Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Continuous emissions monitoring system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous emission monitoring systems (CEMS) were historically used as a tool to monitor flue gas for oxygen, carbon monoxide and carbon dioxide to provide information for combustion control in industrial settings. They are currently used as a means to comply with air emission standards such as the United States Environmental Protection Agency's (EPA) Acid Rain Program, other federal emission programs, or state permitted emission standards. Facilities employ the use of CEMS to continuously collect, record and report the required emissions data.

Generator monitoring, control and efficiency

InactiveUS6912889B2Analysing fluids using sonic/ultrasonic/infrasonic wavesReciprocating combination enginesElectricityEmbedded system

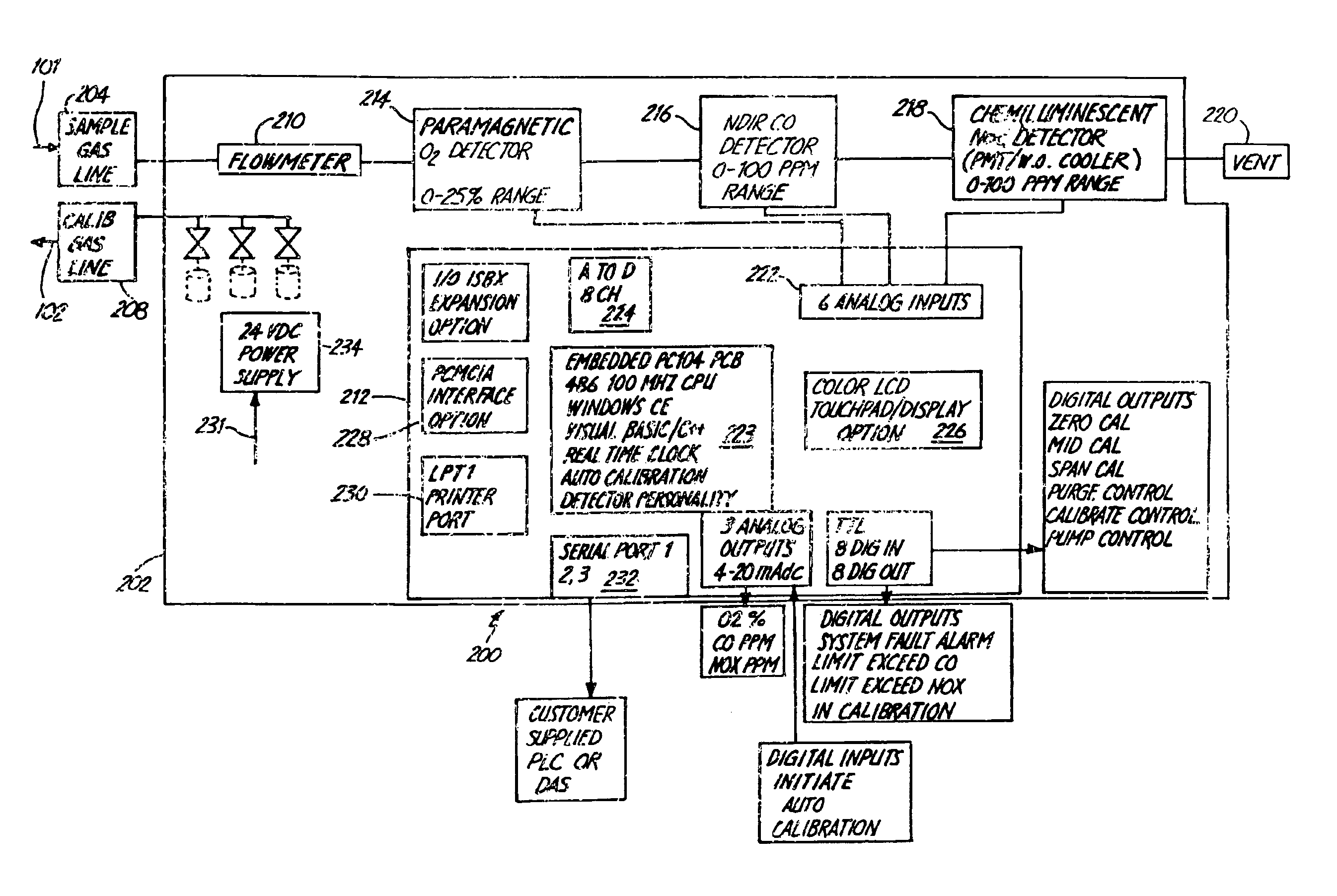

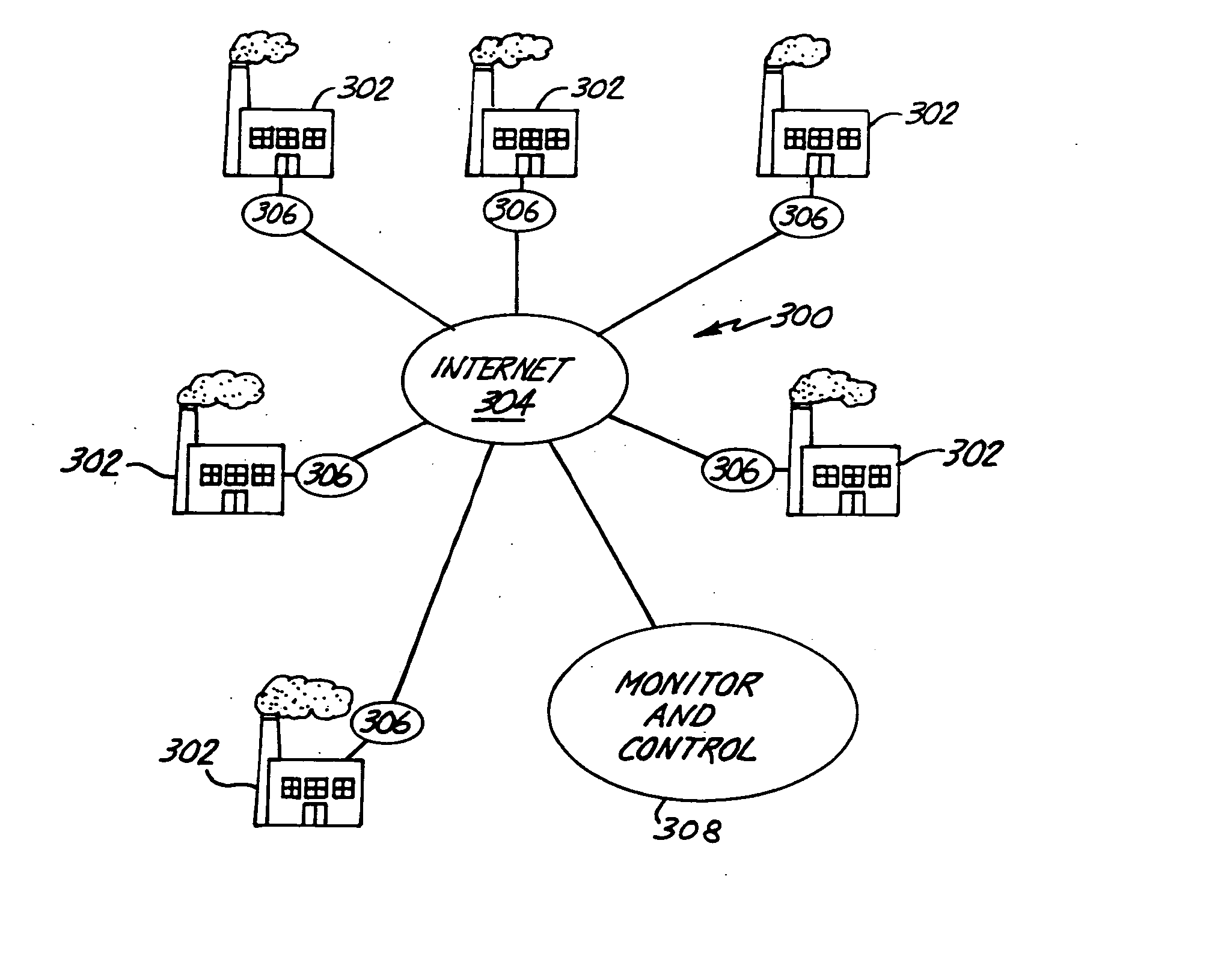

A system for generating electricity includes a generator and an interface. The generator is coupled to the interface and provides data to the interface regarding electricity generation. The interface is coupled to a control node for monitoring and controlling the generator. The control node may be coupled to the generator through a medium such as the internet. In some aspects of the invention, a continuous emissions monitoring system is provided for fossil-fuel based generators to enhance operation and reduce emissions of such generators.

Owner:ROSEMOUNT ANALYTICAL

Conditioning system and method for use in the measurement of mercury in gaseous emissions

ActiveUS20050061110A1Avoid reorganizationReduced form requirementsGas treatmentSamplingBoron nitrideSilicon boride

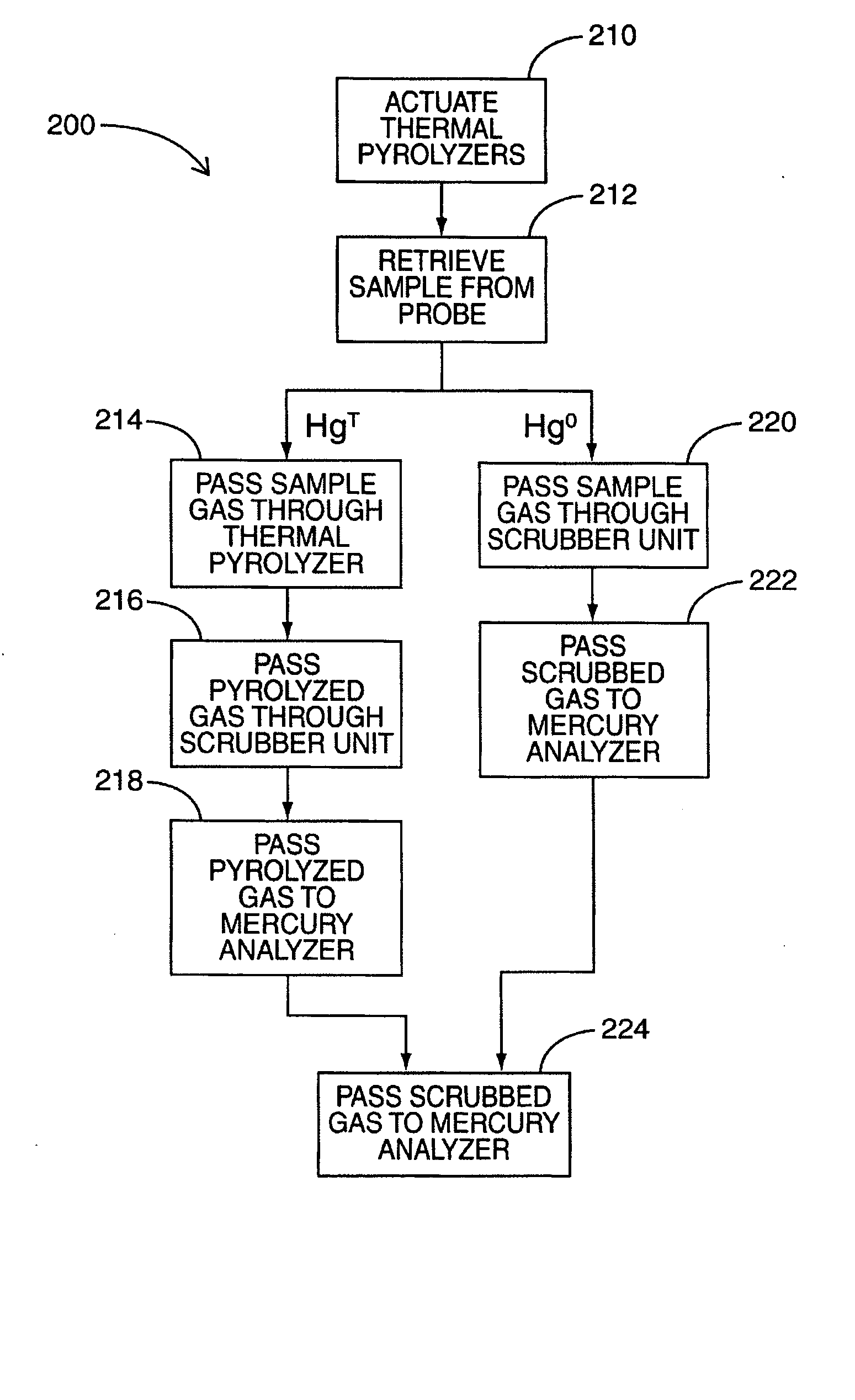

Embodiments of the invention relate generally to systems used to measure mercury in gaseous emissions. In one aspect, the invention is directed to the use of silicon carbide as material for a thermal pyrolysis unit. In another aspect, at least one of silicon nitride, silicon boride, and / or boron nitride is used as material for a thermal pyrolysis unit. In another aspect, the invention is directed to an improved pyrolyzer design, in which a thermal pyrolysis unit comprises a tailpiece that allows water to be injected at the heated exit of the thermal pyrolysis unit. In another aspect, the invention is directed to the use of a coalescing filter in a scrubbing unit. In another aspect, the invention is directed to the use of a hydrophobic filter element in a scrubbing unit. One or more of these elements may be used in a conditioning module of a continuous emissions monitoring system, for example.

