Trampoline bamboo fiber table tennis racket bottom plate

The technology of table tennis racket and natural bamboo fiber is applied in the direction of racket, wooden veneer joint, sports accessories, etc., which can solve the problems of high price, short service life, unenvironmental protection of reinforcing materials such as carbon-aromatic blended glass fiber, etc. To achieve the effect of light weight, weight reduction and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

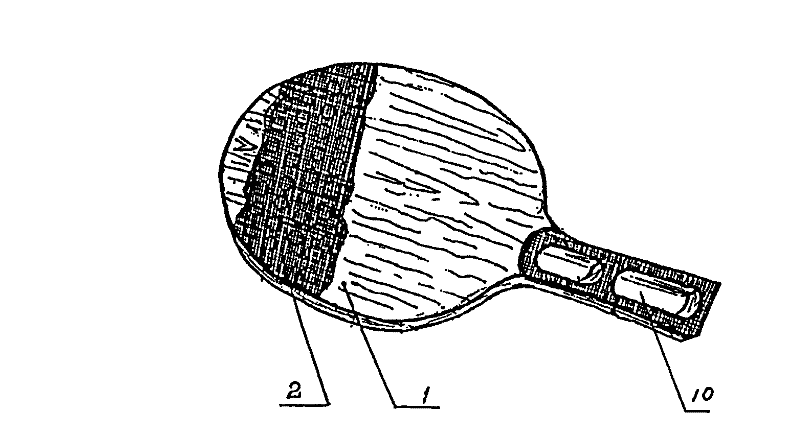

[0054] Embodiment 1: A kind of trampoline type bamboo fiber table tennis racket bottom plate with 7 layers of structure

[0055] The bottom plate of the table tennis racket is composed of a clapper and a handle, wherein the thickness of the clapper is 6.0-10mm, and it is composed of 7 layers of plates, including:

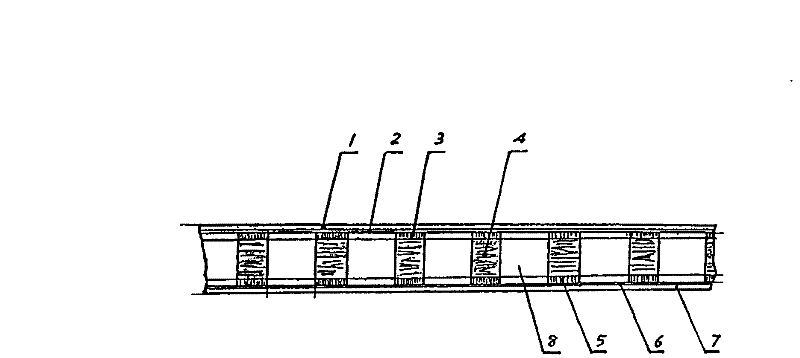

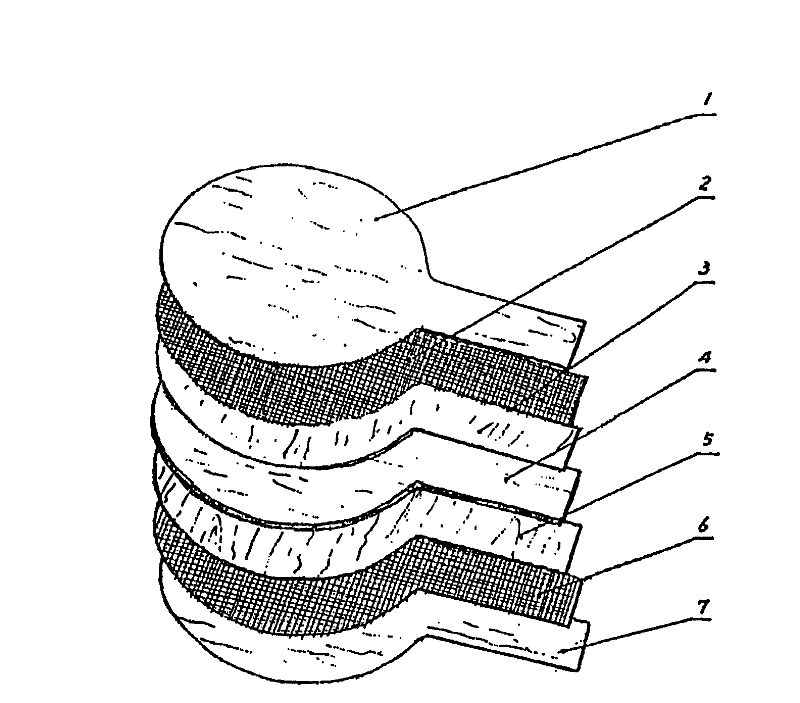

[0056] ① A central plank layer 4 of natural wood with a thickness of 3-5 mm and a longitudinal grain located on the central layer;

[0057] ②The upper veneer layer 3 fixed on the central thick veneer layer 4 and having a transverse grain natural wood thickness of 0.3-1.6 mm;

[0058] ③The lower veneer layer 5 is fixed under the central plank layer 4 and has a natural wood thickness of 0.3-1.6 mm with transverse texture;

[0059] The central thick plate layer 4, the upper thin plate layer 3 and the lower thin plate layer 5 form a composite core plate layer with a thickness of 3.6-8.2 mm, and a penetration hole with a diameter of Φ4.8 mm is evenly drilled on the comp...

Embodiment 2

[0065] Embodiment 2: a kind of trampoline formula bamboo fiber table tennis racket bottom plate with 9 layers of structure

[0066] The bottom plate of the table tennis racket is composed of a clapper and a handle, wherein the thickness of the clapper is 6.0-10mm, and it is composed of 9 layers of plates, including:

[0067] ① A central plank layer 4 of natural wood with a thickness of 3-5 mm and a longitudinal grain located on the central layer;

[0068] ②The upper veneer layer 3 fixed on the central thick veneer layer 4 and having a transverse grain natural wood thickness of 0.3-1.6 mm;

[0069] ③The lower veneer layer 5 is fixed under the central plank layer 4 and has a natural wood thickness of 0.3-1.6 mm with transverse texture;

[0070] The central thick plate layer 4, the upper thin plate layer 3 and the lower thin plate layer 5 form a composite core plate layer with a thickness of 3.6-8.2 mm, and a penetration hole with a diameter of Φ4.8 mm is evenly drilled on the c...

Embodiment 3

[0076] Embodiment 3: a kind of trampoline type bamboo fiber table tennis racket bottom plate with 11 layers of structure

[0077] The bottom plate of the table tennis racket is composed of a clapper plate and a handle, the thickness of the clapper plate is 6.0-10mm, and it is composed of 11 layers of plates, including:

[0078] ① The center plank layer 4 located at the center level, with a longitudinal grain natural wood thickness of 3-5mm;

[0079] ②The upper veneer layer 3 fixed on the central thick veneer layer 4 and having a transverse grain natural wood thickness of 0.3-1.6 mm;

[0080] ③The lower veneer layer 5 is fixed under the central plank layer 4 and has a natural wood thickness of 0.3-1.6 mm with transverse texture;

[0081] The central thick plate layer 4, the upper thin plate layer 3 and the lower thin plate layer 5 form a composite core plate layer with a thickness of 3.6-8.2 mm, and a penetration hole with a diameter of Φ4.8 mm is evenly drilled on the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com