Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about "Linoleum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

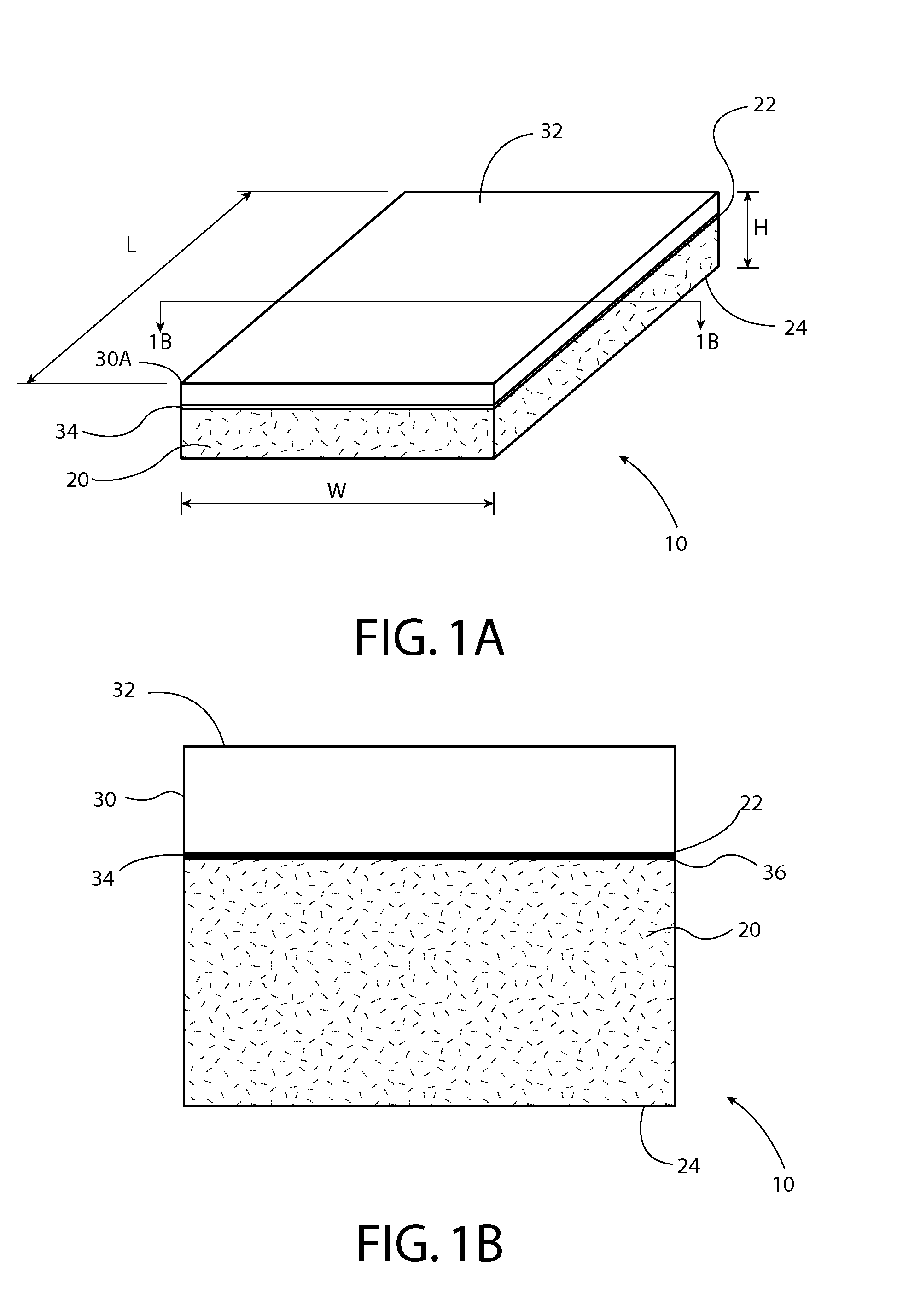

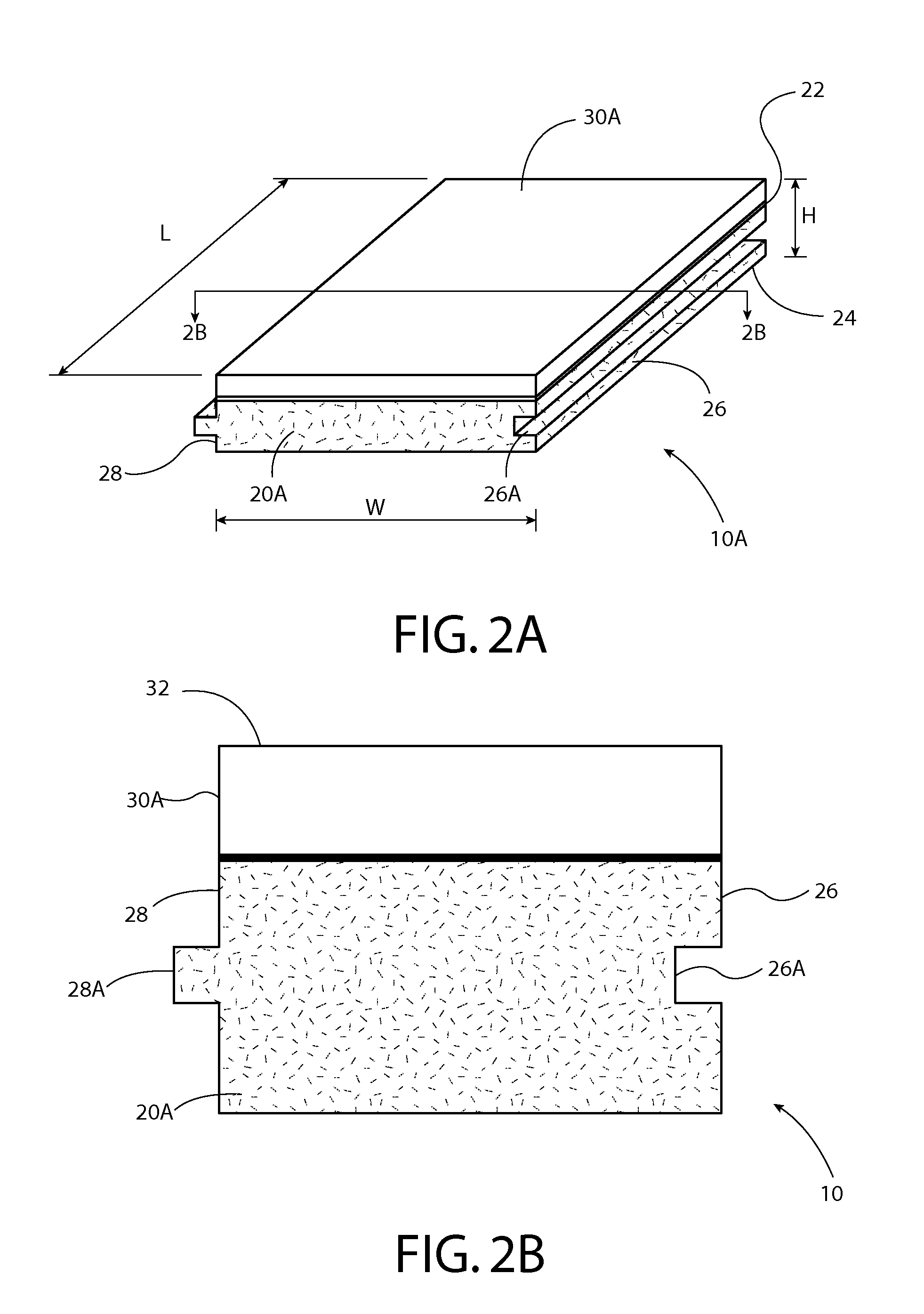

Engineered Waterproof Flooring and Wall Covering Planks

Owner:SHAW INDS GROUP

Light-storage luminescent coating and luminous fibre therefor

InactiveCN1817984AImprove luminosityLong glow timeLuminescent paintsTents/canopiesFiberStrontium aluminate

A light-collecting luminescent pigment and luminescent fiber thereof are disclosed. The pigment consists of light-collecting powder with strontium aluminate as substrate 30-45wt%, refractive reflecting powder 10-15wt% and carrier 40-60wt%. It has excellent wetting ability and adhesion. It can be used for luminescent fiber and other luminescent products.

Owner:吴振华

Preparation method of polytetrafluoroethylene glass fiber breathable varnished cloth

InactiveCN104532504AUniform glue contentImprove breathabilitySingeingLiquid/gas/vapor removalPolymer sciencePolymer chemistry

The invention relates to a preparation method of polytetrafluoroethylene glass fiber breathable varnished cloth. The preparation method comprises the following steps: (1) pre-treating glass cloth; (2) impregnating the glass cloth; (3) drying; (4) roasting; (5) sintering; and (6) cooling to obtain the polytetrafluoroethylene glass fiber breathable varnished cloth. The preparation process provided by the invention has the beneficial effects that by uniformly coating and impregnating alkali-free glass cloth by polytetrafluoroethylene emulsion, the glass fiber cloth is primarily moulded by impregnating, drying, roasting and sintering, so that the preparation process is simplified and the energy consumption is reduced; the polytetrafluoroethylene glass fiber breathable varnished cloth produced is free of bubbles on the surface, uniform in glue content, good in air permeability and low in production cost, has the high-temperature-resisting and high-strength performances of a glass fiber fabric, and also has a series of excellent performances such as insulation and anti-adherence of polytetrafluoroethylene. The polytetrafluoroethylene glass fiber breathable varnished cloth widely applied to all fields is a macromolecular composite material which is high in performance and diversified in function.

