Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124 results about "Continuous emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A continuous emission monitoring system (CEMS) is the total equipment necessary for the determination of a gas or particulate matter concentration or emission rate using pollutant analyzer measurements and a conversion equation, graph, or computer program to produce results in units of the applicable emission limitation or standard.

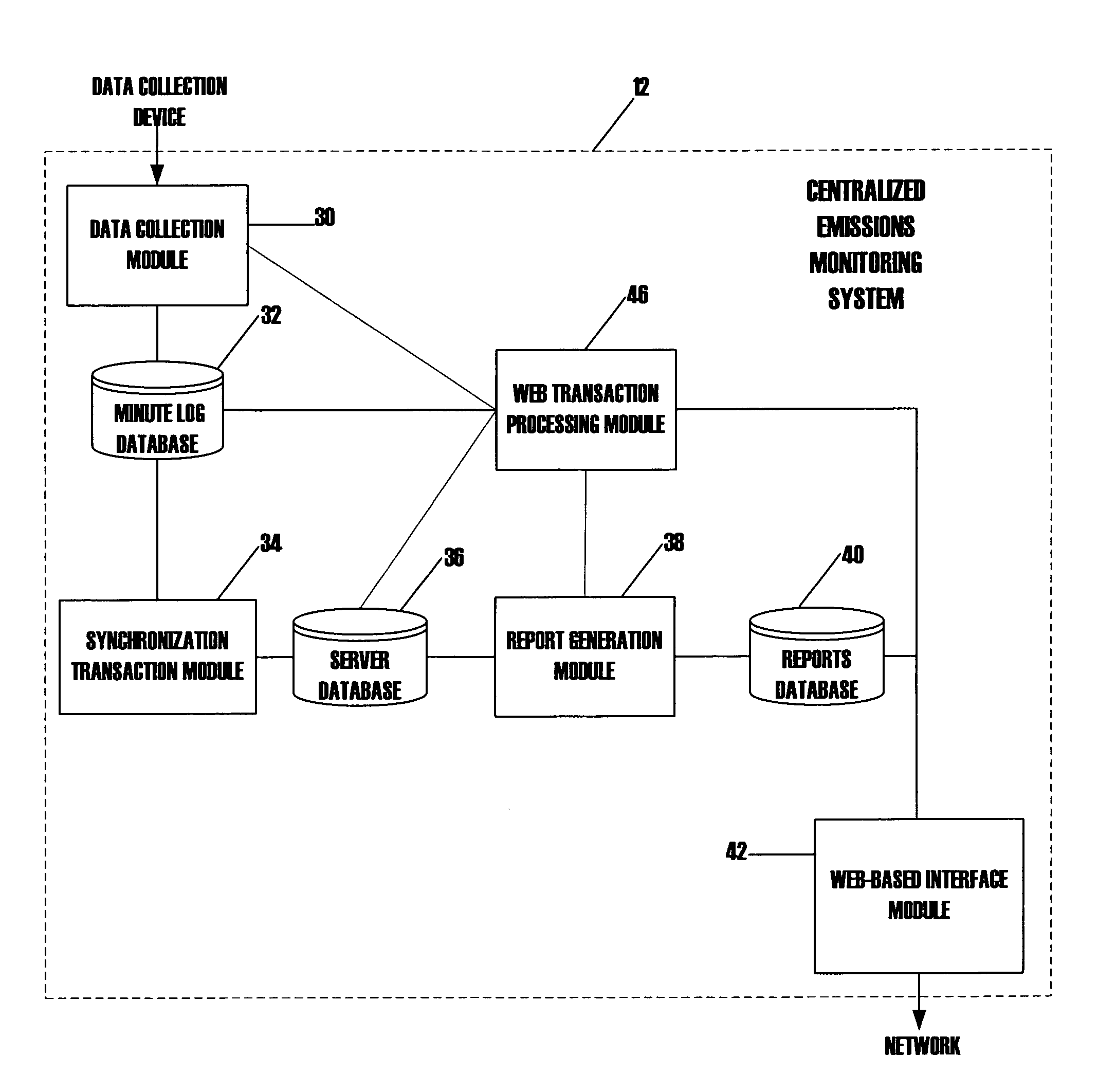

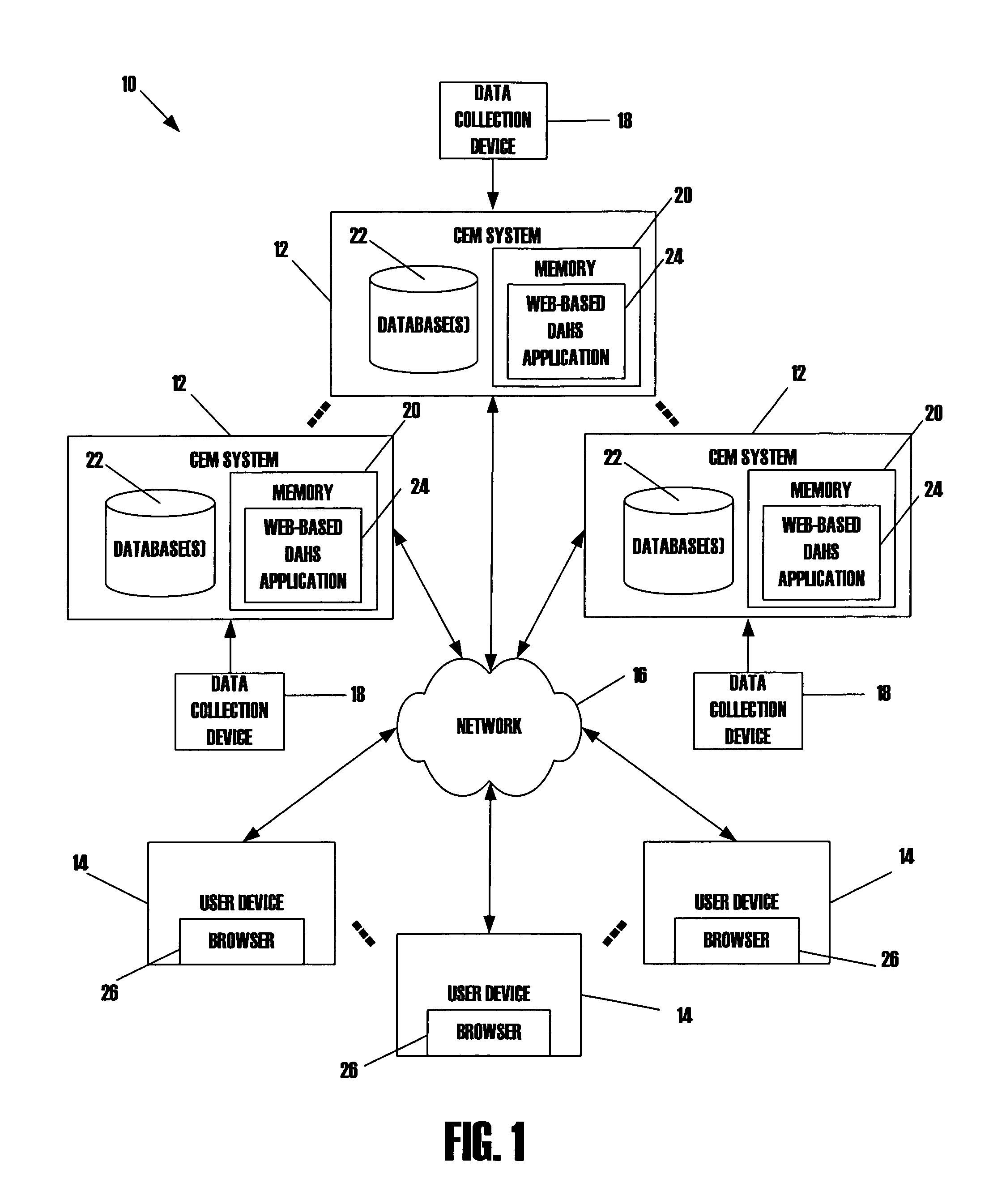

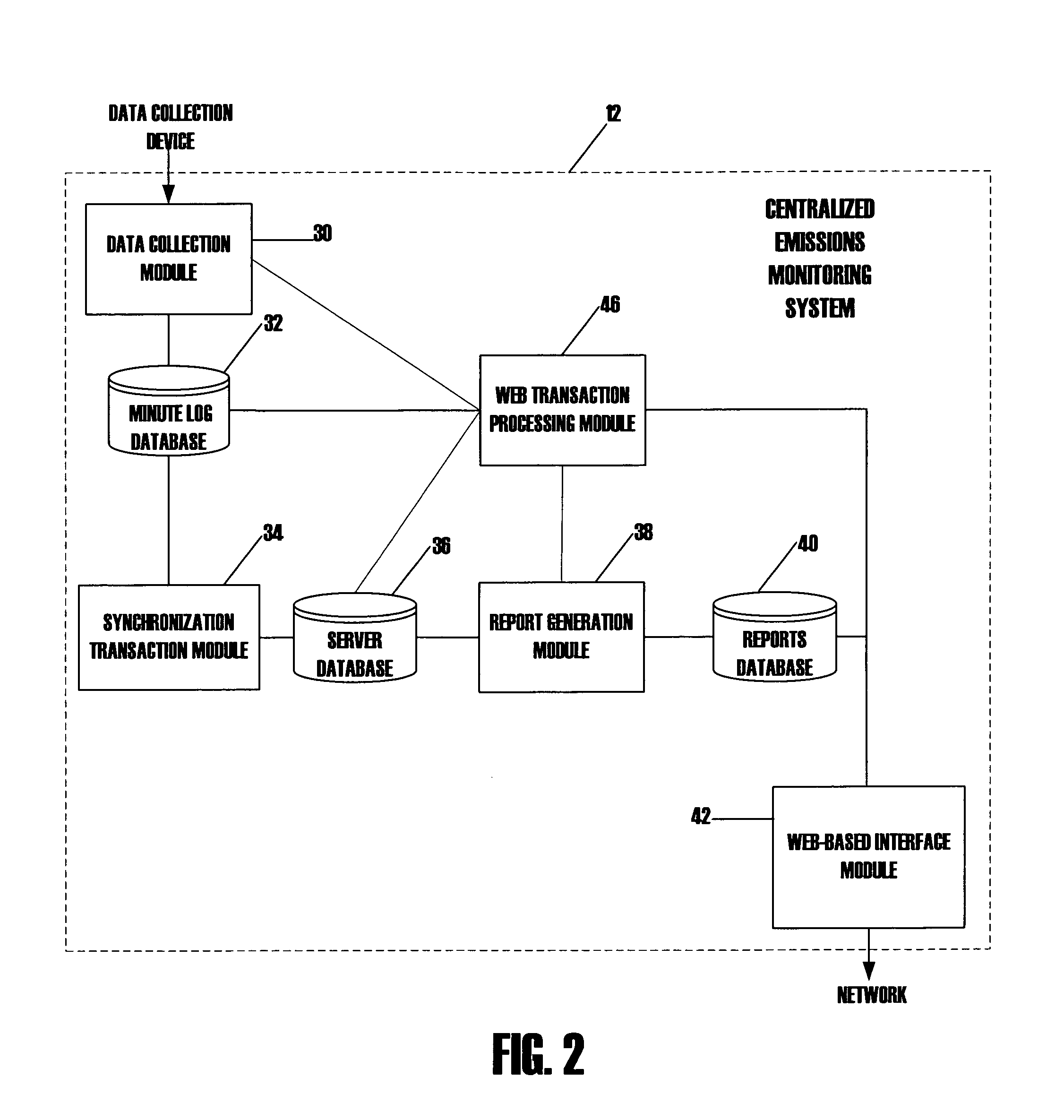

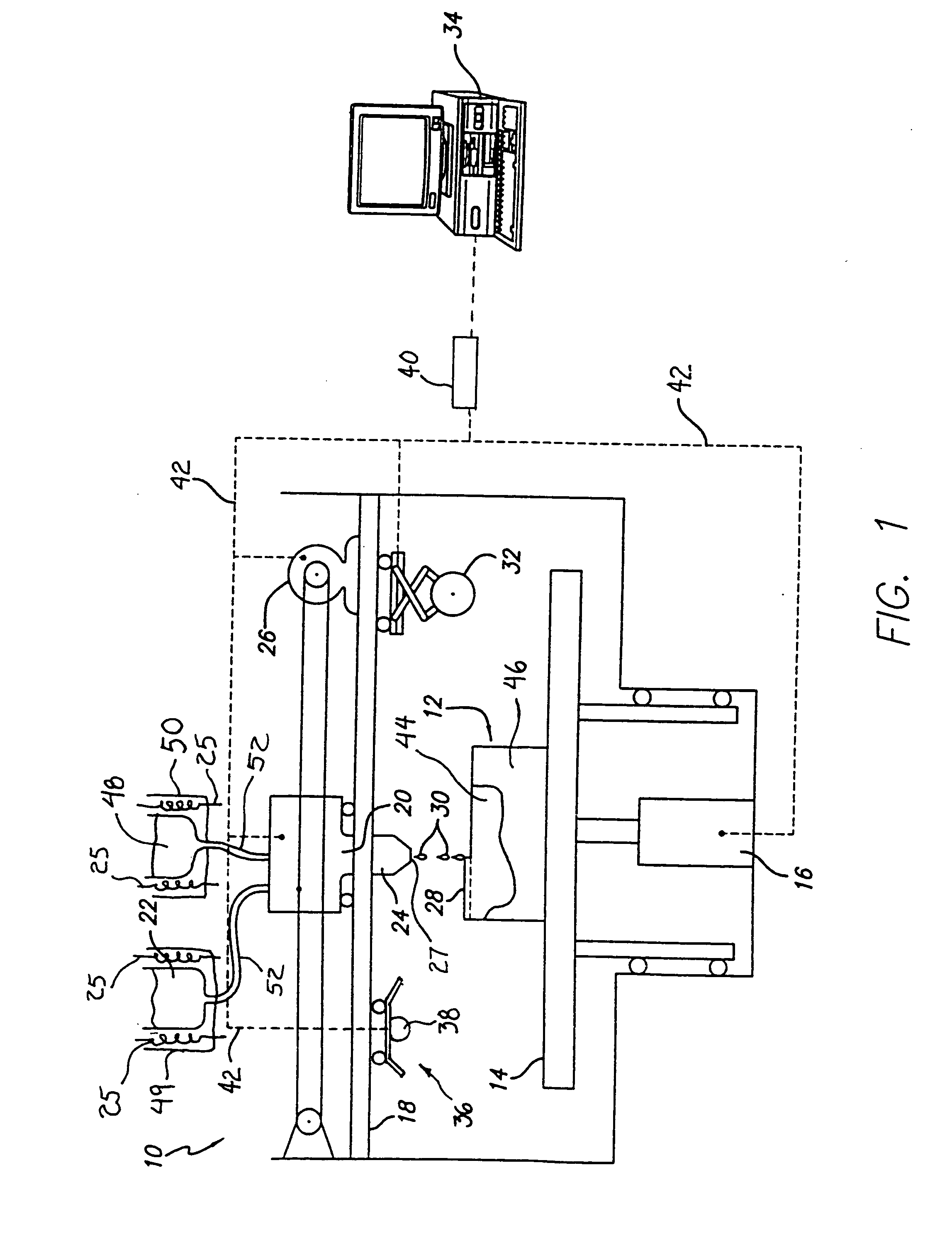

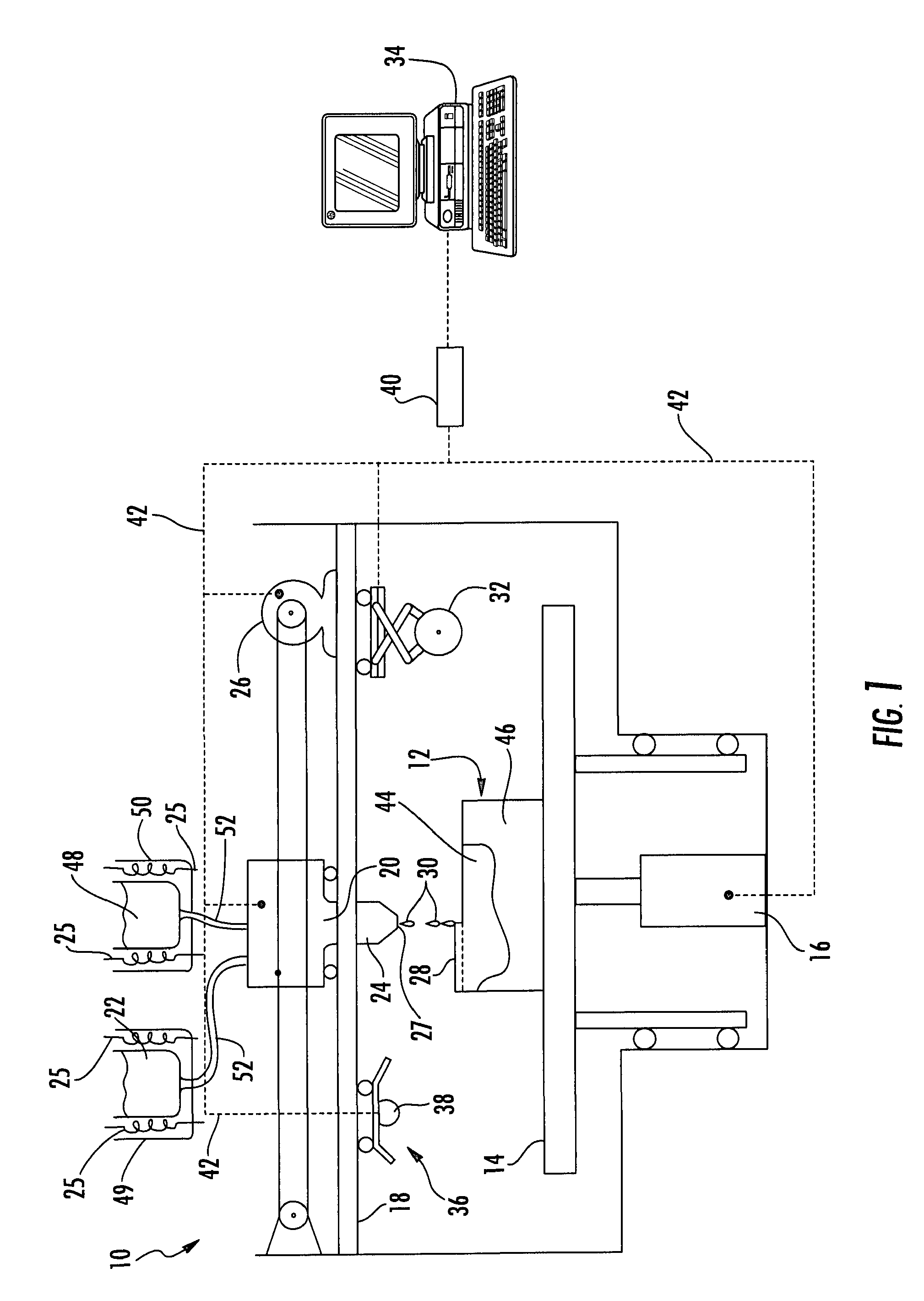

Systems, methods and computer program products for continuous emissions monitoring on-line

InactiveUS7181320B2Improve scalabilityEasy accessLevel controlMachines/enginesPower stationApplication software

Systems, methods and computer program products provide secure access to real-time emissions data from one or more power generating plants via a web-based interface. The user provides log-in information to gain a predefined level of access based on the inputted log-in information, and may access emissions data of one or more power generating plants located remotely with respect to the user. The user can utilize any suitable computing device with a suitable browser application to access the emissions data. Accordingly, the system is highly scalable, in both users and power generating plants being monitored.

Owner:THE BABCOCK & WILCOX CO

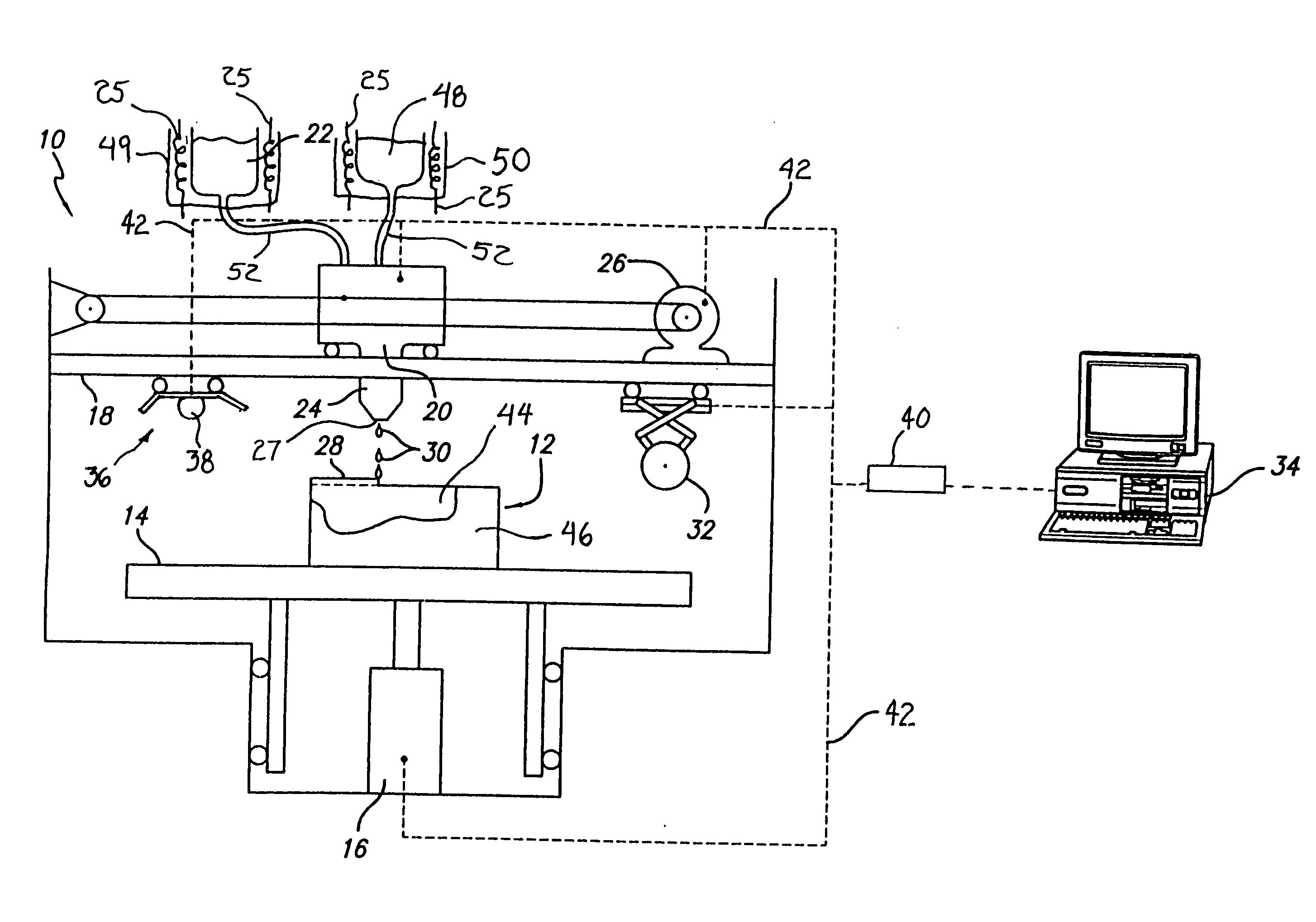

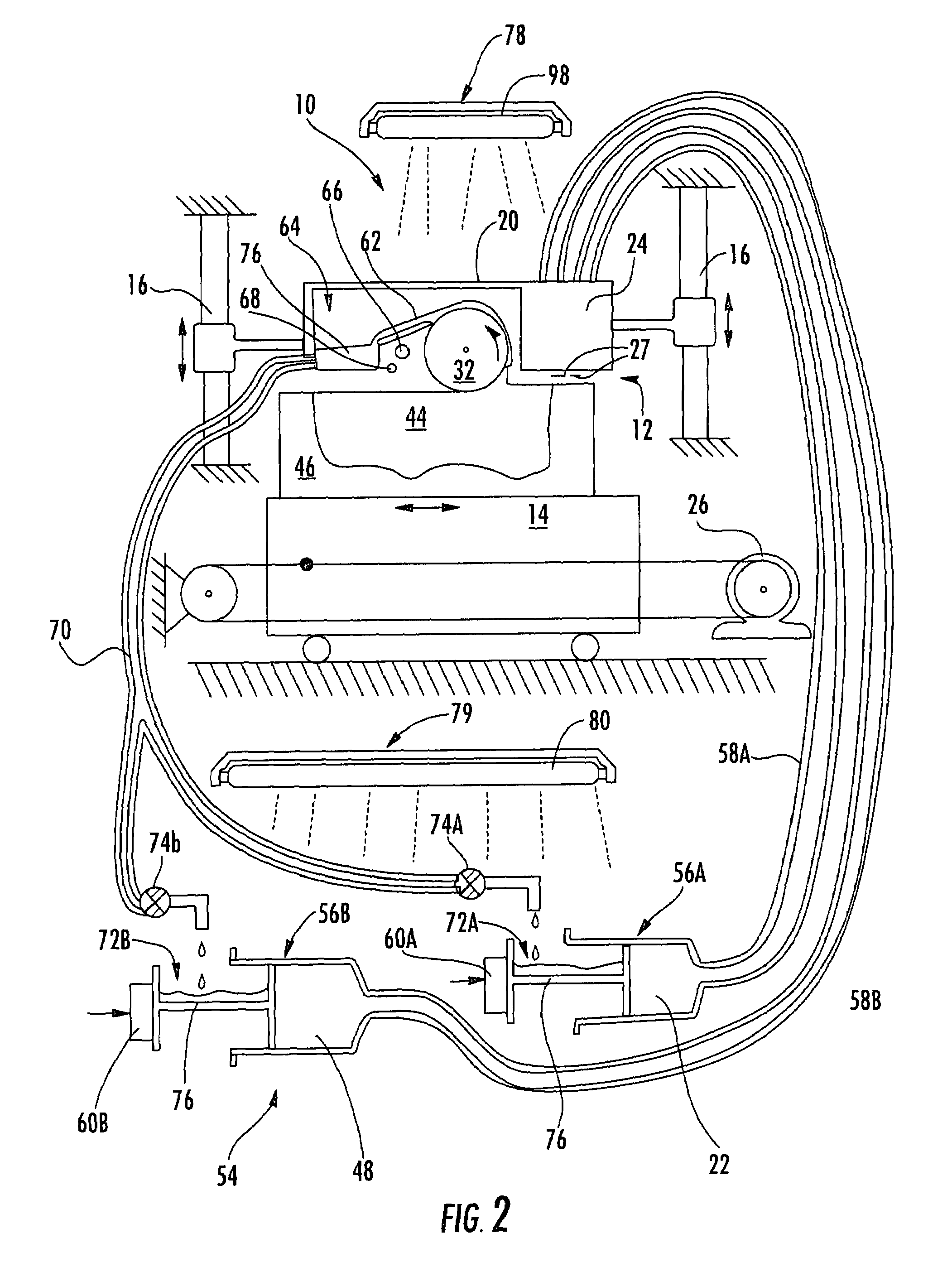

Flash curing in selective deposition modeling

InactiveUS20050253308A1Reduce heatReduce power consumptionAdditive manufacturing apparatusWood working apparatusSelective depositionOxygen

A flash curing system for solid freeform fabrication which generates a plurality of radiation emitting pulses that forms a planar flash. The planar flash initiates curing of a curable material dispensed by a solid freeform fabrication apparatus. The radiation emitting pulses have a high peak power value that releases a sufficient quantity of free radicals from the photoinitiator to initiate curing and overcome the problem of oxygen inhibition. Substantially less power is consumed and less heat generated by the flash curing system compared to conventional continuous emission curing systems.

Owner:3D SYST INC

Flash curing in selective deposition modeling

InactiveUS7270528B2Reduce heatReduce power consumptionAdditive manufacturing apparatusConfectionerySelective depositionPhotoinitiator

A flash curing system for solid freeform fabrication which generates a plurality of radiation emitting pulses that forms a planar flash. The planar flash initiates curing of a curable material dispensed by a solid freeform fabrication apparatus. The radiation emitting pulses have a high peak power value that releases a sufficient quantity of free radicals from the photoinitiator to initiate curing and overcome the problem of oxygen inhibition. Substantially less power is consumed and less heat generated by the flash curing system compared to conventional continuous emission curing systems.

Owner:3D SYST INC

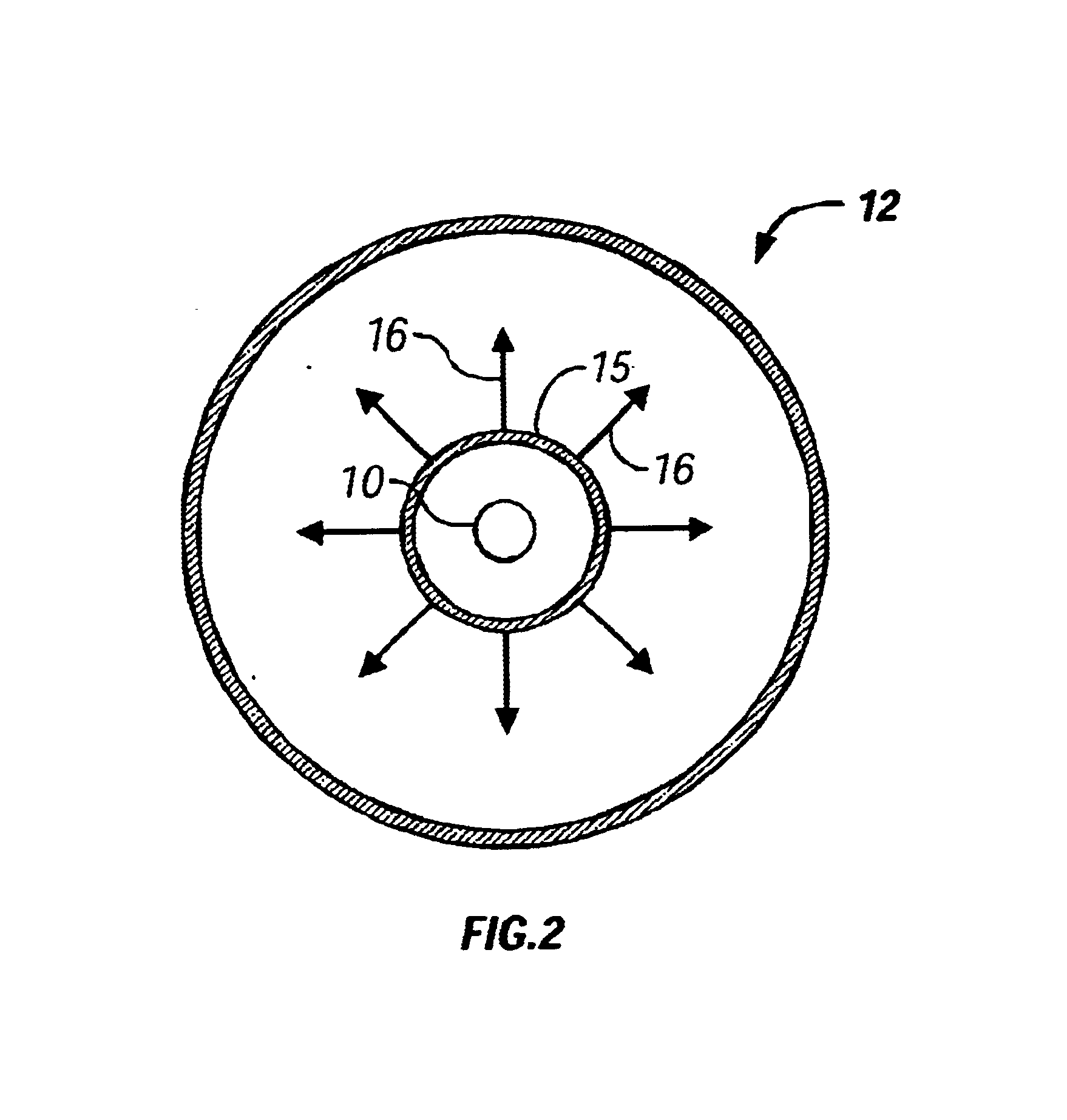

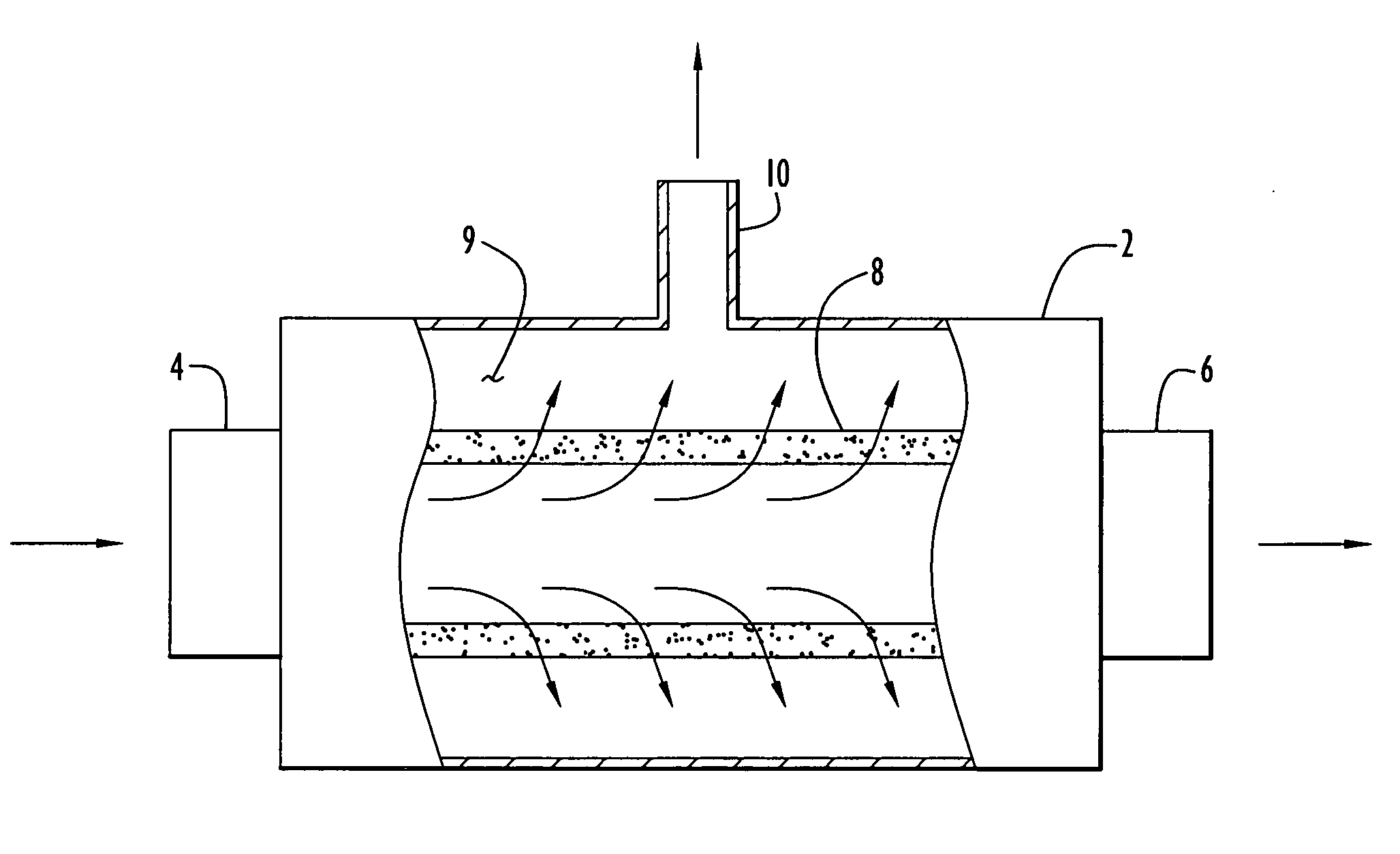

Spent catalyst distributor

The present invention is related to methods and apparatus for improving distributions of both spent catalyst and transport gas into a regenerator of a fluid catalytic cracking unit. Spent catalyst and transport gases move upwardly through a spent catalyst riser and are diverted in a radially outward direction by a deflector cone. The catalyst and transport gas are re-mixed as they move radially outward between two disks before discharging from the outer edges (perimeter) of the distributor into the regenerator in a substantially uniform radial direction. The distributor is adapted to provide continuous discharge from its perimeter so as to cover the entire cross-section of the regenerator.

