Floor covering

A ground and cladding technology, applied in the production field of the ground cladding, can solve the problems of expensive, regional geometric configuration and distribution restrictions, and achieve the effect of easy cleaning and improved appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

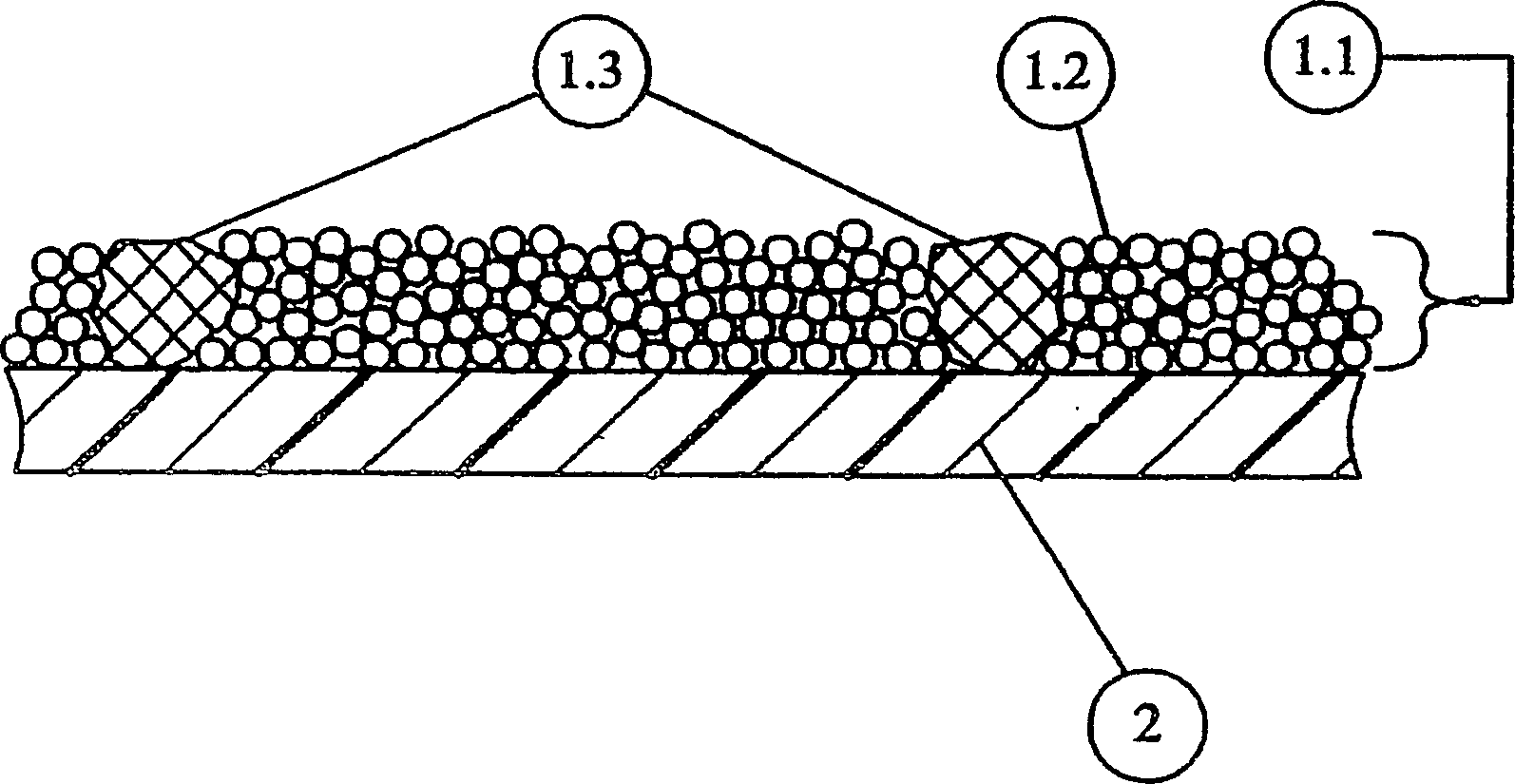

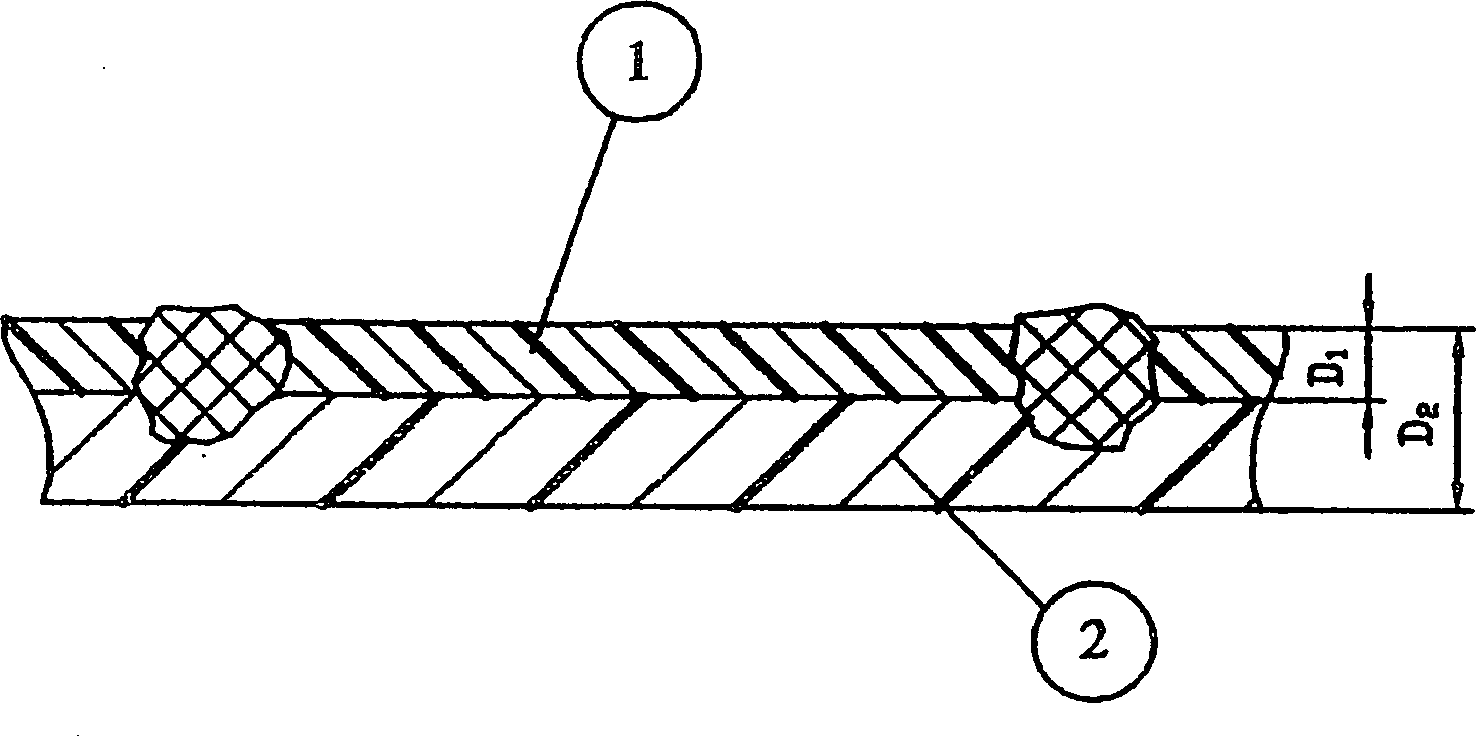

[0022] figure 2 The ground cladding shown in is formed in two layers. This does not preclude an invention in which the upper layer 1 and the lower layer 2 are connected to a base layer arranged below, and the base layer itself can also be made of a polymer or natural material.

[0023] In order to produce this floor covering, it is first envisaged that in the first step, a lower layer made of conductive material is formed. To this end, a rubber mixture composed of the following ingredients is put into a mixer and mixed evenly:

[0024] Butadiene-styrene (SBR) rubber

Glue

High styrene resin (65% styrene

Unit)

Carbon black N770

Chalk

Paraffin

Anti-aging agent

Dibenzothiazole disulfide

11.8%

5.6%

61.5%

14.9%

3.35%

0.7%

0.35%

0.35%

0.2%

0.2%

0.2%

0.85%

100%

[0025] Each of the above data refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com