Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Ultrasonic levitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

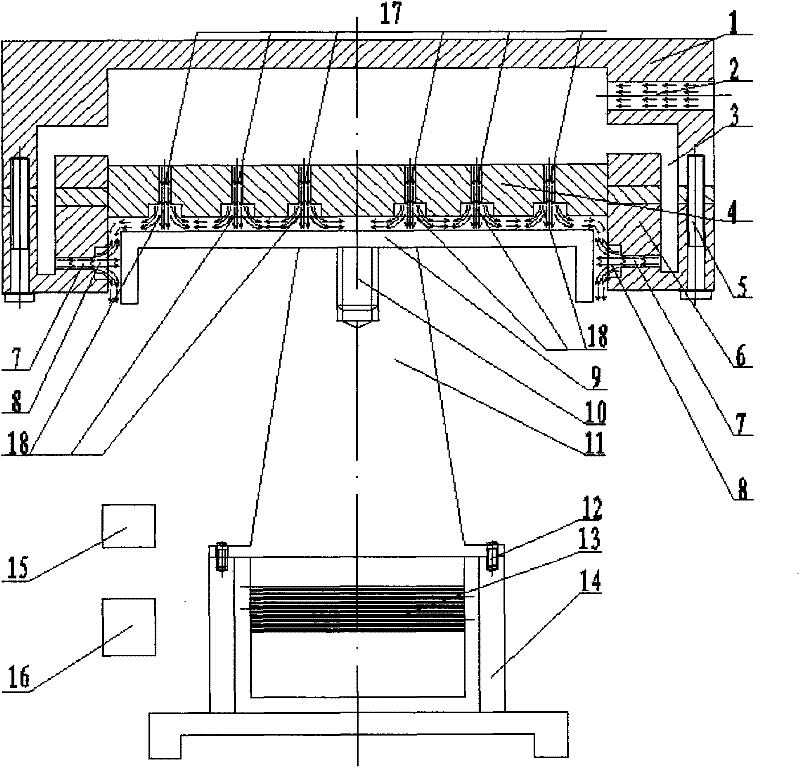

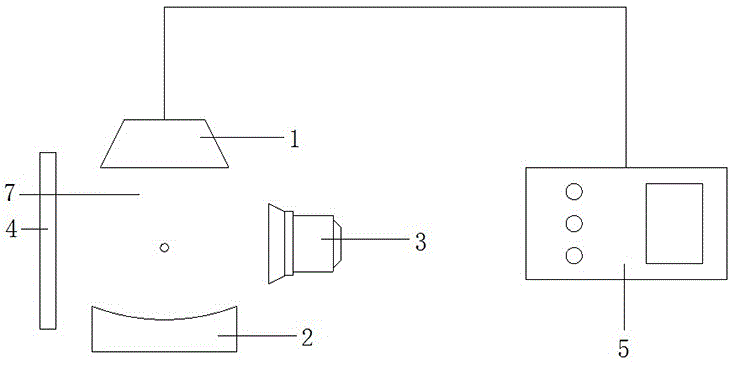

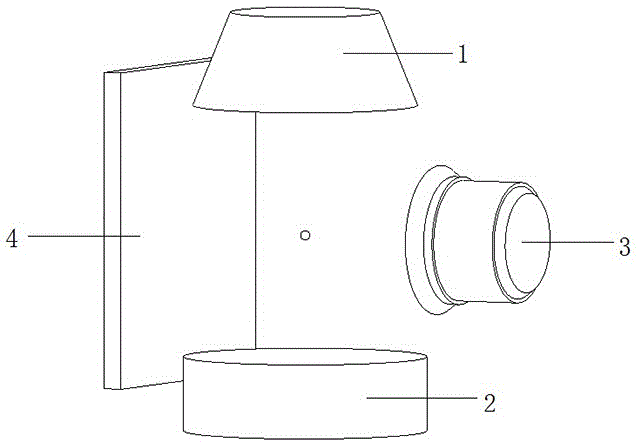

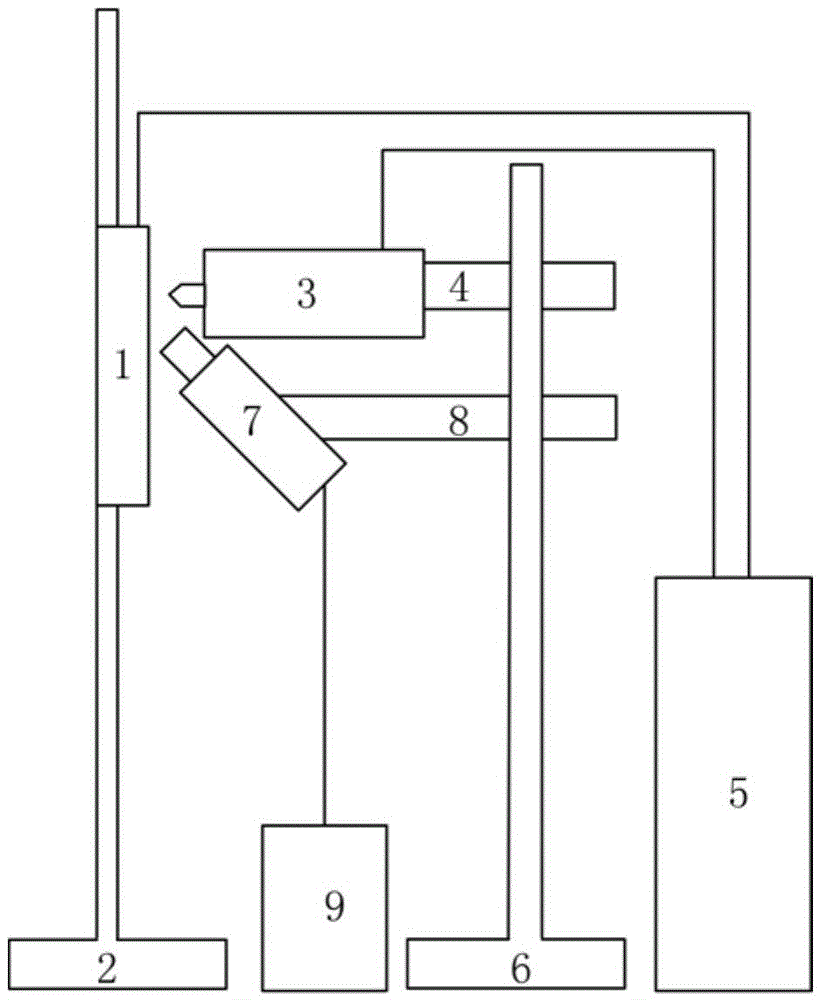

Piezoelectric ultrasonic/high-frequency electromagnetic hybrid suspension non-contact smelting method and device

InactiveCN102519249ARealize non-contact meltingSimple structureFluidised-bed furnacesSuspended particlesMolten state

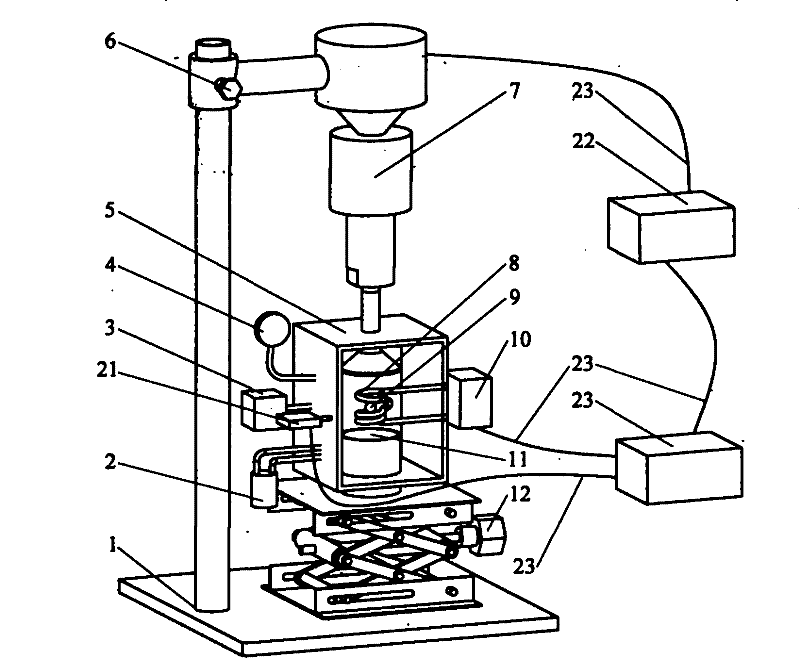

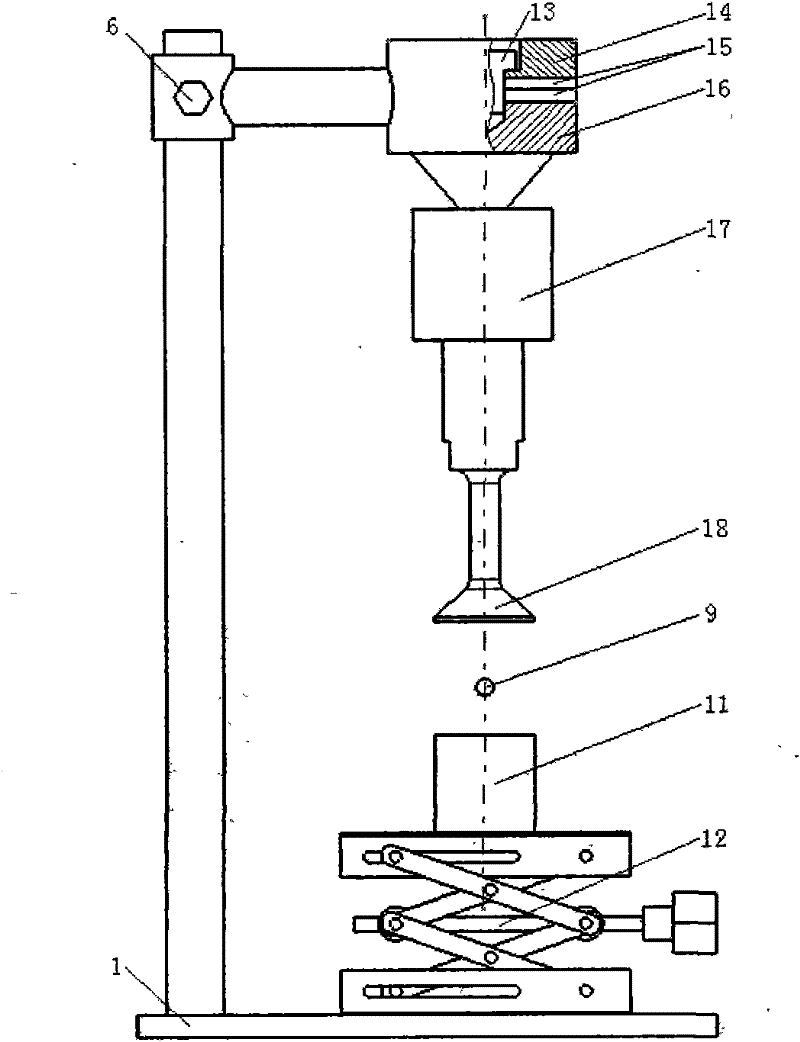

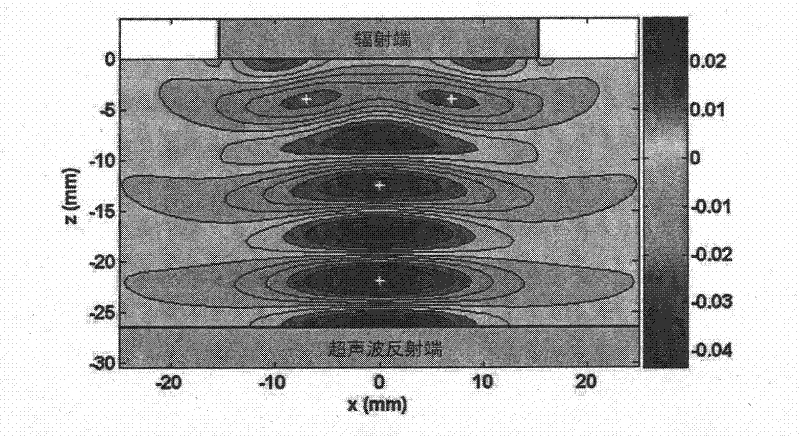

The invention relate to a piezoelectric ultrasonic / high-frequency electromagnetic hybrid suspension non-contact smelting method and a device, which belong to the technical field of non-contact material smelting. The device comprises a sealing box, an ultrasonic generator, an ultrasonic transducer, a high-frequency inductive power source, a high-frequency inductor, a base, deflating and inflating equipment, an infrared temperature measurer, a pressure gauge, an ultrasonic wave reflecting end and an adjusting device of the ultrasonic wave reflecting end. Ultrasonic suspension force and electromagnetic suspension force jointly act on suspended particles (metal), or the electromagnetic suspension force independently acts on the suspended particles, and the suspended particles generate electromagnetic induction in a high-frequency magnetic field generated by the high-frequency inductor, and are heated until the suspended particles are melted. The output power of the high-frequency power source is reduced, a melted article independently acts under the effect of the ultrasonic wave suspension force, and is cooled to form solid in a suspension state. Smelting of materials is completed in a state without a container, high-purity alloy without impurities can be prepared, and non-contact smelting of metal with active chemical properties can be carried out.

