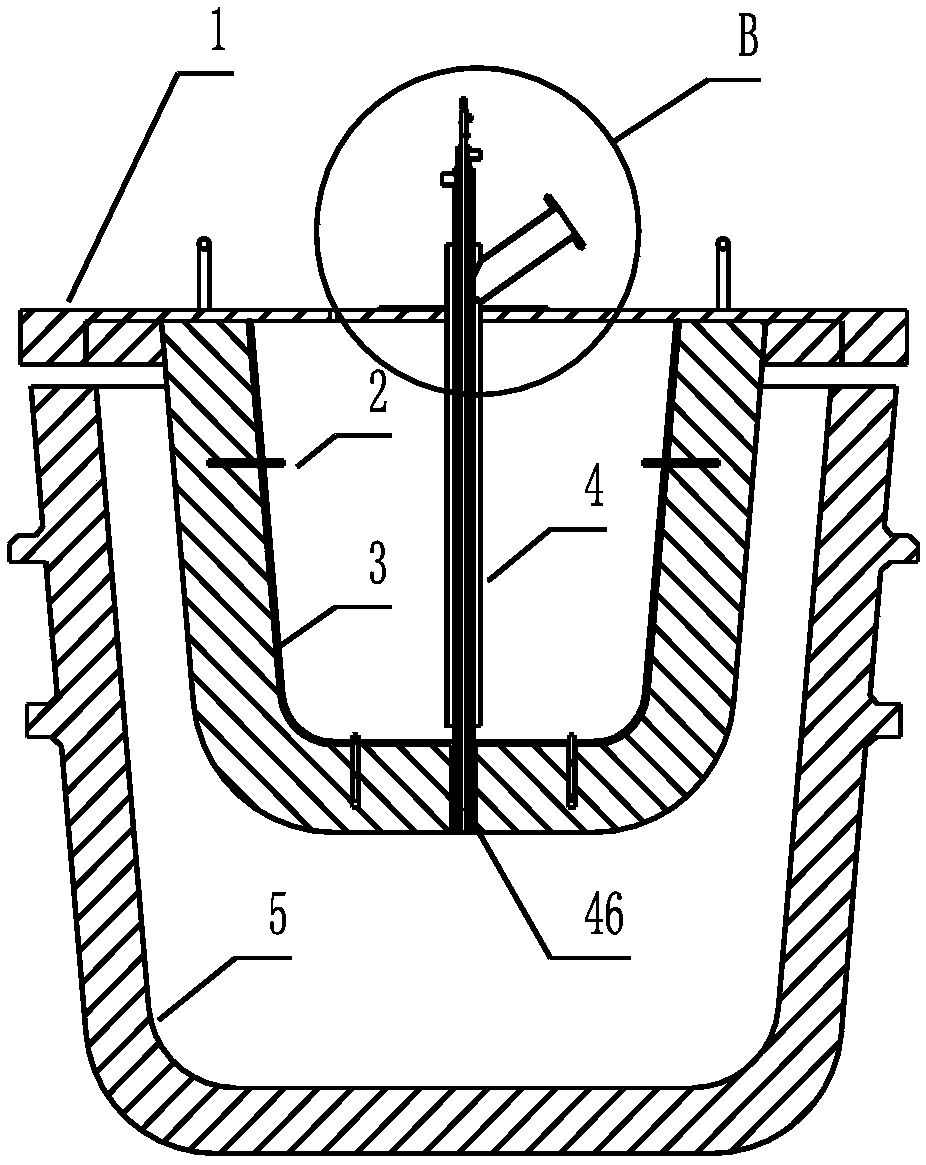

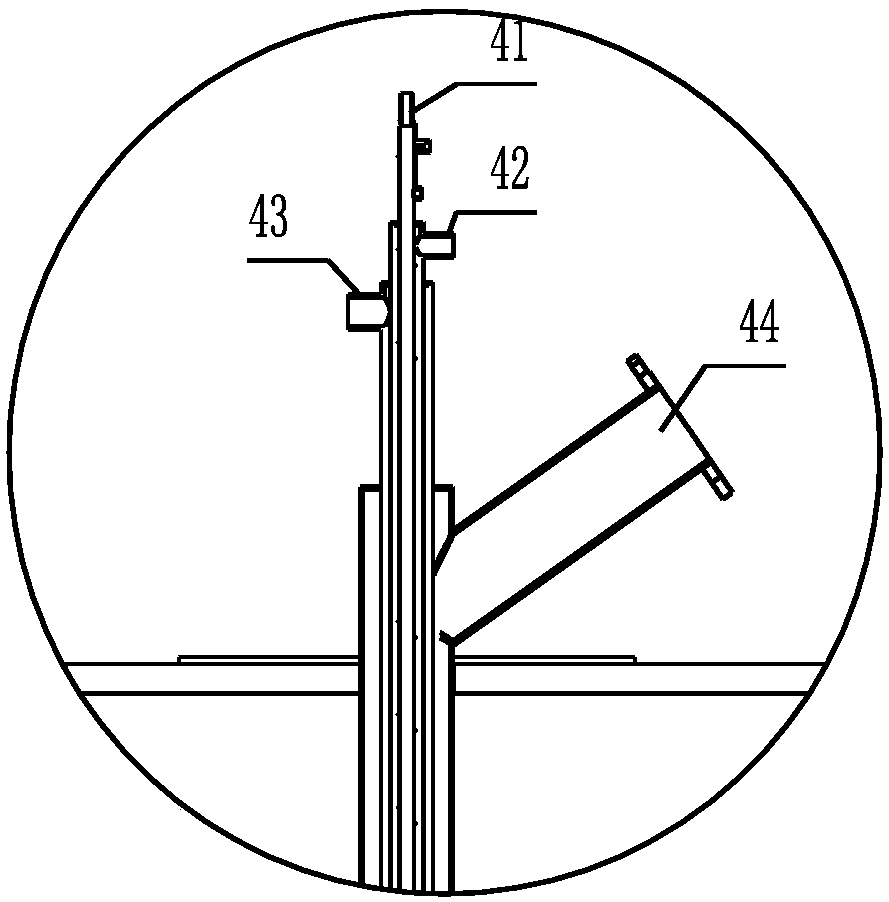

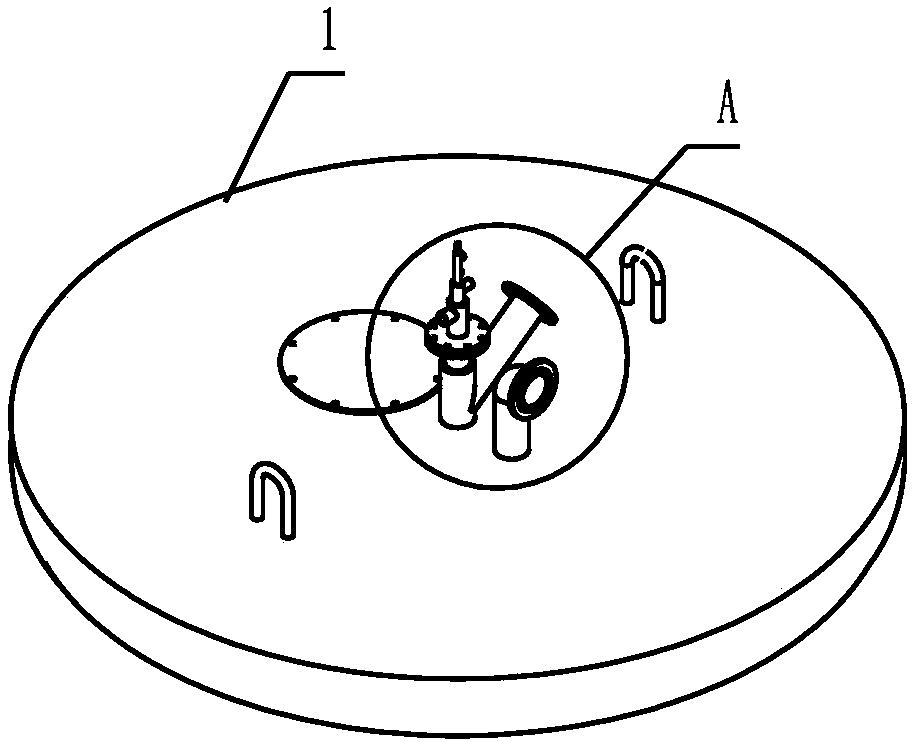

Oxygen-rich intelligent temperature-control ladle baking device and using method thereof

An intelligent temperature control and baking bag technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems that cannot meet the needs of enterprises, low heat conversion efficiency, low baking temperature, etc., and reduce labor labor Strength, safe and reliable operation, and uniform heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] Embodiment 2: A multi-oxygen intelligent temperature-controlled baking device. The structure of this embodiment is the same as that of Embodiment 1. The method of use is to use a PLC controller to control the automatic operation method, and the following steps are used:

[0046] 1) Bag cleaning: Turn on the cooling air supply pump, the cooling air enters the bladder through the cooling air intake pipe, blows out the impurity gas and dust in the bladder, and discharges it through the cooling air exhaust port;

[0047] 2) Open the PLC controller: open the PLC controller and its related equipment connections;

[0048] 3) Setting parameters: Preset the operating parameters on the man-machine panel of the PLC controller, operate in sections, and change the segmental temperature of different supporting gases and the flow ratio of each supporting gas component in each temperature section according to the temperature; set as : Below 600 degrees, use air as supporting gas; 600-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com