Owner:SHELL OIL CO

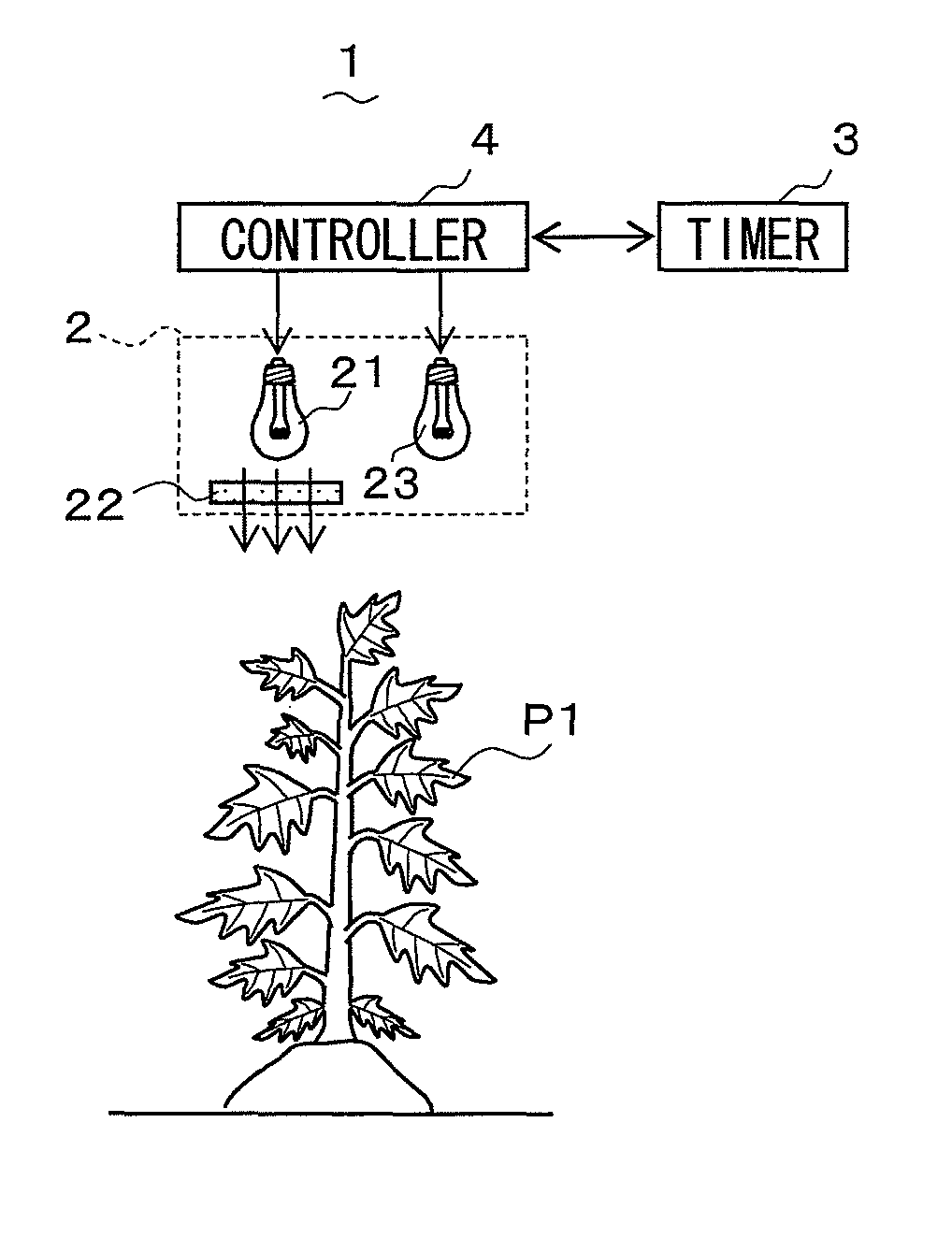

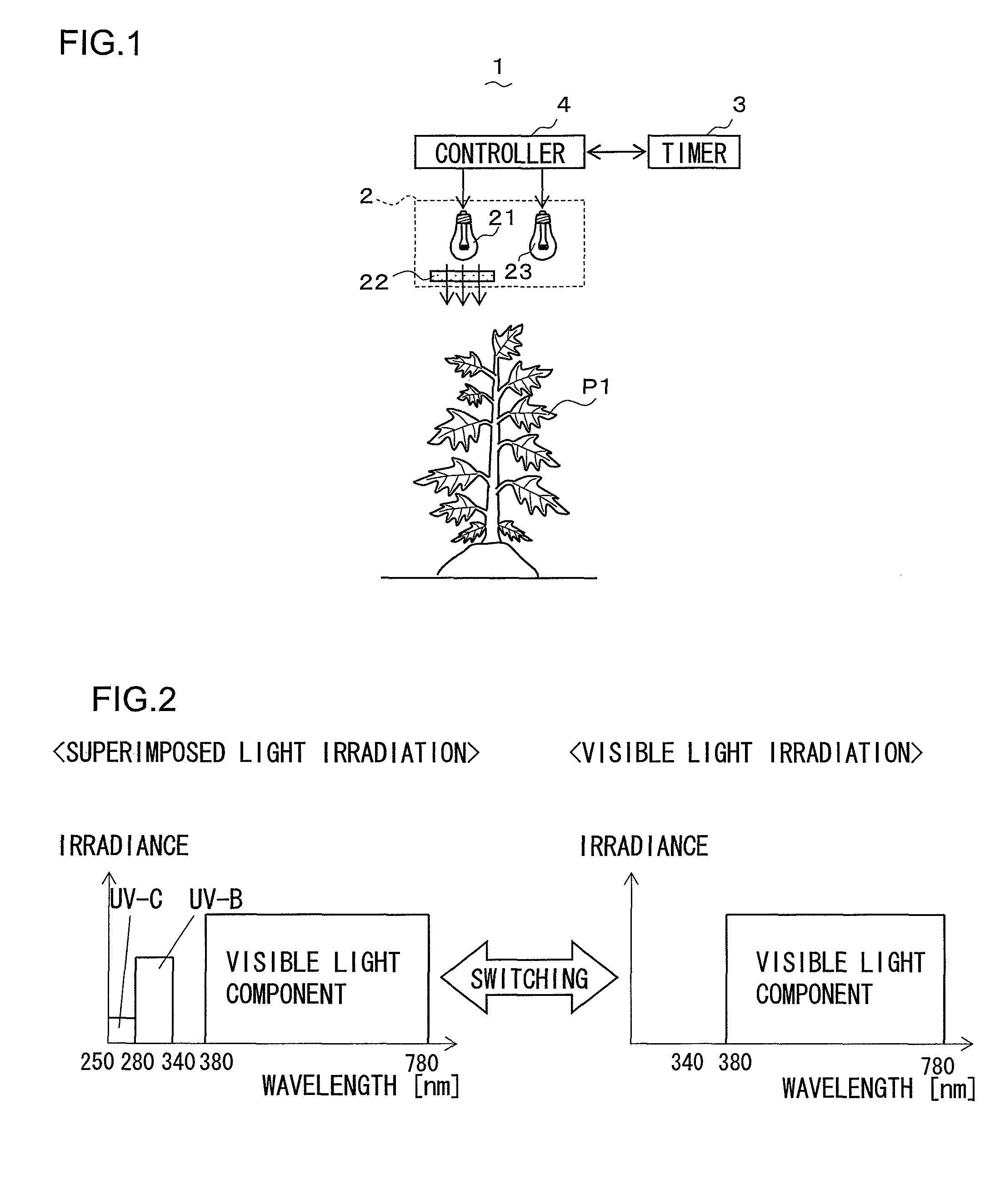

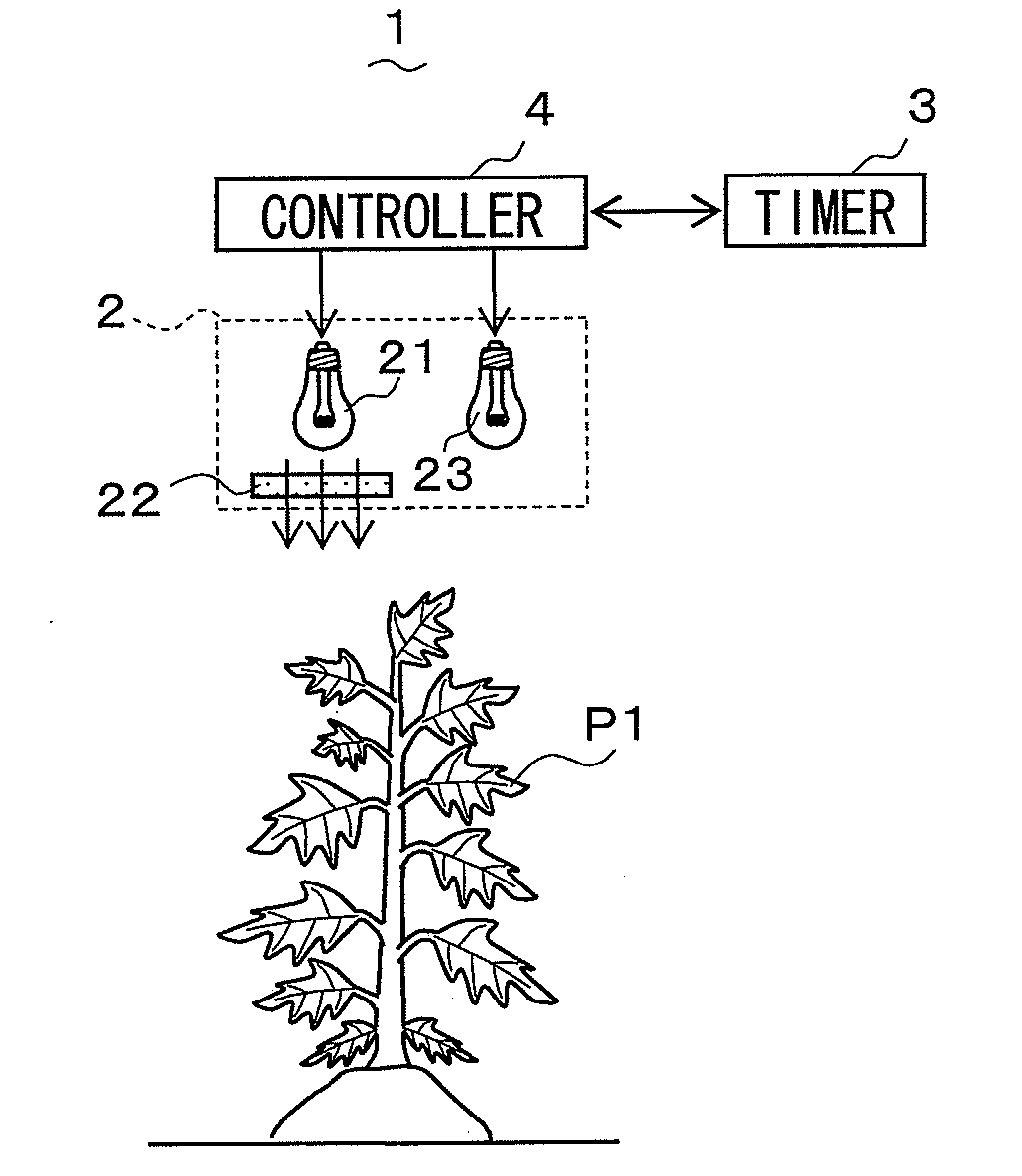

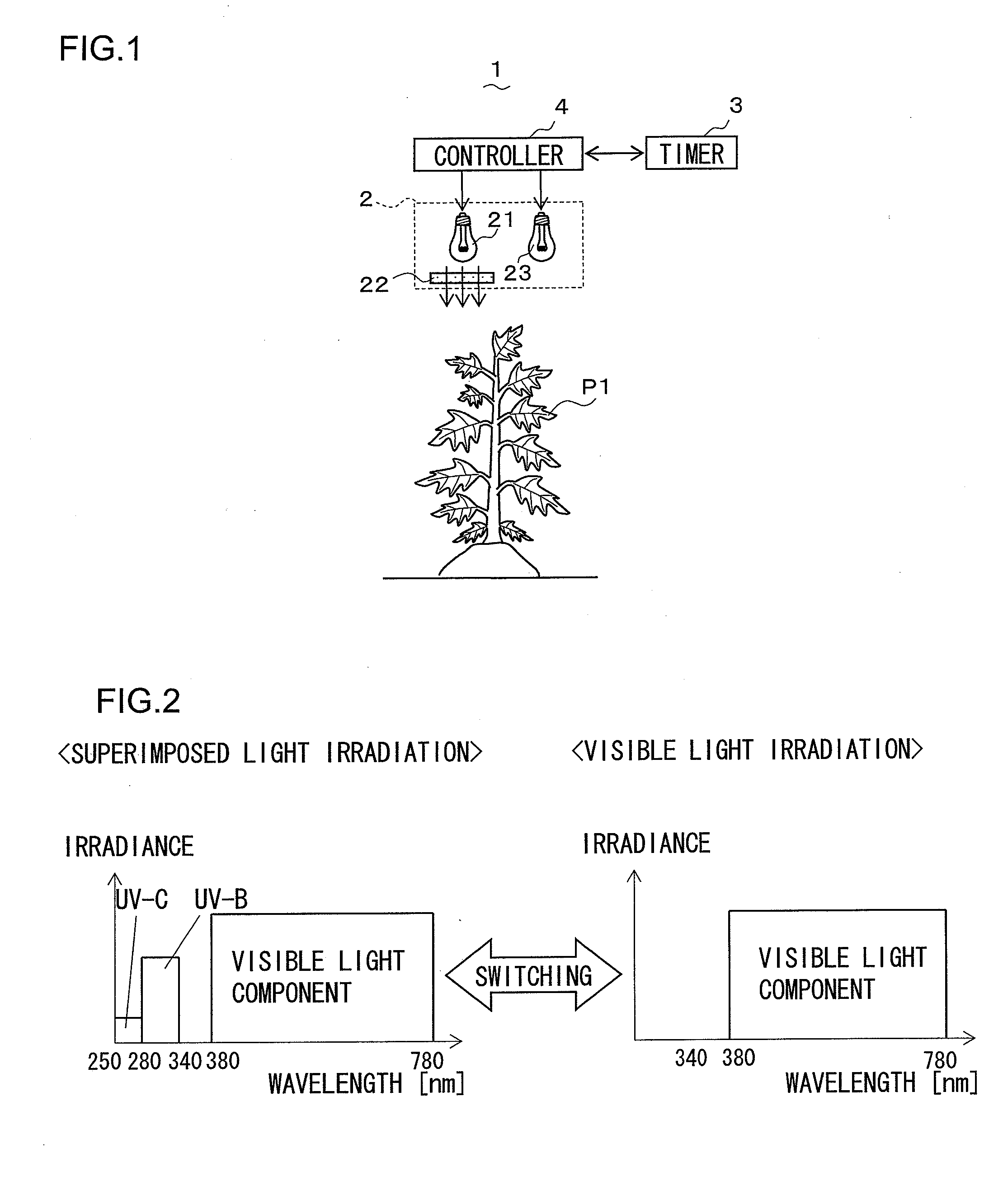

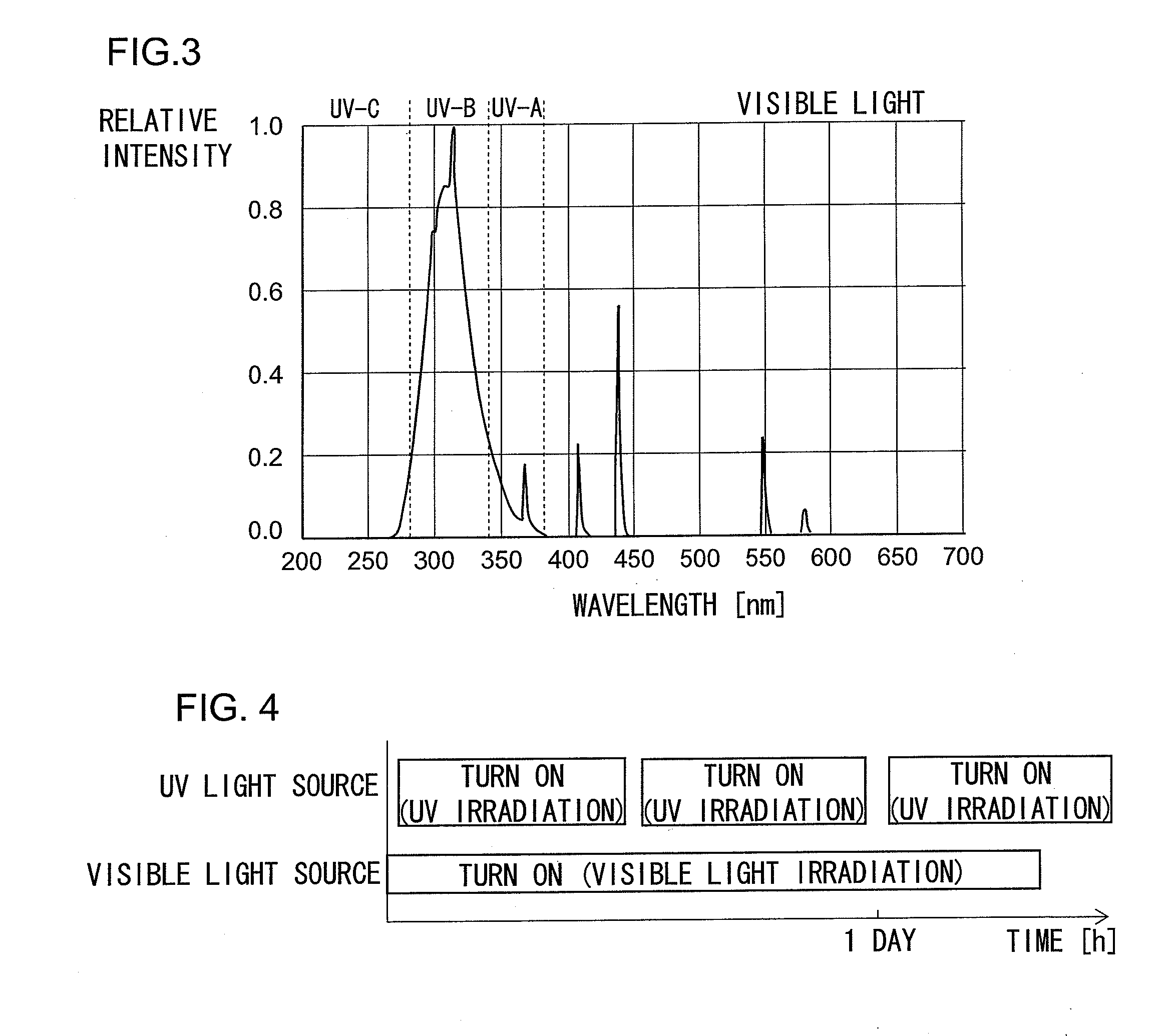

Lighting apparatus for controlling plant disease

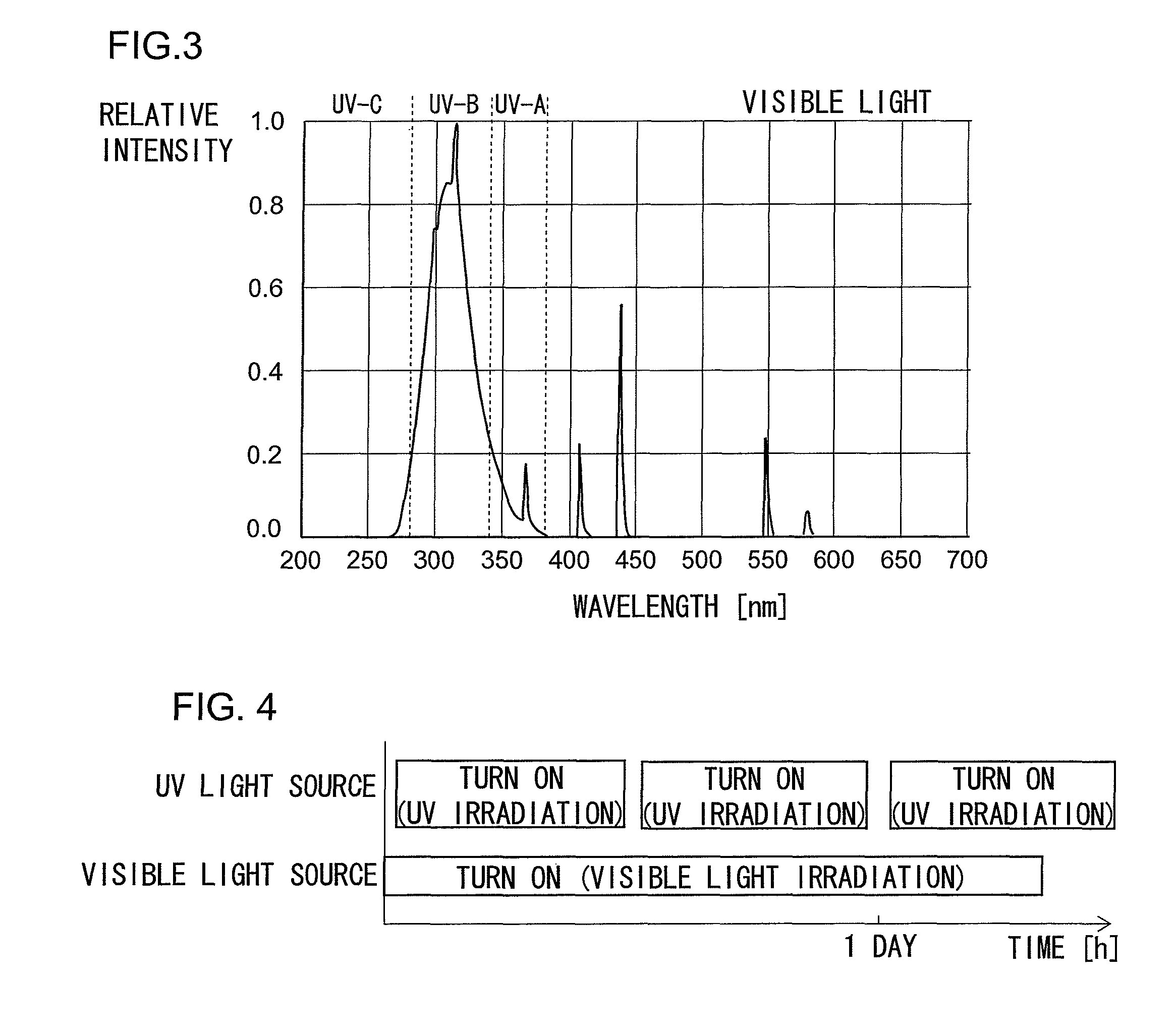

InactiveUS8458954B2Disease resistance of the plant can reliably be inducedLeaf scorch can be preventedRoot feedersElectric lighting sourcesDiseaseUredospore formation

A lighting apparatus for controlling a plant disease is provided to reliably inhibit a spore formation and a hyphal growth of a filamentous fungi, reliably induce a disease resistance, prevent a leaf scorch, and promote a growth of a plant. A UV light source repeats a light irradiation which has an irradiation pattern of combining a light irradiation, in which UV-C and UV-B and a visible light are superimposed, with a visible light irradiation alone at least twice a day. The emission of UV-B and UV-C enables the reliable inhibition of the spore formation of the filamentous fungi, for example. Its intermittent emission prevents a plant from getting too used to ultraviolet rays, promotes a generation of an antibacterial substance, for example, and prevents a leaf scorch. The continuous emission of the visible light enables a promotion of a growth of the plant.

Owner:PANASONIC CORP

Emitter and emission device

InactiveCN105498254AImprove strike accuracyExpand the scope ofAmmunition projectilesIndoor gamesEngineeringMechanical engineering

The invention provides an emitter and an emission device. When a driving seat moves, a plurality of movable blocks are converted into an unlocking state from a locking state, and are dispersed around to form a dispersed and emitting effect, so that targets in a plurality of directions can be attacked and the attacking precision is improved; after the movable blocks are unlocked, the driving seat and a driving rod are unlocked; even if a bullet is blocked by an obstacle and stops running, the driving seat and the driving rod still move frontwards along a channel under the action of inertia, so that the front end of the driving rod stimulates a power medium and a cap head is emitted, and furthermore, continuous emission is carried out; a target range and precision of attacking are further improved.

Owner:陈建宝

Lighting apparatus for controlling plant disease

InactiveUS20110016785A1Spread of plant can be reducedIncrease crop yieldElectrical apparatusElectric lighting sourcesDiseaseUredospore formation

A lighting apparatus for controlling a plant disease is provided to reliably inhibit a spore formation and a hyphal growth of a filamentous fungi, reliably induce a disease resistance, prevent a leaf scorch, and promote a growth of a plant. A UV light source repeats a light irradiation which has an irradiation pattern of combining a light irradiation, in which UV-C and UV-B and a visible light are superimposed, with a visible light irradiation alone at least twice a day. The emission of UV-B and UV-C enables the reliable inhibition of the spore formation of the filamentous fungi, for example. Its intermittent emission prevents a plant from getting too used to ultraviolet rays, promotes a generation of an antibacterial substance, for example, and prevents a leaf scorch. The continuous emission of the visible light enables a promotion of a growth of the plant.

Owner:PANASONIC CORP

Device for delivering a volatile fluid to the atmosphere

A device for delivering a volatile fluid in a continuous manner, over a period of time and without leakage, is disclosed. The device includes a flexible sheet and a semi-rigid sheet that are sealed along their edges to form a closed pocket or reservoir for containing a volatile fluid. The semi-rigid sheet is sealed on a first side to a flexible sheet and sealed on a second side to a vapor permeable membrane. The semi-rigid sheet contains a volatile fluid in the reservoir during storage, preventing contact of the volatile fluid with the vapor permeable membrane before the device is activated. The semi-rigid sheet has a differential score to guide the bounds of an opening that is formed upon activation. Once activated, the vapor permeable membrane provides continuous emission of a volatile fluid from the device.