Owner:JILIN UNIV

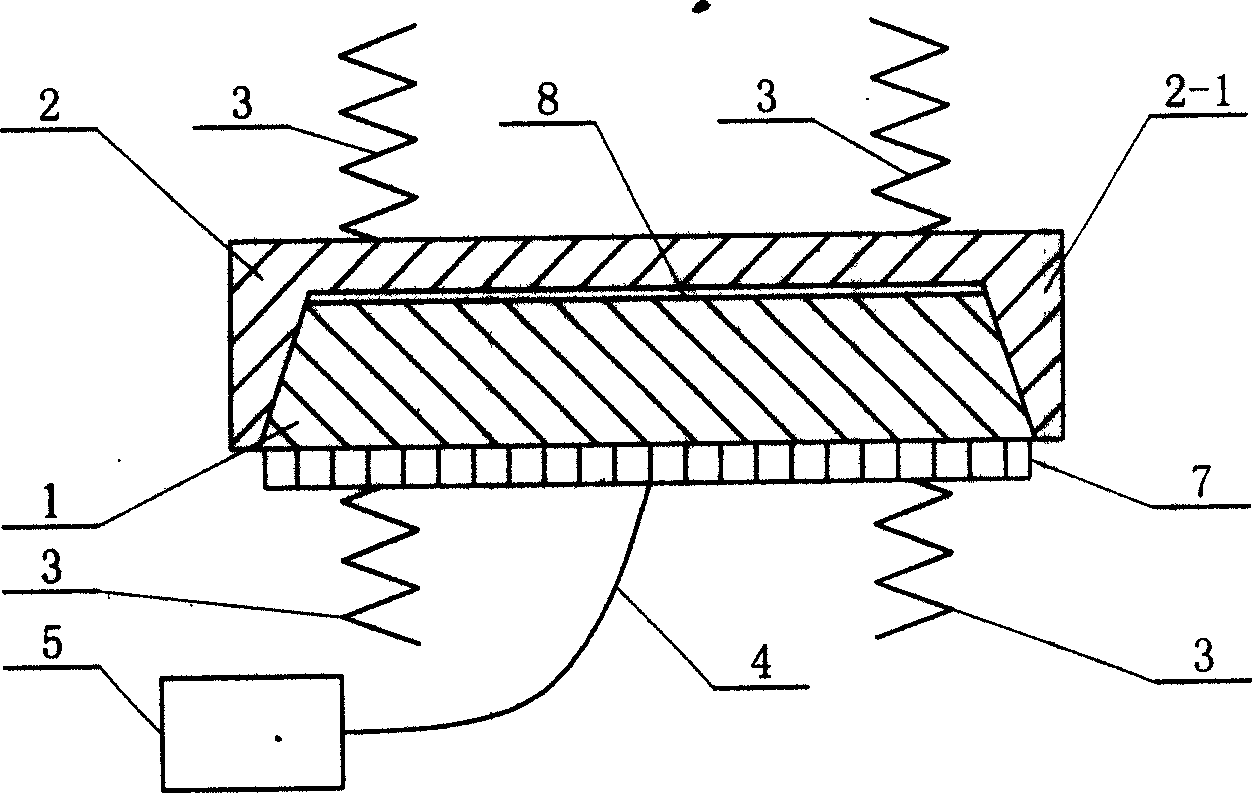

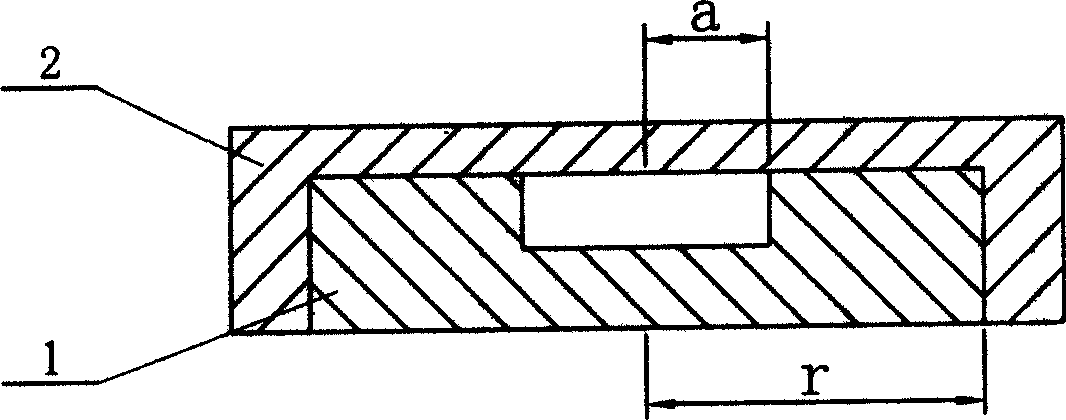

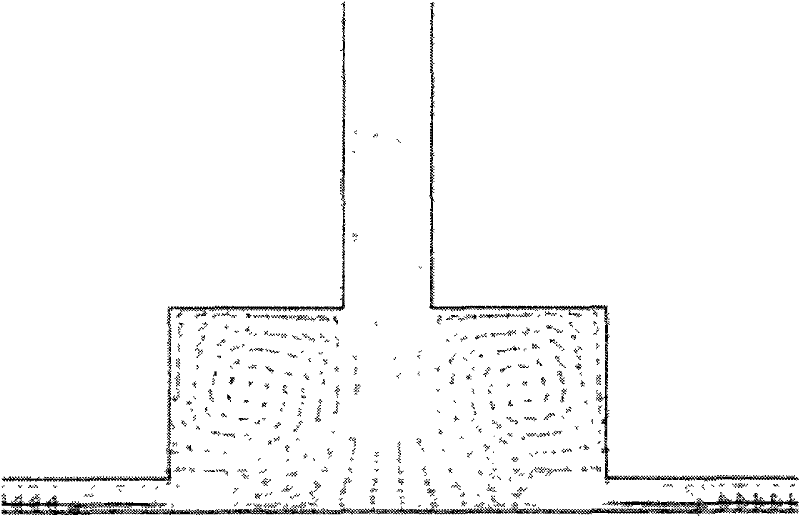

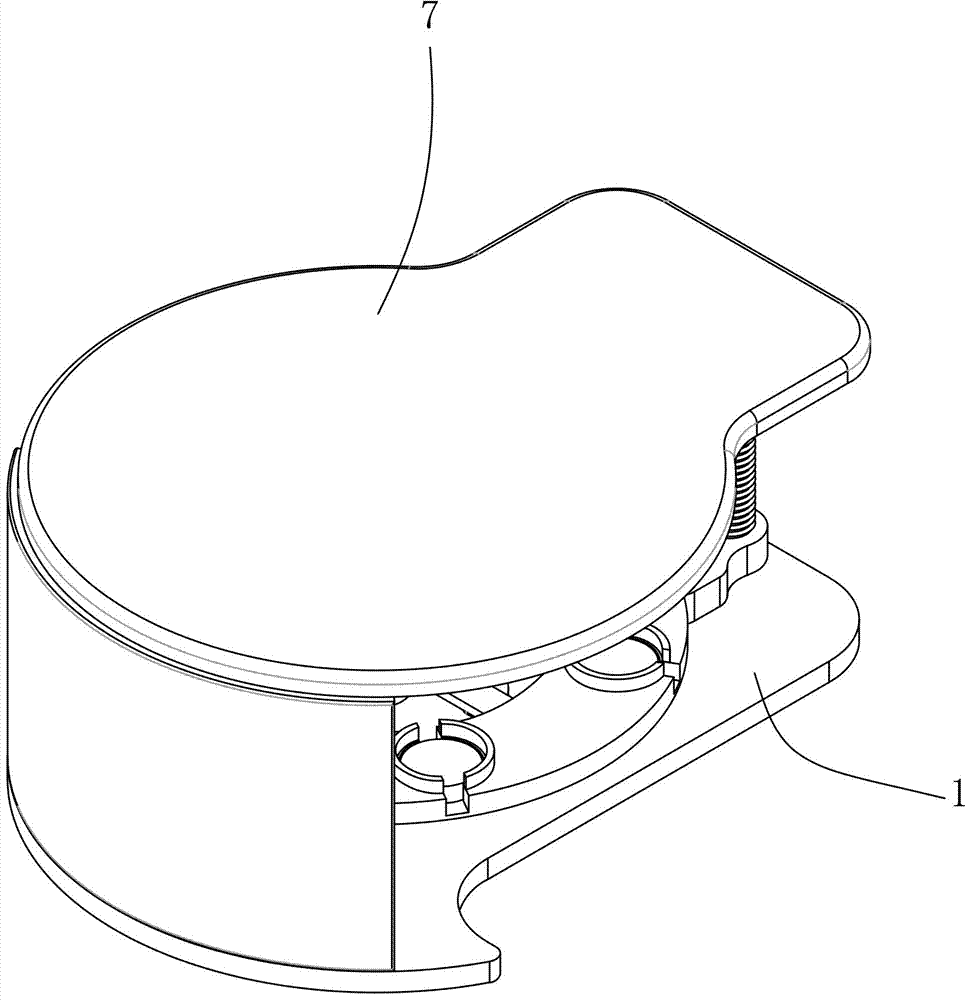

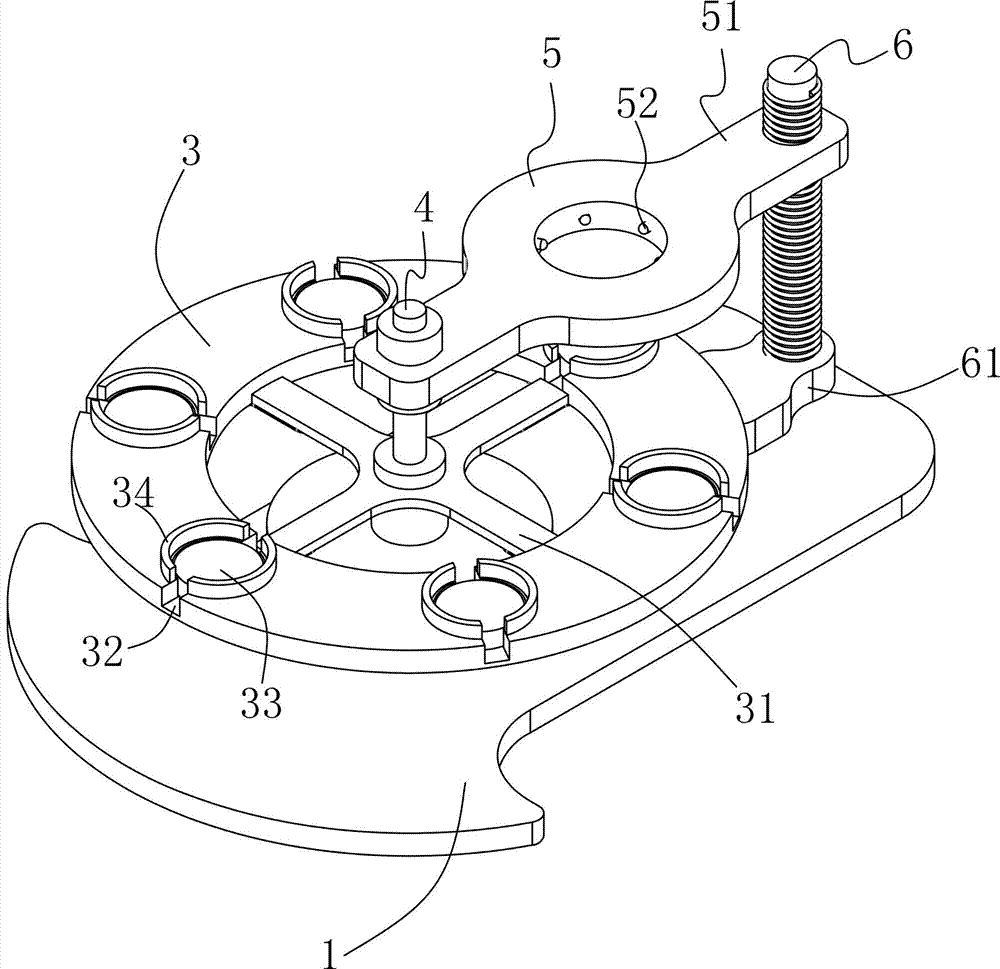

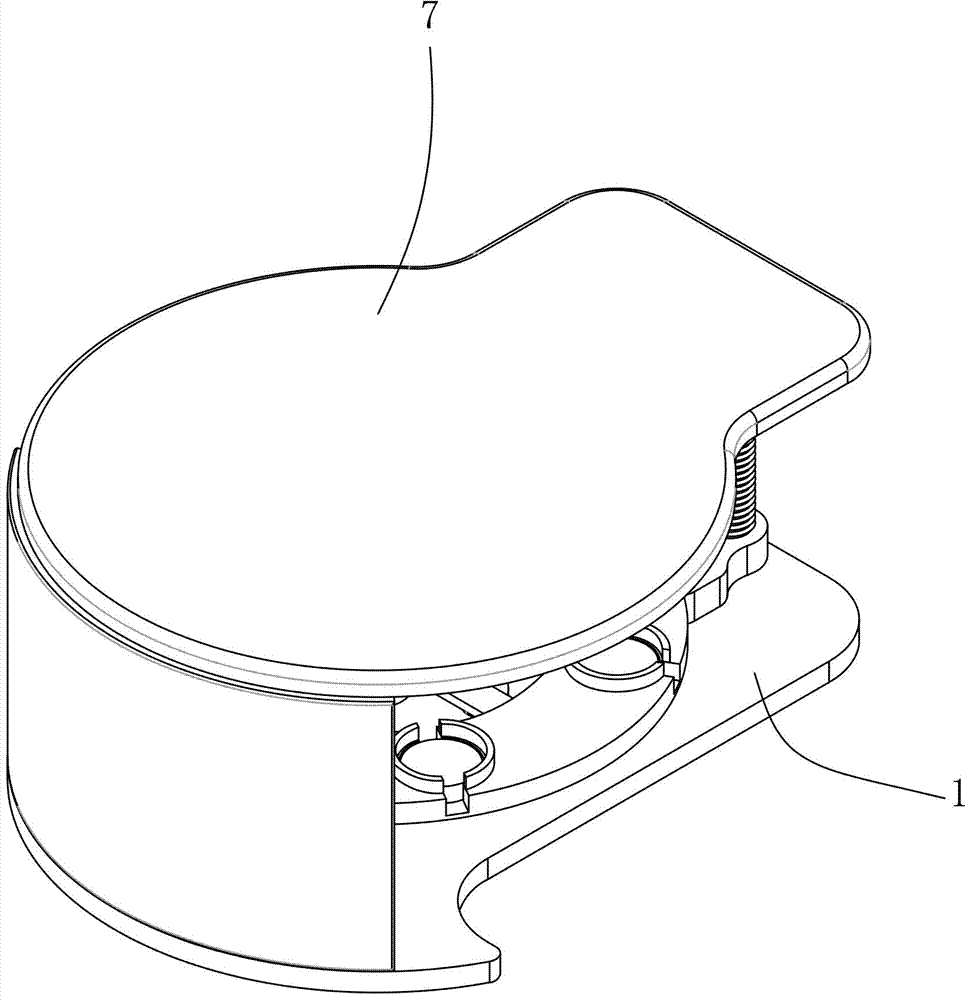

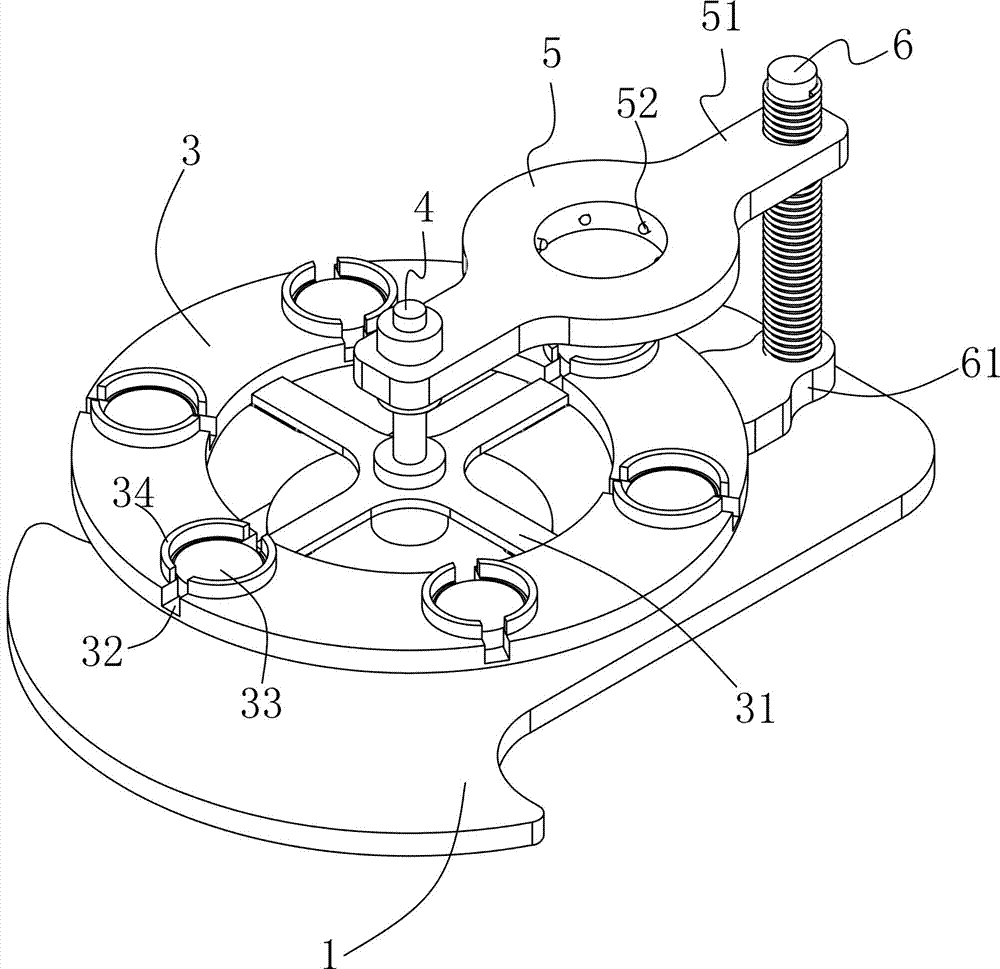

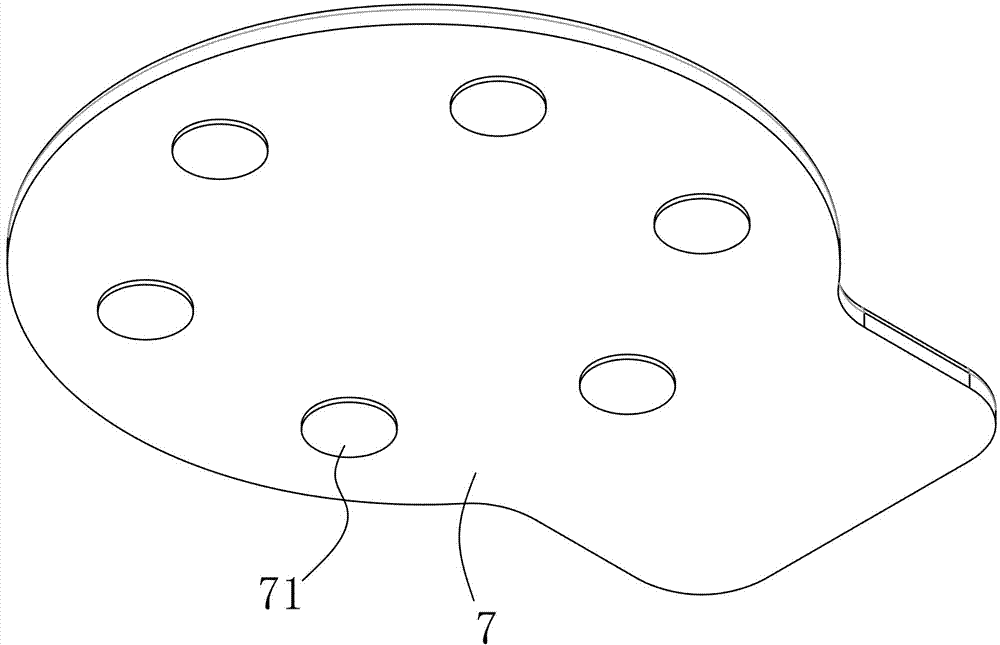

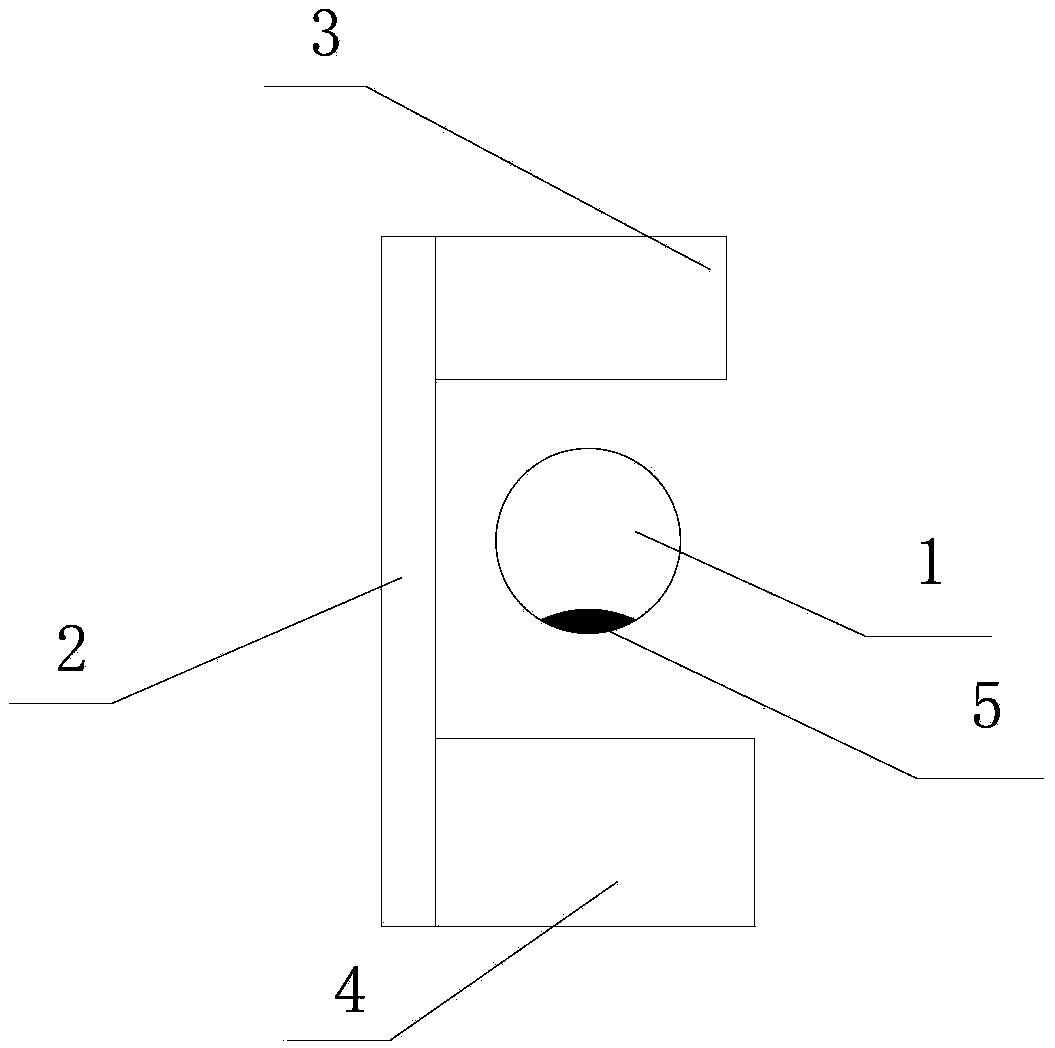

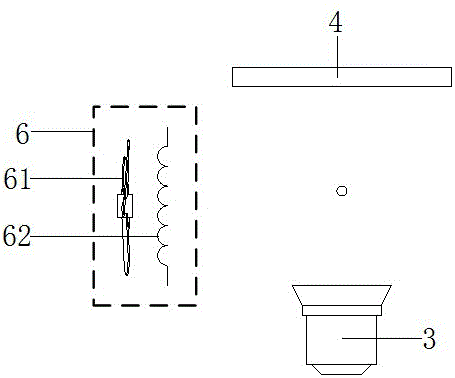

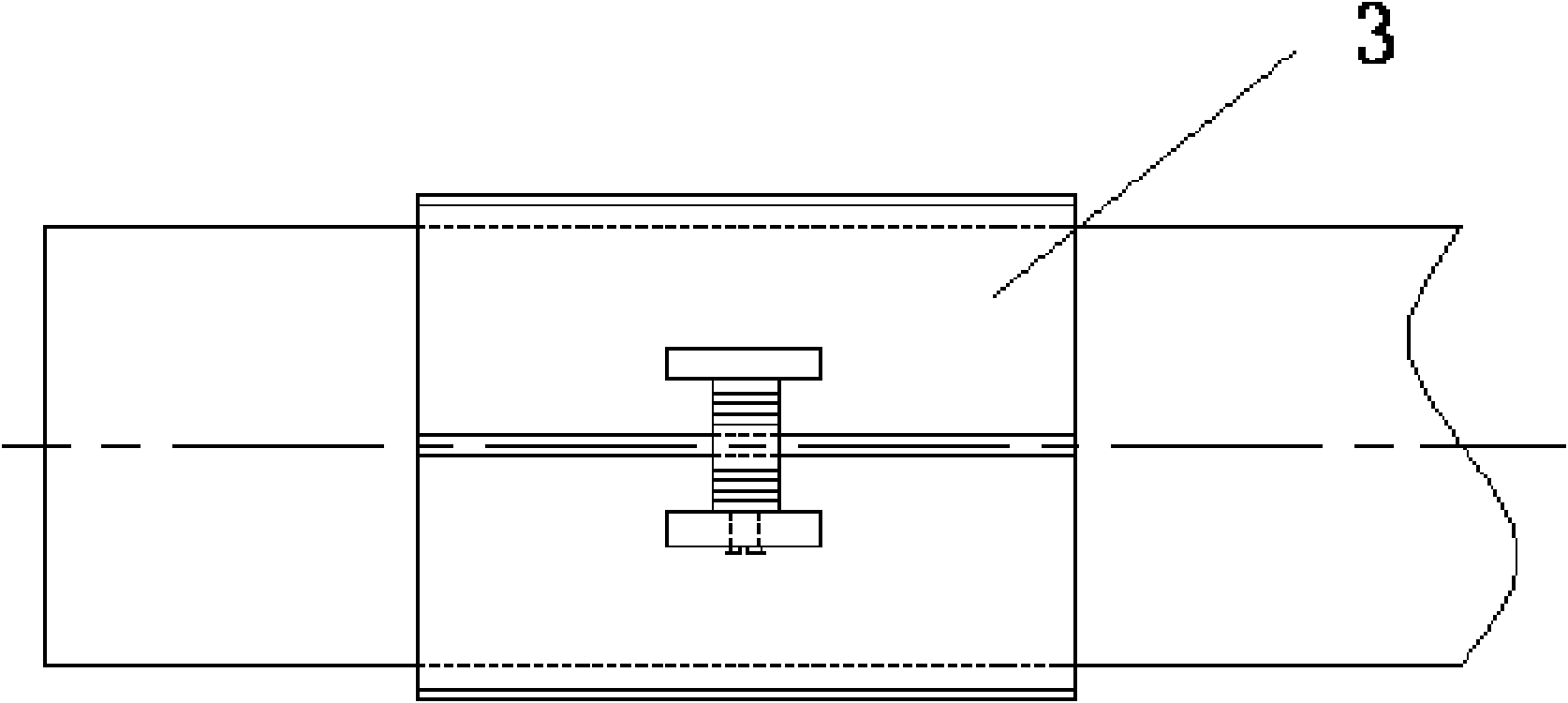

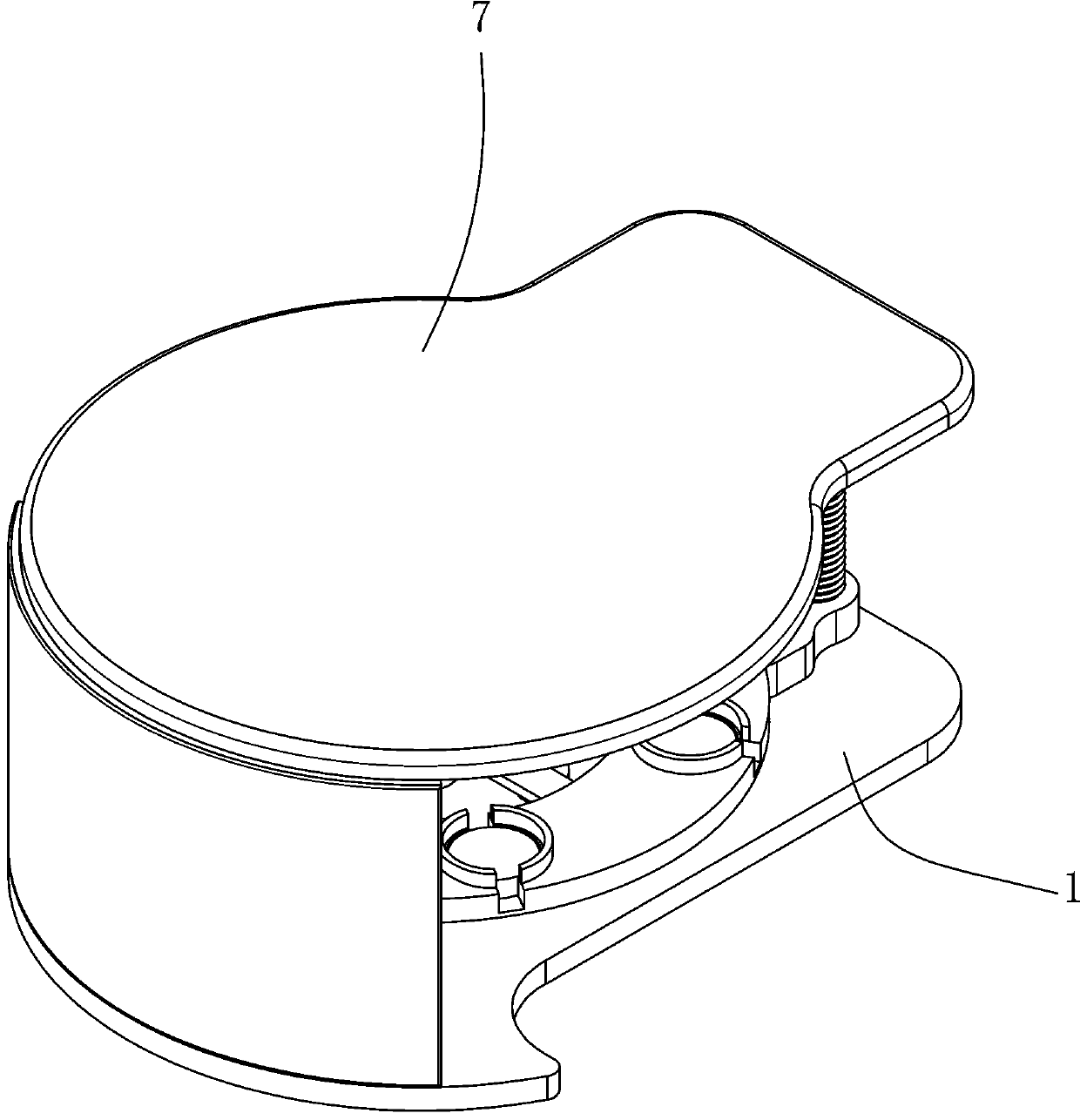

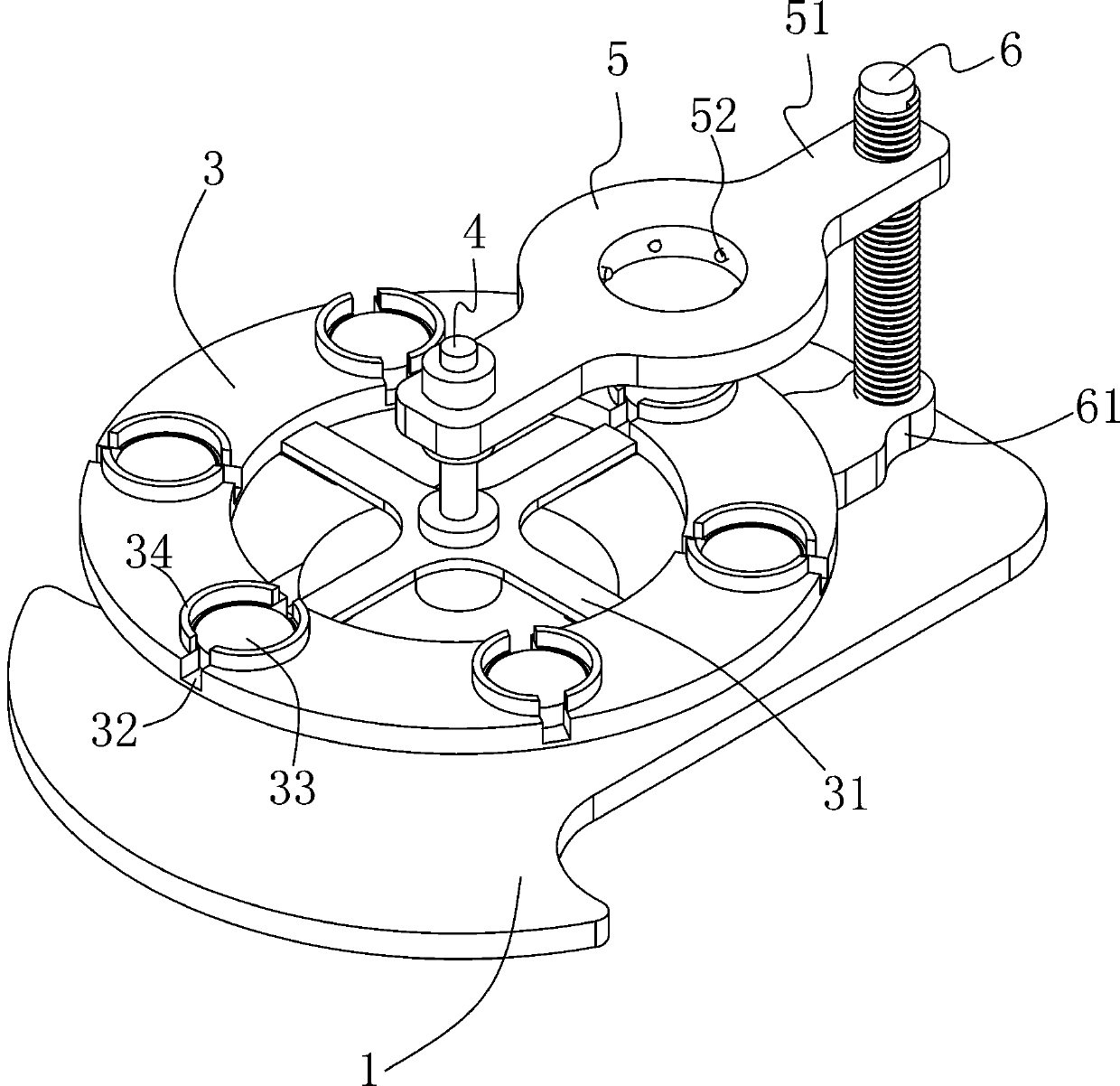

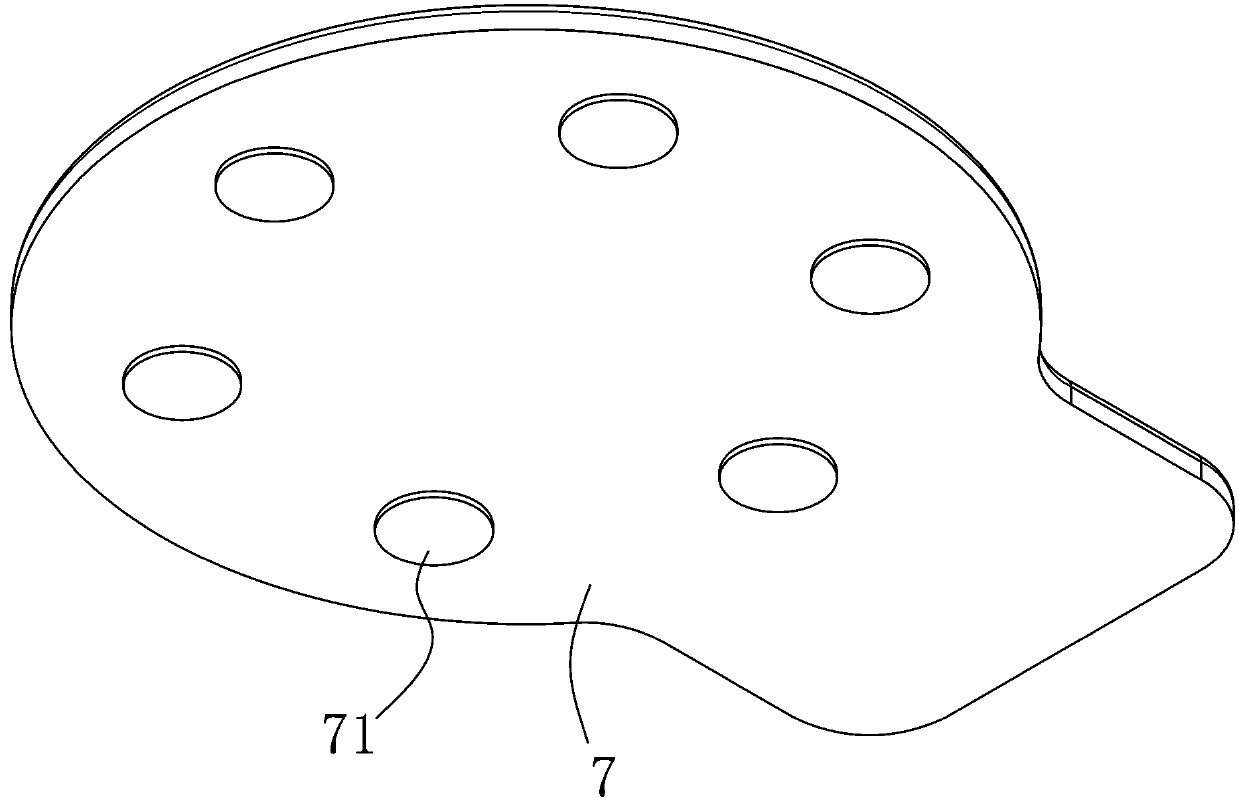

Clutch based on ultrasonic suspending force control

InactiveCN1632341ASimple structureOverall small sizeMagnetically actuated clutchesFriction clutchesElectricityHigh frequency power

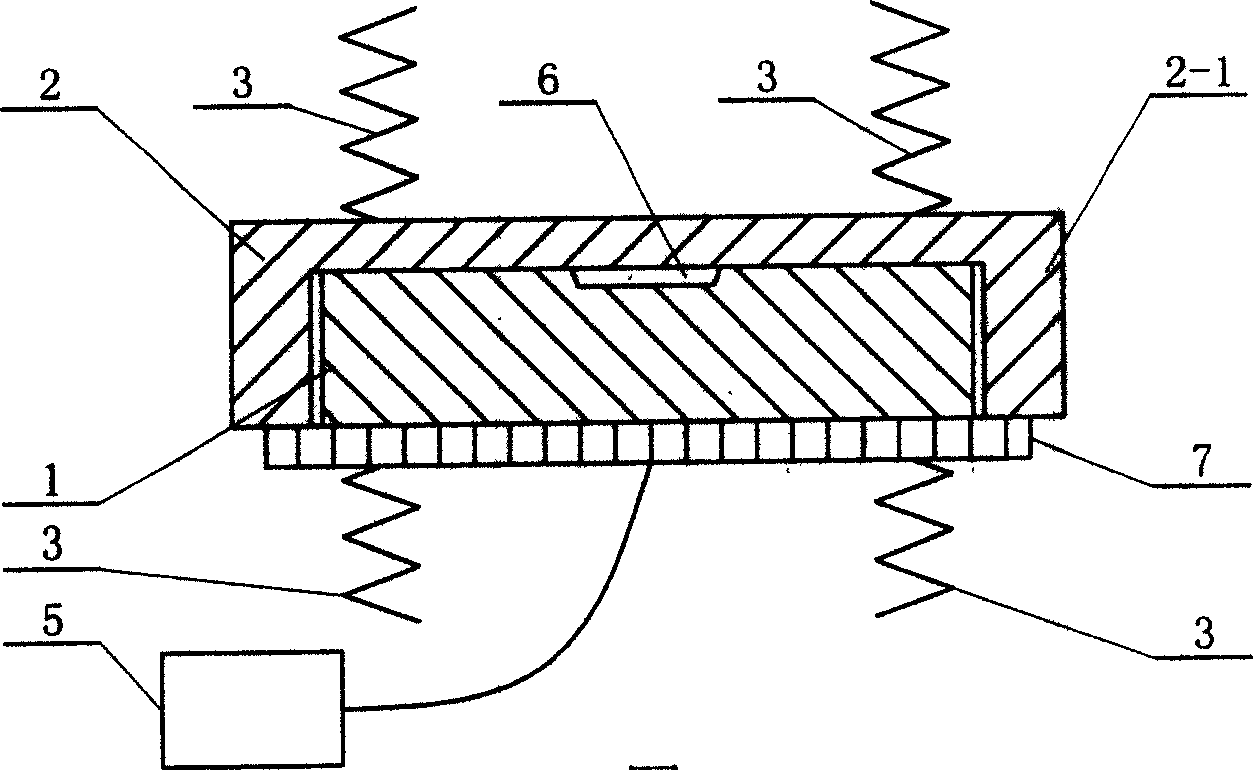

The invention discloses a clutch used for a miniature high-speed rotating shaft. The clutch based on ultrasonic levitation force control is composed of active rotating disc 2, passive rotating disc 1, piezoelectric ceramic sheet 7, return spring 3 and high-frequency power supply 5, and the passive rotating disc 1 is buckled on the ring body 2 of the active rotating disc 2 -1, the end face of the active rotating disc 2 is in contact with one end face of the passive rotating disc 1, the piezoelectric ceramic sheet 7 is fixed on the other end face of the passive rotating disc 1, and the high frequency power supply 5 is connected to the end face of the piezoelectric ceramic sheet 7 On the terminal, the return spring 3 is arranged on the active rotating disk 2 or the passive rotating disk 1 to keep the active rotating disk 2 and the passive rotating disk 1 in contact. Another option is that the inner surface of the torus 2-1 is conical, the rim of 1 is conical, and the inner surface of 2-1 is in contact with the rim of 1. The invention uses ultrasonic levitation force as the driving force for separation, uses friction torque to transmit power, has simple structure, small size, fast response speed and is free from electromagnetic interference.

