Thermoplastic molding compound, method for producing same, and use thereof

A technology of thermoplastic molding and thermoplastic polymers, applied in textiles and papermaking, fiber treatment, varnished cloth, etc., can solve the problems of linoleum linoleum smell, linoleum is easily damaged by alkali, chemical degradation, unsuitability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

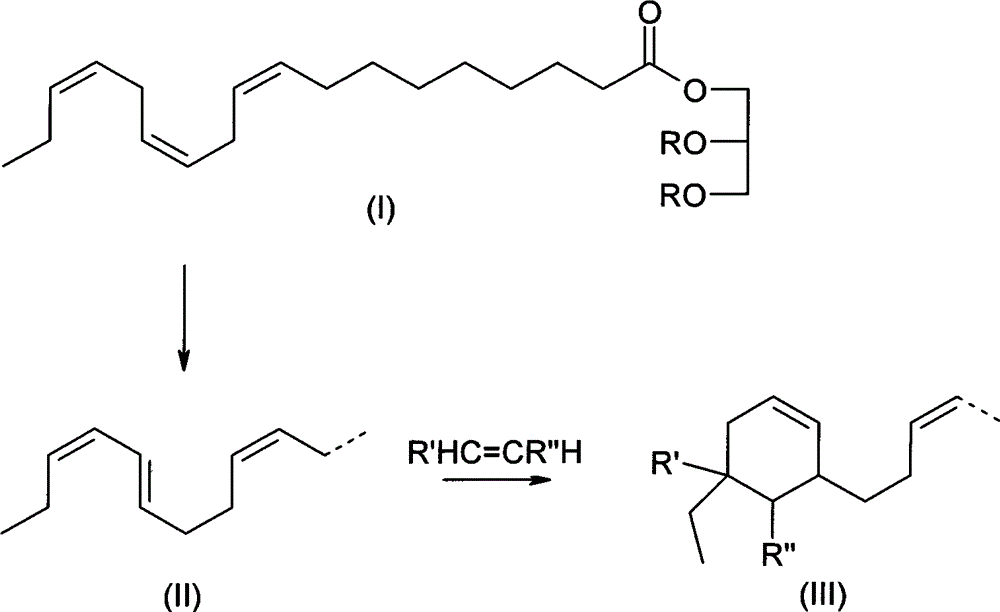

Method used

Image

Examples

Embodiment

[0283] Two experiments based on PS and SAN respectively are described below. Table 1 summarizes the variation of the trials.

[0284] Table 1:

[0285]

[0286] Maleation: 10% (w / w) maleic anhydride based on linseed oil. The expected conversion rate is 65%.

[0287] Crosslinking: Crosslinkers were calculated based on 65% conversion of the maleation reaction.

[0288] Pentaerythritol (4-OH): 1 / 4 equimolar amount of maleic anhydride, 1,4-butanediol (2-OH): 1 / 2 equimolar amount of maleic anhydride

[0289] BUNA-SAN: BUNA565SIC grafted onto styrene (76) / acrylonitrile (24). Only soluble fractions are used in this assay. The grafted rubber contained about 30% (w / w) free SAN copolymer, calculated as part of the matrix.

[0290] Rotation rate: The rotation rate of the List reactor is based on the gearbox, and the maximum reaches 3000rpm. The conversion was calculated to be a rotation rate of 332 rpm for the cleaning shaft and 83 rpm for the agitator shaft.

[0291] Equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com