Curing methods and products produced therefrom

An organic compound, sheet technology, applied to low-emission sheets, "indicates that the specific components related to the term can include acrylate or methyl fields, which can solve problems such as limited cross-linking, achieve TVOC value reduction, emission reduction, The effect of low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] Example 1: Linoleum Base

[0127] First, all the components of the linoleum composition listed in Table 1 below were mixed in a suitable mixing apparatus to form a base mass (mixed mass) as homogeneous as possible. The mixed mass thus obtained is processed into skins and conveyed to a scraper or granulator, after which the granules of the mixed mass thus obtained are conveyed to a calender and pressed, for example as a substrate, under pressure and at a temperature of typically 10°C to 150°C The material is jute. The panels obtained are then stored in an aging cabinet at about 80° C. for 2 to 3 weeks.

[0128] The formulations are listed as an example in Table 1, where the values indicated are in % by weight relative to the amount of the total mixture (linoleum layer). The individual components of the formulations specified in Table 1 were chosen such that for each particular formulation of the linoleum layer a value of 100% by weight was produced.

[0129] Table ...

Embodiment 2

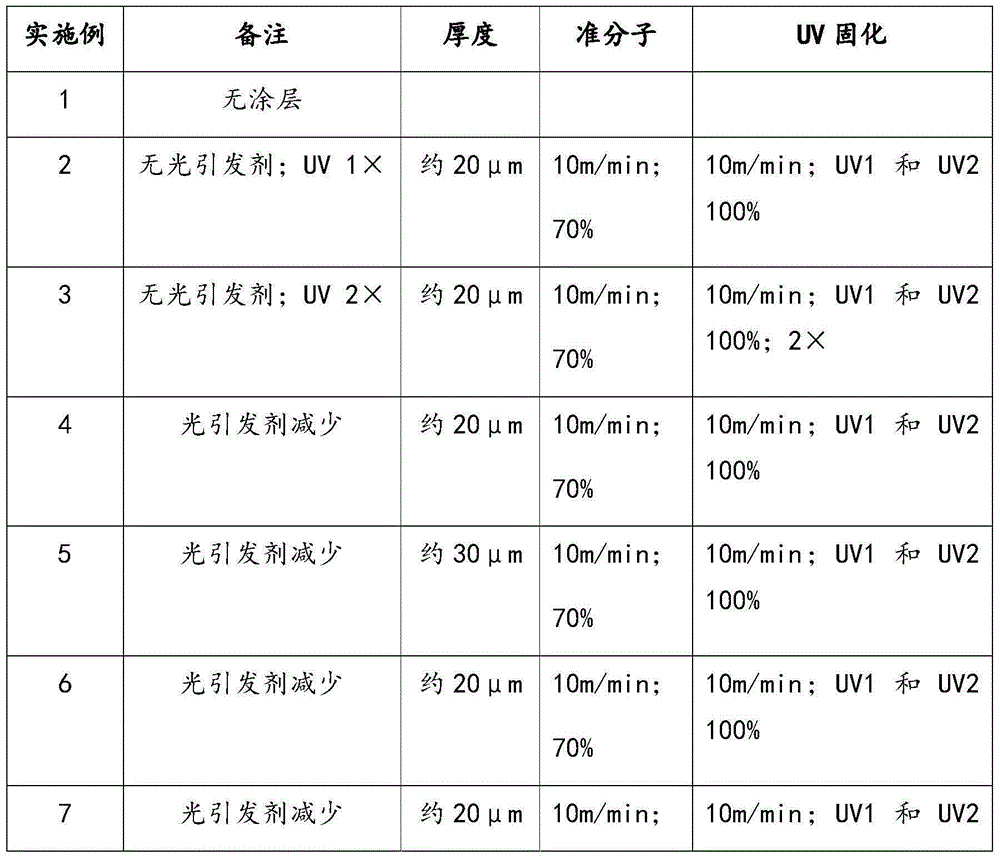

[0131] Example 2: Coated Linoleum Base

[0132] Each roll coat applied a coat, the composition and amount of which is shown in Table 2, to the base layer. As evident from Table 3, the coating was cured initially by irradiation with an excimer lamp (Excirat 172) at a wavelength of 172 nm at a line speed of 10 m / min under a nitrogen atmosphere (oxygen content below 150 ppm). In a second irradiation step with a mercury lamp at the same line speed (Printworld PUVD 270-2, without IR lamp, UV1 and UV2, 160 W / cm power), the curing of the coating is carried out under normal atmosphere.

[0133] Table 2

[0134] Example

Coating Composition

Coating amount

1

uncoated

2

No photoinitiator; 70g M 215 1 and 40g U100 2

16g / m 2

3

Without photoinitiator, 70g M 215 1 and 40g U100 2

18g / m 2

4

1% Esacure as photoinitiator, 70g M215 1 and 40g U100 2

23g / m 2

5

1% Esacure as photoinitiator, ...

Embodiment 3

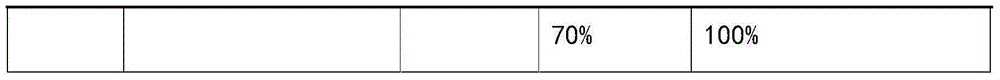

[0145] Example 3: Emissions measurement

[0146] The emissions from these panels obtained were measured using the FLEC test.

[0147] FLEC measurement unit used: Chematec (SCP Seitz Chromatographic Products GmH); measurements were performed after 28 days.

[0148] Table 4

[0149]

[0150] The results of the FLEC tests are presented in Table 5, where it is evident that the uncoated linoleum layer has a TVOC value of up to 170 μg / m 2 h. This value is slightly higher than for PUR-coated linoleum layers.

[0151] Examples 2 and 3, which did not contain a photoinitiator in the coating, had lower TVOC values than the uncoated linoleum layer. However, although they do not contain a photoinitiator, Examples 2 and 3 have significantly higher TVOC values than Examples 4 to 7 according to the invention.

[0152] table 5

[0153] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com