Owner:THE PROCTER & GAMBLE COMPANY

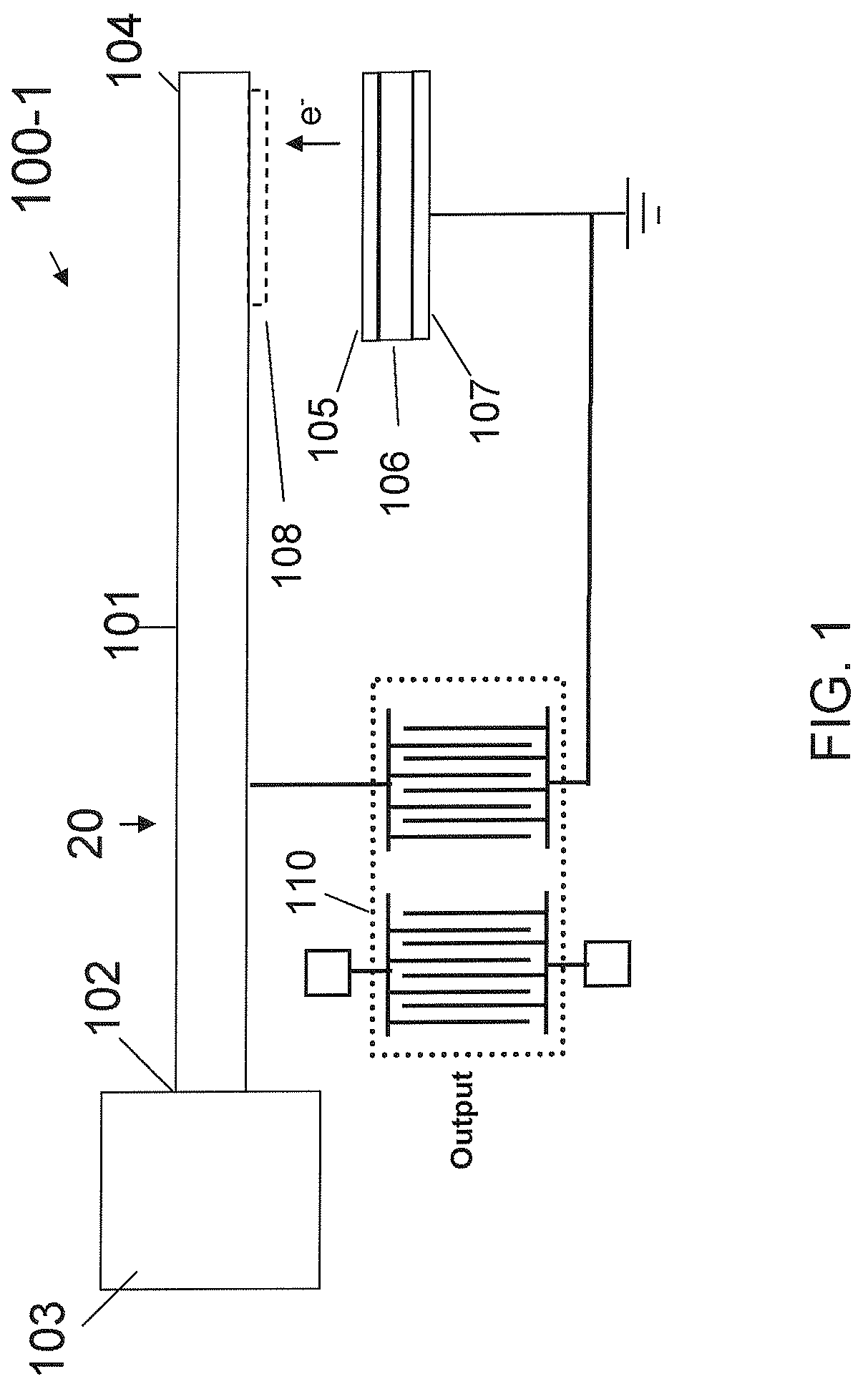

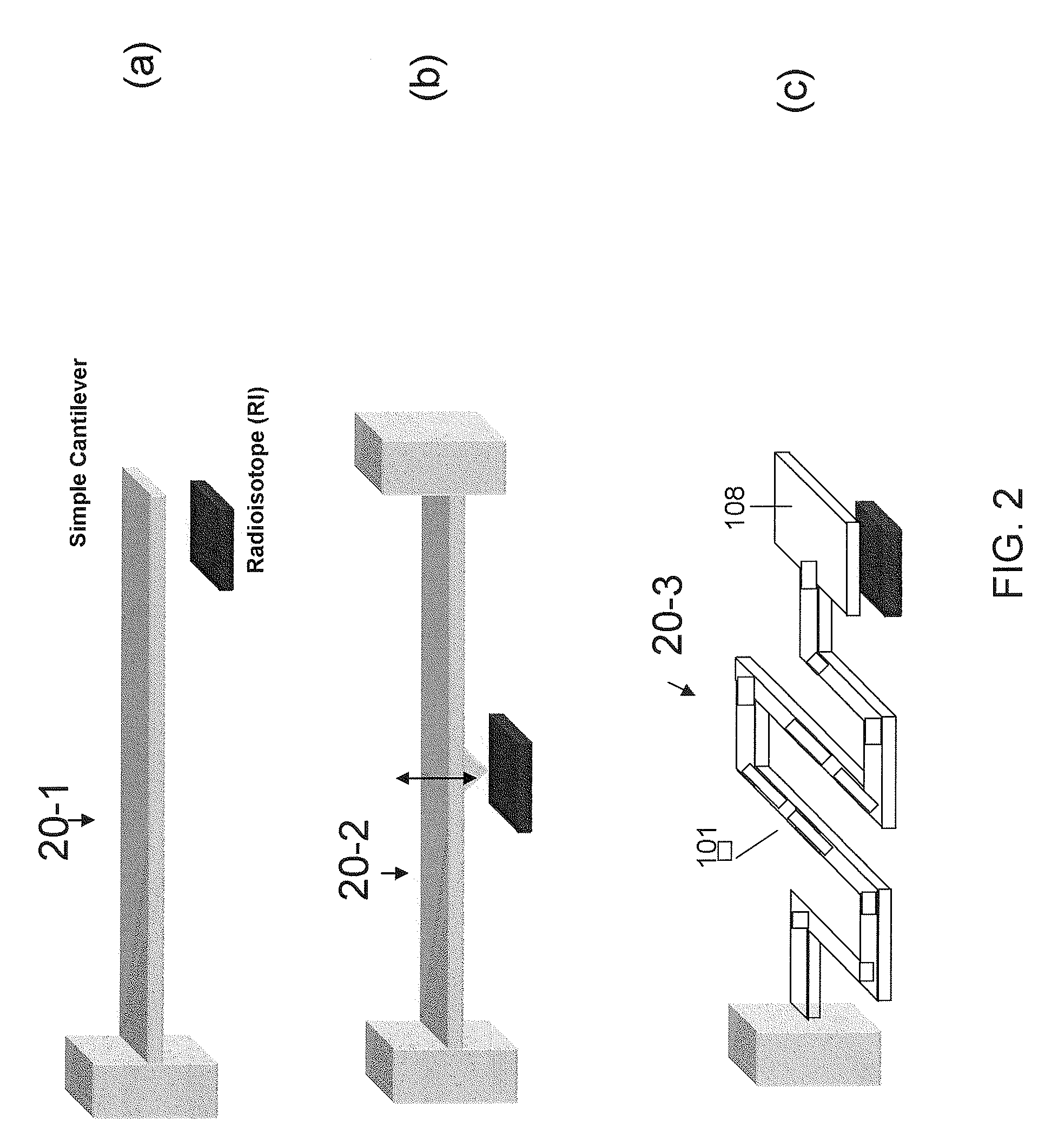

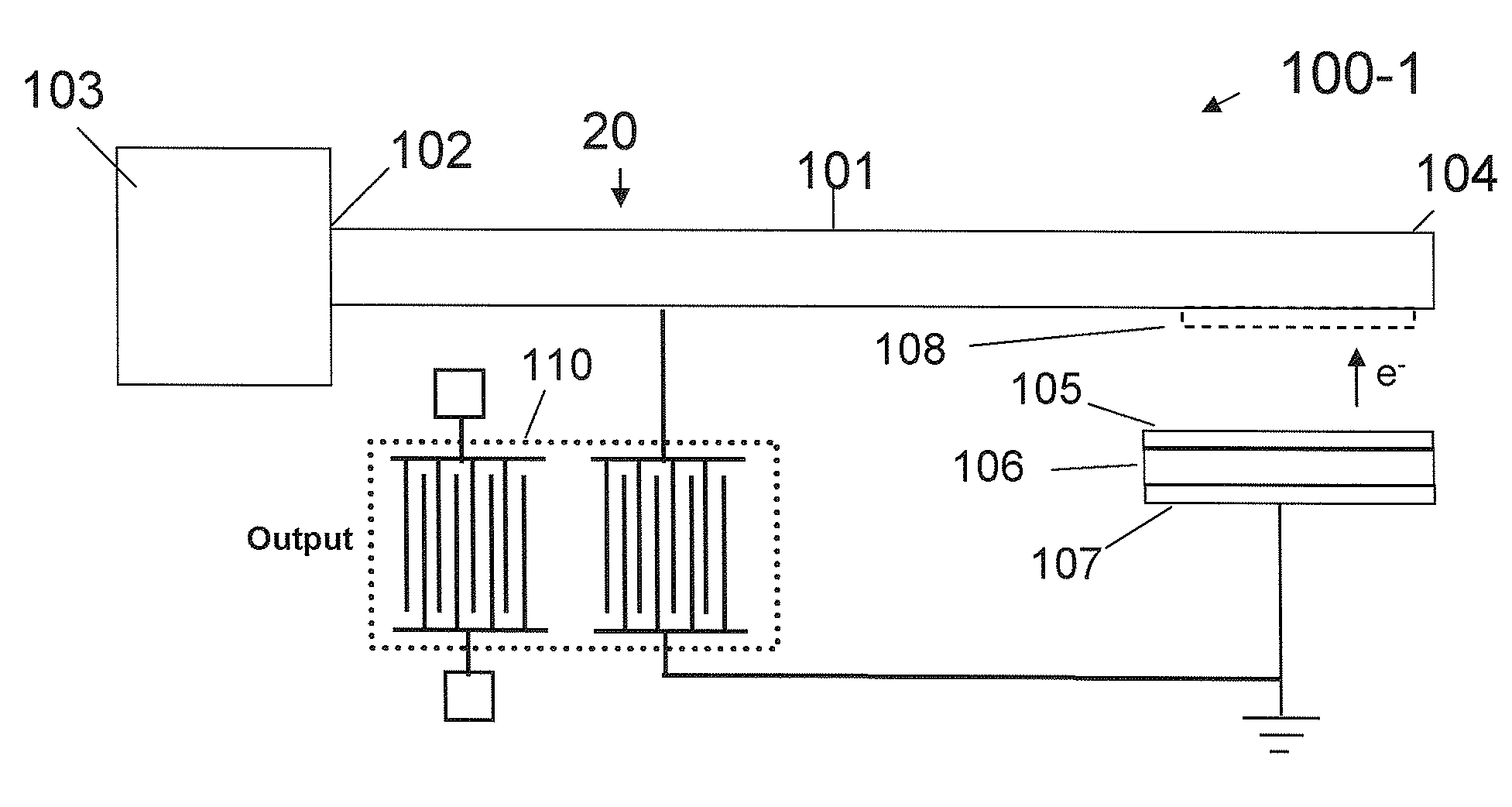

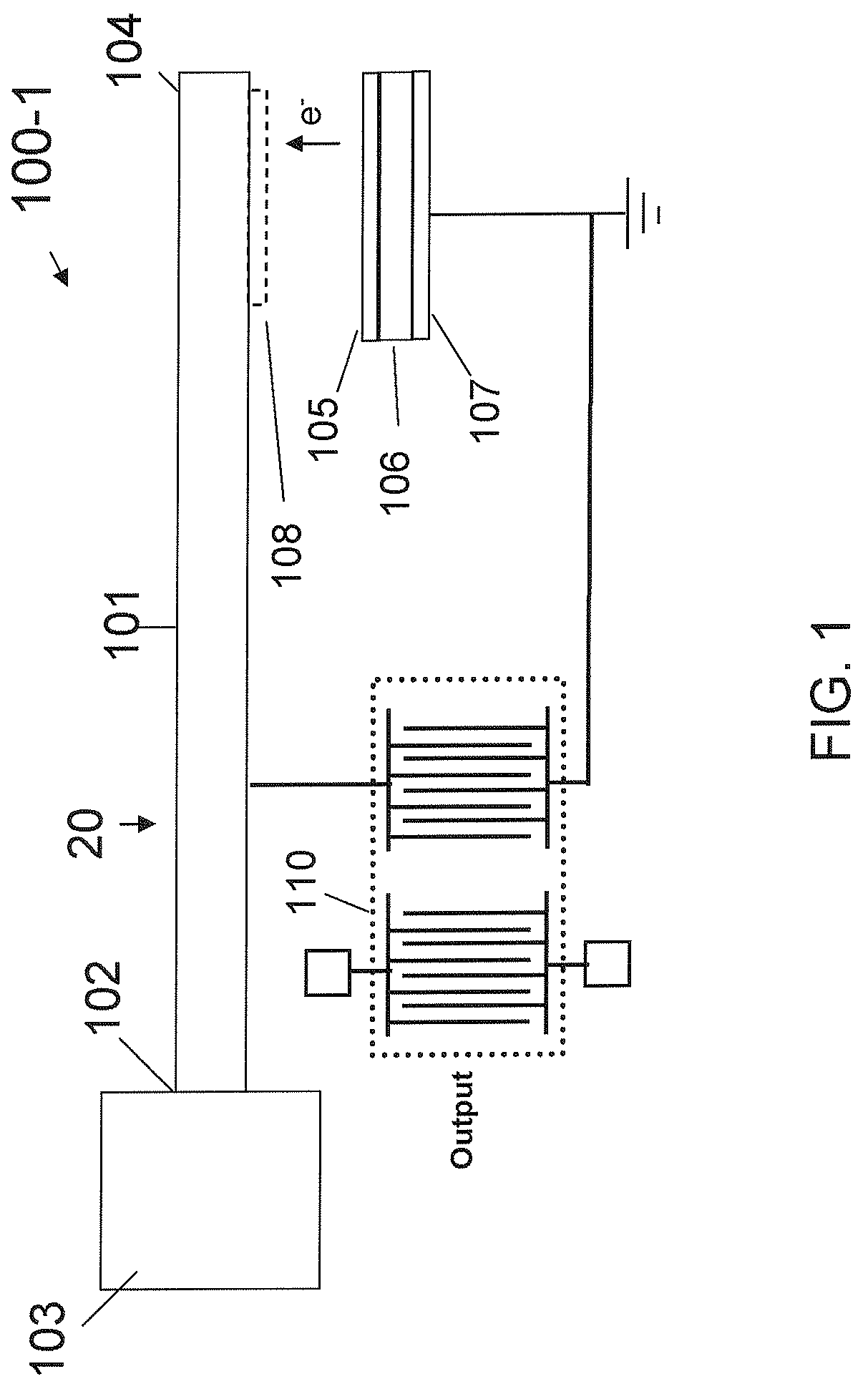

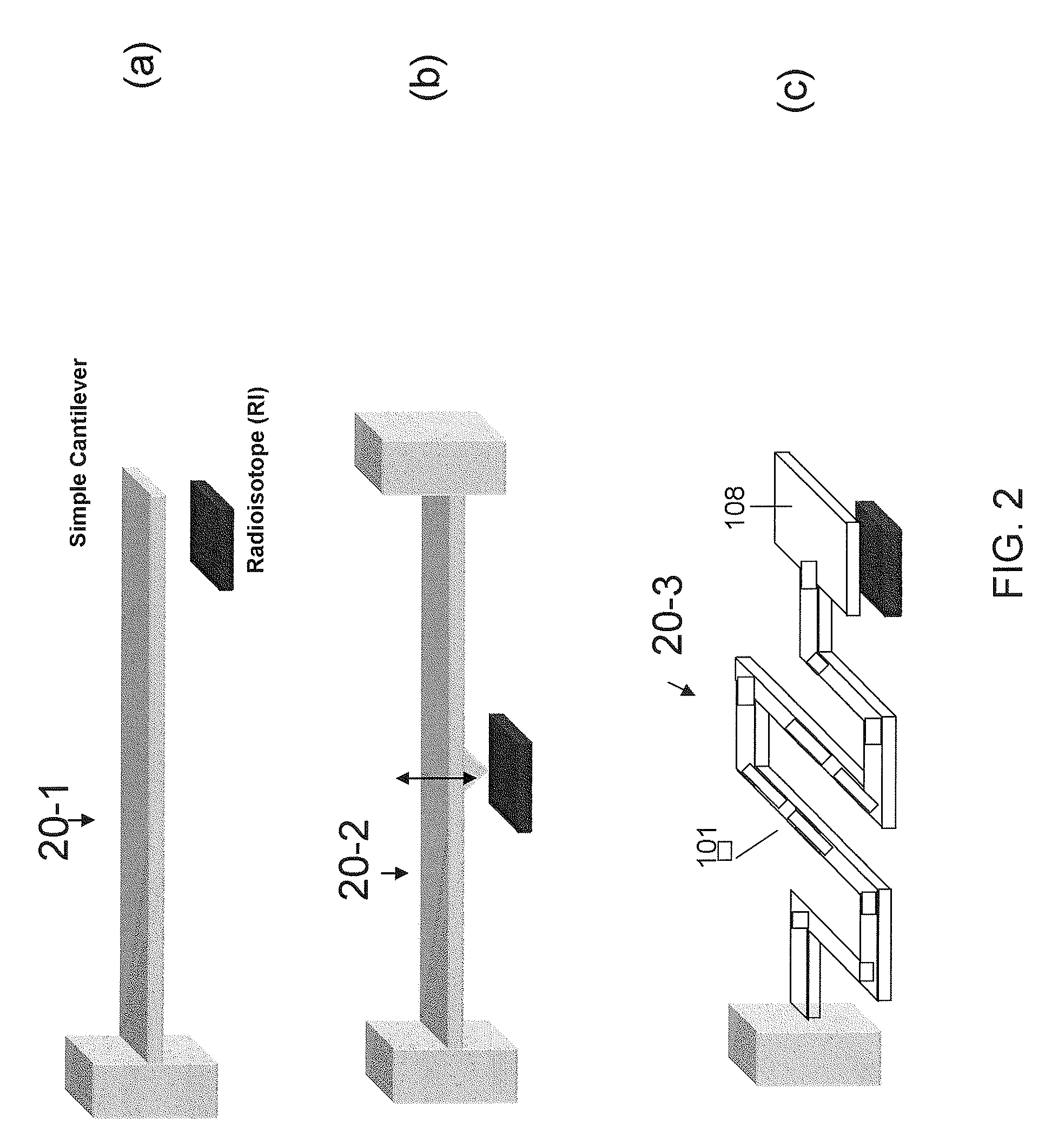

Self-powered, piezo-surface acoustic wave apparatus and method

ActiveUS20110241839A1Impedence networksPiezoelectric/electrostriction/magnetostriction machinesEngineeringSurface acoustic wave

An autonomous, self-powered device includes a radioisotope-powered current impulse generator including a spring assembly comprising a cantilever, and a piezoelectric-surface acoustic wave (P-SAW) structure connected in parallel to the current impulse generator. Positive charges are accumulated on an electrically isolated 63Ni thin film due to the continuous emission of β-particles (electrons), which are collected on the cantilever. The accumulated charge eventually pulls the cantilever into the radioisotope thin-film until electrical discharge occurs. The electrical discharge generates a transient magnetic and electrical field that can excite the RF modes of a cavity in which the electrical discharge occurs. A piezoelectric-SAW resonator is connected to the discharge assembly to control the RF frequency output. A method for generating a tuned RF signal includes inputting an energy pulse to a P-SAW resonator, exciting the resonant frequency thereof, and outputting an RF signal having a frequency tuned to the resonator frequency.

Owner:CORNELL UNIVERSITY

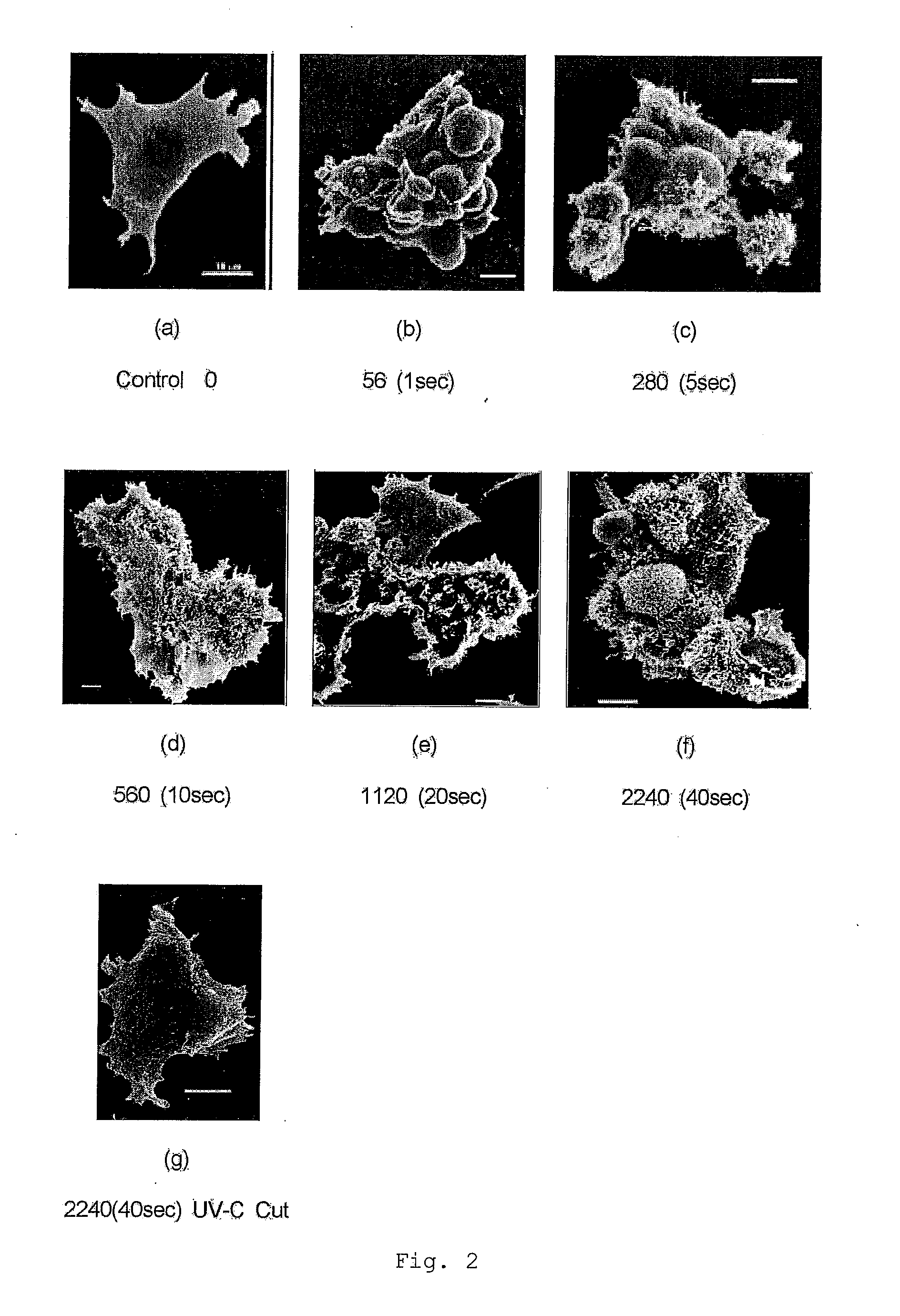

Method for Selectively Damaging and Killing Tumor Cells and Apparatus Therefor

InactiveUS20120171745A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiological bodyIrradiation

A method and an apparatus capable of selectively damaging and killing tumor cells includes a step of irradiating tumor cells with a UV pulse flash having continuous emission spectra ranging at least from 230 to 270 nm, outside a living body of a human or a living body of a non-human animal or in a living body of a non-human animal. The UV pulse flash may have an accumulated irradiation amount per unit area that is achieved at a distance of 8 cm from a light source having an integrated output of, for example, 90, 180-7100 or 14200 J.

