Combustion furnace structure used for biomass fuel combustor and operation method

A biomass fuel and burner technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of increasing the workload of farmers, affecting the quality of tea, artificially adding firewood, etc., to prevent spilling or splashing, Achieve automatic control and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

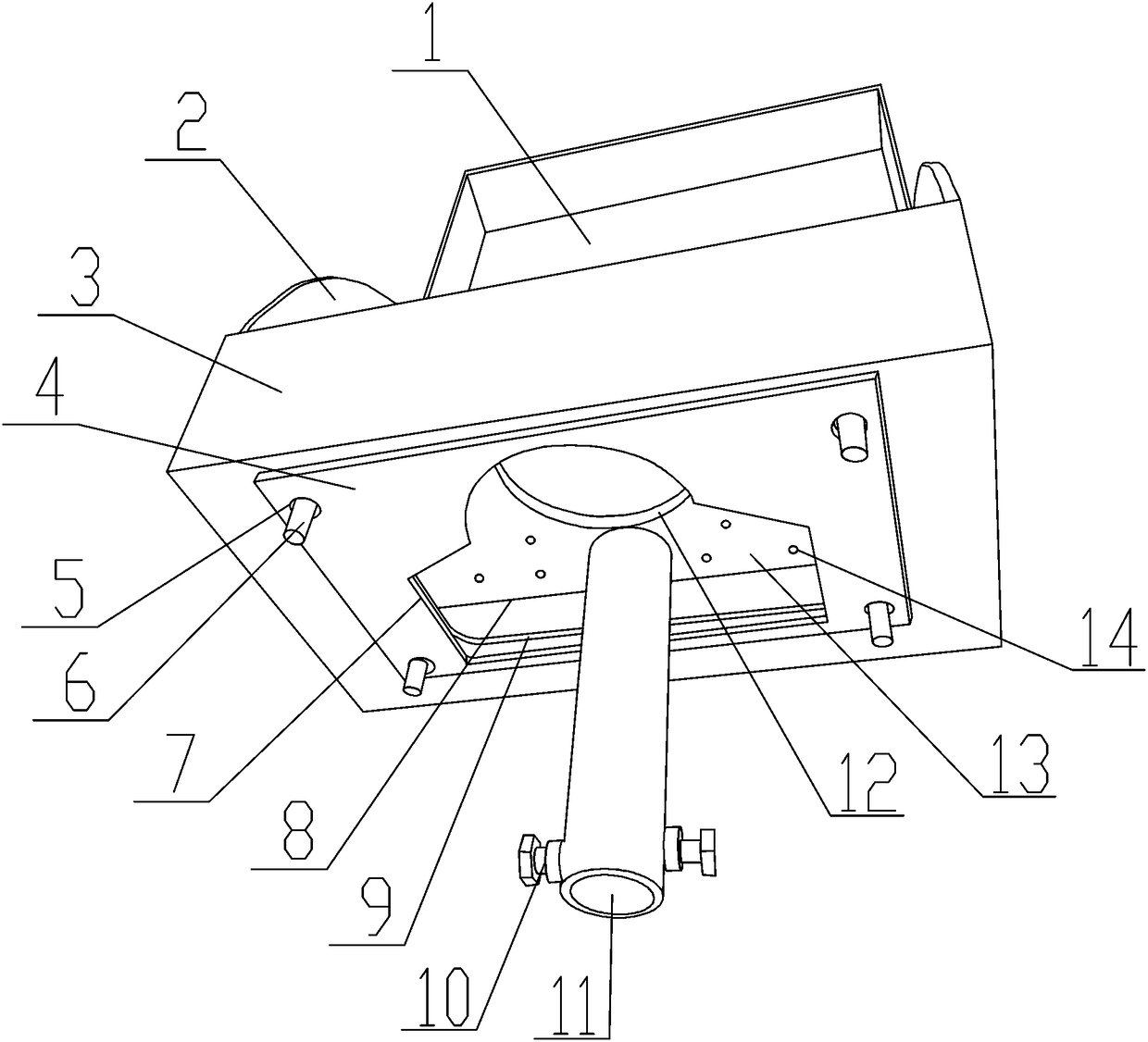

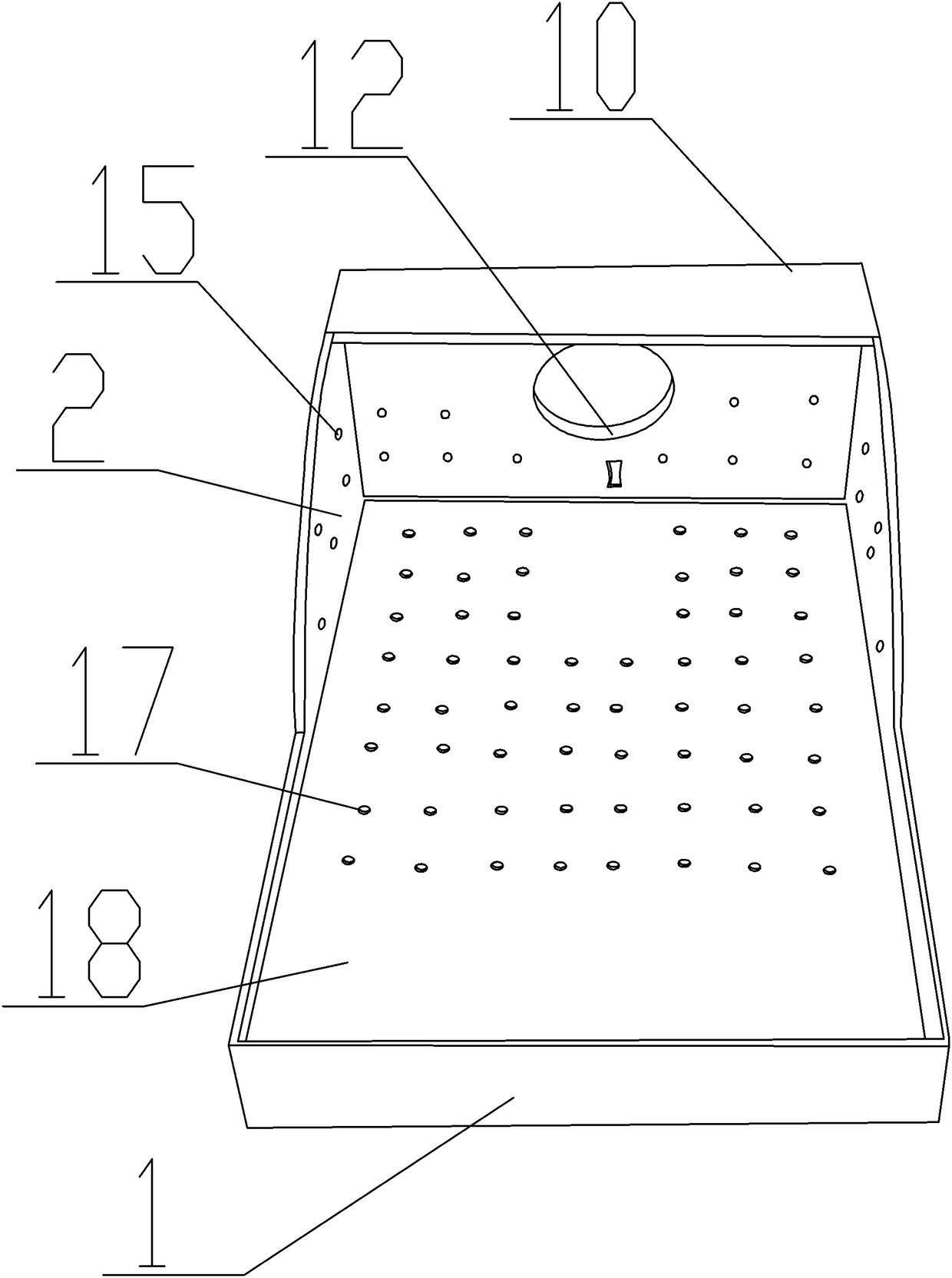

[0039] see Figure 1-3 , a combustion furnace structure for a biomass fuel burner, which includes a carrying box 1, a box body 3 is provided at the tail of the carrying box 1, and side walls are provided on both sides of the box body 3 and the top of the carrying box 1 The baffle plate 2, the central position of the box body 3 is processed with a central through hole 9, the inside of the box body 3 is provided with a windshield 13 at a certain distance from the side wall where the central through hole 9 is located, and the windshield 13 A gap is provided between 13 and the bottom of the carrying box 1, and constitutes a ventilation groove 8. By adopting the combustion furnace structure with the above structure, it can be used in the production of tea by tea factory processing enterprises. The use of biomass fuel to replace traditional wood fuel has a very good environmental protection purpose, ensures the working environment of the tea factory, and effectively reduces the It ...

Embodiment 2

[0050] Any one of the methods for using the combustion furnace structure for the biomass fuel burner comprises the following steps:

[0051] Step1: Fix the igniter inside the installation pipe 11 through the bolt locking mechanism 10;

[0052] Step2: Connect the material conveying through hole 12 on the windshield 13 to the conveying hinge cage used to convey the biomass pellet fuel; connect the conveying hinge cage to the box for storing the biomass pellet fuel;

[0053] Step3: Connect the box body 3 and the carrying box 1 to the air supply box through the connecting plate 4, so that the conveying hinge cage is located inside the air supply box; connect the air supply box to the blowing device;

[0054] Step4: Place the combustion board 18 inside the carrying box 1;

[0055] Step5: Start the igniter to preheat, and then start the conveying hinge cage to supply and convey biomass pellet fuel. Pellet fuel ignition;

[0056] Step6: continue to convey the biomass pellet fuel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com