Automatic ignition firewood-fired stove and ignition method thereof

An automatic ignition and firewood stove technology, applied in the field of woodburning stoves, can solve the problems of difficult ignition of woodburning stoves, and achieve the effects of practical wind control, easy fuel consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

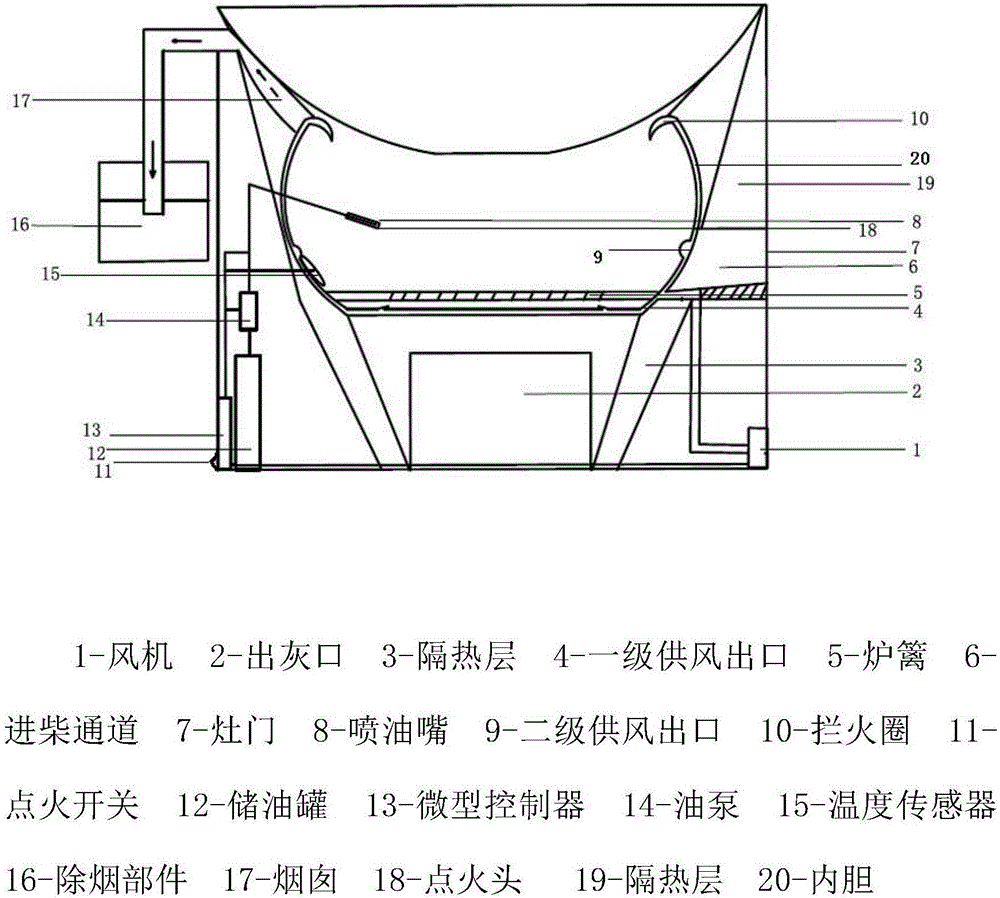

[0017] Embodiment 1 The automatic ignition wood-burning stove provided by this application includes an ignition system and a wood-burning stove body. The wood-burning stove body includes an outer stainless steel shell, an inner heat insulation layer 19, and an inner container 20 located on the innermost side of the stove. The liner 20 is a hollow heat-resistant metal structure, and the lower part of the inner liner 20 is connected to the air supply pipe at a position close to the furnace fence 5; the lower part of the inner liner 20 is also connected with a primary air supply outlet 4 to form a primary air supply system. The first-level air supply system is connected with the inner tank 20; wherein the first-level air supply system is arranged in an annular tubular shape under the furnace fence 5 and the inner tank 20, and there is a first-level air supply outlet 4 on the inner side of the annular tube, which can transfer air from This squirts. In addition, a circle of seconda...

Embodiment 2

[0018] Embodiment 2 The automatic ignition wood-burning stove provided by this application includes an ignition system and a wood-burning stove body. The wood-burning stove body includes an outer stainless steel shell, an inner heat insulation layer 19, and an inner container 20 located on the innermost side of the stove. The liner 20 is a hollow heat-resistant metal structure, and the lower part of the inner liner 20 is connected to the air supply pipe at a position close to the furnace fence 5; the lower part of the inner liner 20 is also connected with a primary air supply outlet 4 to form a primary air supply system. The first-level air supply system is connected with the inner tank 20; the first-level air supply system is arranged under the furnace fence 5 and the inner tank 20 in an annular tubular arrangement, and there is a first-level air supply outlet 4 on the inner side of the annular tube, which can discharge the air Eject from this. In addition, a circle of second...

Embodiment 3

[0019]Embodiment 3 The automatic ignition wood-burning stove provided by this application includes an ignition system and a wood-burning stove body. The wood-burning stove body includes an external stainless steel shell, an internal heat insulation layer 19, and an inner container 20 located on the innermost side of the stove. The liner 20 is a hollow heat-resistant metal structure, and the lower part of the inner liner 20 is connected to the air supply pipe at a position close to the furnace fence 5; the lower part of the inner liner 20 is also connected with a primary air supply outlet 4 to form a primary air supply system. The first-level air supply system is connected with the inner tank 20; the first-level air supply system is arranged under the furnace fence 5 and the inner tank 20, and the first-level air supply system is an annular tubular structure, and there is a first-level air supply system inside the tubular structure. The outlet 4 can eject air therefrom, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com