Owner:JIANGSU TAIFULONG TECH

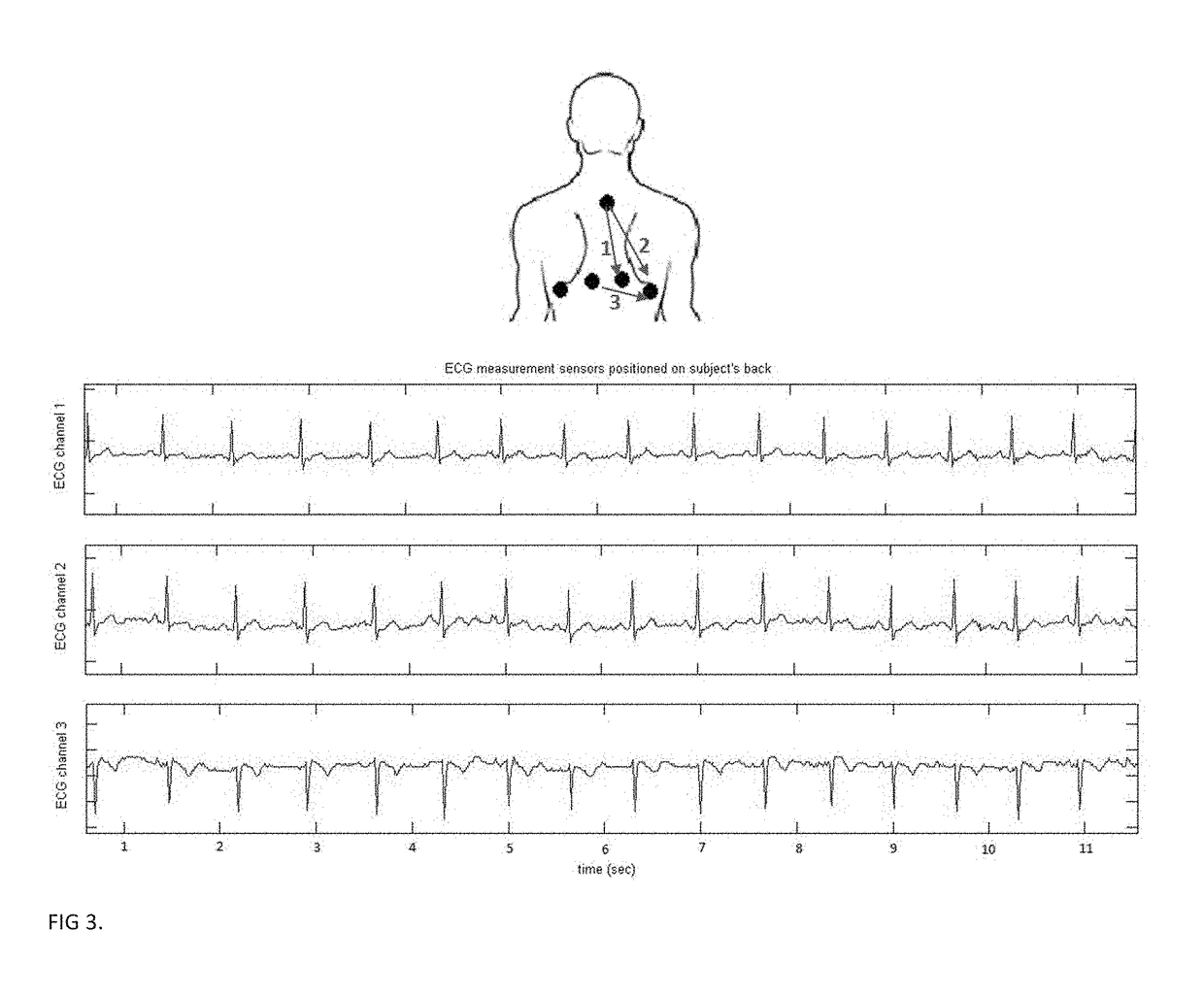

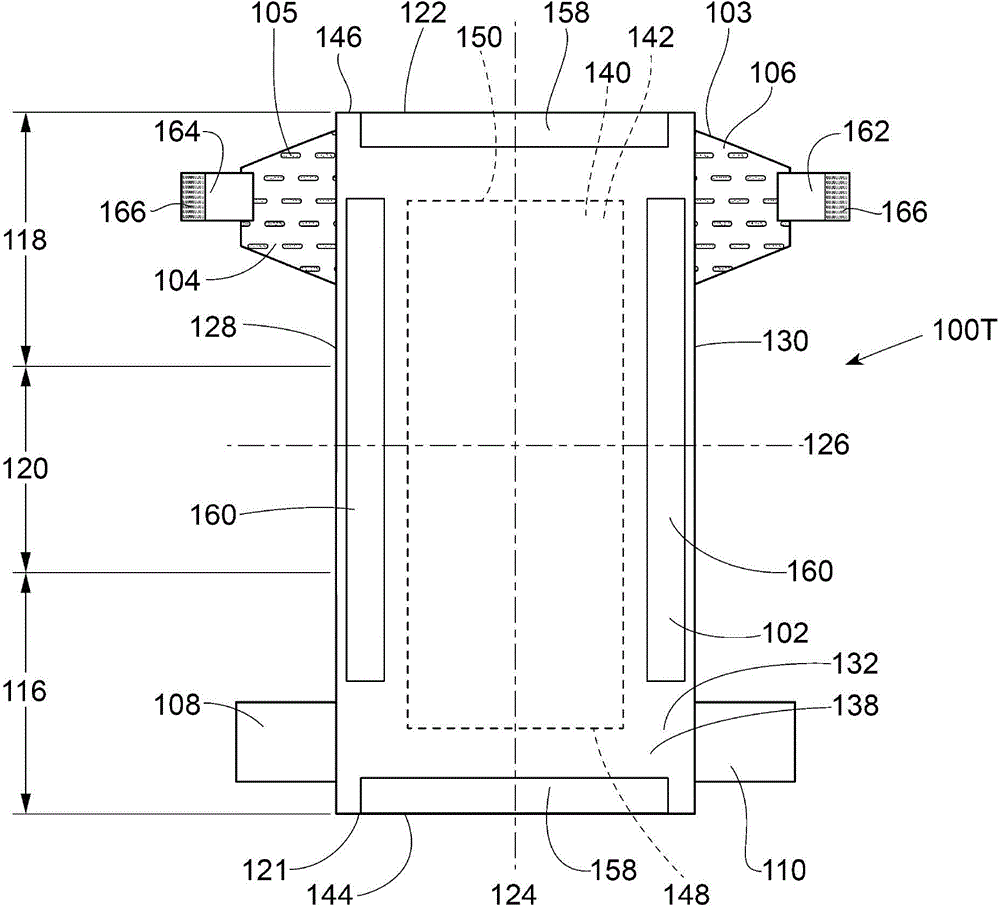

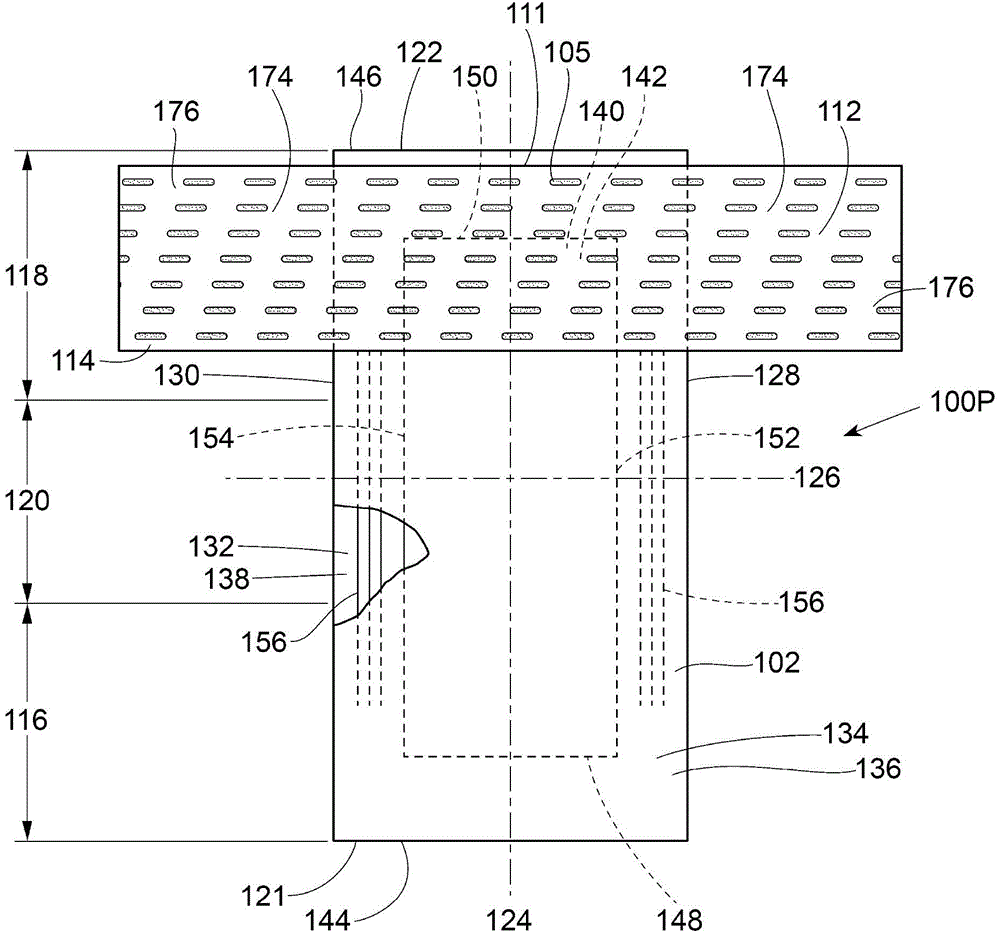

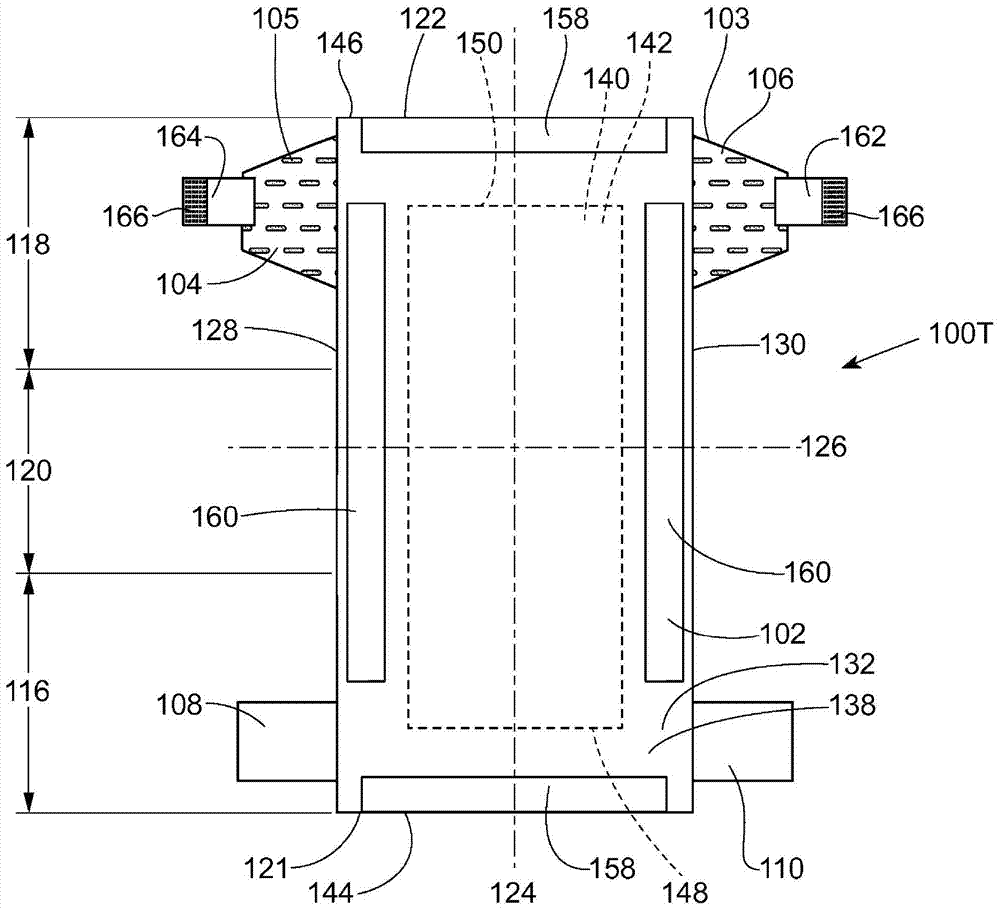

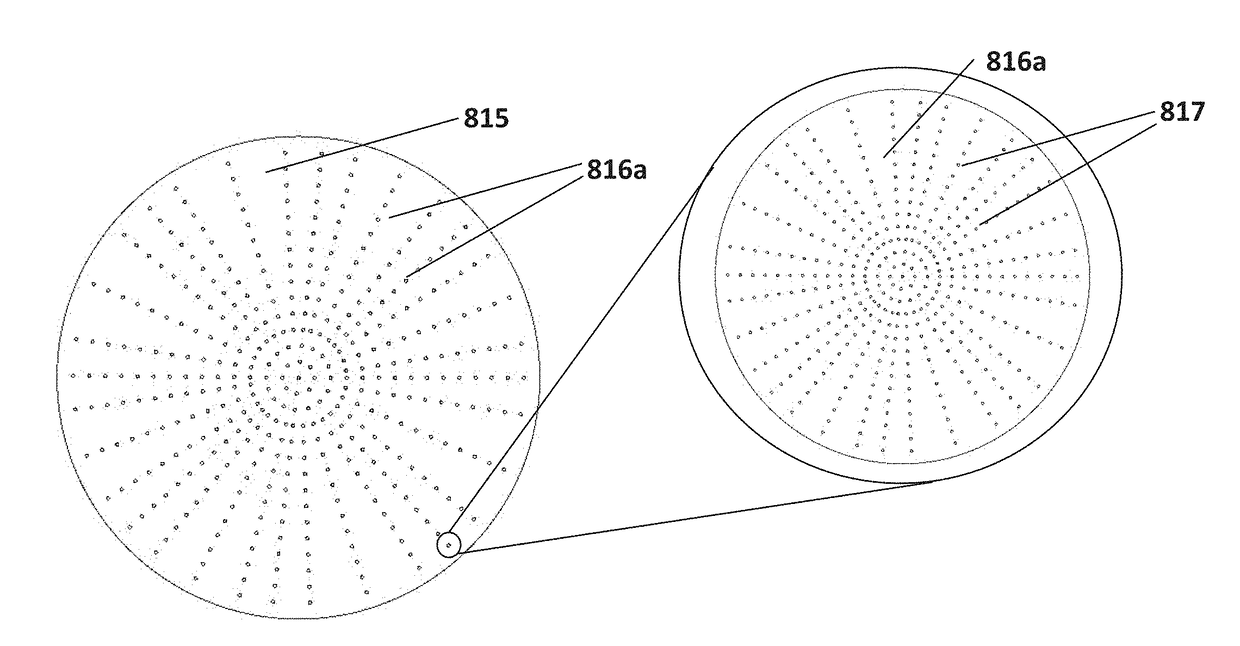

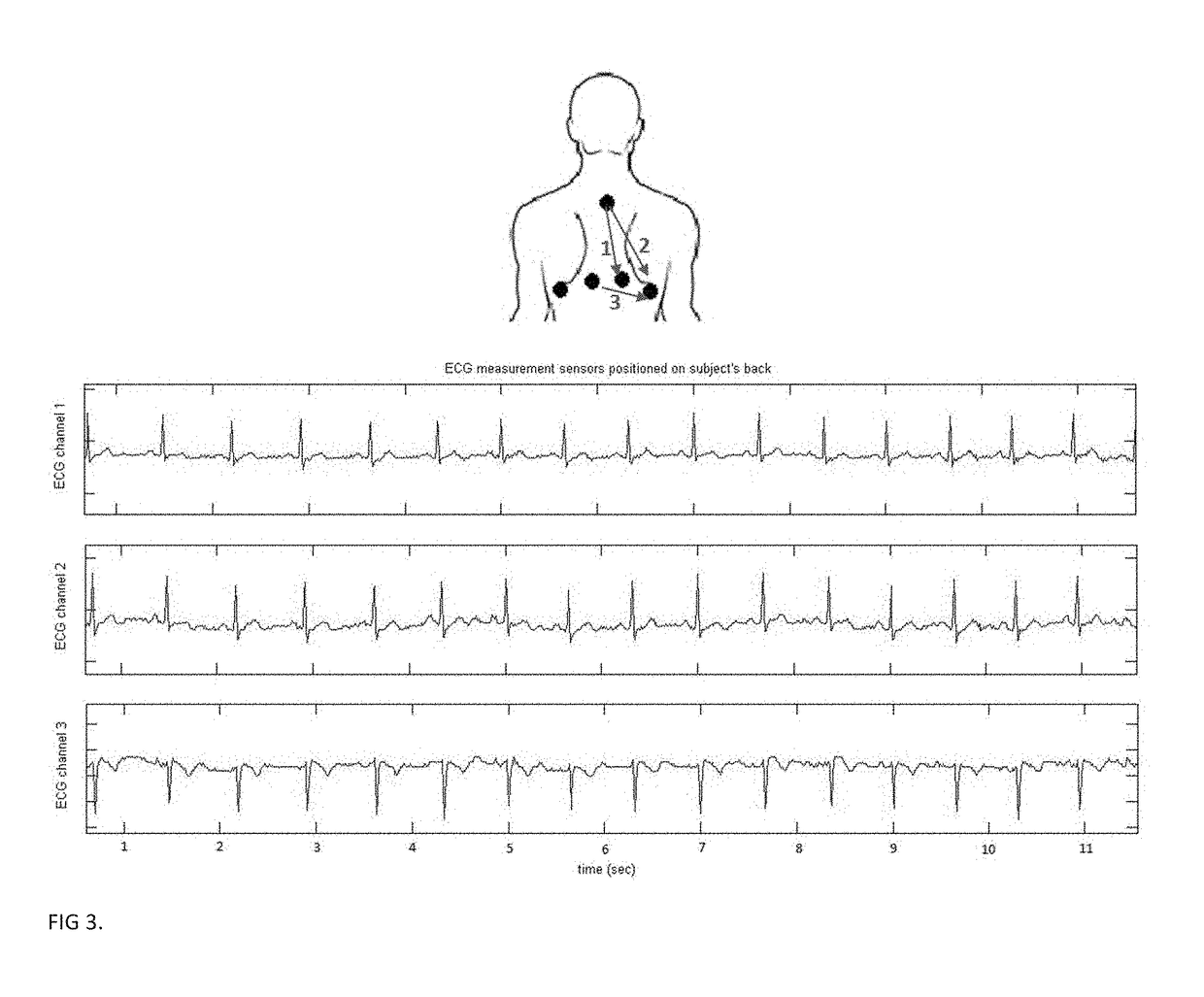

Large scale manufacturing of hybrid nanostructured textile sensors

ActiveUS20170226643A1Material nanotechnologyLiquid surface applicatorsMicro structureTextile sensors

A process for the large-scale manufacturing vertically standing hybrid nanometer scale structures of different geometries including fractal architecture of nanostructure within a nano / micro structures made of flexible materials, on a flexible substrate including textiles is disclosed. The structures increase the surface area of the substrate. The structures maybe coated with materials that are sensitive to various physical parameters or chemicals such as but not limited to humidity, pressure, atmospheric pressure, and electromagnetic signals originating from biological or non-biological sources, volatile gases and pH. The increased surface area achieved through the disclosed process is intended to improve the sensitivity of the sensors formed by coating of the structure and substrate with a material which can be used to sense physical parameters and chemicals as listed previously. An embodiment with the structures on a textile substrate coated with a conductive, malleable and bio-compatible sensing material for use as a biopotential measurement electrode is provided.

Owner:NANOWEAR

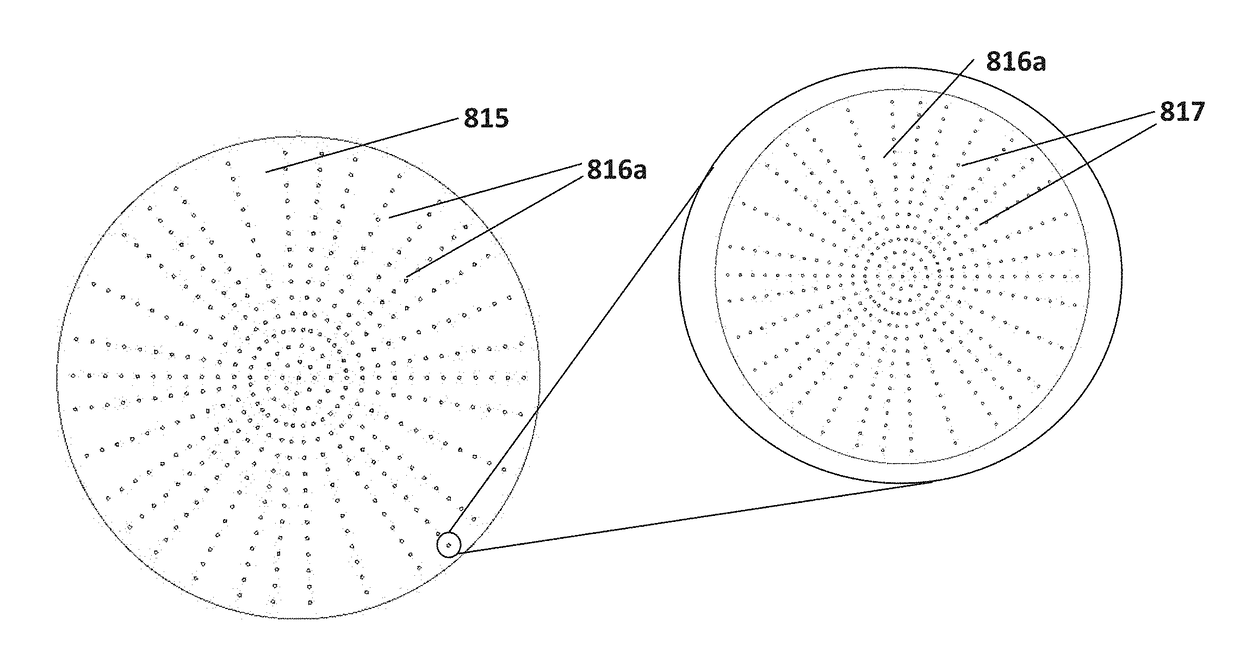

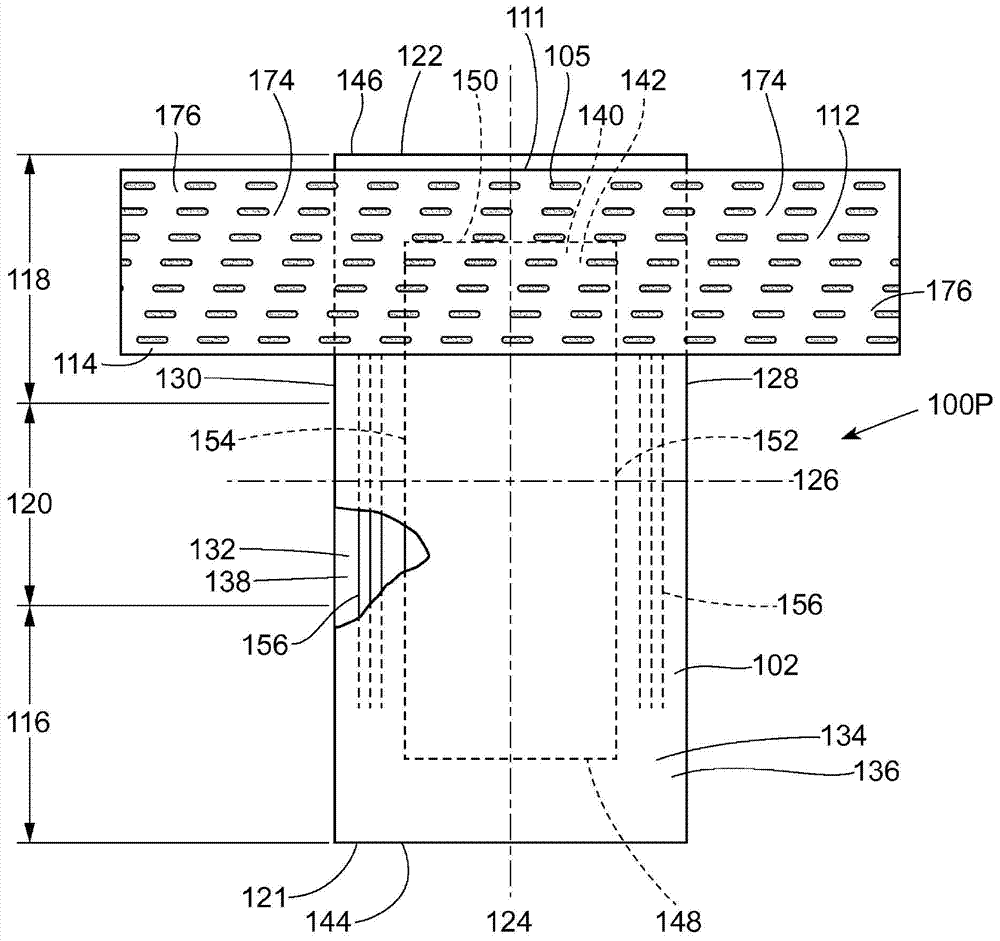

Absorbent articles having a belt portion with a texture zone having a texture ratio

An absorbent article comprises first and second substrates and one or more elastic elements disposed at least partially intermediate the substrates. The second substrate is attached to the first substrate and / or to portions of the elastic elements. The absorbent article comprises an adhesive having a first and second pattern of elements disposed on first substrate, and first and second texture zones. The first texture zone comprises a first portion of the substrates, a first portion of the elastic elements, and the first pattern of elements of the adhesive and forms a background pattern in the first portion of the substrates. The second texture zone comprises a second portion of the substrates, a second portion of the one or more elastic elements, and the second pattern of elements of the adhesive and forms a macro pattern in the second portion of the substrates.

Owner:THE PROCTER & GAMBLE COMPANY

Composite board

A composite board is formed from binding a cover layer to a base layer, wherein the base layer has a composition comprising one or more of the following ingredients: magnesium oxide, recycled magnesium oxide, fibrous chips, wood chips, bamboo chips, chemical additive and water. A method of manufacturing the composite board includes providing the base layer, which includes preparing a semi-arid mixture of the above ingredients, and pouring the mixture through a funnel onto a conveyor belt. The conveyor belt passes the mixture through a series of rollers to remove excess liquid. The layer is cut into panels, which are heat before being sprayed with dried magnesium oxide. A binding agent is applied to one side of the base layer. The cover layer has a bottom surface which is then aligned and bonded to one side of the base layer.

Owner:CHU & SON

Stain-eating coatings

ActiveUS20130052467A1Imparting to surface resistanceWax coatingsCovering/liningsHypochloritePtru catalyst

A coating composition comprising a hardenable film-former and at least 0.5 weight percent of an oxidizing agent sufficient to decolorize a stain on the film-former is disclosed, wherein the oxidizing agent comprises hydrogen peroxide, hypochlorite, and organo-chlorine bleaches and will at least partially decolorize a plurality of stains when applied to the hardened coating, allowed to stand for one hour at room temperature, and evaluated by visual observation of the stain under average overhead fluorescent illumination. The oxidizing agent is not consumed as a catalyst or initiator to polymerize or otherwise cause a reaction in the floor coating before it is applied and before it has hardened. A composition of the invention may include from about 0.8 to about 5 weight percent oxidizing agent and the film-former forms a hardened film resistant to rinsing with tap water.

