cooker cannot realize automatic start-stop and firepower adjustment is solved.

Owner:岩谷气具(珠海)有限公司

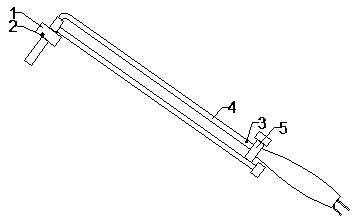

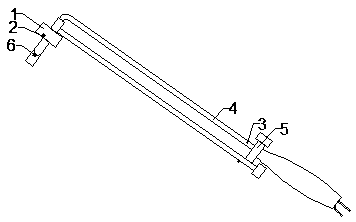

Flame cutting knife

InactiveCN109807428ASimple structureReduce manufacturing costGaseous fuel burnerGas flame welding apparatusBiochemical engineeringInductor

The invention discloses a flame cutting knife. The flame cutting knife comprises a body (1), wherein the body (1) is provided with an acetylene pipe (4). The flame cutting knife also comprises an inductor (3), wherein the inductor (3) is arranged on an inner wall of the acetylene pipe (4). An ignition device (2) is arranged at an outlet of the body (1) and is electrically connected with the inductor (3). According to the flame cutting knife, the inductor (3) is arranged in the acetylene pipe (4), and the ignition device (2) electrically connected with the inductor (3) is arranged at the outletof the body (1), so that the ignition device (2) can be triggered to work immediately once gas flow in the acetylene pipe (4) is detected, and automatic ignition is realized.

Owner:王湘婷

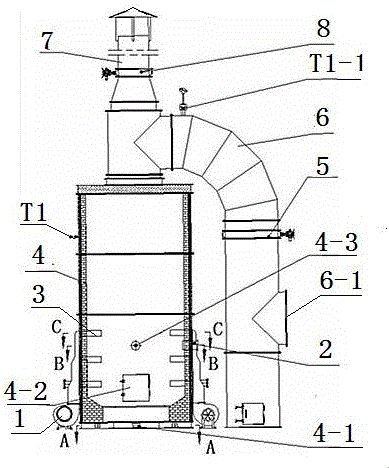

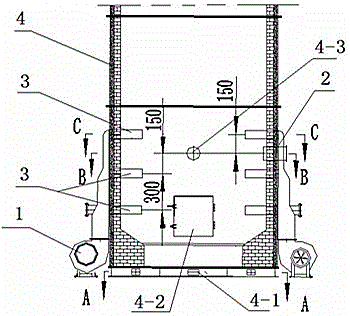

Automatic Ignition and Coking Prevention Furnace for Lignite Processing System

ActiveCN105782957BRealize automatic adjustmentMeet the supporting process requirementsFluidized bed combustionApparatus for fluidised bed combustionBrown coalHot blast

The invention relates to an automatic ignition and anti-coking spraying burning furnace for a brown coal processing system. The automatic ignition and anti-coking spraying burning furnace comprises a furnace body, an overhauling furnace door and a smoke discharging barrel; the automatic ignition and anti-coking spraying burning furnace is characterized in that a natural air inlet is formed in the bottom of a bottom layer of the furnace body, and a fuel blowing-in opening and a fire spraying opening are formed in the positions which are 1.5 m away from the bottom; three layers of air supplementing openings are formed and are formed in the tangential direction of the inner wall; an electric gate valve is installed at the top of the smoke discharging barrel, a hot air pipe is connected to the bottom of the smoke discharging barrel, and an electric gate valve and a temperature measurement sensor are installed at an outlet of the hot air pipe; and a temperature measurement sensor is arranged at the upper portion of the furnace body. By means of the automatic ignition and anti-coking spraying burning furnace, automatic ignition can be achieved, and coking is avoided; and long-time continuous work can be done, automatic temperature adjustment can be achieved, and the mated process requirements of the brown coal processing system can be met.

Owner:SHENYANG YUANDA TECH IND

An automatic fire control burner

InactiveCN103851621BAchieve automatic ignitionOperational securityIncinerator apparatusGaseous fuel burnerCombustorFire control

The invention discloses an automatic fire-controlled combustor, comprising a combustion tube 1, wherein a cylindrical flange body 2 is fixedly arranged on the outer surface of the combustion tube 1, a plurality of combustion-supporting nozzles 3 are fixedly inserted in the flange body 2, and an electric combustion switching device is arranged in the combustion tube 1. The automatic fire-controlled combustor disclosed by the invention has the beneficial effects that the combustion is sufficient, the fire is controlled automatically and the use is convenient.

