Energy-saving and environment-friendly vibrating conveyer

A vibrating conveyor, energy-saving and environment-friendly technology, applied in the field of conveyors, can solve the problems of increased vibration weight, spilling in the air, short service life, etc., and achieve the reduction of requirements, friction reduction, and lower probability of secondary damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

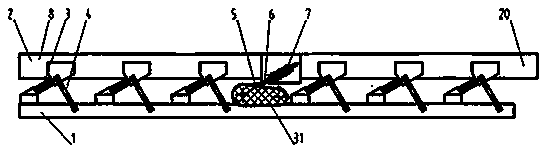

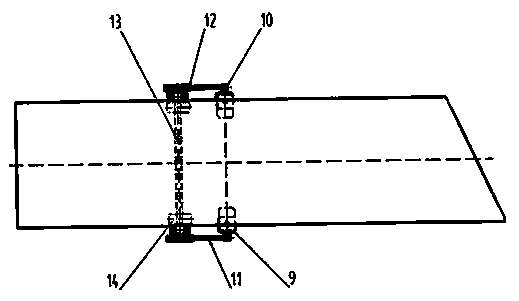

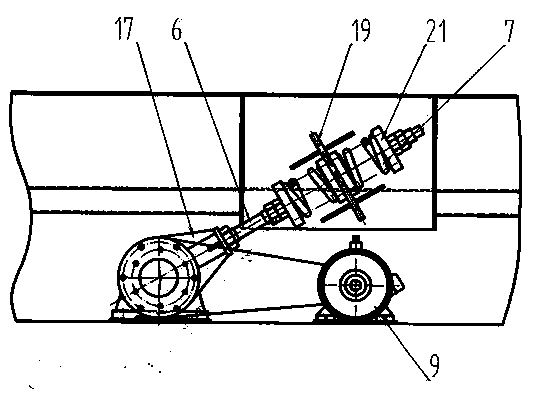

[0009] Embodiments are described in detail in conjunction with the above accompanying drawings, as figure 1 As shown, the tank body 2 is movably connected with the base 1 through the vibration damping support spring 3 and the plate guide support spring 4. The plate guide support spring and the vibration damping spring support spring are arranged in the lower part of the tank body in groups. The number of springs in each group It can be set according to the width and length of the tank (parameter weight). The angle between the centerlines of each group is 90 degrees. It is connected with the base 1 and the tank 2 by bolts and the pressure plate 36. The vibration-damping support spring Using a spiral steel pressure spring, the tank body can be opened or closed. One end of the tank body is the feed end 8, and the other end is the discharge end 20. The transmission device 5 is fixedly connected to the base 1, and the transmission device adopts What is more is motor 9, and describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com