Owner:ECOLAB USA INC

Use of flame retardants in linoleum or cork-based floor coverings

InactiveUS20050048278A1Clearly improved fire behaviorLayered productsWood working apparatusPolymer scienceInorganic compound

The present invention relates to a linoleum-based floor covering with improved flame retardant properties, comprising at least one layer of linoleum, which contains at least one silicon-containing inorganic compound as a flame retardant in an amount of up to 40% by weight relative to the weight of the linoleum layer, and to a method for producing the same. The invention further relates to a cork-based floor covering with improved flame retardant properties, comprising at least one silicon-containing inorganic compound as a flame retardant in an amount of up to 40% by weight relative to the amount of the cork layer.

Owner:DLW AKTIENGES

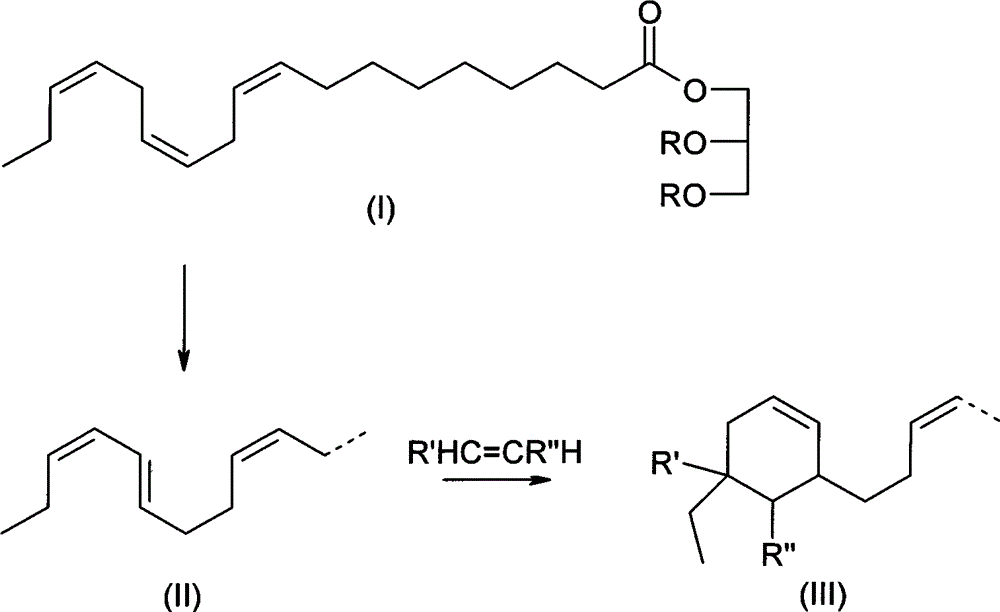

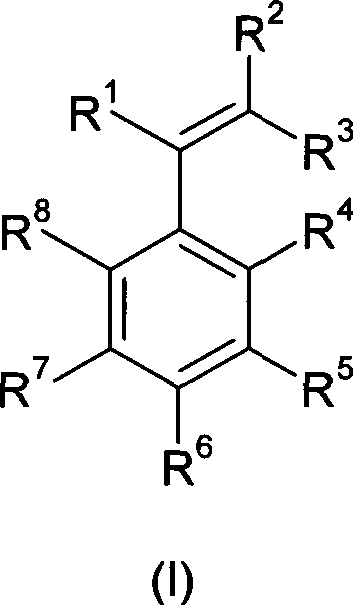

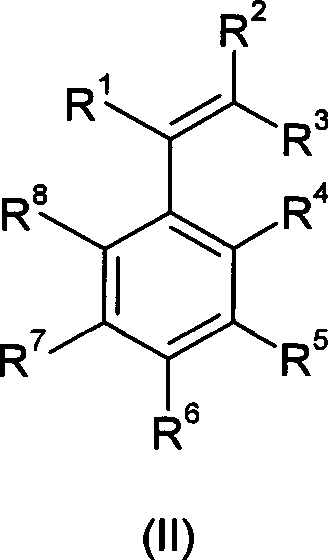

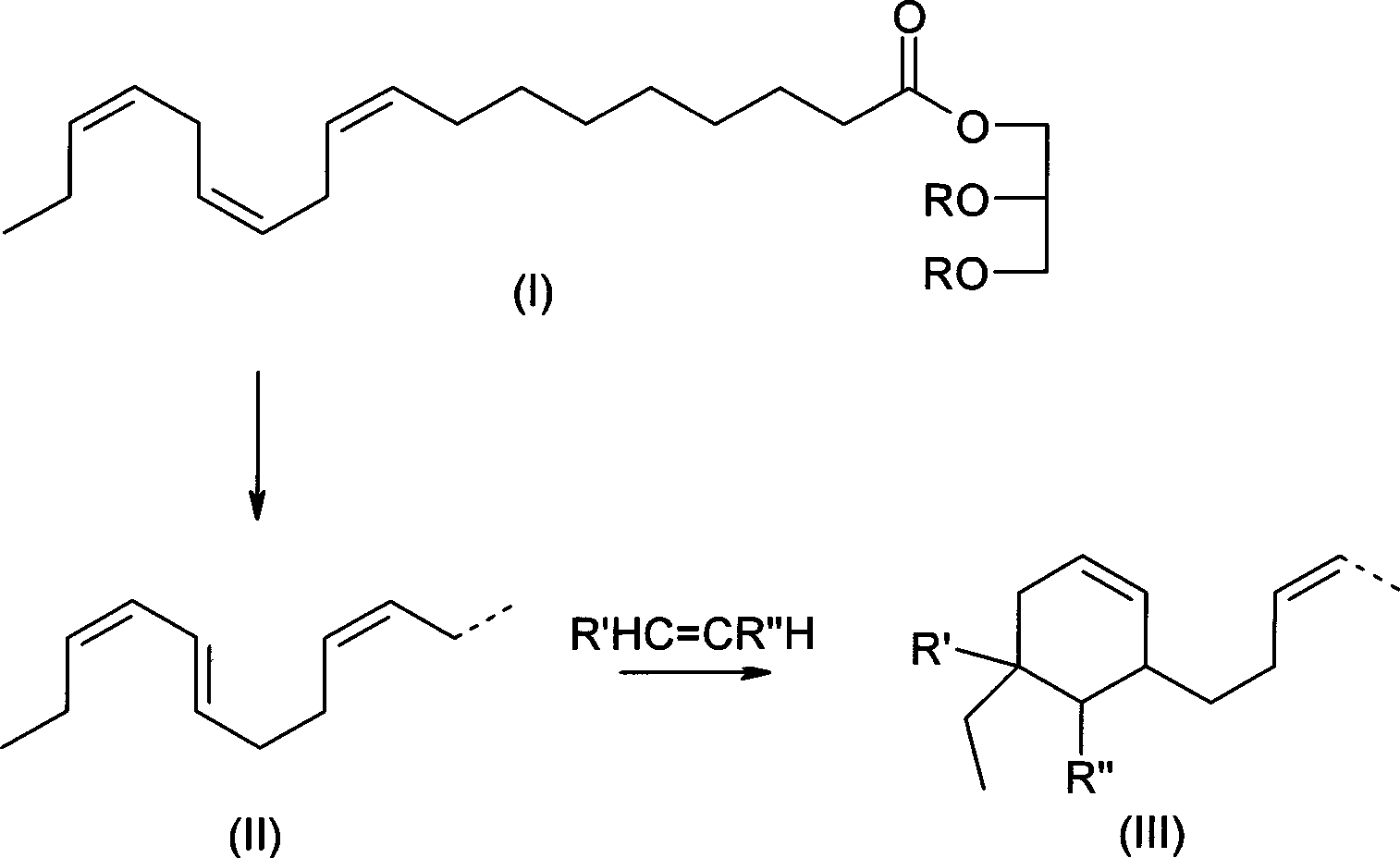

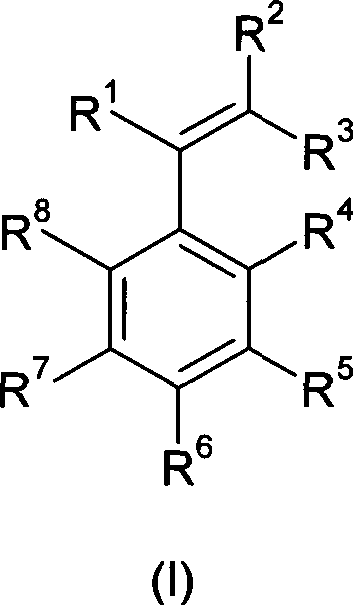

Material containing polyreactions products and method for the production thereof

InactiveUS6150436AEasy to produceImprove material performanceSynthetic resin layered productsCoatingsPolymer scienceCarboxylic acid

PCT No. PCT / EP97 / 07255 Sec. 371 Date Jun. 24, 1999 Sec. 102(e) Date Jun. 24, 1999 PCT Filed Dec. 23, 1997 PCT Pub. No. WO98 / 28356 PCT Pub. Date Jul. 2, 1998This invention relates to materials containing polyreaction products, which contain reaction products of dicarboxylic acids or polycarboxylic acids or derivatives thereof with epoxidation products of carboxylic acid esters and at least one filler, methods for the production thereof, and the use thereof for the production of planar structures based on renewable raw materials.

Owner:AFI LICENSING +1

Strontium aluminate salt dope and impact-resisting coat fibre textile fabric

InactiveCN101165106AHigh hardnessImprove impact resistancePersonal protection gearCoatingsFiberMetallurgy

The strontium aluminate paint is prepared with strontium aluminate powder in 30-45 wt%, carrier in 40-60 wt% and glaze powder in 8-20 wt%, and through mixing through stirring for 2-6 hr. The strontium aluminate paint capable of absorbing the impact energy of bullet and other powerful impact matters is suitable for being coated onto the surface of proper base to raise the impact resistance. The present invention also relates to impact resisting fiber fabric with coating of the strontium aluminate paint for making ballistic protective clothing.

Owner:吴振华

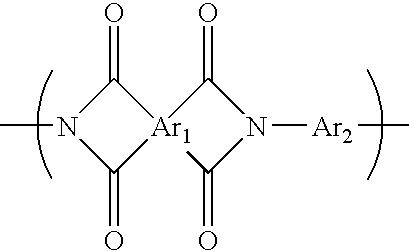

Water-soluble polyimide precursor, aqueous polyimide precursor solution, polyimide, impregnated material with polyimide binder, and laminate

InactiveUS7300972B2Low heat resistanceGood shape retentionSynthetic resin layered productsWoven fabricsFiberHeat resistance

A water-soluble polyimide precursor, which can be suitably applied for aromatic polyimides and exhibits a low reduction in heat resistance and mechanical properties, an aqueous solution of the polyimide precursor and a polyimide obtained from the precursor. A heat-resistant fiber impregnated material and an impregnated sheet-like material are prepared by using the precursor and a laminate is prepared by employing the precursor.

Owner:UBE IND LTD

Absorbent articles having texture zones forming background patterns and macro patterns

An absorbent article comprises first and second substrates and one or more elastic elements disposed at least partially intermediate the substrates. The second substrate is attached to the first substrate and / or to portions of the elastic elements. The absorbent article comprises an adhesive having a first and second pattern of elements disposed on first substrate, and first and second texture zones. The first texture zone comprises a first portion of the substrates, a first portion of the elastic elements, and the first pattern of elements of the adhesive and forms a background pattern in the first portion of the substrates. The second texture zone comprises a second portion of the substrates, a second portion of the one or more elastic elements, and the second pattern of elements of the adhesive and forms a macro pattern in the second portion of the substrates.

