Teflon varnished cloth

A technology of polytetrafluoroethylene and polytetrafluoroethylene layer, which is applied in the field of varnished cloth, can solve the problems of low insulation performance, anti-adhesive performance, poor use performance, etc., and achieve low cost, convenient production, good anti-adhesive and air-permeable performance Effect

Inactive Publication Date: 2014-10-08

包信海

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the existing food drying, chemical fertilizer packaging, textile anti-sticking, motor cable, medical, aerospace industries, most of them use non-woven fabrics and glass cloth for insulation, anti-sticking and ventilation, but their insulation performance and anti-sticking performance are low. poor performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] The present invention will be further described below in conjunction with embodiment.

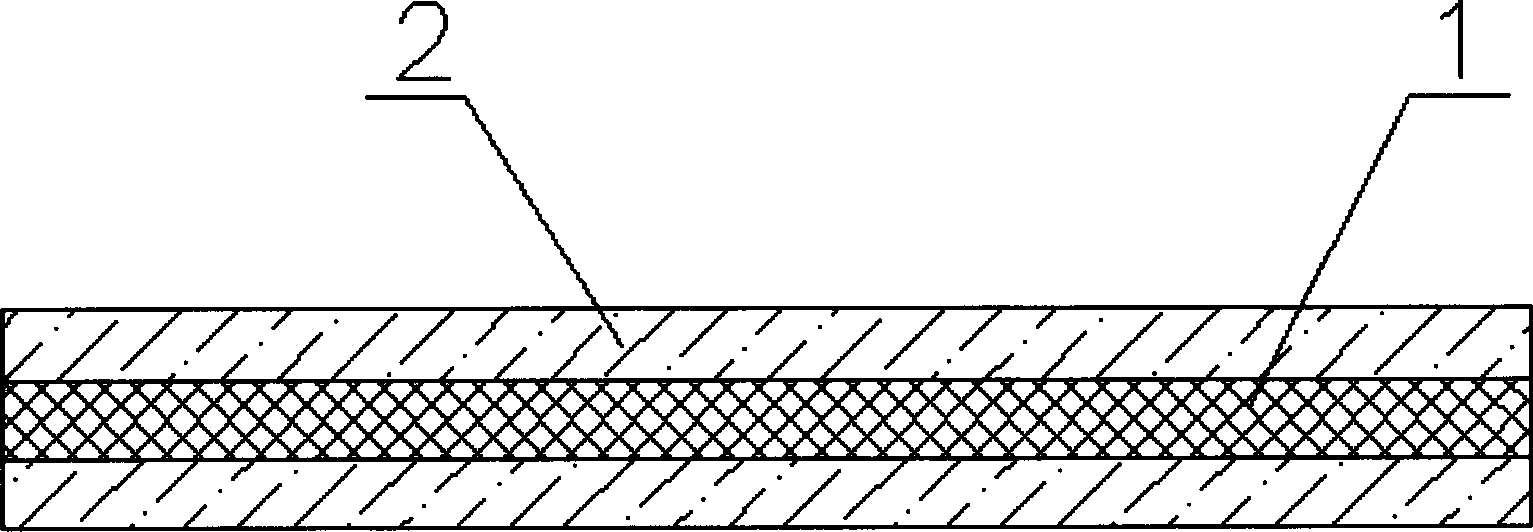

[0010] figure 1 The polytetrafluoroethylene varnish cloth shown includes an alkali-free glass cloth 1 and a polytetrafluoroethylene layer 2, and the polytetrafluoroethylene layer 2 covers both surfaces of the alkali-free glass cloth 1; the thickness of the polytetrafluoroethylene layer is 0.06-0.50mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a Teflon varnished cloth. The Teflon varnished cloth comprises an alkali-free glass cloth and a Teflon layer. The Teflon layer covers any one surface or two surfaces of the alkali-free glass cloth. The Teflon layer has thickness of 0.06-0.50mm. The alkali-free glass cloth is coated with the Teflon layer so that the Teflon varnished cloth is obtained. The Teflon varnished cloth has a simple structure, is prepared conveniently, and has a low cost and good insulation, antistick and ventilating performances.

Description

technical field [0001] The invention relates to a varnished cloth, specifically a polytetrafluoroethylene varnished cloth. Background technique [0002] In the existing food drying, chemical fertilizer packaging, textile anti-sticking, motor cable, medical, aerospace industries, most of them use non-woven fabrics and glass cloth for insulation, anti-sticking and ventilation, but their insulation performance and anti-sticking performance are low. Poor performance. Contents of the invention [0003] Aiming at the deficiencies in the prior art, the invention provides a polytetrafluoroethylene varnished cloth with simple structure, convenient manufacture, good insulation, anti-sticking and air permeability. [0004] The technical solution adopted in the present invention is: a polytetrafluoroethylene varnished cloth, which is characterized in that it includes an alkali-free glass cloth and a polytetrafluoroethylene layer, and the polytetrafluoroethylene layer covers any one s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06N1/00B32B27/06B32B17/02

Inventor 包信海

Owner 包信海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com