Piezoelectric ultrasonic/high-frequency electromagnetic hybrid suspension non-contact smelting method and device

A high-frequency electromagnetic and ultrasonic technology, applied in the field of piezoelectric ultrasonic/high-frequency electromagnetic hybrid suspension non-contact melting, can solve the problems of non-contact cooling and material non-contact cooling, and achieve the effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

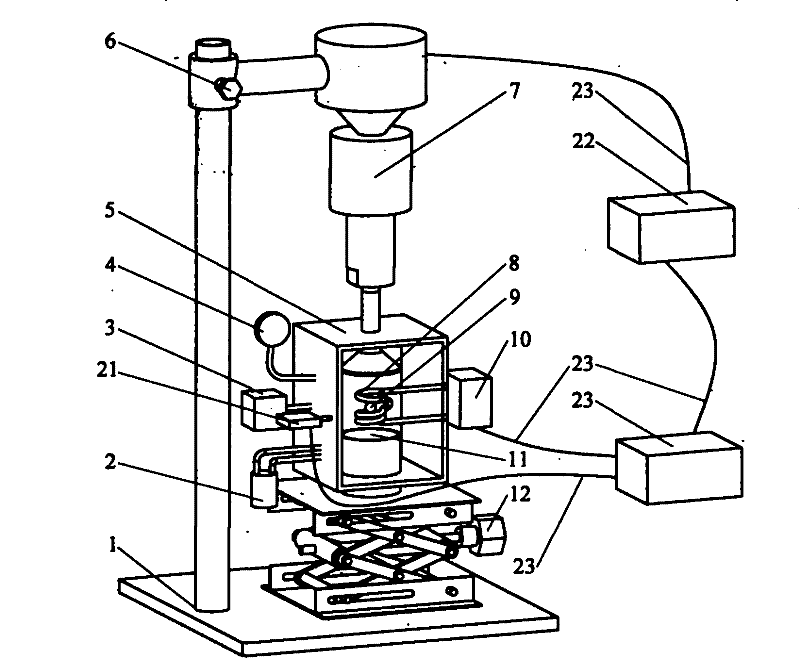

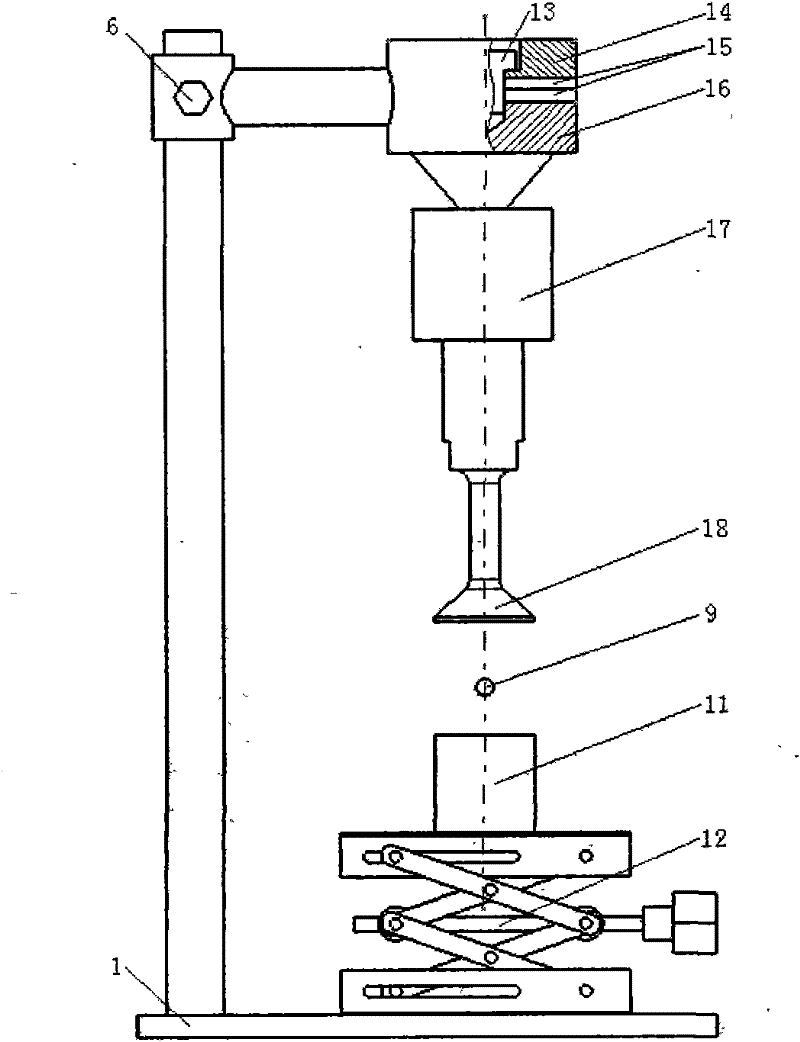

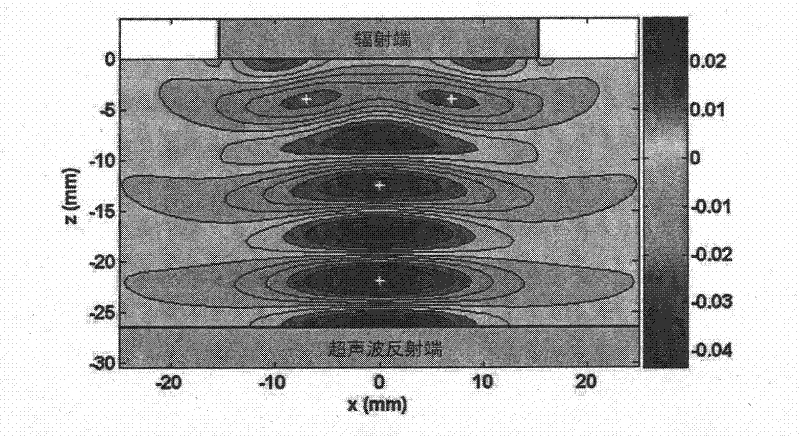

[0022] One embodiment of the present invention is: the air pumping and inflating equipment sucks out the air in the sealed box, and then rushes into the sealed box with inert gas, and the pressure change in the sealed box can be read through the pressure gauge during the process of pumping and inflating. The metal alloy particles are pre-placed on the surface of the ultrasonic reflection end. After the ultrasonic generator is turned on, the distance between the ultrasonic reflection end and the radiation end is adjusted by the ultrasonic reflection end adjustment device, so that the metal alloy particles are suspended, and the suspension position coincides with the position of the electromagnetic suspension. , turn on the high-frequency power supply, the high-frequency inductor generates a changing magnetic field, and interacts with the suspended particles to generate eddy currents, which react against the high-frequency magnetic field to generate electromagnetic force on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com