Large scale manufacturing of hybrid nanostructured textile sensors

a nano-structured textile and nano-technology, applied in spinnerette packs, conductive pattern formation, liquid/solution decomposition chemical coatings, etc., can solve the problems of incompatibility of materials with large-scale textile manufacturing, inability to adapt gel-based electrodes to clothing as re-usable sensors, and inability to form good quality contact between plane-conductive textile-based electrodes,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

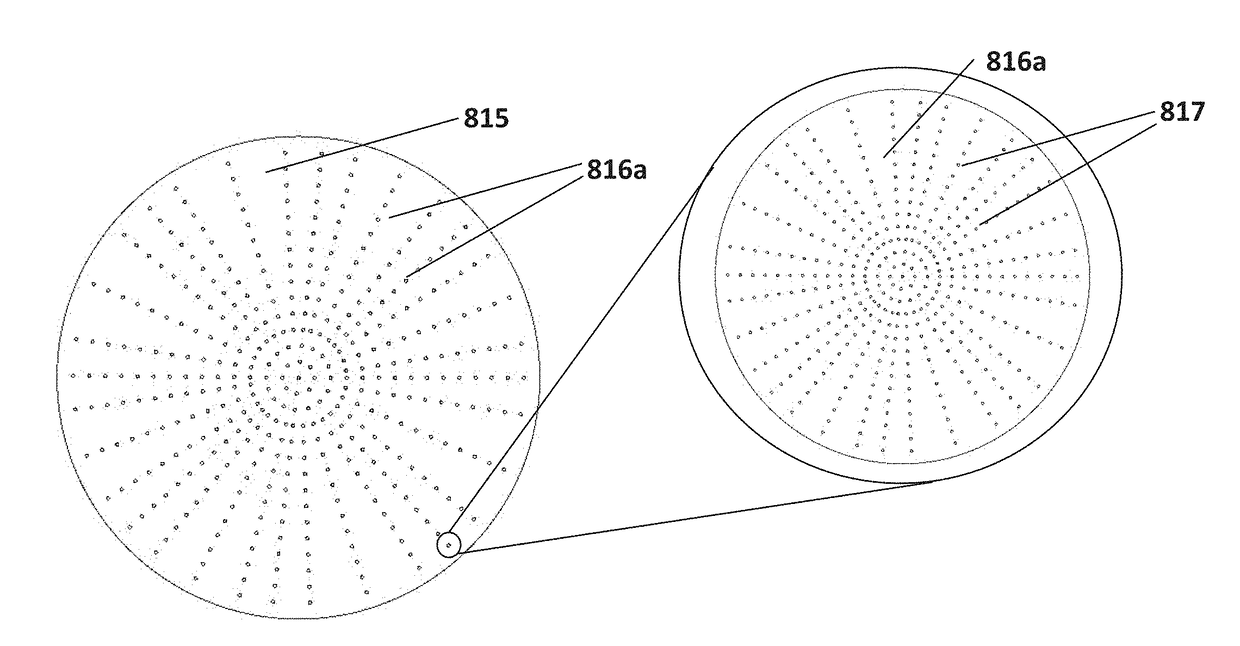

[0020]The present disclosure provides a novel textile based nanostructured sensors that can be fabricated by using specially designed high throughput processes that are compatible with existing textile manufacturing technology.

