Ultrasonic suspension separator

A separator and ultrasonic technology, applied in the direction of precipitation separation, separation methods, chemical instruments and methods, etc., can solve problems such as layering or precipitation, affecting quality, differences in mechanical properties and processing performance, and achieve the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] An ultrasonic suspension separator proposed by the present invention will be further described in detail below through specific implementation methods. Those skilled in the art can understand and implement the technical solution of the present invention, and can also achieve the effects of the present invention.

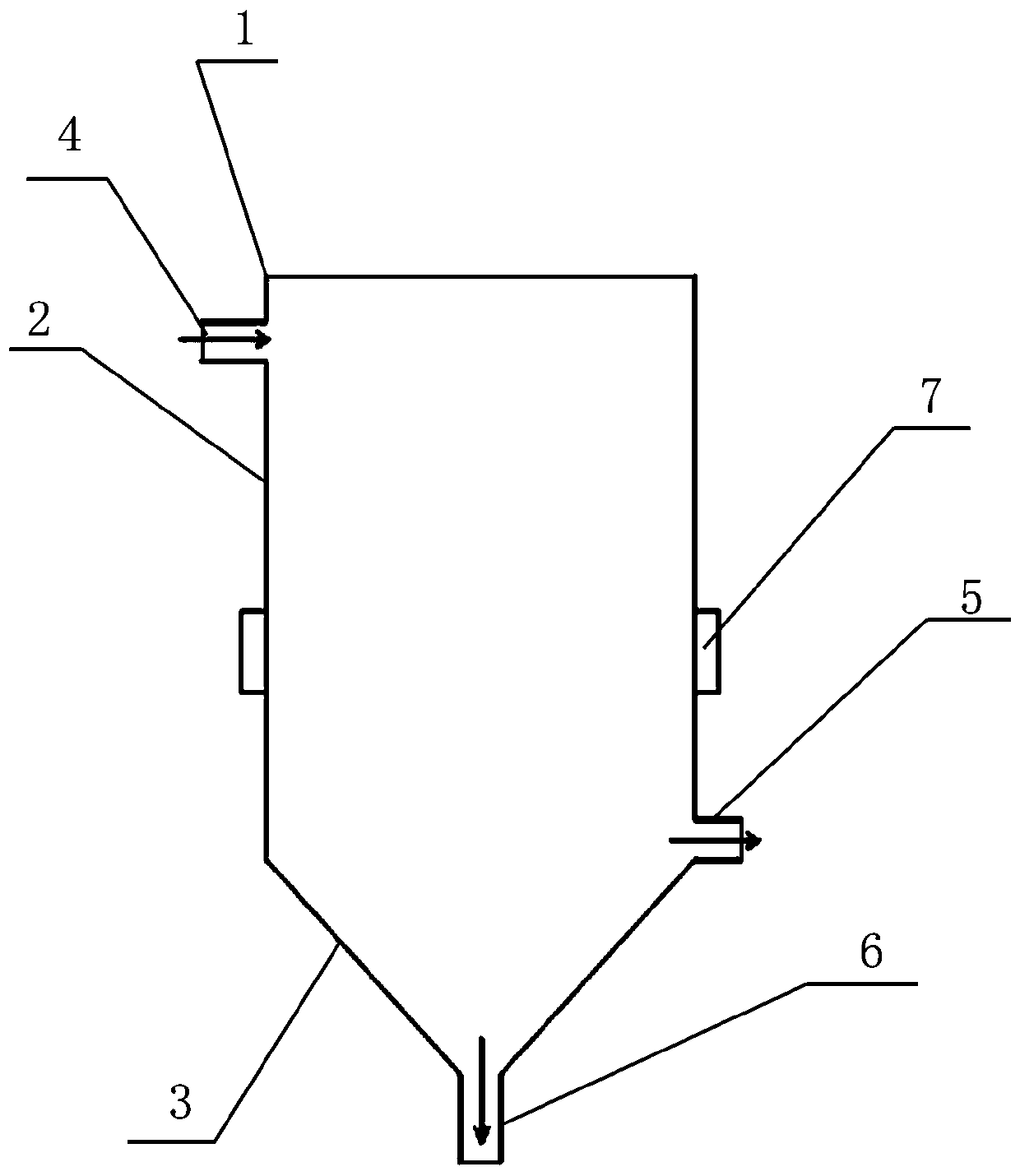

[0009] exist figure 1 Among them, the present invention provides an ultrasonic suspension separator, which includes a separator housing 1, the upper part of the separator housing 1 is set as a main chamber 2, and the main chamber 2 is set as a cylindrical main chamber , the bottom of the separator housing 1 is set as a separation chamber 3, the main chamber 2 communicates with the separation chamber 3, the side of the main chamber 2 top is provided with a suspension stock solution inlet 4, and the main chamber 2 and the separation chamber The separation liquid outlet 5 is provided at the boundary between the 3, and the sediment outlet 6 is provided at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com