Owner:刘书瑶

Automatic start-stop and fire regulation device based on gas stove

ActiveCN110425580AAchieve automatic ignitionTurn off the fireDomestic stoves or rangesLighting and heating apparatusMotor driveStart stop

Owner:岩谷气具(珠海)有限公司

Multi-body-position large moxibustion device

PendingCN109758360ABurn fasterSolve the problem of quick smoke exhaustDevices for heating/cooling reflex pointsWhole bodyEngineering

The invention discloses a multi-body-position large moxibustion device. The multi-body-position large moxibustion device comprises a hollow box frame of an integrated structure; the box frame comprises at least two groups of first supporting boxes and second supporting boxes; at least two moxibustion device bodies are arranged between the supporting boxes; the box frame is internally provided witha smoke discharge structure communicated with the moxibustion device bodies. The multi-body-position large moxibustion device is suitable for moxibustion of multiple body parts covered by the whole human body, and the moxibustion process is safe and efficient.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A manufacturing machine for industrial multi-sided fiberboard

ActiveCN113043416BEfficient removalAchieve automatic ignitionIrregularity removal devicesDomestic articlesProcess engineeringMachine

The present invention relates to a manufacturing machine, in particular to a manufacturing machine for industrial multi-sided fiberboard. The invention provides a manufacturing machine for industrial polygonal fiberboard, which can automatically and efficiently remove burrs, has high safety performance, and has good burr removal effect. A machine for manufacturing multi-sided fiberboards for industrial use, comprising a first fixing part, the number of the first fixing parts is two; a second fixing part, the second fixing parts are arranged on the two first fixing parts; the first fixing part is The plate, the two first fixing parts are provided with a first plate; the fixing mechanism, the fixing mechanism is arranged on the first plate; the dehairing mechanism, the second fixing part is provided with a dehairing mechanism. In the invention, the fiberboard is clamped by the fixing mechanism, and the ignition operation is performed by means of the dehairing mechanism, thereby realizing the purpose of effectively removing the burr from the fiberboard.

Owner:上犹耀兴复合材料有限公司

Automatic ignition and anti-coking spraying burning furnace for brown coal processing system

ActiveCN105782957ARealize automatic adjustmentMeet the supporting process requirementsFluidized bed combustionApparatus for fluidised bed combustionAuto regulationBrown coal

The invention relates to an automatic ignition and anti-coking spraying burning furnace for a brown coal processing system. The automatic ignition and anti-coking spraying burning furnace comprises a furnace body, an overhauling furnace door and a smoke discharging barrel; the automatic ignition and anti-coking spraying burning furnace is characterized in that a natural air inlet is formed in the bottom of a bottom layer of the furnace body, and a fuel blowing-in opening and a fire spraying opening are formed in the positions which are 1.5 m away from the bottom; three layers of air supplementing openings are formed and are formed in the tangential direction of the inner wall; an electric gate valve is installed at the top of the smoke discharging barrel, a hot air pipe is connected to the bottom of the smoke discharging barrel, and an electric gate valve and a temperature measurement sensor are installed at an outlet of the hot air pipe; and a temperature measurement sensor is arranged at the upper portion of the furnace body. By means of the automatic ignition and anti-coking spraying burning furnace, automatic ignition can be achieved, and coking is avoided; and long-time continuous work can be done, automatic temperature adjustment can be achieved, and the mated process requirements of the brown coal processing system can be met.

Owner:SHENYANG YUANDA TECH IND

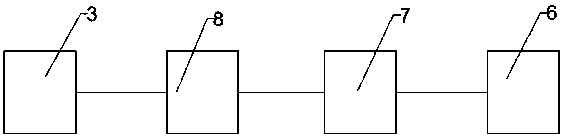

Flame cutter

InactiveCN109807429ASimple structureReduce manufacturing costGaseous fuel burnerGas flame welding apparatusEngineeringInductor

The invention discloses a flame cutter, which comprises a main body (1), wherein the main body (1) is provided with an acetylene pipe (4), the flame cutter further comprises an inductor (3) and an ignition device (2); the inductor (3) is arranged on the inner wall of the acetylene pipe (4); the ignition device (2) comprises a conductive rod (7), an ignition nozzle (6) and a controller (8) which are electrically connected in sequence; the controller (8) and the conductive rod (7) are arranged on the outer side wall of the outlet of the main body (1); the ignition nozzle (6) is arranged on the inner wall of the outlet of the main body (1); and the controller (8) is electrically connected with the inductor (3). According to the device, the inductor (3) is arranged in the acetylene pipe (4), and the ignition device (2) electrically connected with the inductor (3) is arranged at the outlet of the main body (1), so that once the inductor (3) detects that gas flows in the acetylene pipe (4),the ignition device (2) can be triggered to work immediately, so automatic ignition is realized.

Owner:王湘婷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com