Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Thin disc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

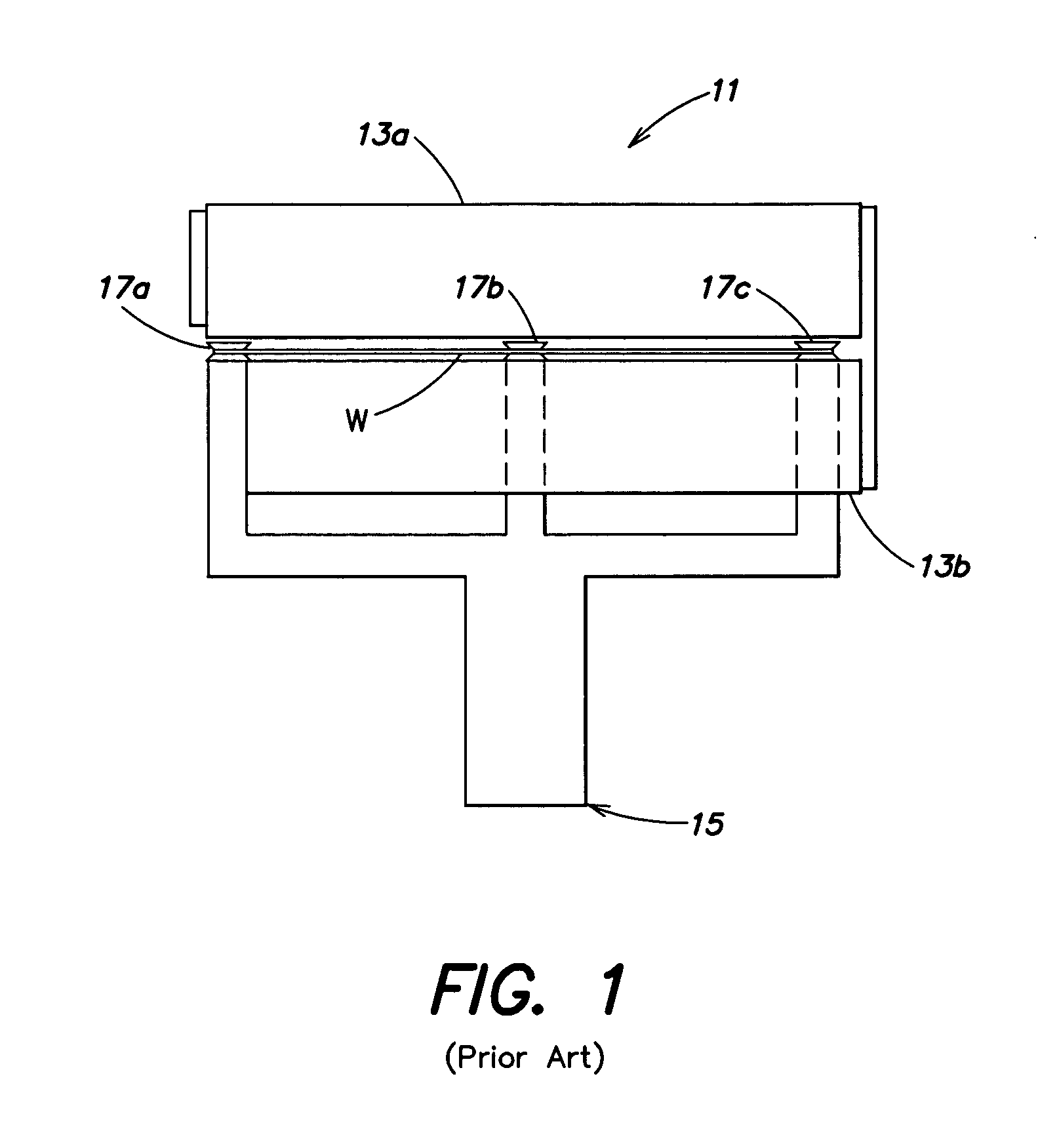

Low cost high-pressure