Owner:TEKRAN INSTR CORPORTION

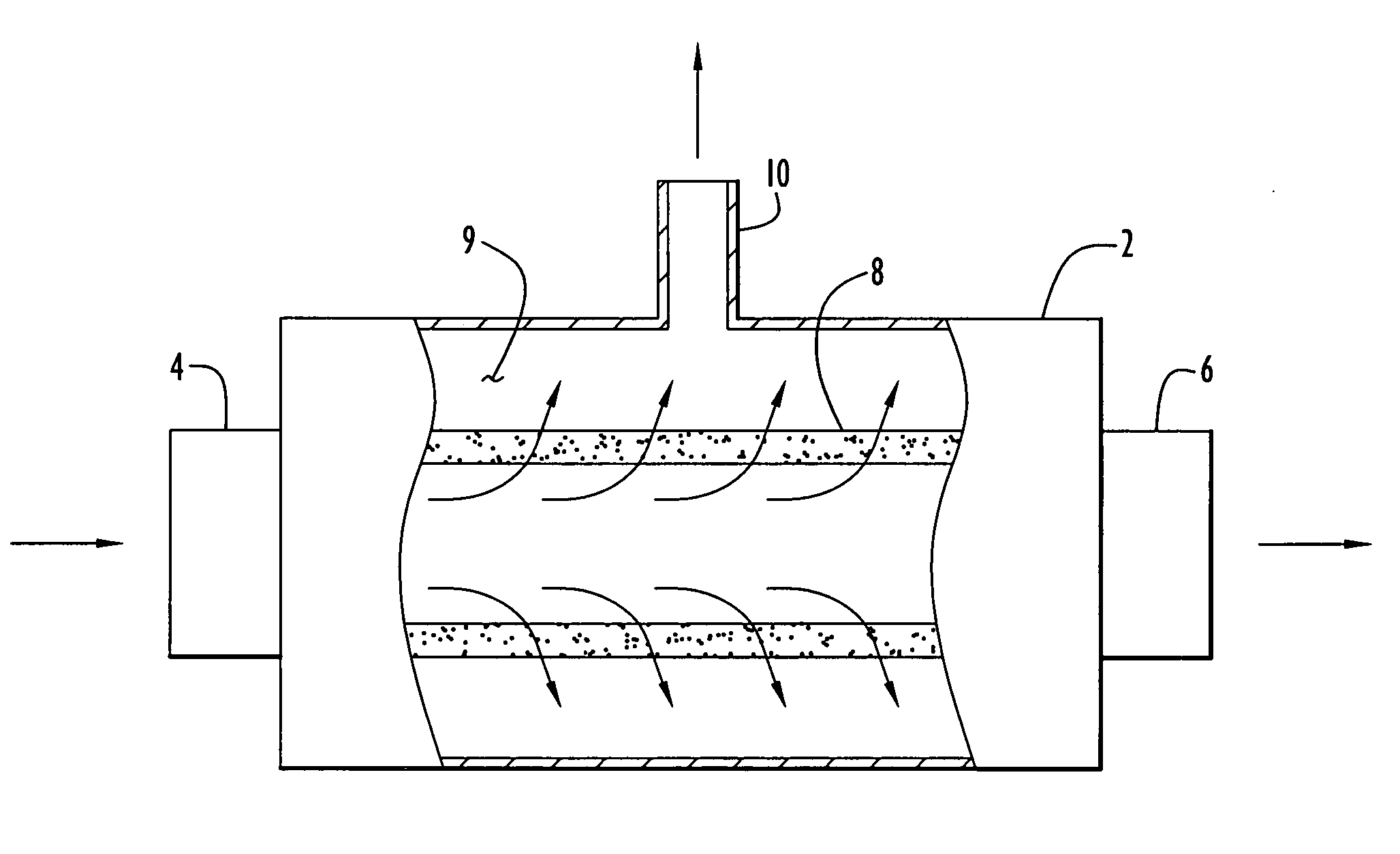

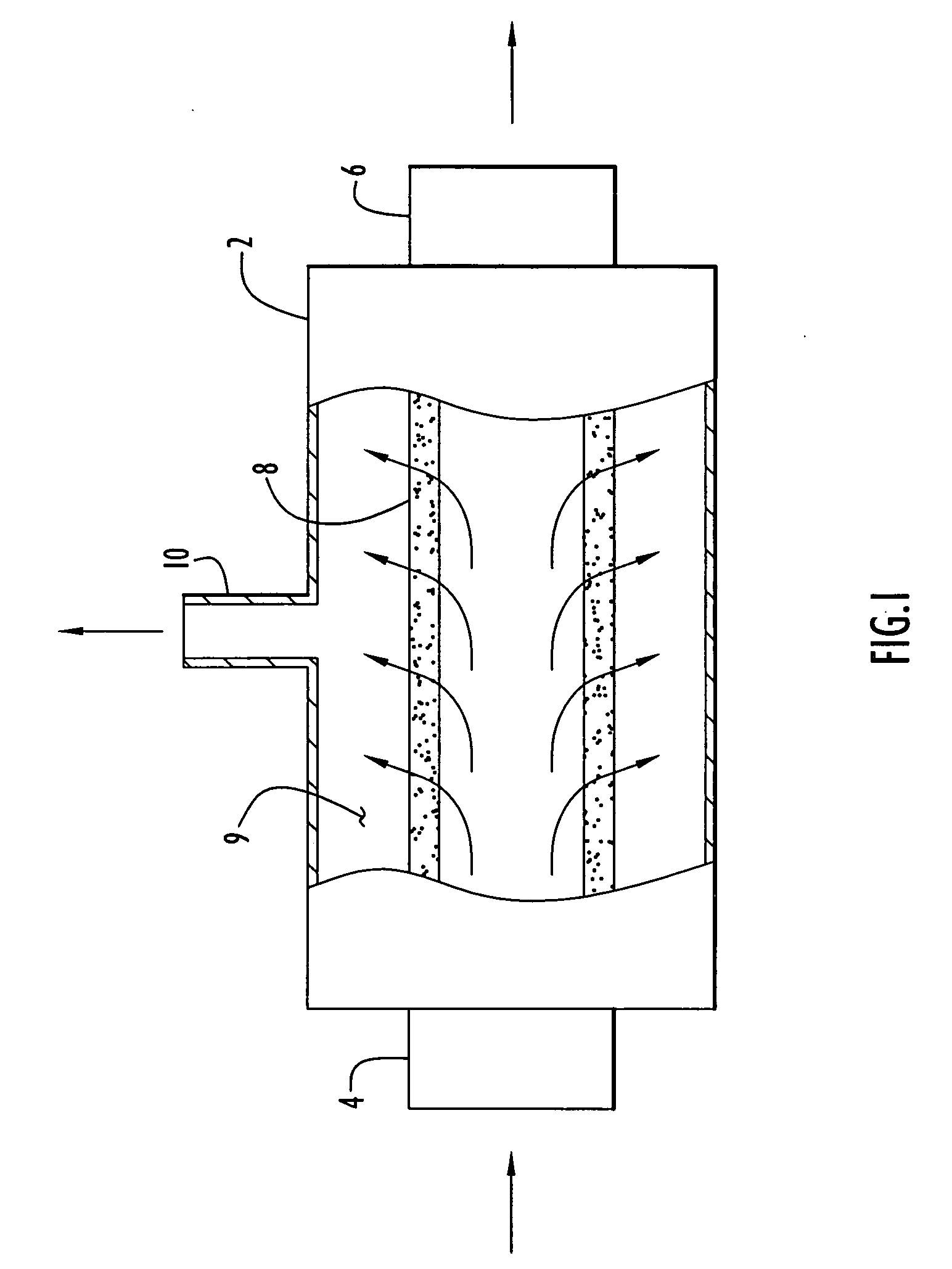

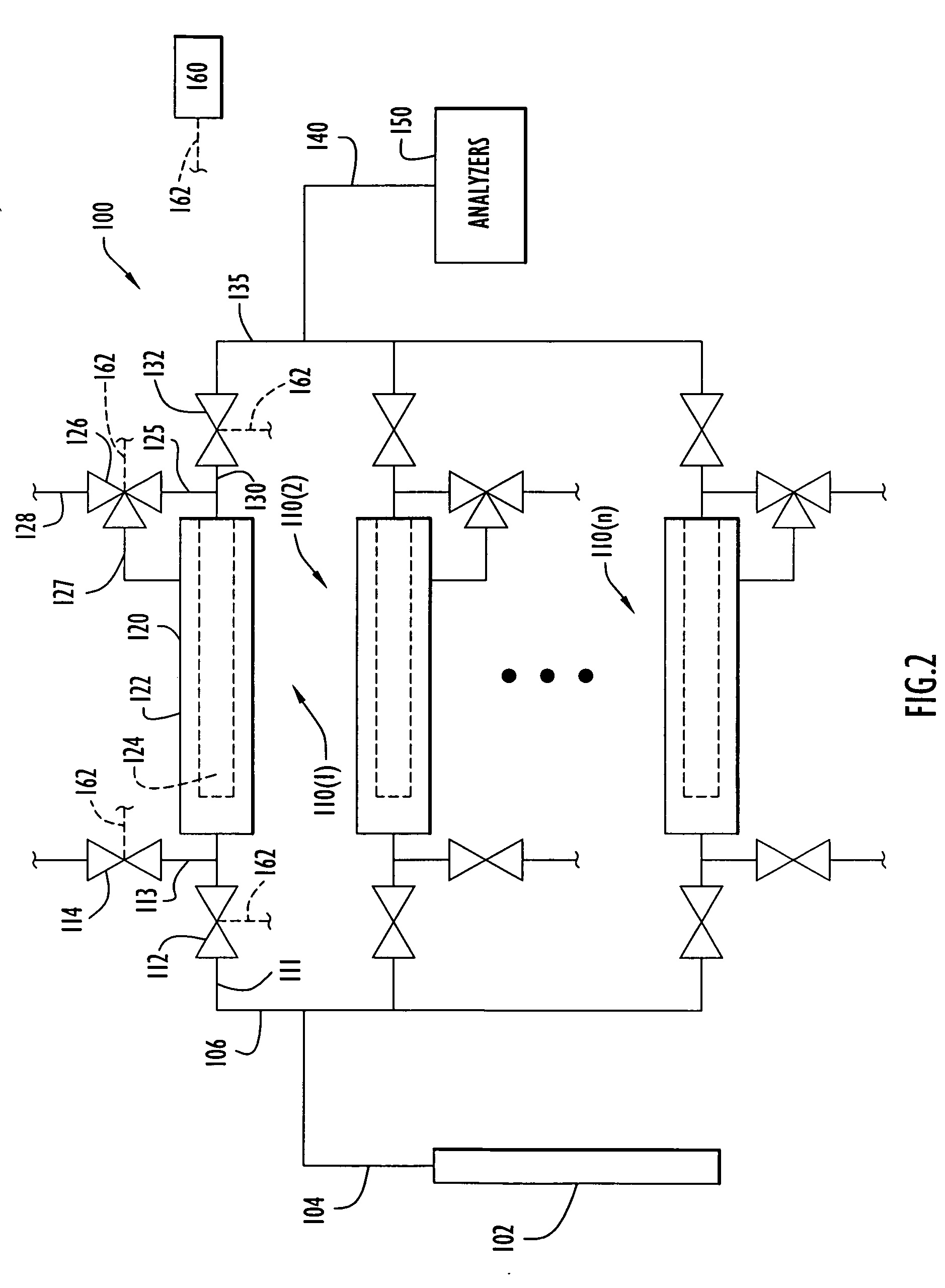

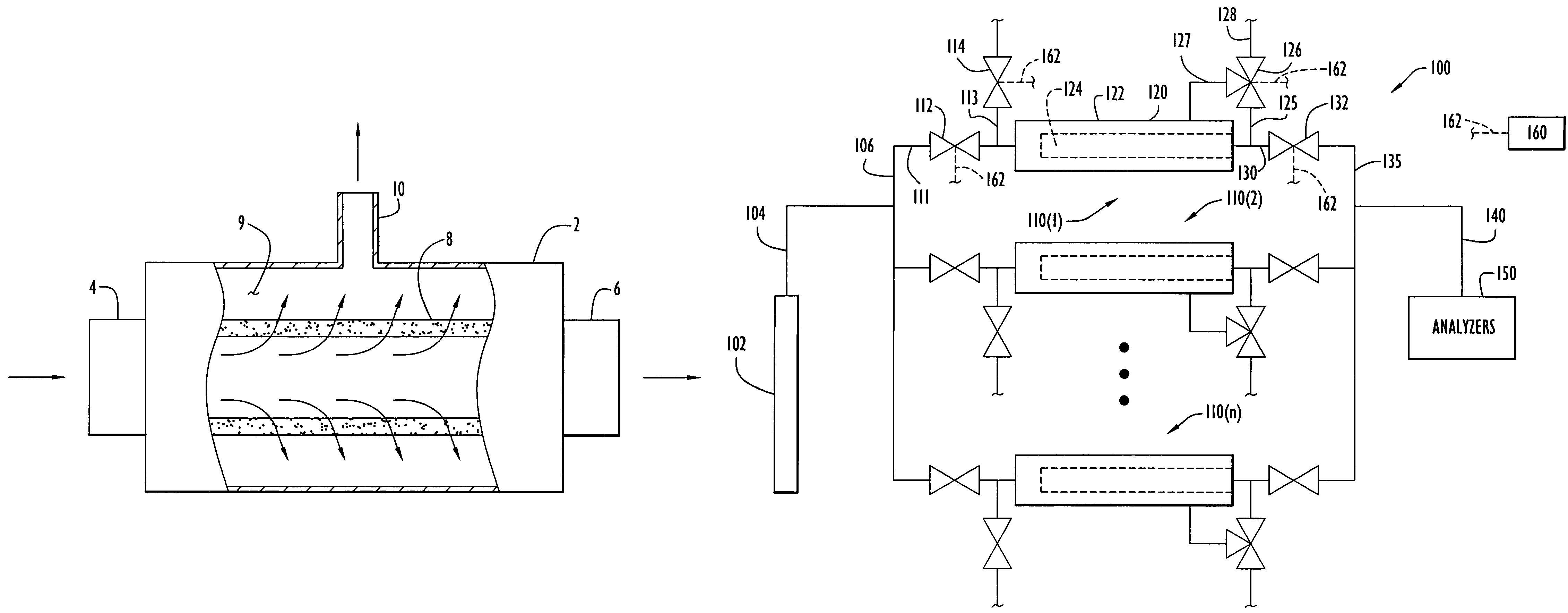

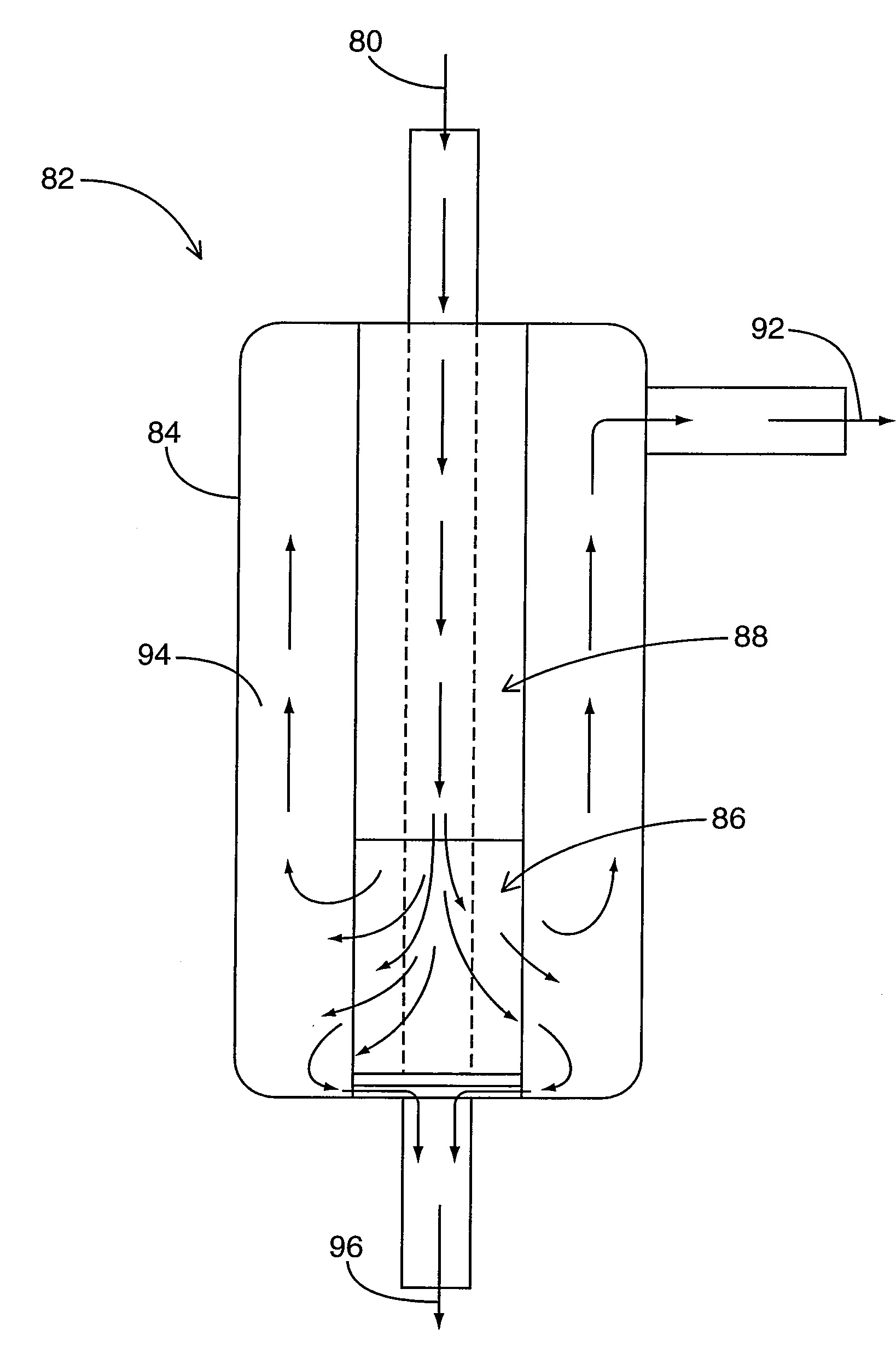

Filtering particulate materials in continuous emission monitoring systems

InactiveUS20060249023A1Facilitate effective blowbackAvoid problemsCombination devicesAuxillary pretreatmentParticulatesFilter system