Owner:HARBIN INST OF TECH

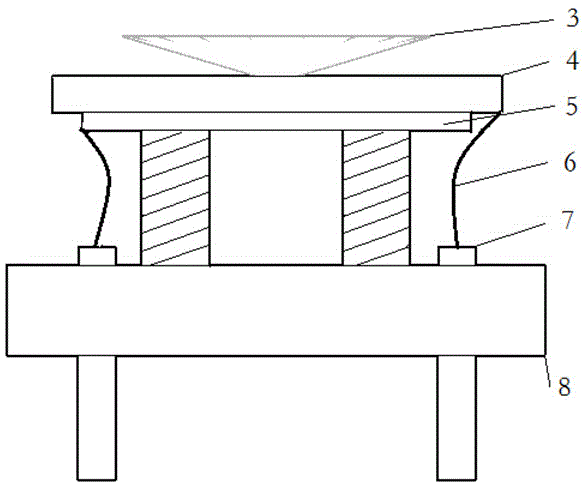

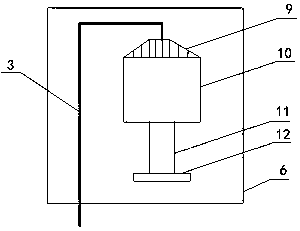

Ultrasonic levitation and air floatation mixed suspension damping device

The invention relates to a novel ultrasonic levitation and air floatation mixed suspension damping device, fulfills the aim of damping by utilizing the novel ultrasonic levitation and air floatation mixed suspension and belongs to the field of precision driving. An ultrasonic transducer disc is fixedly connected with an ultrasonic transducer. A working platform is fixedly connected with an air floatation bearing. A platform base is fixedly connected with the air floatation bearing. Axial orifices and pressure chambers are distributed on the air floatation bearing. Radial orifices and pressure chambers are distributed on the platform base. The air floatation bearing is placed on the ultrasonic transducer disc. Therefore, the whole connected air floatation bearing is suspended by ultrasonic levitation and air floatation. In the mixed suspension process, the ultrasonic levitation improves the cyclone phenomenon and the vibration of a pneumatic hammer when an air floatation device independently works. The novel mixed suspension device has the advantages that the novel ultrasonic levitation and air floatation mixed suspension damping device is easy to operate, has simple structure and has higher suspension rigidity than the single air floatation device which independently works; and the micro low frequency vibration of the air floatation device is reduced.

Owner:JILIN UNIV

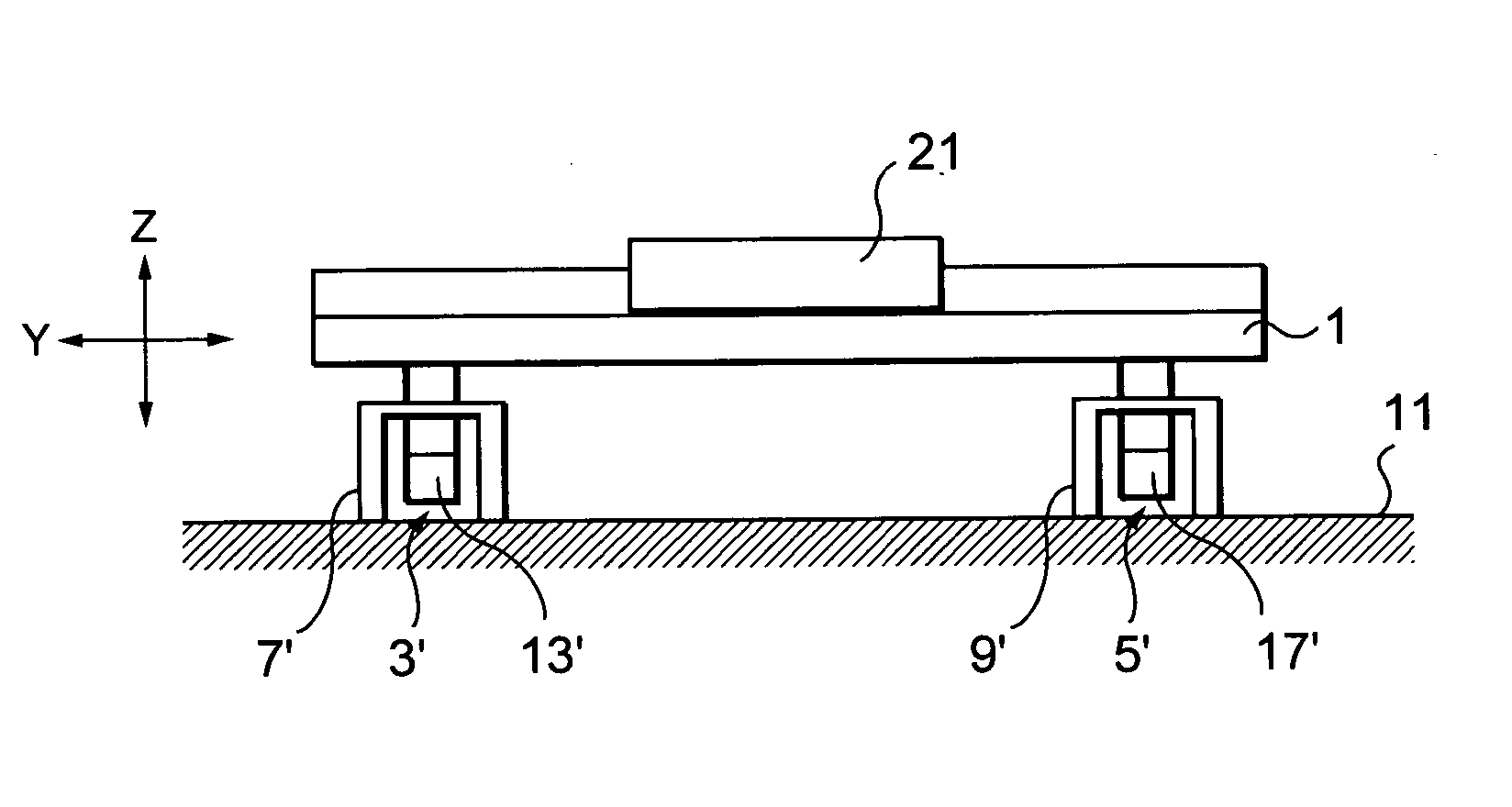

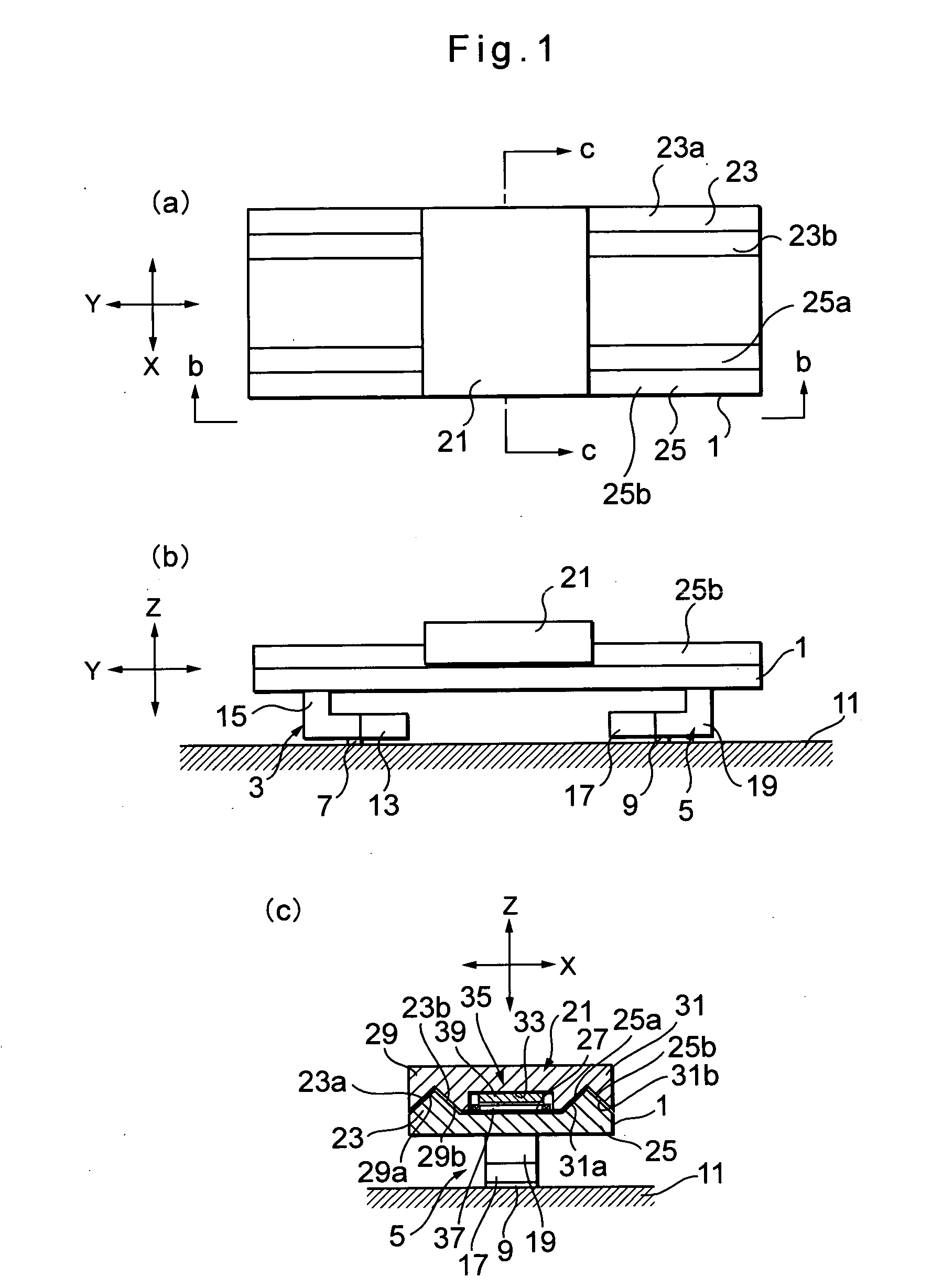

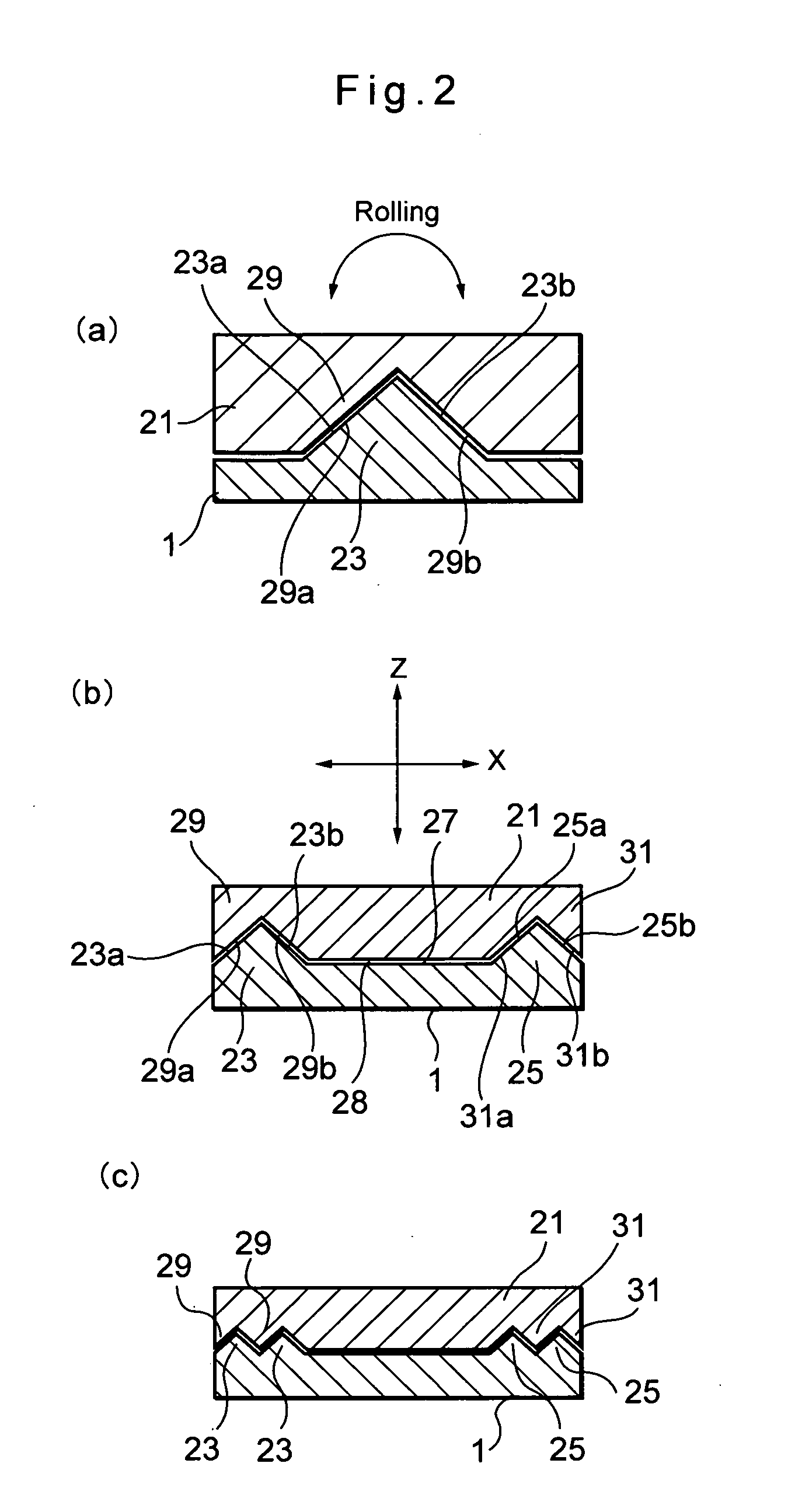

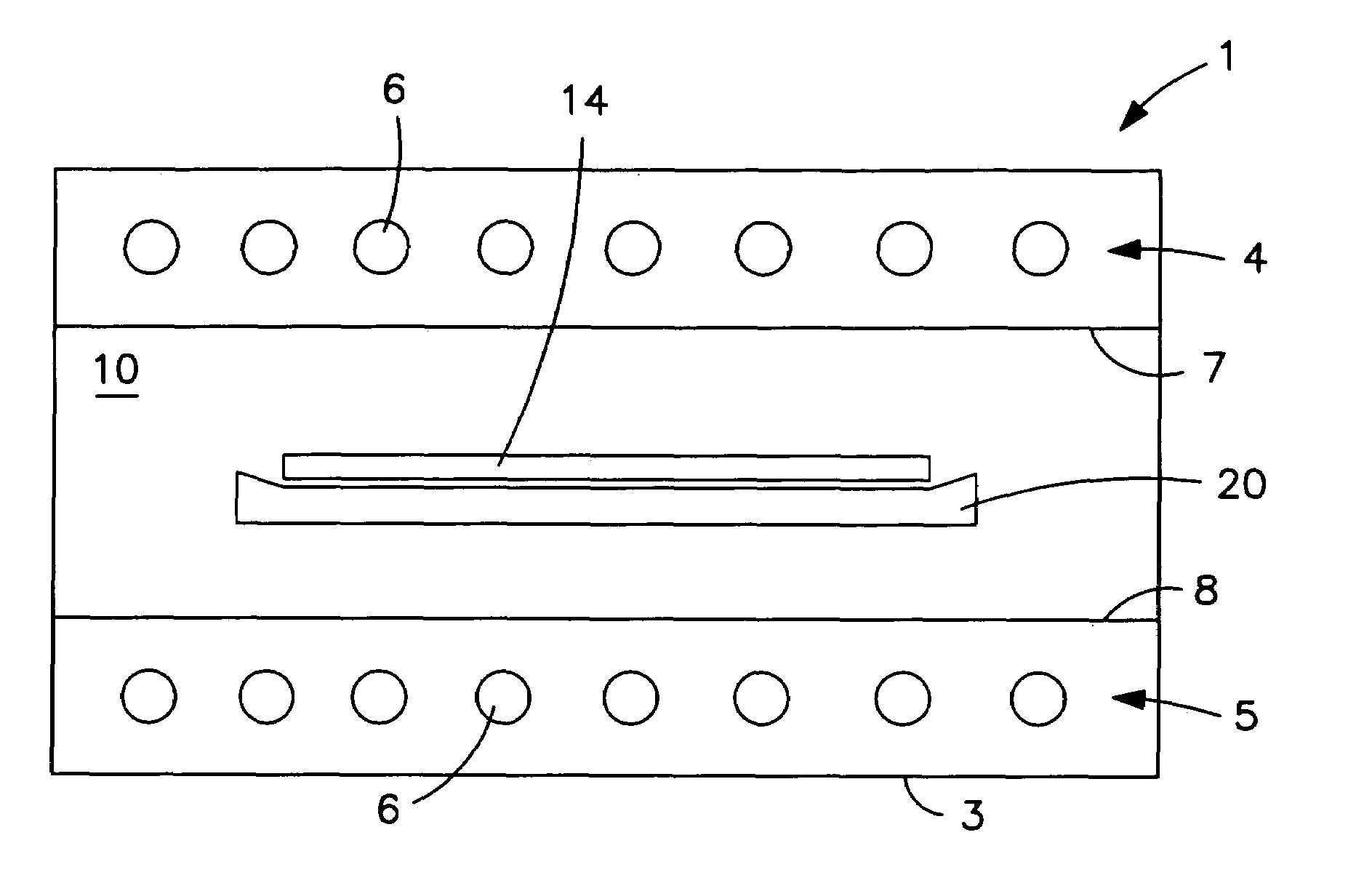

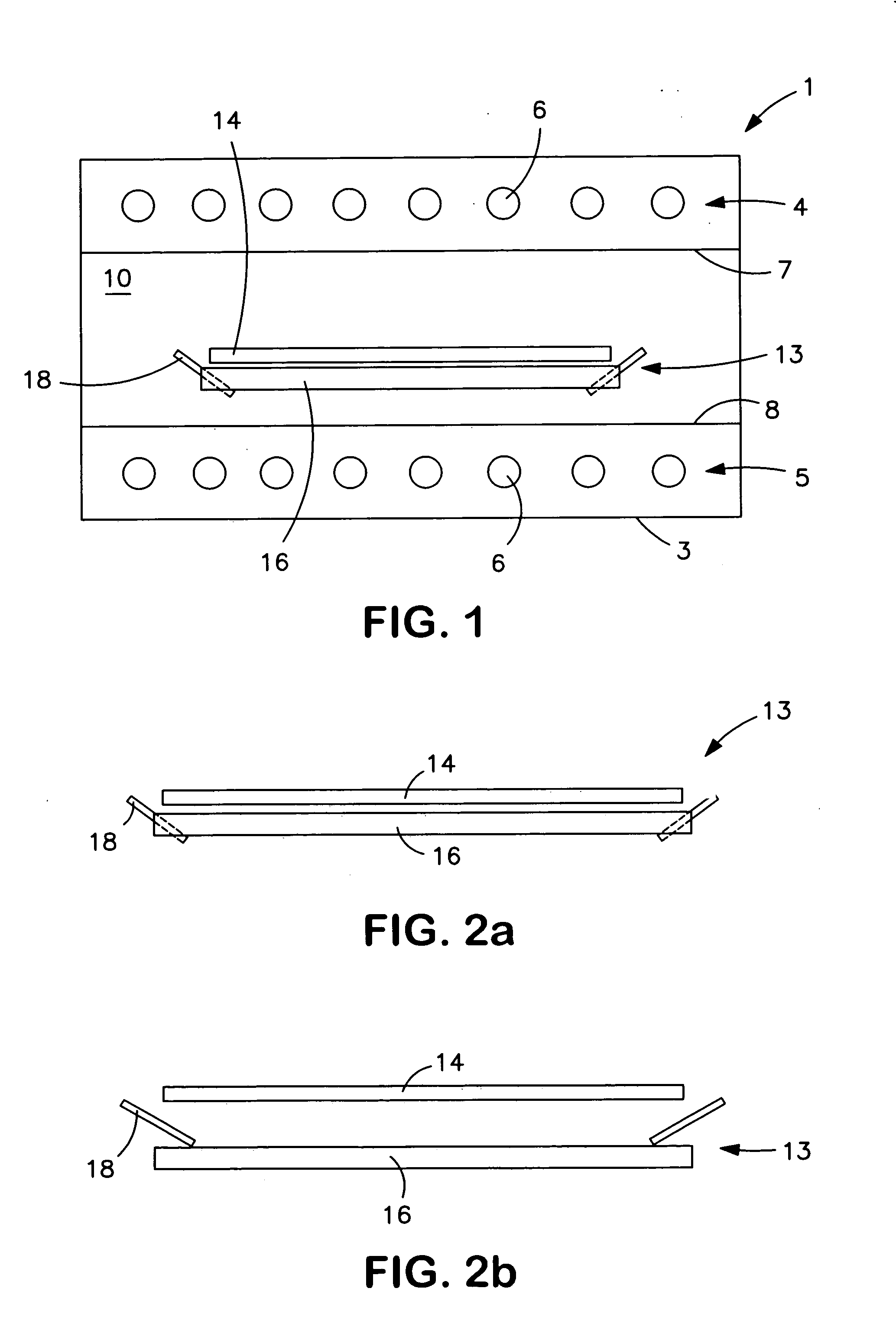

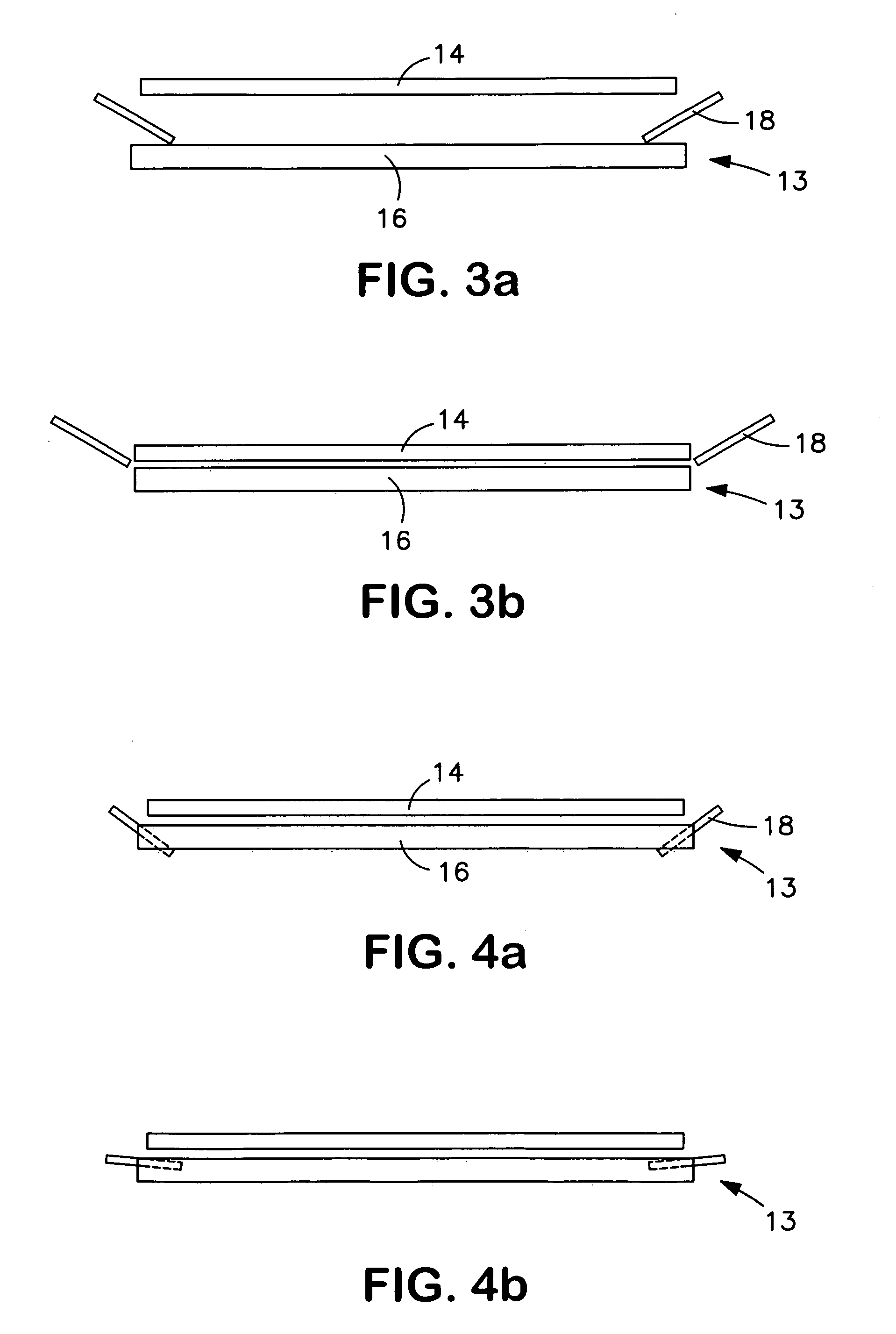

Ultrasonic float-up device

InactiveUS20060244342A1Effectively cope with precision positioningPrevent suspensionPiezoelectric/electrostriction/magnetostriction machinesSound producing devicesLevitationUltrasonic levitation

An ultrasonic levitation device having a fixed section and a movable section disposed to be movable relative to the fixed section, the fixed section or movable section having a vibration generating device disposed therein to generate ultrasonic vibrations, thereby allowing the movable section to levitate on a levitation surface, wherein all or part of a fixed section-side guide disposed in the fixed section is formed convex or concave in the levitation direction, while all or part of a movable section-side guide disposed in the movable section is formed concave or convex in the levitation direction, the movable section-side guide being opposed to and disposed on the fixed section-side guide.