Owner:TOKAI UNIV +1

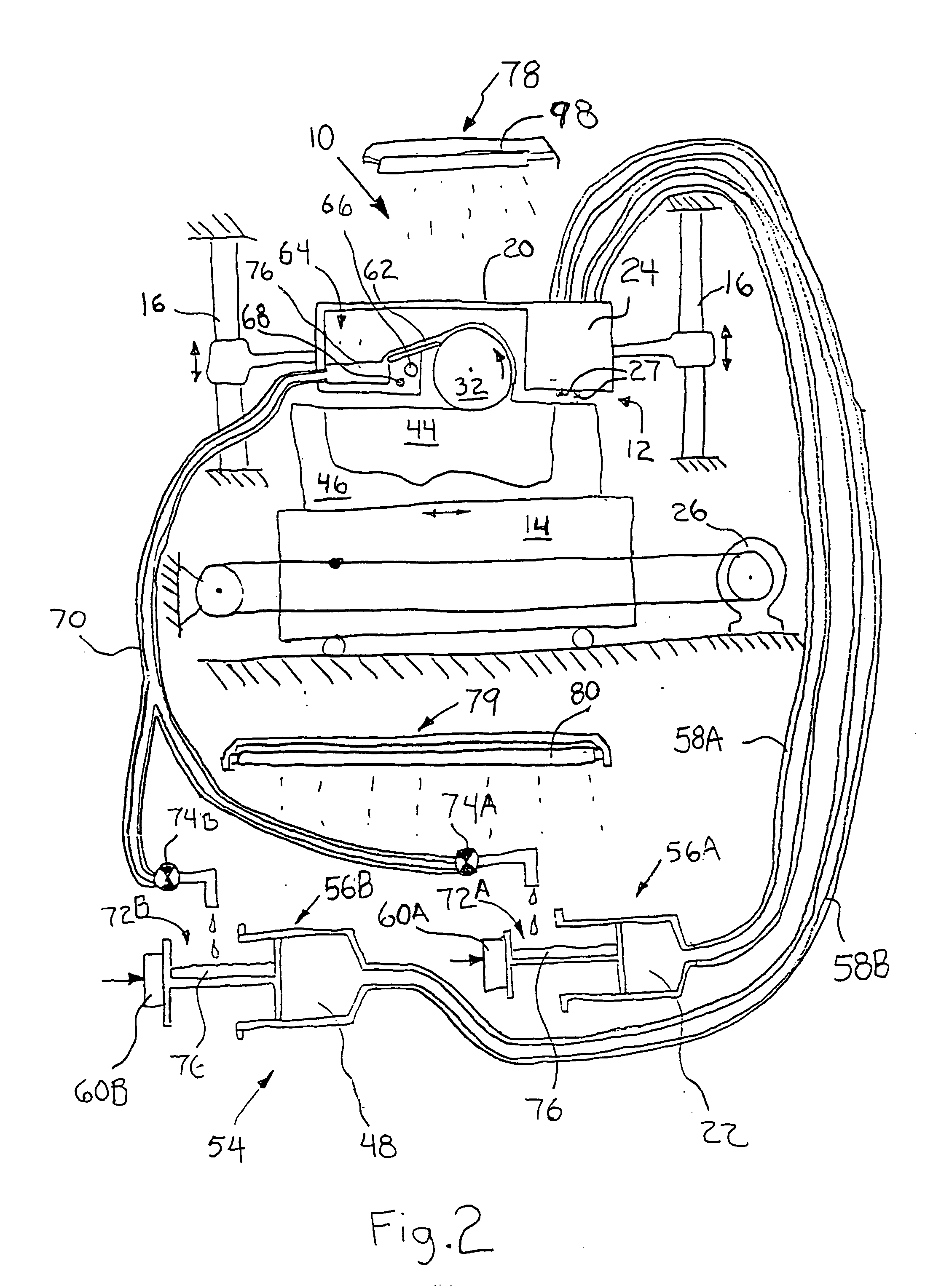

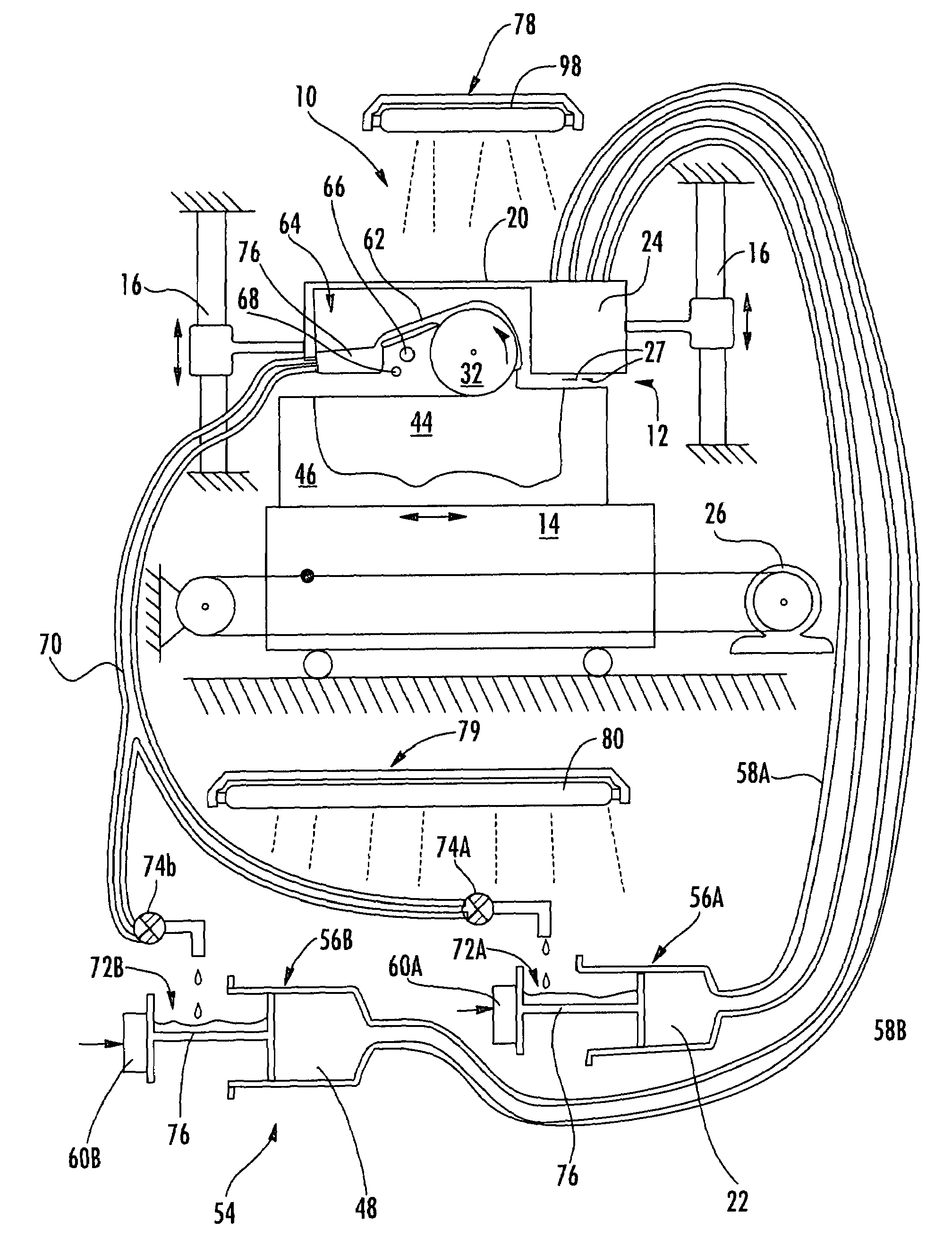

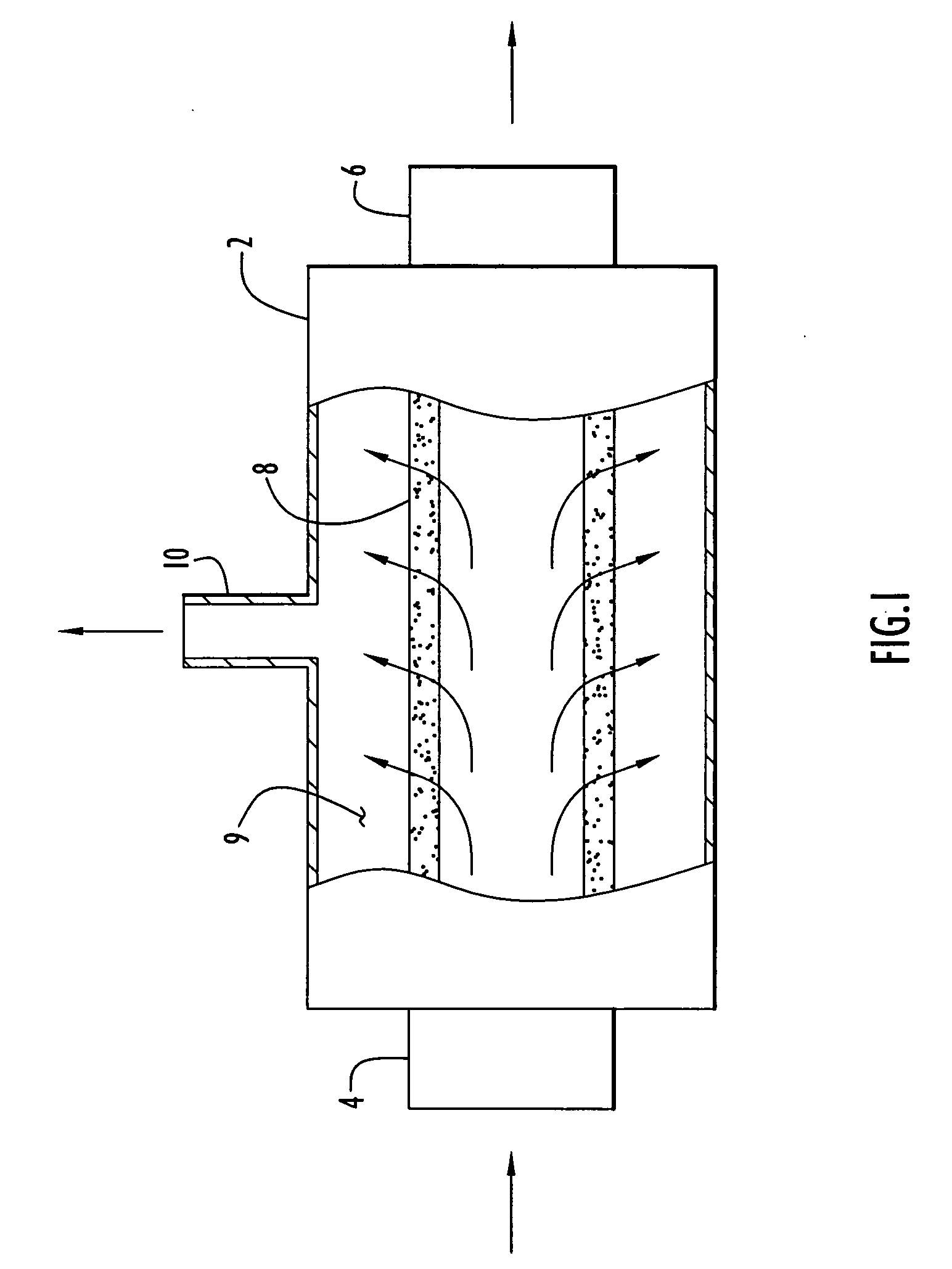

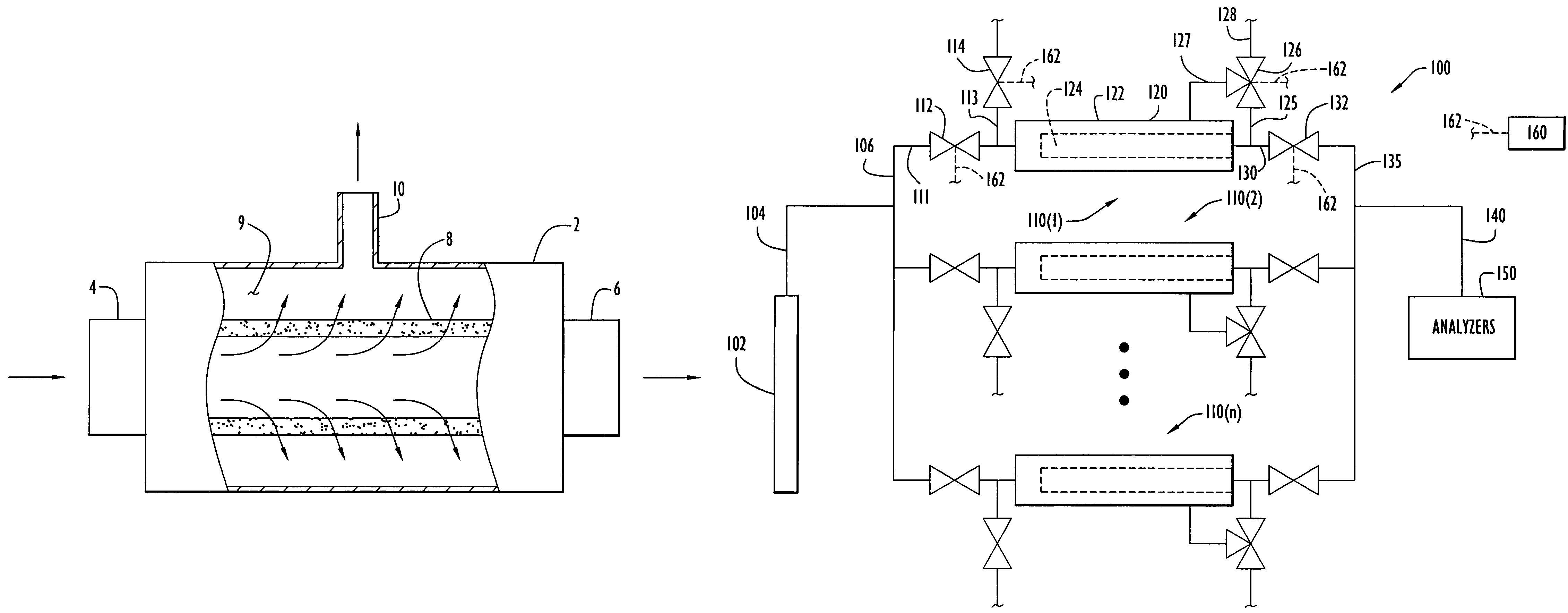

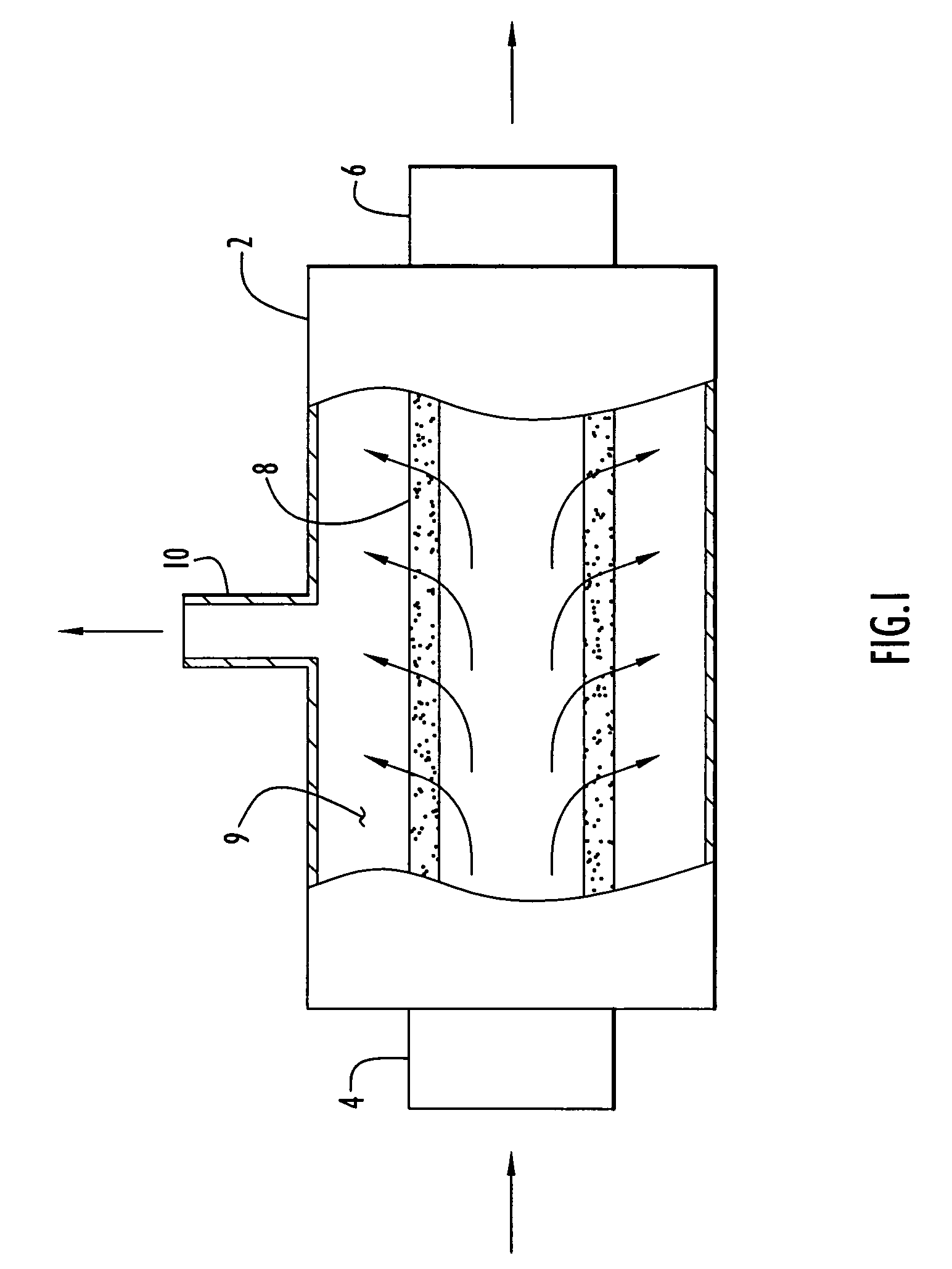

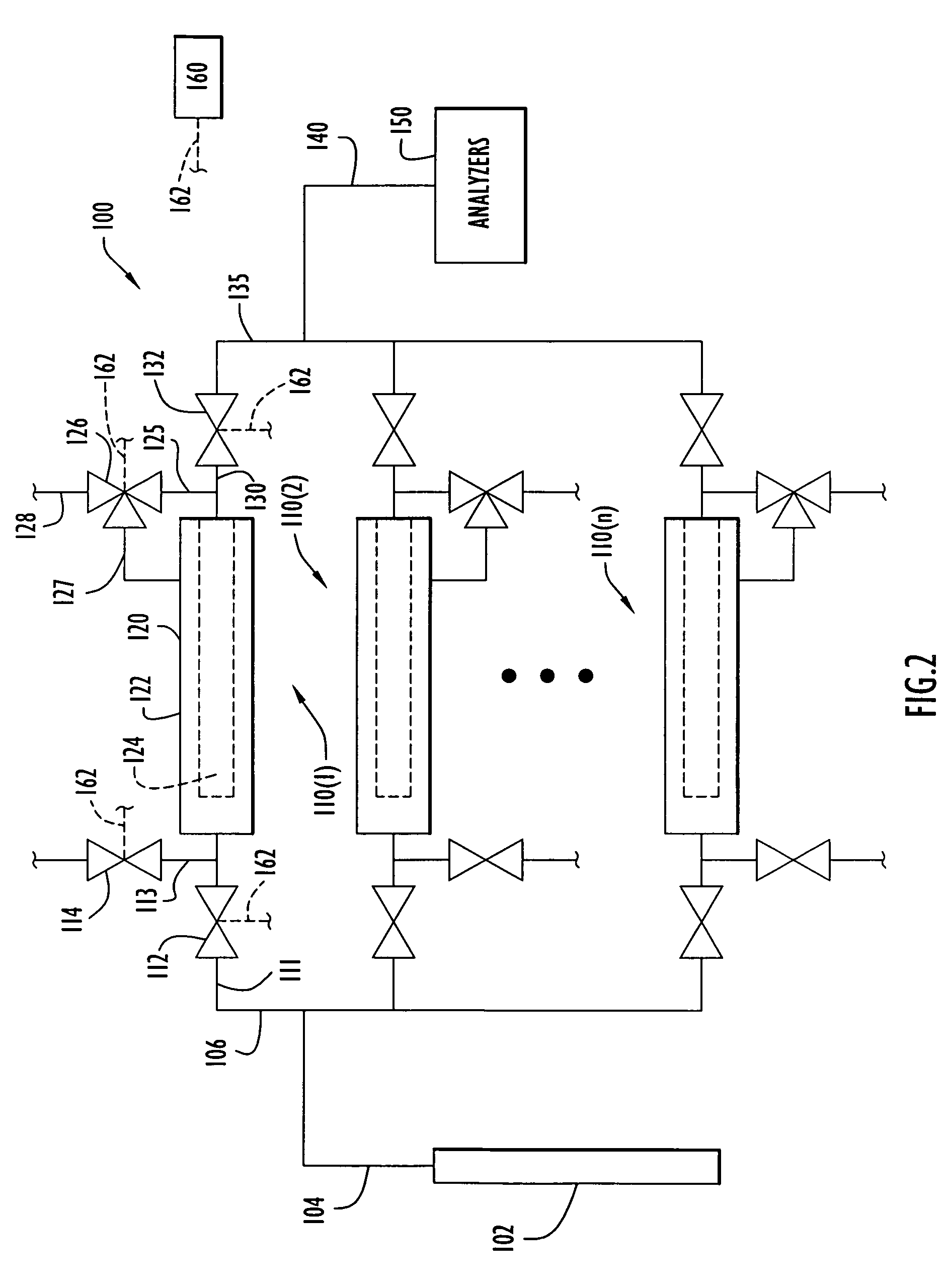

Filtering particulate materials in continuous emission monitoring systems

InactiveUS20060249023A1Facilitate effective blowbackAvoid problemsCombination devicesAuxillary pretreatmentParticulatesFilter system

A filtering system for monitoring fluid emissions from a process includes a plurality of filter assembly sections arranged in a parallel fluid flow manner with respect to each other so as to selectively receive a sample fluid (e.g., a sample gas) entering at an inlet of the system. Each filter assembly section includes a filter unit to filter particulate materials from a fluid flowing through the filter, first and second valves disposed at upstream and downstream locations of the filter unit, and a blowback flow path configured to selectively direct a cleaning fluid through the filter unit in a direction that opposes a direction in which the sample fluid flows through the filter unit. Each filter assembly section can be selectively isolated from other portions of the system so as to prevent the sample fluid from flowing through the filter assembly section while allowing a cleaning fluid to be delivered through the blowback flow path of the filter assembly section.

Owner:AIR LIQUIDE AMERICA INC

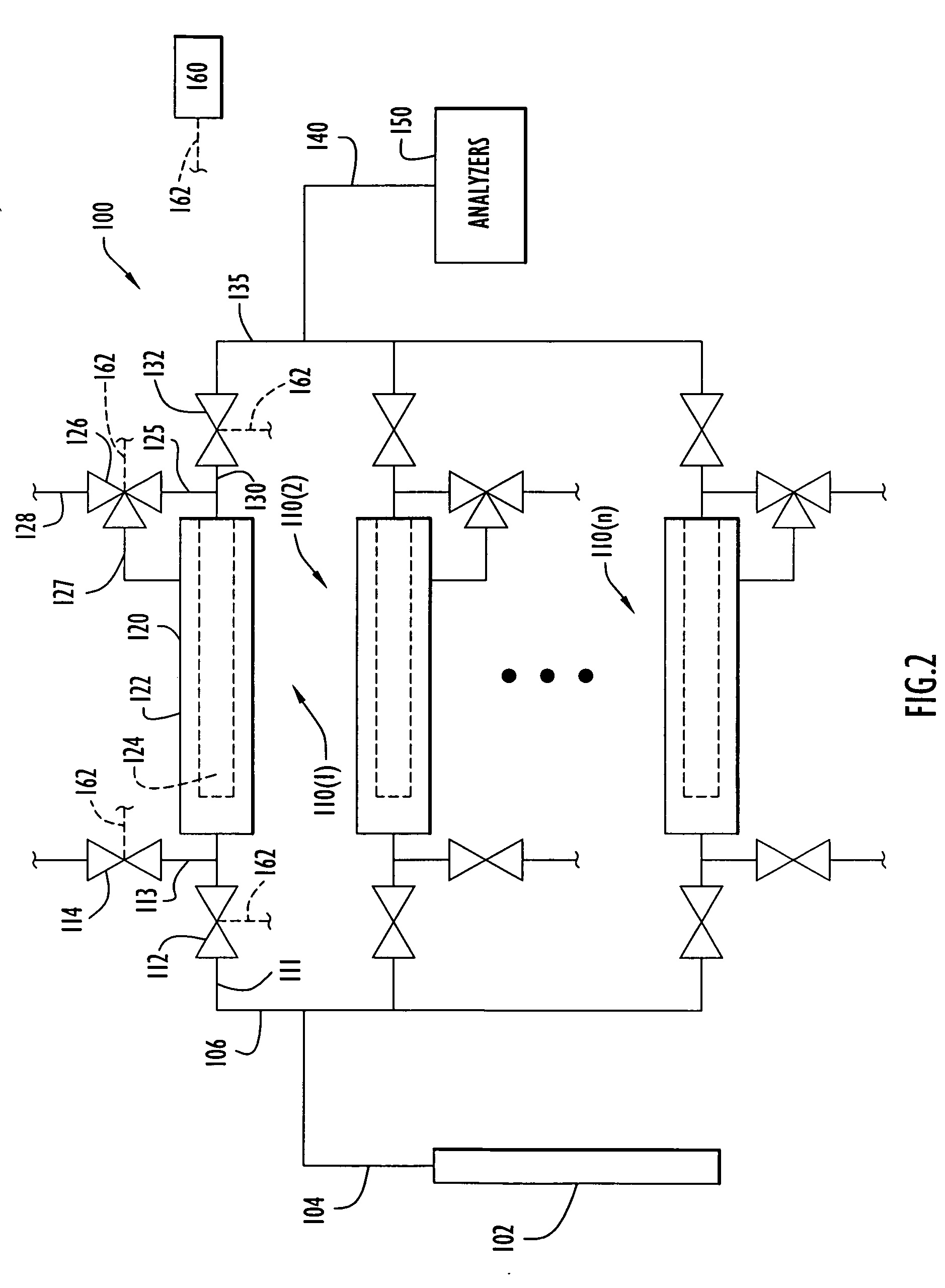

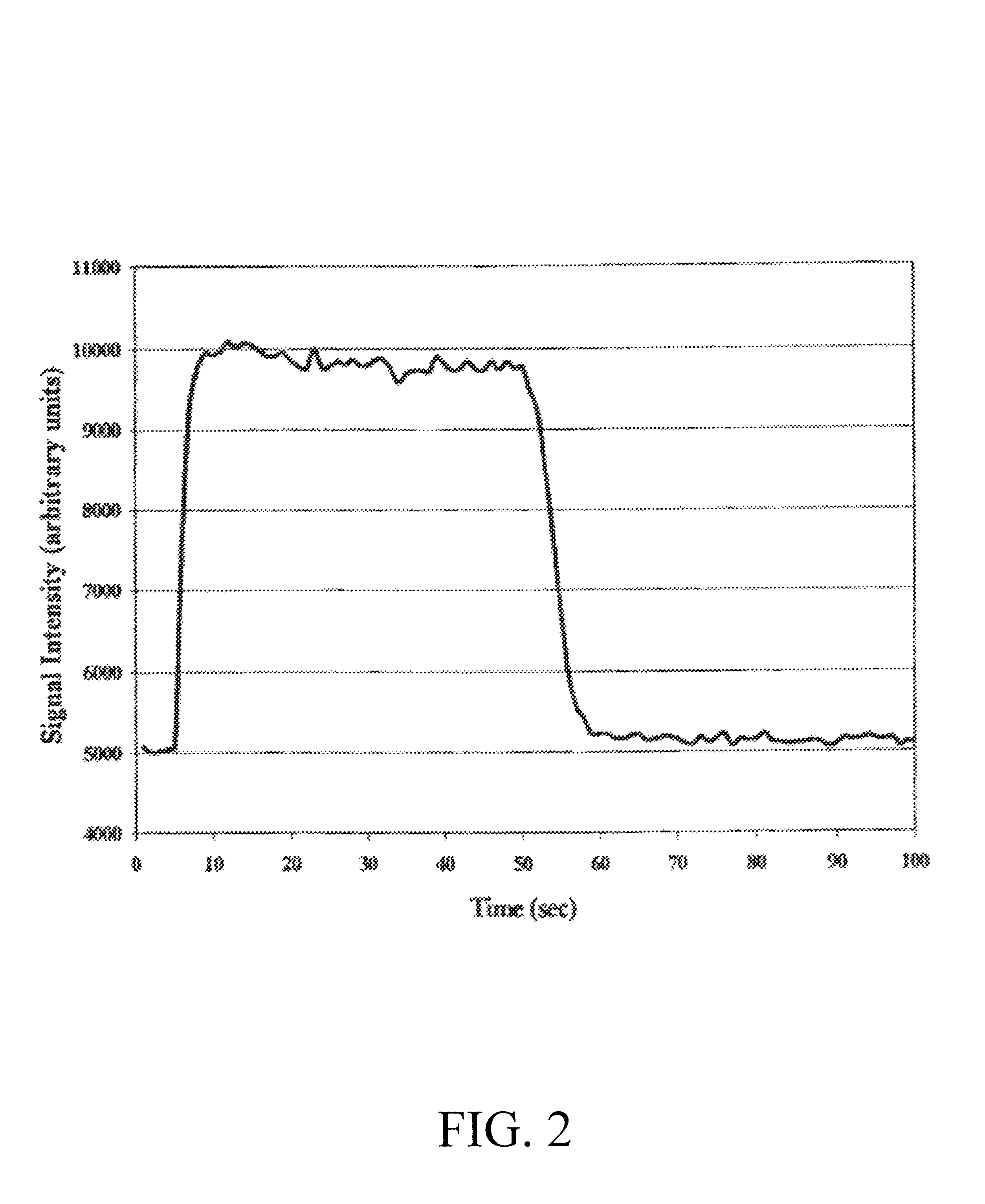

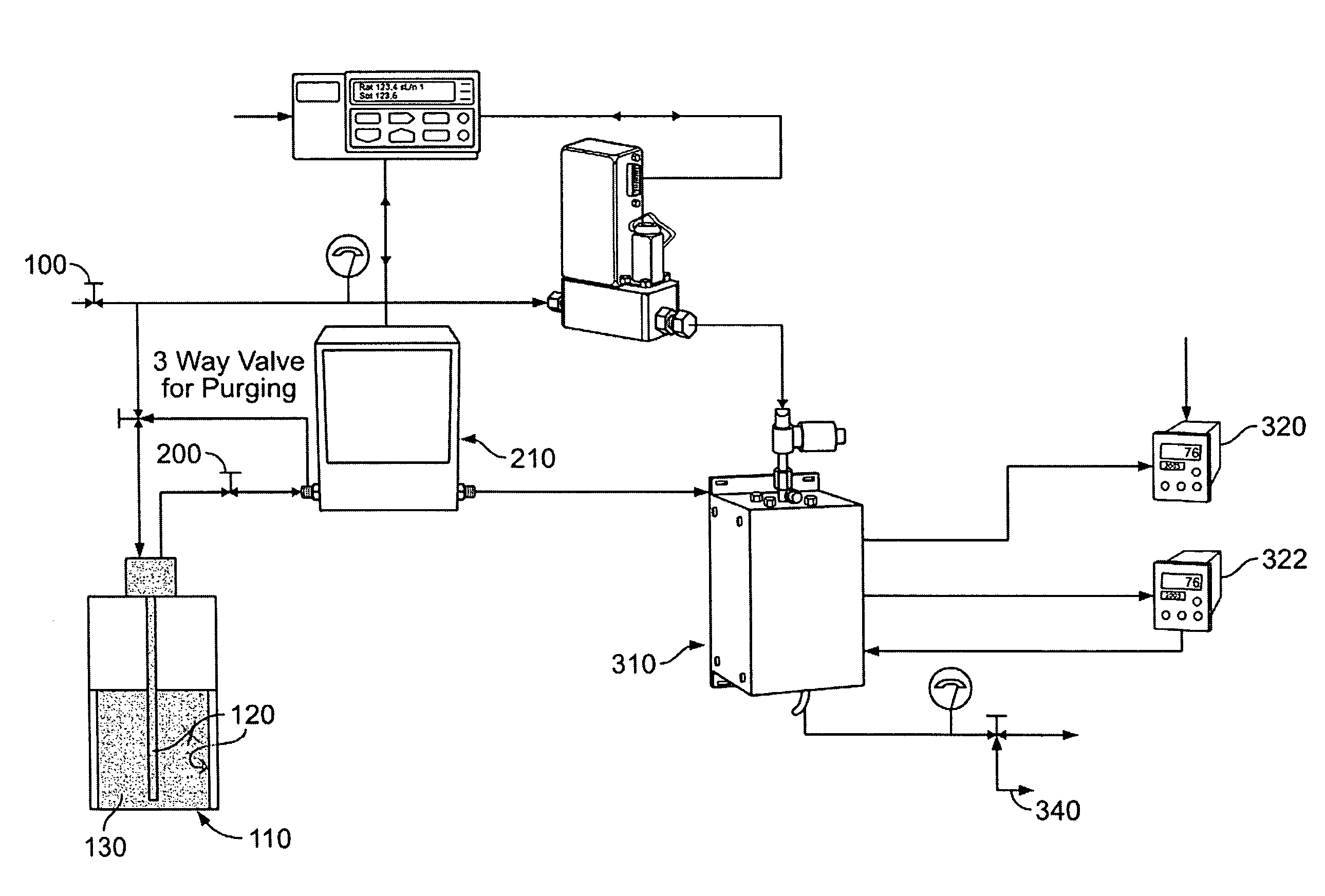

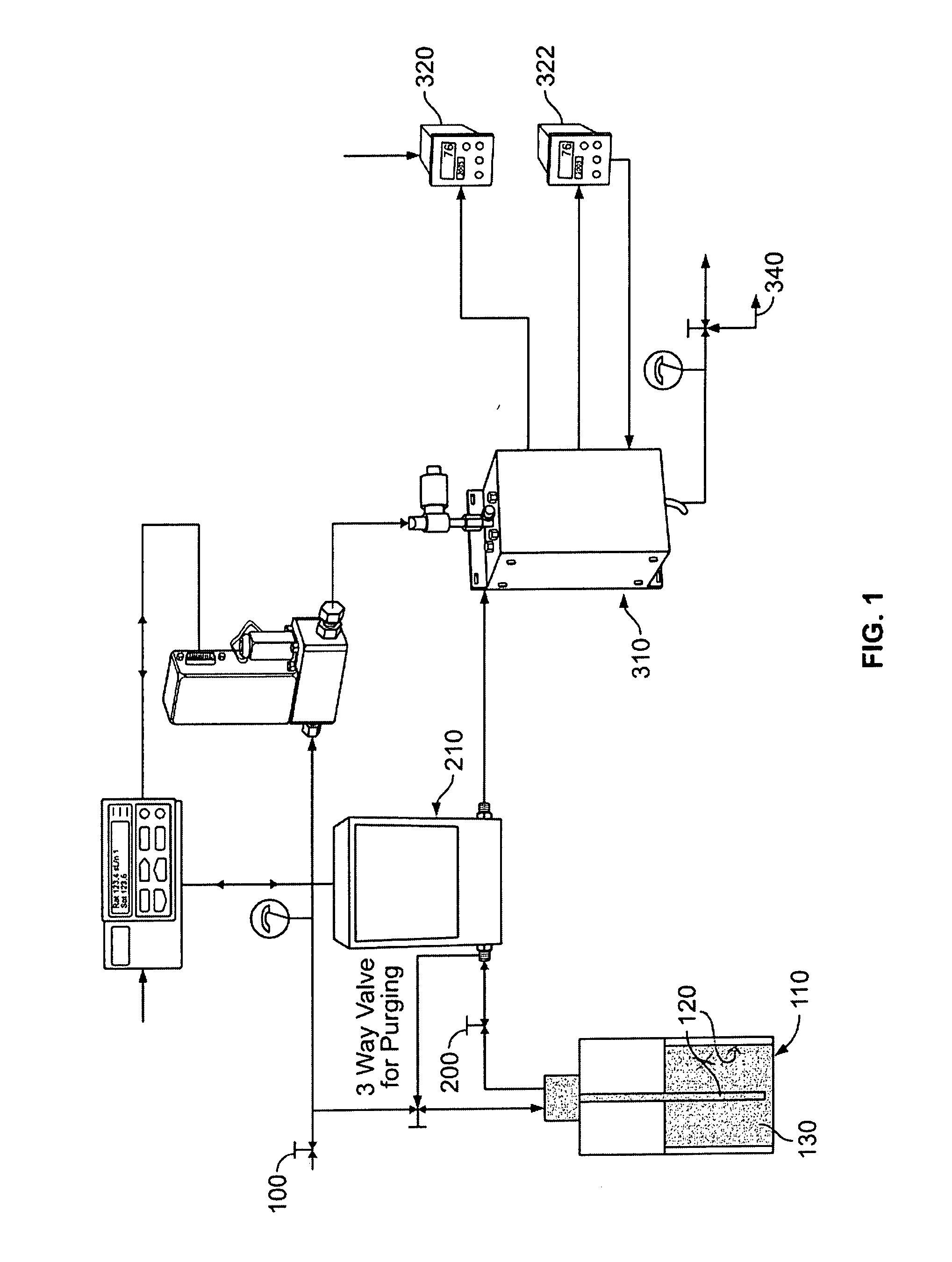

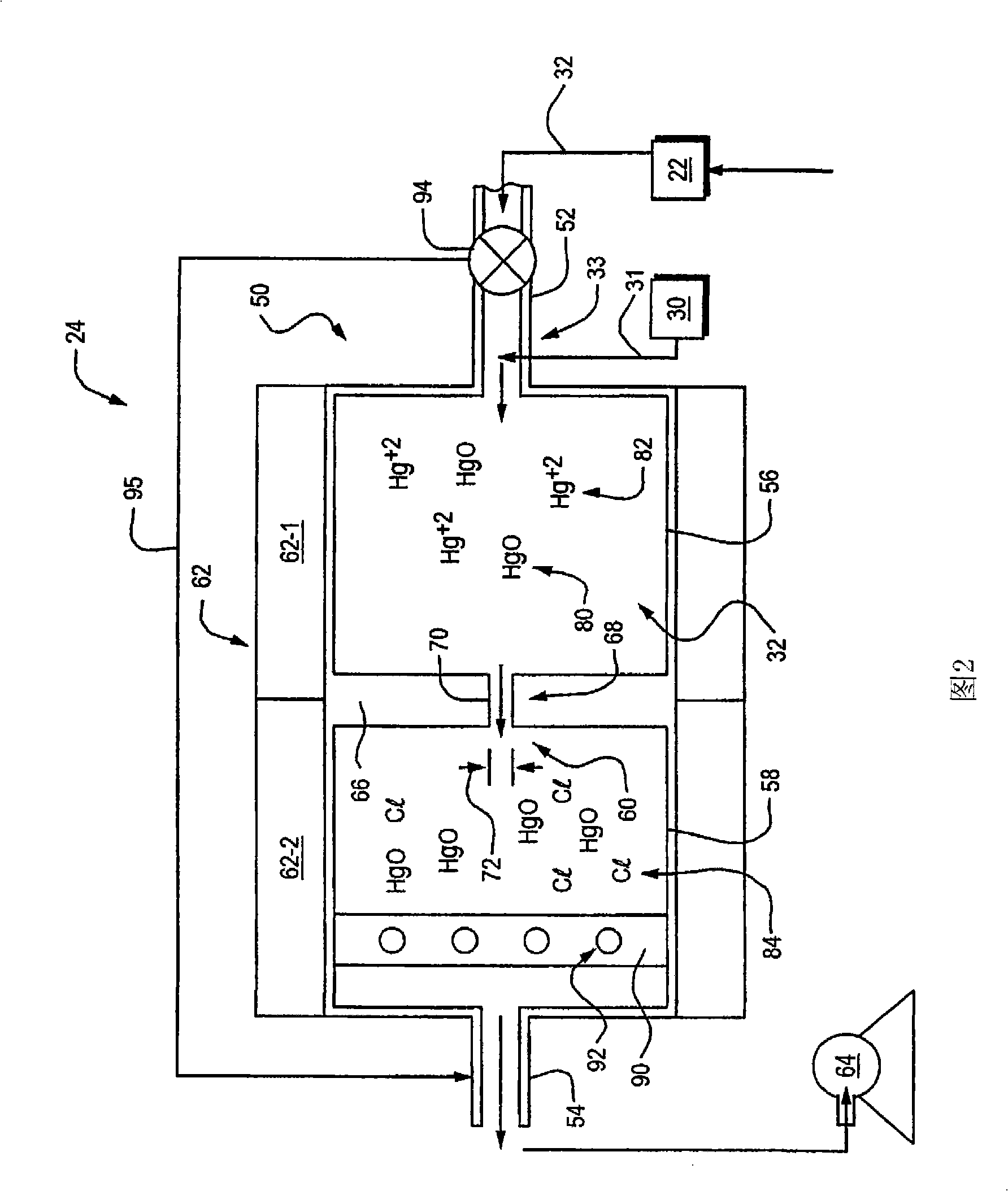

Calibration scheme for continuous monitoring of mercury emissions from stationary sources by plasma emission spectrometry

InactiveUS6690462B2Radiation pyrometrySpectrum investigationLinear relationshipOptical emission spectrometry

The disclosed invention relates to a calibration method, system and apparatus for a multimetals continuous emissions monitor system (hereinafter "multimetals CEMS"). More specifically, this invention relates to a calibration scheme for continuous monitoring of mercury emissions from stationary sources by plasma emission spectrometry. A source of mercury vapor, preferably a mercury permeation tube, entrains mercury vapor into a constant flow of carrier air. The carrier air mixes with a constant flow of diluent air in an aerosol mixer. The mixer is operably coupled to the analyzer. A gaseous mixture having a calibration mercury concentration flows from the mixer into the analyzer at a constant rate. A graph having coordinates of analyzer signal intensity and mercury concentration is used to plot the calibration scheme. A first signal intensity generated by the analyzer in response to the calibration mercury concentration is used for the first plot on the graph. A second signal intensity generated by the analyzer in response to a blank having zero mercury concentration is used as the second plot on the graph. A linear relationship between the analyzer signal intensity and the mercury concentration on the graph is established from the first plot and the second plot. The slope intercept and slope are used to create a mathematical relationship between the analyzer signal intensity and the mercury concentration. This enables the analyzer to be calibrated by inserting a known mercury concentration into the analyzer and adjusting the signal intensity to conform to the signal intensity calculated from the graph or mathematical relationship.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