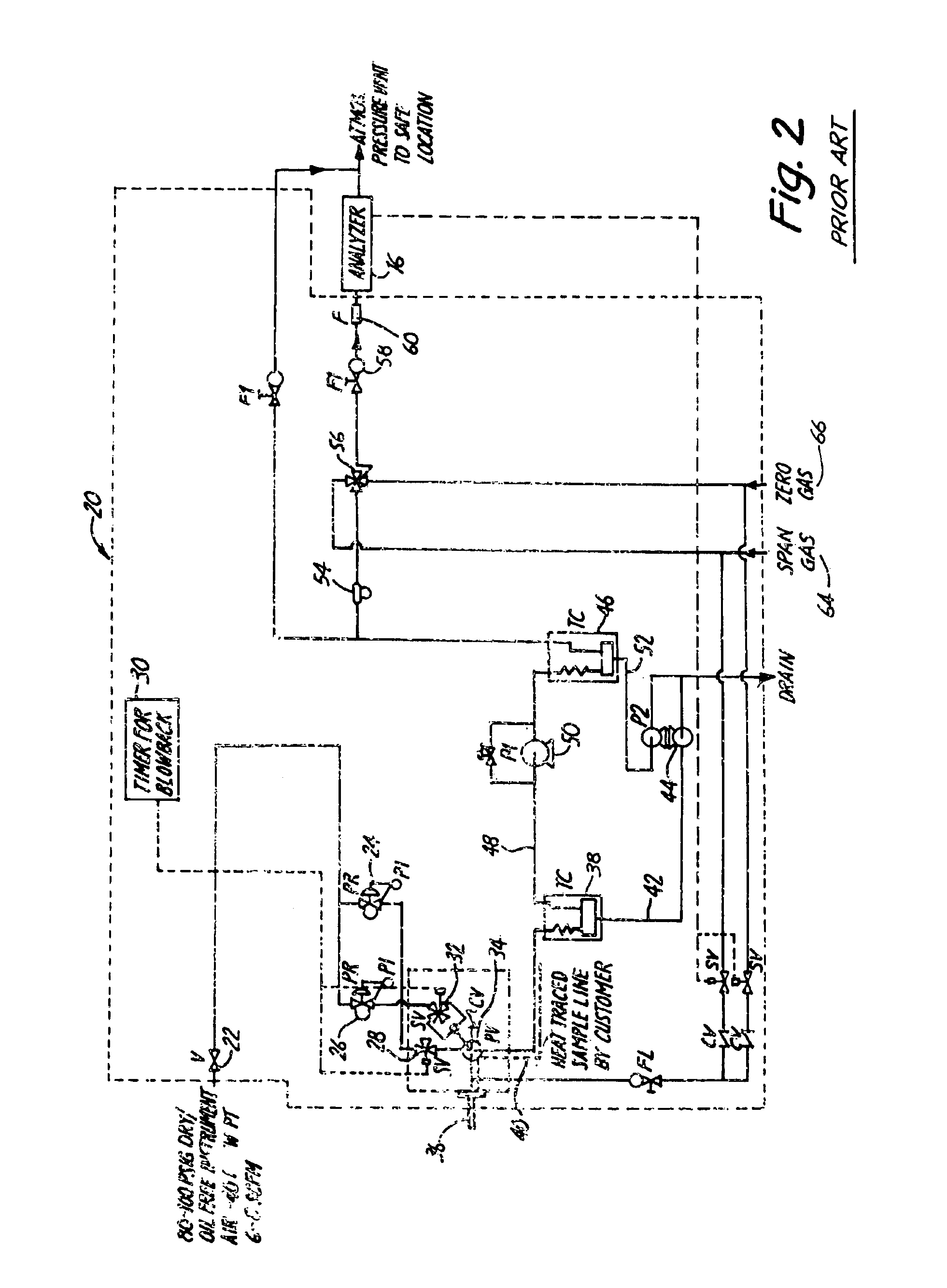

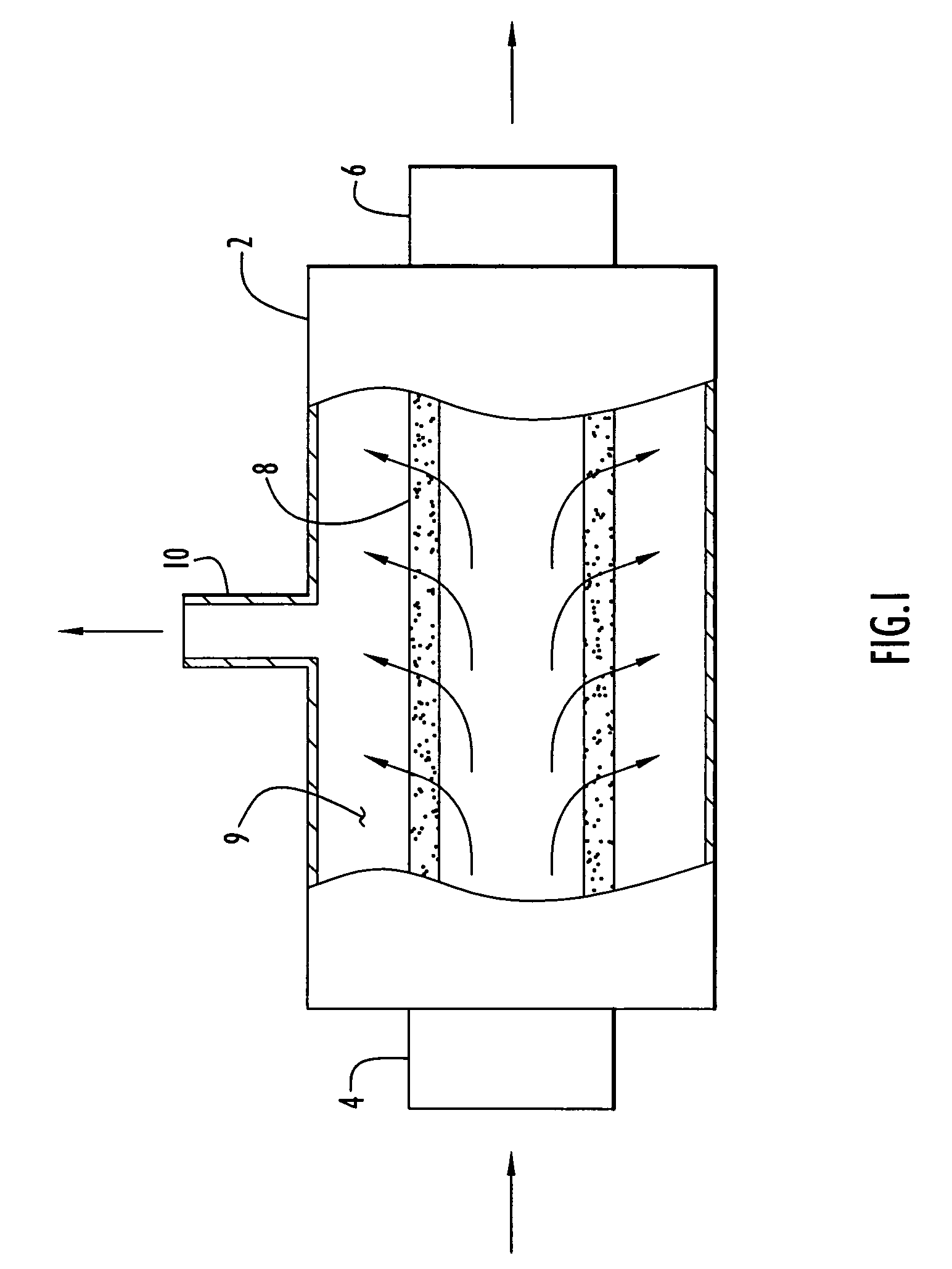

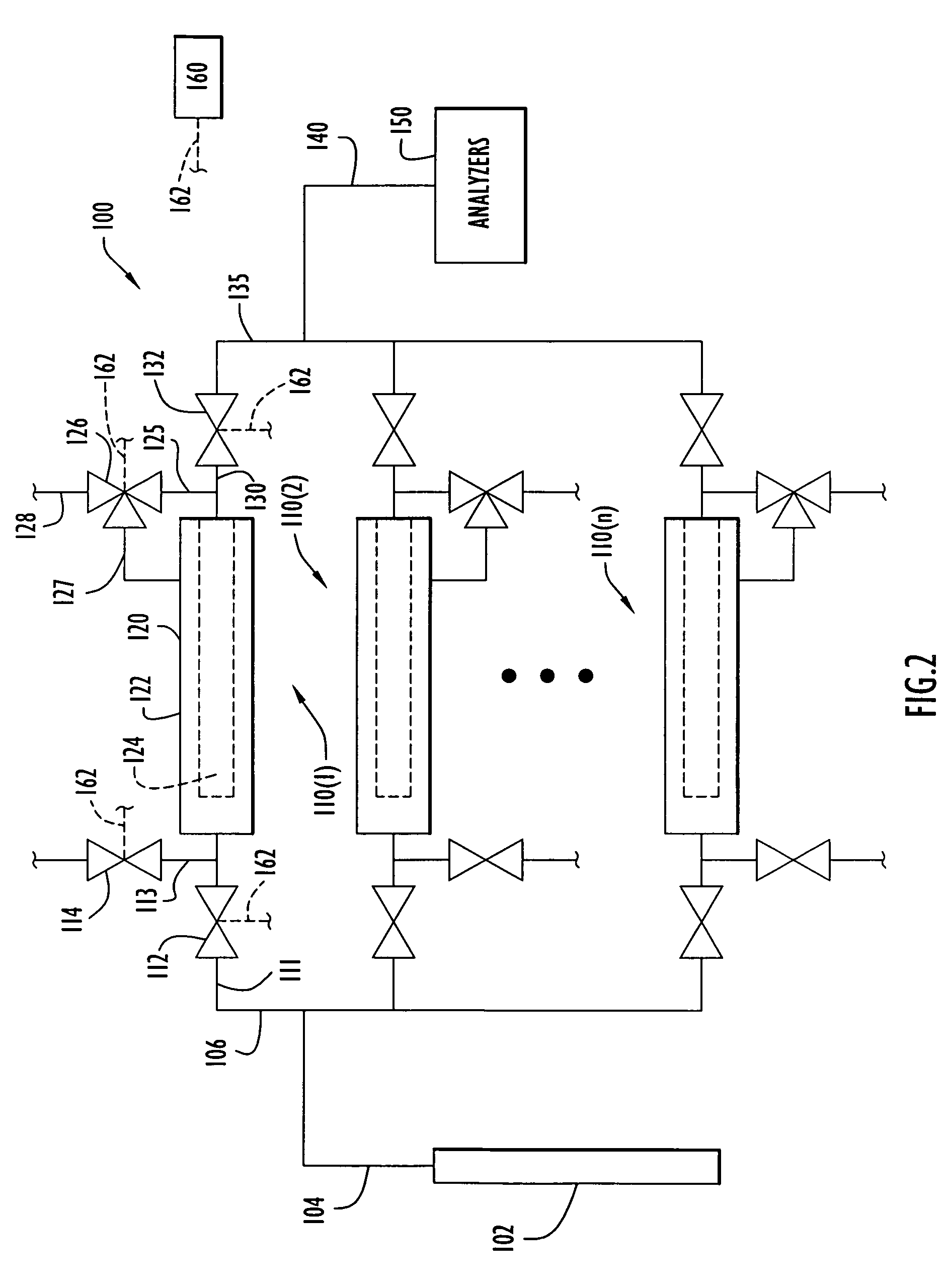

A filtering system for monitoring fluid emissions from a process includes a plurality of filter assembly sections arranged in a parallel fluid flow manner with respect to each other so as to selectively receive a sample fluid (e.g., a sample gas) entering at an inlet of the system. Each filter assembly section includes a filter unit to filter particulate materials from a fluid flowing through the filter, first and second valves disposed at upstream and downstream locations of the filter unit, and a blowback flow path configured to selectively direct a cleaning fluid through the filter unit in a direction that opposes a direction in which the sample fluid flows through the filter unit. Each filter assembly section can be selectively isolated from other portions of the system so as to prevent the sample fluid from flowing through the filter assembly section while allowing a cleaning fluid to be delivered through the blowback flow path of the filter assembly section.

Owner:AIR LIQUIDE AMERICA INC

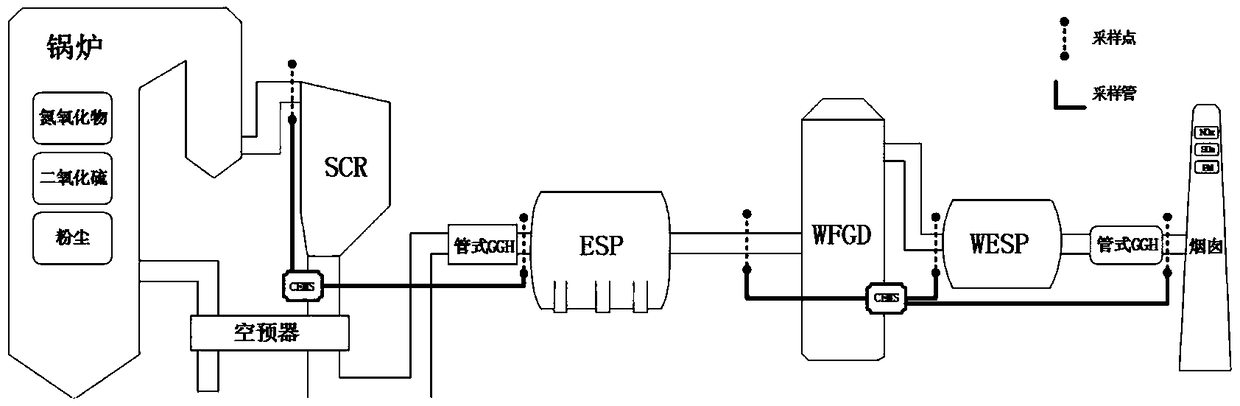

Ammonia spraying amount control method and system for selective catalytic reduction (SCR) flue gas denitration system

ActiveCN110368808AGuaranteed validityGuaranteed accuracyDispersed particle separationModel parametersEngineering

The invention discloses an ammonia spraying amount control method and system for a selective catalytic reduction (SCR) flue gas denitration system. A hearth combustion NOx data model and a SCR reaction mechanism are combined, an ammonia spraying amount calculation model is established, model parameters are identified by operation data and the model parameters are adjusted timely, ammonia sprayingfeedforward amount is calculated through the and a control system is introduced, so that the ammonia spraying amount control quality is improved, and the adjusted instantaneity and accuracy of the ammonia spraying amount is guaranteed. When a continuous emission monitoring system (CEMS) is demarcated or purged, feedforward control weight is adjusted by a feedforward coefficient, meanwhile, the feedback effect is weakened, and thus the influence of the working condition change of the CEMS on the ammonia spraying amount control is avoided.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

Generator monitoring, control and efficiency

InactiveUS20050072220A1Less timeAnalysing fluids using sonic/ultrasonic/infrasonic wavesInternal combustion piston enginesElectricityEmbedded system

A system for generating electricity includes a generator and an interface. The generator is coupled to the interface and provides data to the interface regarding electricity generation. The interface is coupled to a control node for monitoring and controlling the generator. The control node may be coupled to the generator through a medium such as the internet. In some aspects of the invention, a continuous emissions monitoring system is provided for fossil-fuel based generators to enhance operation and reduce emissions of such generators.