sensor

InactiveUS20070095144A1Low costLess materialFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesPressure senseHigh pressure

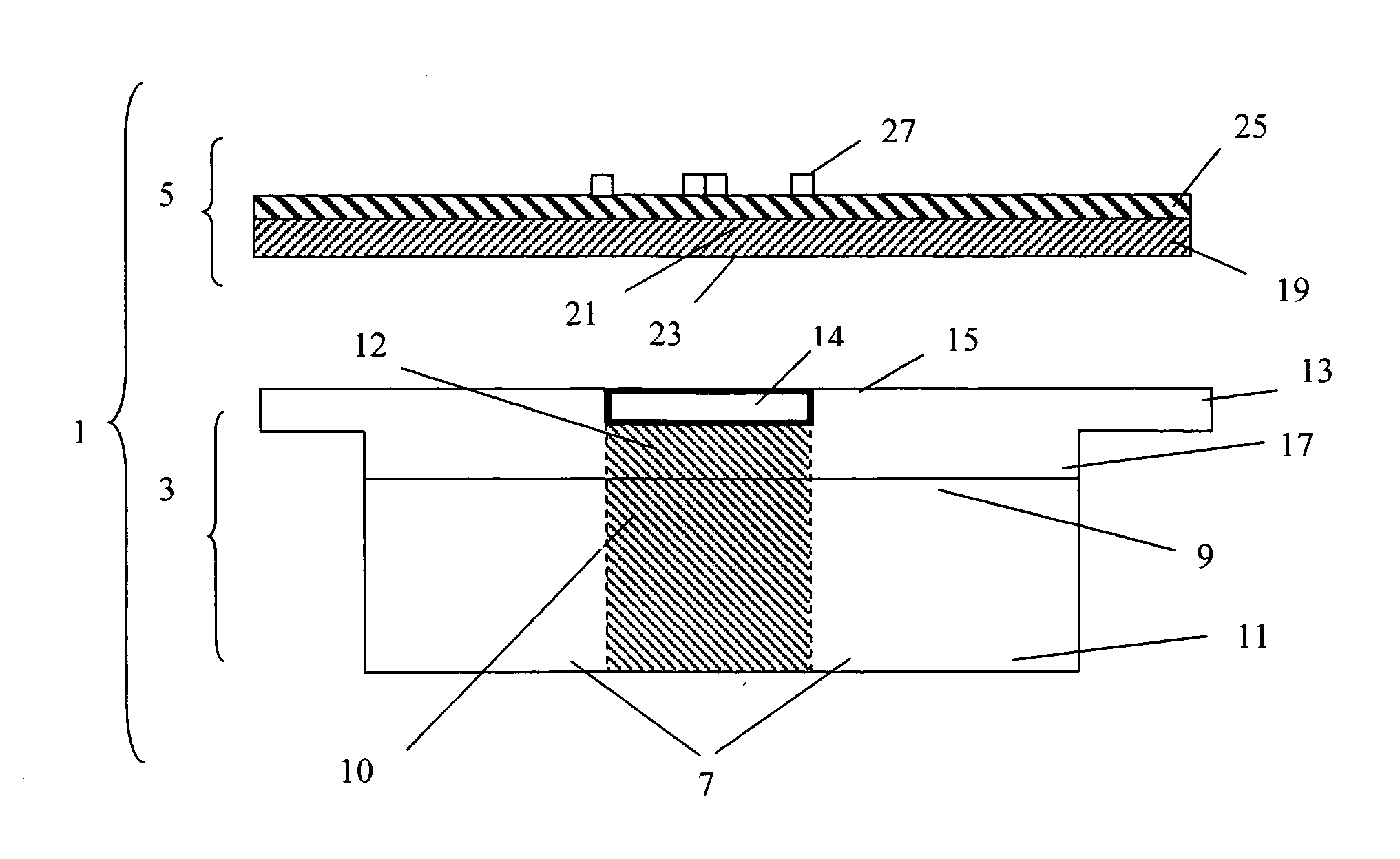