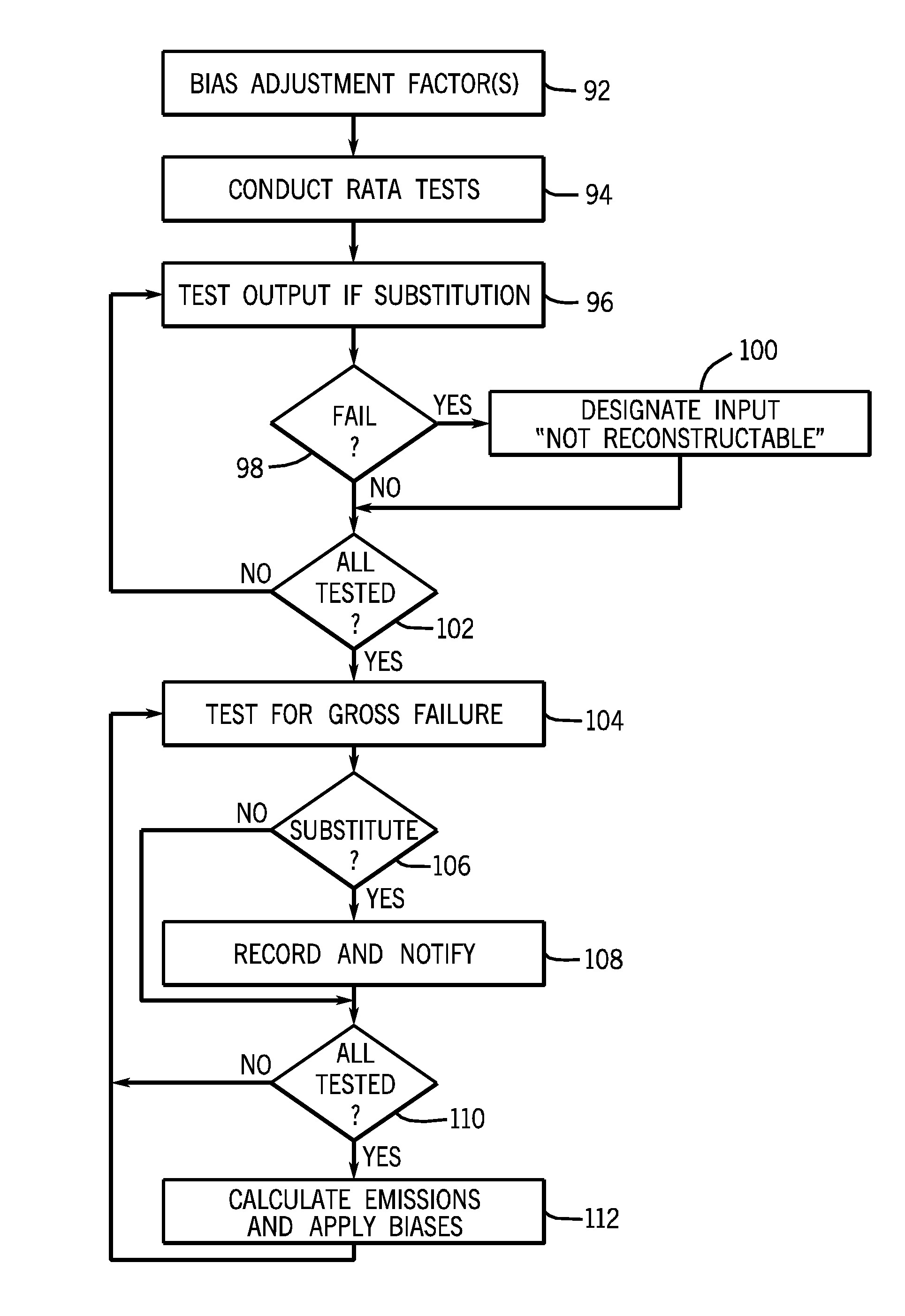

Sensor validation and value replacement for continuous emissions monitoring

ActiveUS8650009B2Simulator controlComputation using non-denominational number representationSensing dataModel system

Owner:ROCKWELL AUTOMATION TECH

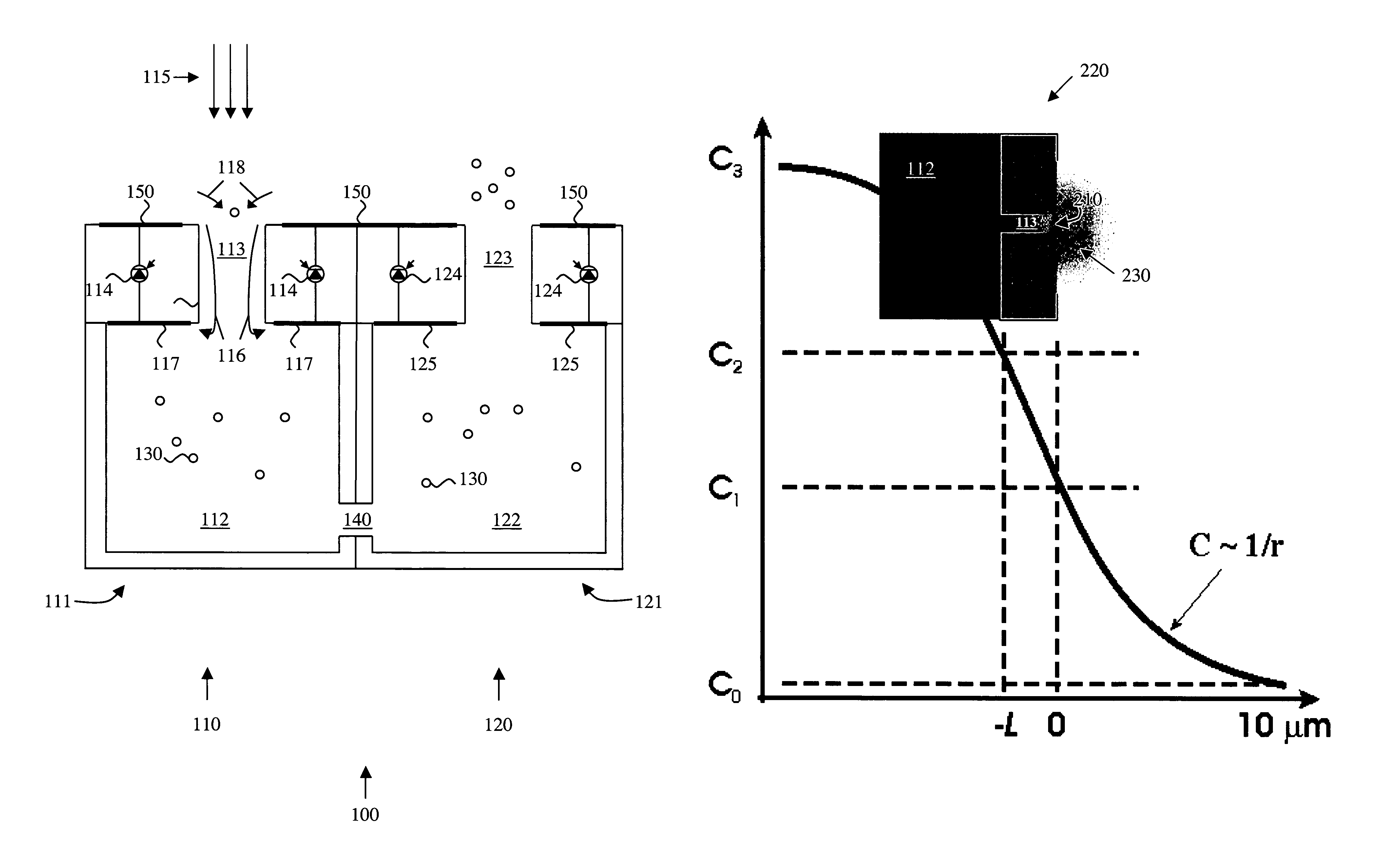

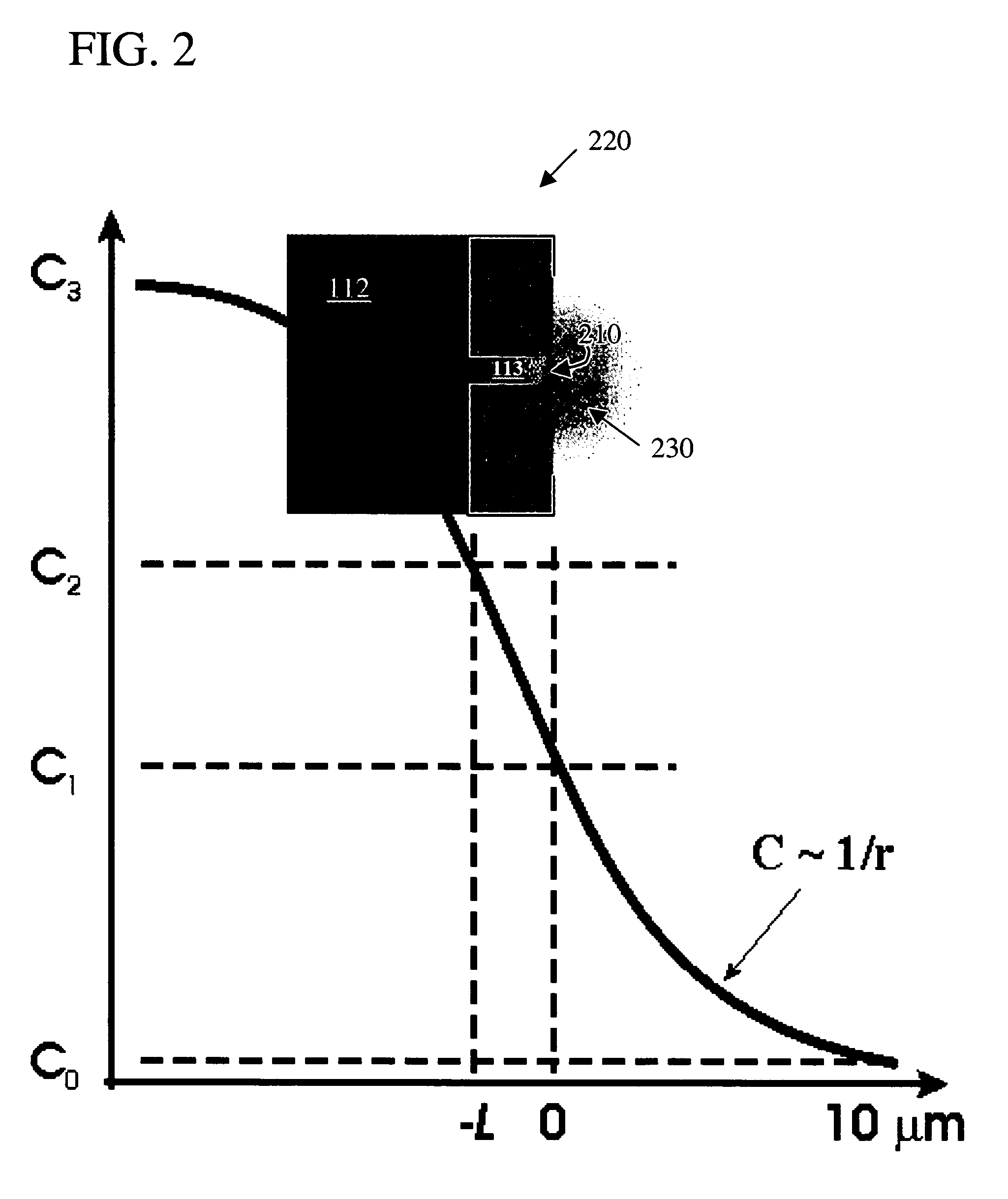

Optically controlled microfluidic chip

InactiveUS7556621B2Way accurateEmission reductionEye implantsHead electrodesNeuronal stimulationOptical control

An optically controlled microfluidic chip is provided for administering a fluid to a neuronal site. The chip is made of at least one unit or pixel, each of which constitutively emits fluid in the dark, and reduces emission of fluid in response to light. The individual pixels are capable of being individually controlled, thereby translating a spatial pattern of incident light into a spatial pattern of neuronal stimulation. Each pixel contains a housing, an aperture in the housing, and a reservoir containing fluid that is connected to the aperture. The aperture is designed to allow continuous emission of fluid from the reservoir through the aperture when the pixel is in the dark. Each pixel also includes an optical control, which reduces the emission of fluid from the reservoir through the aperture in response to light.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

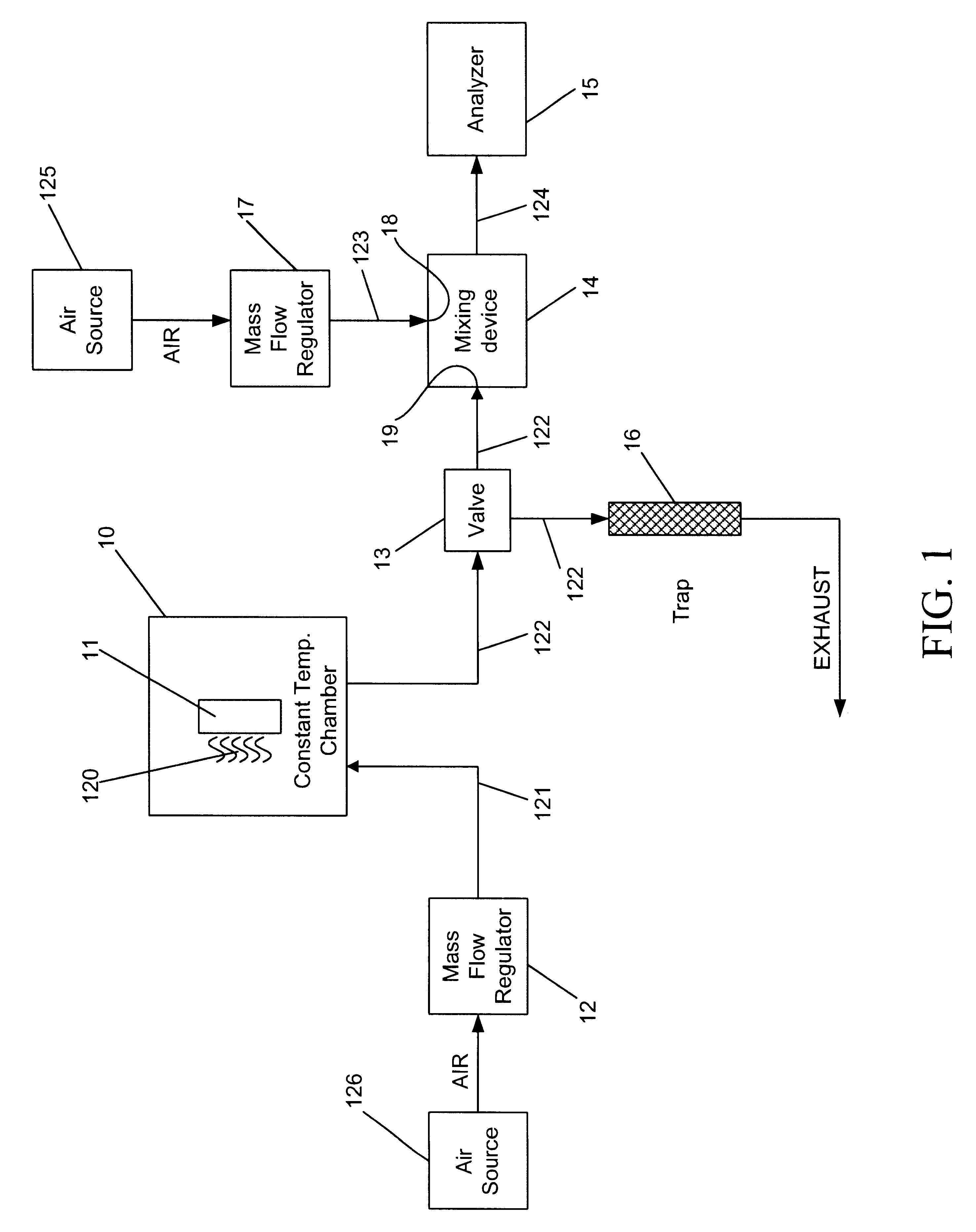

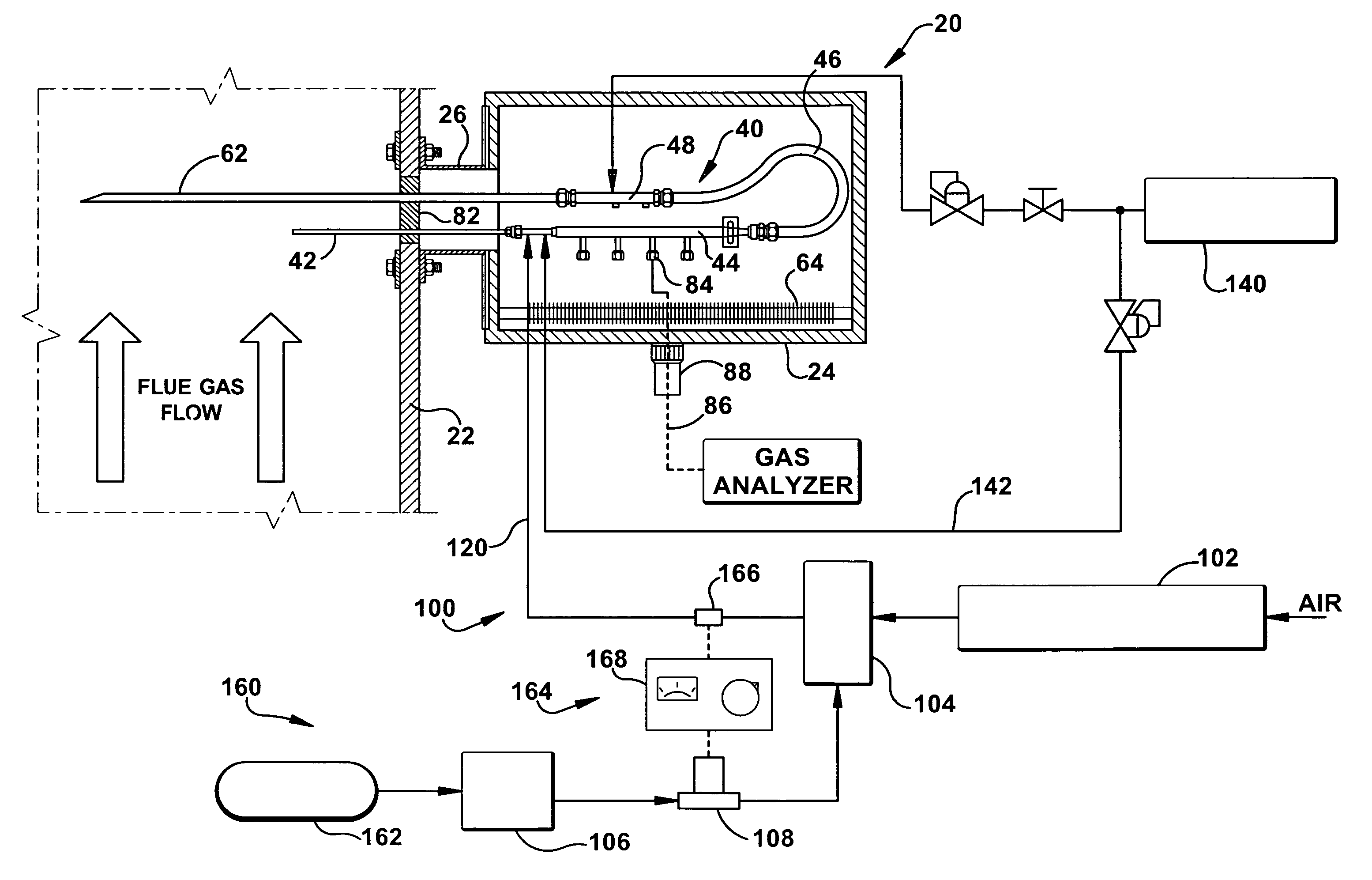

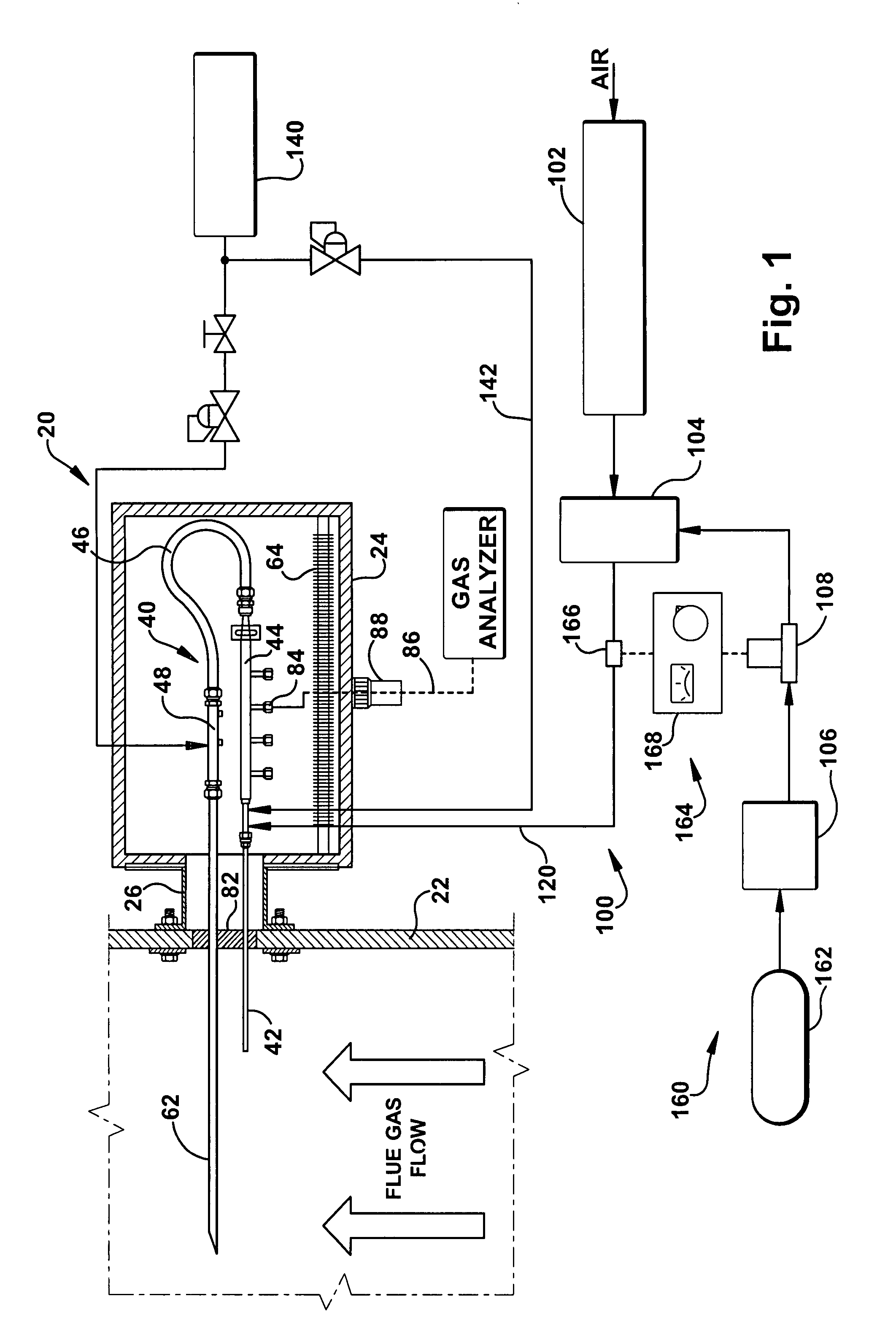

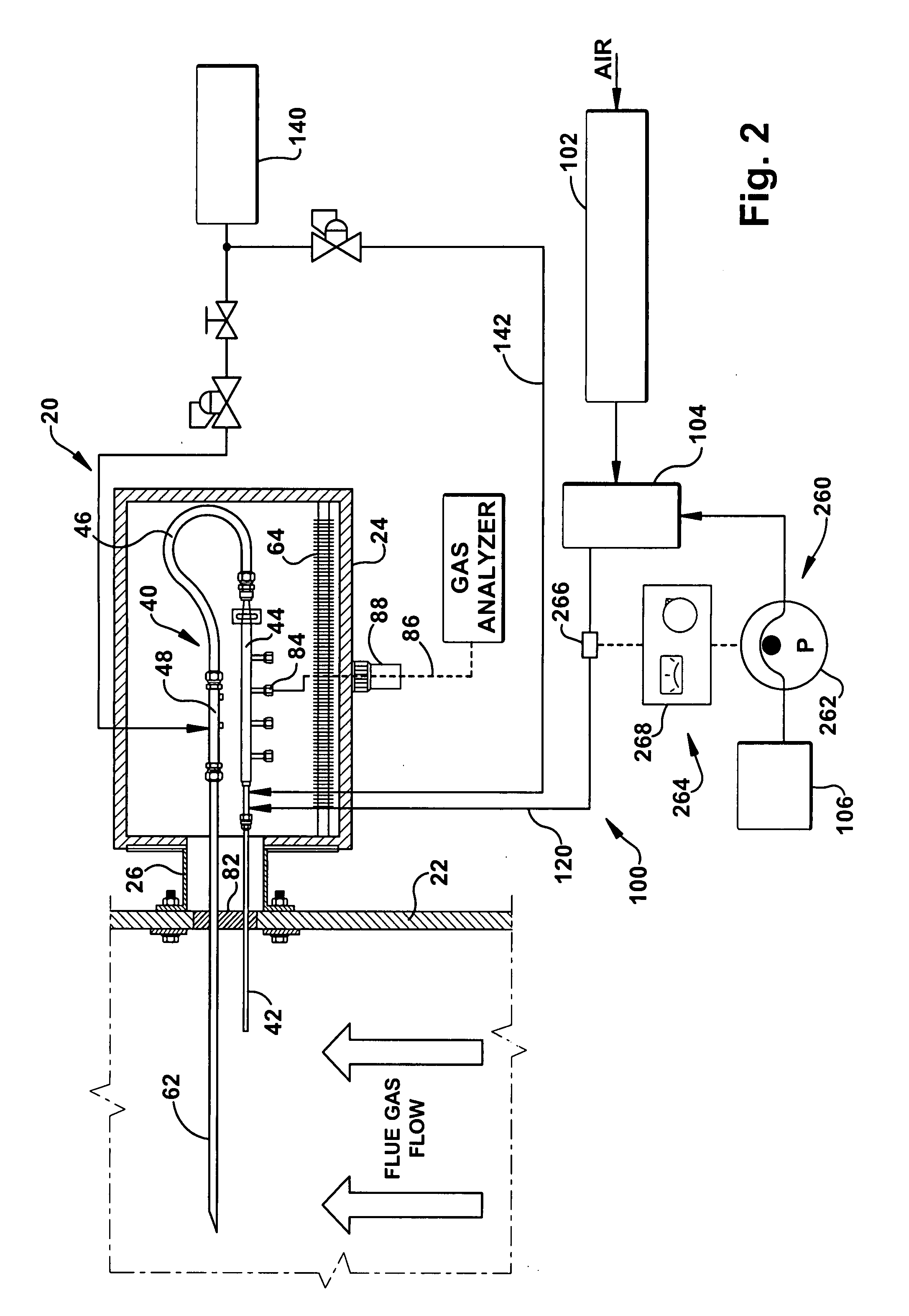

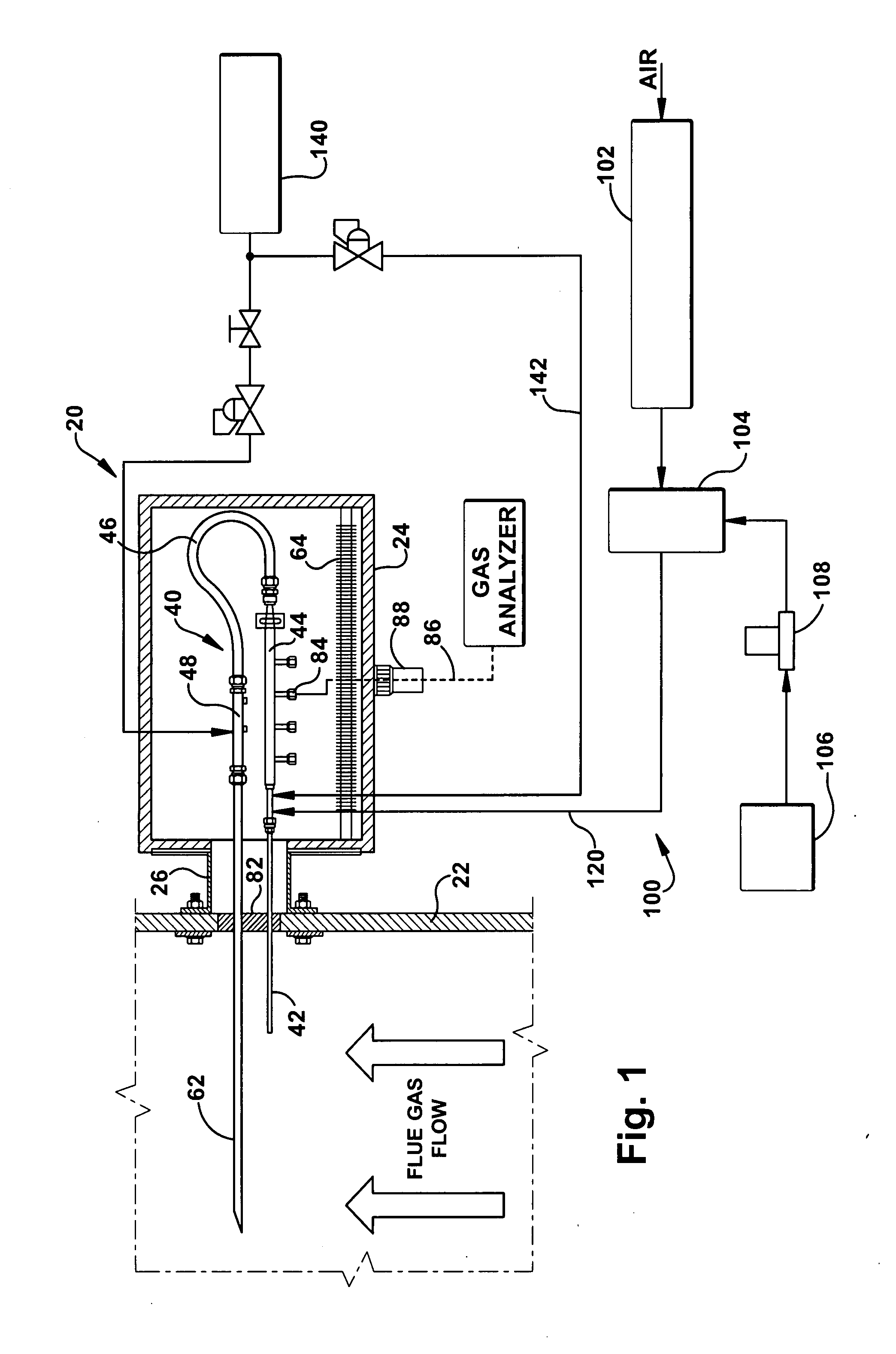

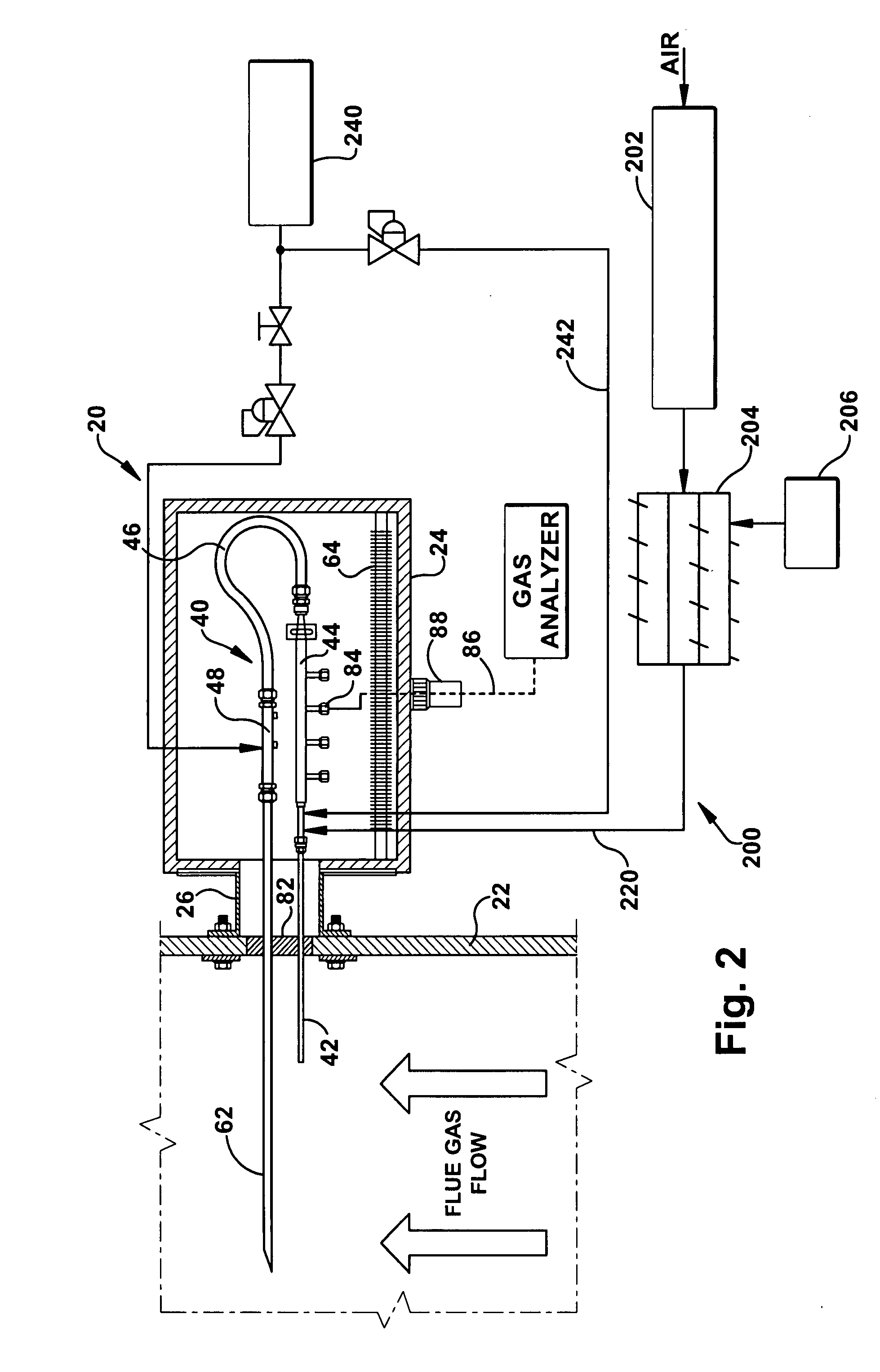

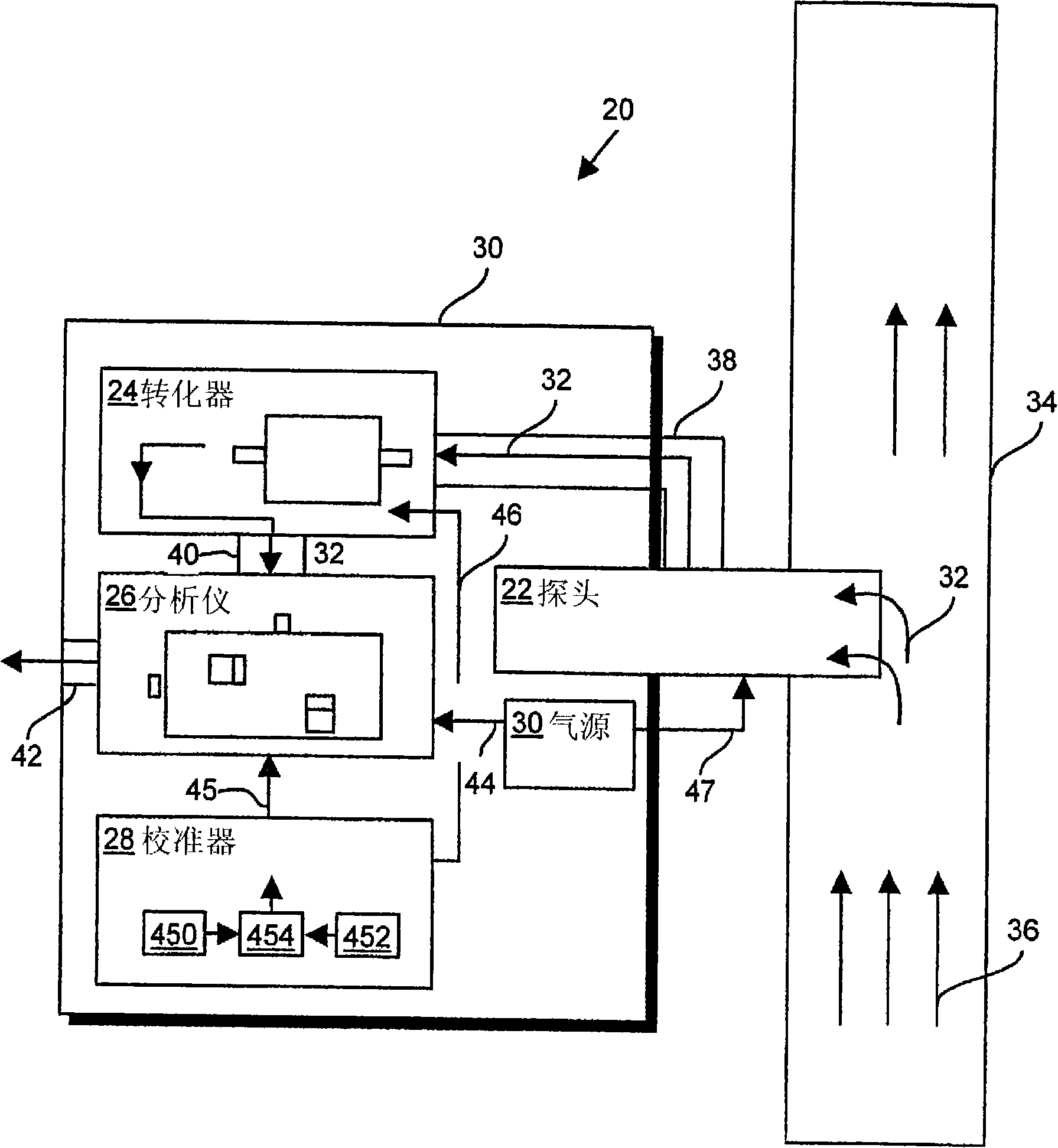

Controlled humidification calibration checking of continuous emissions monitoring system