Owner:THE PROCTER & GAMBLE COMPANY

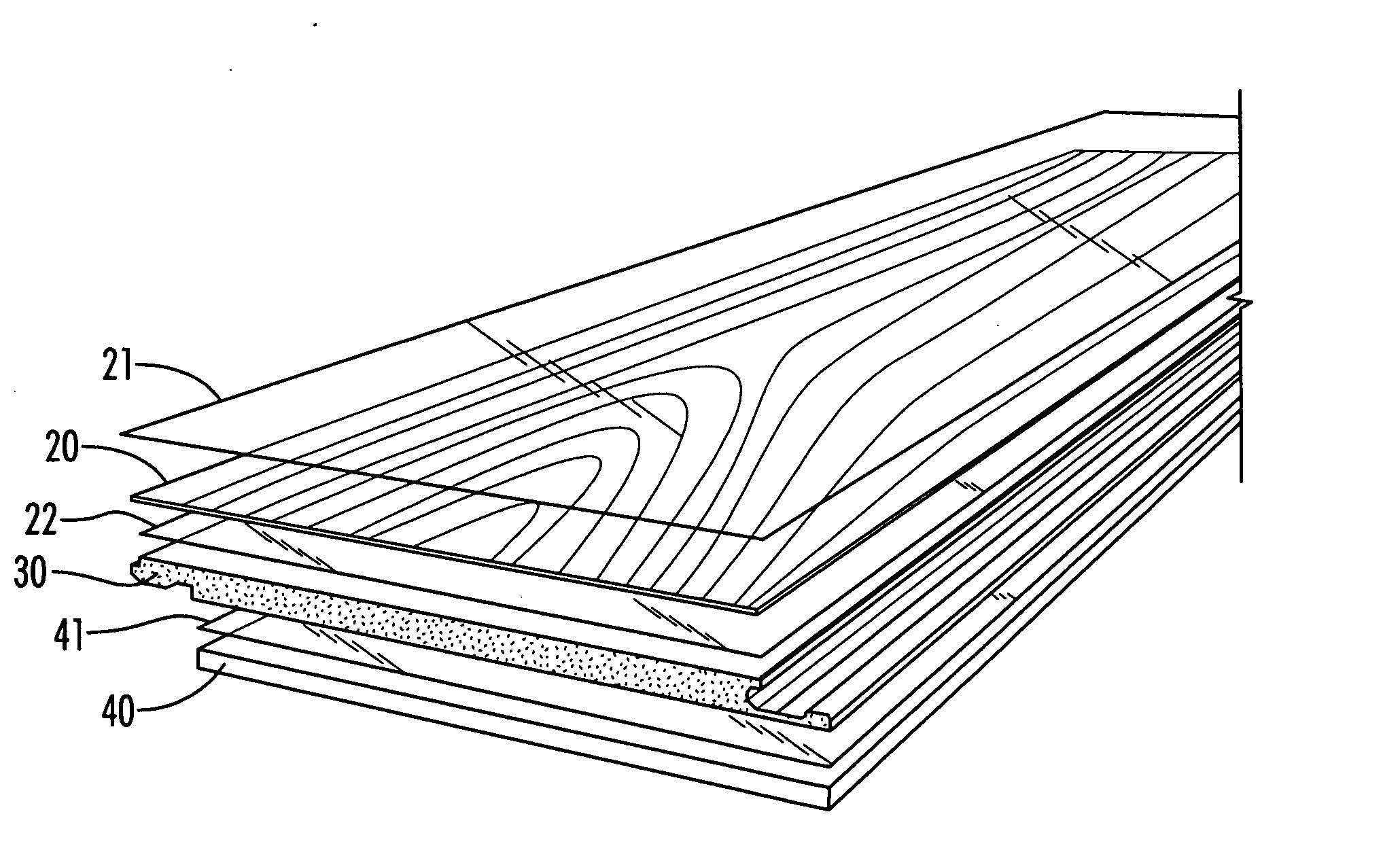

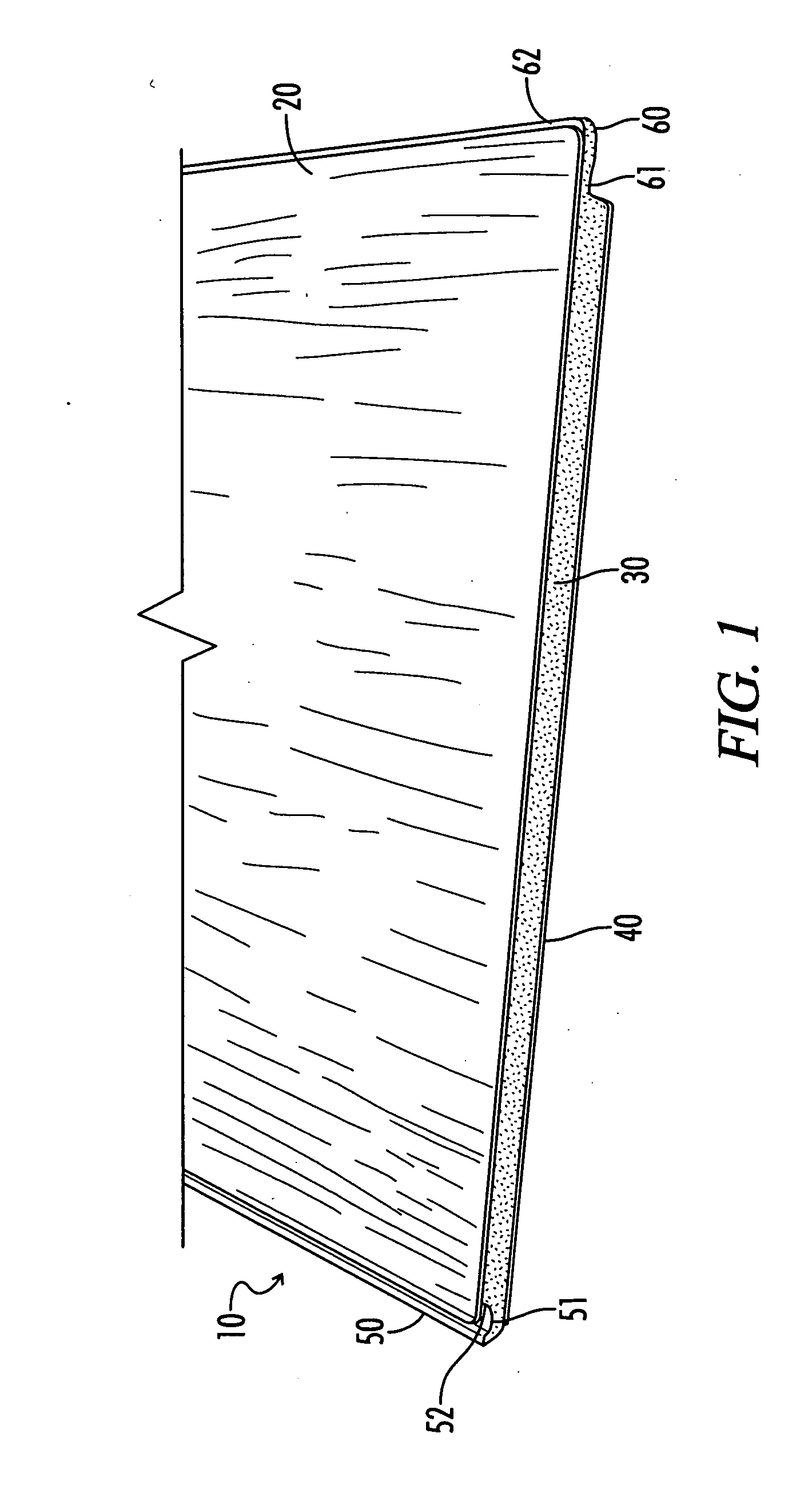

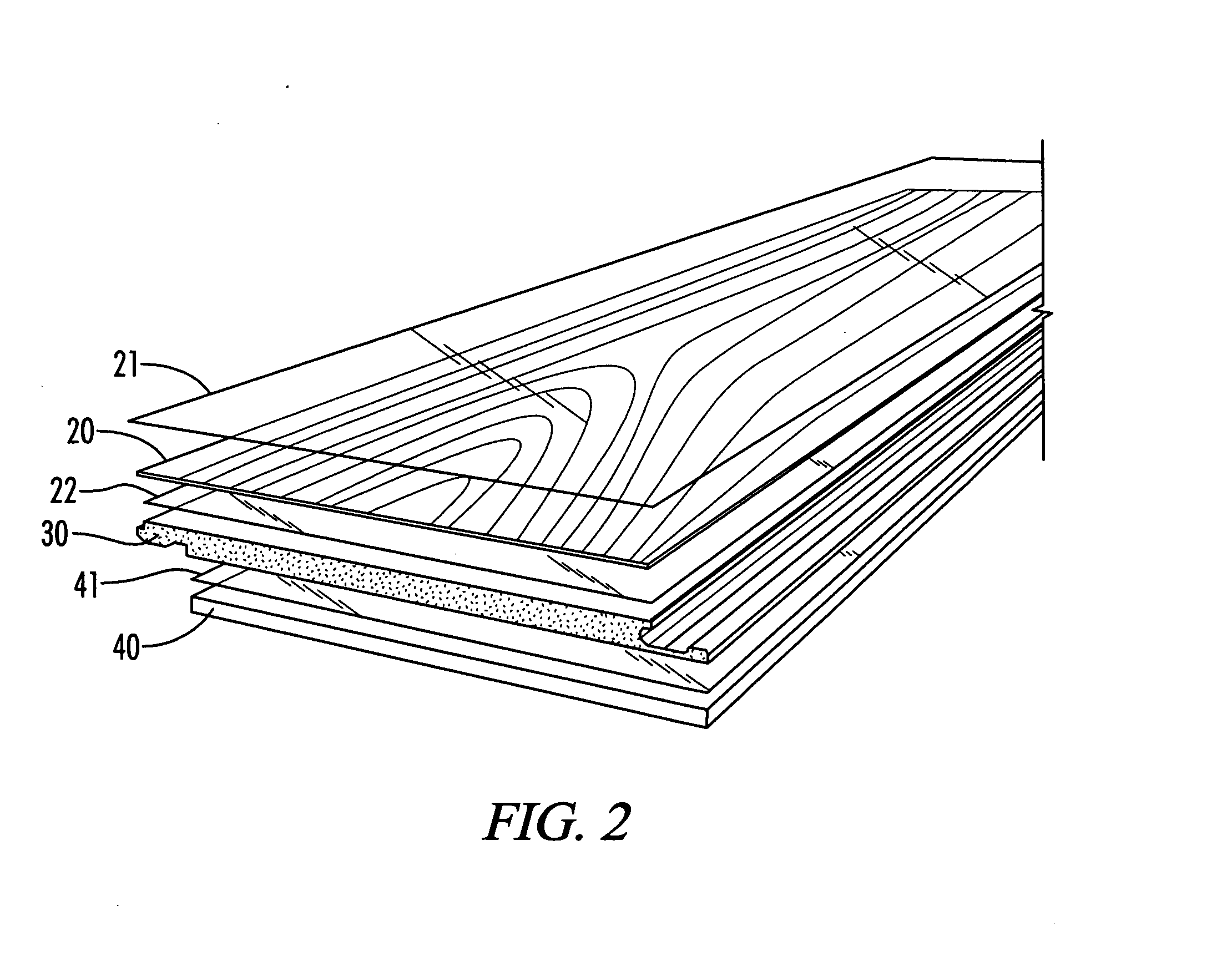

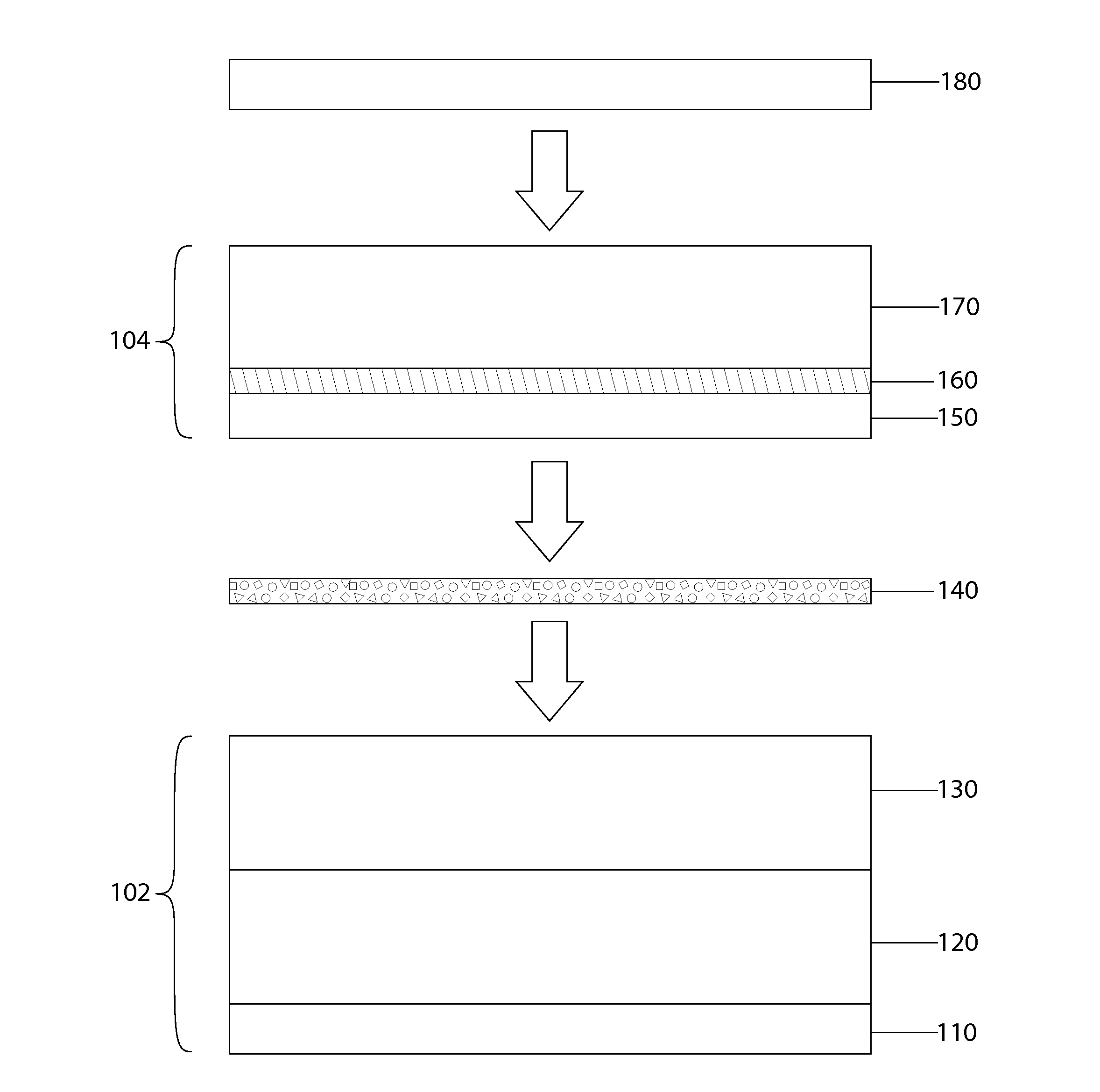

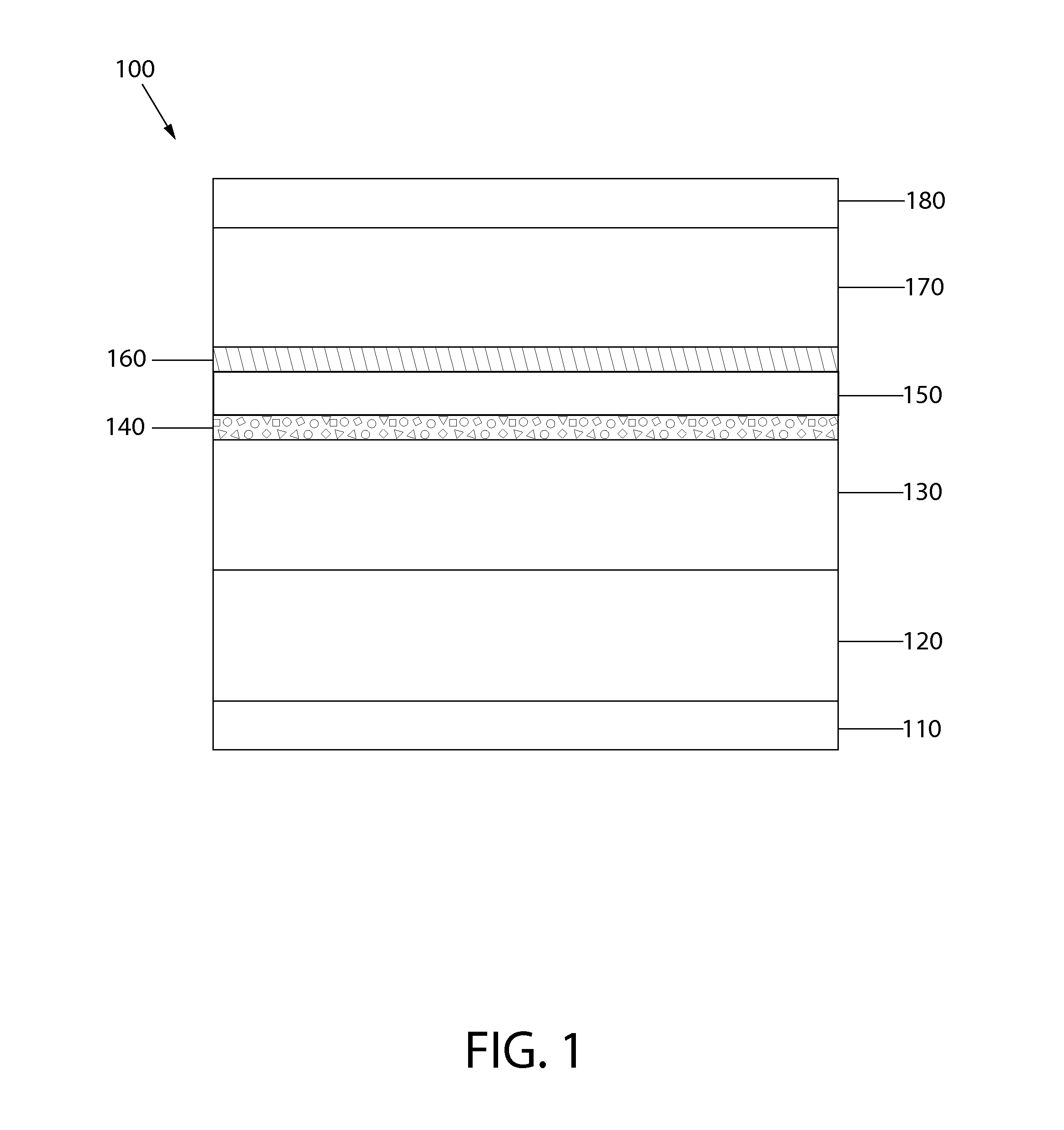

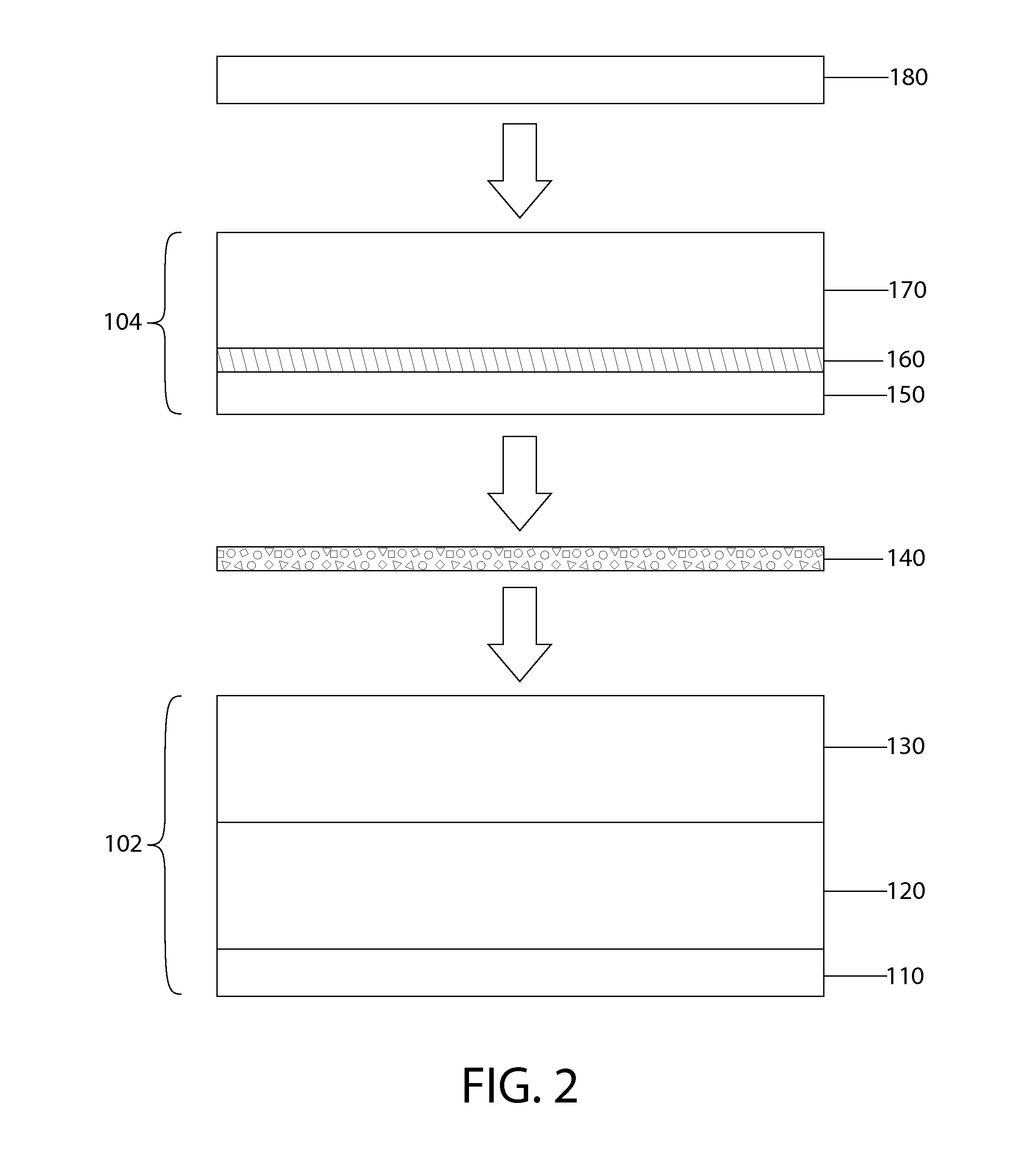

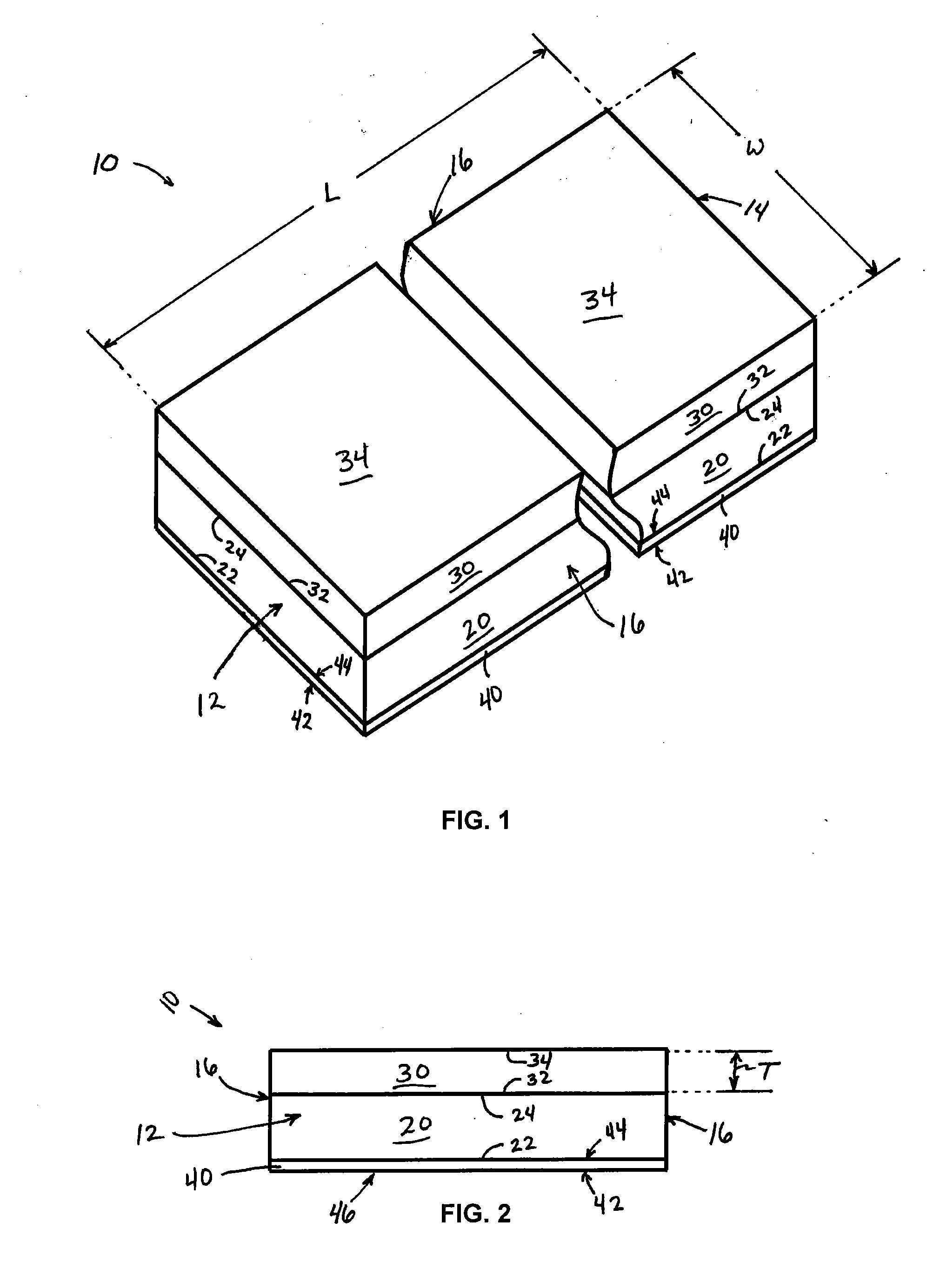

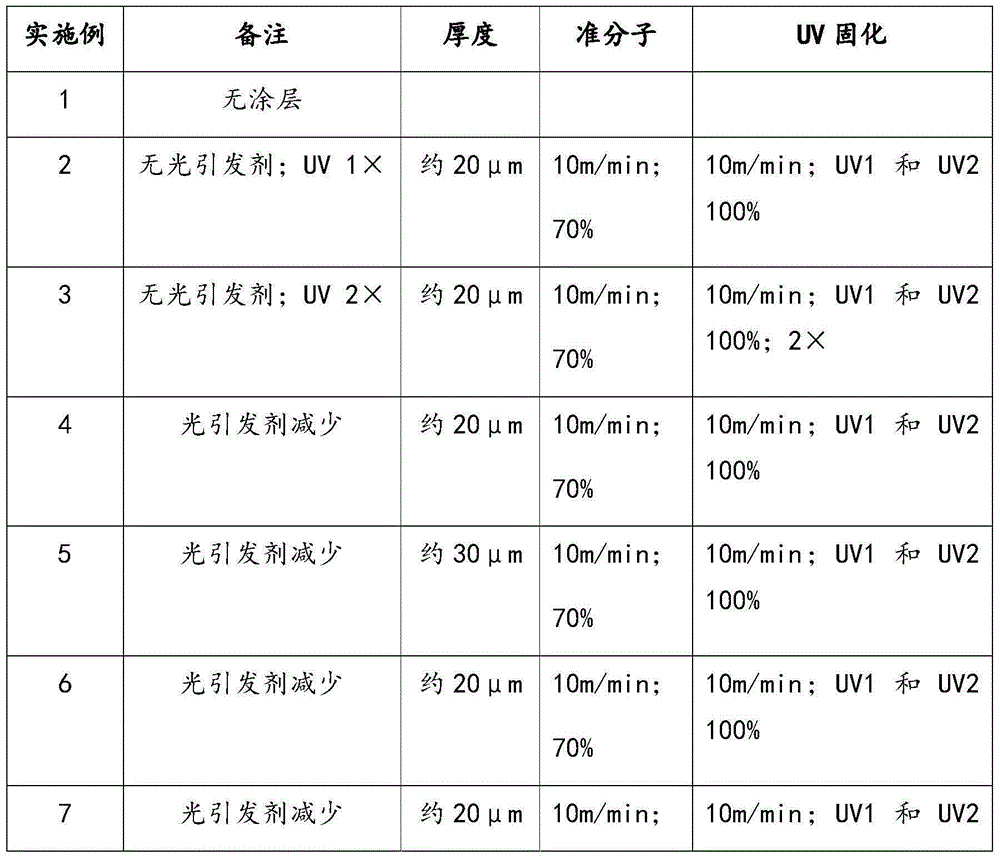

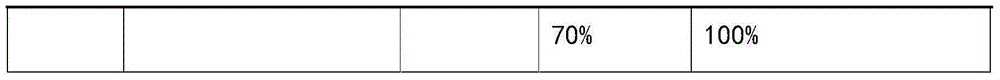

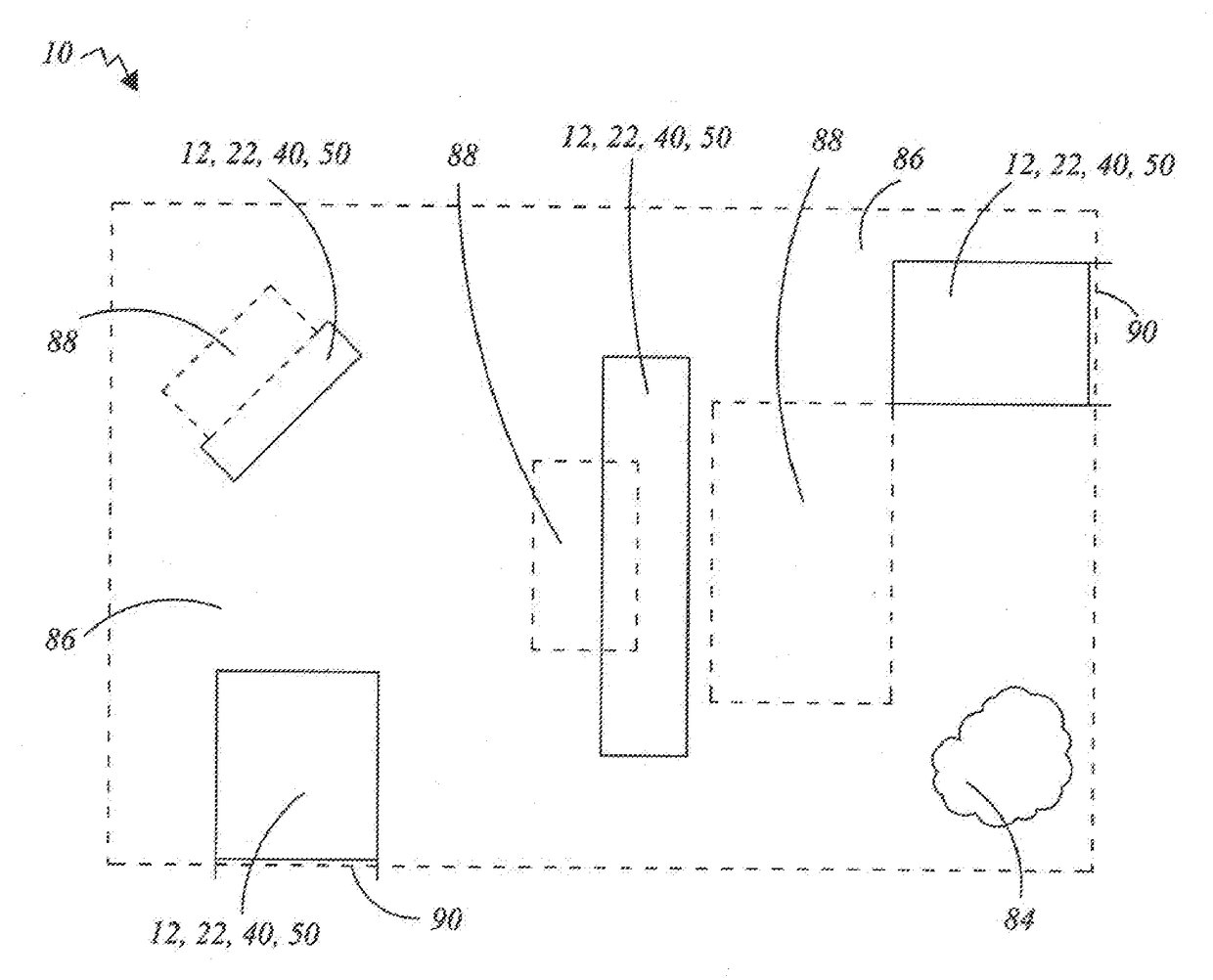

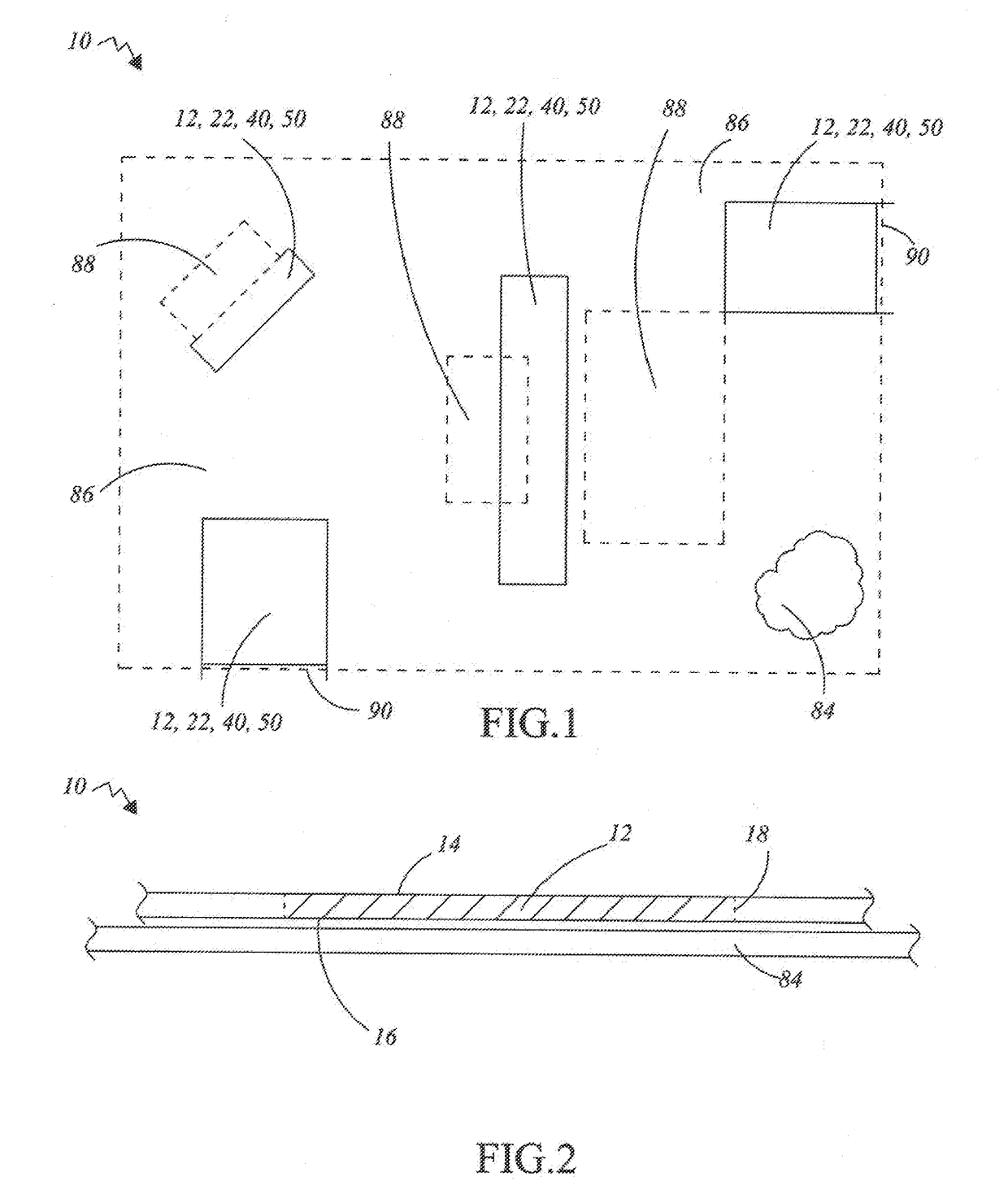

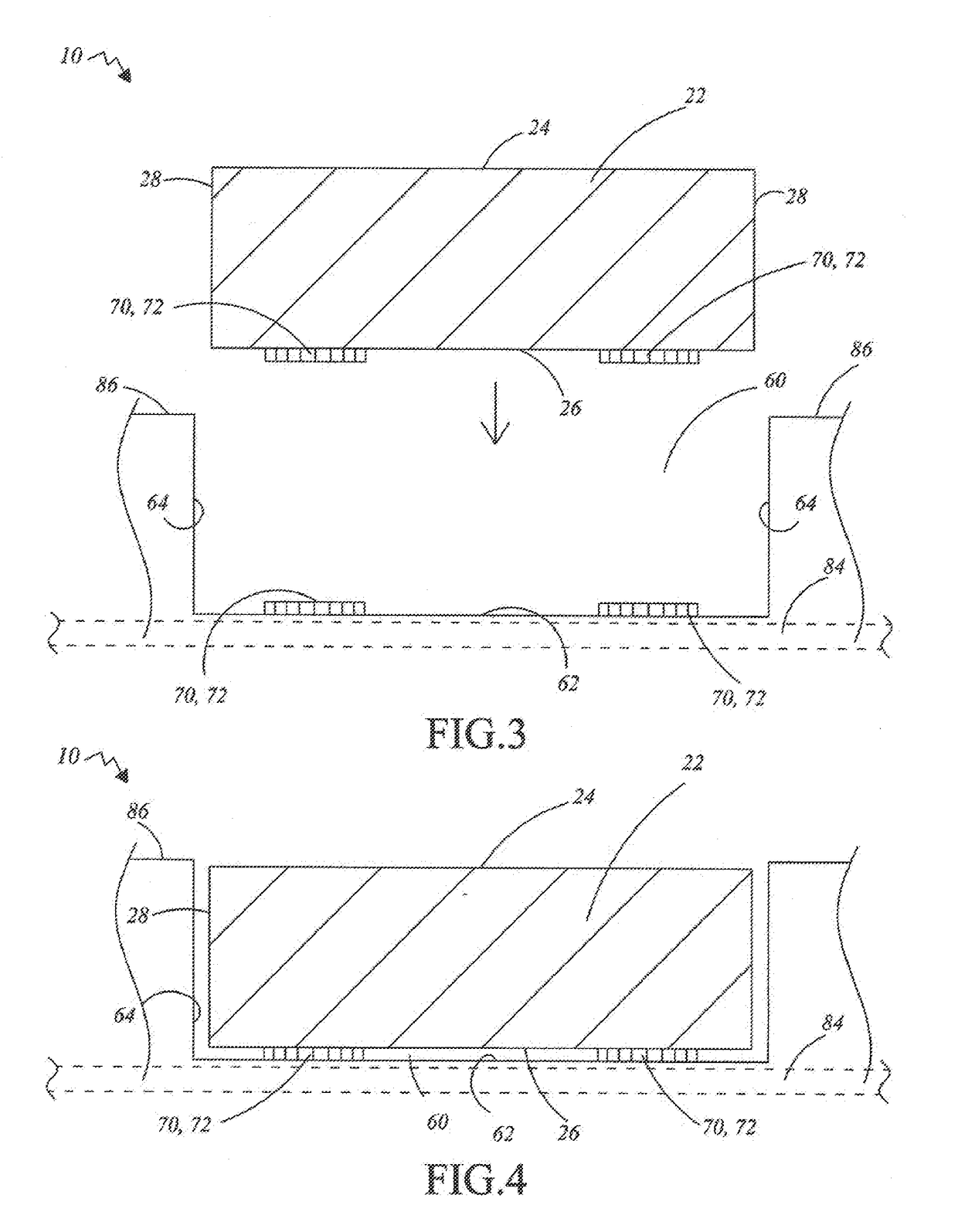

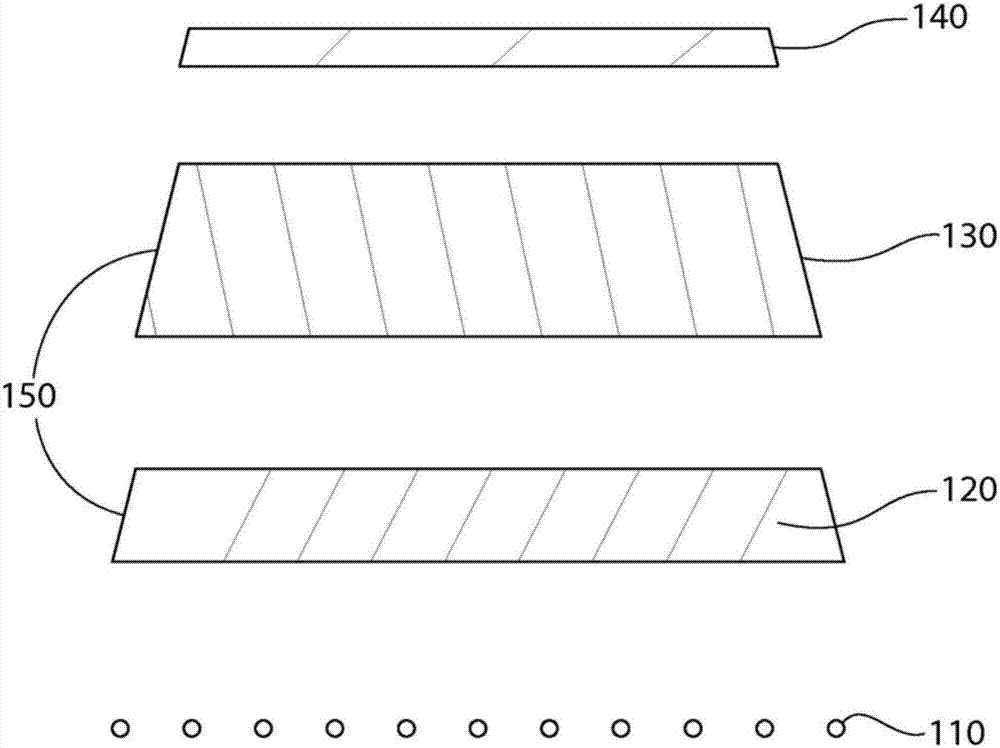

Linoleum flooring

A linoleum flooring product in one embodiment includes a linoleum substrate and a printed wear layer comprising a decorative indicia. The printed wear layer includes a wear layer and an ink print layer. The linoleum substrate may include a base linoleum layer applied on a backing material, and in some embodiments further includes a visual linoleum layer formed on top of the base linoleum layer. The printed wear layer may be adhesively bonded onto the linoleum substrate. In one embodiment, an ultraviolet curable adhesive may be used. A related method for forming the linoleum flooring product is also provided.

Owner:AFI LICENSING

Water-soluble polyimide precursor, aqueous polyimide precursor solution, polyimide, impregnated material with polyimide binder, and laminate

InactiveUS20060057916A1Low heat resistanceGood shape retentionSynthetic resin layered productsWoven fabricsFiberHeat resistance

A water-soluble polyimide precursor, which can be suitably applied for aromatic polyimides and exhibits a low reduction in heat resistance and mechanical properties, an aqueous solution of the polyimide precursor and a polyimide obtained from the precursor. A heat-resistant fiber impregnated material and an impregnated sheet-like material are prepared by using the precursor and a laminate is prepared by employing the precursor.

Owner:UBE IND LTD

Multiple Layer Surface Covering

ActiveUS20110206901A1Nice appearanceEasy to installMouldsFilm/foil adhesivesPolyvinyl chlorideEngineering

A multi-layer surface covering includes at least a first and a second layer made of a polyvinyl chloride material, each of the two layers having a different density. One of the two layers includes a pigment such that the layer resembles teak. A surface of the colored layer is at least partly abraded to resemble a wood grain. The surface covering may additionally include grooves cut into the surface to resemble individual wood planks. The grooves additionally provide traction and drainage of liquid from the surface to an edge of the covering.