Owner:ROSEMOUNT ANALYTICAL

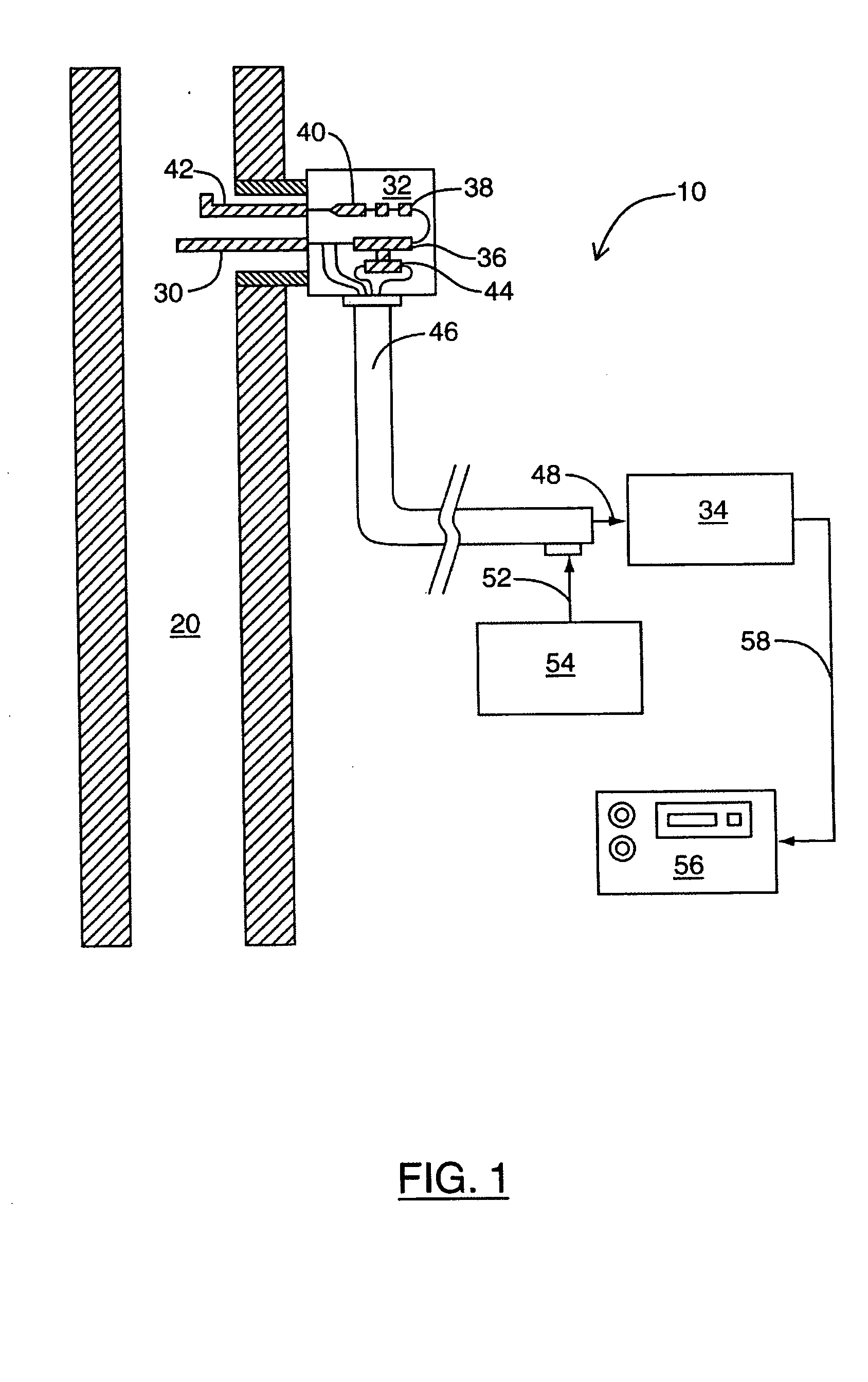

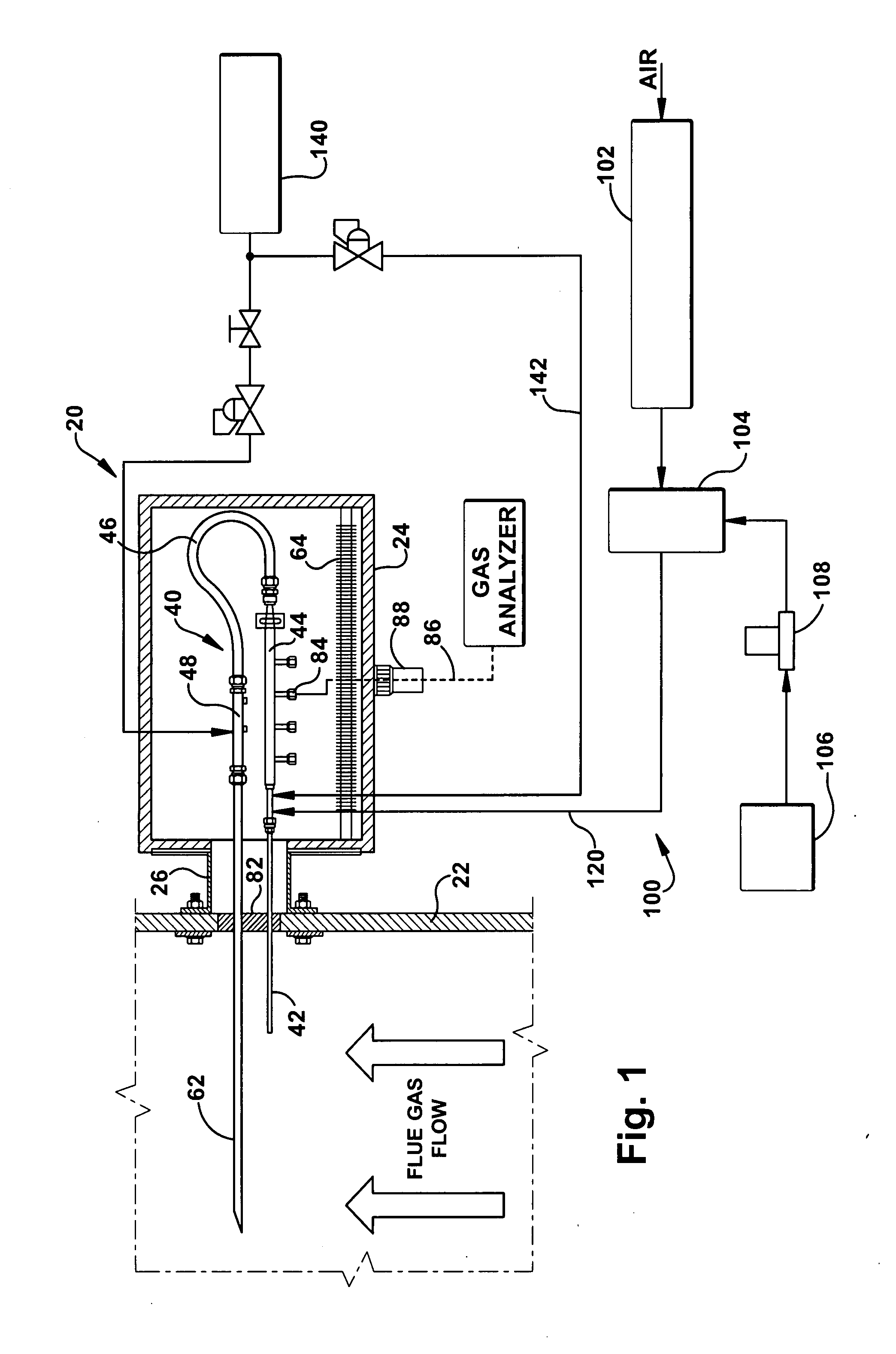

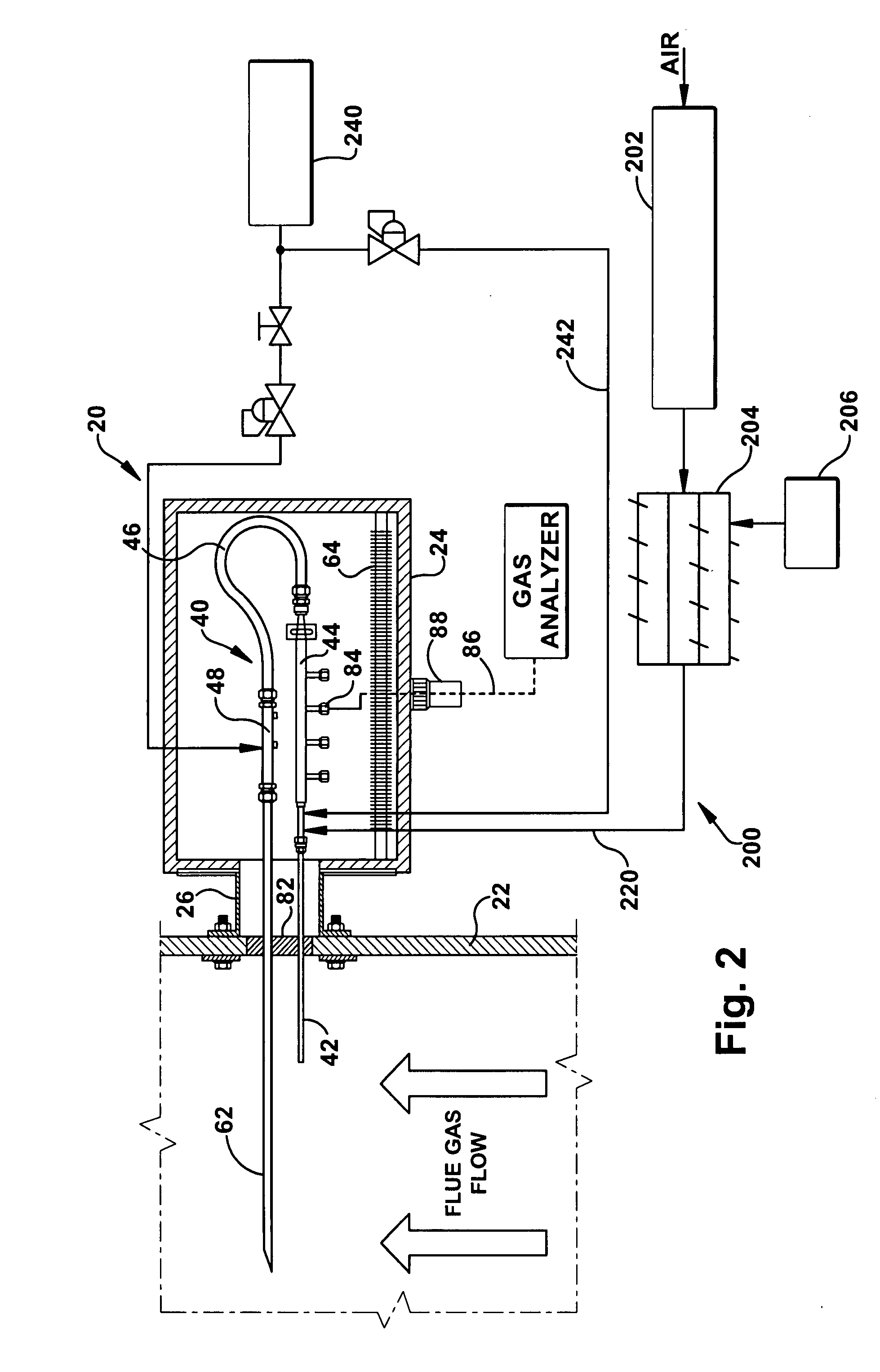

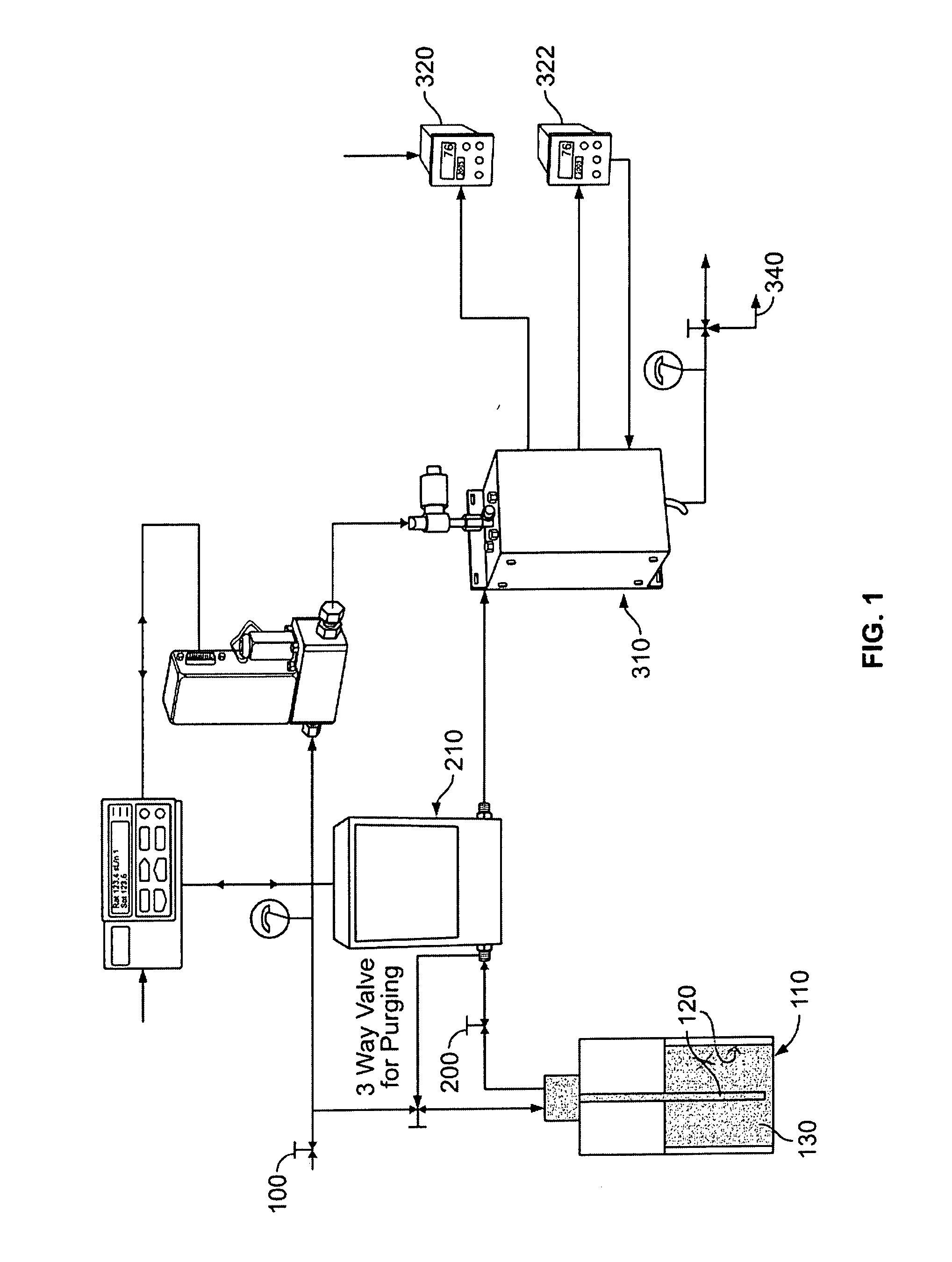

Controlled humidification calibration checking of continuous emissions monitoring system

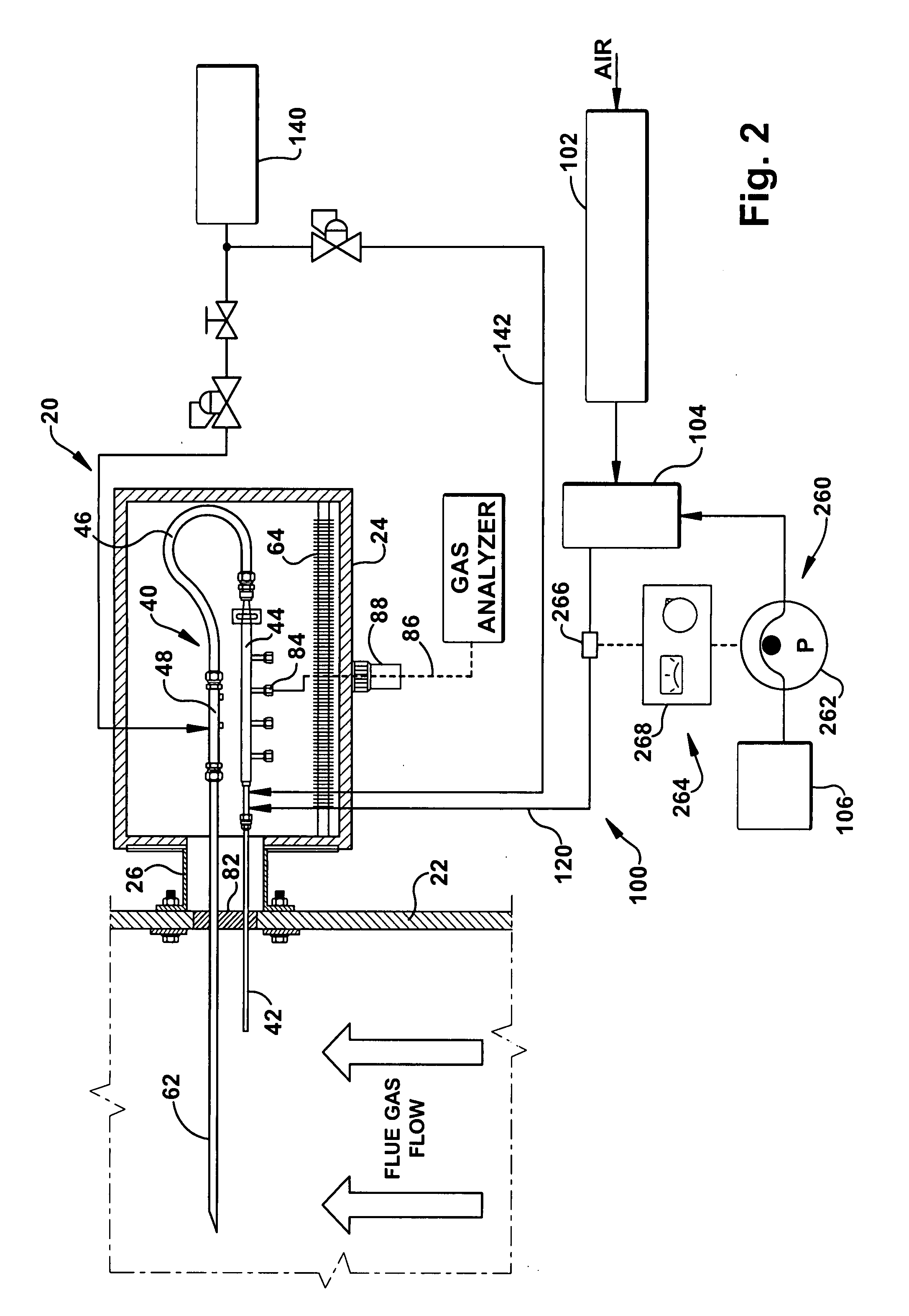

InactiveUS20090000349A1Accurate measurementWithdrawing sample devicesMaterial analysis by electric/magnetic meansAnalyteEngineering