InactiveUS20090000349A1Accurate measurementWithdrawing sample devicesMaterial analysis by electric/magnetic meansAnalyteEngineering

A continuous emissions monitoring system is in fluid communication with a flue stack conducting exhaust gas from a combustion source. The continuous emissions monitor system comprises an analyzer for measuring concentrations of an analyte present in the exhaust gas. A probe is in fluid communication with the flue stack to acquire a sample of exhaust gas from the flue stack. The probe is also in fluid communication with and located upstream of the analyzer. The probe tends to remove analyte from the sample. A calibration checking system is in fluid communication with the probe. The calibration checking system includes a source that provides a flow of a known concentration of calibration material to be measured by the analyzer. The calibration material is the same as the analyte. A humidifier is associated with the source to provide moisture to a flow of calibration material. The moisture acts to cleanse removed analyte from the probe and thereby enable an accurate measurement of the concentration of the calibration material. A supply system is operatively connected with the humidifier to provide a desired amount of a liquid to the humidifier.

Owner:THE BABCOCK & WILCOX CO

Calibration checking for continuous emissions monitoring system

InactiveUS20080282764A1Accurate measurementFuel testingMaterial analysis by electric/magnetic meansAnalyteEngineering

A continuous emissions monitoring system is in fluid communication with a flue stack conducting exhaust gas from a combustion source. The continuous emissions monitor system comprises an analyzer for measuring concentrations of an analyte present in the exhaust gas. A probe is in fluid communication with the flue stack to acquire a sample of exhaust gas from the flue stack. The probe is also in fluid communication with and located upstream of the analyzer. The probe tends to remove analyte from the sample. A calibration checking system is in fluid communication with the probe. The calibration checking system includes a source that provides a flow of a known concentration of calibration material to be measured by the analyzer. The calibration material is the same as the analyte. A humidifier is associated with the source to provide moisture to a flow of calibration material. The moisture acts to cleanse removed analyte from the probe and thereby enable an accurate measurement of the concentration of the calibration material.

Owner:BABCOCK & WILCOX POWER GENERATION GRP INC

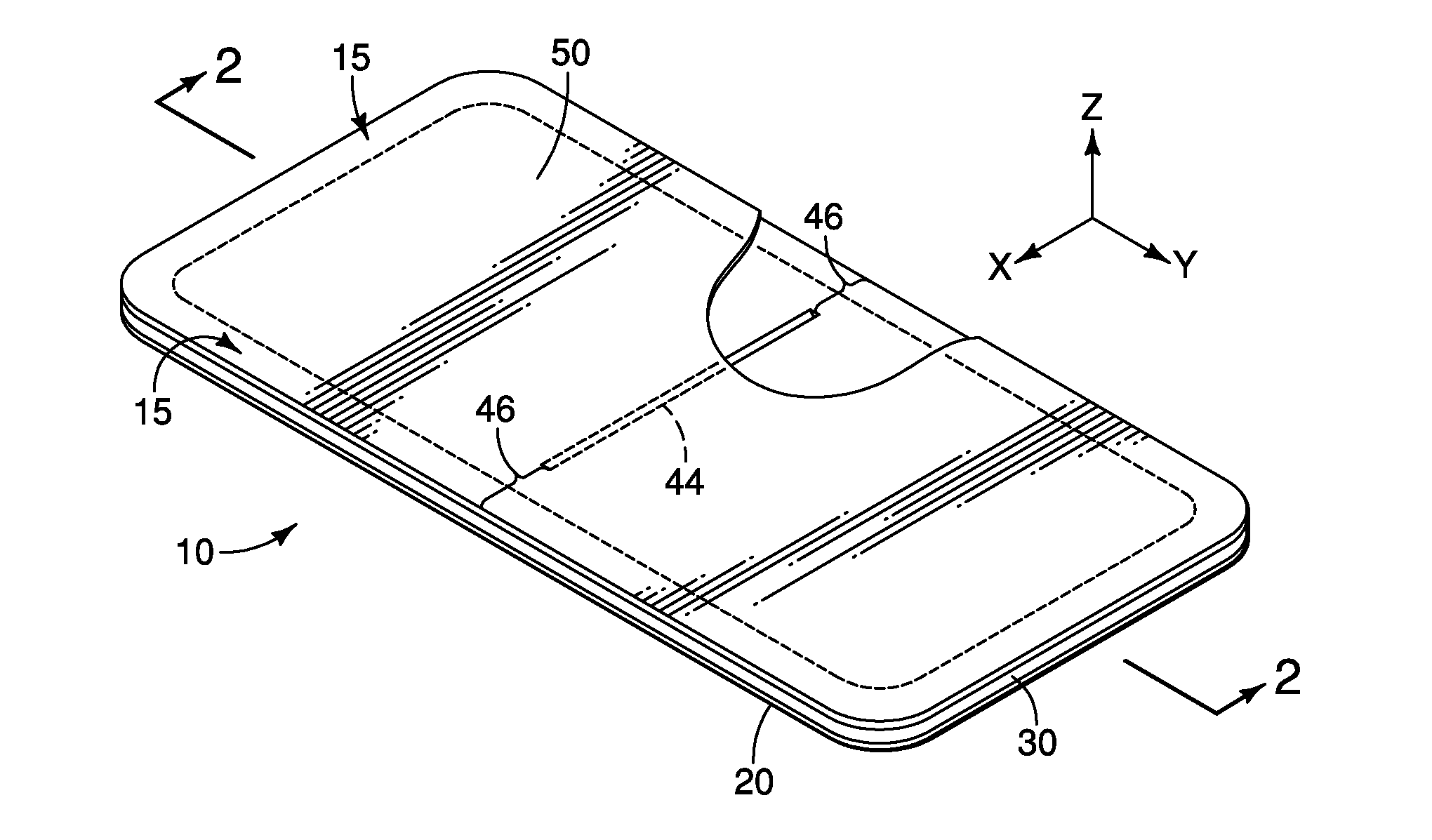

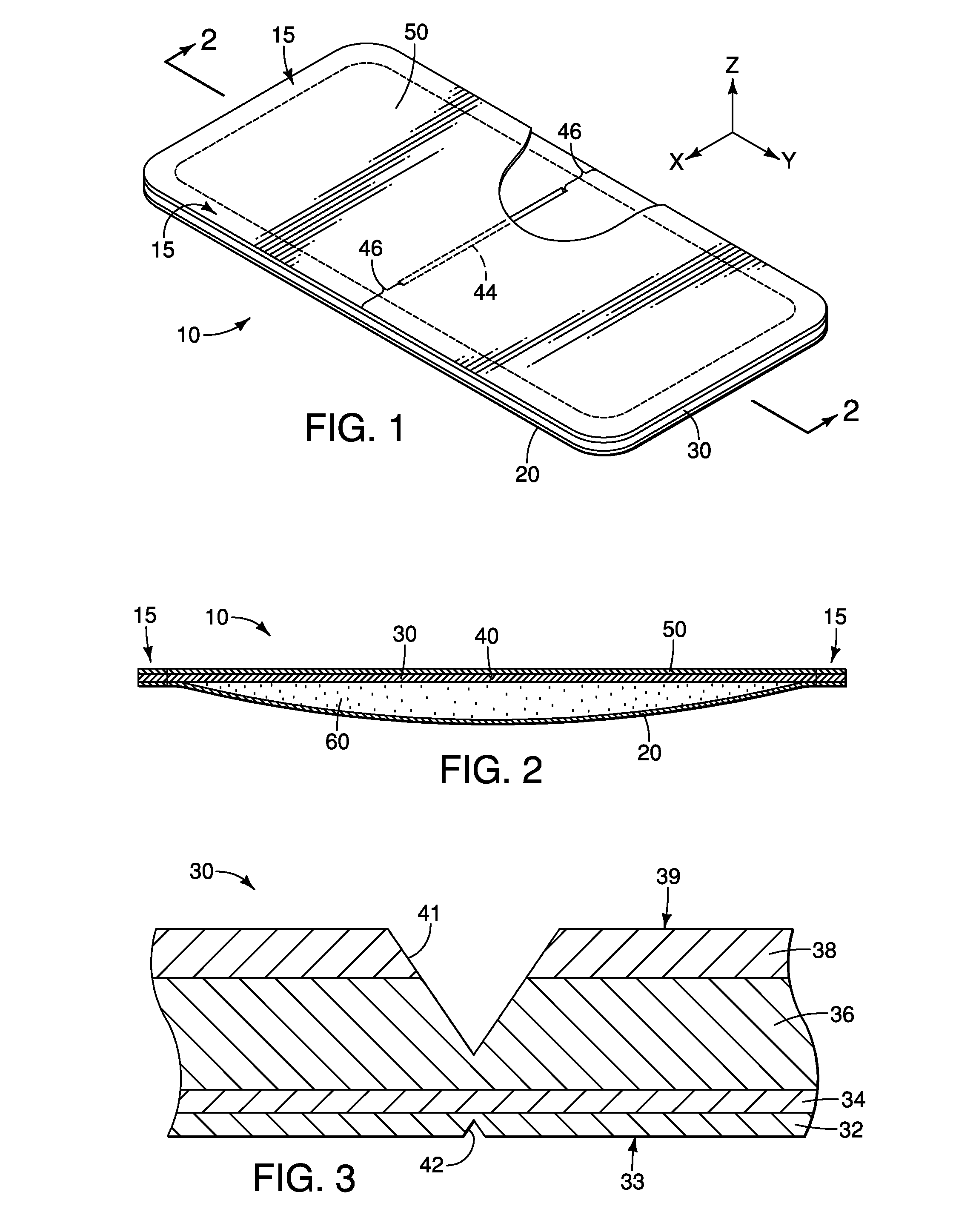

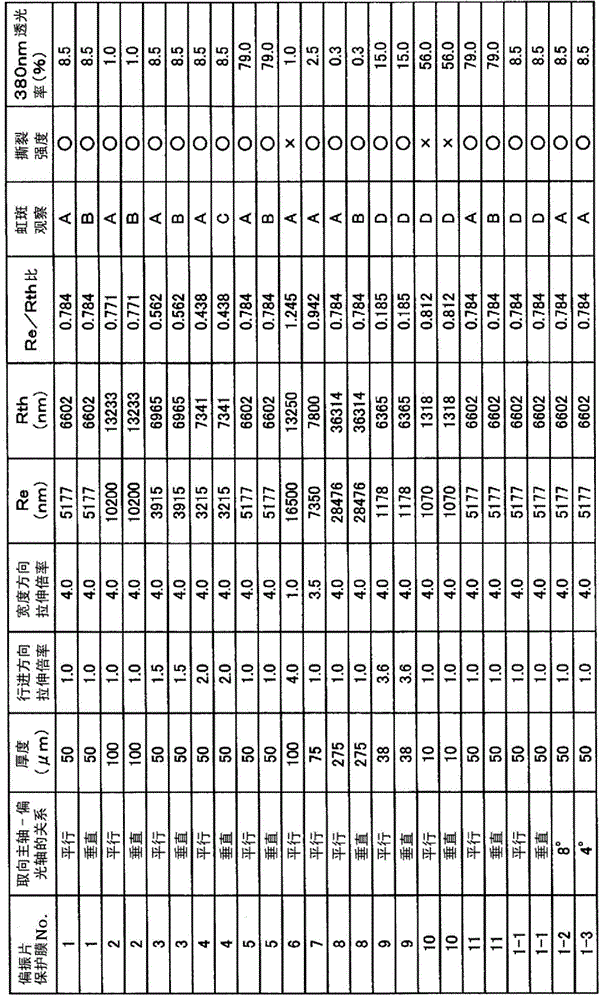

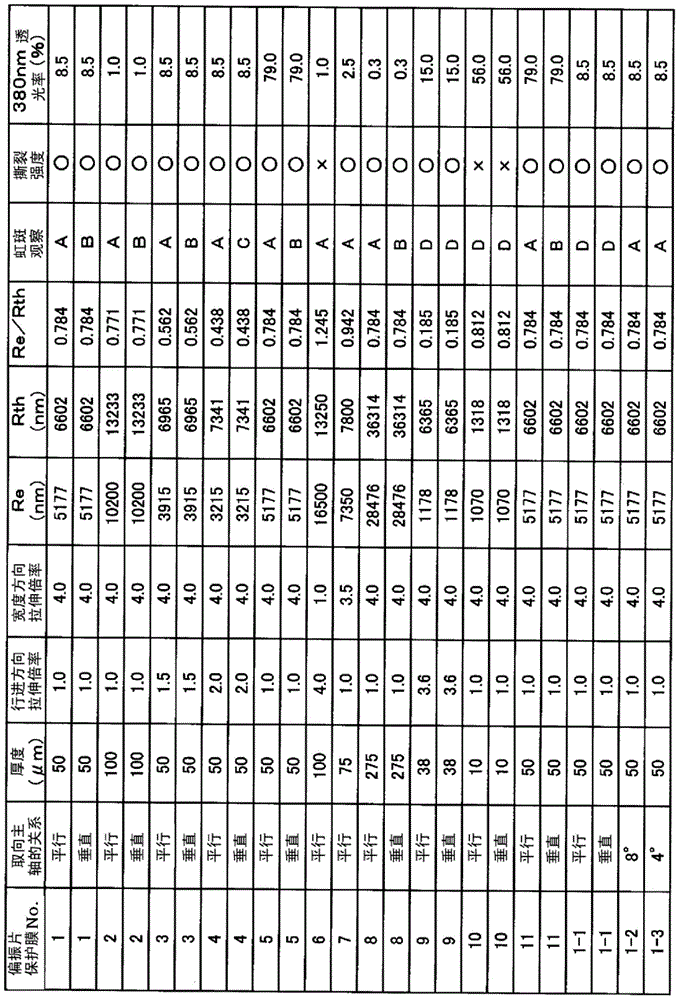

Liquid crystal display device, polarizing plate and polarizer protective film

ActiveCN103959148AModerate mechanical strengthInhibitionPolarising elementsNon-linear opticsTectorial membranePolyester

A purpose of the present invention is to further suppress the occurrence of spectral irregularities in a liquid crystal display device that uses a light emitting diode as a light source, and uses an oriented polyester film having a given retardation as a polarizer protective film. The liquid crystal display device includes a backlight light source, two polarizing plates, and a liquid crystal cell disposed between the two polarizing plates. The backlight light source is a white light source having a continuous emission spectrum. The two polarizing plates are each formed from a polarizer and protective films on both sides of the polarizer. At least one of the protective films on either side is an oriented polyester film having a retardation of 3,000 to 30,000 nm. The polarizing axis of the polarizer and the main orientation axis of the oriented polyester film, which is a protective film of the polarizer, are substantially parallel.

Owner:TOYOBO CO LTD

Filtering particulate materials in continuous emission monitoring systems

InactiveUS7569093B2Facilitate effective blowbackCombination devicesAuxillary pretreatmentParticulatesFilter system

A filtering system for monitoring fluid emissions from a process includes a plurality of filter assembly sections arranged in a parallel fluid flow manner with respect to each other so as to selectively receive a sample fluid (e.g., a sample gas) entering at an inlet of the system. Each filter assembly section includes a filter unit to filter particulate materials from a fluid flowing through the filter, first and second valves disposed at upstream and downstream locations of the filter unit, and a blowback flow path configured to selectively direct a cleaning fluid through the filter unit in a direction that opposes a direction in which the sample fluid flows through the filter unit. Each filter assembly section can be selectively isolated from other portions of the system so as to prevent the sample fluid from flowing through the filter assembly section while allowing a cleaning fluid to be delivered through the blowback flow path of the filter assembly section.

Owner:AIR LIQUIDE AMERICA INC

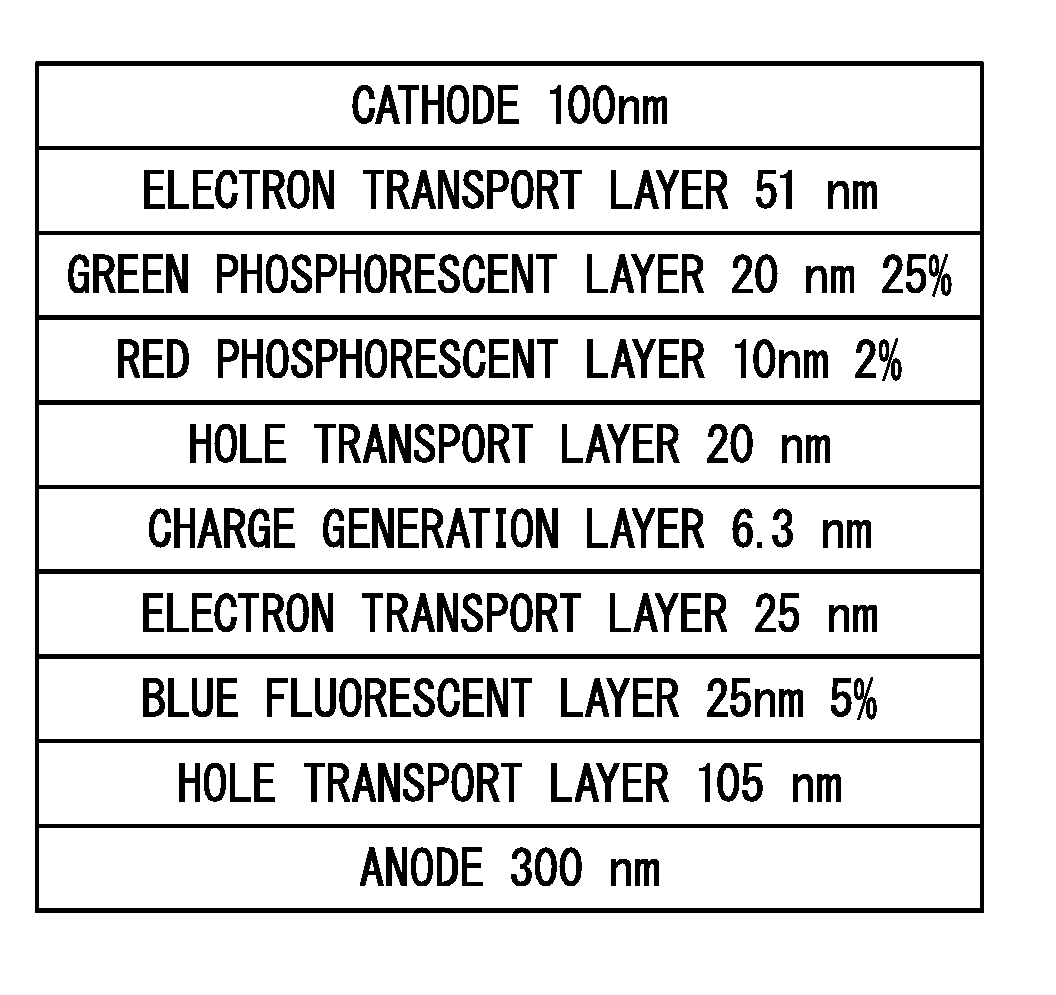

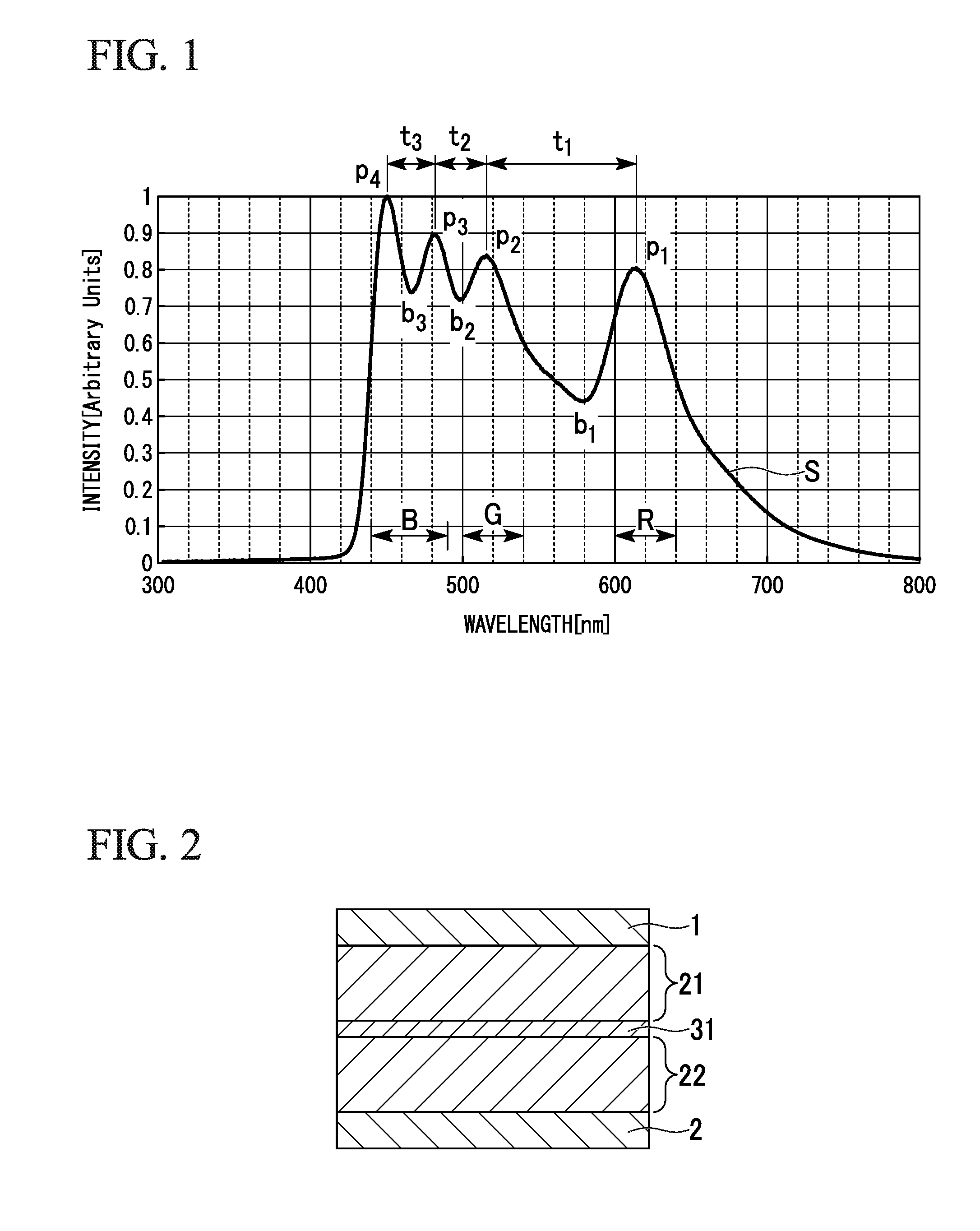

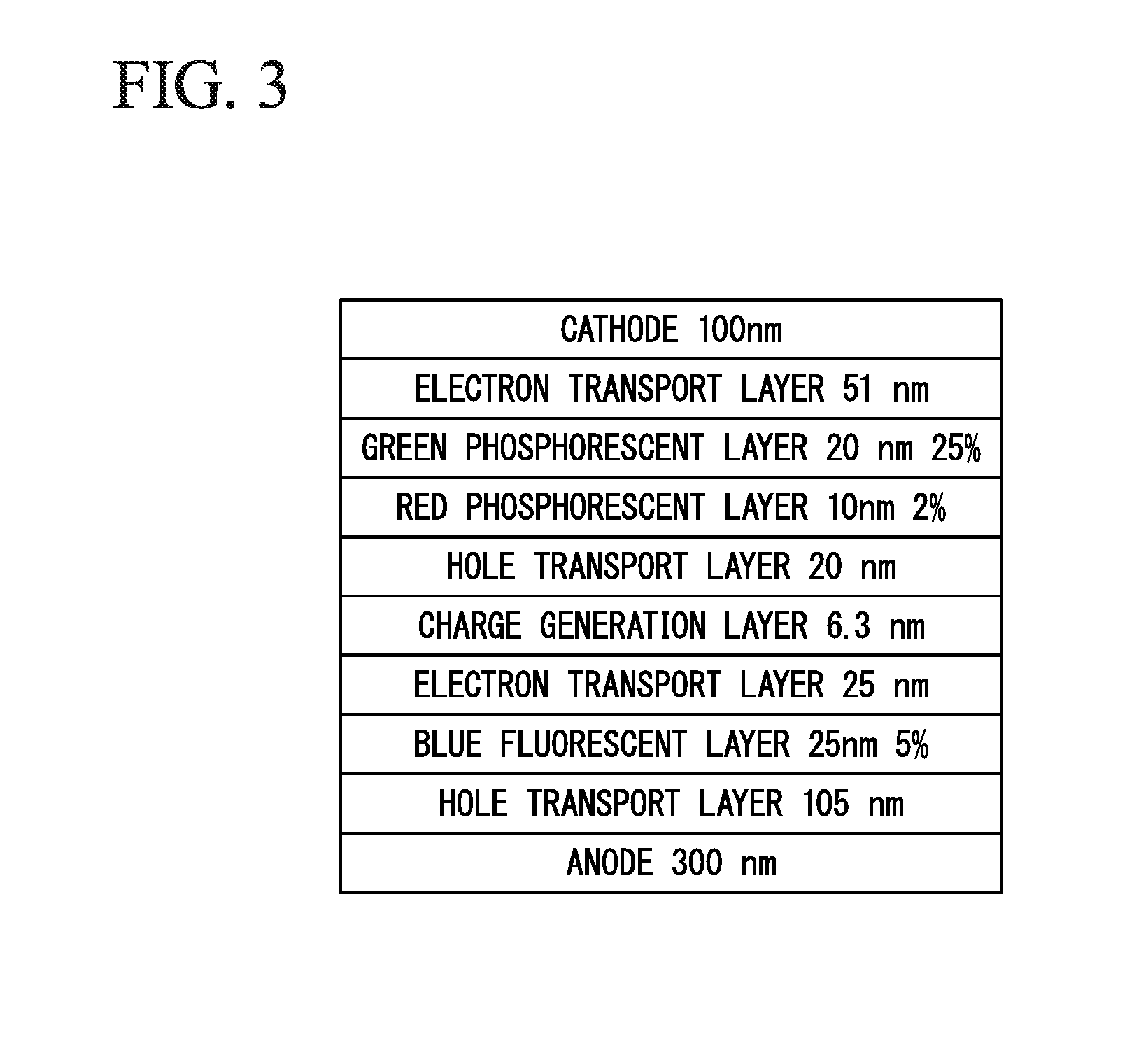

Organic electroluminescent element and lighting device

ActiveUS20150207091A1Good colorElectroluminescent light sourcesSolid-state devicesSimple Organic CompoundsLength wave

Provided is an organic electroluminescent element that can obtain white light with excellent color rendering properties and is particularly suitable for a light source of a lighting device. The organic electroluminescent element includes a plurality of light emitting units that are provided between a cathode and an anode and include at least a light emitting layer made of an organic compound. White light emitted from the plurality of light emitting units has a continuous emission spectrum (S) in a wavelength range of at least 380 nm to 780 nm. The emission spectrum (S) includes one peak wavelength (p1) in a red wavelength range (R) of 600 nm to 640 nm, one peak wavelength (p2) in a green wavelength range G of 500 nm to 540 nm, and two peak wavelengths (p3) and (pa) in a blue wavelength range B of 440 nm to 490 nm.

Owner:XIANYANG CHVT NEW DISPLAY TECH CO LTD

Liquid crystal display device, polarizing plate, and polarizer protective film

ActiveCN103959149AModerate mechanical strengthInhibitionPolarising elementsNon-linear opticsPolyesterPolarizer

The purpose of the present invention is to further suppress the occurrence of spectral irregularities in a liquid crystal display device that uses a light emitting diode as a light source, and uses an oriented polyester film having a given retardation as a polarizer protective film. This liquid crystal display device includes a backlight light source, two polarizing plates, and a liquid crystal cell disposed between the two polarizing plates. The backlight light source is a white light source having a continuous emission spectrum. The two polarizing plates are each formed from a polarizer and protective films on both sides of the polarizer. At least one of the protective films on either side is an oriented polyester film having a retardation of 3000 to 30000 nm. The main orientation axes of the oriented polyester films configuring the two polarizing plates are substantially parallel to each other.