Owner:IAI CORP

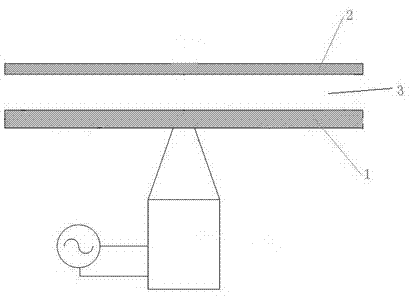

Method and apparatus for thermally treating disk-shaped substrates

ActiveUS7098157B2Simple and economical mannerEnabling changeDrying solid materials without heatSemiconductor/solid-state device manufacturingUltrasonic levitationSemiconductor

A method and apparatus for thermally treating disk-shaped substrates, especially semiconductor wafers, in a rapid heating unit having at least one first radiation source, which is spaced from a given substrate for heating the substrate. The substrate is heated in a heating phase and is cooled in a cooling phase that follows the heating phase. During at least a portion of the cooling phase, the substrate is supported at a distance of from 50 μm to 1 mm via ultrasonic levitation from a heating / cooling plate. For example by means of an ultrasonic electrode.

Owner:MATTSON TECHNOLOGY +1

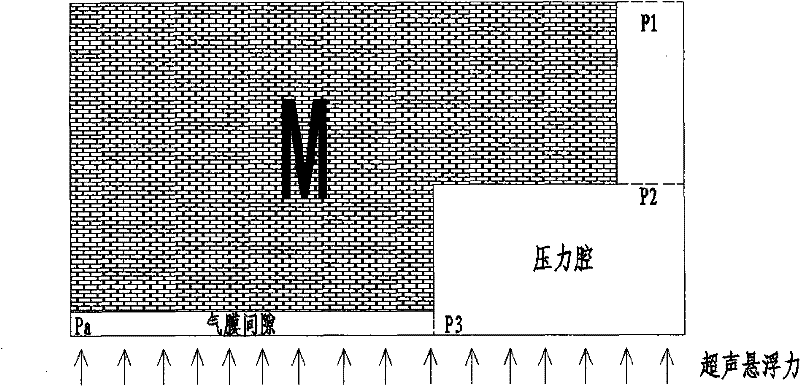

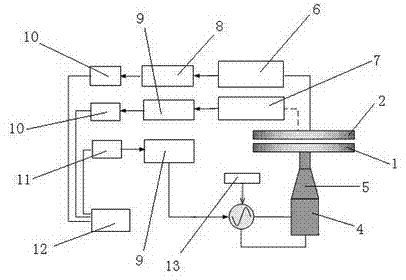

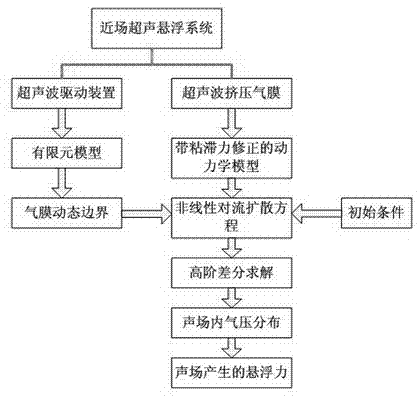

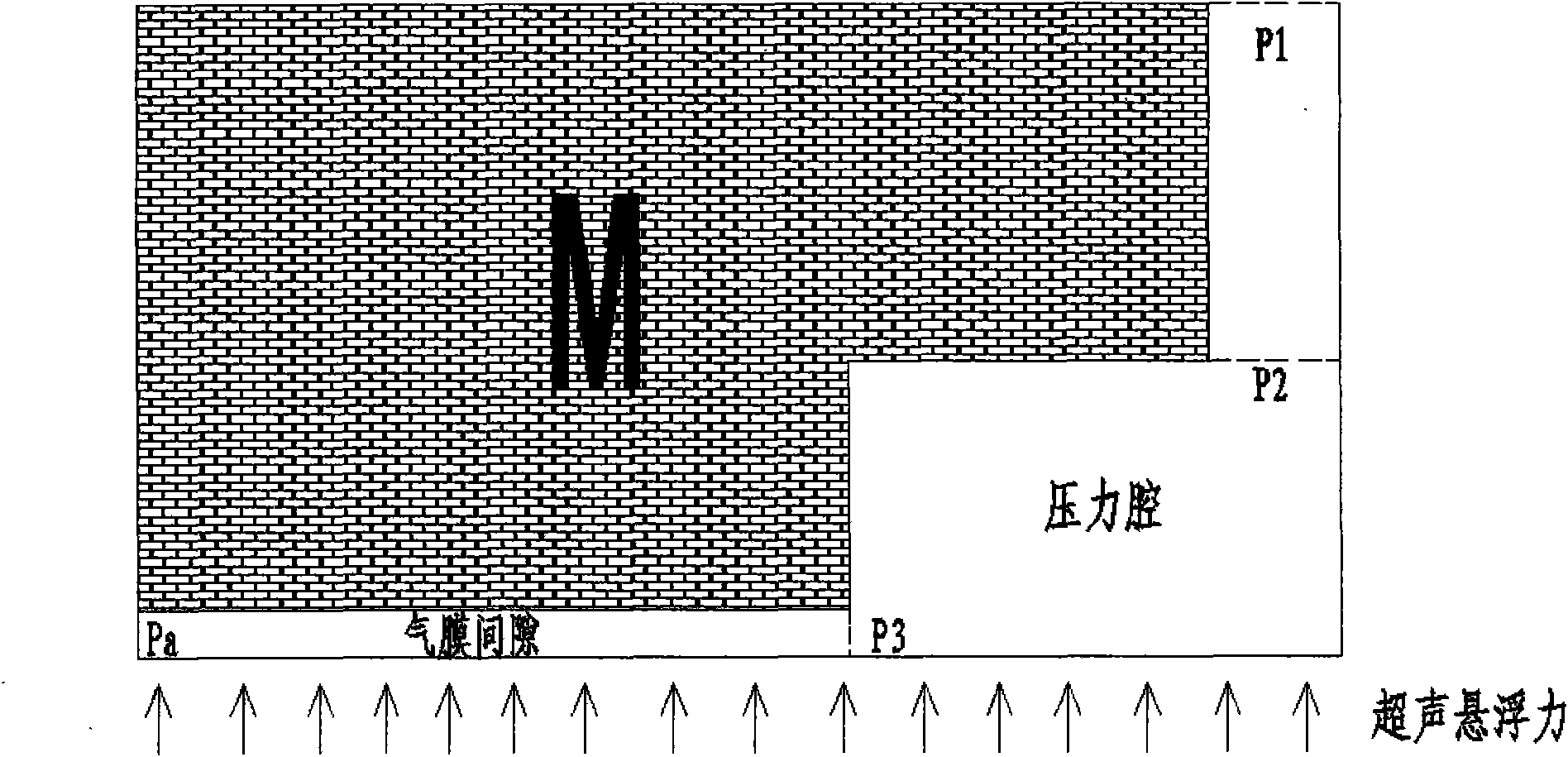

Accurately quantitative calculation method for near-field ultrasonic levitation force

InactiveCN102567563AHigh precisionTrue and effective descriptionSpecial data processing applicationsElement modelUltrasonic levitation

An accurately quantitative calculation method for near-field ultrasonic levitation force can be used for modeling, designing and optimizing of a non-contact type ultrasonic levitation system and a transmission positioning system. The accurately quantitative calculation method includes: building a finite element model of an ultrasonic generating device, performing model analysis and harmonic response analysis, building one-to-one mapping relation of driving input and output, building an extrusion gas-film kinetic model considering inertia of gas and determining parameters of the model; obtaining a specific format of numerical solution of the parameters of the model according to difference scheme; and acquiring gas pressure and levitation force of an extrusion gas film by the numerical solution. By the accurately quantitative calculation method, accuracy in modeling and solving is improved as compared with that of the prior art. Besides, the accurately quantitative calculation method is accurate and feasible for production design and optimization of ultrasonic equipment.

Owner:SHANGHAI JIAO TONG UNIV

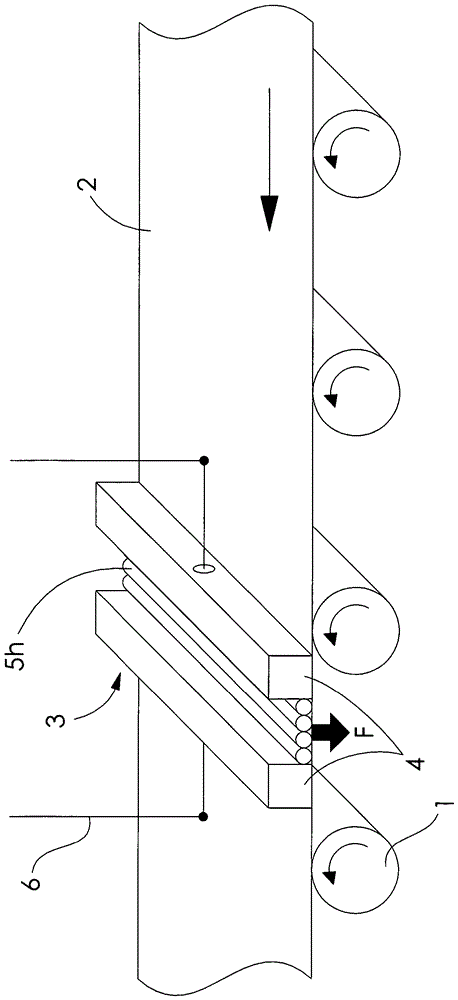

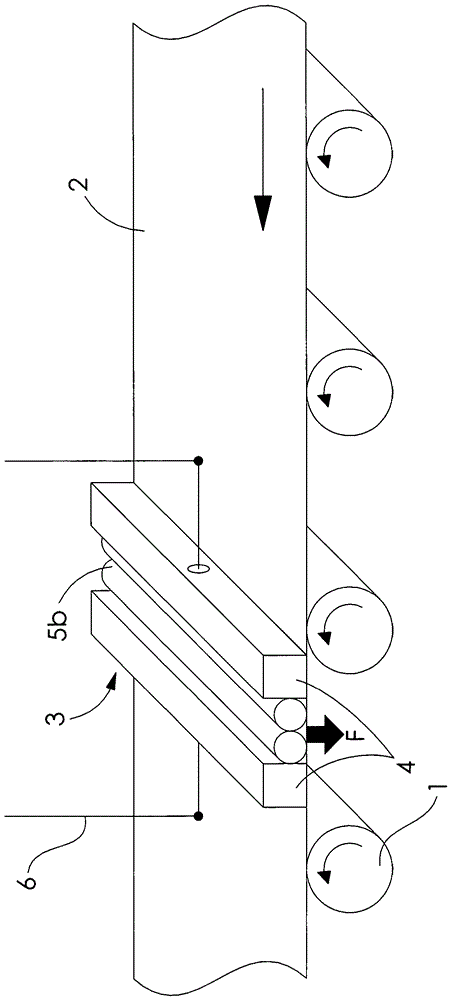

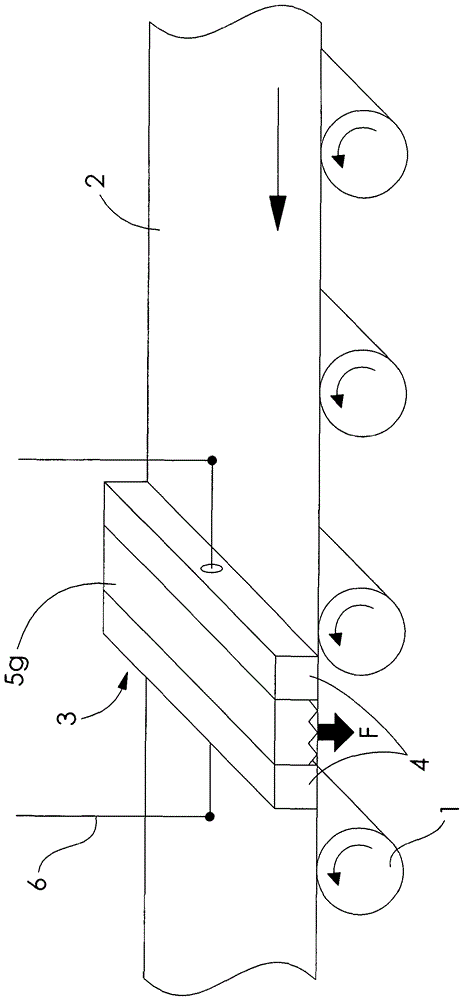

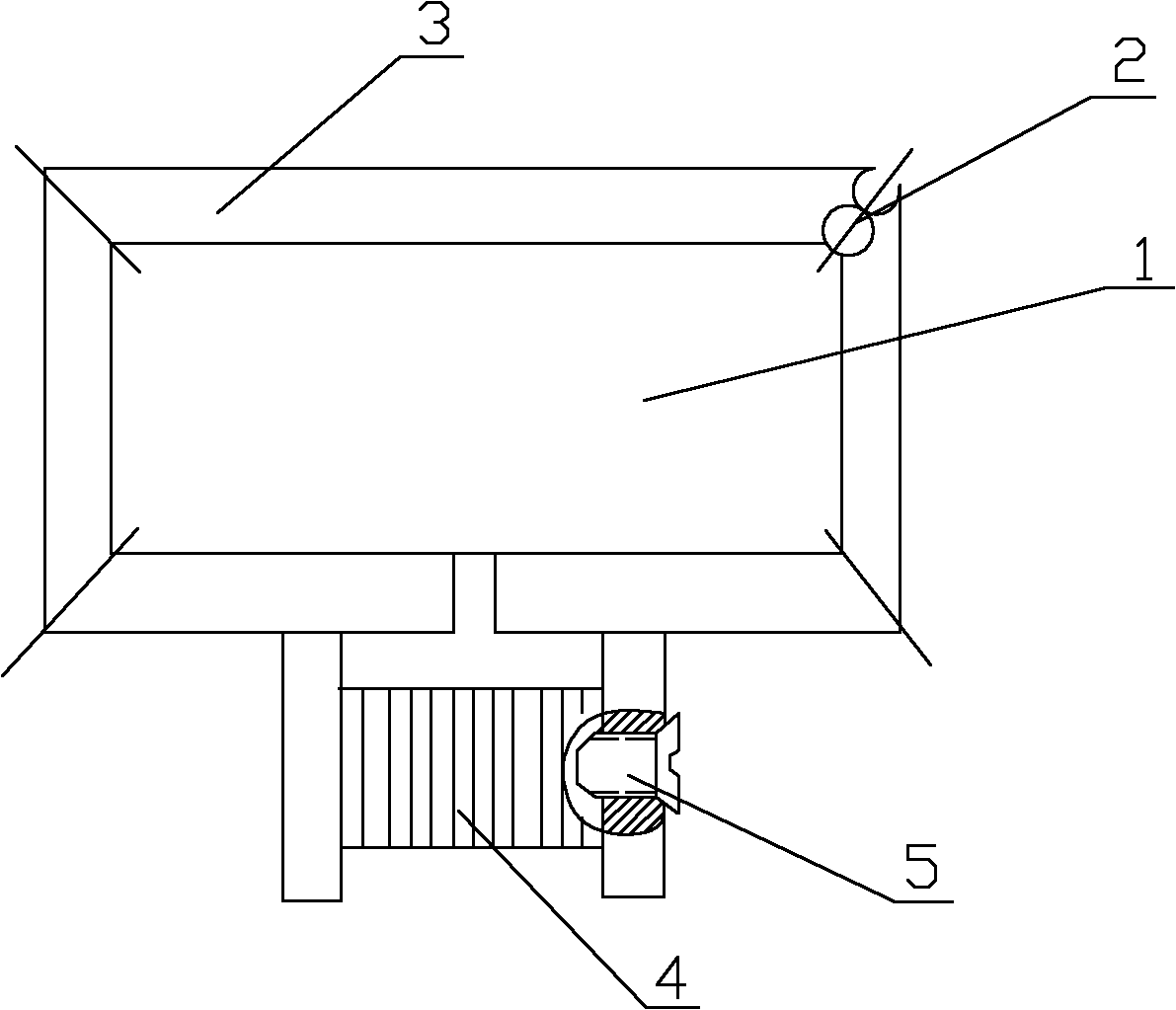

Device for treating or machining a surface

InactiveCN105960308APrecise positioningAvoid measurement errorsLiquid surface applicatorsSpraying apparatusUltrasonic levitationAdhesive

The invention relates to a device for treating or acting on workpiece surfaces by means of an actuator, such as a cutting or engraving laser or a nozzle for applying oils, paints, adhesives, dyes, or etchants for example. In particular, the invention relates to a device which is suitable for acting on workpieces with relatively large surfaces relative to the dimensions of the actuator, such as on strip materials for example. An ultrasonic levitation force field is generated by means of a sonotrode (4), which is coupled to the actuator into a working unit (3), such that the movably suspended working unit (3) is supported on the workpiece surface in a hovering manner. The ultrasonic levitation force field allows a highly precise positioning of the working unit (3) relative to the workpiece surface so as to allow a precise treatment or machining of the workpiece surface.

Owner:ZS HANDLING

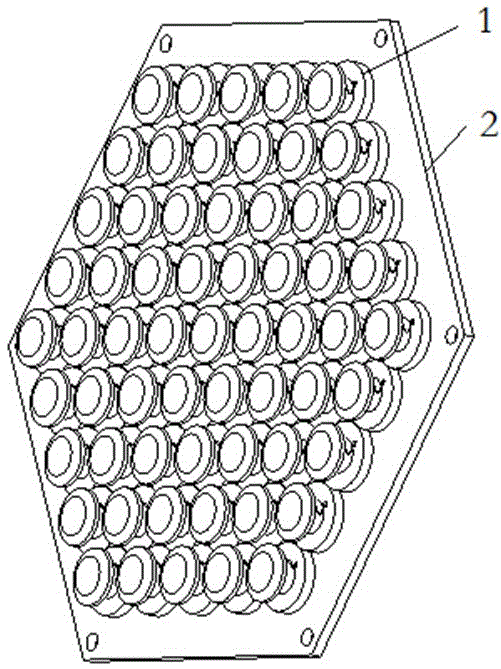

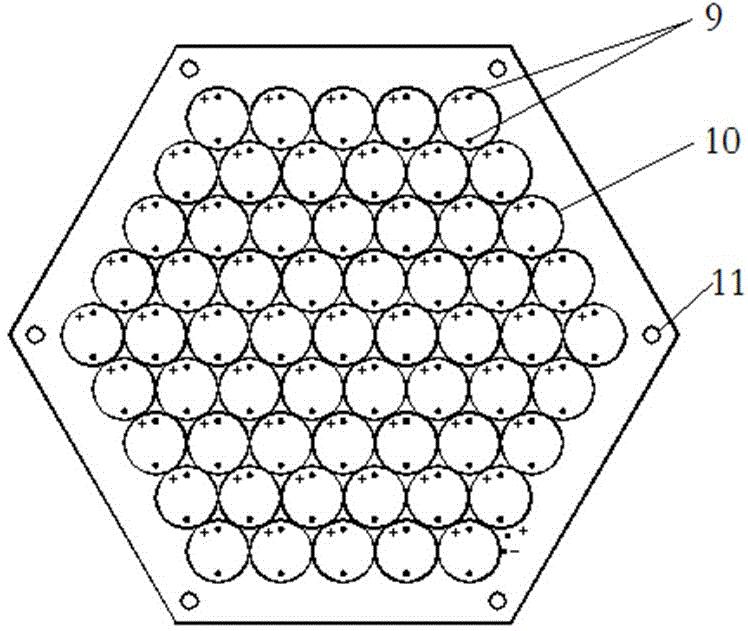

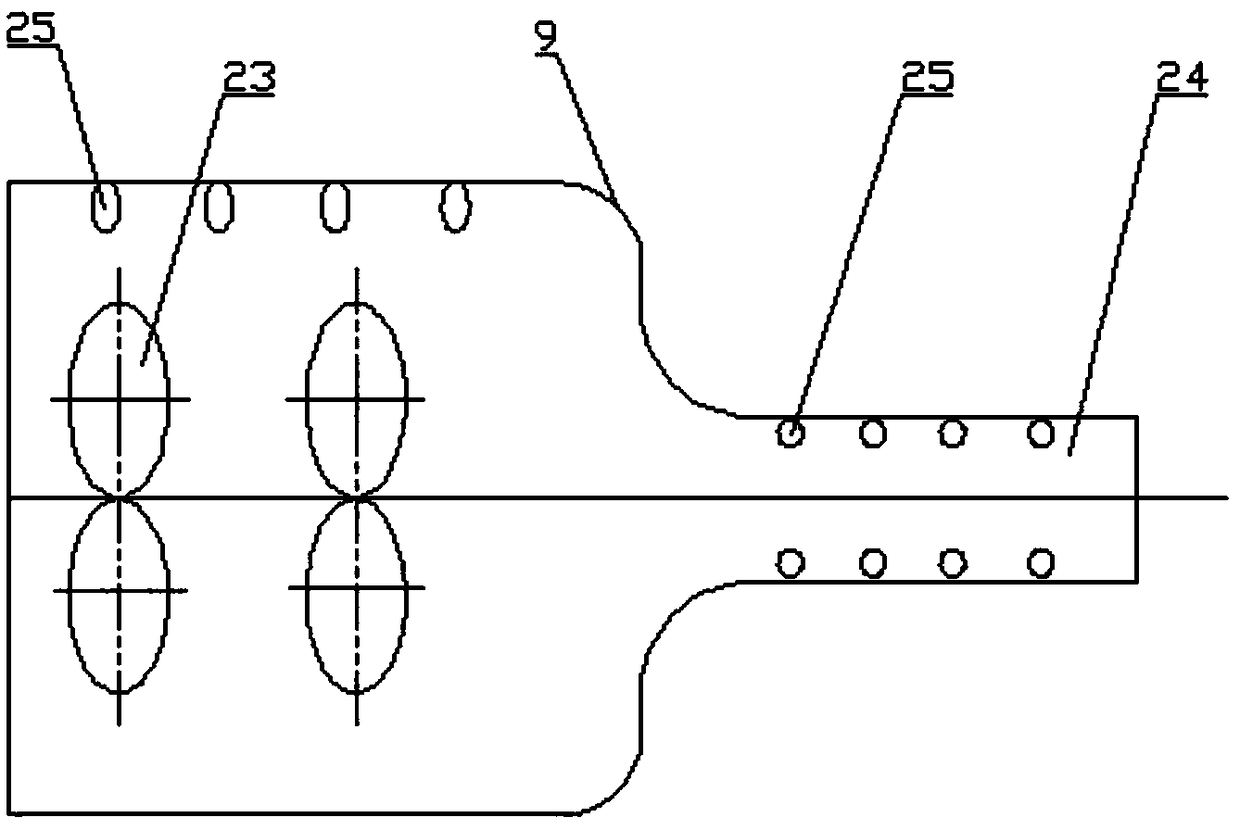

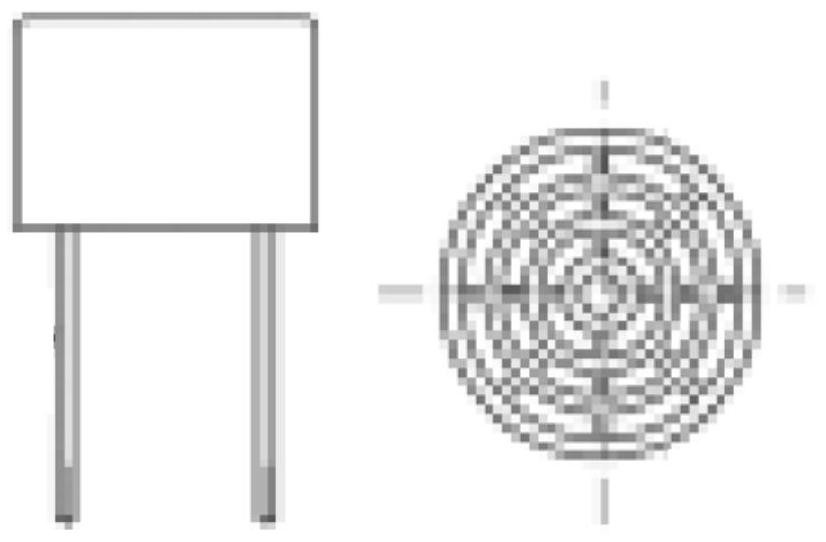

Same-phase dense-arrangement array type ultrasonic emitting unit

ActiveCN106076794AHigh strengthHigh intensity high directivityMechanical vibrations separationChemical reactionUltrasonic levitation

The invention belongs to the technical field of ultrasonic emission and particularly relates to a same-phase dense-arrangement array type ultrasonic emitting unit capable of emitting high-strength and high-directivity ultrasonic waves. The same-phase dense-arrangement array type ultrasonic emitting unit is composed of a same-phase ultrasonic transducer array and a printed circuit board. According to the requirement, ultrasonic transducers of different physical performances and geometric sizes are designed, arrayed in a dense-arrangement manner and correspondingly inserted into the printed circuit board matched with the dense-arrangement array. An ultrasonic signal subjected to power amplification is input into the same-phase dense-arrangement array type ultrasonic emitting unit, and the same-phase dense-arrangement array type ultrasonic emitting unit is made to emit out the high-strength and high-directivity ultrasonic waves. The same-phase dense-arrangement array type ultrasonic emitting unit capable of emitting the high-strength and high-directivity ultrasonic waves can be used for directional spreading of the sonic waves and can also be used for the fields of ultrasonic suspension, distance measurement, remote control, imaging, emulsification, sterilization, chemical reaction promoting, biological research performing and the like.