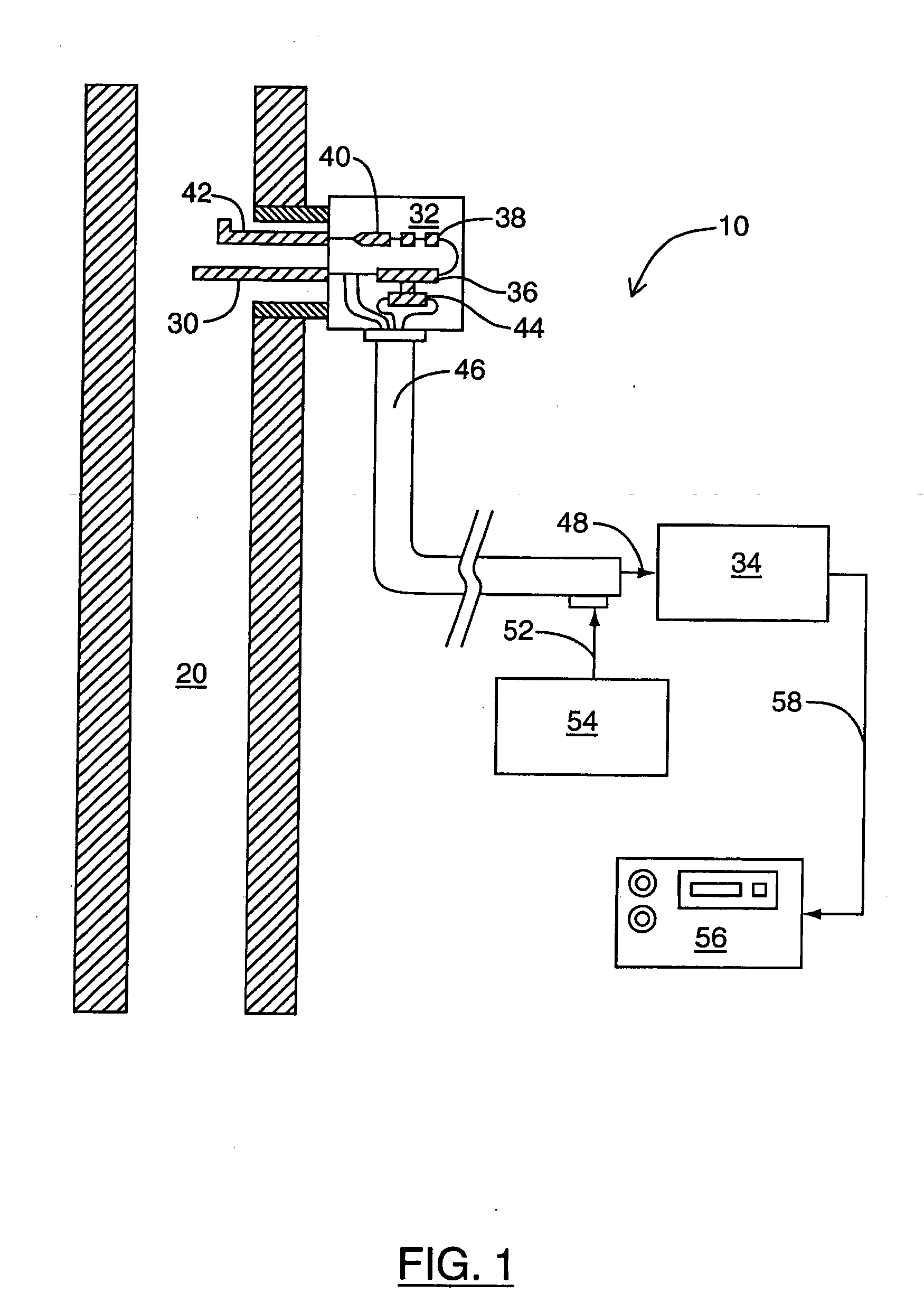

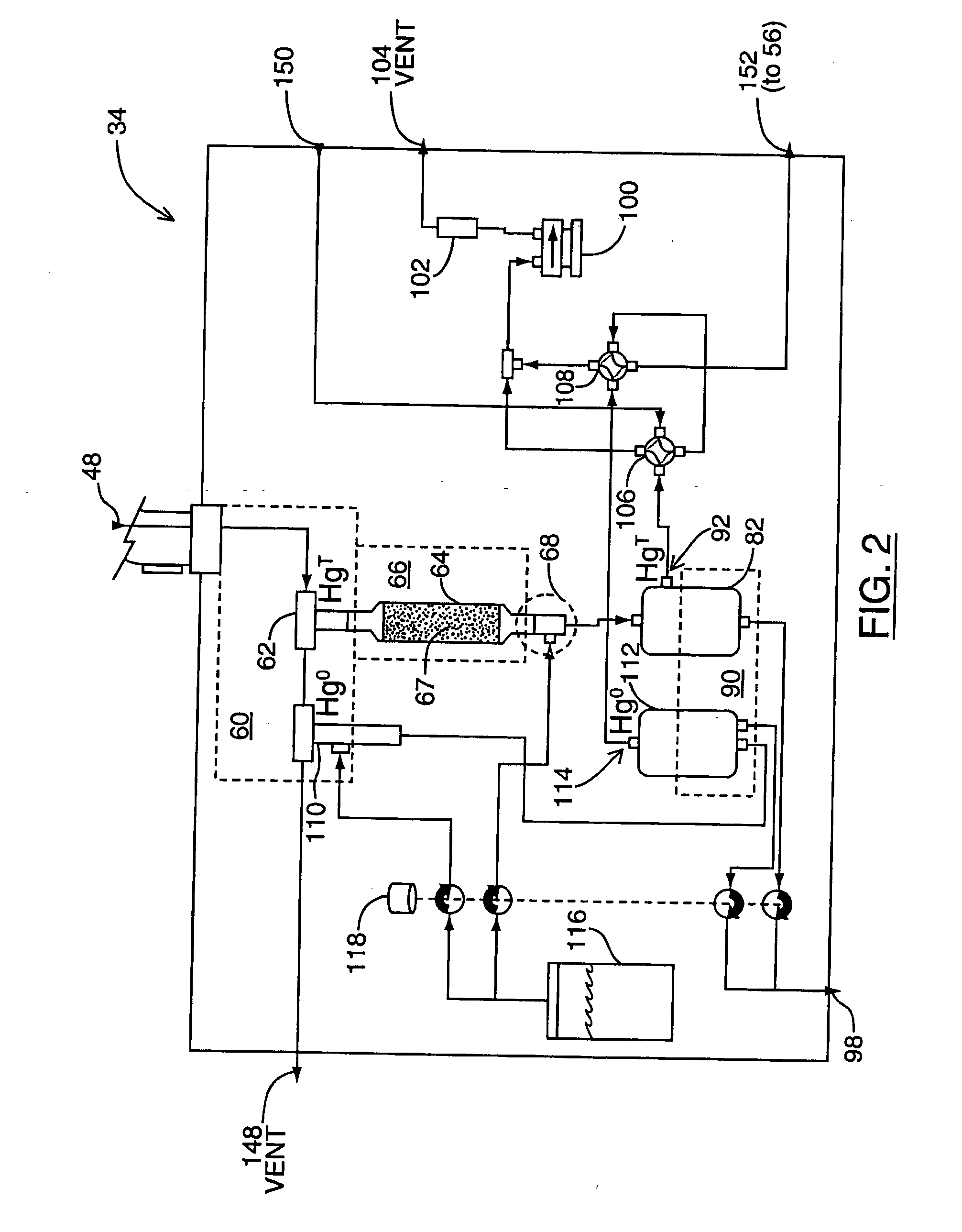

A continuous emissions monitoring system is in fluid communication with a flue stack conducting exhaust gas from a combustion source. The continuous emissions monitor system comprises an analyzer for measuring concentrations of an analyte present in the exhaust gas. A probe is in fluid communication with the flue stack to acquire a sample of exhaust gas from the flue stack. The probe is also in fluid communication with and located upstream of the analyzer. The probe tends to remove analyte from the sample. A calibration checking system is in fluid communication with the probe. The calibration checking system includes a source that provides a flow of a known concentration of calibration material to be measured by the analyzer. The calibration material is the same as the analyte. A humidifier is associated with the source to provide moisture to a flow of calibration material. The moisture acts to cleanse removed analyte from the probe and thereby enable an accurate measurement of the concentration of the calibration material. A supply system is operatively connected with the humidifier to provide a desired amount of a liquid to the humidifier.

Owner:THE BABCOCK & WILCOX CO

Calibration checking for continuous emissions monitoring system

InactiveUS20080282764A1Accurate measurementFuel testingMaterial analysis by electric/magnetic meansAnalyteEngineering

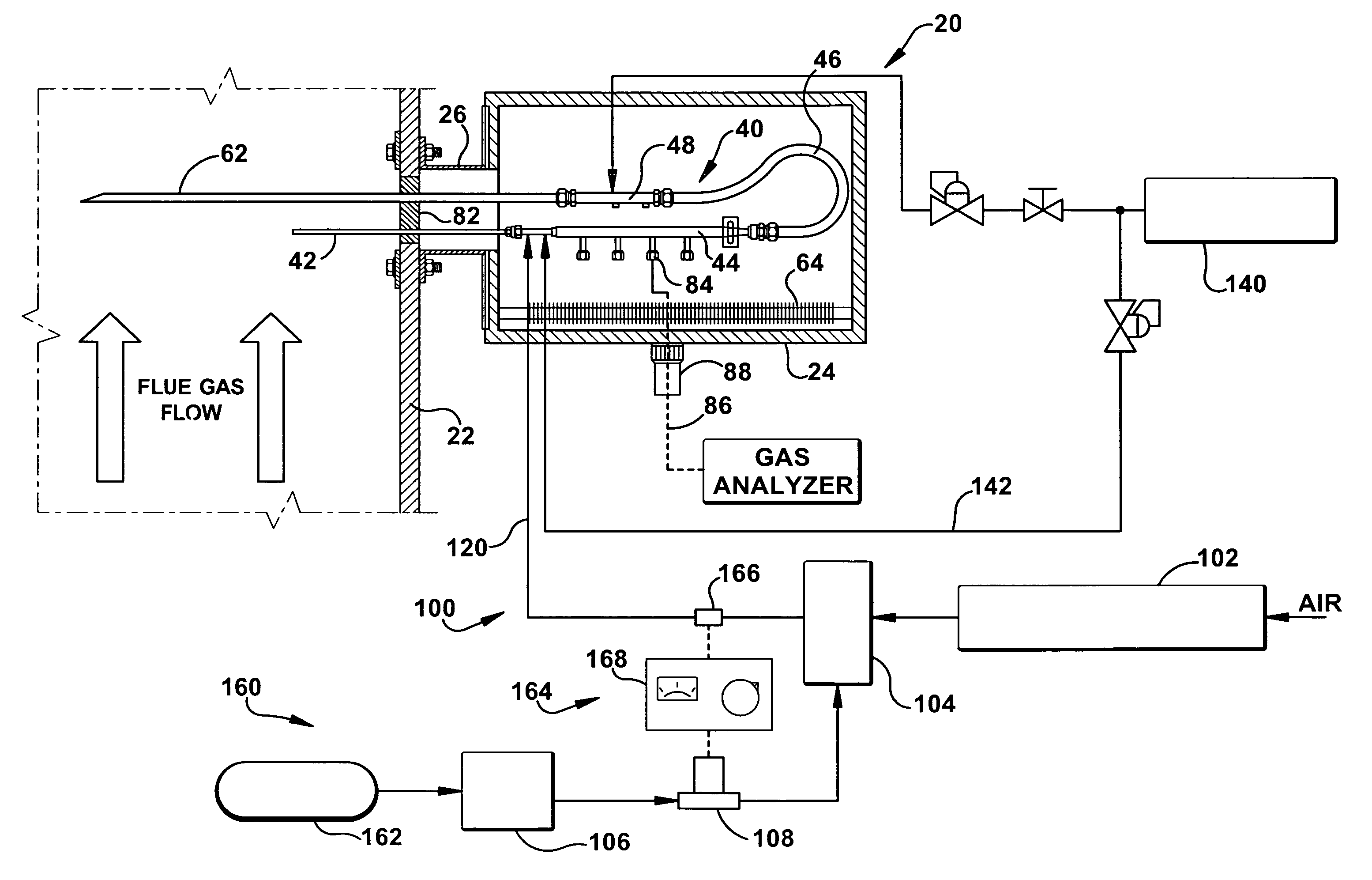

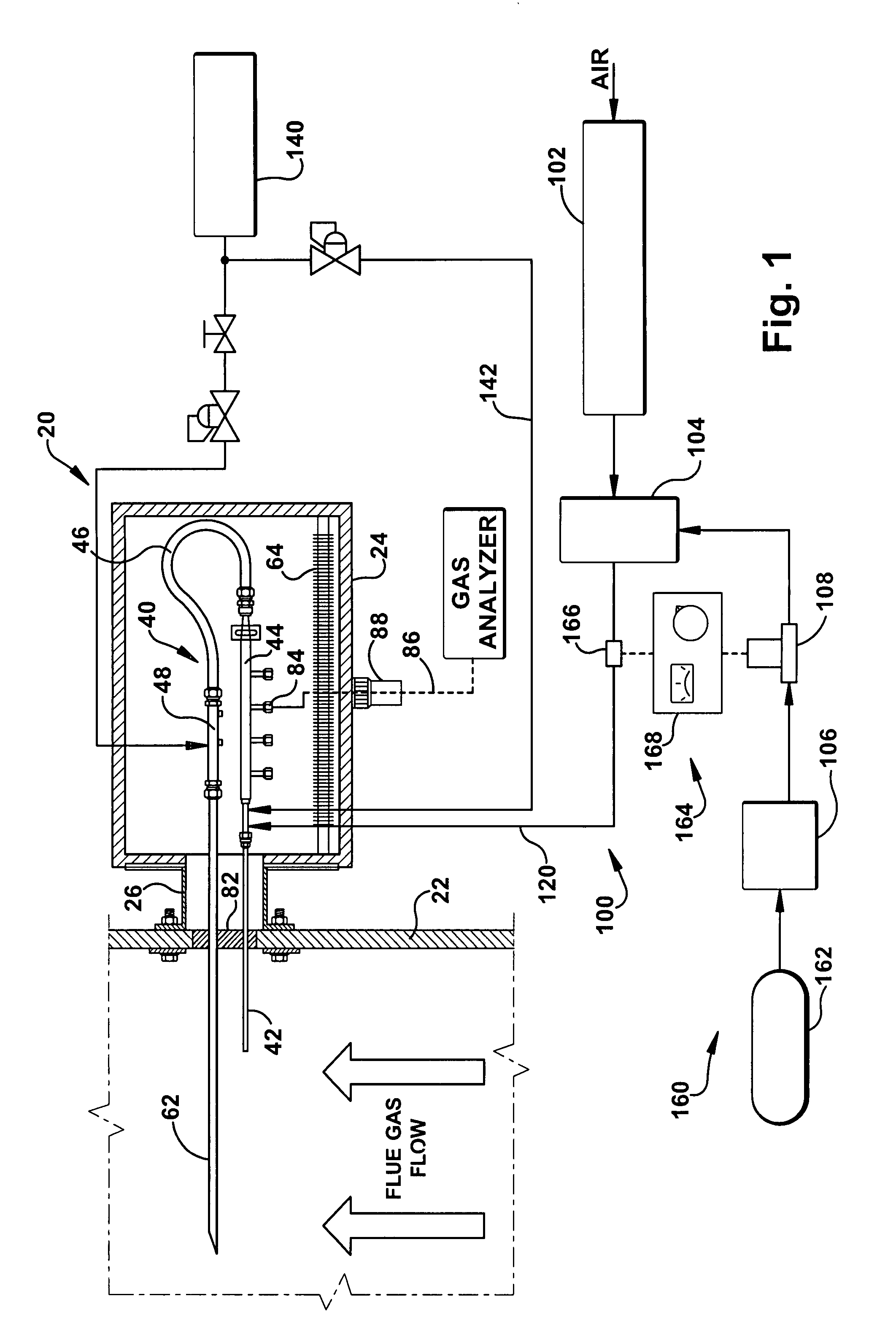

A continuous emissions monitoring system is in fluid communication with a flue stack conducting exhaust gas from a combustion source. The continuous emissions monitor system comprises an analyzer for measuring concentrations of an analyte present in the exhaust gas. A probe is in fluid communication with the flue stack to acquire a sample of exhaust gas from the flue stack. The probe is also in fluid communication with and located upstream of the analyzer. The probe tends to remove analyte from the sample. A calibration checking system is in fluid communication with the probe. The calibration checking system includes a source that provides a flow of a known concentration of calibration material to be measured by the analyzer. The calibration material is the same as the analyte. A humidifier is associated with the source to provide moisture to a flow of calibration material. The moisture acts to cleanse removed analyte from the probe and thereby enable an accurate measurement of the concentration of the calibration material.

Owner:BABCOCK & WILCOX POWER GENERATION GRP INC

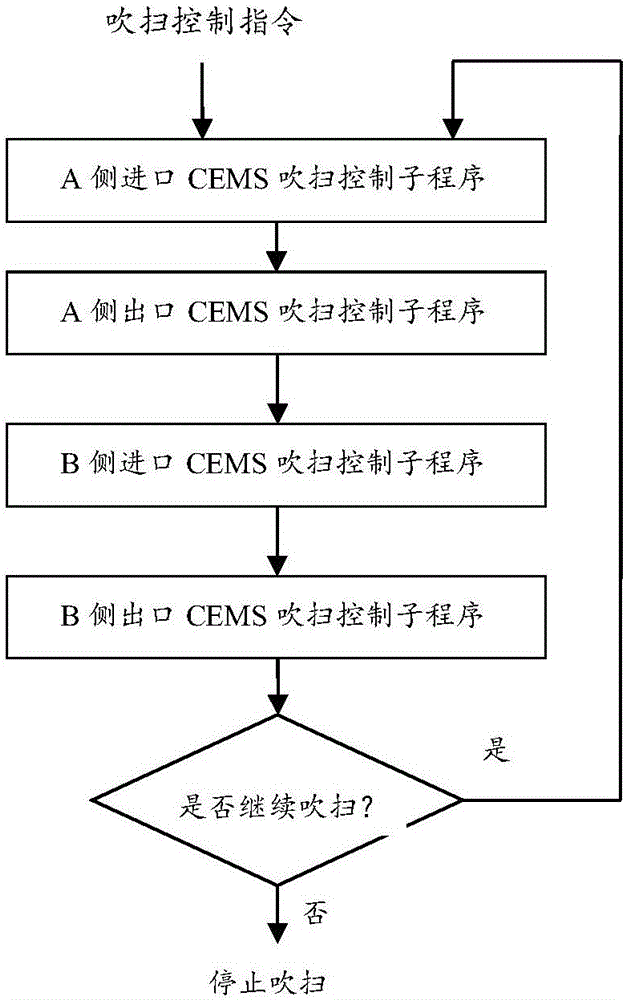

Ammonia spraying regulation automatic control method for denitrification system of thermal power plant

ActiveCN106422709ARealize automatic and orderly purgingGuaranteed controllableGas treatmentControlling ratio of multiple fluid flowsAutomatic controlEngineering

The invention provides an ammonia spraying regulation automatic control method for a denitrification system of a thermal power plant. The method comprises the following steps of 1, using a DCS to conduct circular blowing control on sampling channels of CEMS (Continuous Emission Monitoring System) analyzers on an inlet and an outlet of each flue according to the number of flues of a same boiler; 2, acquiring the analysis values of the CEMS analyzers on the inlet and the outlet of the current flue in the process of blowing control, and adjusting the opening degree of an ammonia spraying door of the current flue according to a preset specific value relation; and 3, if the CEMS analyzers on the inlet and the outlet of the current flue are maintained or blown, replacing with the analysis values of CEMS analyzers on an inlet and an outlet of another flue. According to the provided CEMS analyzer blowing control method, the CEMS analyzers of the denitrification system can be automatically and orderly blown; besides, an automatic control strategy for ammonia spraying is designed for the blowing control method, and the blowing of the CEMS analyzers is controlled; and through the set logic switch, the ammonia spraying door is guaranteed to be constantly controllable, the undisturbed switching is guaranteed after blowing is finished, and the adjusting effect is improved.

