Water proof coating adaptable for cap fabric and cap produced thereby

A technology for waterproof coatings and hats, applied in the field of coatings, can solve problems such as inability to prevent moths, easily damaged fabrics, and lack of air permeability, and achieve the effects of avoiding ultraviolet rays, improving service life, and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

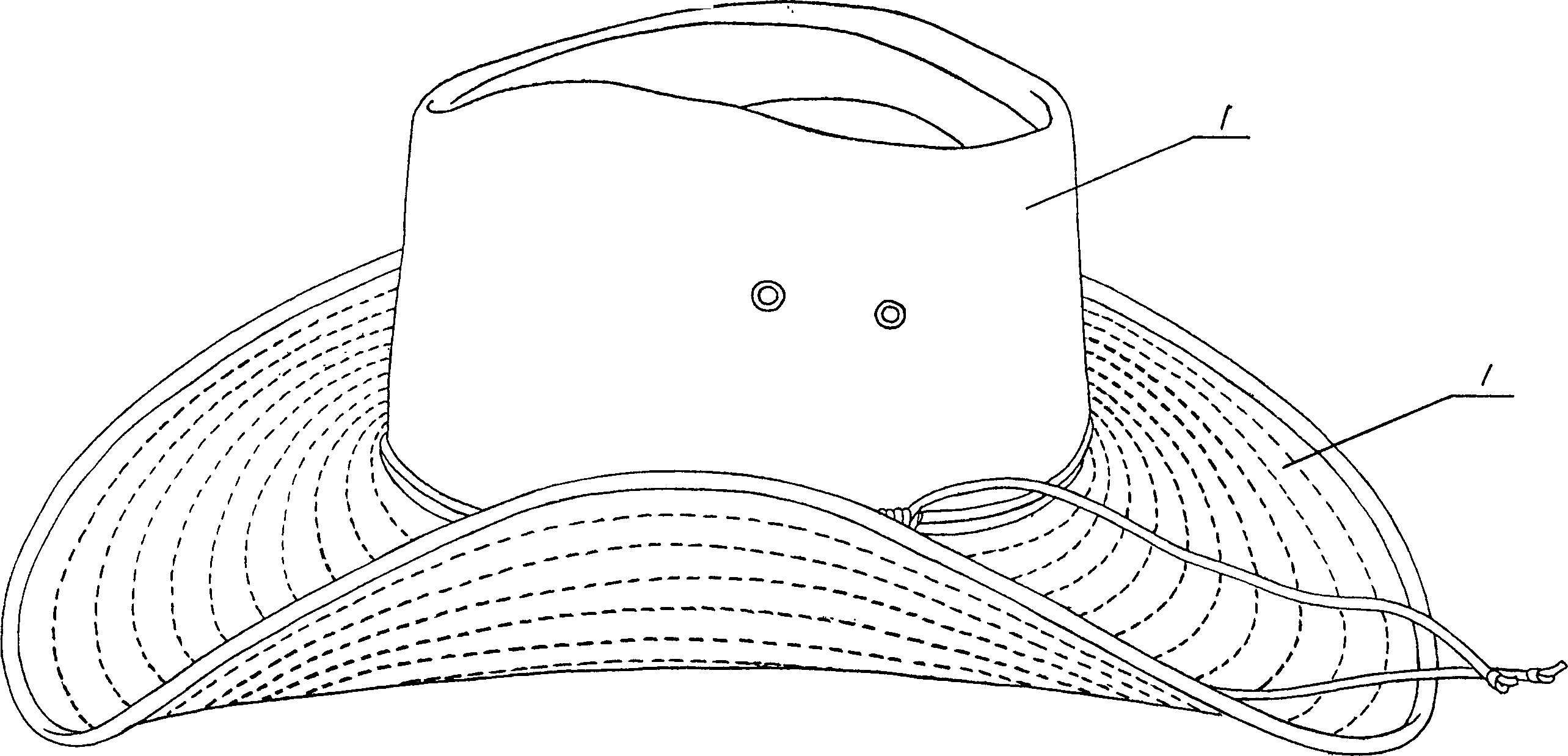

Image

Examples

Embodiment 1

[0016] Weigh 5 kg of paraffin and heat to melt. Then weigh 90 kilograms of Vaseline, 4 kilograms of silicone oil, and 1 kilogram of NuvaHPC, add them to the above-mentioned melted paraffin and mix them, fully stir them, shake them well, and then apply them on the outer surface of the hat body to form a protective layer.

Embodiment 2

[0018] Take by weighing 30 kilograms of paraffin, heating and melting. Weigh 50 kg of Vaseline, 10 kg of silicone oil, and 10 kg of Nuva HPC into the above-mentioned melted paraffin and mix, fully stir, and shake well to apply on the outer surface of the cap body to form a protective layer.

Embodiment 3

[0020] Take by weighing 16 kilograms of paraffin, heat and melt. Then weigh 70 kg of Vaseline, 8 kg of silicone oil, and 6 kg of NuvaHPC, add them to the above-mentioned melted paraffin and mix, fully stir, and shake well to apply on the outer surface of the cap body to form a protective layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com