Owner:FUDAN UNIV

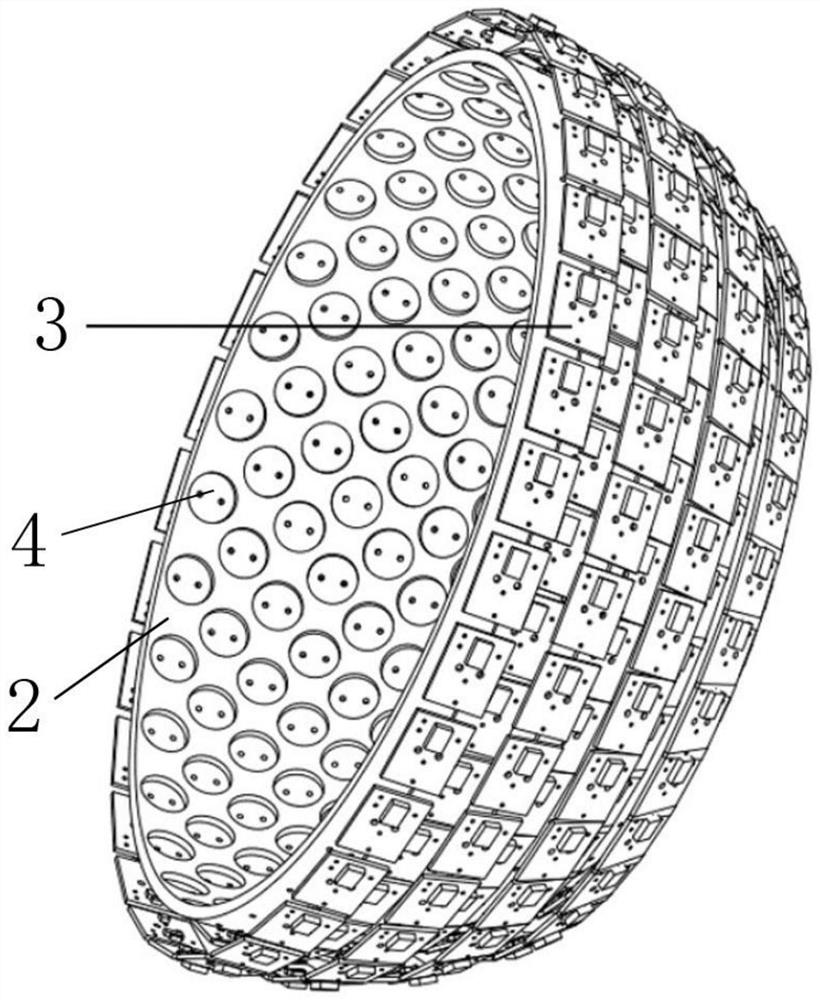

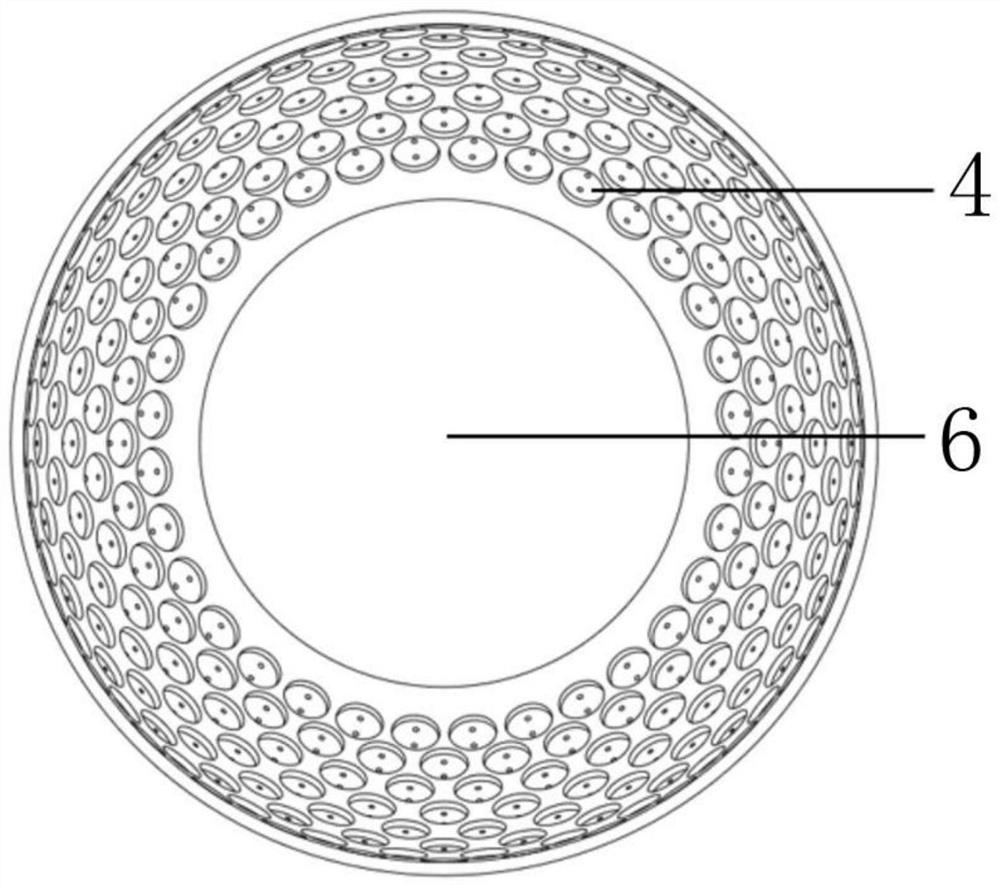

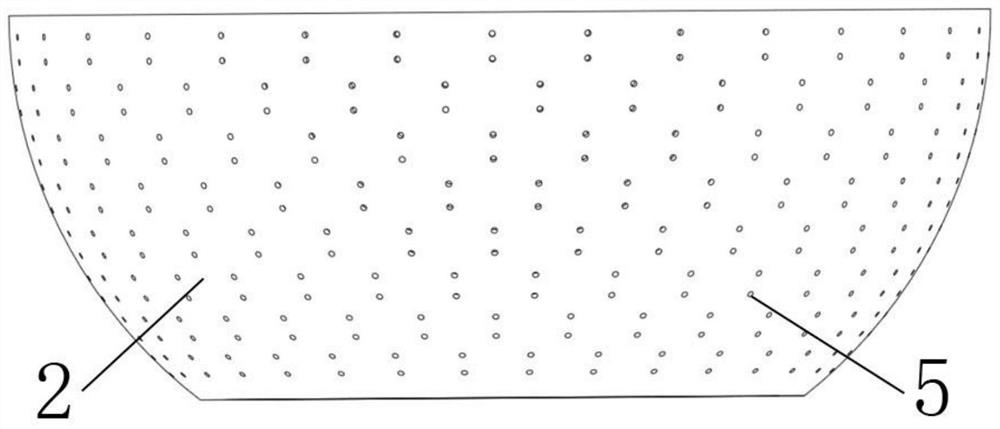

Ultrasonic levitation device

ActiveCN111889342AWon't hurtSuspension stabilityMechanical vibrations separationUltrasonic levitationEngineering

The invention discloses an ultrasonic levitation device which comprises a transducer array, a concave spherical bracket, drivers, a controller and a direct current stabilized voltage supply, wherein the transducer array is arranged on the inner side of in the concave spherical bracket and acoustic beams generated by each transducer in the transducer array pass through the centre of sphere of the concave spherical bracket, each transducer in the transducer array is connected to one driver correspondingly, the drivers are fixed to the outer side of the concave spherical bracket, all the driversare connected to the controller, the direct current stabilized voltage supply is connected to the controller and all the drivers for providing direct current voltages to the controller and all the drivers, and the transducer array controlled by the controller changes the phases of the transducers continuously to generate a spiral-shaped spiral sound field. As the phases of the transducers are changed continuously to form the spiral-shaped spiral sound field, objects suspending at the center of the spiral-shaped spiral sound field is not limited by wavelength of sound waves, so that the objectcan be suspended stably.

Owner:GUANGDONG MEDICAL UNIV

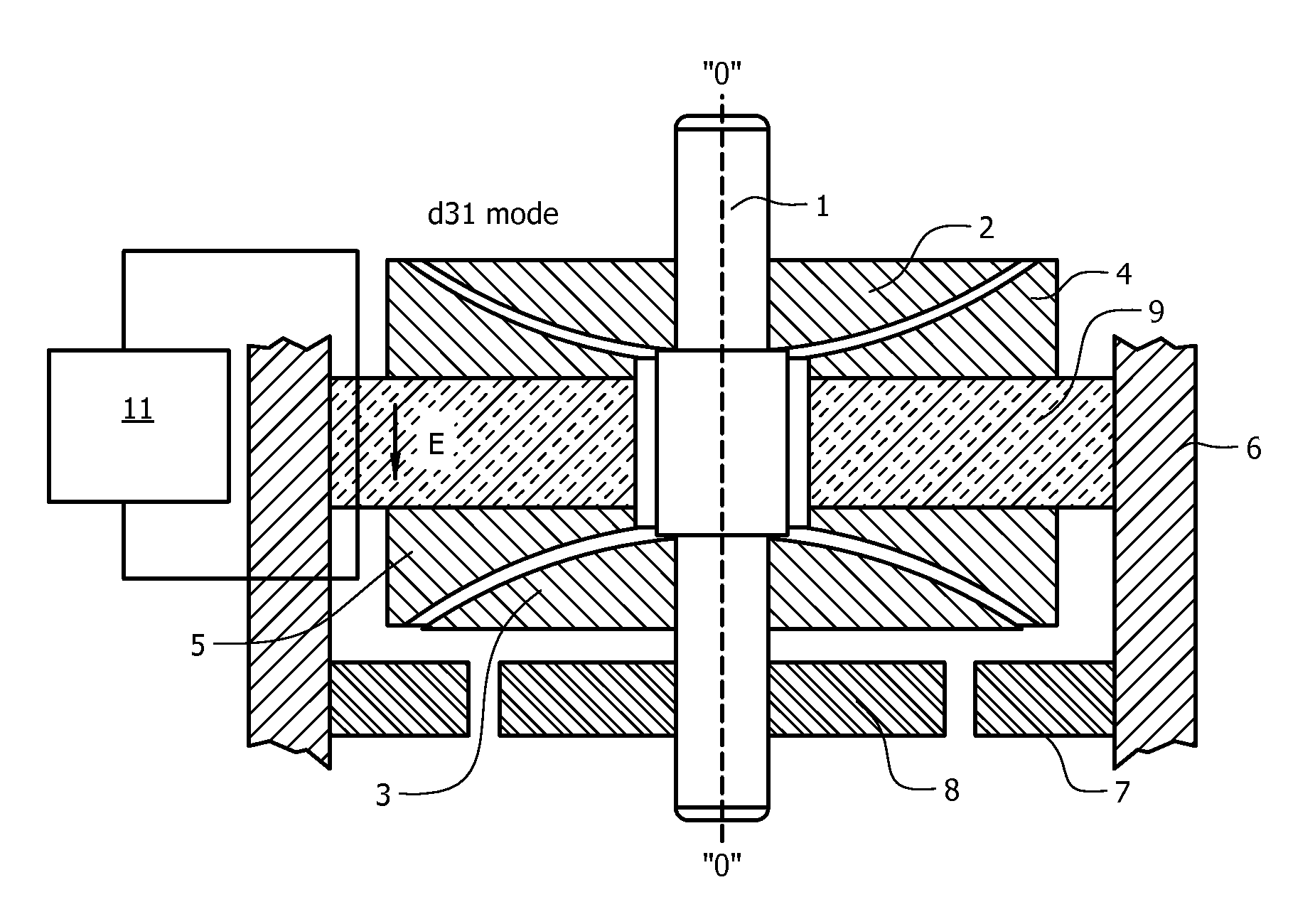

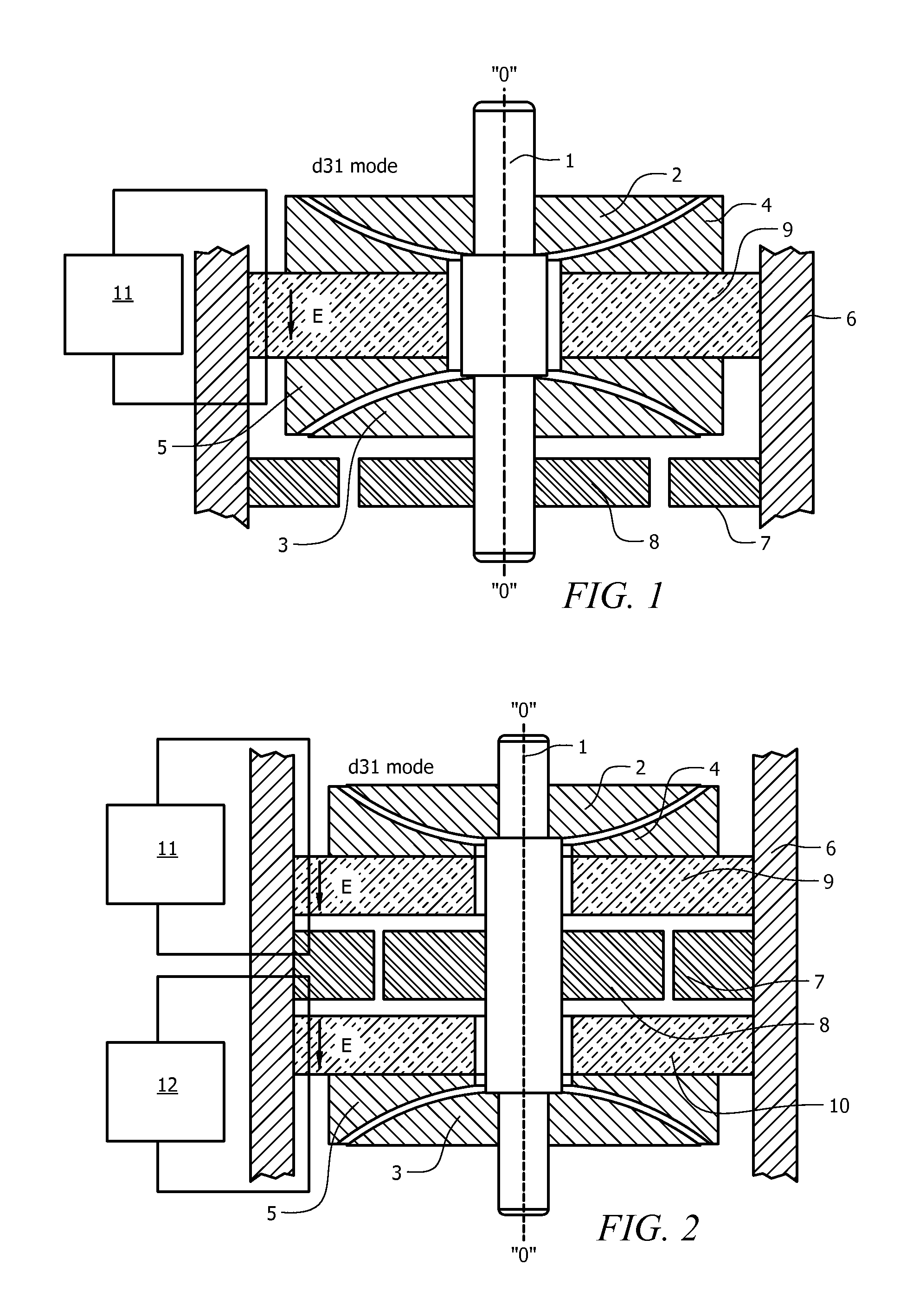

Electric motors and generators with opposing non-contact piezoelectric bearing supports

InactiveUS20120049679A1Improved technical characteristicReduce power consumptionGas cushion bearingsSliding contact bearingsNon-contact ultrasoundUltrasonic levitation

Electric motors and generators, in which a non-contact ultrasonic suspension of the rotor of the electric motor, are provided. The non-contact ultrasonic suspension is achieved by the formation of an elevated-pressure gaseous microfilm between conjugated surfaces of saddle-resonators and trunnions of a bearing system.

