Automatic ignition and anti-coking spraying burning furnace for brown coal processing system

A processing system and automatic ignition technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of large occupied area, difficulty in cleaning, difficulty in re-ignition, etc., achieve automatic temperature adjustment, and meet the requirements of supporting processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

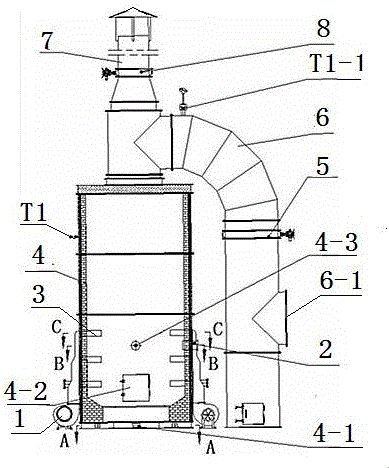

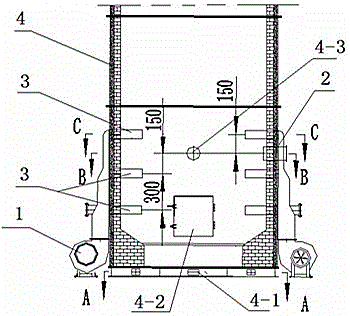

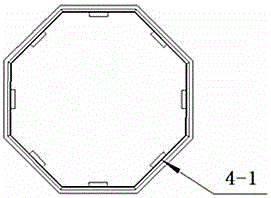

[0015] see figure 1 -5. The specific structure is as follows: The furnace body 4 is a cylindrical shape with an outer diameter of 3 meters, divided into three layers, composed of three cylindrical parts assembled from top to bottom, connected by flanges, and its height from bottom to top is respectively 2 meters, 1.5 meters, 1.5 meters. The outer surface is welded with steel plates, lined with refractory bricks, and a tamped insulation material layer is set between the refractory bricks and the outer steel plate; the furnace base is an octagonal welded channel steel, and the bottom of the furnace body 4 has eight natural air inlets 4-1 , Under the action of an external induced draft fan (not shown in the figure), the combustion-supporting air can be sucked in; there is a fuel blowing inlet 2 at 1.5 meters from the bottom. The fuel blowing inlet at the outer end of the furnace is connected to the fuel pipe and the fuel fan (external equipment, picture Not shown in), on the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com