Owner:DATANG HANCHENG NO 2 POWER GENERATION

Filtering particulate materials in continuous emission monitoring systems

InactiveUS7569093B2Facilitate effective blowbackCombination devicesAuxillary pretreatmentParticulatesFilter system

A filtering system for monitoring fluid emissions from a process includes a plurality of filter assembly sections arranged in a parallel fluid flow manner with respect to each other so as to selectively receive a sample fluid (e.g., a sample gas) entering at an inlet of the system. Each filter assembly section includes a filter unit to filter particulate materials from a fluid flowing through the filter, first and second valves disposed at upstream and downstream locations of the filter unit, and a blowback flow path configured to selectively direct a cleaning fluid through the filter unit in a direction that opposes a direction in which the sample fluid flows through the filter unit. Each filter assembly section can be selectively isolated from other portions of the system so as to prevent the sample fluid from flowing through the filter assembly section while allowing a cleaning fluid to be delivered through the blowback flow path of the filter assembly section.

Owner:AIR LIQUIDE AMERICA INC

Conditioning system and method for use in the measurement of mercury in gaseous emissions

ActiveUS20060042418A1Avoid reorganizationReduced form requirementsGas treatmentDispersed particle separationBoron nitrideSilicon oxide

Embodiments of the invention relate generally to systems used to measure mercury in gaseous emissions. In one aspect, the invention is directed to the use of an inert covalently bonded material selected from silicon carbide (SiC), silicon oxides (SiOn, n=1-2), silicon nitride (e.g. Si3N4), silicon boride (e.g. SiB6), boron nitride (e.g. BN) and mixtures thereof as material for a thermal pyrolysis unit. In another aspect, the invention is directed to an improved pyrolyzer design, in which a thermal pyrolysis unit comprises a tailpiece that allows water to be injected at the heated exit of the thermal pyrolysis unit. In another aspect, the invention is directed to the use of a coalescing filter in a scrubbing unit. In another aspect, the invention is directed to the use of a hydrophobic filter element in a scrubbing unit. One or more of these elements may be used in a conditioning module of a continuous emissions monitoring system, for example.

Owner:TEKRAN INSTR CORPORTION

Measurement delay correction method for online continuous monitoring system of flue gas

ActiveCN108956876ACorrected monitoring valueSolve the problem of measurement delayAnalysing gaseous mixturesNeural learning methodsTime delaysIterative method

The invention provides a measurement delay correction method for an online continuous monitoring system of flue gas. The method includes the following three parts: a proposal of a time delay calculation method combining space and analysis, establishment of a prediction model and prediction of different pollutant concentrations under different sampling sections. Through measurement of the flow velocity of the flue gas in each of flue gas sampling tubes and the actual length of the sampling tubes, measurement time delay in the sampling tubes is calculated by comprehensively considering the influence of sampling instrument parameters and other factors; a neural network prediction model is established by given input and output quantities; a sampling value of a pollutant is predicted by utilizing an iterative method, and the output quantity of the last moment is used as a part of the input quantity of the next moment which is updated together with a prediction process; and historical sampling values of different pollutants are selected as the model input quantity, a true pollutant concentration value at the current moment is predicted and output. The measurement time delay correction method proposed by the invention can improve the real-time performance and accuracy of monitoring pollutants by a continuous emission monitoring system of the flue gas.

Owner:ZHEJIANG UNIV

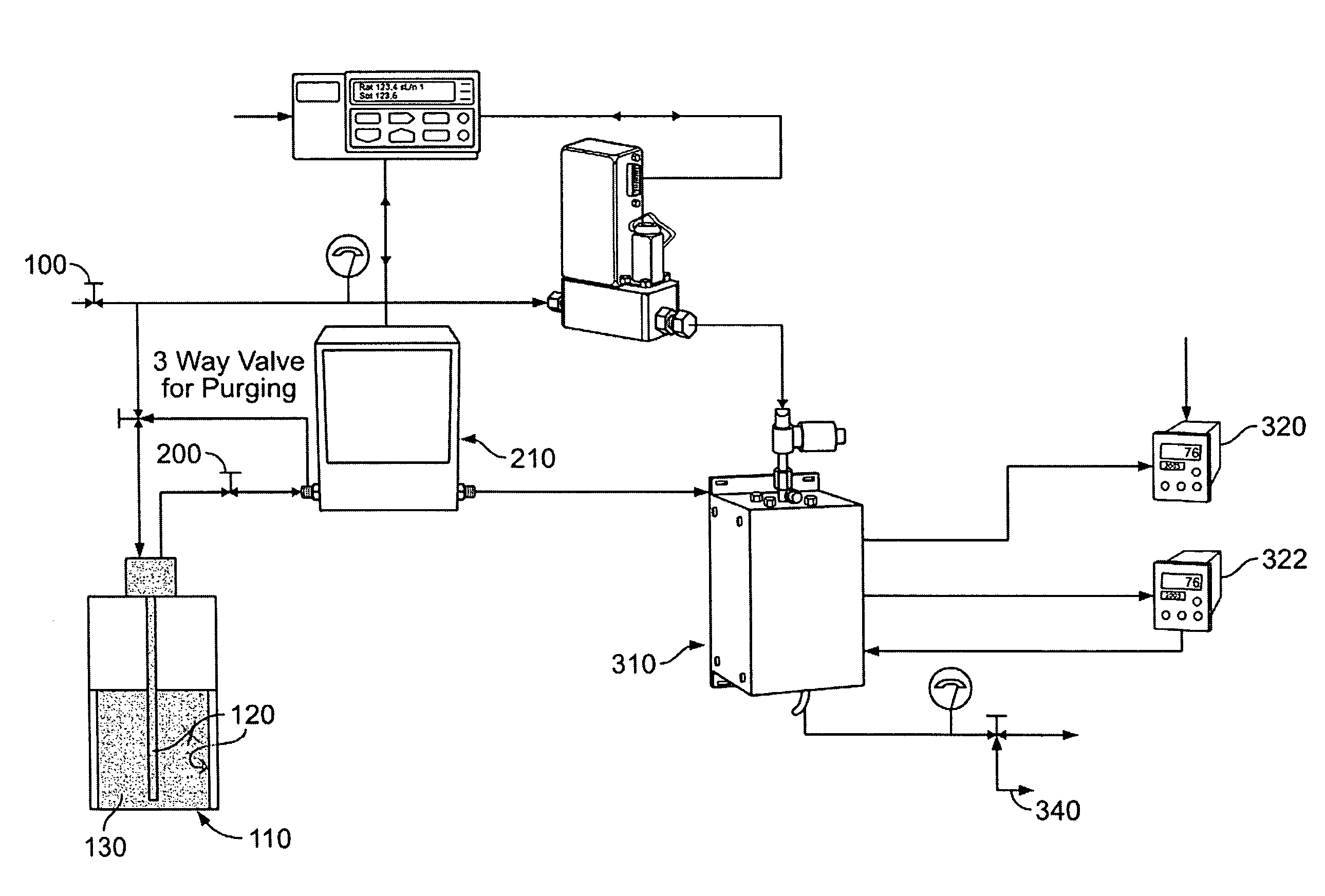

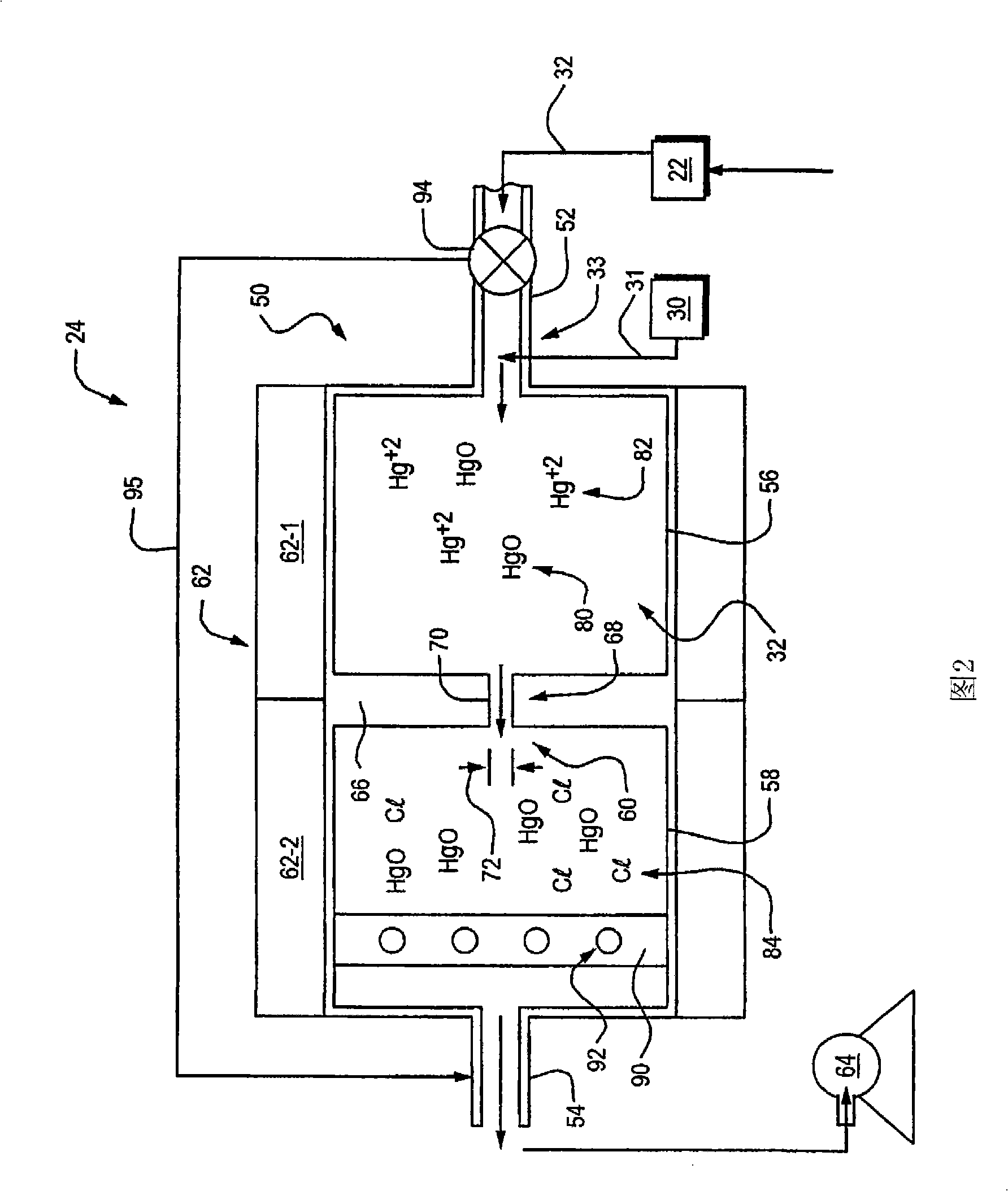

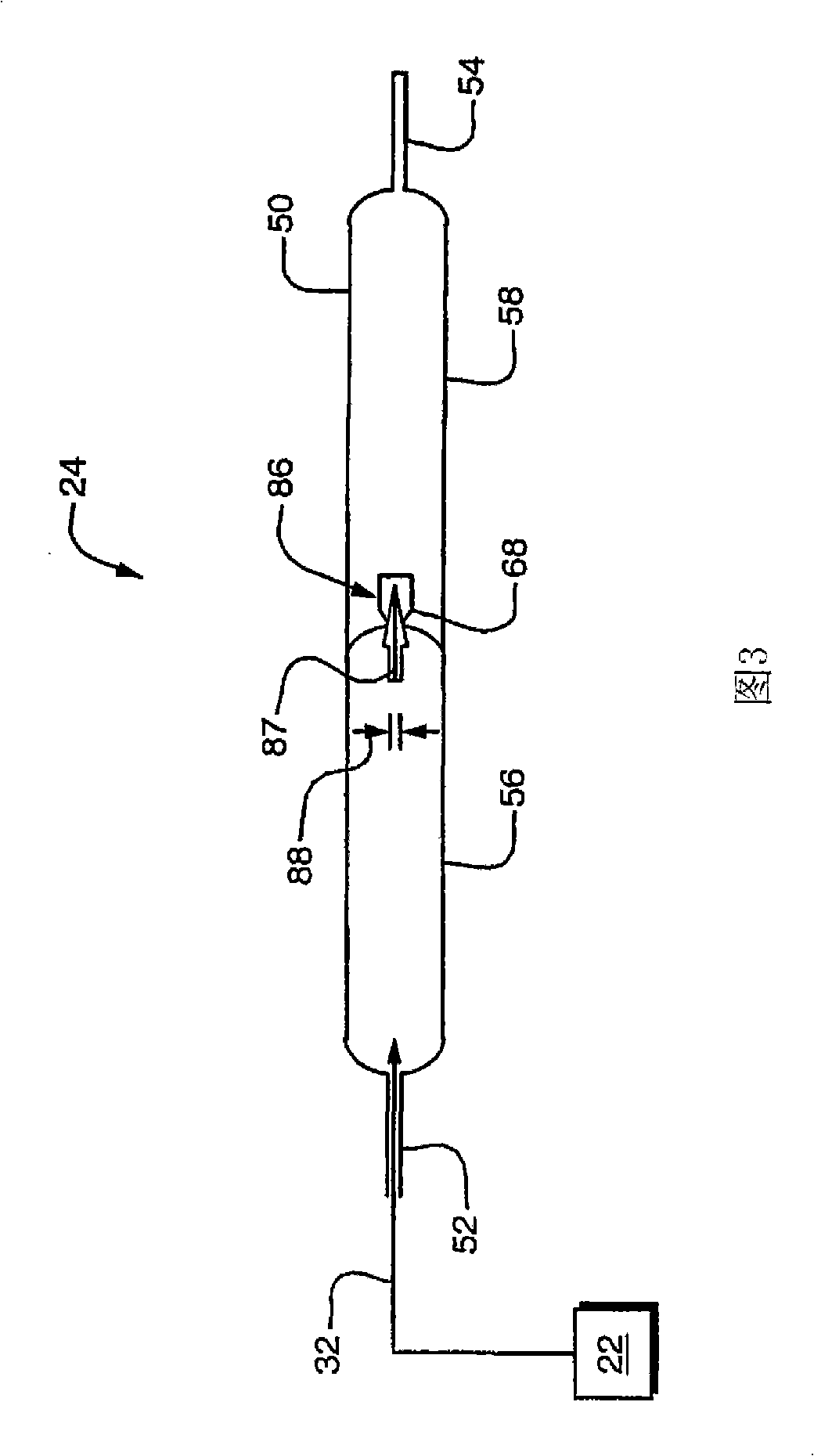

Mercury Ionic Gas Standard Generator For A Continuous Emissions Monitoring System

InactiveUS20090098656A1Replacement is neededLiquid surface applicatorsGas treatmentFlue gasAqueous solution

A mercury ionic gas standard generator for use in the continuous emissions monitoring of exhaust flue gas streams is disclosed. More specifically, the mercury ionic gas standard generator uses a reservoir being coated with an inert silicon-based coating for transporting a volume of an aqueous ionic mercury solution to a liquid mass flow controller and vaporizer.