Owner:DTI MOTION CORP

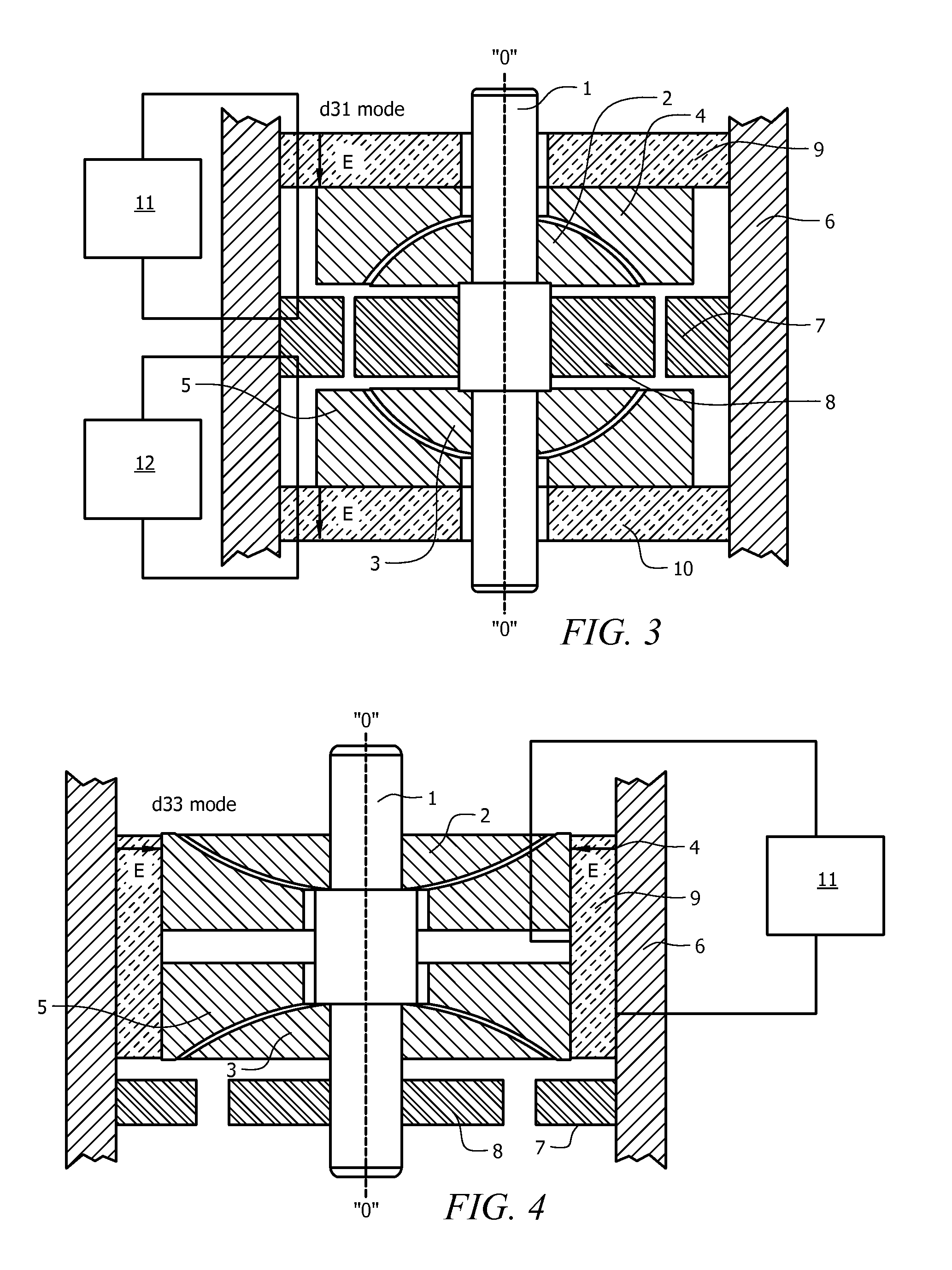

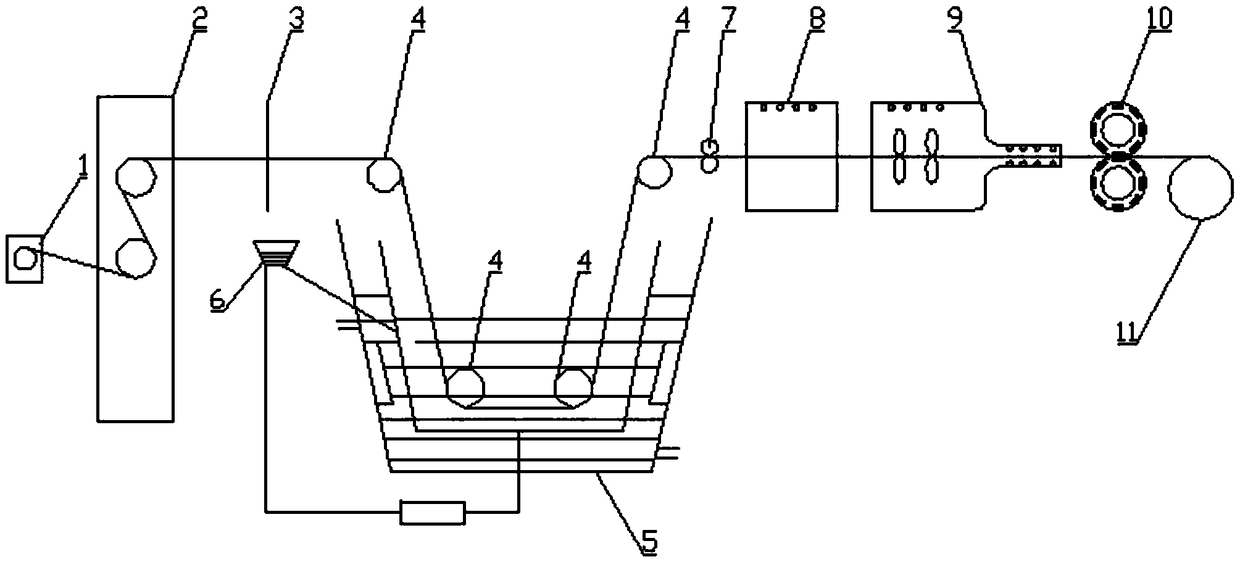

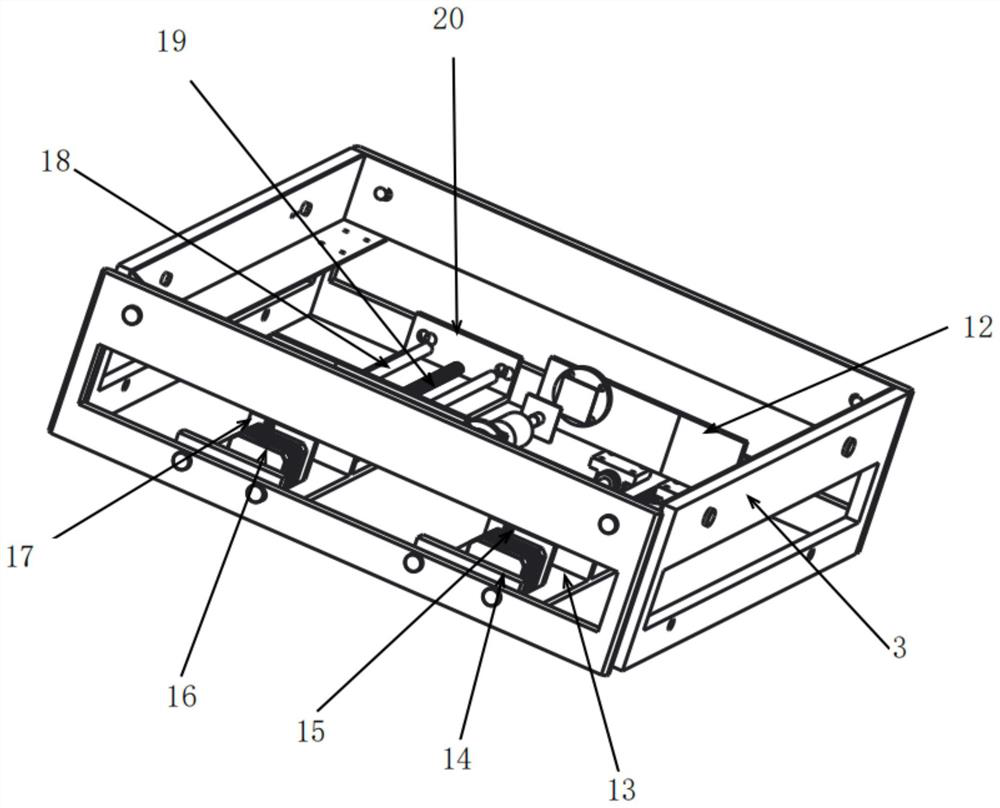

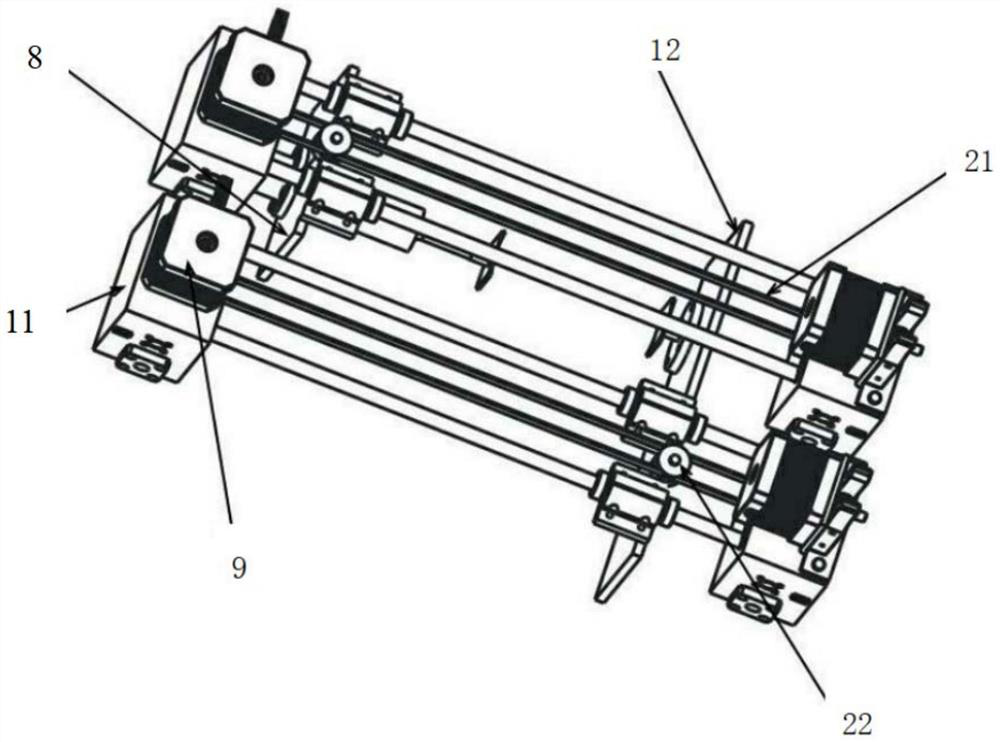

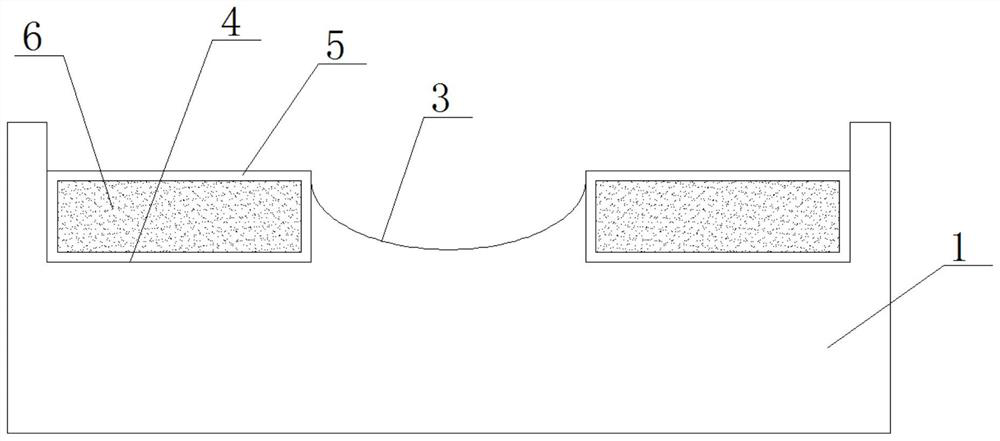

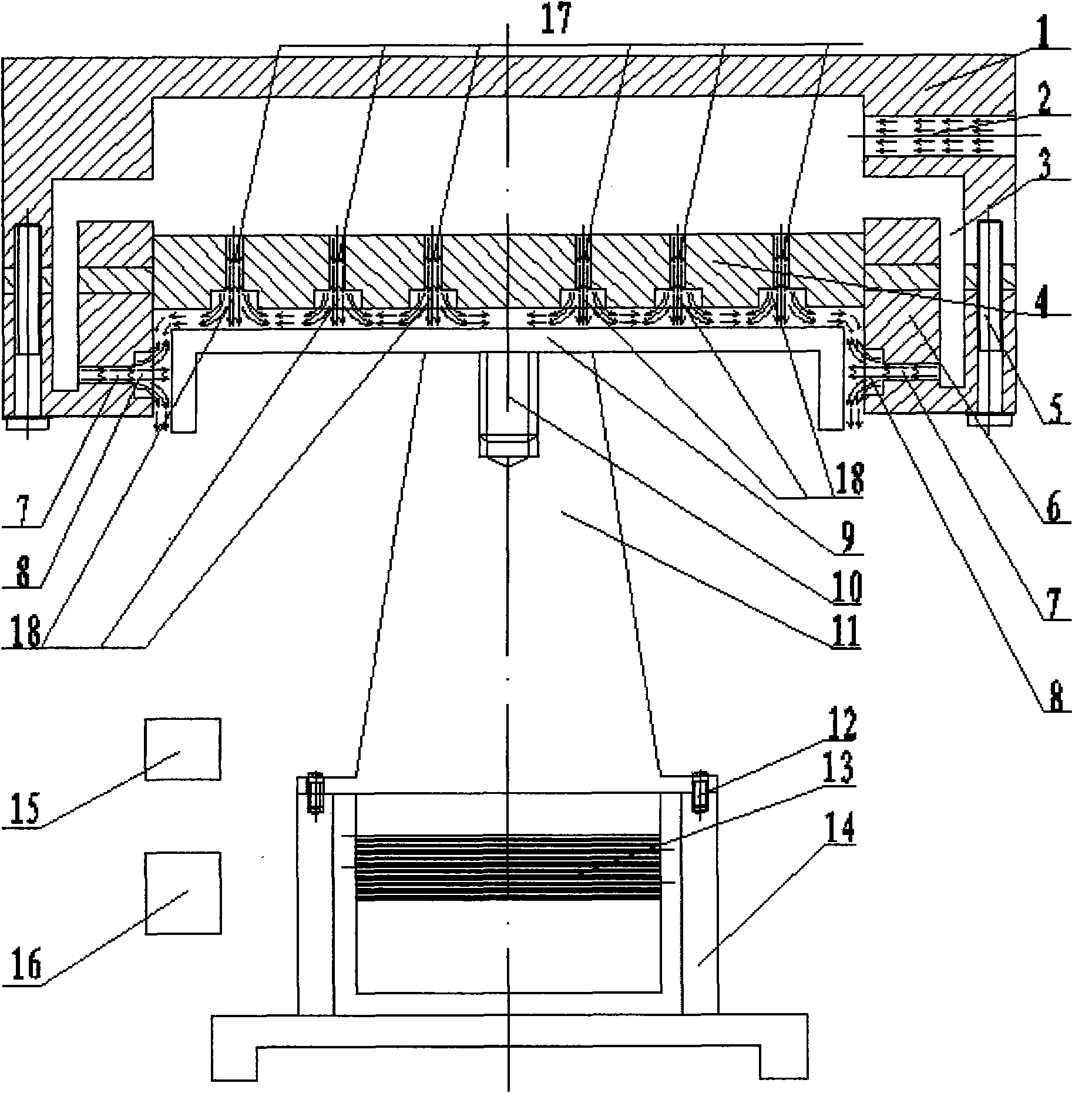

Forming device for preparing continuous fiber reinforced thermoplasticity prepreg through ultrasonic suspension liquid method

The invention discloses a forming device for preparing continuous fiber reinforced thermoplasticity prepreg through an ultrasonic suspension liquid method. The forming device sequentially comprises ayarn frame, a tension system, a yarn separating system, a guide roller, an ultrasonic wave suspension liquid powder groove system, an airflow powder feeding system, a guide mechanism, a drying chamber, a fusion chamber, a cooling system and a rolling system. According to the forming device, the ultrasonic wave suspension liquid powder groove system can avoid powder agglomeration and gathering; theairflow powder feeding system can achieve automatic precise feeding according to needs, and the prepreg can be distributed in resin beneficially; a transcrystallinity generation chamber in the fusionchamber can increase the transcrystallinity generation rate of the resin, and the interface bonding strength of fiber and the resin is improved; and the cooling speed of the cooling system can be adjusted, the thermoplasticity resin crystallinity degree is controllable, and the covering performance of the prepreg can be adjusted beneficially according to needs.

Owner:XIAN TECH UNIV

Ultrasonic suspension surrounding paint-spraying complete machine

ActiveCN107952604AConvenient auto-rotatePrecision SprayingSpray boothsUltrasonic levitationEngineering

The invention discloses an ultrasonic suspension surrounding paint-spraying complete machine. The ultrasonic suspension surrounding paint-spraying complete machine comprises a bottom rack, and the topsurface of the bottom rack is provided with at least one set of paint-spraying device; each paint-spraying device comprises a bottom plate, each bottom plate is provided with a first rotating motor,and the power output end of each first rotating motor is connected with a rotating frame; the ultrasonic suspension surrounding paint-spraying complete machine further comprises a rotating disc ring,and the rotating disc ring and the rotating frames are arranged concentrically and fixed together; the top surface of the rotating disc ring is provided with a plurality of storing grooves formed around the center of the rotating disc ring; each storing groove is internally provided with an ultrasonic generator; and convenient automatic rotating for spraying is achieved, a spraying disc can be adjusted up and down to adapt to spraying items of different weights, operation can be completed more efficiently while accurate spraying is conducted, and the efficiency is high.

Owner:惠州市惠尔明电子科技有限公司

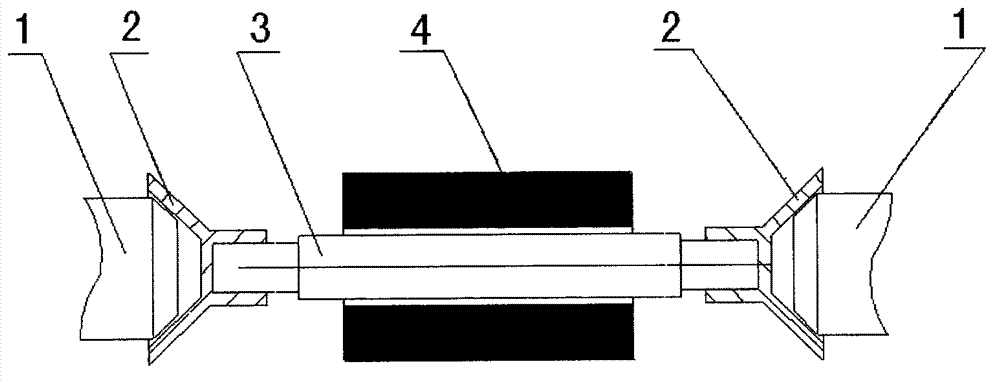

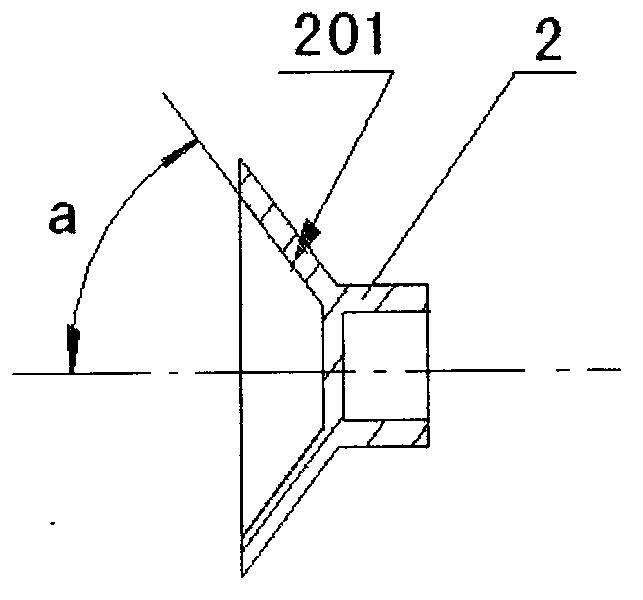

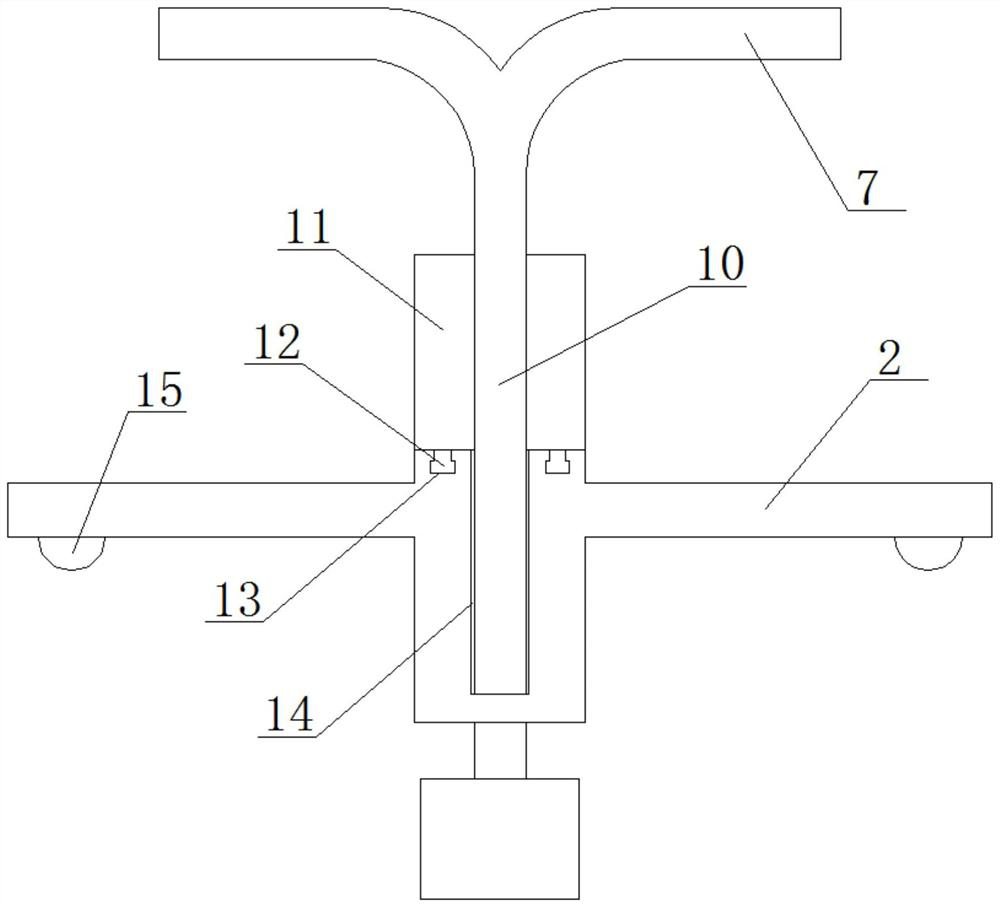

Novel method for supporting high-speed motor rotor

InactiveCN102904369ASimple structureEasy to controlMechanical vibrations separationSupports/enclosures/casingsUltrasonic levitationEngineering

The invention discloses a non-contact method for supporting a high-speed motor rotor by using ultrasonic vibration. A bearing bush 2 with a conical surface is sleeved at each of the left end and the right end of the motor rotor 3; the bearing bushes 2 are respectively connected with an ultrasonic transducer 1; the inner conical surfaces of the bearing bushes 2 are matched with the outer conical surfaces of the ultrasonic transducers 1; when the ultrasonic transducers 1 are in an ultrasonic vibration states, the outer conical surfaces have suspension capacity; under the mutual action of the outer conical surfaces of the ultrasonic transducers 1 and the inner conical surfaces of the bearing bushes 2, suspension force is transmitted to the motor rotor 3, and motor rotor 3 is suspended under the extrusion action of the suspension force on two sides, so that an aim of supporting the motor rotor 3 without any contact is fulfilled; and moreover, the motor rotor 3 and a stator 4 are in a clearance non-friction state, so that high-rotating-speed rotation can be realized. The method has the advantages that an ultrasonic suspension supporting system is simple in structure, easy to control and high in stability; electromagnetic coupling does not exist between an ultrasonic suspension process and a motor, so that any influence on a rotating magnetic field of the motor can be avoided; and besides the conventional air floating, liquid floating or magnetic suspension, the invention provides another novel non-contact method for supporting the high-speed motor rotor.

Owner:JILIN UNIV

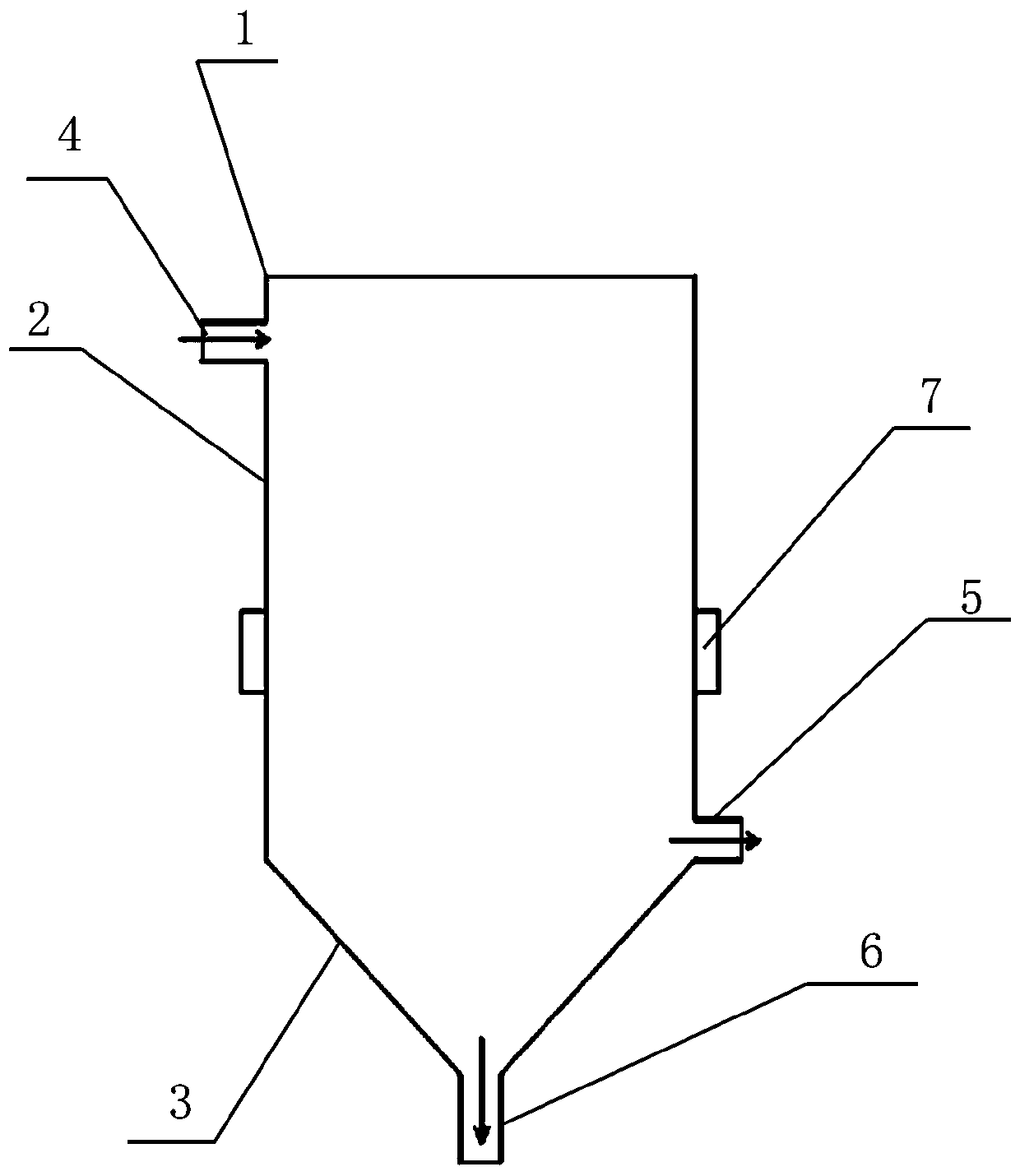

Ultrasonic suspension separator

PendingCN108101151AAchieve separationImprove separation efficiencyWater/sewage treatment with mechanical oscillationsTreatment involving sedimentationUltrasonic levitationSlag

The invention discloses an ultrasonic suspension separator. The ultrasonic suspension separator is characterized by comprising a separator casing (1), wherein a main chamber (2) is formed in the upperpart of the separator casing (1), a separation chamber (3) is formed in the lower part of the separator casing (1), and the main chamber (2) is communicated with the separation chamber (3); a suspension stock solution inlet (4) is formed in the side surface of the upper part of the main chamber (2), a separation liquid outlet (5) is formed in the boundary between the main chamber (2) and the separation chamber (3), a sediment outlet (6) is formed in the bottom of the separation chamber (3), and two ultrasonic generators (7) are symmetrically arranged on the outer surface of the main chamber (2). According to the ultrasonic suspension separator, components with higher specific gravity in a suspension mixture can settle after ultrasonic treatment on the suspension mixture, and accordingly,separation of slag and liquid in the suspension mixture is realized.

Owner:江苏梅兰化工有限公司

Ultrasonic suspension surrounding type paint spraying device

ActiveCN107983554AConvenient auto-rotatePrecision SprayingLiquid spraying apparatusUltrasonic levitationUltrasonic generator

The invention discloses an ultrasonic suspension surrounding type paint spraying device. The ultrasonic suspension surrounding type paint spraying device comprises a base plate. A first rotary motor is arranged on the base plate. The power output end of the first rotary motor is connected with a rotary frame. The ultrasonic suspension surrounding type paint spraying device further comprises a rotary disc ring. The rotary disc ring and the rotary frame are arranged concentrically and fixed together. A plurality of storage grooves around the center of the rotary disc ring are formed in the top surface of the rotary disc ring. An ultrasonic generator is arranged in each storage groove. According to the ultrasonic suspension surrounding type paint spraying device, paint can be conveniently sprayed automatically and rotatably; and a spraying disc can be adjusted upwards and downwards to adapt to to-be-painted articles with different weights, work can be completed more efficiently while accurate spraying is achieved, and the efficiency is high.

Owner:惠州市惠尔明电子科技有限公司

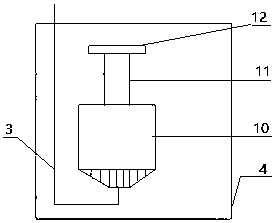

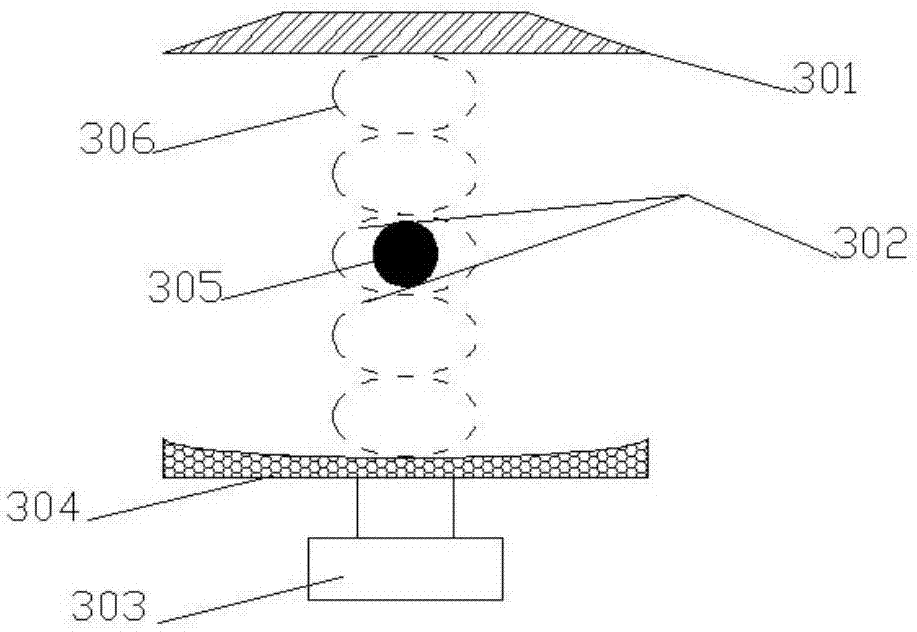

Supersonic suspended globe

InactiveCN103794129ASimple structureReasonable designPlanetaria/globesStructure of the EarthUltrasonic levitation

The invention discloses a supersonic suspended globe. The supersonic suspended globe comprises a frame, an upper supersonic emitter, a lower supersonic emitter and a globe body, wherein the upper supersonic emitter is fixedly mounted above the globe, and the lower supersonic emitter is fixedly mounted under the globe; the upper supersonic emitter and the lower supersonic emitter are equally sized, and are arranged facing each other, such that standing waves are generated between the upper supersonic emitter and the lower supersonic emitter; and the globe body is arranged between the upper supersonic emitter and the lower supersonic emitter in a suspension state under the action of the standing waves, and is internally provided with a load for enabling the globe body to be stable. The supersonic suspended globe has the advantages of reasonable structure and good use effect, and solves the problems that the conventional globe, which uses the magnetic principles to realize the suspension of the globe, is poor in stability, and the globe is easy to drop under the action of an external force or firmly held by the magnet of the upper frame. The supersonic suspended globe is stable in suspension, and can rotate with almost no resistance.

