Lithium ion battery phosphatic composite cathode material and preparation method thereof

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

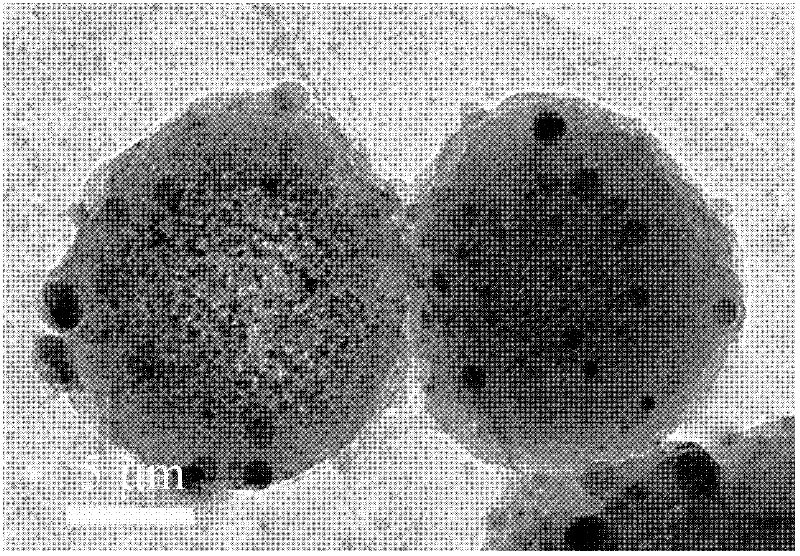

[0028] a. Prepare the core active material by one spray: use lithium acetate, ammonium vanadate, ammonium dihydrogen phosphate, and citric acid (added according to the residual carbon content of the product as 2%) as raw materials, add an appropriate amount of deionized water, and place in a constant temperature water bath at 80°C Stir for 6 hours to form a sol, then press LiFePO 4 with Li 3V 2 (PO 4 ) 3 The molar ratio of 10:1, adding nano-sized LiFePO 4 Powder, ultrasonically dispersed uniformly, the resulting mixture was spray-dried at 150°C, then calcined at 800°C for 4 hours in an inert atmosphere, cooled and ground to obtain the core LiFePO of lithium vanadium phosphate-coated lithium iron phosphate 4 / Li 3 V 2 (PO 4 ) 3 .

[0029] b. Secondary spraying to prepare a composite positive electrode material with a multi-nuclear core-shell structure: a certain amount of glucose (the quality of carbon contained in it is 5% of the quality of the inner core material) is...

Embodiment 2

[0031] a. Prepare the core active material by spraying once: take lithium carbonate, vanadyl oxalate, phosphoric acid, polyethylene glycol (according to the residual carbon content in the product is 3% to add) as raw material, add appropriate amount of deionized water, oil at 70 ℃ Stir in the bath for 10 hours to form a sol, then press LiFePO 4 with Li 3 V 2 (PO 4 ) 3 The molar ratio of 100:1, adding nano-sized LiFePO 4 Powder, magnetically stirred to disperse evenly, the resulting mixture was spray-dried at 200°C, then calcined at 550°C for 20 hours in an inert atmosphere, cooled and ground to obtain the nuclear active material LiFePO, which is lithium vanadium phosphate-coated lithium iron phosphate 4 / Li 3 V 2 (PO 4 ) 3 .

[0032] b. Secondary spraying to prepare a composite positive electrode material with a multi-nuclear core-shell structure: a certain amount of sucrose (the quality of carbon contained in it is 15% of the quality of the inner core material) is di...

Embodiment 3

[0034] a. Preparation of core active material by spraying once: using lithium hydroxide, triethanolamine vanadium peroxide, triammonium phosphate, oxalic acid (added according to the residual carbon content of the product as 1%) as raw materials, adding an appropriate amount of deionized water, and keeping the temperature at 60°C Stir in a water bath for 12 hours to form a sol, then press LiFePO 4 with Li 3 V 2 (PO 4 ) 3 The molar ratio of 5:1, adding nano-sized LiFePO 4 Powder, mechanically stirred and dispersed evenly, the resulting mixture was spray-dried at 250°C, then calcined at 900°C for 2 hours in an inert atmosphere, cooled and ground to obtain the core active material LiFePO, which is lithium vanadium phosphate-coated lithium iron phosphate 4 / Li 3 V 2 (PO 4 ) 3 .

[0035] b. Secondary spraying to prepare the composite positive electrode material of the polynuclear core-shell structure: a certain amount of citric acid (the quality of its contained carbon is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com