Control system of heavy oil burner of carbon rotary kiln

A heavy oil combustion and control system technology, applied in the direction of burners, controlled combustion, combustion methods, etc., can solve the problems of difficult oil, poor combustion effect, low flame intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

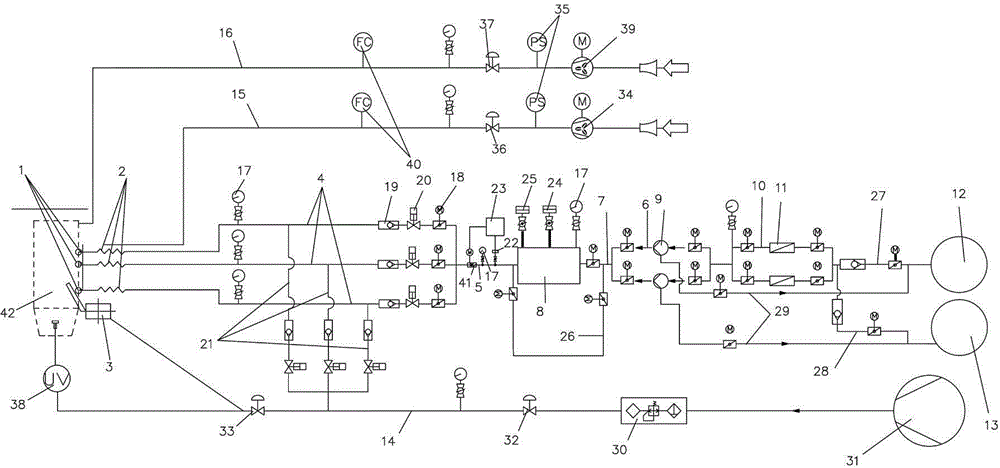

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] As shown in the figure, a carbon rotary kiln heavy oil burner control system of the present invention includes three fuel injection nozzles 1 in the kiln head 42 of the rotary kiln, and each fuel injection nozzle 1 is located at the end of the fuel injection gun 2. An igniter 3 is provided at the oil nozzle 1, a plastic air pipeline 16 is provided inside the kiln head 42, and a combustion-supporting air pipeline 15 is provided on the outer circumference of the fuel injection nozzle 1; each fuel injection gun 2 is connected with an oil supply pipeline 4 , three oil supply pipelines 4 are connected to the oil outlet pipe 5 of the heavy oil heater, the oil inlet pipe 7 of the heavy oil heater is connected to one end of the booster oil pipe 6, and the oil heater is between the oil outlet pipe 5 of the heavy oil heater and the oil inlet pipe 7 of the heavy oil heater 8. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com