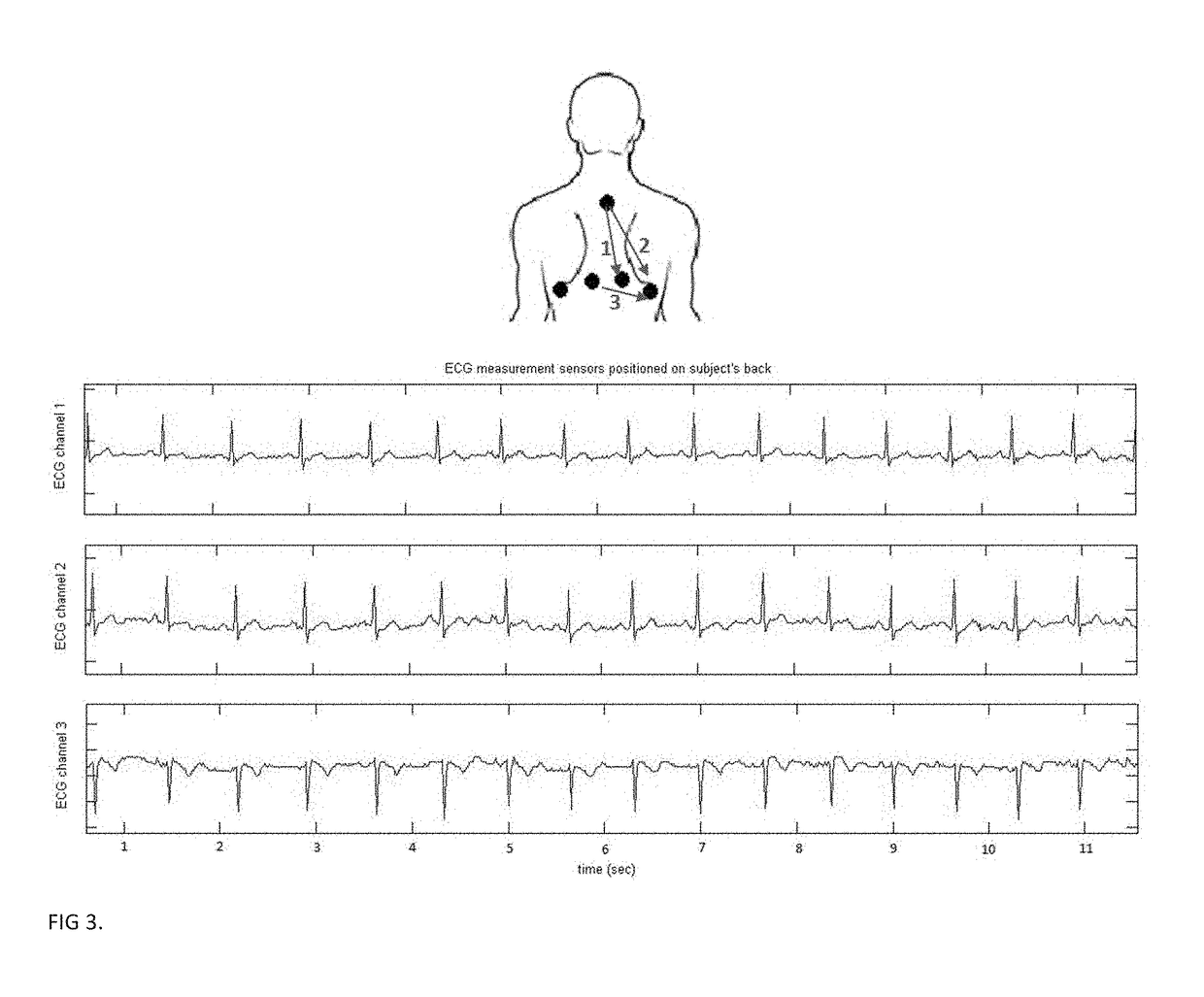

[0021]Nanostructured textile-based dry sensors and electrodes are better suited for long term monitoring and measurement of biopotential signals such as electrocardiography (ECG or EKG), electroencephalography (EEG), electrooculography (EOG), electromyography (EMG) and bioimpedance with very low baseline noise, because of their improved sensitivity and ability to perform adequately with the natural moisture level of skin. Such textile based electrodes can be seamlessly integrated into garments of daily use such as vests, brassieres, bed sheets, wrist band, head band, chest band, arm band, gloves, and socks. In combination with state of the art embedded wireless network devices that can communicate with smart phone, laptop or directly to a remote server through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com