Owner:TOYOBO CO LTD

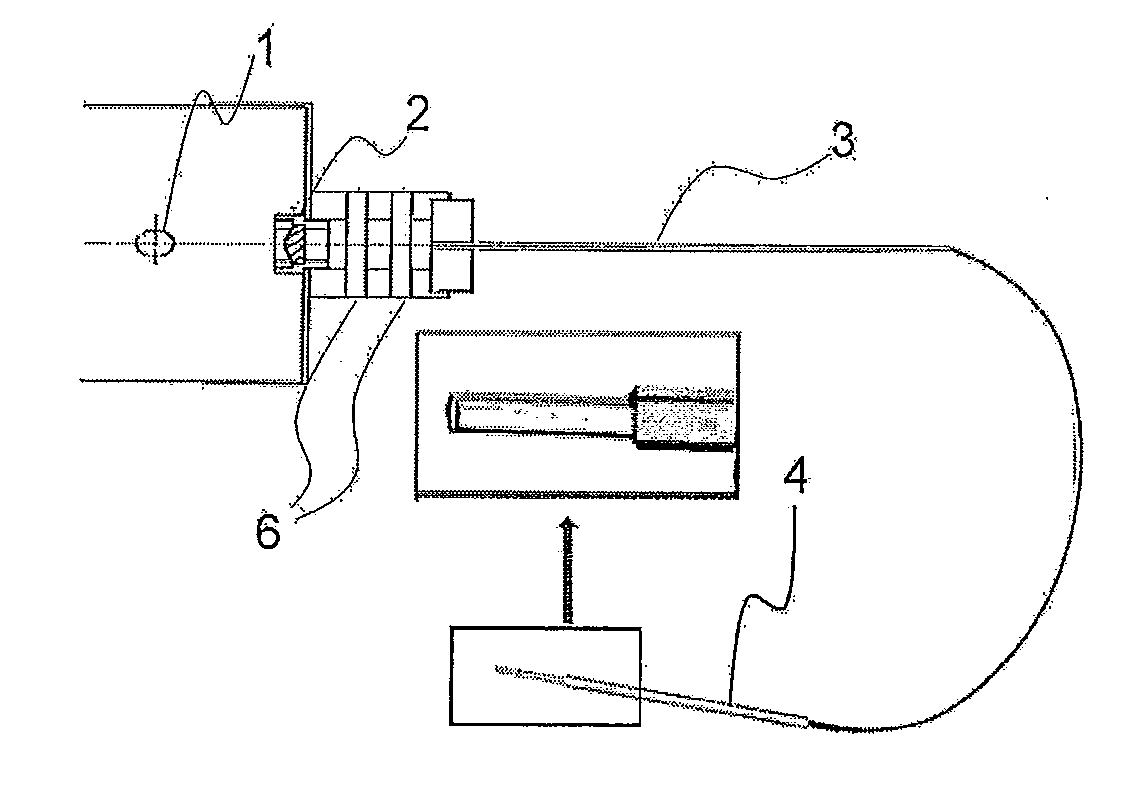

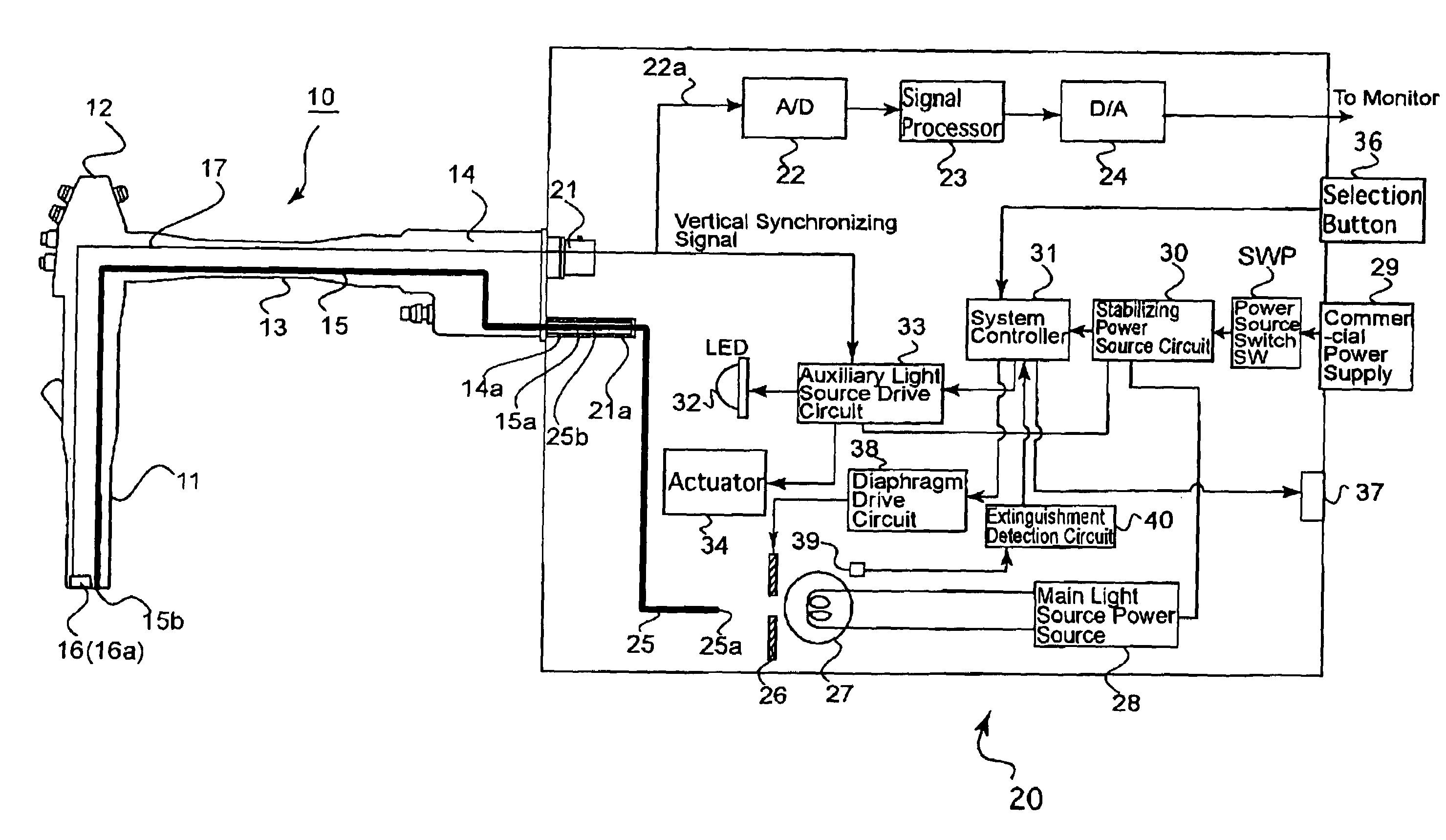

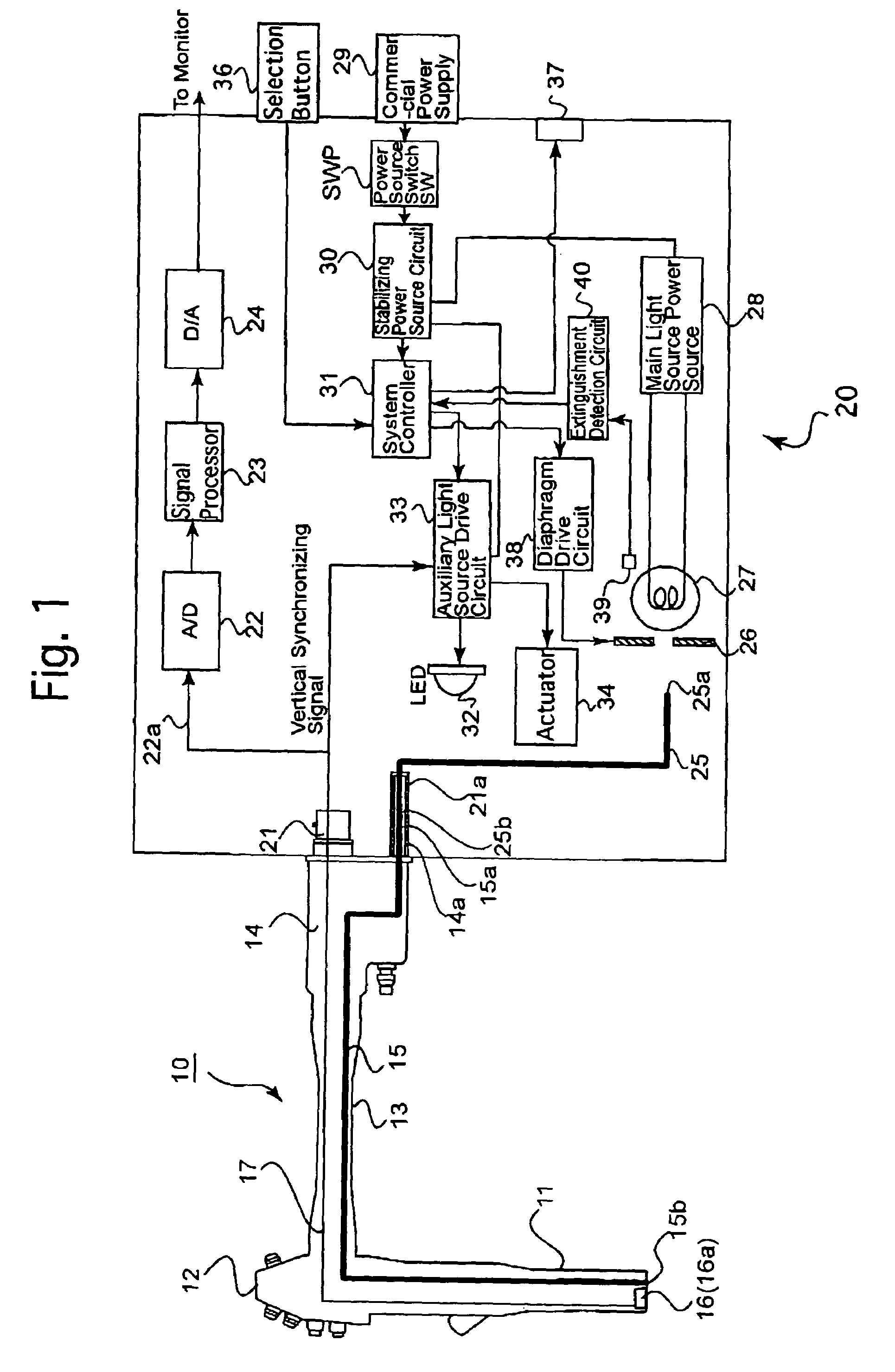

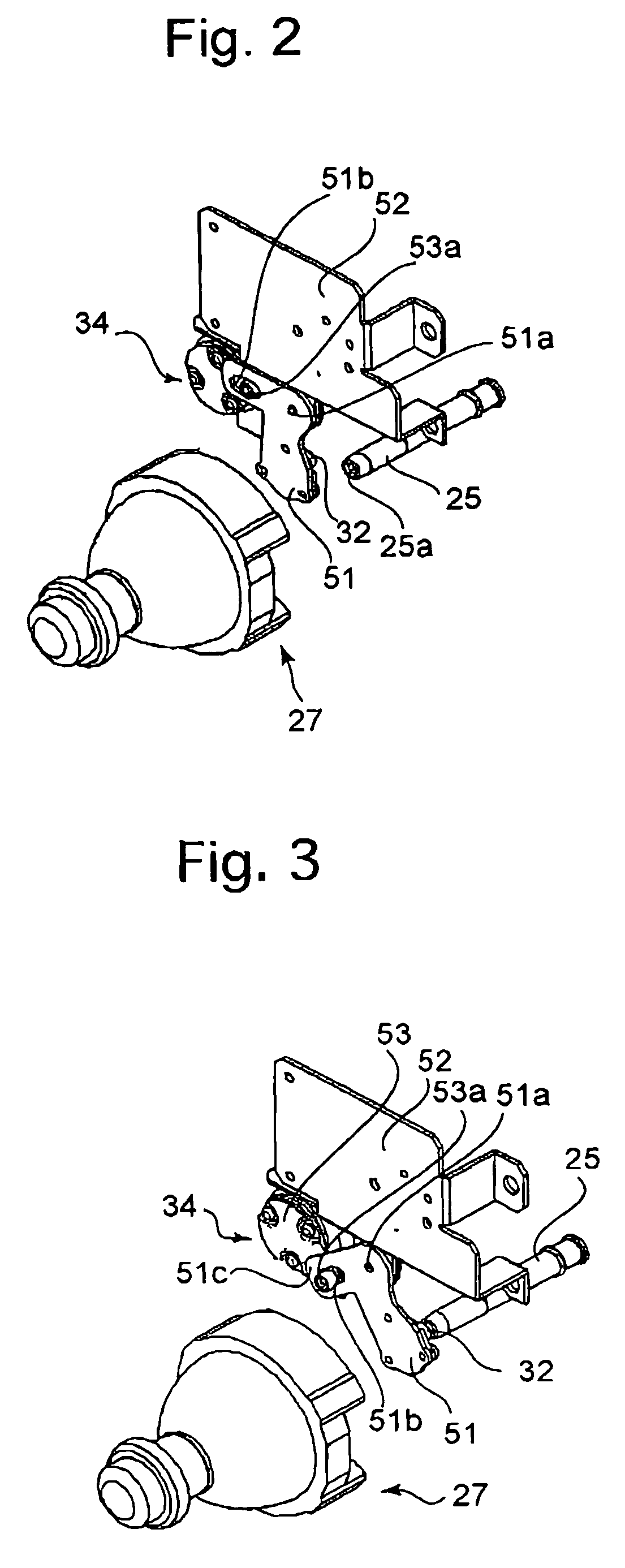

Light source apparatus for endoscope

InactiveUS7077804B2Drawback can be obviatedTelevision system detailsMechanical apparatusLight guideOptoelectronics

A light source apparatus for an endoscope including a main light source; a light guide member whose incident end face is opposed to the main light source and which guides light incident thereon to an emission end face thereof; an auxiliary light source which is activated to emit light when no light is emitted from the main light source and which is supported to move between a stand-by position in which the auxiliary light source is located out of a main light path between the main light source and the incident end face and an operative position in which the auxiliary light source is located in the main light path and is opposed to the incident end face when the main light source is inoperative; and an auxiliary light source emission control device for driving the auxiliary light source at a continuous emission mode to emit light of a predetermined intensity or at an intermittent emission mode to emit light of an intensity higher than the predetermined intensity.

Owner:HOYA CORP

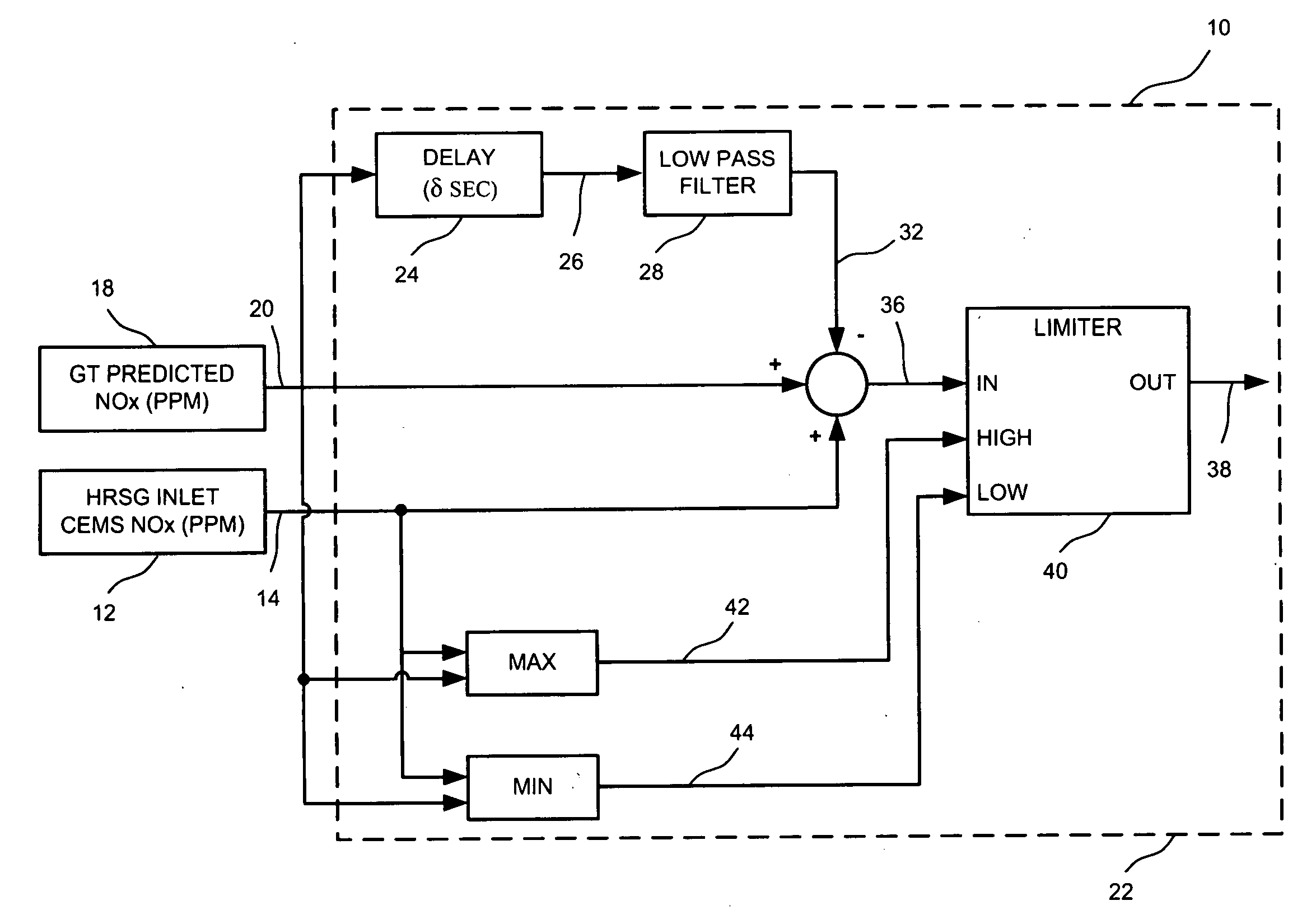

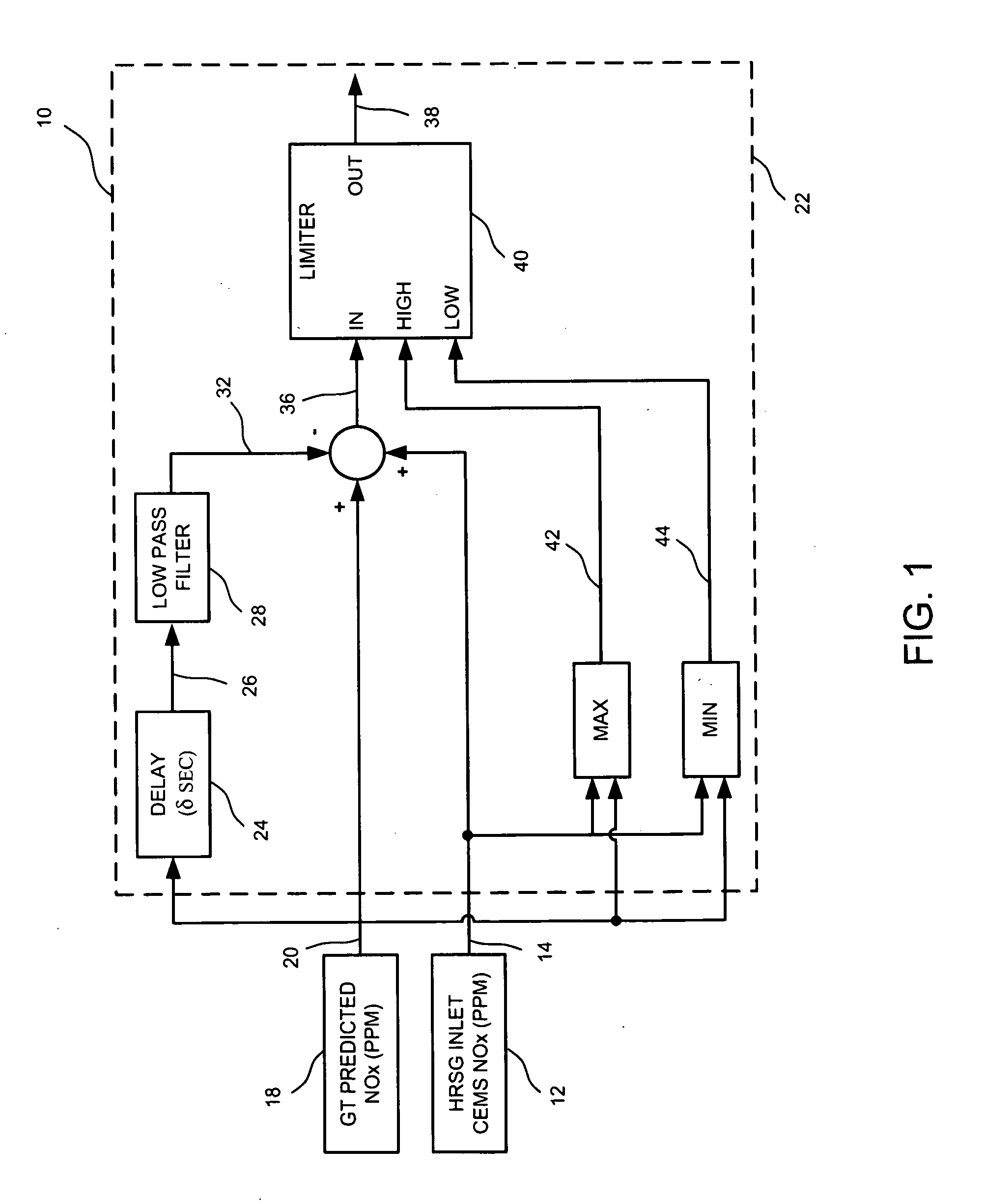

SYSTEM AND METHOD FOR OBTAINING AN OPTIMAL ESTIMATE OF NOx EMISSIONS

A control system for providing an optimal estimate of NOx emission in an exhaust during a selective catalytic reduction process is provided. The control system includes a continuous emission monitoring sensor configured to generate a responsive signal representing a first estimate of NOx emission; wherein the responsive signal has a first time lag between a time of measurement of NOx emission and the time when the corresponding responsive signal is made available by the continuous emission monitoring sensor, and the continuous emission monitoring sensor has a first time constant. The control system also includes a virtual sensor configured to generate a relatively faster responsive signal representing a second estimate of NOx emission. The control system further includes a processor that includes a time delay compensation circuit configured to introduce a second time lag in the relatively faster responsive signal, wherein the second time lag matches the first time lag. The processor also includes a low pass filter circuit coupled to the time delay compensating circuit, wherein the low pass filter circuit has a second time constant matching the first time constant to generate a time delayed signal representing a third estimate of NOx emission. The processor is further configured to subtract the time delayed signal from the summation of the responsive signal and the relatively faster responsive signal to generate the optimal estimate of the NOx emission, wherein the optimal estimate is fed as a feedforward signal into an injection system in the selective catalytic reduction process.

Owner:GENERAL ELECTRIC CO

Mercury Ionic Gas Standard Generator For A Continuous Emissions Monitoring System

InactiveUS20090098656A1Replacement is neededLiquid surface applicatorsGas treatmentFlue gasAqueous solution

A mercury ionic gas standard generator for use in the continuous emissions monitoring of exhaust flue gas streams is disclosed. More specifically, the mercury ionic gas standard generator uses a reservoir being coated with an inert silicon-based coating for transporting a volume of an aqueous ionic mercury solution to a liquid mass flow controller and vaporizer.

Owner:GENERAL ELECTRIC CO

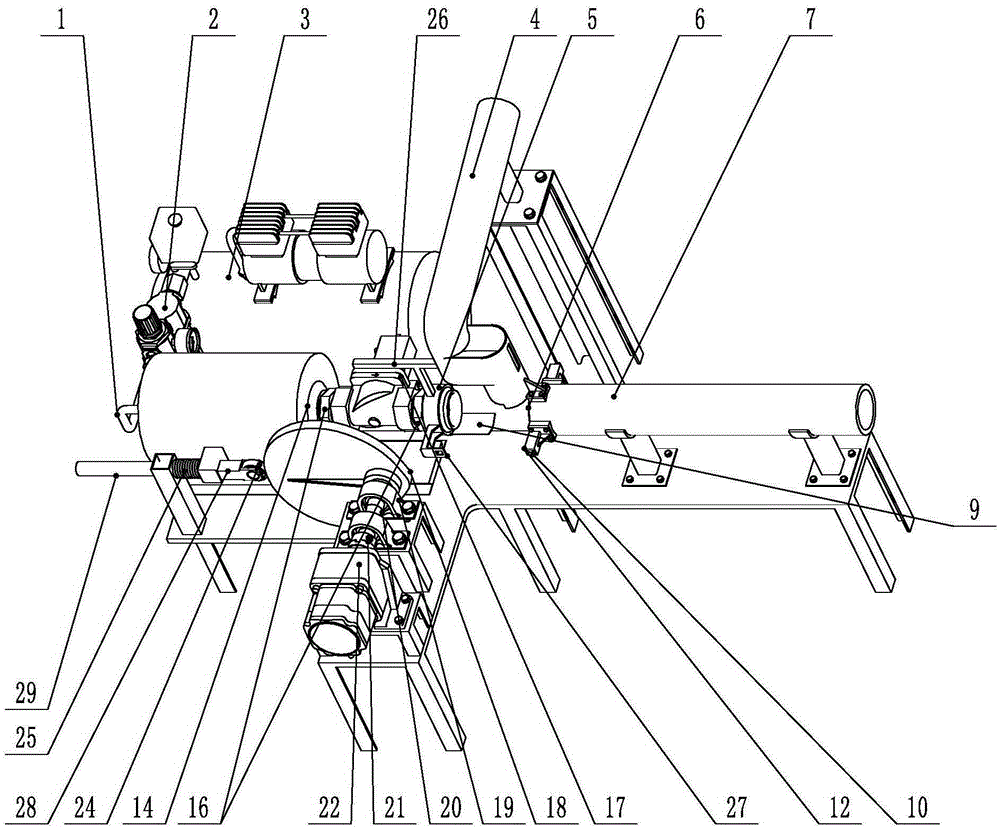

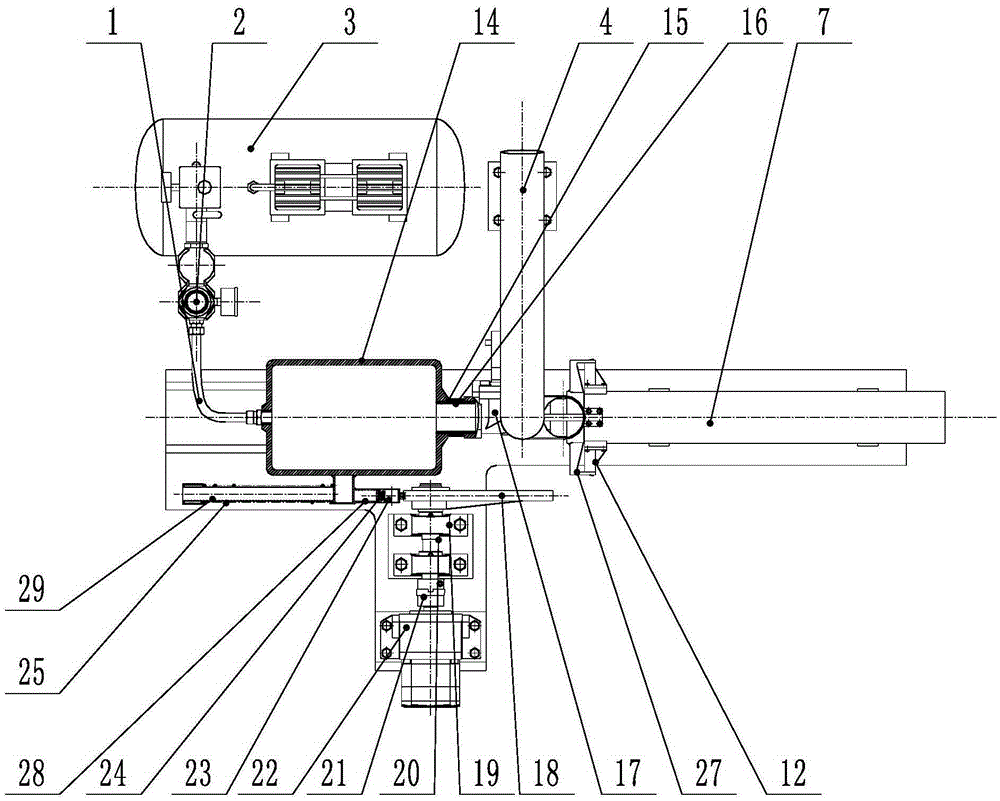

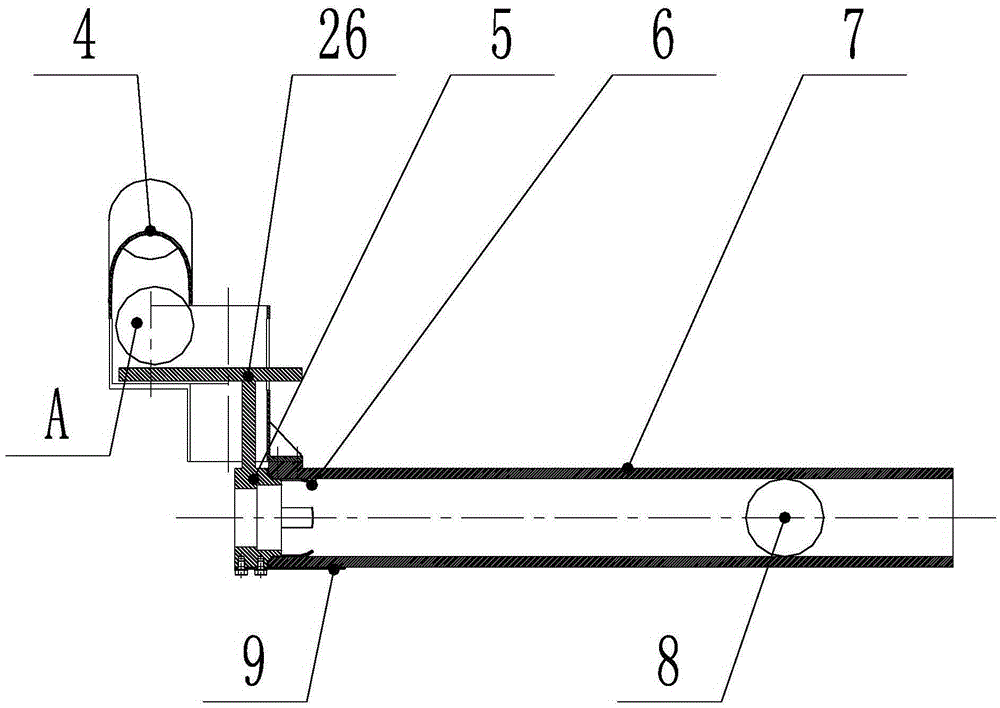

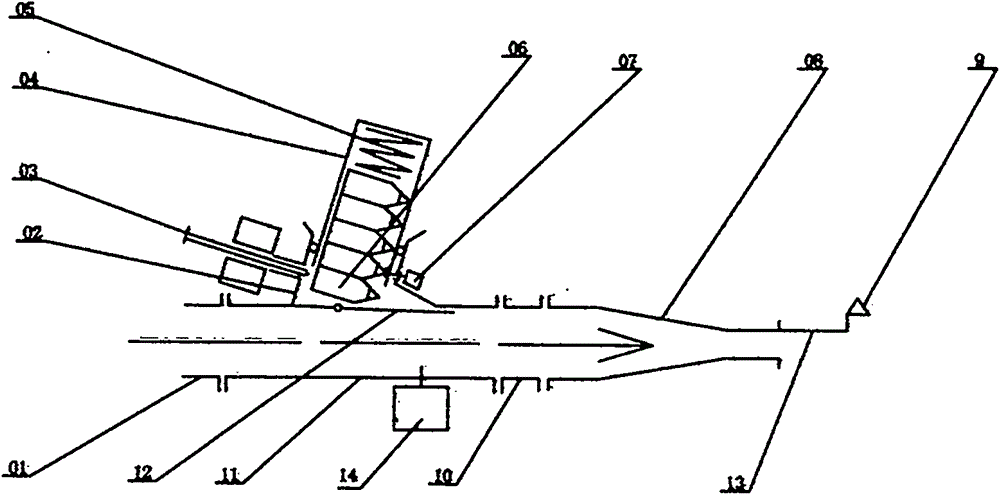

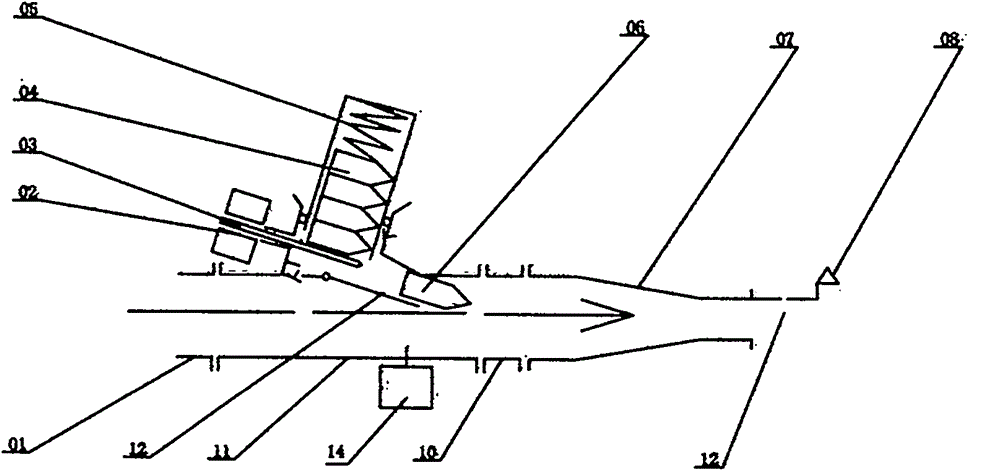

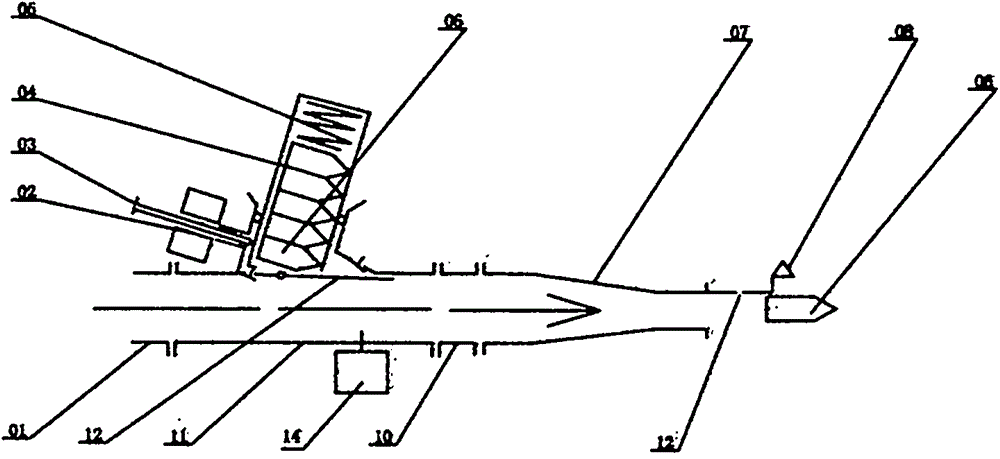

Steel ball continuous emission device for ball grinder impact detection

InactiveCN105387984ASimple structureSmall sizeMaterial strength using repeated/pulsating forcesShock testingGas compressorMiniaturization

The present invention discloses a steel ball continuous emission device for ball grinder impact detection. The device comprises an air compressor (3), a pressure reducing valve (2), an air chamber (14), a ball inlet pipe (4), a bore (7), and a cam mechanism. The air chamber (14) is connected to the pressure reducing valve (2) through a soft pipe (1). The pressure reducing valve (2) is connected to the air outlet of the air compressor (3). The air outlet of the air chamber (14) is connected to a solenoid shut-off valve (17) through an external screwed pipe joint (16). The solenoid shut-off valve (17) is connected to an air inlet end disk (5) through the external screwed pipe joint (16) and is used for controlling the closing and opening of the air outlet of the air chamber (14). The cam mechanism is used for realizing the periodical feeding and retreat of the air inlet end disk (5). The targets of the control of the impact emission steel ball speed and the miniaturization of a device size can be realized, steel balls can be continuously loaded with intervals, and the continuous impact emission can be realized.