Owner:GENERAL ELECTRIC CO

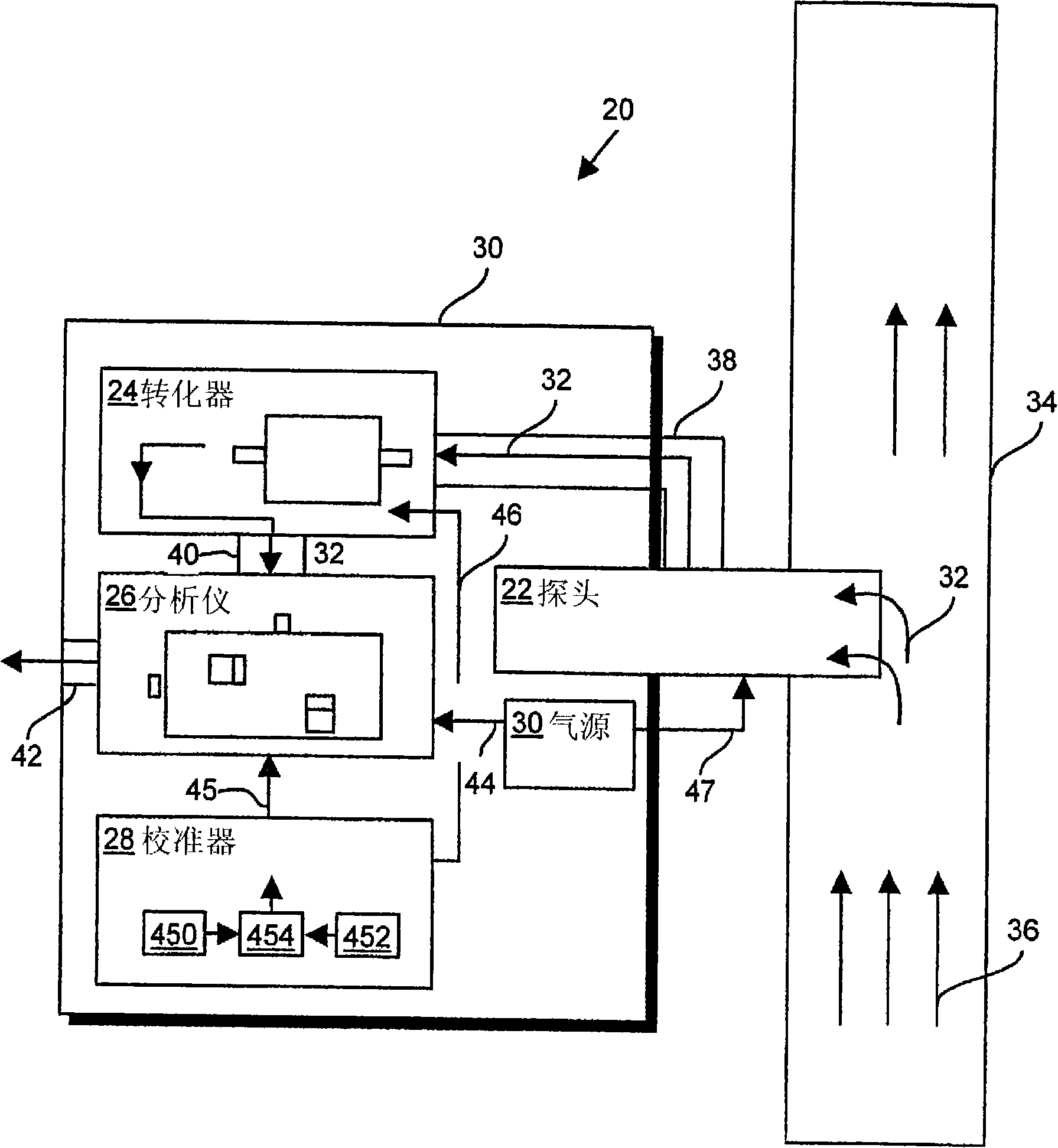

Method and apparatus for monitoring mercury in a gas sample

A converter of the Continuous Emission Monitoring System (CEMS) receives a gas sample containing vaporized mercury from a probe. The converter converts oxidized mercury present within the gas sample into an elemental mercury component and an oxidizing component using thermal cracking. The converter also reduces the pressure of the gas sample to minimize recombination of the elemental mercury component with the oxidizing components. A mercury analyzer of the system receives the reduced pressure gas sample from the converter and detects the fluorescence of the elemental mercury within the sample. The mercury analyzer holds the gas sample at the reduced pressure to reduce an effect of fluorescence quenching on the fluorescence of the elemental mercury within the sample and provides substantially accurate measurement of the concentration of the elemental mercury in the gas sample.

Owner:THERMO ELECTRON A DE

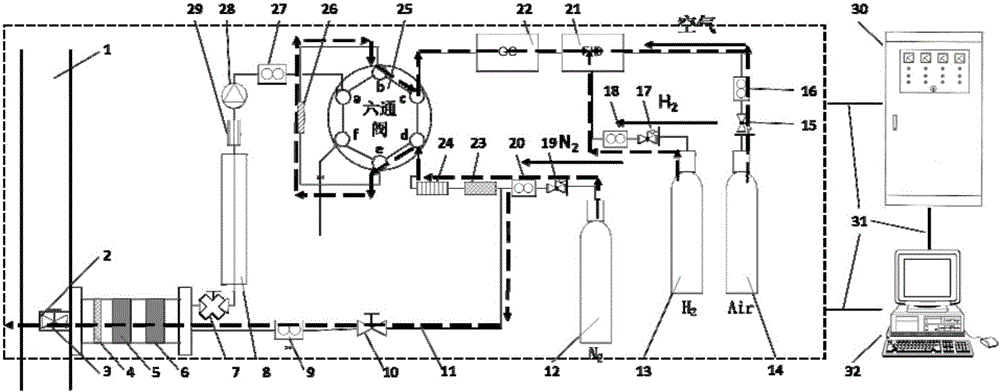

Continuous emission monitoring system for volatile organic compound pollutants in industrial flue gas

InactiveCN105738572AAvoid enteringAvoid condensation lossAir quality improvementMaterial analysisIndustrial gasControl system

The invention relates to a continuous emission monitoring system for volatile organic compound pollutants in industrial flue gas, and belongs to the technical field of continuous emission monitoring of industrial flue gas. The system comprises five parts, namely, a sampling subsystem, a back flushing subsystem, a gas supply subsystem, a gas detection subsystem and a control subsystem, wherein the sampling subsystem is used for continuously sampling flue gas in a flue into a sample loop; the back flushing subsystem is used for cleaning a sampling probe; the gas supply subsystem is used for providing carrier gas for back flushing of the sampling probe and sample feeding and analysis of the detection subsystem; the gas detection subsystem is used for analyzing components and concentration of VOCs in sample gas on line; the control system is used for controlling running of the whole detection system and monitoring the concentration of VOCs in the flue gas on line. According to the system, the flue gas is continuously acquired and stored in the sample loop, and online sample feeding and detection of the sample gas is implemented through a six-way valve, so that sampling, detection, back flushing and a standby mode are switched; the system has the characteristics of being safe, reliable, highly accurate, low in replacement and maintenance cost, convenient to control and the like.

Owner:TSINGHUA UNIV

Intelligent fault detection device of continuous emission monitoring system (CEMS)

InactiveCN102980610AImprove running stabilityReduce operating costsMeasurement devicesOperational costsMaterial resources

The invention discloses an intelligent fault detection device of a continuous emission monitoring system (CEMS). The intelligent fault detection device of the CEMS comprises a parameter acquisition unit, a data fault analysis unit, and a fault alarming unit, wherein the parameter collecting unit collects physical characteristic data and system data of each component of the CEMS through running a parameter acquisition sensor group, the data fault analysis unit analyzes a fault component and fault information of the fault component of the CEMS according to the physical characteristic data and system data collected by the parameter collecting unit, the fault alarming unit is connected with external devices or the network and is used for receiving fault information of the fault component generated by the data fault analysis unit and sends out a fault alarming signal. The intelligent fault detection device of the CMES can be widely applied to industries like thermal power plants, waste incineration power plants, chemical plants and paper-making. The intelligent fault detection device of the CMES can greatly improve operational stability of the CEMS, reduce manpower and material resources needed to operate the CEMS, and therefore the running cost and expense of the CEMS are reduced.

Owner:智谱特环境科技(北京)有限公司

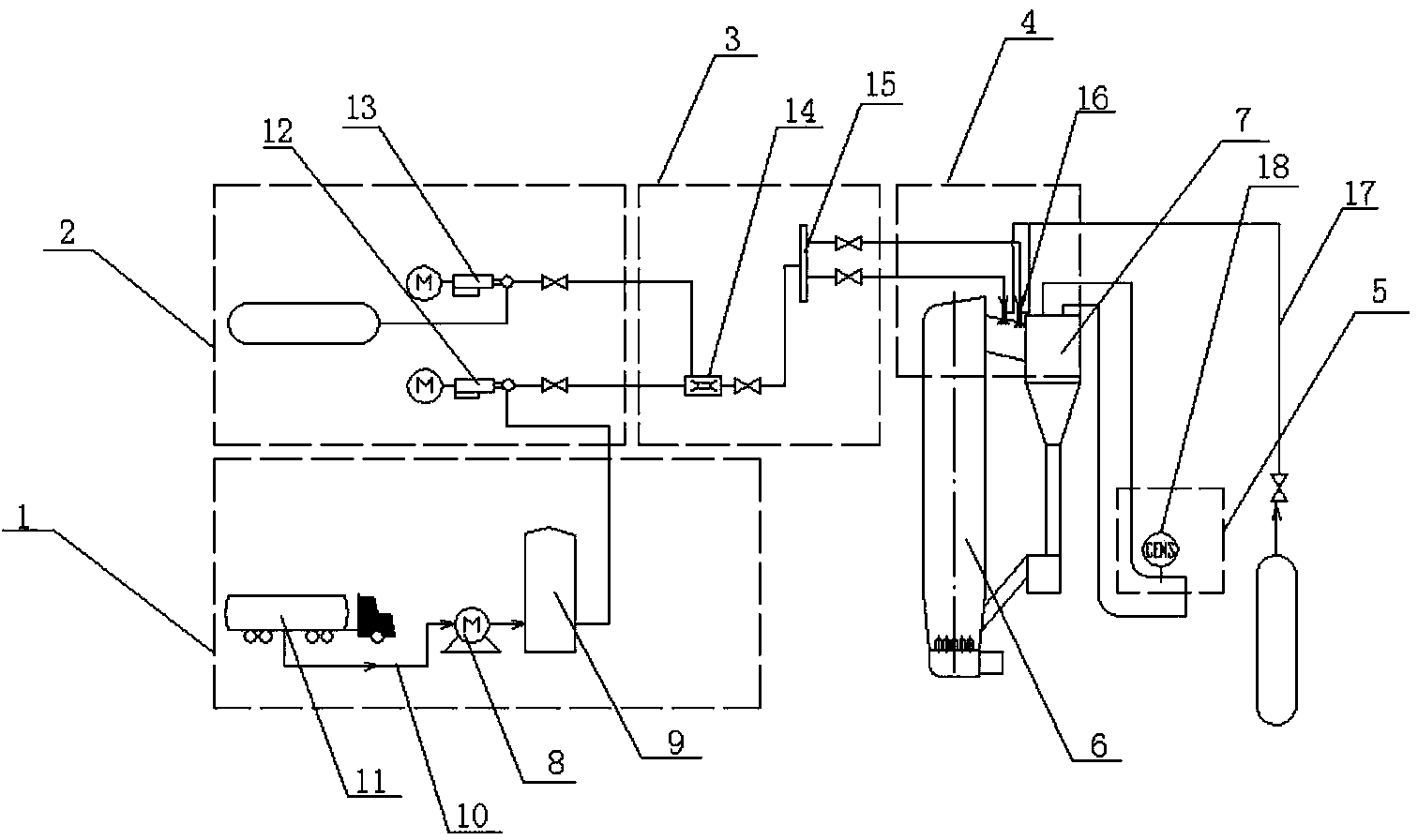

SNCR denitration system of circulating fluidized bed boiler based on flow-state reconstruction

InactiveCN103691292ASmall excess airReasonable temperatureLighting and heating apparatusDispersed particle separationFluidized bedWater storage tank

The invention belongs to the technical field of SNCR (Selective Non-Catalytic Reduction) denitration devices of circulating fluidized bed boiler equipment and particularly relates to an SNCR denitration system of a circulating fluidized bed boiler based on flow-state reconstruction. The SNCR denitration system mainly solves the problems of high investment cost and running cost and low denitration efficiency existed in the denitration of the existing boiler. The technical scheme is that the SNCR denitration system comprises a circulating fluidized bed boiler hearth and a circulating fluidized bed boiler separator, as well as an ammonia water unloading and storing system, an ammonia water diluted water delivery system, a mixing and distributing system, a spray injection system and a test system; ammonia water is delivered from a tank wagon to an ammonia water storage tank through a pipeline and an ammonia unloading pump for storing; the test system belongs to a CEMS (Continuous Emission Monitoring System) test system, and an input end of the CEMS test system is connected with the circulating fluidized bed boiler separator. The SNCR denitration system has the advantages of low cost and good denitration effect.

Owner:TAIYUAN BOILER GROUP +1

Method and system for denitration control of thermal power plant

InactiveCN107551774AReduce cloggingReduce resistanceControlling ratio of multiple fluid flowsDispersed particle separationEngineeringAmmonia

The invention discloses a method and a system for denitration control of a thermal power plant. The method comprises the following steps: calculating an O'clock every hour average value of NOX emission amount according to an NOX emission concentration value detected at a chimney by a CEMS (Continuous Emission Monitoring System); then judging whether the O'clock every hour average value is within apreset NOX emission threshold value range or not, increasing the ammonia spraying amount if the O'clock every hour average value is higher than a preset NOX emission threshold value, and reducing theammonia spraying amount if the O'clock every hour average value is smaller than the preset NOX emission threshold value. Compared with a traditional method for controlling the ammonia spraying amountaccording to an emitted NOX real-time concentration value, environment protection assessment standard can be met by just ensuring that the O'clock every hour average value accords with the preset NOXemission threshold value no matter how big an emitted NOX real-time concentration value is, the ammonia spraying amount can be accurately controlled on the premise that the NOX emission amount according with the environment protection requirements is ensured, and the situation that too much or too less ammonia is sprayed can be prevented from happening, so that the probability of blocking an airpre-heater is reduced, the resistance of a draught fan is reduced, and the overhauling cost is reduced.

Owner:CHINA RESOURCES POWER HUBEI

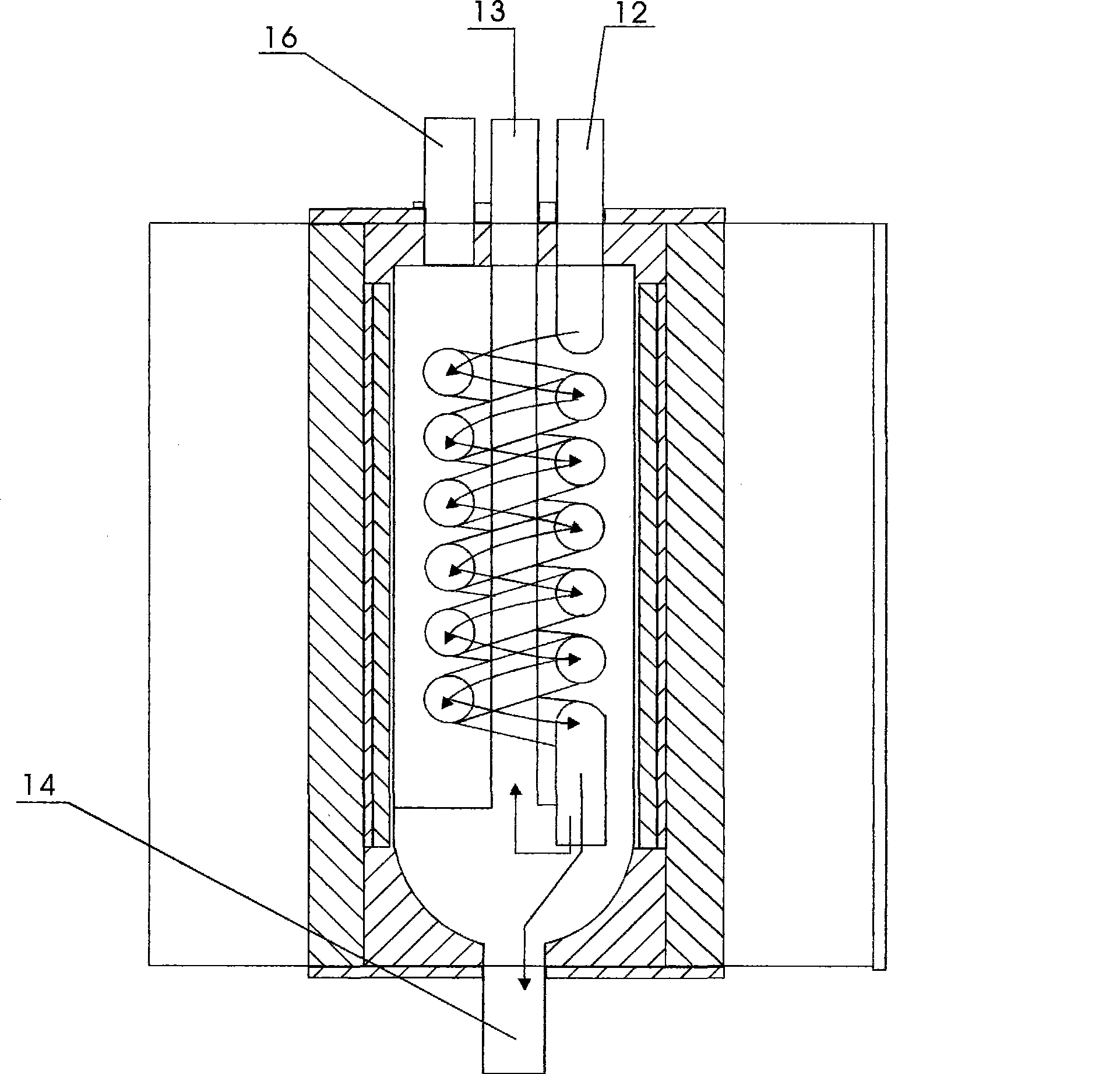

Continuous flue gas monitoring electronic refrigerator

InactiveCN101498526ATo achieve the effect of dehydration and dryingReduce noiseMachines using electric/magnetic effectsRefrigeration safety arrangementPlatinum resistanceEngineering

Owner:UNIVERSTAR SCI & TECH SHENZHEN

Automatic slurry supply control system of limestone-gypsum wet flue gas desulfurization device

InactiveCN106268273AEasy to controlRegulation stabilityGas treatmentDispersed particle separationAutomatic controlControl system

The invention provides an automatic slurry supply control system of a limestone-gypsum wet flue gas desulfurization device and belongs to the field of automatic control. The slurry supply system comprises a computer PLC (programmable logic controller), a pulverized coal bunker slurry supply pump, a limestone slurry supply pump, a desulfurization CEMS (continuous emission monitoring system) analysis meter, three PH meters and two densimeters, wherein the computer PLC is taken as a core controller, and operation, stop and frequency modulation control of related equipment are completed through instruction input of a host computer, input of various sensors and input of related analog quantity. With the adoption of the automatic slurry supply control system of the limestone-gypsum wet flue gas desulfurization device, regulation of the SO2 value of treated gas after automatic slurry supply is stable, control is easier, equipment is not required to be repeatedly operated by an operator, so that the burden of the operator is greatly reduced, and stable operation of a desulfurization system is guaranteed.