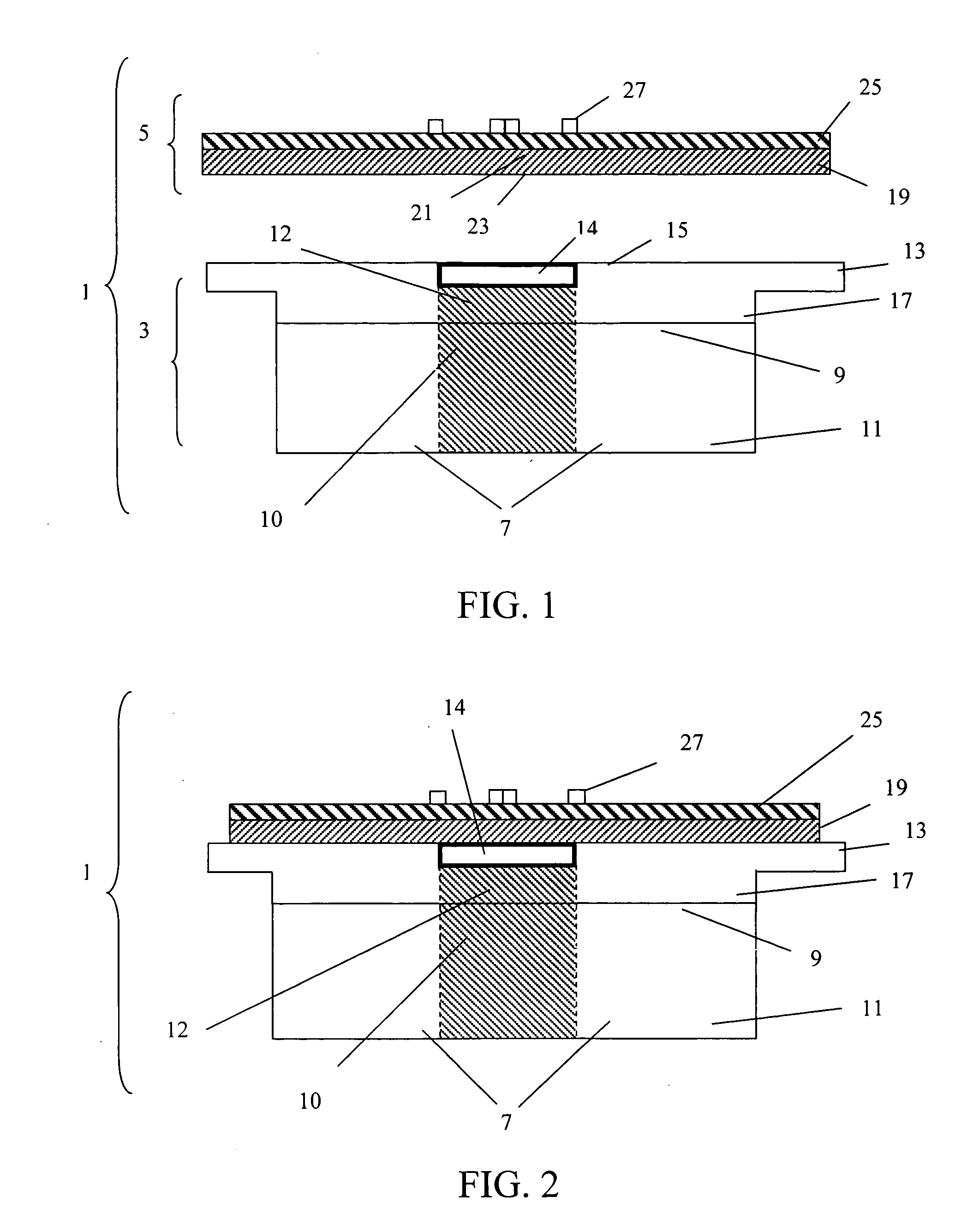

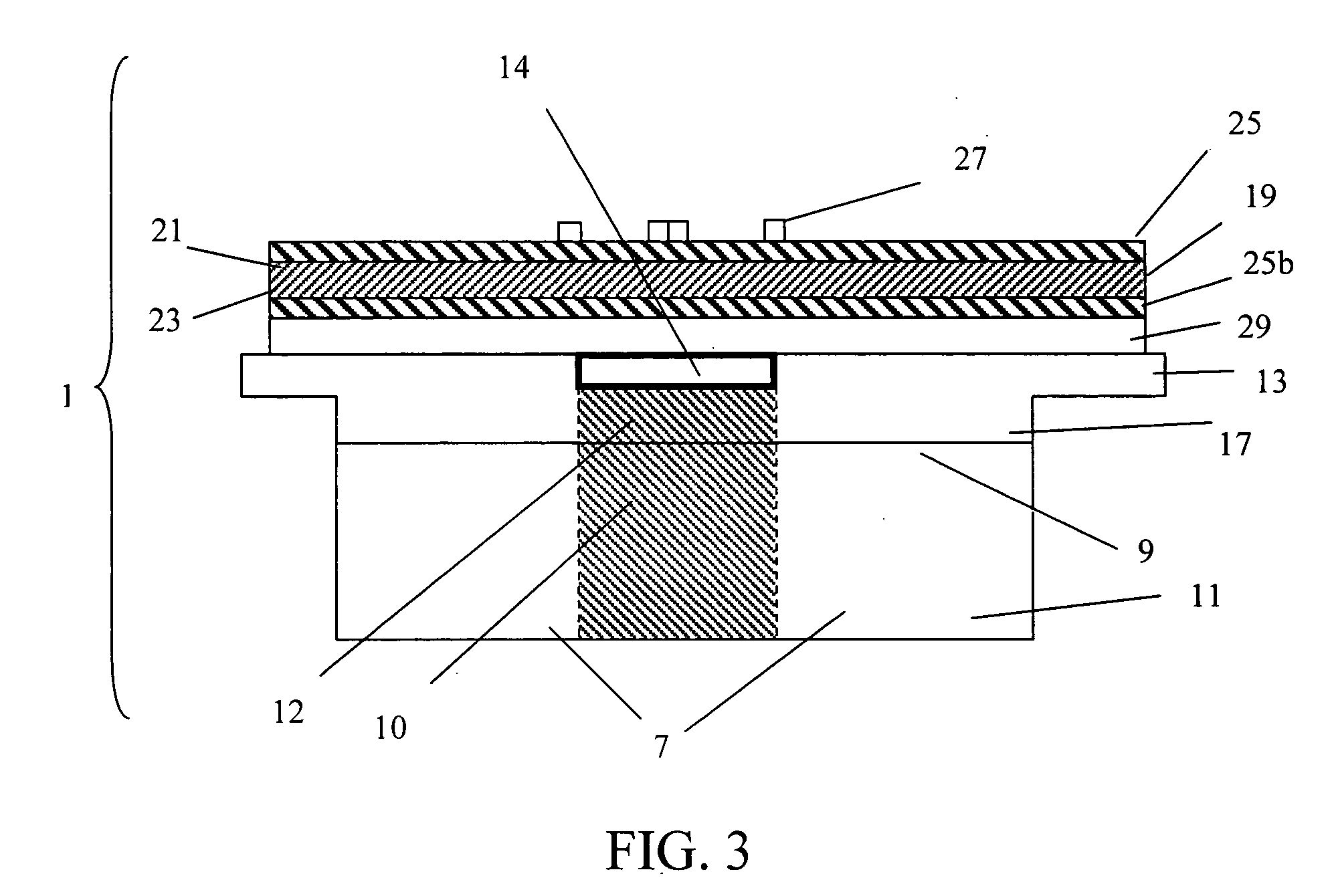