Owner:XIAN JINHE OPTICAL TECH

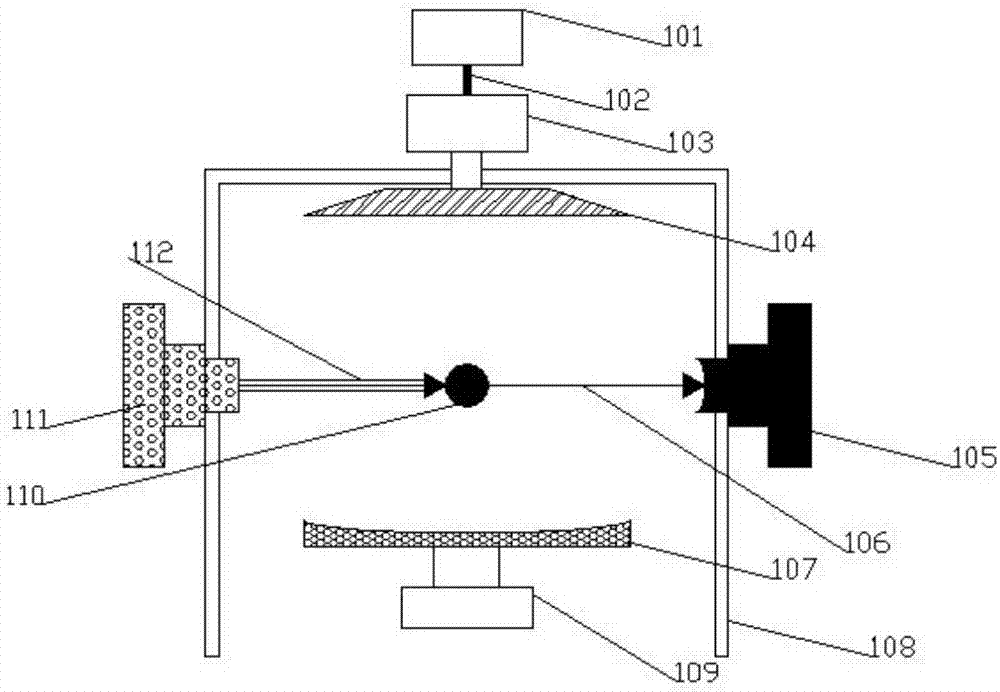

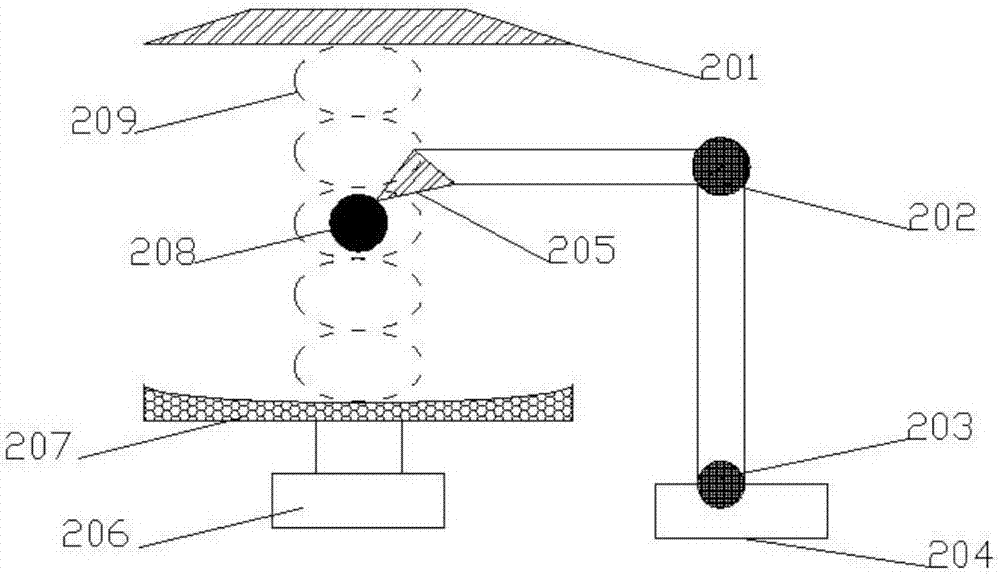

Fogdrop generation device and method

ActiveCN106259268AEfficient acquisitionSmall particle sizeInsect catchers and killersImaging processingUltrasonic levitation

The invention discloses a fogdrop generation device and method. The fogdrop generation device comprises a transmitting end, a reflecting end, an imaging device, a light emitting backboard and an ultrasonic signal generator. The transmitting end is connected with the ultrasonic signal generator and used for transmitting ultrasonic waves vertically downwards. The reflecting end is vertically opposite to the transmitting end and is used for reflecting the ultrasonic waves transmitted by the transmitting end, and the space between the transmitting end and the reflecting end forms a fogdrop suspension zone. The imaging device is arranged on the horizontal side of the fogdrop suspension zone and used for imaging fogdrops in real time. The light emitting backboard is horizontally opposite to the imaging device and is used for providing imaging lighting. An auxiliary evaporating system is further arranged on one side of the fogdrop suspension zone and used for accelerating evaporation of fogdrops. A vessel-free evaporation method is adopted, after large fogdrops injected by a traditional injector in a pushed mode are subjected to ultrasonic suspension, the particle size is monitored through an image processing method and is reduced through an accelerated evaporation method, and thus fogdrops with the designated particle size are obtained.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

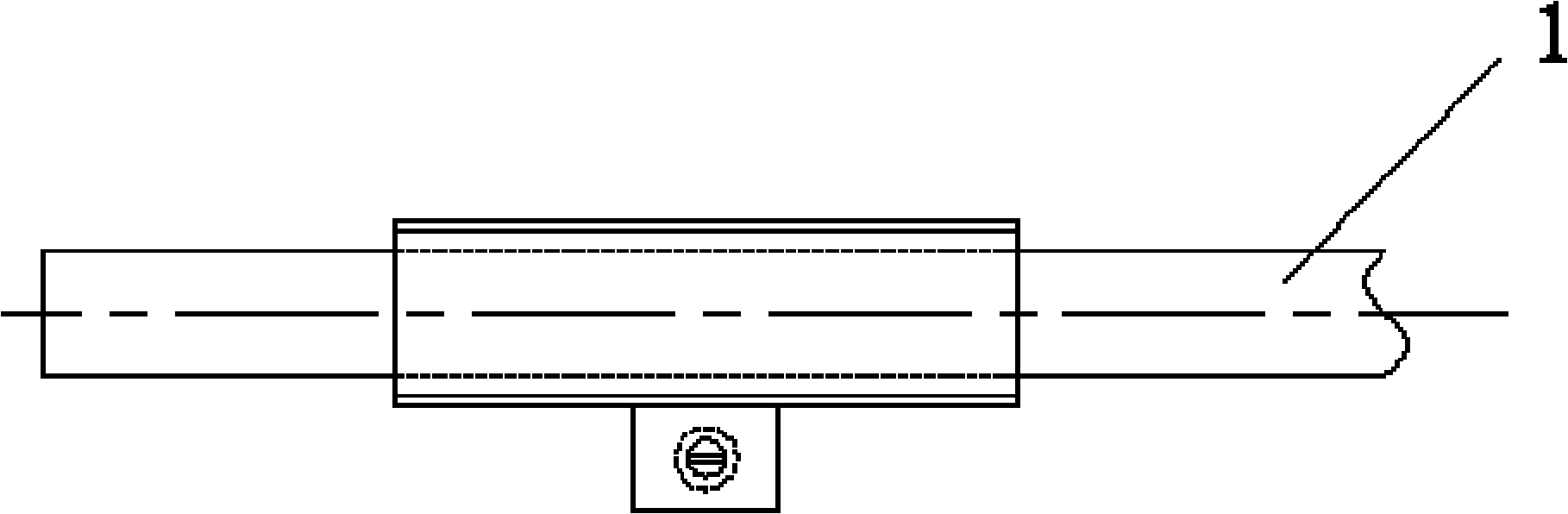

A linear guide rail ultrasonic suspension extrusion film hydrostatic bearing

The invention discloses a linear supersonic wave suspended extruded film static pressure bearing. The bearing comprises a linear guide rail, a suspended sleeve, a piezoelectric stack performer, and a fastening screw, the end face of the suspended sleeve is rectangular in shape, and the suspended sleeve is arranged on the linear guide rail. The bearing is characterized in that: the linear supersonic wave suspended extruded film static pressure bearing also comprises a flexible hinge; a rectangular sleeve is formed by connecting four surfaces of the suspended sleeve with the flexible hinge; oneof the four rectangular surfaces of the suspended sleeve is provided with an air gap penetrating the width; two sides of the air gap are provided with vertical walls for fastening the piezoelectric stack performer; and the piezoelectric stack performer is fastened on the vertical walls by the fastening screw, and initial pretightening force is adjusted by the fastening screw. A system of the bearing which has the advantages of no contact, low wearing, high precision, simple structure, no need of any subsidiary gas source equipment and the like can be widely applied to precise machineries, apparatuses, instruments, pneumatic suspension positioning and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

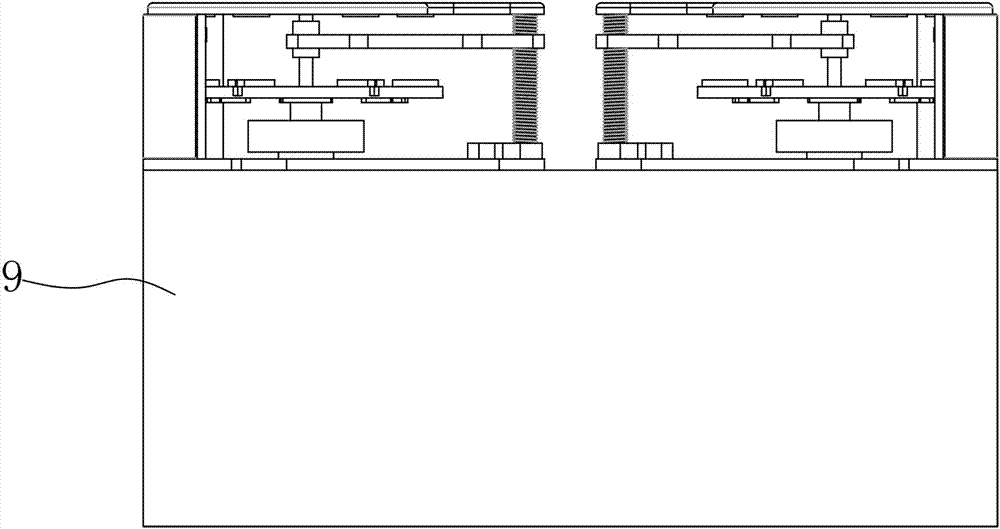

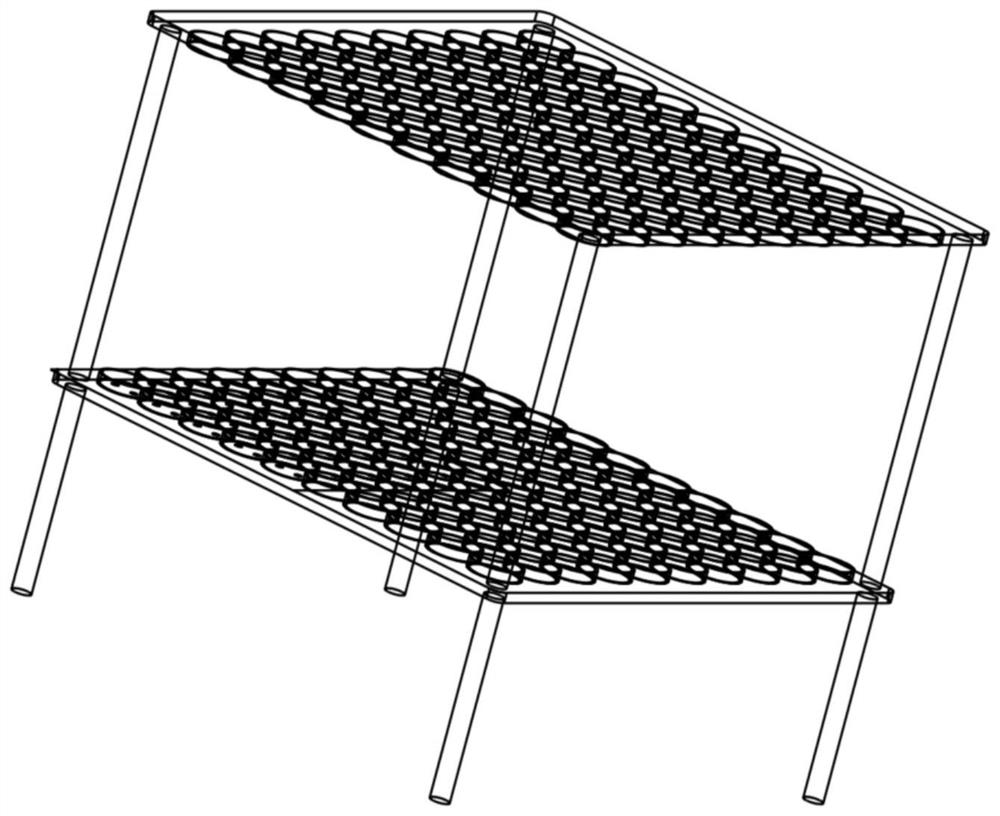

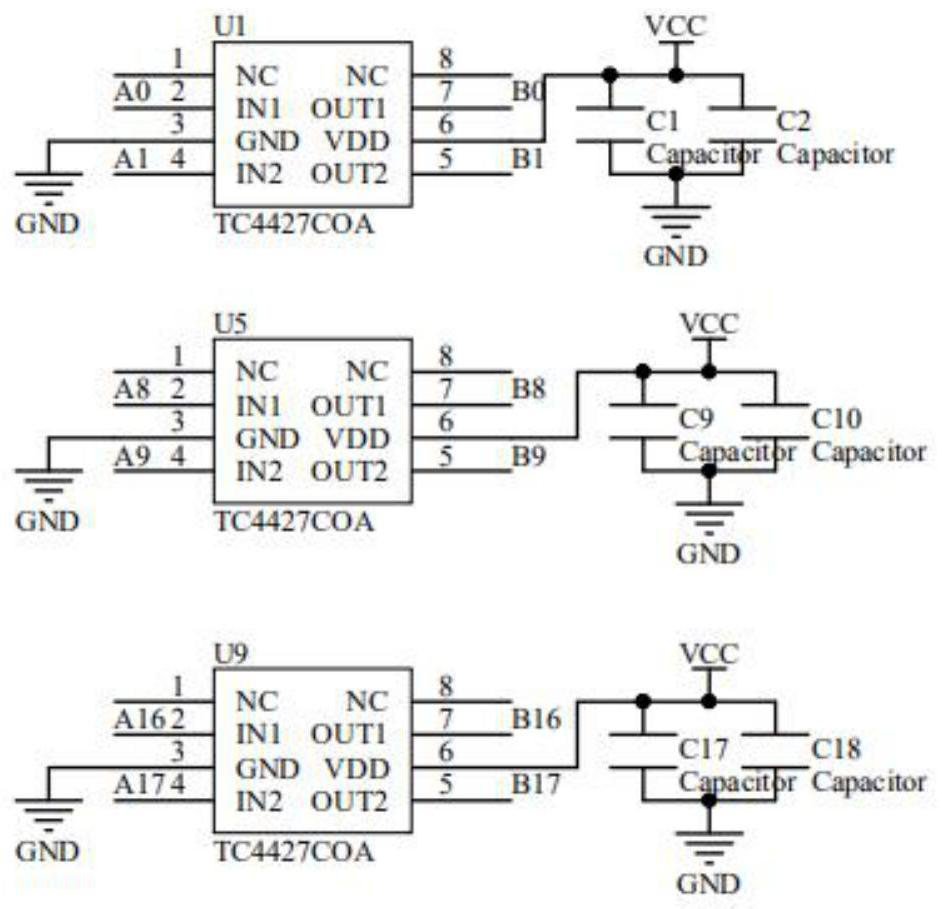

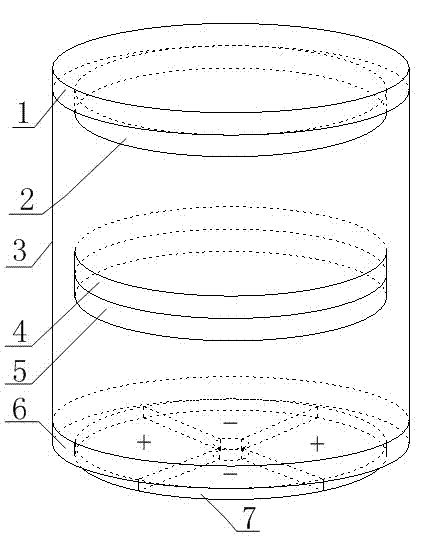

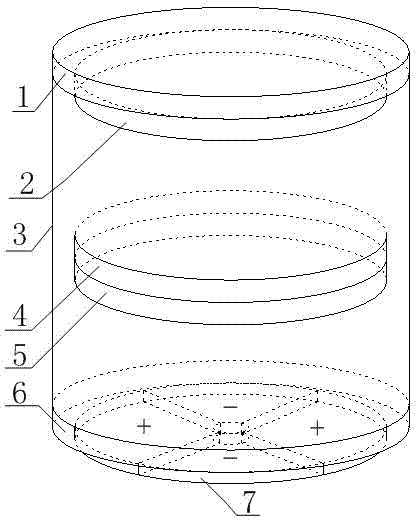

Double-array correlation standing wave field ultrasonic suspension and control system and method based on FPGA

PendingCN112180794ADynamic handling is sharpPhase output delay error reductionProgramme controlComputer controlSuspended particlesUltrasonic levitation

The invention discloses a double-array correlation standing wave field ultrasonic suspension and control system and method based on an FPGA. The system comprises an upper supporting plate, a lower supporting plate, a plurality of ultrasonic transducers distributed on the upper supporting plate and the lower supporting plate, and a driving module used for driving the ultrasonic transducers. The driving module comprises a plurality of chips which are connected in parallel; the suspension method comprises the following steps of: s1, reversely solving the phase and duty ratio information of each ultrasonic transducer on two correlation ultrasonic transducer arrays at each moment of particle control by utilizing the characteristics, positions and motion parameters of suspended particles; and s2, calculating the phases and the duty ratios of all the ultrasonic transducers, and transmitting the phases and the duty ratios into software; and s3, through software, carrying out input design, timesequence constraint, analysis integration and board-level debugging on a time sequence circuit required by the ultrasonic phased array; according to the invention, operation control is carried out based on the time sequence circuit designed by the FPGA, so that the phase output delay error is greatly reduced.

Owner:CHONGQING UNIV

Ultrasonic levitation accelerometer

InactiveCN102384983AHigh sensitivityCompact structureAcceleration measurementCapacitanceAccelerometer

The invention discloses an ultrasonic levitation accelerometer. The ultrasonic levitation accelerometer comprises a shell, wherein a suspended substance is arranged in the shell; a piezoelectric ceramic sheet is arranged at the bottom of the shell; and an upper polar plate of a capacitor is arranged on the lower surface of the interior of the shell and a lower polar plate of the capacitor is arranged on the upper surface of the suspended substance. Compared with the prior art, the ultrasonic levitation accelerometer is more compact in structure and has higher precisions in both processing and assembling; and meanwhile, the ultrasonic levitation accelerometer is more convenient to mount and apply. As no mechanical bearing structures are used for bearing the mass of a sensitive element, the influence on mechanical elasticity is eliminated; and the sensitivity of the accelerometer provided by the invention can be very high in theory.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