Owner:国能宁夏大坝三期发电有限公司

Quoting Tool and Design Module for Continuous Emission Monitoring Systems

InactiveUS20160071042A1Small margin of errorMeet the requirementsResourcesCommerceItem reductionUser input

Disclosed is a quoting tool and a design module for continuous emission monitoring system (CEMS). In one embodiment, the quoting tool is accessible via a website, and provides an interactive user interface for receiving user input and a request for a quote. When the quote is calculated and approved, the user input is used to automatically generate design drawings via the design module, which utilizes CAD API programming. Each of the quoting tool and the design module receives optimization input from a knowledge base to minimize errors and increase quality. The finalized design drawings are used to create bill of materials for assembling CEMS products. Because the instant invention streamlines the process of calculating quotes and drafting design drawings, the present system is configured to reduce project lead times and labor associated therewith.

Owner:JM STANLEY

Ultraviolet absorption measurement method for waste gas sulfur dioxide of stationary pollution source

ActiveCN104406932AEliminate or reduce pollutionEliminate or reduce adsorptionColor/spectral properties measurementsUltraviolet absorptionLength wave

The invention discloses an ultraviolet absorption measurement method for waste gas sulfur dioxide of a stationary pollution source. According to the method, an ultraviolet absorption method sulfur dioxide analyzer or multiple groups of gas analyzers with an ultraviolet absorption method sulfur dioxide analysis function is / are used as multiple monitors; sulfur dioxide is used for absorbing light with the characteristic wavelength of 240-330nm in a near ultraviolet light region, and the concentration of sulfur dioxide in waste gas is quantified according to the lambert-beer law; then the sulfur dioxide discharging rate is obtained by further calculation. An ultraviolet absorption method can adapt to wider measurement on SO2 discharged by the stationary source; by the method, the requirements on supervising monitoring on an on-site pollution source, comparison monitoring on a CEMS (continuous emission monitoring system) and checking of data effectiveness are met.

Owner:山东省环境监测中心站

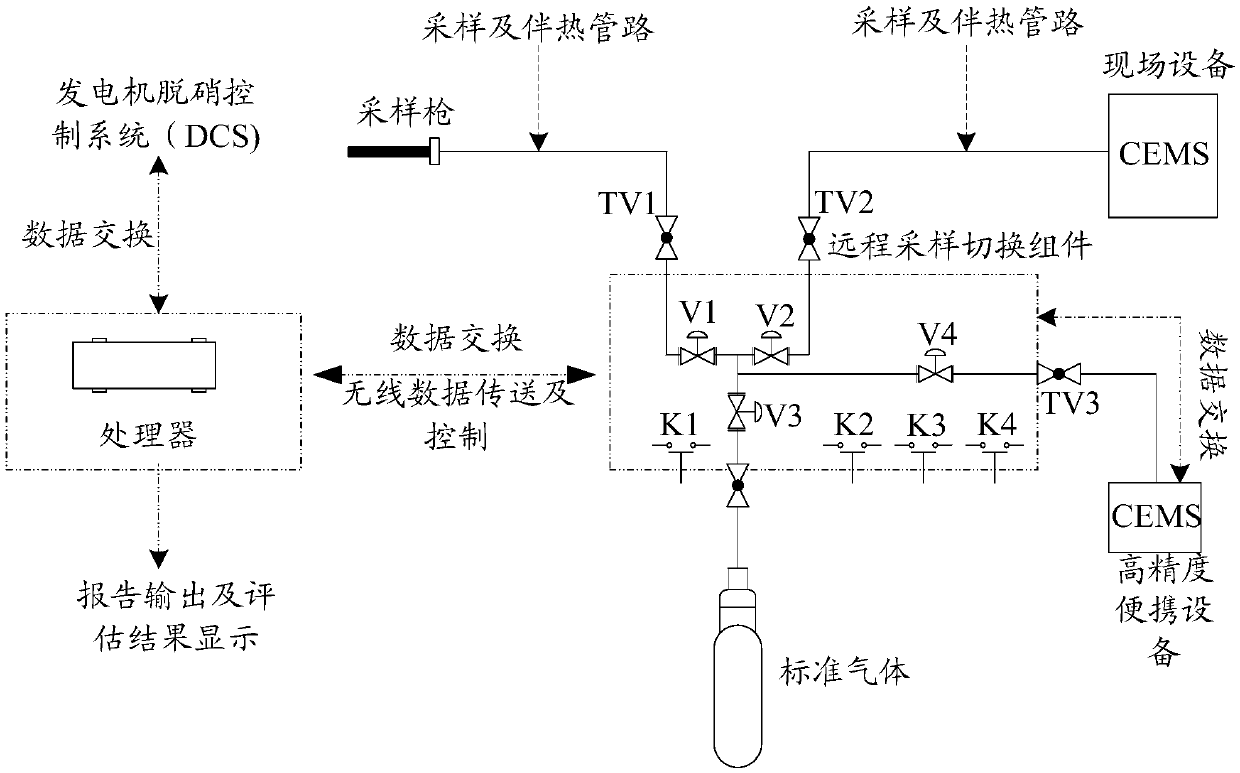

Estimation method and system for measurement properties of CEMS (Continuous Emission Monitoring System) of denitration system

ActiveCN108956886AImprove denitrification performanceImprove reliabilityGas analyser calibrationControl systemEstimation methods

The embodiment of the invention discloses an estimation method and system for measurement properties of a CEMS (Continuous Emission Monitoring System) of a denitration system. The method comprises thefollowing steps: calculating various pre-set performance indexes of the CEMS according to a plurality of paths of measurement data of a denitration control system under standard working conditions and a dynamic operation process of working conditions to be evaluated; evaluating current measurement properties of the CEMS in the denitration control system according to the differences of all the performance indexes of the standard working conditions and the working conditions to be evaluated, wherein the standard working conditions are working condition with normal dynamic properties of the denitration control system and and the measurement data comprises an inlet NOx concentration, an outlet NOx concentration and an FGD outlet NOx concentration of a reactor of the denitration control system. The estimation method can be used for effectively evaluating the measurement properties of the CEMS, so that whether the measurement properties of the CEMS are worsened or not and the seriousness ofa worsening degree can be known, and furthermore, problems of the CEMS can be rapidly found and eliminated in time, which is conducive to ensuring and improving the denitration performance and reliability of the denitration control system and improving the control performance of the denitration control system of a thermal power unit.

Owner:润电能源科学技术有限公司

Continuous emission monitoring system

InactiveCN104655177AReal-time data collectionReal-time transmissionMeasurement devicesParticulatesData acquisition

The invention provides a continuous emission monitoring system, belongs to the technical field of monitoring systems and particularly relates to a continuous emission monitoring system. The invention provides the continuous emission monitoring system which is compact in structure and convenient to mount The continuous emission monitoring system comprises a pollutant sampler, a particulate matter measuring instrument, a flue gas temperature detection device, a flue gas pressure detection device, a flue gas flow detection device, a data acquisition system, a data control system, a data processing communication system and a monitoring system and is structurally characterized in that the data control system is respectively connected with the pollutant sampler, the particulate matter measuring instrument, the flue gas temperature detection device, the flue gas pressure detection device, the flue gas flow detection device, the data acquisition system, the data processing communication system and the monitoring system; a particulate matter analysis system is used for monitoring the concentration and the emission quantity of solid or liquid particulate matters in flue gas.

Owner:徐世铭

Intelligent denitration method and intelligent denitration device for spray drying tower

ActiveCN107486004AReduce usagePrevent impact pollutionGas treatmentDispersed particle separationNitrogen oxidesControl system

The invention discloses an intelligent denitration method and an intelligent denitration device for a spray drying tower. The device comprises a control system, a CEMS (continuous emission monitoring system) online monitoring module, a reducing agent conveying module, a reducing agent preparation module and a spray gun; the intelligent denitration method monitors the content of nitric oxide in the drying tower in real time through a CEMS, controls the system to control the whole denitration process, uses the intelligent spray gun to accurately control the use amount of a reducing agent, and prevents the excessive reducing agent from overflowing to corrode equipment, affect the product quality and pollute the environment; the method in the scheme can control the denitration operations of a plurality of spray drying towers at the same time through one control system, control in a combined manner, improve the working efficiency, reduce the launching of the equipment, and save the cost.

Owner:FOSHAN HUAQING ZHIYE ENVIRONMENTAL PROTECTION TECH CO LTD

Conditioning system and method for use in the measurement of mercury in gaseous emissions

ActiveUS20090000484A1Avoid reorganizationReduced form requirementsCombination devicesGas treatmentProduct gasBoron nitride

Embodiments of the invention relate generally to systems used to measure mercury in gaseous emissions. In one aspect, the invention is directed to the use of silicon carbide as material for a thermal pyrolysis unit. In another aspect, at least one of silicon nitride, silicon boride, and / or boron nitride is used as material for a thermal pyrolysis unit. In another aspect, the invention is directed to an improved pyrolyzer design, in which a thermal pyrolysis unit comprises a tailpiece that allows water to be injected at the heated exit of the thermal pyrolysis unit. In another aspect, the invention is directed to the use of a coalescing filter in a scrubbing unit. In another aspect, the invention is directed to the use of a hydrophobic filter element in a scrubbing unit. One or more of these elements may be used in a conditioning module of a continuous emissions monitoring system, for example.

Owner:TEKRAN INSTR CORPORTION

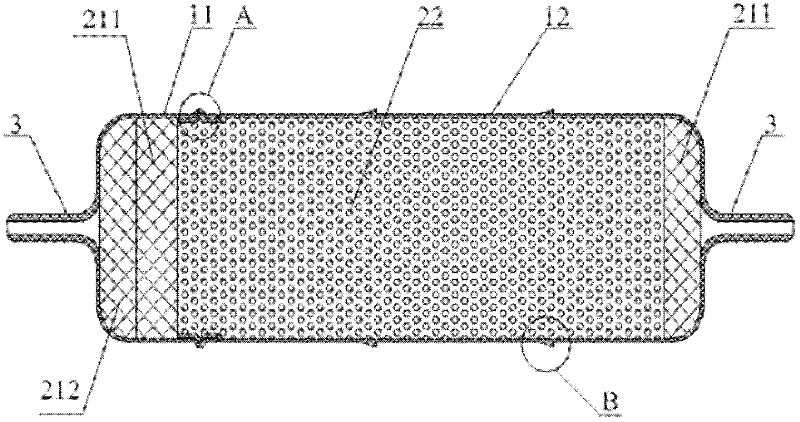

Pretreatment system

InactiveCN102445374AEfficient removalEffective absorptionPreparing sample for investigationFlue gasEngineering

The invention discloses a pretreatment system, which comprises a dehumidifying device, a dust removing device and an acid mist filter, wherein the acid mist filter is arranged between the dehumidifying device and the dust removing device. Before being transmitted to a flue gas analysis cabinet under the action of a pump, flue gas enters the pretreatment system provided by the invention firstly, so that dehumidifying and dust removing treatment can be performed on flue gas, sulfur trioxide in the flue gas can be removed and absorbed effectively, corrosion and damage of acid mist formed by sulfur trioxide on a CEMS (Continuous Emission Monitoring System) are prevented, and the maintenance quantity and maintenance cost of the system are lowered greatly.

Owner:BEIJING SDL TECH

Online monitoring device of denitration CEMS (Continuous Emission Monitoring System) system

InactiveCN108195786AWell mixedAccurate response to NO concentration valueWithdrawing sample devicesPreparing sample for investigationDifferential absorptionEngineering

The invention discloses an online monitoring device of a denitration CEMS (Continuous Emission Monitoring System) system. The online monitoring device comprises a sampling unit and an analysis unit, wherein the sampling unit comprises a multi-point sampling mechanism and a back blowing mechanism; the analysis unit comprises a host machine cabinet and a secondary machine cabinet. Sine samples are taken from multiple points, sample gases are uniformly mixed, and measurement of gas concentrations is achieved through an ultraviolet differential absorption spectrums, an actual NO concentration value of a denitration working condition can be precisely reflected, out-of-standard emission caused by great NO concentration variations is avoided, and the economic cost can be reduced for users. The online monitoring device is good in packaging property, small in number of external equipment and exposed devices, and effectively applicable to various complex environments.

Owner:安徽蓝盾光电子股份有限公司

Controlled humidification calibration checking of continuous emissions monitoring system

InactiveUS8443648B2Accurate measurementSamplingMaterial analysis by electric/magnetic meansAnalyteEngineering

A continuous emissions monitoring system is in fluid communication with a flue stack conducting exhaust gas from a combustion source. The continuous emissions monitor system comprises an analyzer for measuring concentrations of an analyte present in the exhaust gas. A probe is in fluid communication with the flue stack to acquire a sample of exhaust gas from the flue stack. The probe is also in fluid communication with and located upstream of the analyzer. The probe tends to remove analyte from the sample. A calibration checking system is in fluid communication with the probe. The calibration checking system includes a source that provides a flow of a known concentration of calibration material to be measured by the analyzer. The calibration material is the same as the analyte. A humidifier is associated with the source to provide moisture to a flow of calibration material. The moisture acts to cleanse removed analyte from the probe and thereby enable an accurate measurement of the concentration of the calibration material. A supply system is operatively connected with the humidifier to provide a desired amount of a liquid to the humidifier.

Owner:THE BABCOCK & WILCOX CO

CEMS (Continuous Emission Monitoring System) sampling system and method for horizontal flue of main discharge port of coal-fired unit

PendingCN113984458AEliminate the problem of uneven concentration fieldEliminate defects that cannot represent the overall pollutant emission situationWithdrawing sample devicesHydrologyMechanical engineering

The invention relates to a CEMS (continuous emission monitoring system) sampling system for a horizontal flue at a main discharge port of a coal-fired unit. The CEMS sampling system comprises sampling branch pipes, back flushing electromagnetic valves, sampling electromagnetic valves, a mixing main pipe, flow regulating valves, a dilution unit and a probe controller. A plurality of groups of sampling branch pipes are arranged on the measuring section of a main discharge port flue, a plurality of sampling branch pipes form a group, the lengths of the sampling branch pipes in the same group are arranged in equal difference, and the tops of the sampling branch pipes are equal in height. Each sampling branch pipe is connected to the mixing main pipe through one sampling electromagnetic valve and one flow regulating valve in sequence, and the mixing main pipe is connected to a gas analyzer through the dilution unit and the probe controller in sequence. An outlet pipeline of each sampling branch pipe is connected with a back flushing pipeline, and a back flushing electromagnetic valve is arranged on the back flushing pipeline. The system and the method have the beneficial effects that multi-point sampling is performed at the main discharge port of the coal-fired unit, so that the problem of non-uniform pollutant concentration field caused by a flow field can be eliminated, and the defect that single-point measurement data cannot represent the overall pollutant discharge condition is overcome.

Owner:ZHEJIANG ZHENENG TECHN RES INST +1

Pressure relief protection system for CEMS (continuous emission monitoring system) back blowing unit

PendingCN107478777AAvoid harmHollow article cleaningMaterial analysisEngineeringMechanical engineering

The invention provides a pressure relief protection system for a CEMS (continuous emission monitoring system) back blowing unit, and belongs to the technical field of CEMS systems. The pressure relief protection system comprises a back blowing gas source, a sampling probe, a sampling and analyzing unit and a heat tracing pipe, and further comprises a two-position three-way electromagnetic valve and a controller, wherein the ports of the two-position three-way electromagnetic valve are connected with the heat tracing pipe, the back blowing gas source and the sampling and analyzing unit respectively; the sampling probe is connected with the two-position three-way electromagnetic valve through the heat tracing pipe; a pressure relief device is arranged between the back blowing gas source and the two-position three-way electromagnetic valve; and the two-position three-way electromagnetic valve and the pressure relief device are electrically connected with the controller. The pressure relief protection system is used for reducing damage of back blowing gas to sampling and analyzing unit equipment in the case of gas channel blockage.

Owner:ANHUI BISHUI ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com