Owner:BUSHEY RICHARD D +1

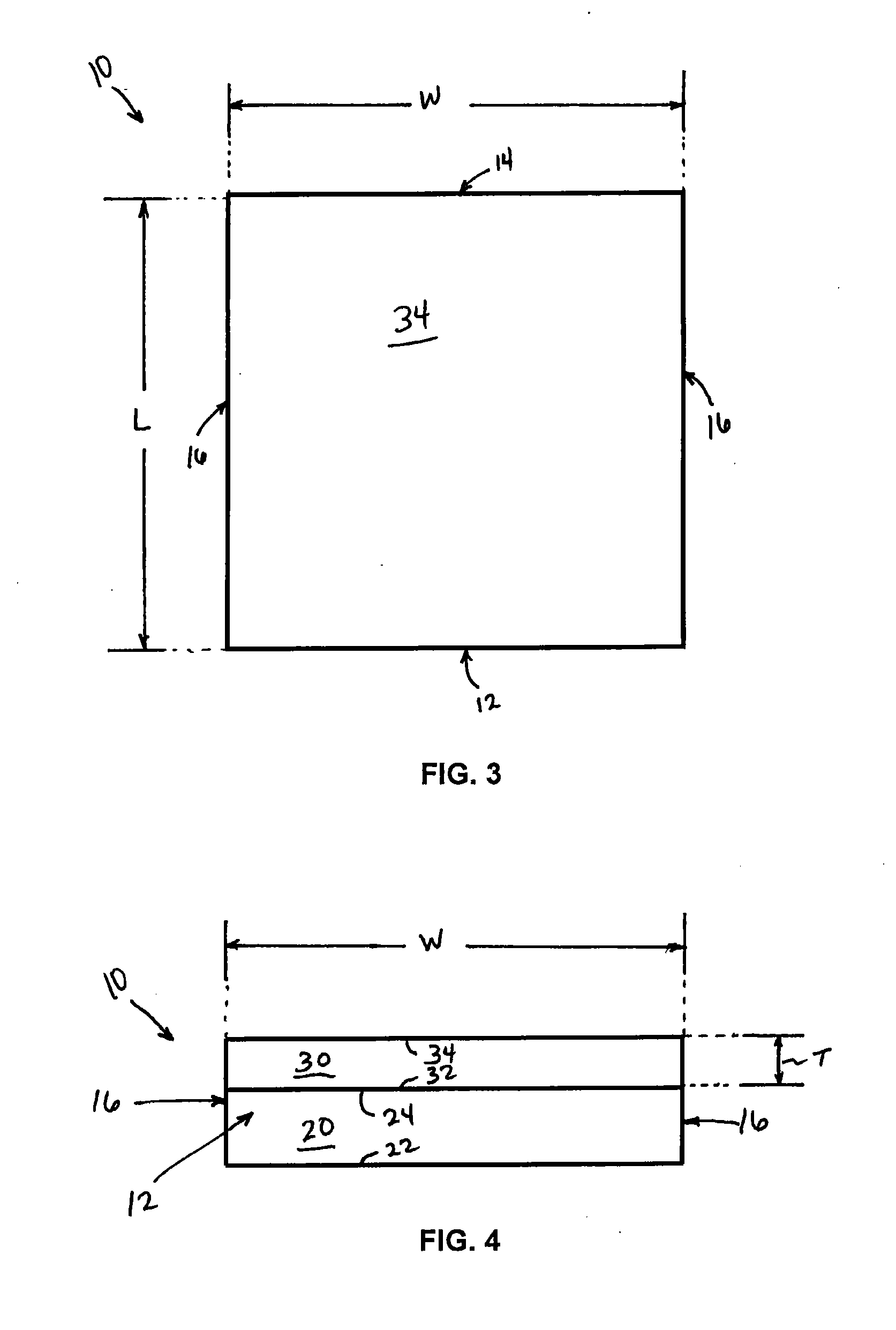

Curing methods and products produced therefrom

InactiveCN104937164ATVOC value decreasesReduce emissionsPretreated surfacesConstructions elementsSimple Organic CompoundsHigh energy

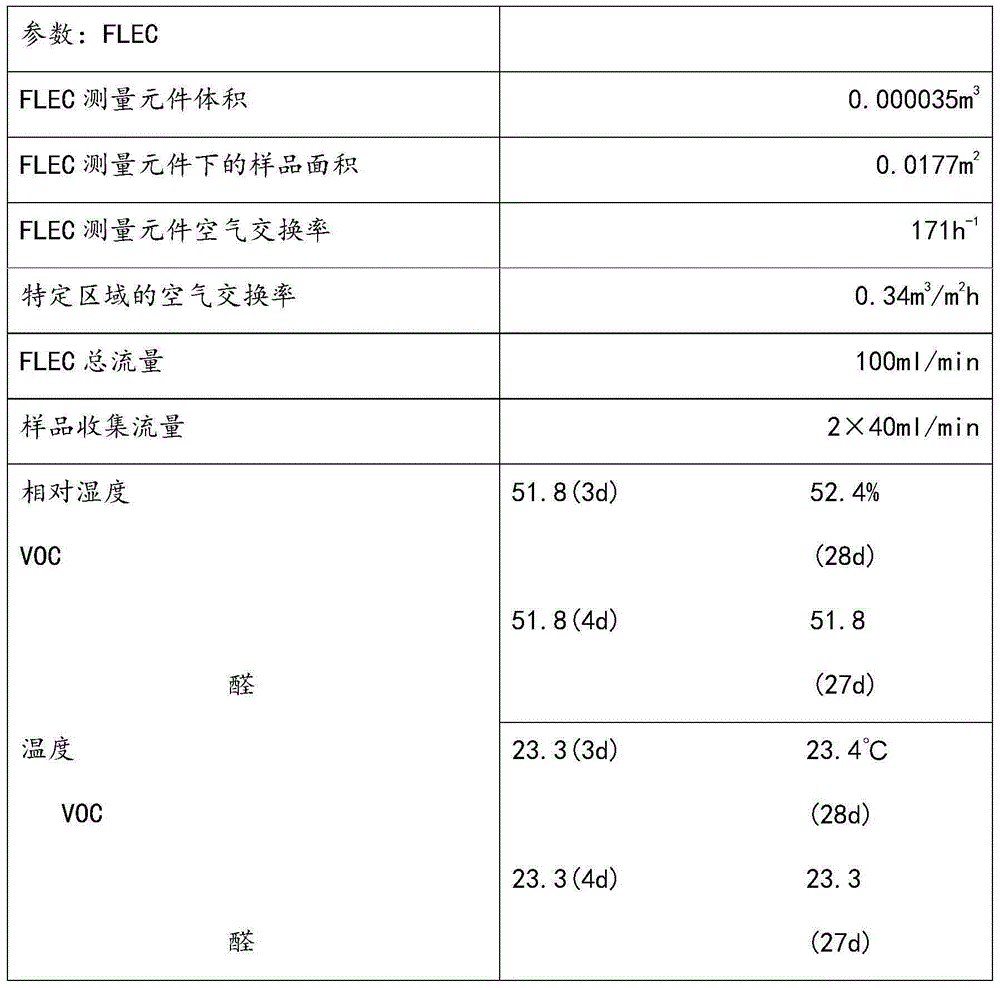

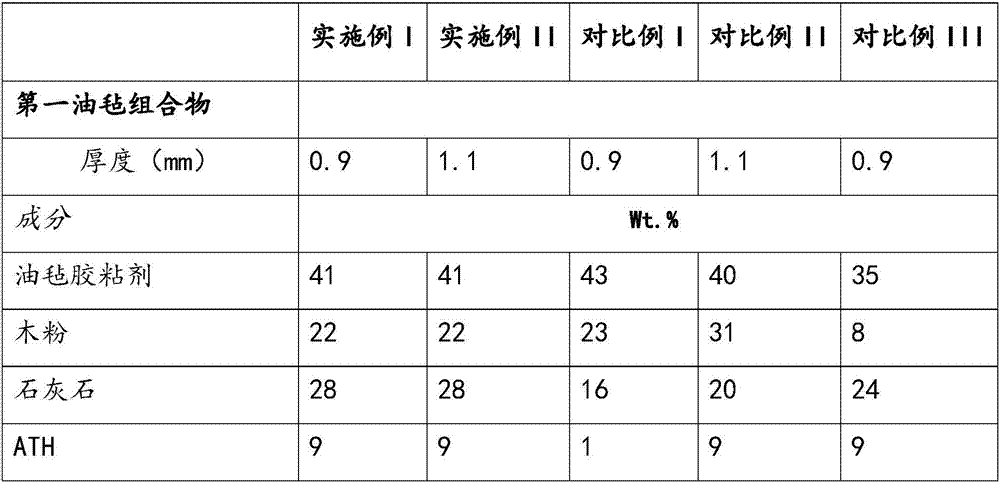

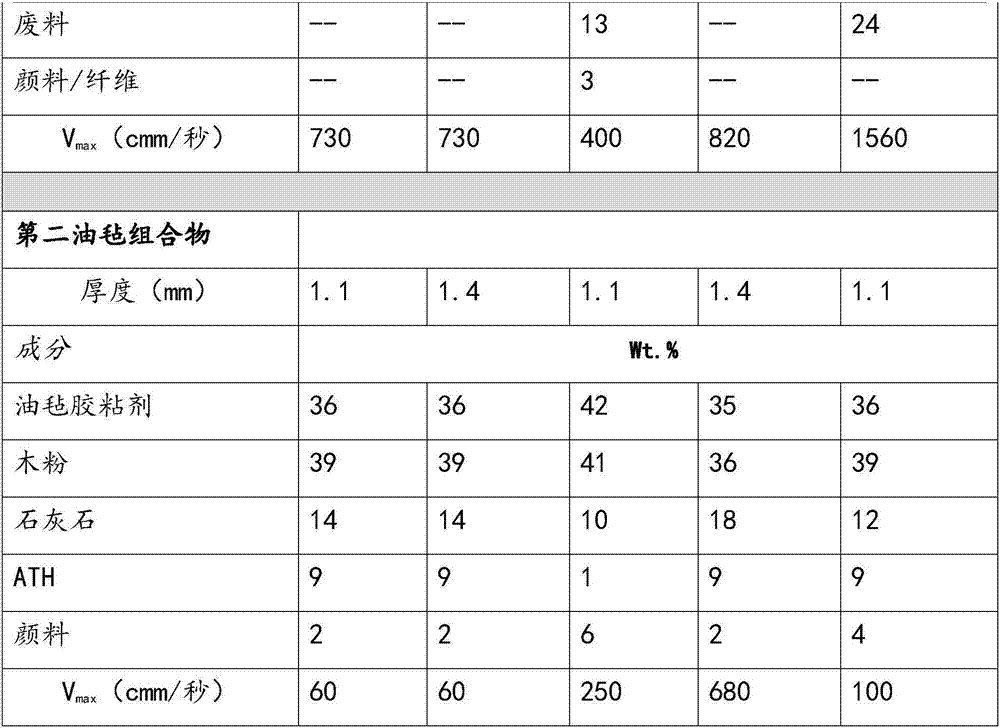

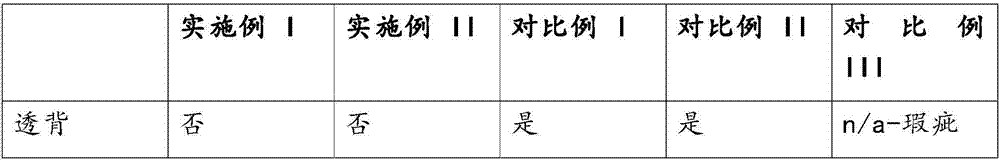

Described herein are low-emission sheet materials, comprising at least one base layer and a (meth) acrylate-based coating arranged thereon, wherein the sheet material has a TVOC (total volatile organic compounds) value of ≤ 50μg / m2.h, measured according to ISO 16000-10 by means of a field and laboratory emission cell (FLEC). Also described herein, are methods for making and using wear layers and sheet materials comprising same, obtained by irradiation at a wavelength from 10nm to 200 nm or by irradiation wing a source of high-energy photons in combination with a UV radiator.

Owner:ARMSTRONG WORLD INDUSTRIES

Stain-eating coatings

A coating composition comprising a hardenable film-former and at least 0.5 weight percent of an oxidizing agent sufficient to decolorize a stain on the film-former is disclosed, wherein the oxidizing agent comprises hydrogen peroxide, hypochlorite, and organo-chlorine bleaches and will at least partially decolorize a plurality of stains when applied to the hardened coating, allowed to stand for one hour at room temperature, and evaluated by visual observation of the stain under average overhead fluorescent illumination. The oxidizing agent is not consumed as a catalyst or initiator to polymerize or otherwise cause a reaction in the floor coating before it is applied and before it has hardened. A composition of the invention may include from about 0.8 to about 5 weight percent oxidizing agent and the film-former forms a hardened film resistant to rinsing with tap water.

Owner:ECOLAB USA INC

Multiple film coating construction process

InactiveCN1632261AOvercome shrinkageOvercome pryingCovering/liningsPaperhangingPremature agingMoisture

A new compound film coating construction technology. Background Art Only pasting the laminating material on the decorative base surface, air, moisture or dust are easy to invade the adhesive layer, prompting the premature aging of the laminating material and the adhesive layer, causing the laminating material to shrink, pry, and empty. The drum or the whole peels off, affecting the decorative effect. On the basis of the background technology, the present invention selects an ultra-thin composite film material with a thickness of 0.01-0.5mm to cover the decoration base surface, and then applies a finishing paint on the composite film material. The self-expansion and contraction force of the ultra-thin lamination film is small, and the adhesion of the primer is enough to resist the expansion and contraction of the ultra-thin lamination film, so that it can be integrated with the decorative base surface. It is difficult for dust to invade the adhesive layer, which eliminates the possibility of premature aging of the lamination material and the adhesive layer, and overcomes the defects of shrinkage, prying, hollowing or overall peeling off of the lamination material. The invention is particularly suitable for use in the technical field of building decoration construction.

Owner:上海伊亮环保科技有限公司

Aesthetically pleasing linoleum based surface coverings

Owner:ARMSTRONG WORLD INDUSTRIES

Large scale manufacturing of hybrid nanostructured textile sensors

ActiveUS20180080126A9Material nanotechnologyLiquid surface applicatorsMicro structureTextile sensors

A process for the large-scale manufacturing vertically standing hybrid nanometer scale structures of different geometries including fractal architecture of nanostructure within a nano / micro structures made of flexible materials, on a flexible substrate including textiles is disclosed. The structures increase the surface area of the substrate. The structures maybe coated with materials that are sensitive to various physical parameters or chemicals such as but not limited to humidity, pressure, atmospheric pressure, and electromagnetic signals originating from biological or non-biological sources, volatile gases and pH. The increased surface area achieved through the disclosed process is intended to improve the sensitivity of the sensors formed by coating of the structure and substrate with a material which can be used to sense physical parameters and chemicals as listed previously. An embodiment with the structures on a textile substrate coated with a conductive, malleable and bio-compatible sensing material for use as a biopotential measurement electrode is provided.

Owner:NANOWEAR

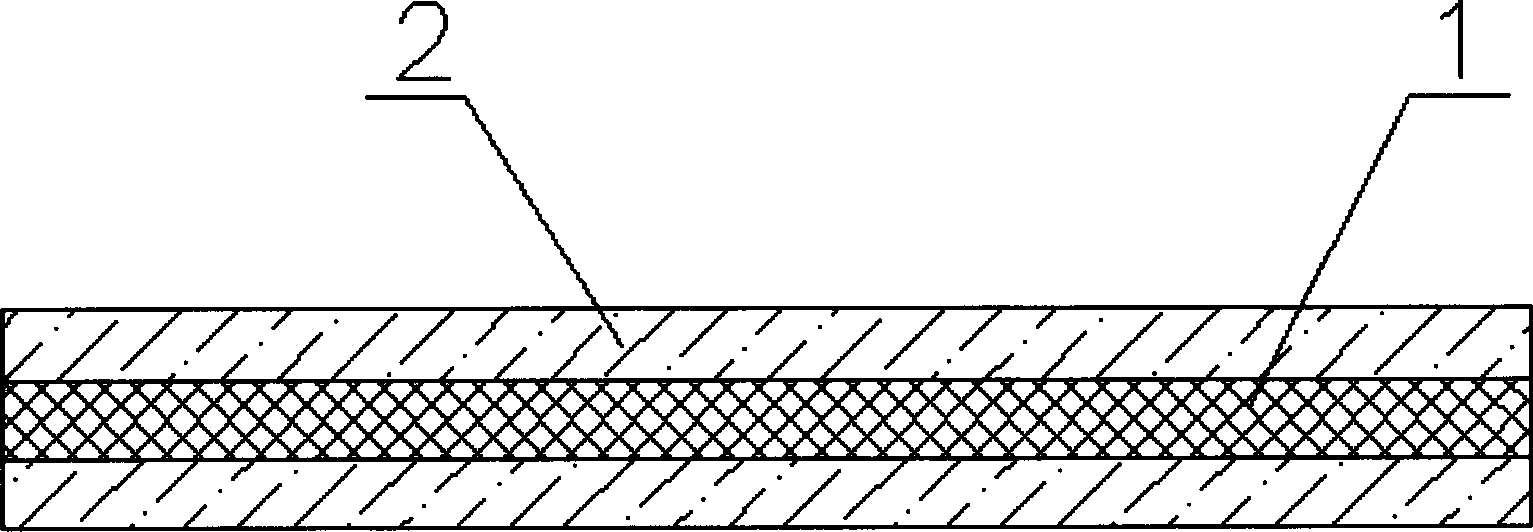

Teflon varnished cloth

InactiveCN104088159ASimple structureEasy to manufactureSynthetic resin layered productsGlass/slag layered productsAlkali freeEngineering