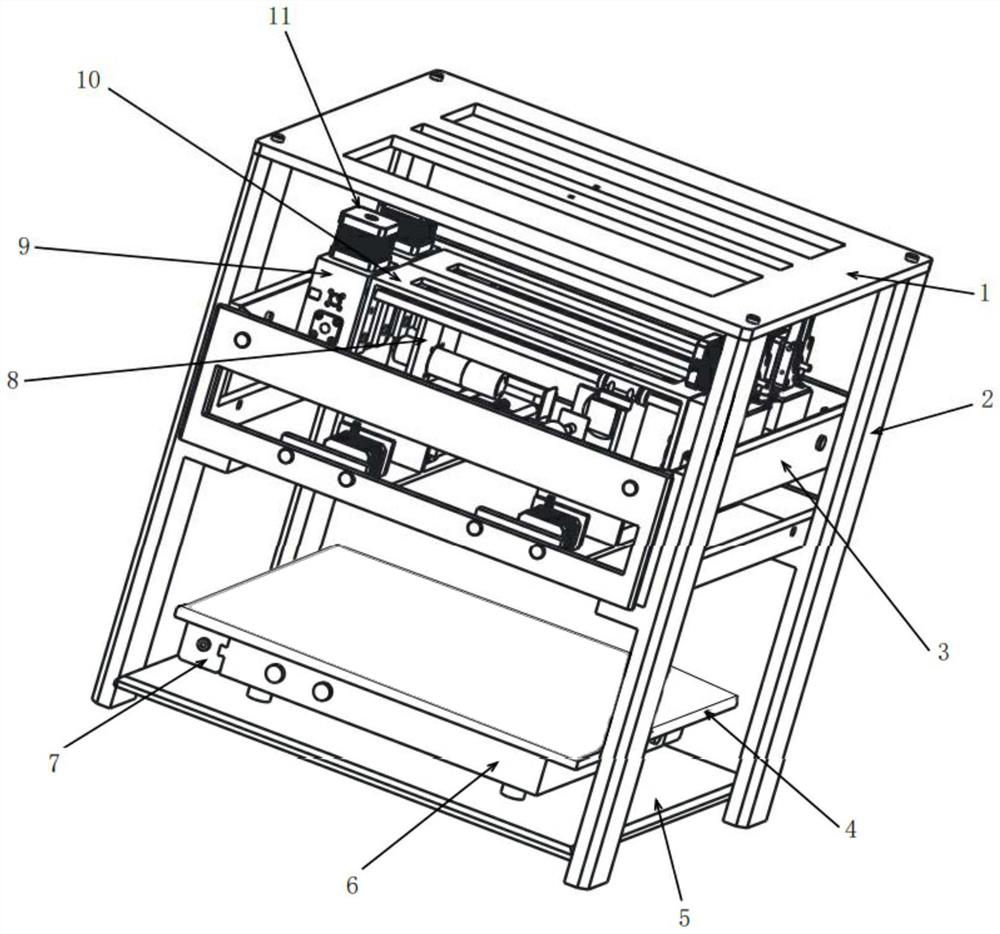

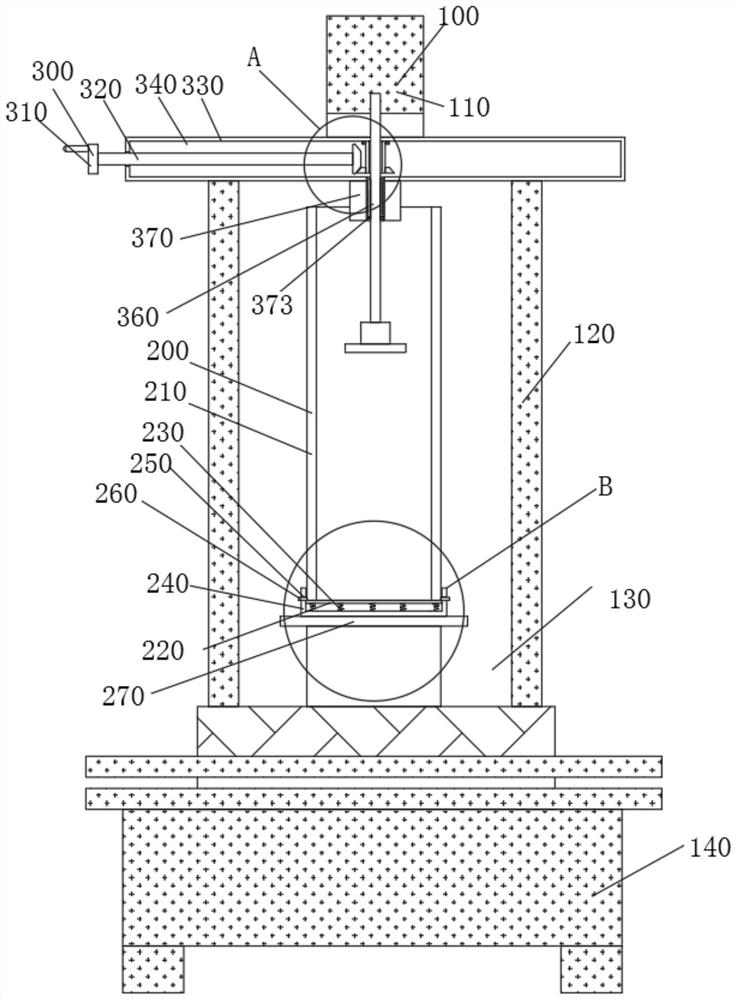

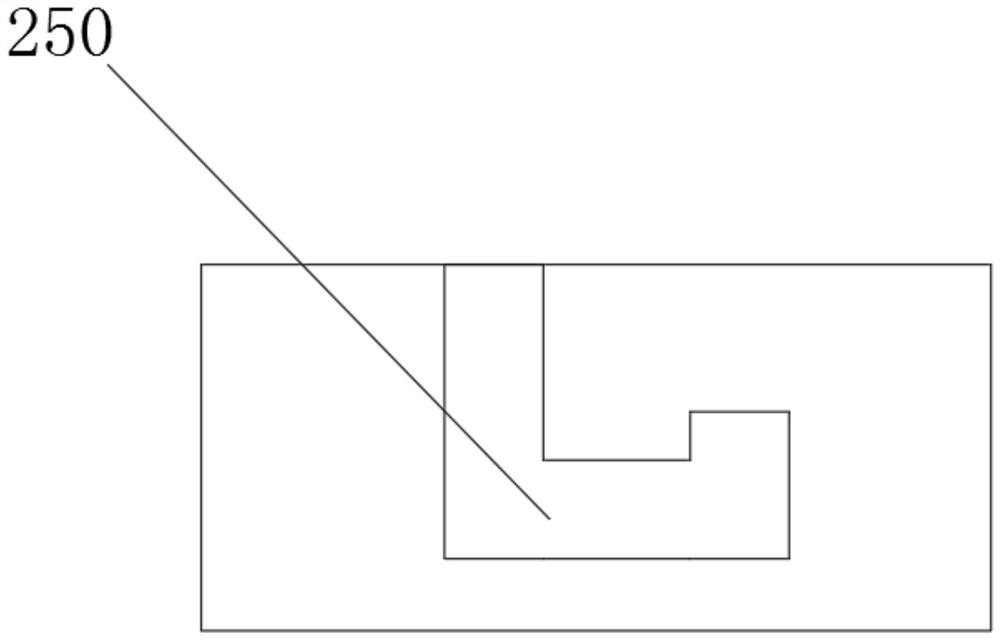

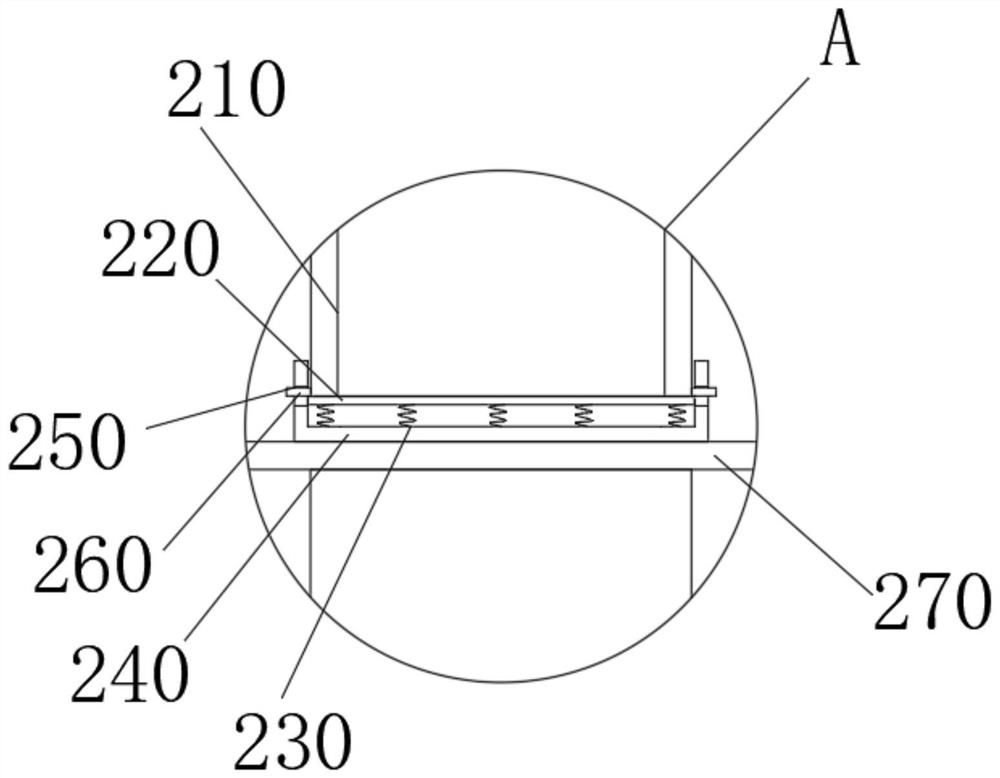

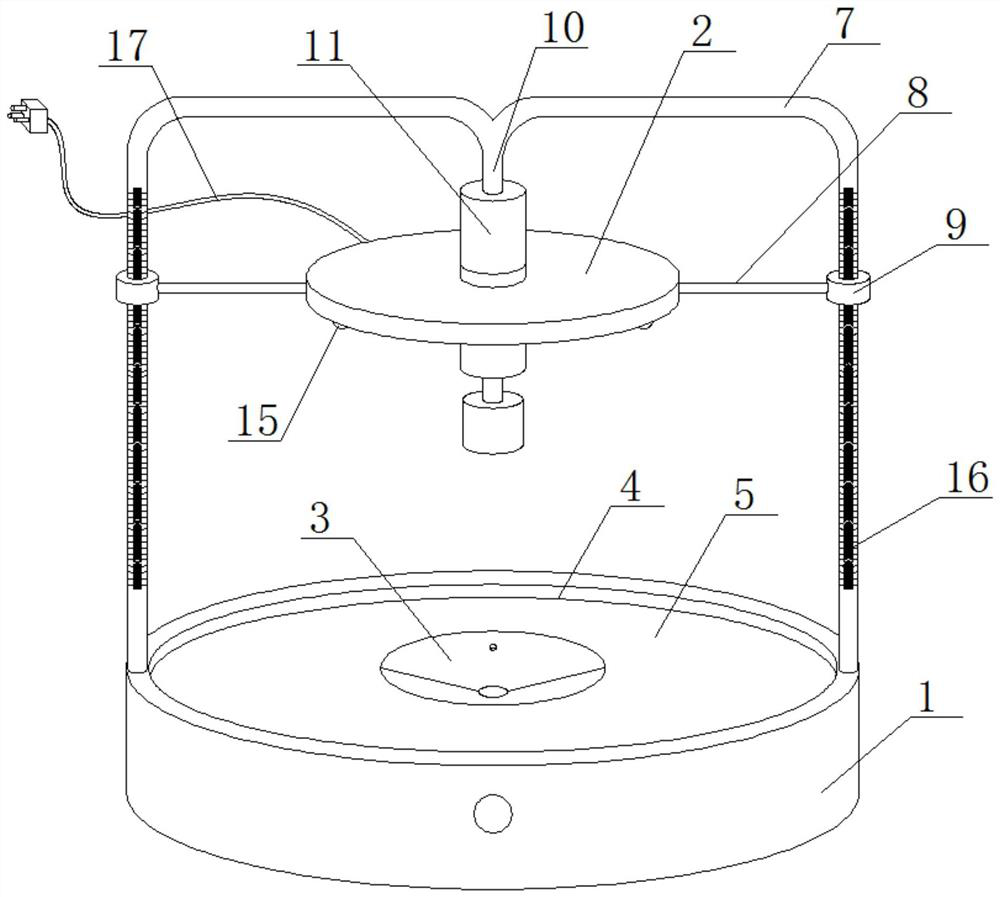

Ultrasonic suspension device applied to three-dimensional (3D) printing field

PendingCN112829292AGuaranteed stabilityChange hover positionAdditive manufacturing apparatusMechanical vibrations separationUltrasonic levitationReciprocating motion

The invention discloses an ultrasonic suspension device applied to the field of three-dimensional (3D) printing. The ultrasonic suspension device applied to the field of 3D printing comprises a frame, a workbench, a piezoelectric transducers, suspension supporting mechanisms and a suspension guiding device. The workbench comprises a printing working platform, two driving motors and a supporting working platform. The number of the suspension supporting mechanisms is two; each suspension supporting mechanism is provided with one piezoelectric transducer; the center line of one piezoelectric transducer is in the front-back direction; the center line of the other piezoelectric transducer is in the left-right direction; and the layout form that the center lines of the two piezoelectric transducers are mutually orthogonal is formed. According to the ultrasonic suspension device applied to the field of 3D printing provided by the invention, the stability of radiation force generated by radiation heads and reflection ends of the piezoelectric transducers can be ensured by fixing the piezoelectric transducers in the orthogonal direction in the plane by using the suspension supporting structures. According to the ultrasonic suspension device applied to the field of 3D printing provided by the invention, the reciprocating motion of the ultrasonic transducers is indirectly controlled, so that the suspension position of particles in resonant cavities of the piezoelectric transducers is changed, and the controllability of stable suspension of the particles in the in-plane suspension motion process is realized.

Owner:DALIAN JIAOTONG UNIVERSITY

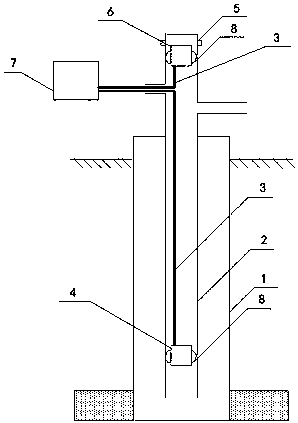

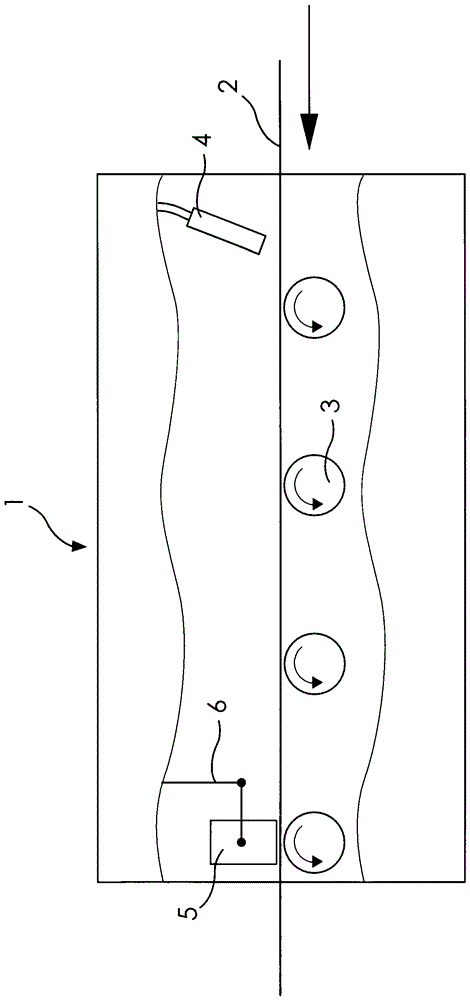

Gas well ultrasonic levitation, liquid discharge and gas production system and implementation method

ActiveCN109695437AEnsure continuous riseReduce flow pressureFluid removalVibration devicesWater dischargeUltrasonic levitation

The invention provides an acoustic levitation system and a gas well ultrasonic levitation, liquid discharge and gas production method. A new acoustic levitation method is introduced in the field of water discharge and gas production. The acoustic levitation system comprises a well bottom acoustic transmitter, a well mouth acoustic generator, a centralizing and clamping device and a ground controller; two columns of sound waves transmitted by the well bottom and the well mouth have the same amplitude and frequency, are stable, have opposite transmission directions, and generate standing wave phenomenon at a certain position in a shaft. Shaft liquid drops are levitated by standing wave and flow towards the well mouth under the driving of gas flow, so that gas well continuous liquid carryingproduction is realized, continuous ascending of the liquid drops in the shaft can be guaranteed, the whole life cycle of the gas shaft is maintained to be in an effusion-free production state, the well bottom flow pressure is completely reduced and the gas well is produced to be exhausted. The acoustic levitation system is suitable for various sizes of pipe column combined gas wells, does not needto change the pipe column during operation, can adjust the sound wave frequency according to the liquid production condition of the gas well, can meet the gas wells with various liquid production conditions, and is clean and environmentally friendly.

Owner:SOUTHWEST PETROLEUM UNIV

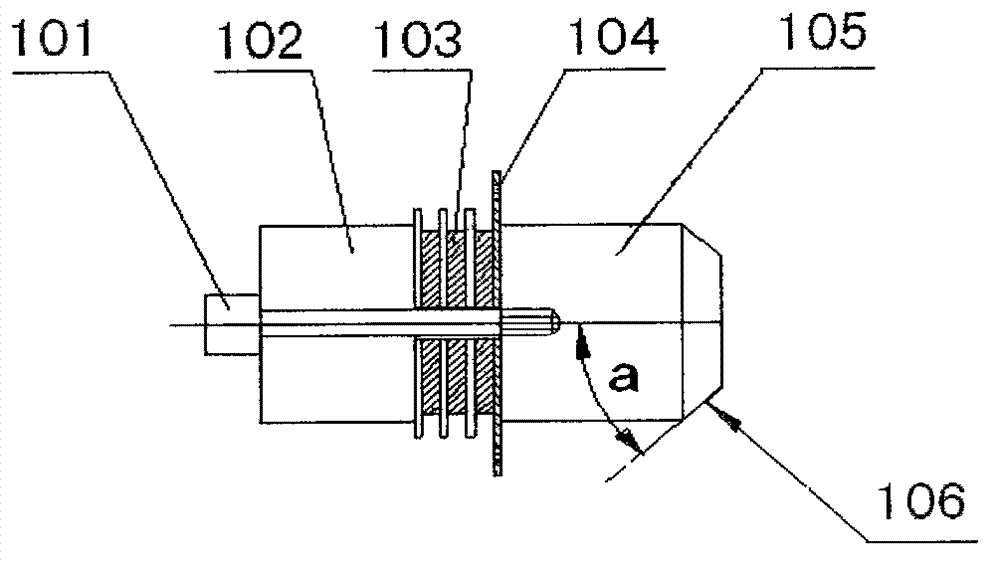

Gas tungsten arc welding system based on near-field ultrasonic levitation technology

InactiveCN105643063AEfficient weldingAvoid runningWelding/cutting auxillary devicesAuxillary welding devicesUltrasonic levitationWelding power supply

The invention belongs to the technical field of welding and discloses a gas tungsten arc welding system based on a near-field ultrasonic levitation technology. The gas tungsten arc welding system comprises a welding system consisting of a gas tungsten arc welding gun and a welding power supply and an ultrasonic levitation system consisting of an ultrasonic generator and an ultrasonic generator power control box; the ultrasonic generator comprises an transducer and an amplitude-change pole; the ultrasonic generator is used for acting on a welding pool while a gas tungsten arc welding gun welds a workpiece to be welded; and the end part of the amplitude-change pole of the ultrasonic generator is positioned below the welding pool at a welding station except a downward welding station. According to the gas tungsten arc welding system disclosed by the invention, the near-field ultrasonic levitation technology and a gas tungsten arc welding technology are combined, and a relative position of the ultrasonic levitation system and the welding system is specified, so that an electric arc force borne by pool metal and an ultrasonic levitation force are mutually overlapped, the electric arc force and gravity borne by the pool metal reach a balanced state, the flowing of the pool metal under the action of gravity is prevented, and high-efficiency welding and high forming rate of weld joints are realized.

Owner:TIANJIN UNIV

No-clean detection device

InactiveCN107202766ALess typesReduce difficultyColor/spectral properties measurementsUltrasonic levitationTransmittance

The invention provides a detection device, and mainly relates to a no-clean detection device. By changing a positioning mode of a solution sample, a no-clean effect is achieved. The detection device comprises a spectrophotometer, an acoustic levitation apparatus and an auxiliary positioning device. According to the no-clean detection device, by an ultrasonic levitation technology, a to-be-detected sample is levitated in the air, wherein the to-be-detected sample is placed at an ultrasonic standing wave stabilizing center by the auxiliary positioning device. Absorption or transmittance of the to-be-detected sample can be measured by spectrophotometer so as to complete substance color characteristic measurement of the sample. After measurement is completed, recovery and cleaning of the to-be-detected sample can be completed by an absorption device. The device provides a convenient and environmental-friendly measurement method so as to avoid pollution of sample residues or residual liquid to the testing environment pollution of an equipment system.

Owner:宁夏软件工程院有限公司

Ultrasonic suspension device with anti-interference mechanism

InactiveCN112303395AGood suspensionSuspension stabilityMachine framesStands/trestlesLow noiseInterference resistance

The invention relates to the technical field of ultrasonic suspension, in particular to an ultrasonic suspension device with an anti-interference mechanism. The device comprises an ultrasonic suspension device main body, the ultrasonic suspension device main body comprises an ultrasonic suspension device upper cover, and the bottom of the ultrasonic suspension device upper cover is provided with an adjusting mechanism; an ultrasonic suspension device machine body is fixedly installed at the bottom of the adjusting mechanism, a first cavity is formed in the ultrasonic suspension device machinebody, an ultrasonic suspension device base is fixedly installed at the bottom of the ultrasonic suspension device machine body, and first sliding grooves are formed at the positions, close to the twoends of a supporting plate, of the two ends of a fixed bottom plate; and first fixing blocks are fixedly mounted in the first sliding grooves, a support plate is fixedly mounted at the bottom of the fixed bottom plate, and the adjusting mechanism is arranged at the bottom of the ultrasonic suspension device upper cover, so that the problem of low noise interference resistance of the device is solved, better suspension of the device is facilitated, an object can suspend in the device more stably, and working efficiency is improved.

Owner:漳州市龙文区健达电子科技有限公司

An ultrasonic suspension surround painting device

ActiveCN107983554BConvenient auto-rotatePrecision SprayingLiquid spraying apparatusUltrasonic levitationEngineering

The invention discloses an ultrasonic suspension surrounding type paint spraying device. The ultrasonic suspension surrounding type paint spraying device comprises a base plate. A first rotary motor is arranged on the base plate. The power output end of the first rotary motor is connected with a rotary frame. The ultrasonic suspension surrounding type paint spraying device further comprises a rotary disc ring. The rotary disc ring and the rotary frame are arranged concentrically and fixed together. A plurality of storage grooves around the center of the rotary disc ring are formed in the top surface of the rotary disc ring. An ultrasonic generator is arranged in each storage groove. According to the ultrasonic suspension surrounding type paint spraying device, paint can be conveniently sprayed automatically and rotatably; and a spraying disc can be adjusted upwards and downwards to adapt to to-be-painted articles with different weights, work can be completed more efficiently while accurate spraying is achieved, and the efficiency is high.

Owner:惠州市惠尔明电子科技有限公司

Ultrasonic suspension device

InactiveCN112340464AAvoid damagePrevent ultrasonic levitation effectsNon-mechanical conveyorsUltrasonic levitationEngineering

The invention provides an ultrasonic suspension device which comprises a base and an ultrasonic generator. A spherical reflecting face is formed at the center position of the top of the base, an annular containing groove is formed in the top of the base, the spherical reflecting face is located at the center position of the annular containing groove, an annular cloth bag is placed in the annular containing groove, and the annular cloth bag is filled with fine sand. A U-shaped mounting rod is fixedly mounted at the top of the base, and mounting rods are fixedly connected to the two sides of theultrasonic generator. The design of the ultrasonic suspension device is reasonable, the annular cloth bag filled with the fine sand is placed in the annular containing groove in the base, when ultrasonic suspension is carried out, related tools can be placed on the annular cloth bag, and therefore the situation that noise is generated and consequently ultrasonic suspension is influenced can be effectively avoided, the tools can be prevented from being damaged, and practicability is high.

Owner:漳州市龙文区健达电子科技有限公司

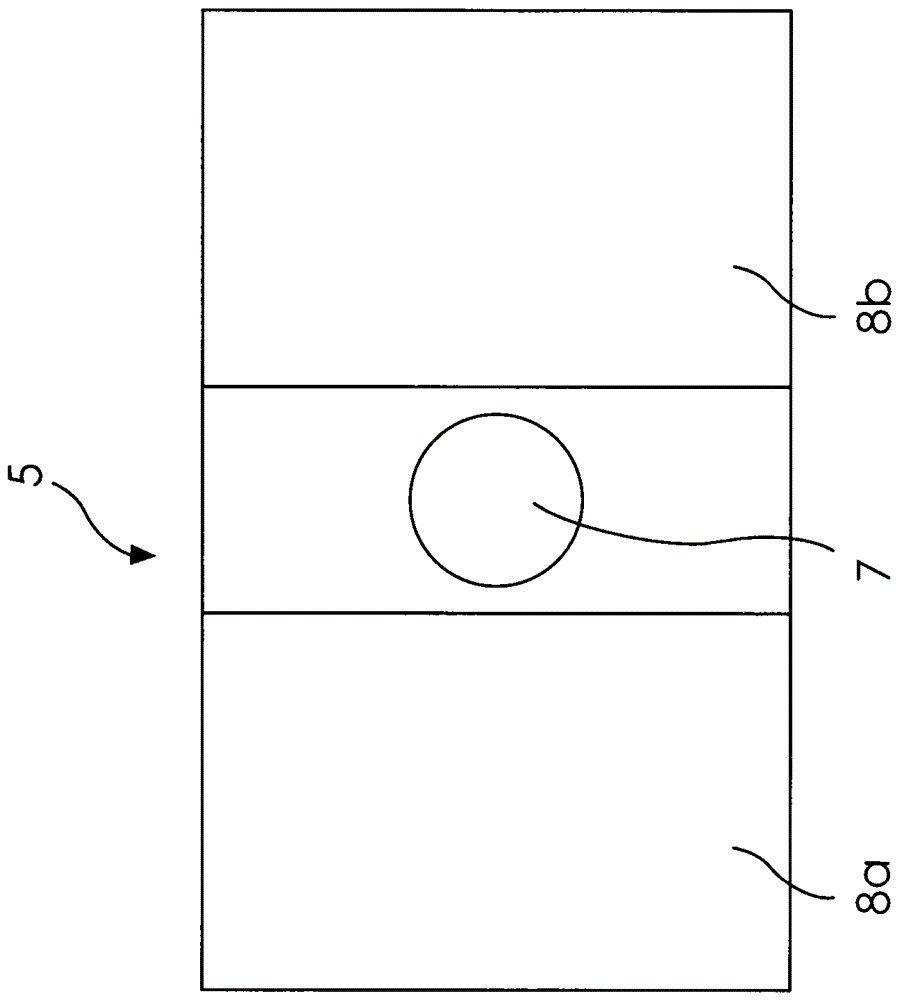

Device for inspecting workpiece surfaces and strip materials

InactiveCN105960589AOptimize layoutAvoid harmful effectsGas cushion bearingsUsing electrical meansUltrasonic levitationEngineering

The invention relates to a device for inspecting workpiece surfaces, having the following features: a sensor (7) which is designed to inspect a workpiece surface, a sonotrode (8a, 8b) which has a sound-radiating surface and is rigidly connected to the sensor (7) in order to form a sensor unit (5), and a movable positioning device (6), which is coupled to the sensor unit (5), for positioning the sensor unit (5) opposite the workpiece surface. The positioning device (6) has pressing means which press the sensor unit (5) in the direction of the workpiece surface, and the sound-radiating surface of the sonotrode (8a, 8b) vibrates ultrasonically such that an ultrasonic levitation force field is produced in the presence of a gaseous medium between the workpiece surface and the sound-radiating surface. The force field generates a counterforce directed against the pressing force, whereby the sensor unit (5) is kept at a distance to the workpiece surface in a hovering manner, and the sensor is designed to detect different physical effects, such as surface-structure deviations or color deviations for example.

Owner:ZS HANDLING

Ultrasonic levitation and air floatation mixed suspension damping device

InactiveCN102518740BReduce tiny low-frequency vibrationsEasy to operateSpringsShock absorbersUltrasonic sensorUltrasonic levitation

The invention relates to a novel ultrasonic levitation and air floatation mixed suspension damping device, fulfills the aim of damping by utilizing the novel ultrasonic levitation and air floatation mixed suspension and belongs to the field of precision driving. An ultrasonic transducer disc is fixedly connected with an ultrasonic transducer. A working platform is fixedly connected with an air floatation bearing. A platform base is fixedly connected with the air floatation bearing. Axial orifices and pressure chambers are distributed on the air floatation bearing. Radial orifices and pressure chambers are distributed on the platform base. The air floatation bearing is placed on the ultrasonic transducer disc. Therefore, the whole connected air floatation bearing is suspended by ultrasonic levitation and air floatation. In the mixed suspension process, the ultrasonic levitation improves the cyclone phenomenon and the vibration of a pneumatic hammer when an air floatation device independently works. The novel mixed suspension device has the advantages that the novel ultrasonic levitation and air floatation mixed suspension damping device is easy to operate, has simple structure and has higher suspension rigidity than the single air floatation device which independently works; and the micro low frequency vibration of the air floatation device is reduced.

Owner:JILIN UNIV

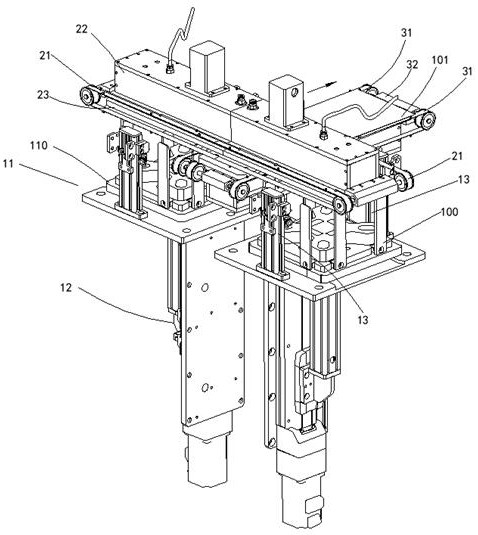

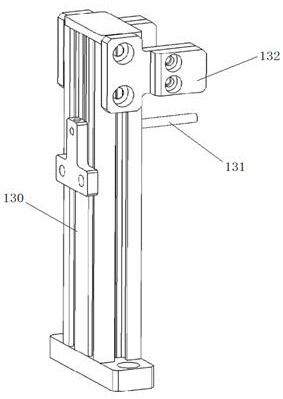

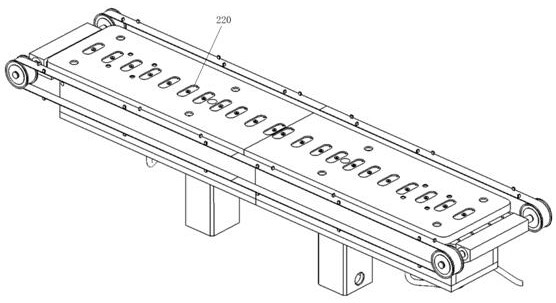

Material box type silicon wafer transfer mechanism

PendingCN112234010ACompact structureSmall footprintFinal product manufactureSemiconductor/solid-state device manufacturingUltrasonic levitationSolar battery

The invention discloses a material box type silicon wafer transfer mechanism which comprises a silicon wafer separation module, a silicon wafer transfer module and a silicon wafer conveying module, and is characterized in that the silicon wafer separation module transfers stacked silicon wafers in a material box to the silicon wafer transfer module one by one; the silicon wafers are conveyed to the silicon wafer transfer module through a first ultrasonic suspension conveying belt in a suspended mode and are conveyed to a lower-section station by a second ultrasonic suspension conveying belt. According to the material box type silicon wafer transfer mechanism, the non-contact type conveying of the material box type solar cell silicon wafers is achieved, the transferring efficiency of transferring the material box type silicon wafers is improved, the problems of cracking, damage, scratching, pollution and the like of the silicon wafers can be effectively avoided, the quality of the silicon wafers is improved, resource waste is reduced, and the material box type silicon wafer transfer mechanism is compact in structure and small in occupied space.

Owner:苏州映真智能科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com