An automatic fire control burner

A technology of burners and combustion tubes, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of precisely controlling the size of the combustion flame, blowing out the flame, and not easy to ignite the flame, so as to achieve safe and reliable operation, full burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

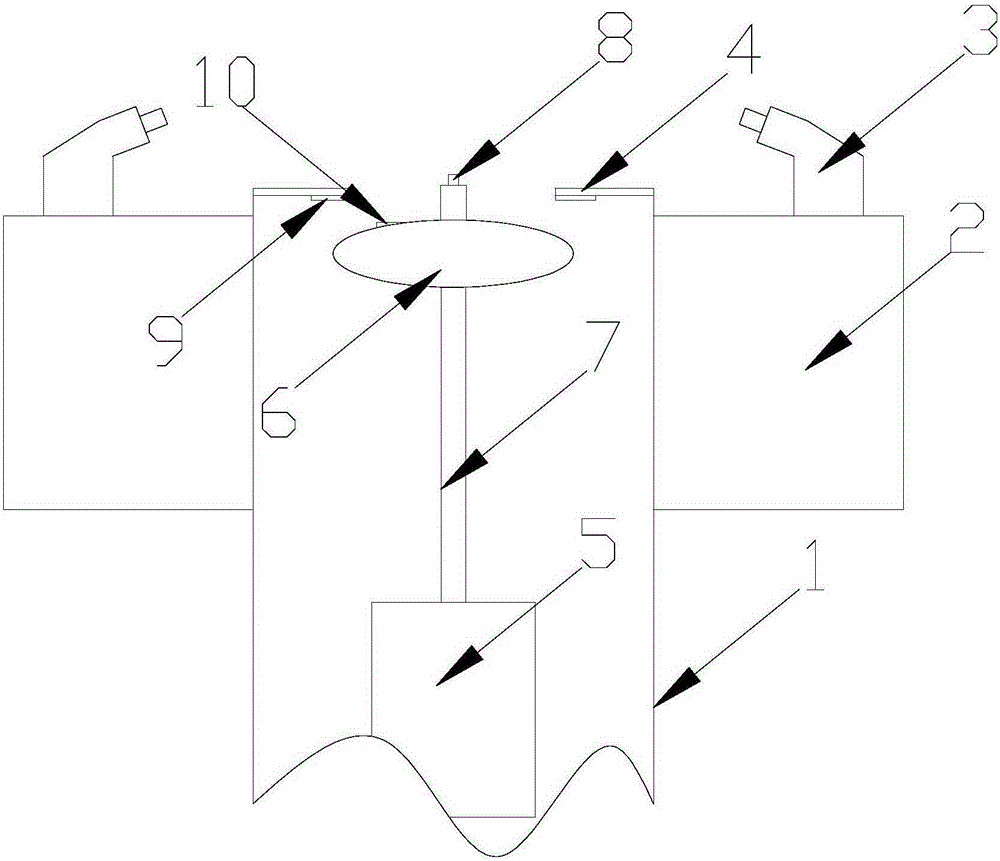

[0015] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 It is a structural schematic diagram of the automatic fire control burner of the present invention. As shown in the figure, an automatic fire control burner includes a combustion tube 1, a cylindrical flange body 2 is fixed on the outer surface of the combustion tube 1, and the flange The body 2 is fixedly inserted with a plurality of gas-supporting nozzles 3, and the combustion tube 1 is provided with an electric switch fire device. Wherein, the inner edge of the port of the combustion tube 1 is welded with an annular baffle 4; The valve 6, the connecting rod 7 connecting the cylinder 5 and the lower end surface of the mushroom valve 6, and the ceramic ignition rod 8 fixed at the center of the upper end surface of the mushroom valve 6 are composed of four parts; the diameter of the mushroom valve 6 is smaller than that of the combustion tube The inner diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com