Biomass fuel combustion machine and operation method thereof

A biomass fuel and burner technology, applied in the direction of combustion methods, solid fuel combustion, combustion equipment, etc., can solve the problems of increasing the workload of farmers, affecting the quality of tea, adding firewood manually, etc., to prevent spilling or splashing, High degree of automation and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

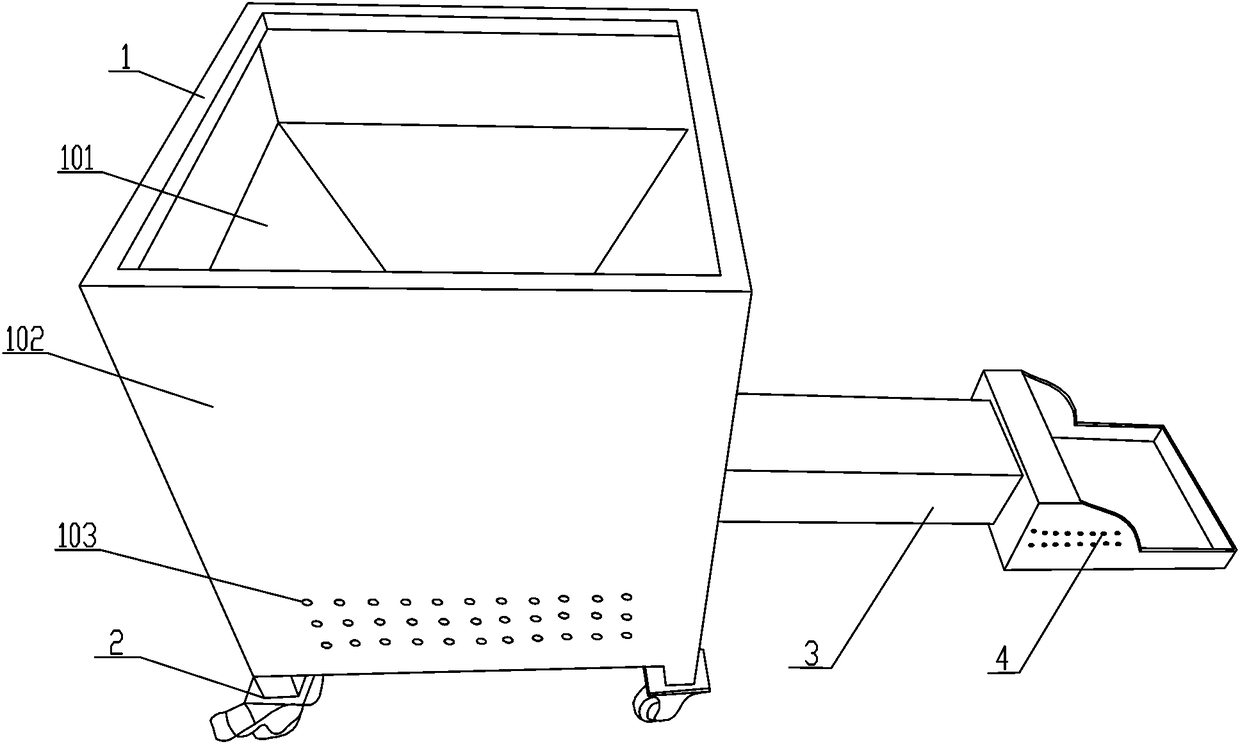

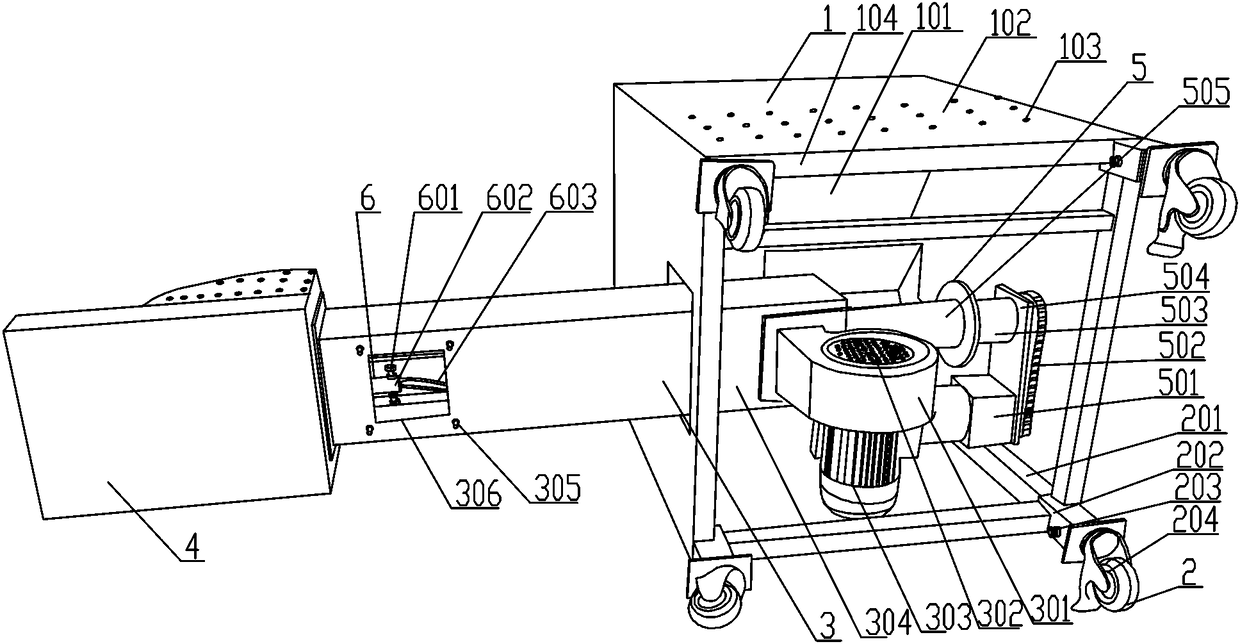

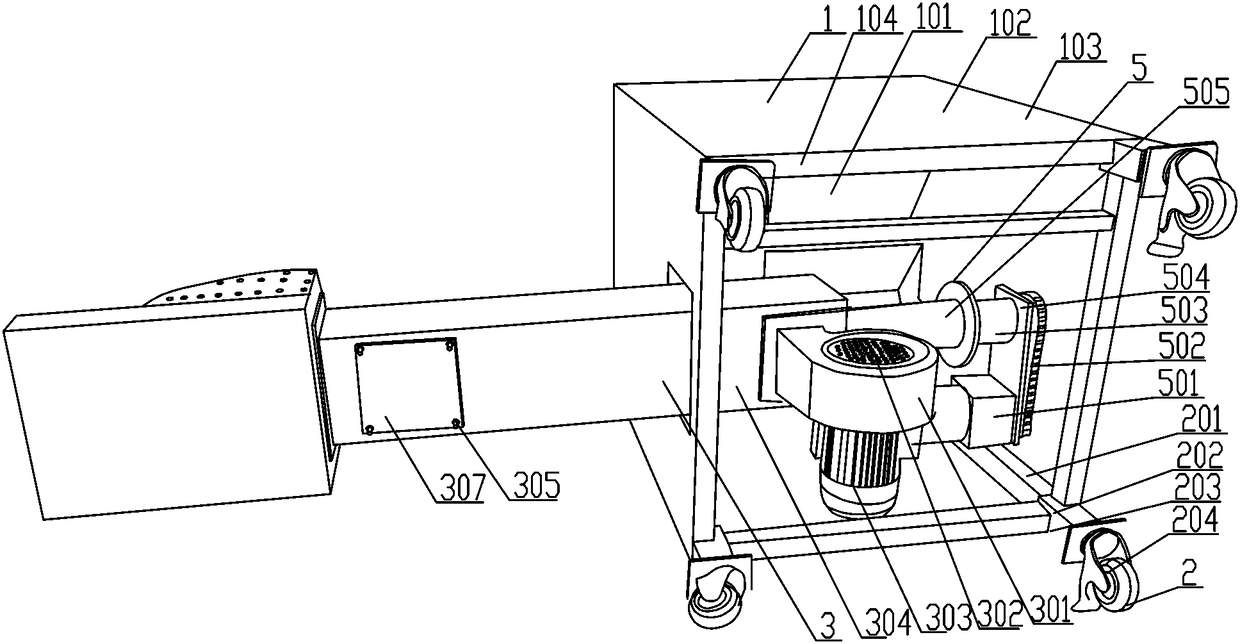

[0055] see Figure 1-6 , a biomass fuel burner, which includes a frame box assembly 1 for storing particulate fuel, the four corners of the bottom of the frame box assembly 1 are installed with a lifting adjustment mechanism 2 for adjusting its height, the frame box The feeding funnel 101 of the body assembly 1 is connected to the material conveying device 5 for conveying the granular fuel, and the material conveying device 5 is matched with the air supply device 3, and a combustion furnace assembly 4 for burning the granular fuel is installed at its end , an ignition device 6 for ignition is installed on the combustion furnace assembly 4 . By adopting the burner with the above structure, it can be flexibly applied to equipment that needs heat source heating. During its use, move it to the side of the equipment that needs to be heated, and then adjust its height through the lifting adjustment mechanism 2 to adapt to different High equipment, then the material is transported b...

Embodiment 2

[0071] The use method of any one of the biomass fuel burners includes the following steps:

[0072] Step1: According to the height of the required heating equipment, adjust the height of the burner through the lifting adjustment mechanism 2;

[0073] Step2: Extend the combustion furnace assembly 4 of the burner into the combustion chamber of the required heating equipment;

[0074] Step3: Put the biomass pellet fuel inside the rack box assembly 1;

[0075] Step4: Start the ignition device 6 for preheating, and start the material delivery device 5 to deliver the biomass pellet fuel to the combustion plate assembly 7 of the combustion furnace assembly 4;

[0076] Step5: The material on the combustion furnace assembly 4 will be ignited by the ignition device 6, and then continue to transport the biomass pellet fuel for combustion;

[0077] Step6: After the combustion is stable, start the air supply device 3 to supply air to the combustion furnace assembly 4 through the air supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com