Owner:包信海

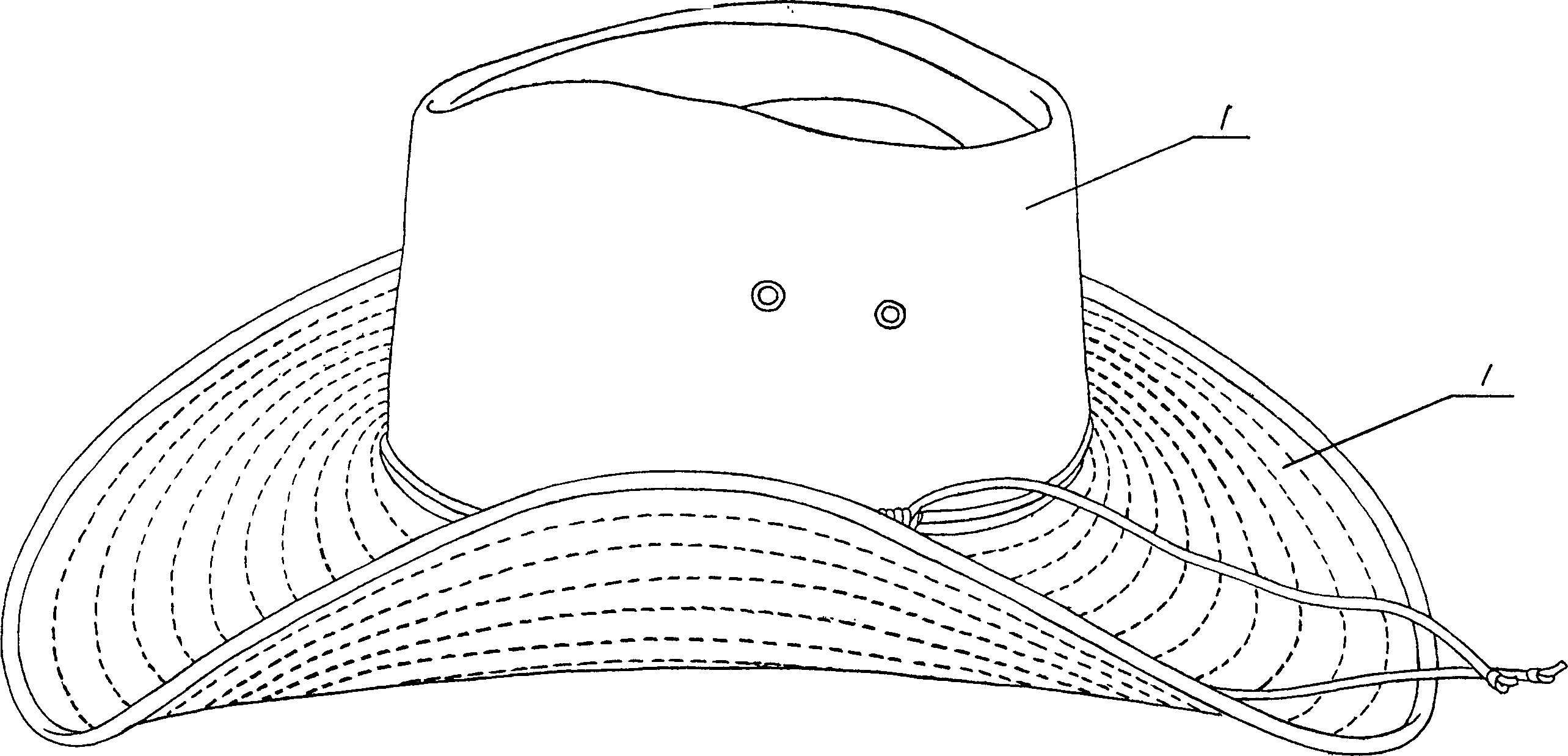

Water proof coating adaptable for cap fabric and cap produced thereby

InactiveCN1803955AEasy to storeAvoid infringementWax coatingsAntifouling/underwater paintsMINERAL WAXUltraviolet

The invention discloses a waterproofing paint suitable for making cap face fabric, as well as the cap made therefrom, wherein the waterproofing paint comprises the following raw materials (by weight percent): vaseline 50-90%, mineral wax 5-30%, silicon oil 4-10%, Nuva 1-10%. The cap comprises a body member and a protective coating, wherein the protective coating is made of the following raw materials (by weight percent): vaseline 50-90%, mineral wax 5-30%, silicon oil 4-10%, and Nuva 1-10%.

Owner:王德强

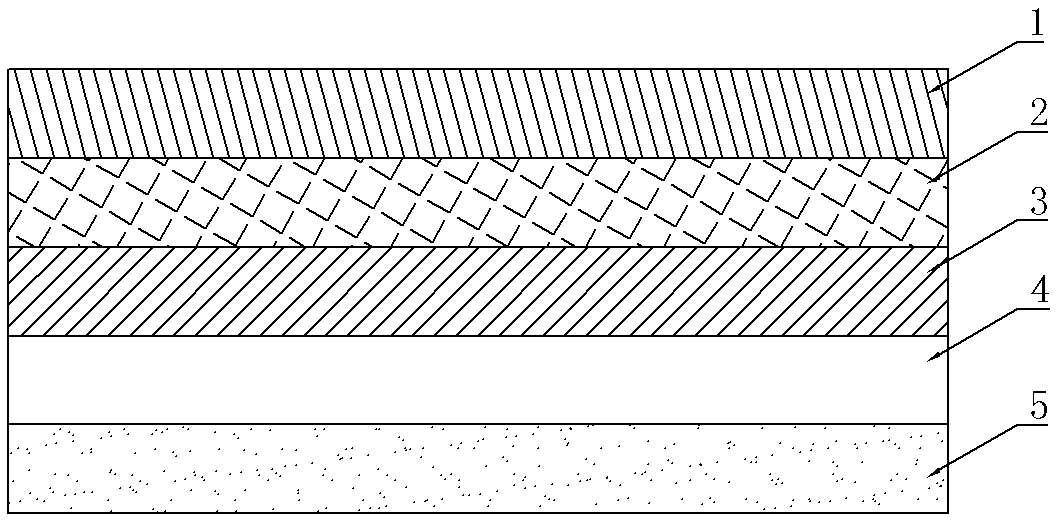

Back rubber waterproof jet-drawing painting canvas and production method thereof

InactiveCN108505348ABeautiful colorHigh saturationOther artistic work equipmentsCoatingsWater basedEmulsion

The invention provides back rubber waterproof jet-drawing painting canvas, aiming at solving the technical problems that the existing canvas is poor in jet drawing effect and waterproof effect and iseasily wrinkled. The back rubber waterproof jet-drawing painting canvas comprises an ink absorbing surface layer, an ink absorbing middle layer, an ink absorbing inner layer, a base material and a bonding layer which are arranged from top to bottom; the back rubber waterproof jet-drawing painting canvas is characterized in that the ink absorbing surface layer is prepared from the following raw materials in parts by weight: 35 parts of vinyl acetate emulsion, 18 parts of natural stone powder, 6.5 parts of polyvinyl alcohol, 3.8 parts of powdered silicon dioxide and 4.3 parts of cationic water-based color fixing agent; the ink absorbing middle layer is prepared from the following raw materials in parts by weight: 30 parts of vinyl acetate emulsion, 16 parts of natural stone powder and 4 parts of polyvinyl alcohol; the ink absorbing inner layer is prepared from the following raw materials in parts by weight: 35 parts of vinyl acetate emulsion and 18 parts of natural stone powder.

Owner:江苏奥力新材料股份有限公司

Flooring Having At Least One Replaceable Section

InactiveUS20170191274A1Quickly and easily sectionEasy to disassembleAdhesivesFlooringMechanical engineeringEngineering

Owner:KOHANTAB DANIAL

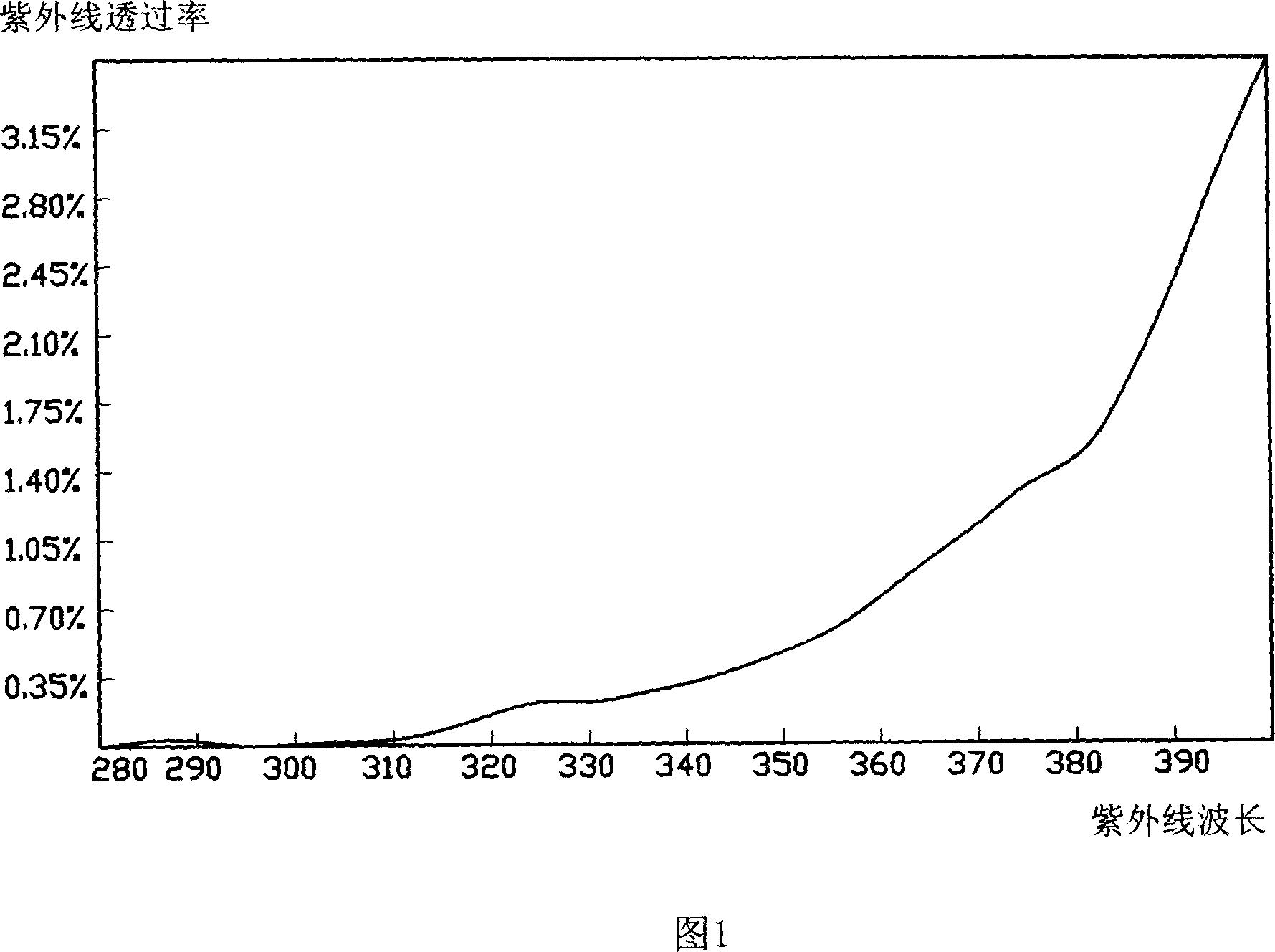

Imaginary powder type umbrella face fabric coating and coating method thereof

InactiveCN101063023ABright and beautifulImproves UV protectionCoatingsLinoleumMass ratioCross linker

The invention discloses a magic powder type umbrella lining coating and coating method, which comprises the following steps: dissolving 20-25% (mass ratio) magic powder with dissolvent; adding 55-60% PA liquid cement; stirring evenly; adding into 1-3% cross linker, 0. 5-1. 5% antisticking agent and dissolvent; controlling total quantity of the dissolvent at 14-20%; stirring evenly; forming spare glue X1; repeating the step; preparing glue X2; coating PA glue on the grey cloth; placing on machine bench; adjusting adze scraper to proper height; coating the X1 on the grey cloth; controlling the temperature between 120 deg. c and 130 deg. c; drying; coating the X2 on the face fabric; controlling the temperature at 135-145 deg. c; controlling the car speed at 40-55m / min; This invention possesses good effect of ultraviolet resistance.

Owner:HANGZHOU PARADISE UMBRELLA GROUP

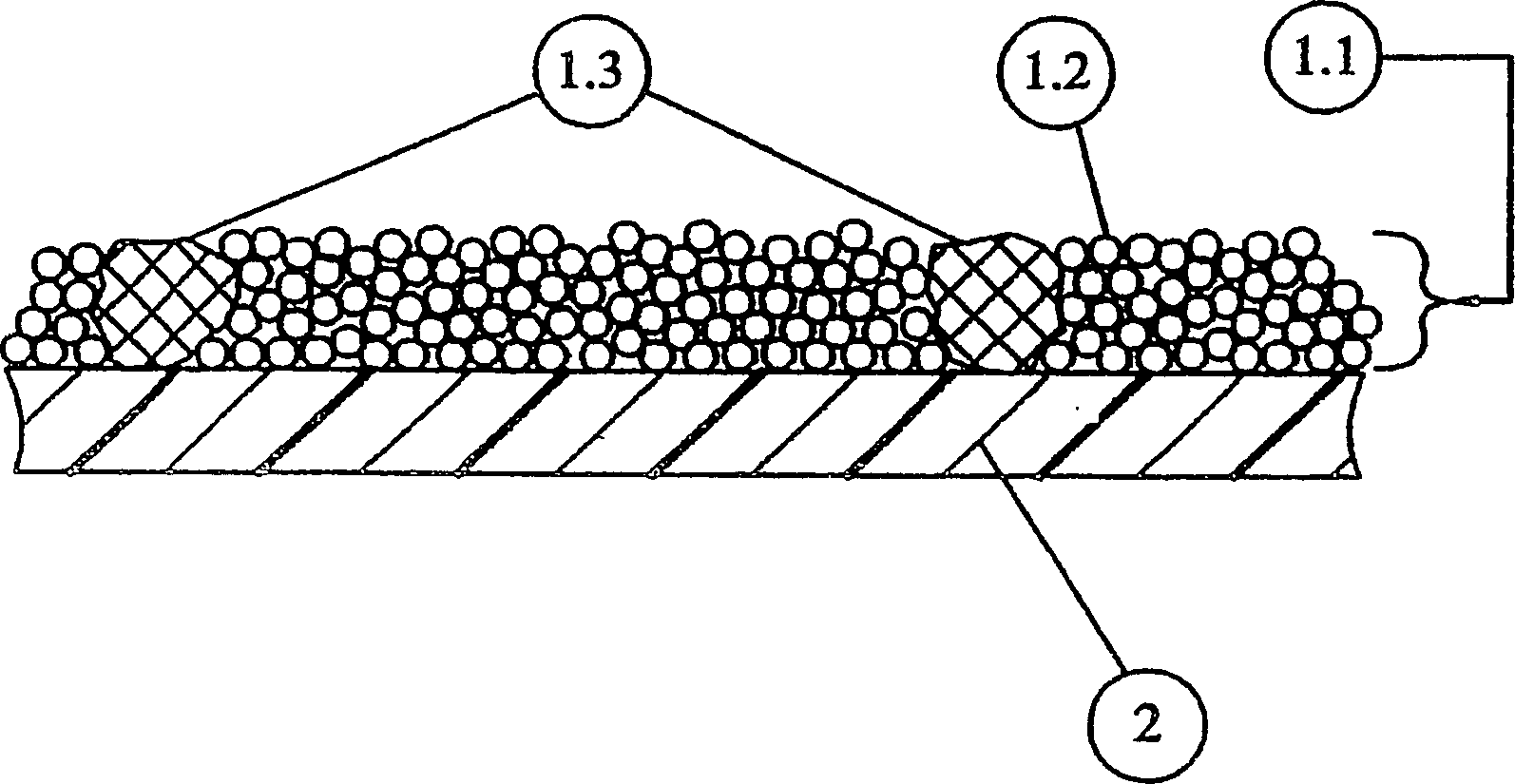

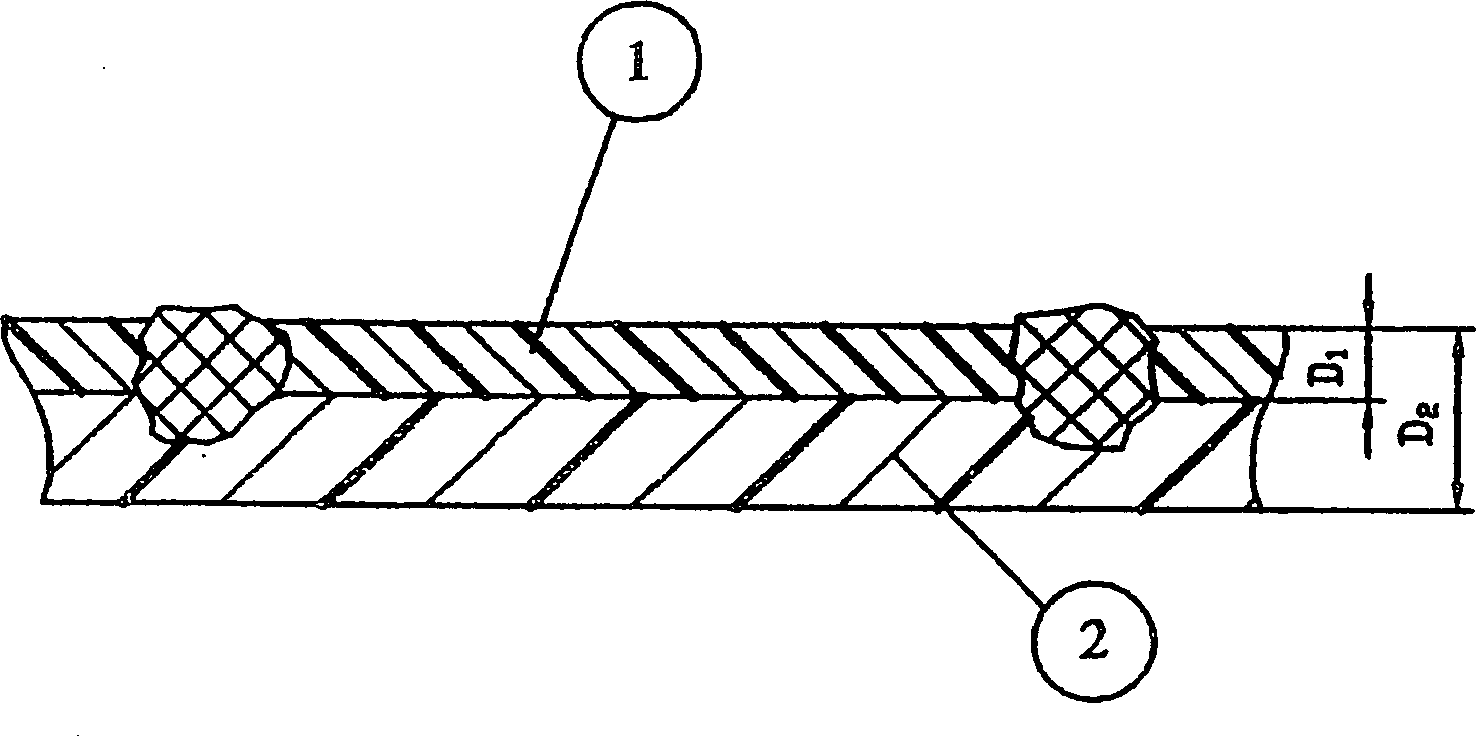

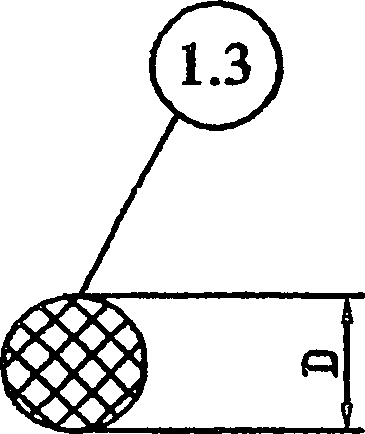

Floor covering

InactiveCN1277981CStrong reboundEasy to cleanCovering/liningsCellulosic plastic layered productsEngineeringUpper floor

The invention relates to a floor covering consisting of at least two interconnected layers, comprising an electrically conductive rubber lower layer (2) that is arranged below a light-coloured upper rubber layer (1). The upper layer (1) is perforated in partial sections that are distributed in a pattern over its surface with electrically conductive rubber being embedded in said sections. The upper layer (1) is created by pouring (1.1) first light-coloured particles (1.2), consisting of an electrically insulating rubber onto the lower layer and embedding second particles (1.3) therein, the latter consisting of electrically conductive rubber that is at least pre-vulcanised. The second particles (1.3) have a diameter D, which is determined by screen analysis and is at least equal to the thickness D1 of the upper layer and for practical purposes no greater than the sum of the thickness of the upper and lower layer D2. The first (1.2) and the second particles (1.3) are compressed together and with the lower layer (2) in a pore-free manner and are bonded by vulcanisation. At least one of the second particles (1.3) is present in a surface area unit of 31.7 cm2 of the floor covering, with the proviso that the surface area of the second particles (1.3) constitutes a maximum 50 % of the entire surface area of the floor covering.

