Steam boiler capable of burning biomass

A technology for steam boilers and biomass, which is applied to steam boilers, combustion product treatment, steam generation, etc., can solve the problem of not revealing the biomass fuel feeding method, combustion air distribution method, etc., and achieves simple structure, safe and reliable operation. , the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

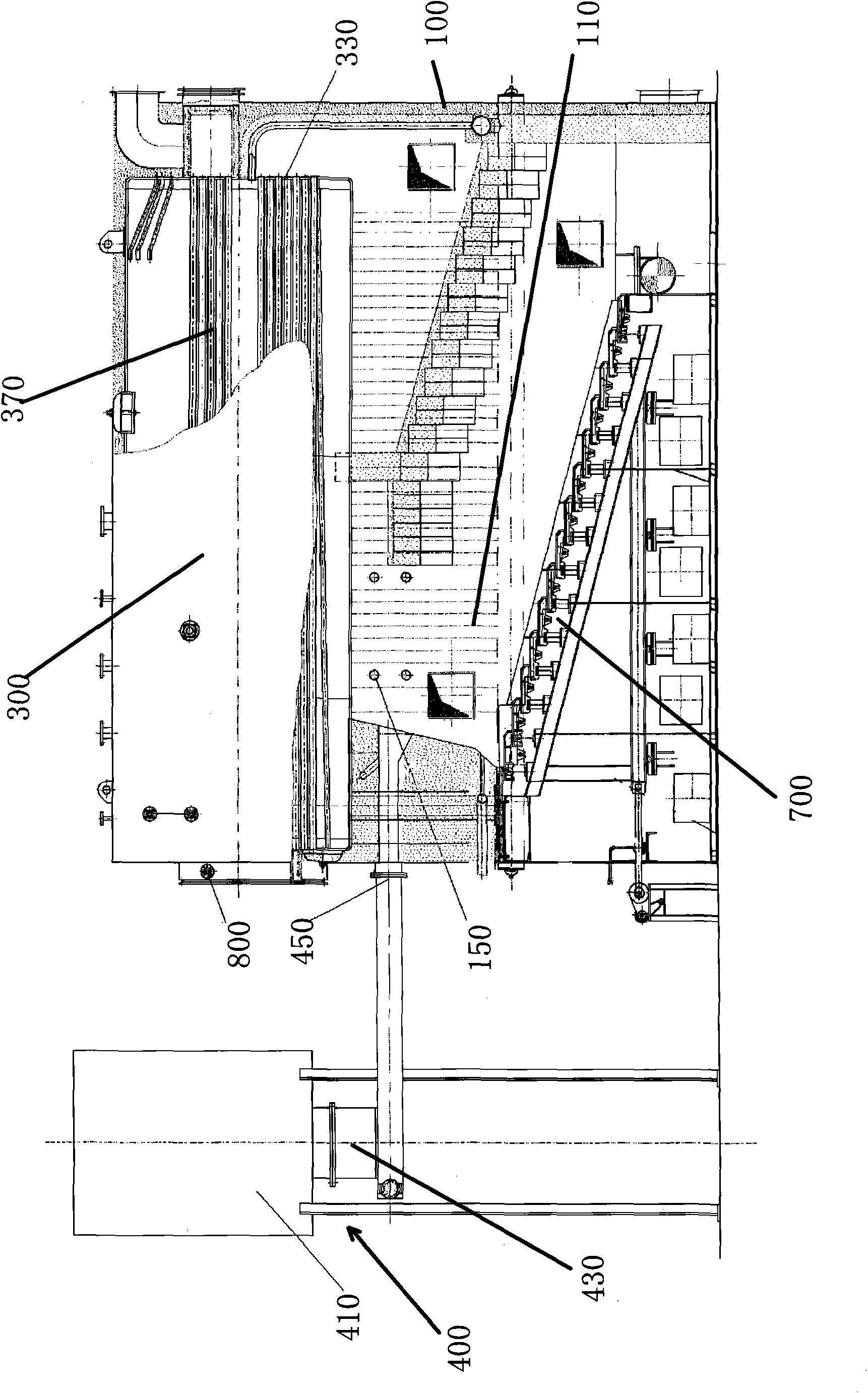

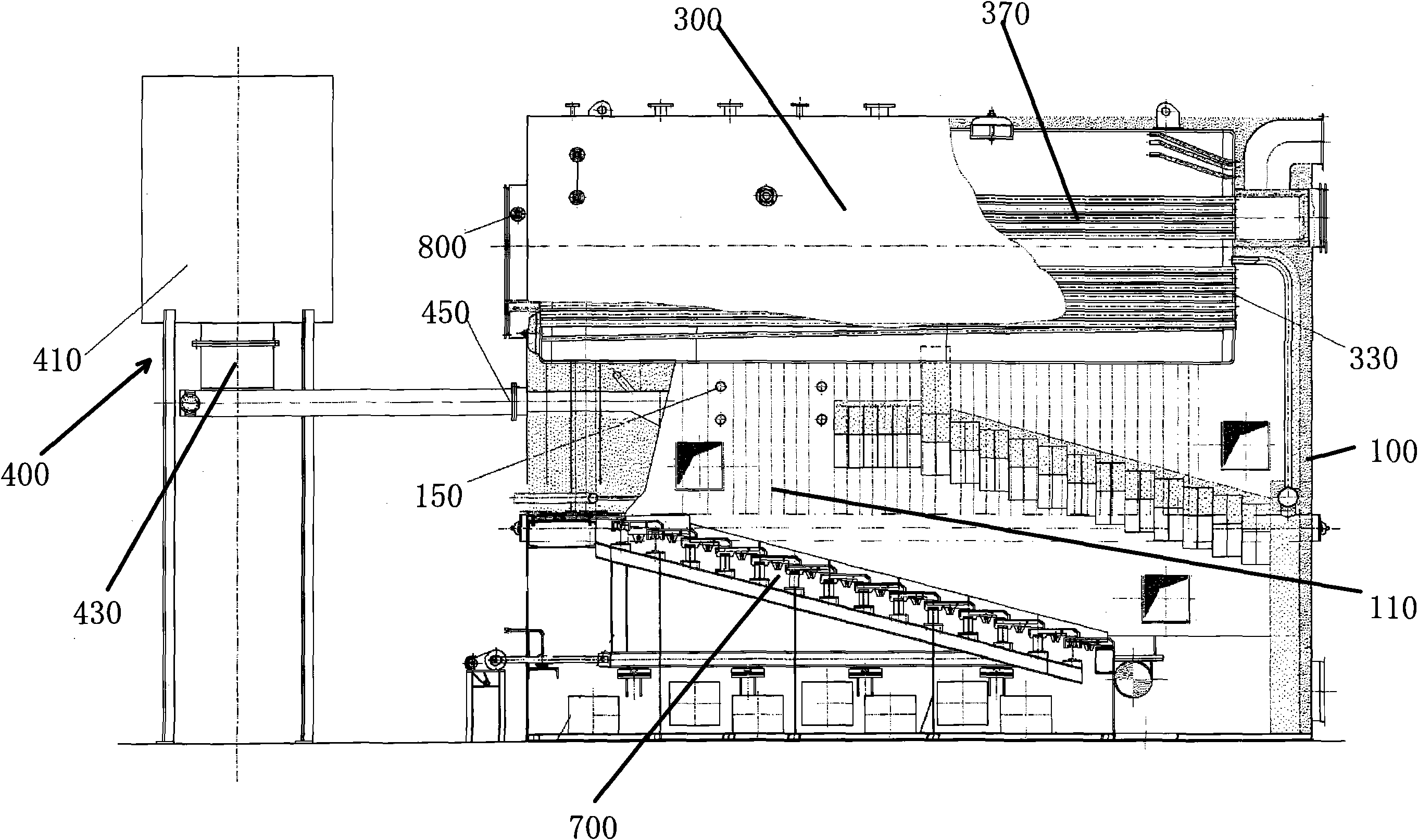

[0019] Please refer to figure 1 , the biomass-fired steam boiler of the present invention includes: a boiler body 100, which is provided with a furnace 110 for burning and releasing heat of biomass fuel and a heat exchange device 300 above the furnace 110; a feed system 400, which is connected with the boiler The main body 100 is connected to send the biomass fuel into the furnace 110 for combustion; and, the steam-water pipeline system (not labeled), which is connected to the heat exchange device 300 to exchange the heat generated by the biomass combustion; wherein, the furnace 110 A reciprocating fire grate 700 made of RTSi5 material is provided, and the reciprocating fire grate 700 is arranged at an inclination angle of about 15 degrees relative to the horizontal plane from the proximal end of the furnace close to the feeding system 400 to the far end of the furnace far away from the feeding system 400. The downward inclination makes the biomass fuel falling on the reciproc...

Embodiment 2

[0025] As another kind of scheme of the present invention, other parts are identical with embodiment 1, and difference is:

[0026] The material of the reciprocating grate is made of other refractory materials except RTSi5.

[0027] The reciprocating grate 700 slopes downward at an inclination angle of about 20 degrees relative to the horizontal plane from the proximal end of the furnace close to the feeding system 400 to the far end of the furnace away from the feeding system 400 .

[0028] About 50% of the total supply air volume of the biomass-fired steam boiler is the first-level wind, about 35% of the total supply air volume is the third-level wind, and about 15% of the total supply air volume is the third-level wind .

[0029] A fire wall is built at the exit of the furnace to help stop the fire, so that the fuel has sufficient combustion space and combustion time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com