Owner:CHINA UNIV OF MINING & TECH +1

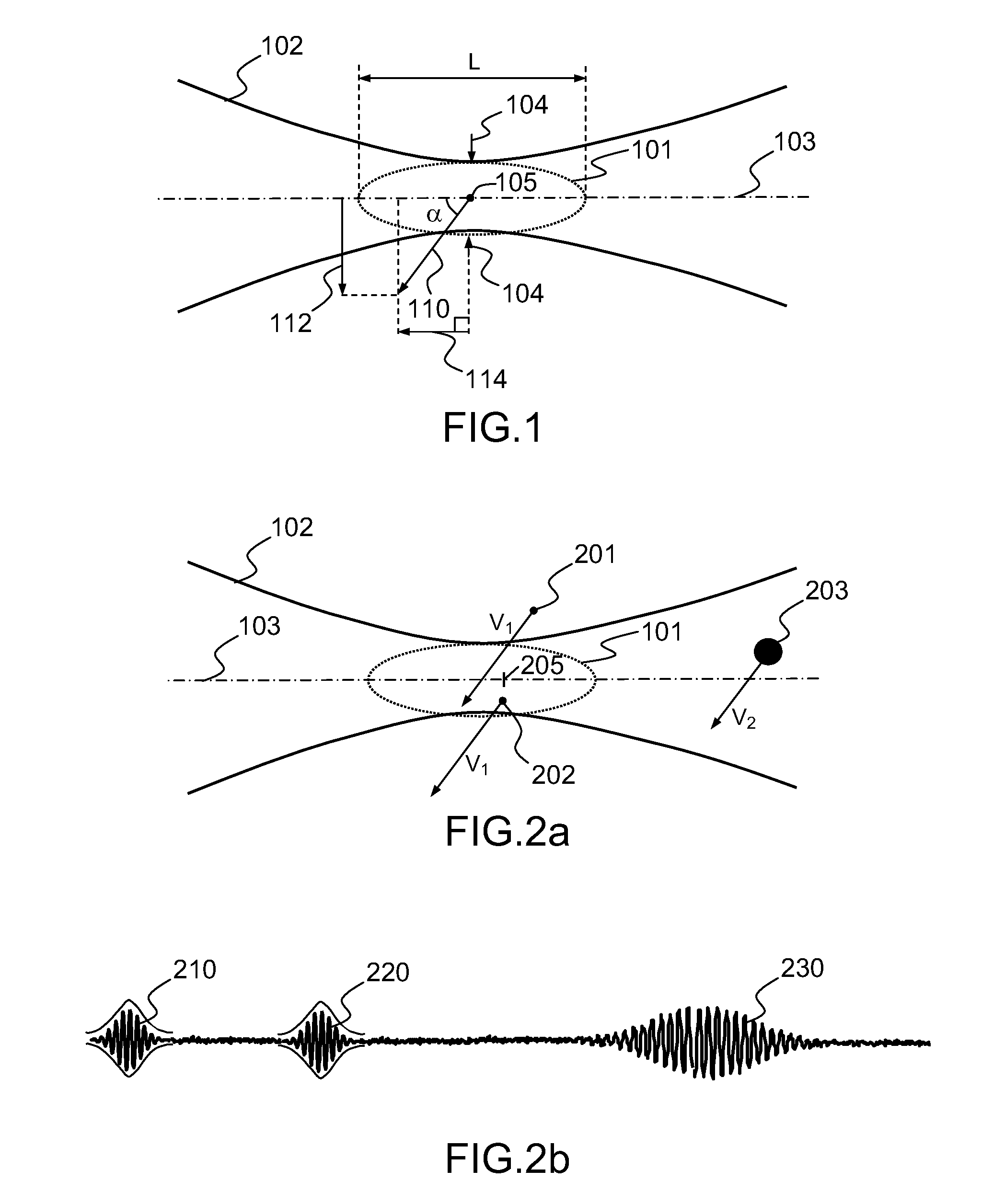

Single-Particle LIDAR Anemometry Method and System

ActiveUS20110181863A1Reduce power/sensitivity requirementGood bijectionDevices using optical meansFluid speed measurementFrequency modulationDisplacement velocity

The present invention concerns a single-particle LIDAR anemometry method and system comprising the continuous emission of one or more light beams through a gas containing particles, said beam being focused onto a measurement volume, a step of detecting a signal backscattered by particles passing through said volume, the method being characterized in that it comprises at least the following phases:determining in a time period Δt the frequency of each of the pulses included in the backscattered signal;distinguishing pulses based on duration and / or intensity and / or frequency-modulation criteria; andestimating the displacement velocity of said beam relative to the gas from several of the frequencies determined over the time period Δt excluding those corresponding to the pulses distinguished during the preceding stepA notable application of the invention is for the measurement of the airspeed of an aircraft

Owner:THALES SA

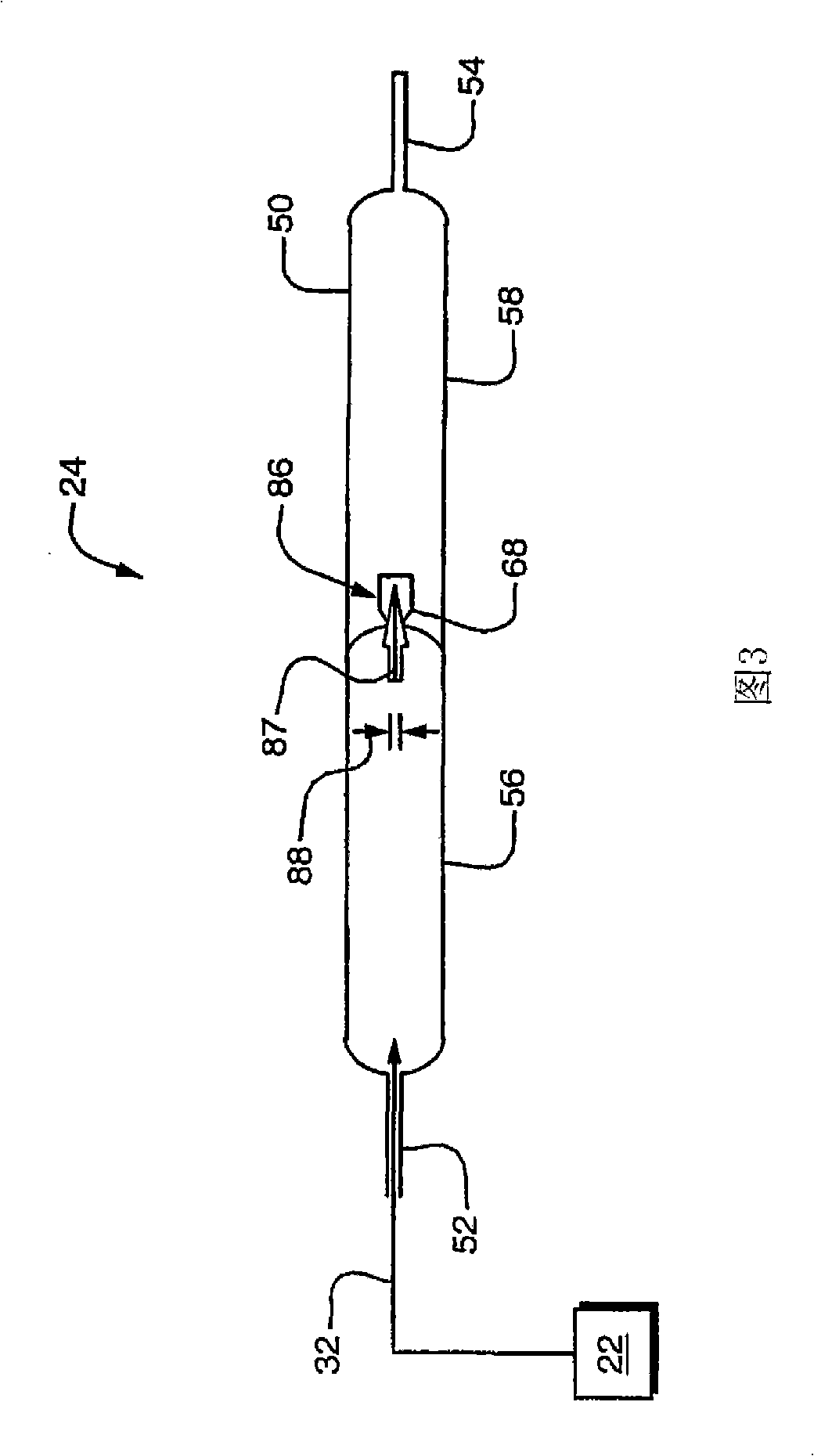

Method and apparatus for monitoring mercury in a gas sample

A converter of the Continuous Emission Monitoring System (CEMS) receives a gas sample containing vaporized mercury from a probe. The converter converts oxidized mercury present within the gas sample into an elemental mercury component and an oxidizing component using thermal cracking. The converter also reduces the pressure of the gas sample to minimize recombination of the elemental mercury component with the oxidizing components. A mercury analyzer of the system receives the reduced pressure gas sample from the converter and detects the fluorescence of the elemental mercury within the sample. The mercury analyzer holds the gas sample at the reduced pressure to reduce an effect of fluorescence quenching on the fluorescence of the elemental mercury within the sample and provides substantially accurate measurement of the concentration of the elemental mercury in the gas sample.

Owner:THERMO ELECTRON A DE

Self-powered, piezo-surface acoustic wave apparatus and method

ActiveUS8860553B2Electric signal transmission systemsAcceleration measurement using interia forcesEngineeringSurface acoustic wave

An autonomous, self-powered device includes a radioisotope-powered current impulse generator including a spring assembly comprising a cantilever, and a piezoelectric-surface acoustic wave (P-SAW) structure connected in parallel to the current impulse generator. Positive charges are accumulated on an electrically isolated 63Ni thin film due to the continuous emission of β-particles (electrons), which are collected on the cantilever. The accumulated charge eventually pulls the cantilever into the radioisotope thin-film until electrical discharge occurs. The electrical discharge generates a transient magnetic and electrical field that can excite the RF modes of a cavity in which the electrical discharge occurs. A piezoelectric-SAW resonator is connected to the discharge assembly to control the RF frequency output. A method for generating a tuned RF signal includes inputting an energy pulse to a P-SAW resonator, exciting the resonant frequency thereof, and outputting an RF signal having a frequency tuned to the resonator frequency.

Owner:CORNELL UNIVERSITY

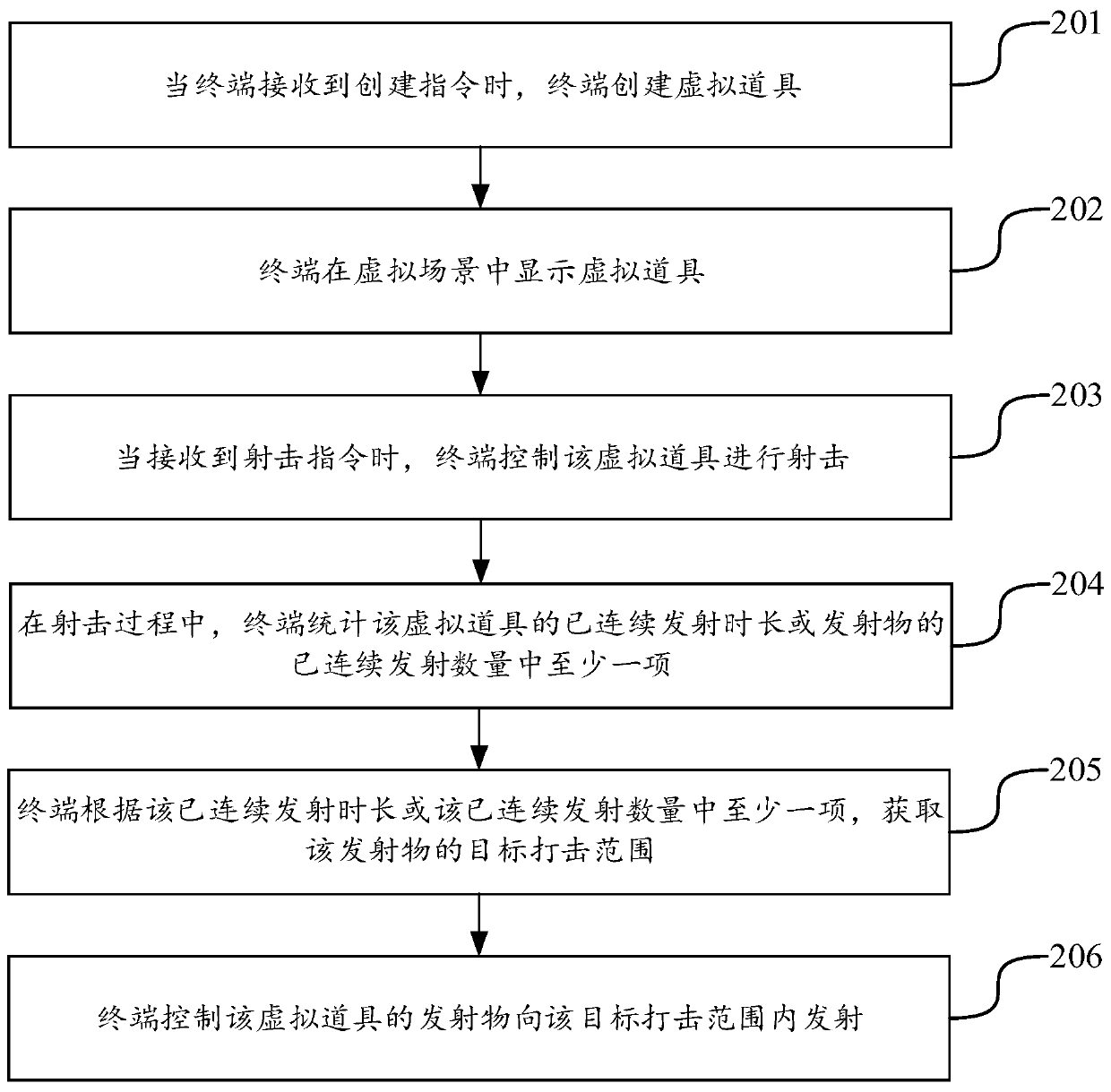

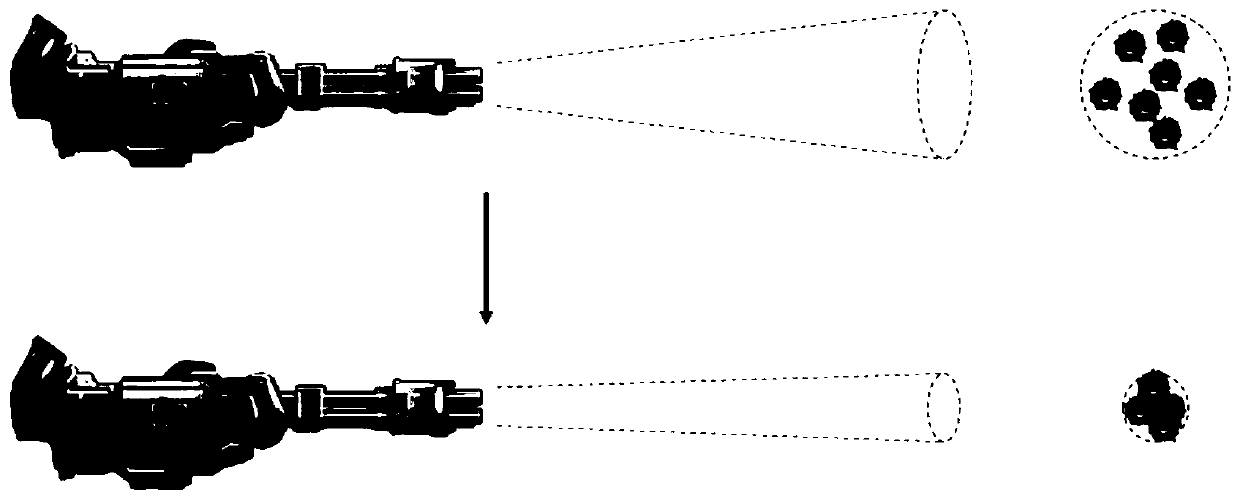

Virtual prop control method and device, equipment and storage medium

PendingCN110585716AImprove control effectRetain recoilVideo gamesComputer scienceComputer engineering

The application discloses a virtual prop control method and device, equipment and a storage medium and belongs to the technical field of computers. The application provides a virtual prop control method, the striking range of an emission object can be determined according to at least one of the continuous emission duration of a virtual prop or the continuous emission number of the emission object,and the striking range is negatively correlated with the at least one piece of data, so that the striking range of the emission object is gradually reduced as the continuous shooting duration increases and the emission number increases, the recoil force of simulating the virtual prop can be retained, the operation of a user is simplified, the fairness of the game is ensured, and the control effect of the virtual prop is good.

Owner:TENCENT TECH (SHENZHEN) CO LTD

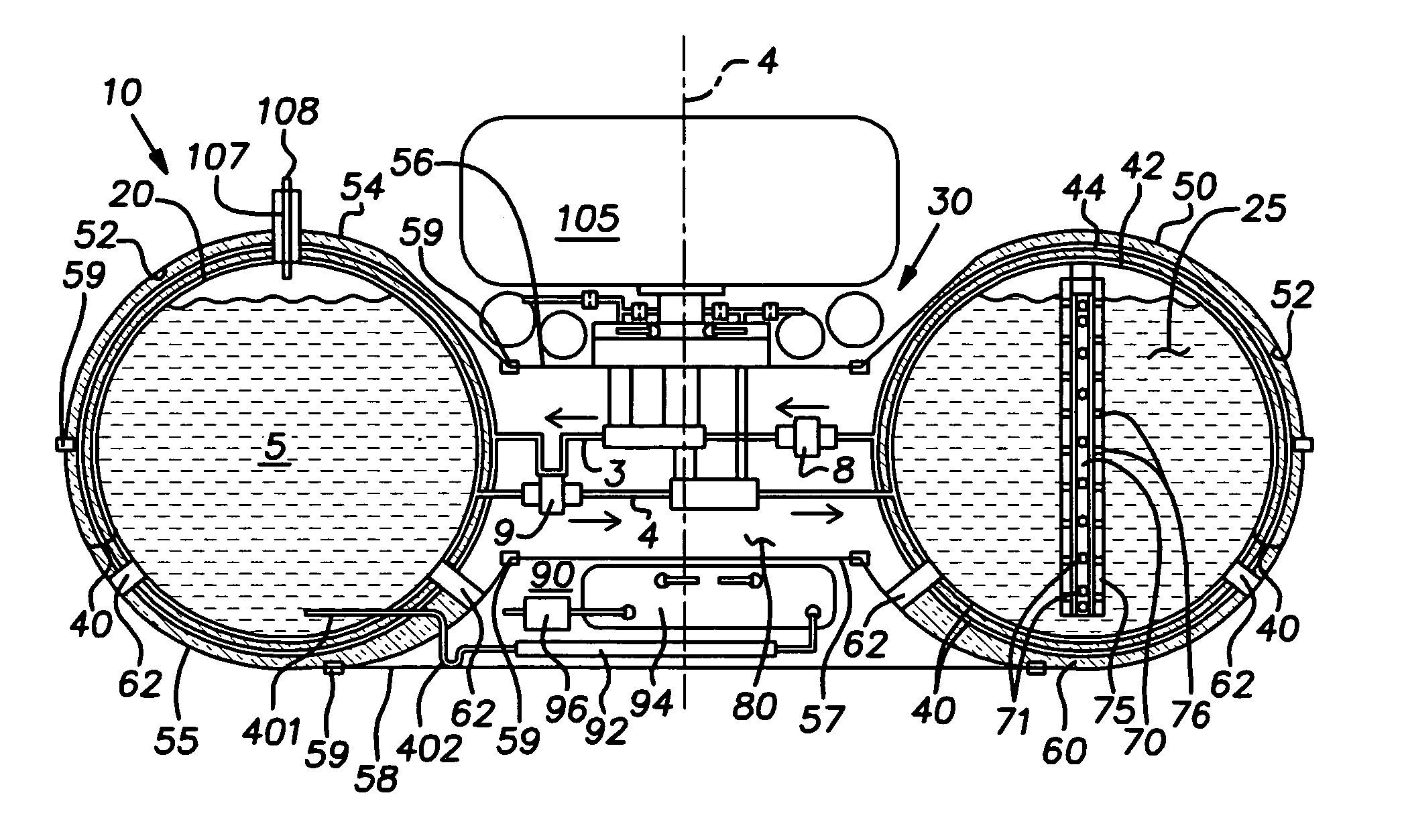

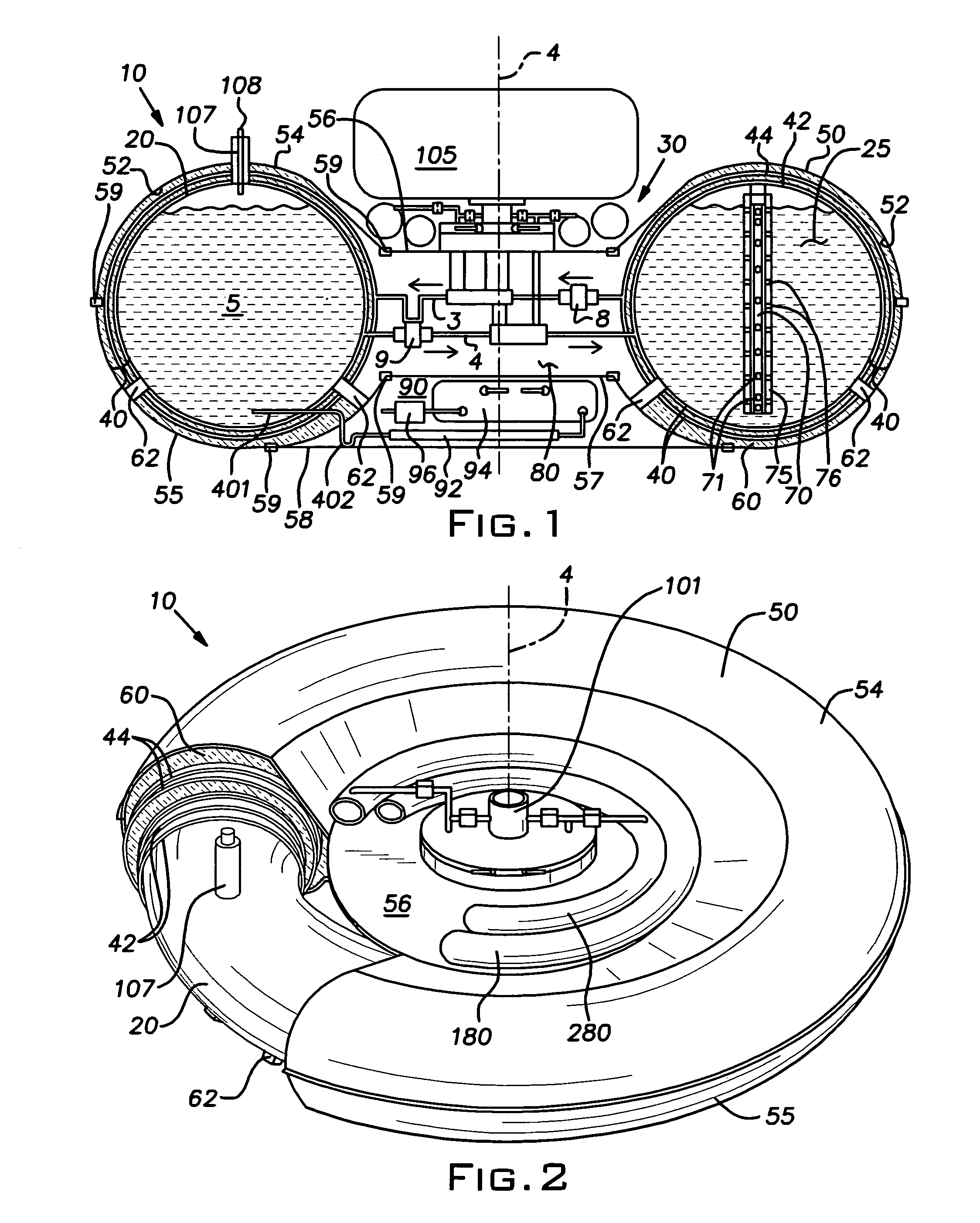

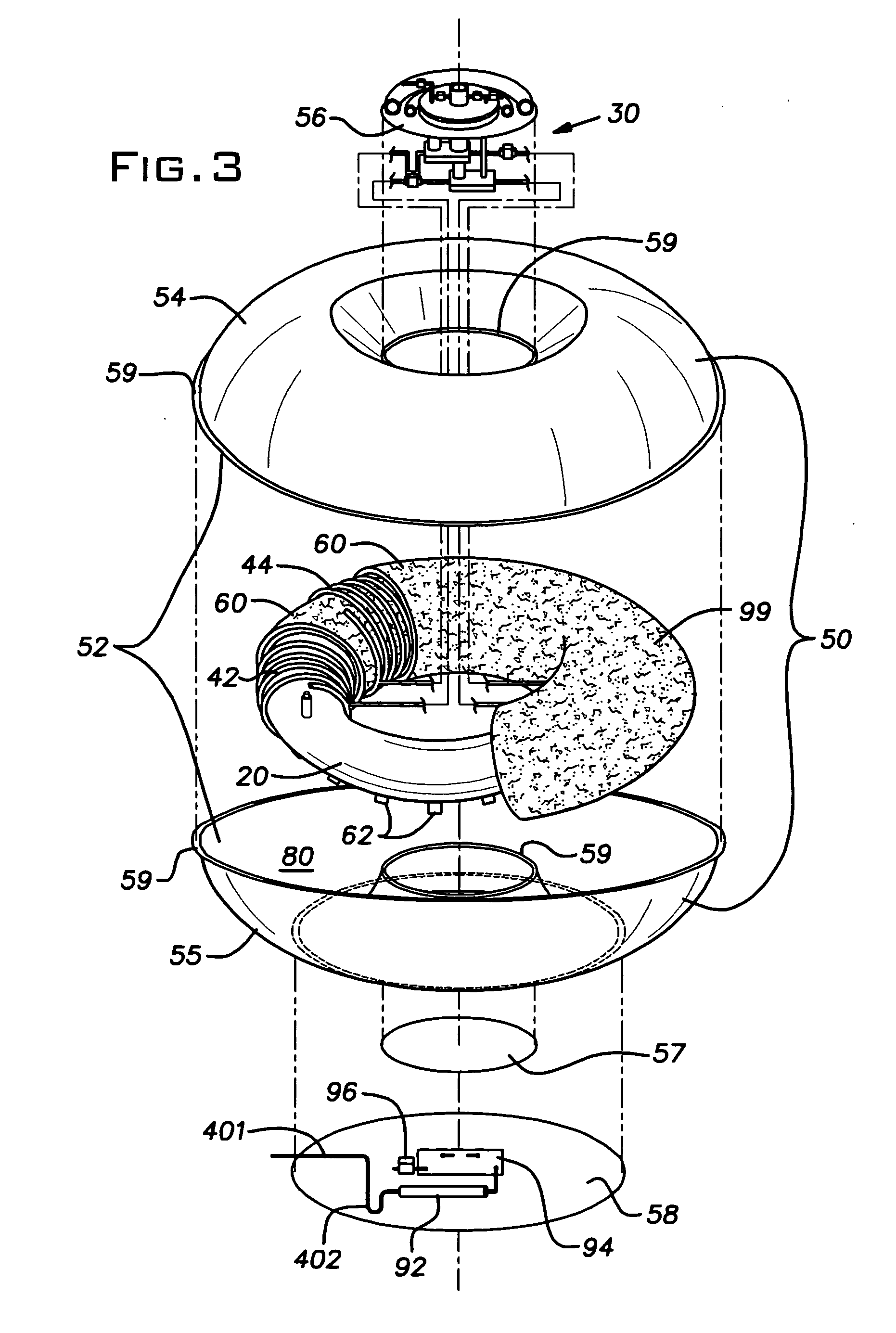

No-vent liquid hydrogen storage and delivery system

A hydrogen storage and delivery system is provided having an orifice pulse tube refrigerator and a liquid hydrogen storage vessel. A cooling system, coupled to the orifice pulse tube refrigerator, cools the vessel and abates ambient heat transfer thereto in order to maintain the liquid hydrogen in the vessel at or below its saturation temperature. Hydrogen boil-off, and the necessity to provide continuous venting of vaporized hydrogen are minimized or avoided. In a preferred embodiment, the hydrogen storage vessel has a toroidal shape, and the pulse tube refrigerator is a two stage pulse tube refrigerator and extends within a central void space defined at the geometric center of the toroidal storage vessel. Also in a preferred embodiment, the cooling system includes first and second thermal jackets, each having a substantially toroidal shape and enclosing the storage vessel, wherein each of the thermal jackets is thermally coupled to one of the first or second stages of the pulse tube refrigerator in order to cool the vessel and to abate ambient heat leak thereto. The hydrogen storage and delivery system is particularly suitable for use in vehicles, such as passenger automobiles.

Owner:SIERRA LOBO

Device for real time emission of fire extinguishing bomb by fire-fighting lance

The invention relates to a device for real time emission of a fire extinguishing bomb by a fire-fighting lance. The device utilizes a fire extinguishing bomb with specific gravity similar to that of water, and utilizes a hollow conical fire-fighting lance to emit high-speed water flows as carriers for carrying the fire extinguishing bomb into a fire-fighting point in the scene of a fire so that the bomb explodes in a set zone and dual fire extinguishing effects are produced, wherein the dual fire extinguishing effects comprises instant oxygen deficit around the explosion site because of large shock wave produced by explosion, and dense small water drop superhigh-speed ejection for rapidly weakening fire behavior and even extinguishing fire. The device can realize continuous emission and is a fast and efficient fire extinguishing device. The water used by the device comprises a fire-fighting liquid.

Owner:谢志明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com