Owner:NORA SYST

Thermoplastic molding compound, method for producing same, and use thereof

The invention relates to a thermoplastic molding compound, at least containing particles made of non-oxidatively polymerized vegetable oil, which is cross-linked via functional groups, as component (A), at least one thermoplastic polymer as component (B), optionally at least one resin as component (C), optionally at least one filler as component (D), and optionally further additives. The invention further relates to a method for producing same, and to the use thereof.

Owner:STYROLUTION EURO

Thermoplastic molding compound, method for producing same, and use thereof

The invention relates to a thermoplastic molding compound, at least containing particles made of non-oxidatively polymerized vegetable oil, which is cross-linked via functional groups, as component (A), at least one thermoplastic polymer as component (B), optionally at least one resin as component (C), optionally at least one filler as component (D), and optionally further additives. The invention further relates to a method for producing same, and to the use thereof.

Owner:STYROLUTION EURO

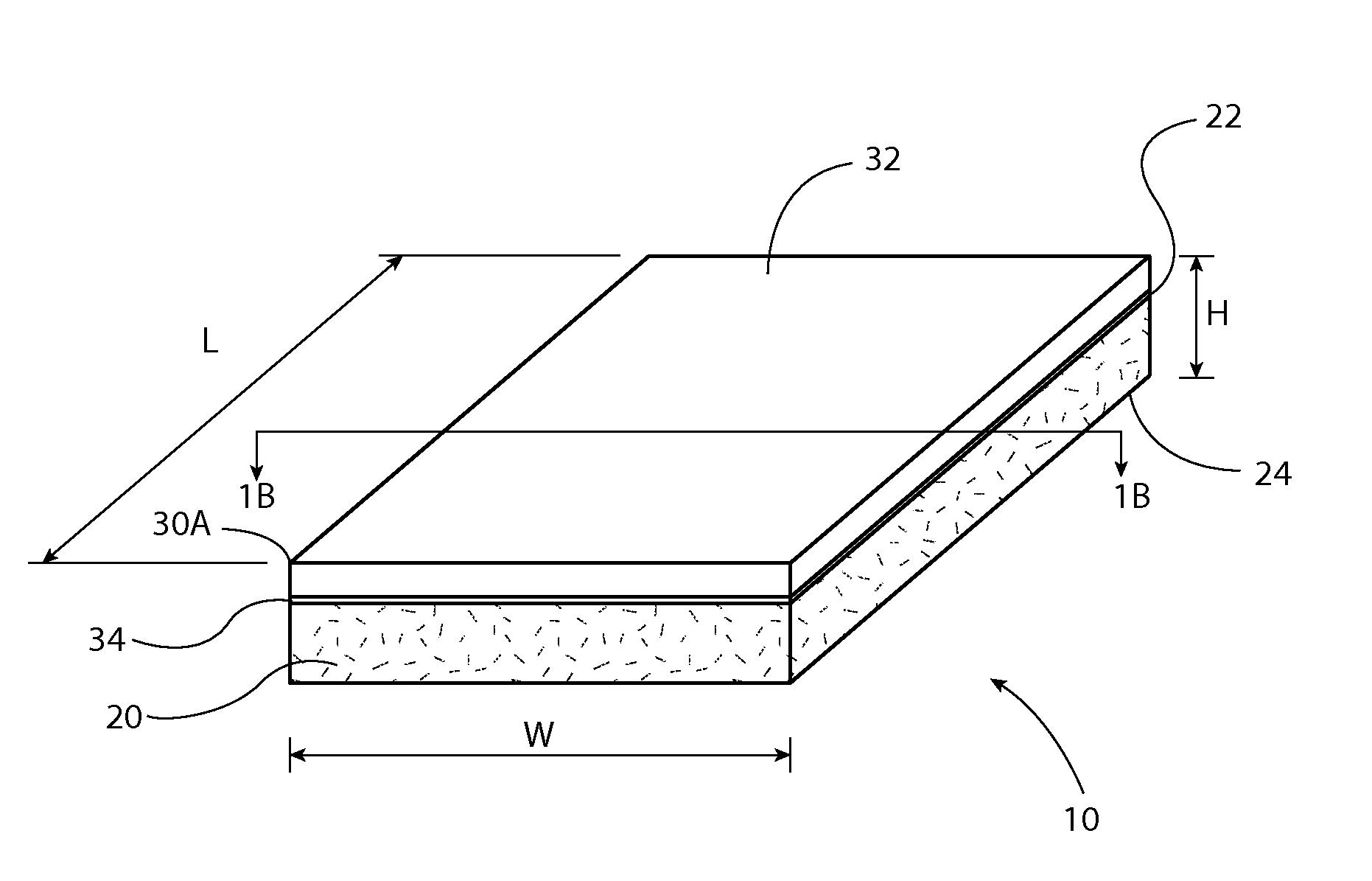

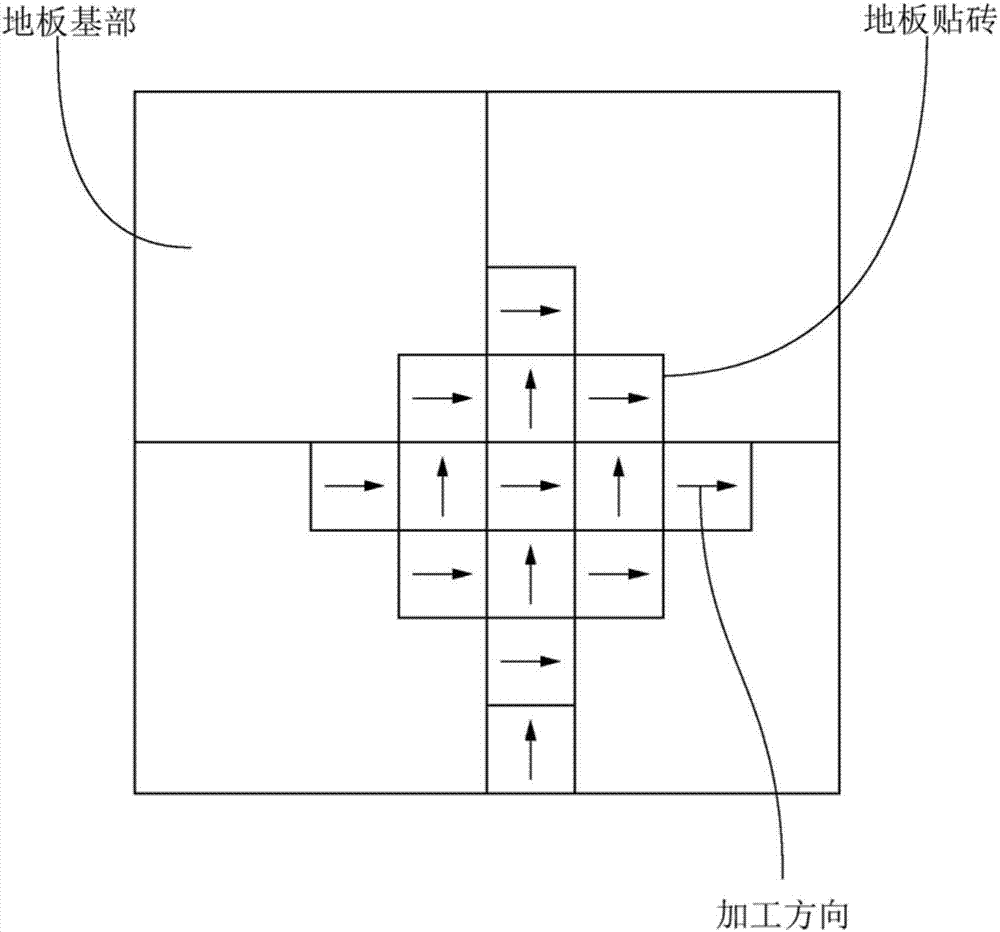

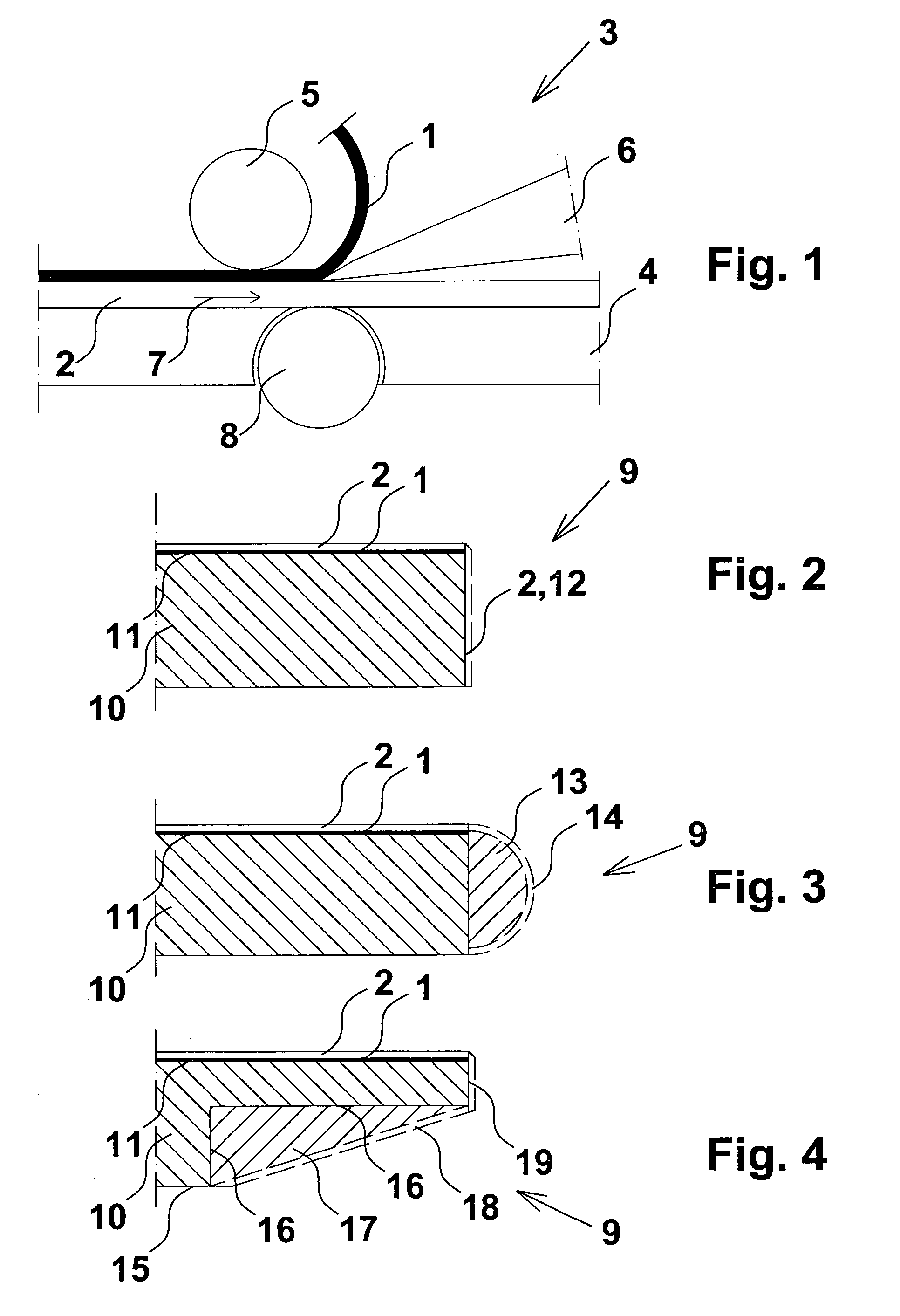

Linoleum based flooring with edge detail

Described herein are surface coverings comprising: a linoleum core; a top major surface having a first length and a first width, the top major surface terminating at a first edge; a bottom major surface having a second length and a second width, the bottom major surface terminating at a second edge; and a peripheral edge surface extending between the first and second edges, the peripheral edge surface being planar and oriented obliquely to the top and bottom major surfaces; wherein at least one of the first length or first width is smaller than the second length or second width respectively. Methods of making and using these surface coverings are also described.

Owner:AFI许可有限公司

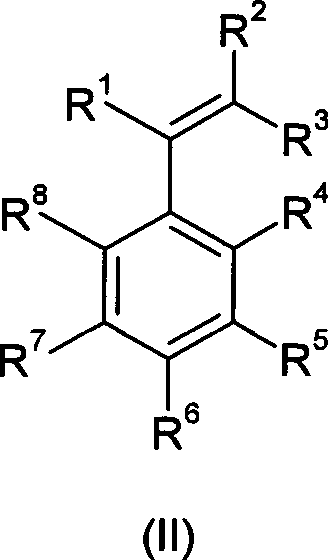

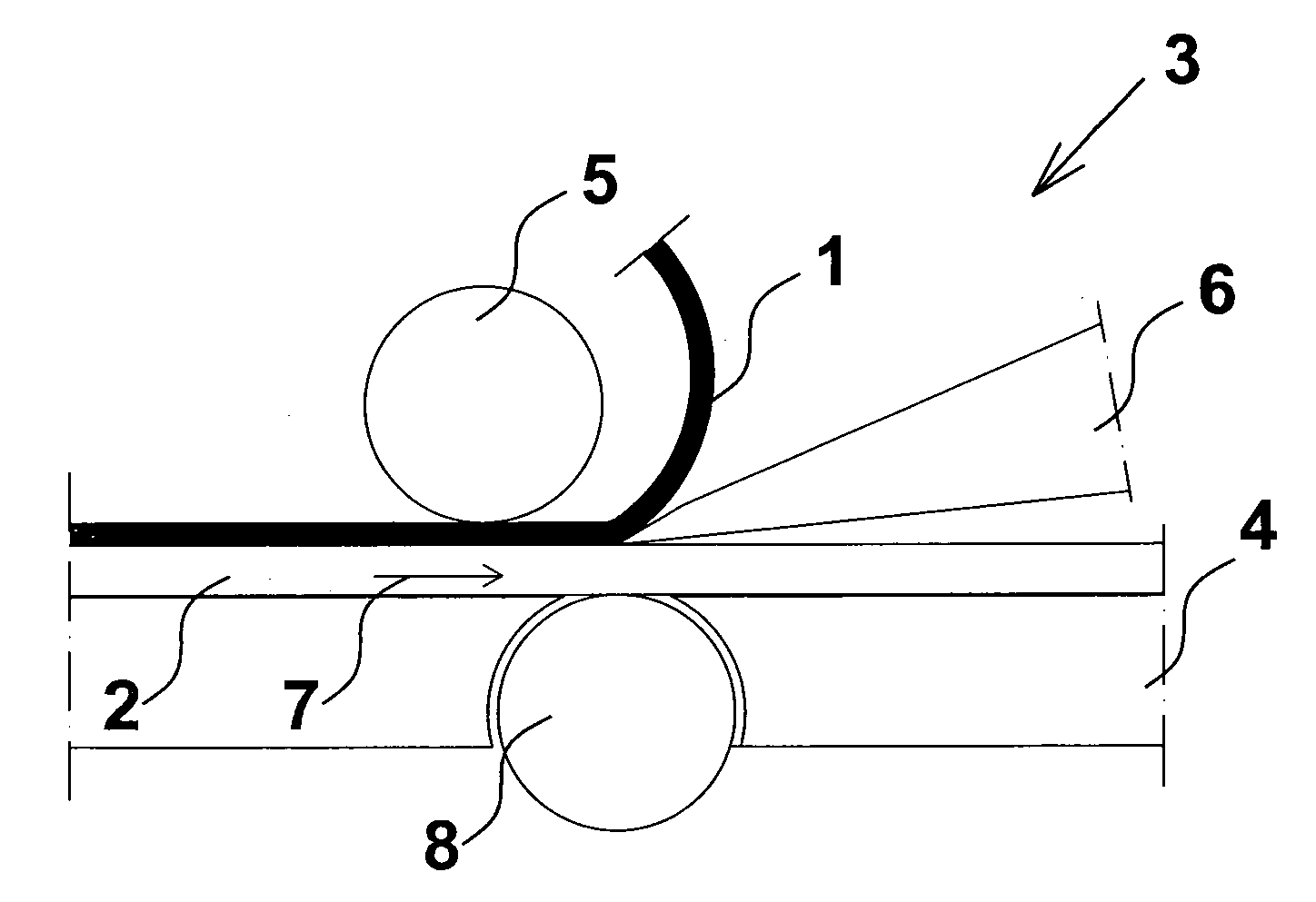

Linoleum covered plate where the edge of the plate is covered with linoleum band without base

A method where linoleum with a base is introduced in an apparatus, the linoleum conveyed on a working surface and advanced against a cutting edge, the cutting edge being arranged such that the linoleum, while moving in the apparatus, is separated from the base. By this method, an even back side is achieved on the linoleum band, making the band suited for further processing since no irregularities appear on the back side where the base is removed, and the front side is without any damages and scratches from the process. Linoleum from which the base has been removed according to this method contributes to a good finish on the produced linoleum covered edge, since the even back side propagates to the front side of the linoleum covered plate edge, which then appears even and has a good aesthetic effect, making it attractive.

Owner:WO PRODN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com