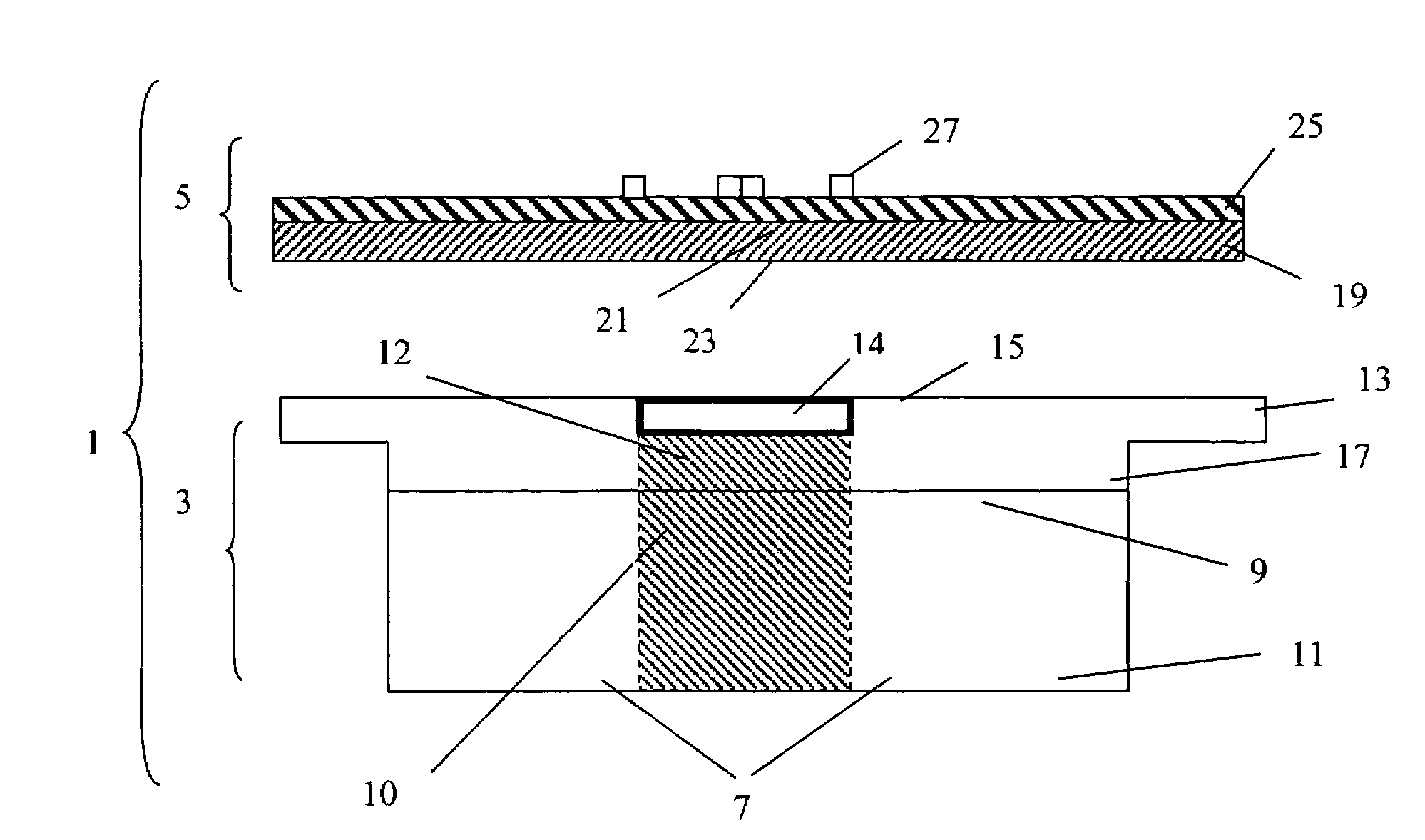

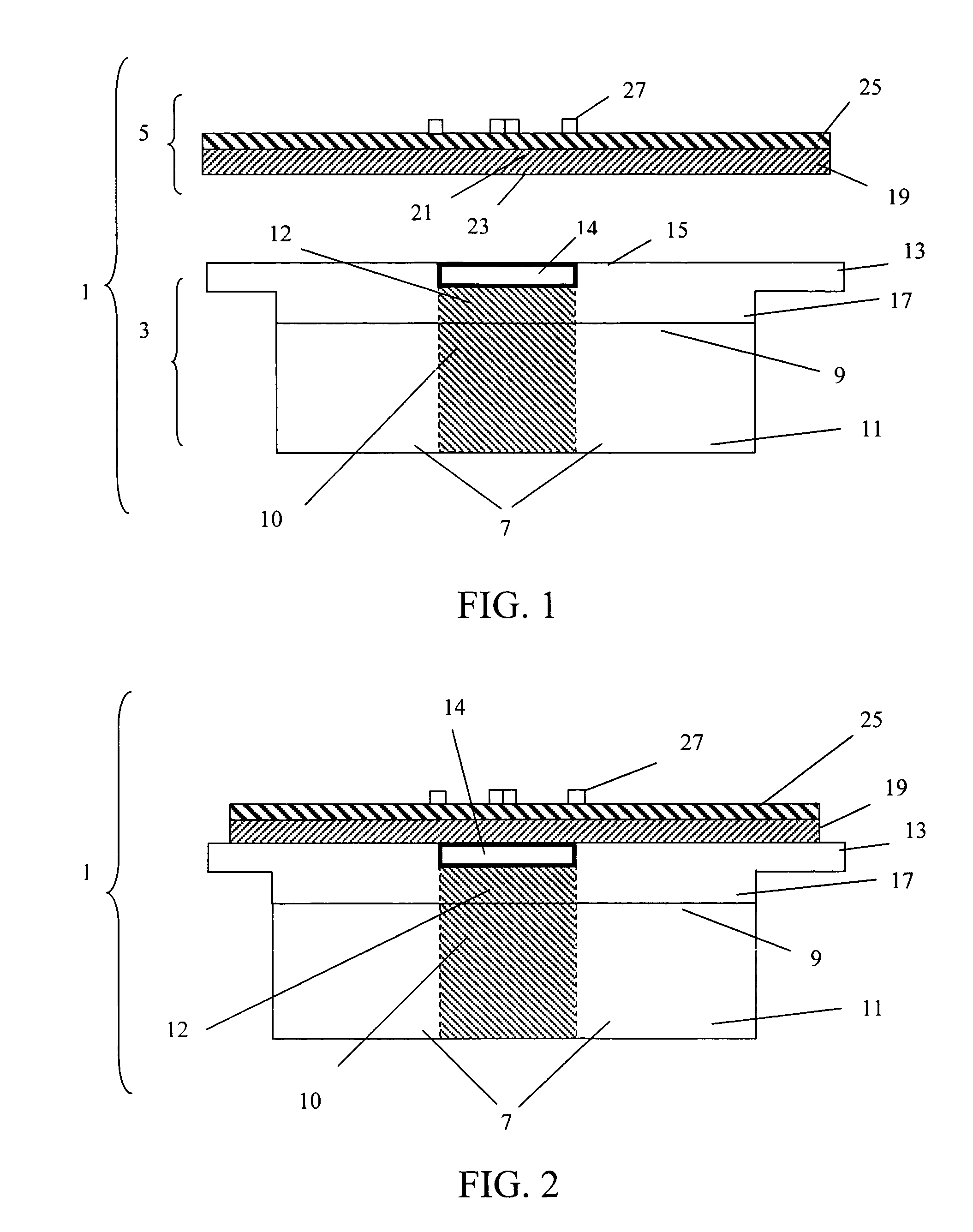

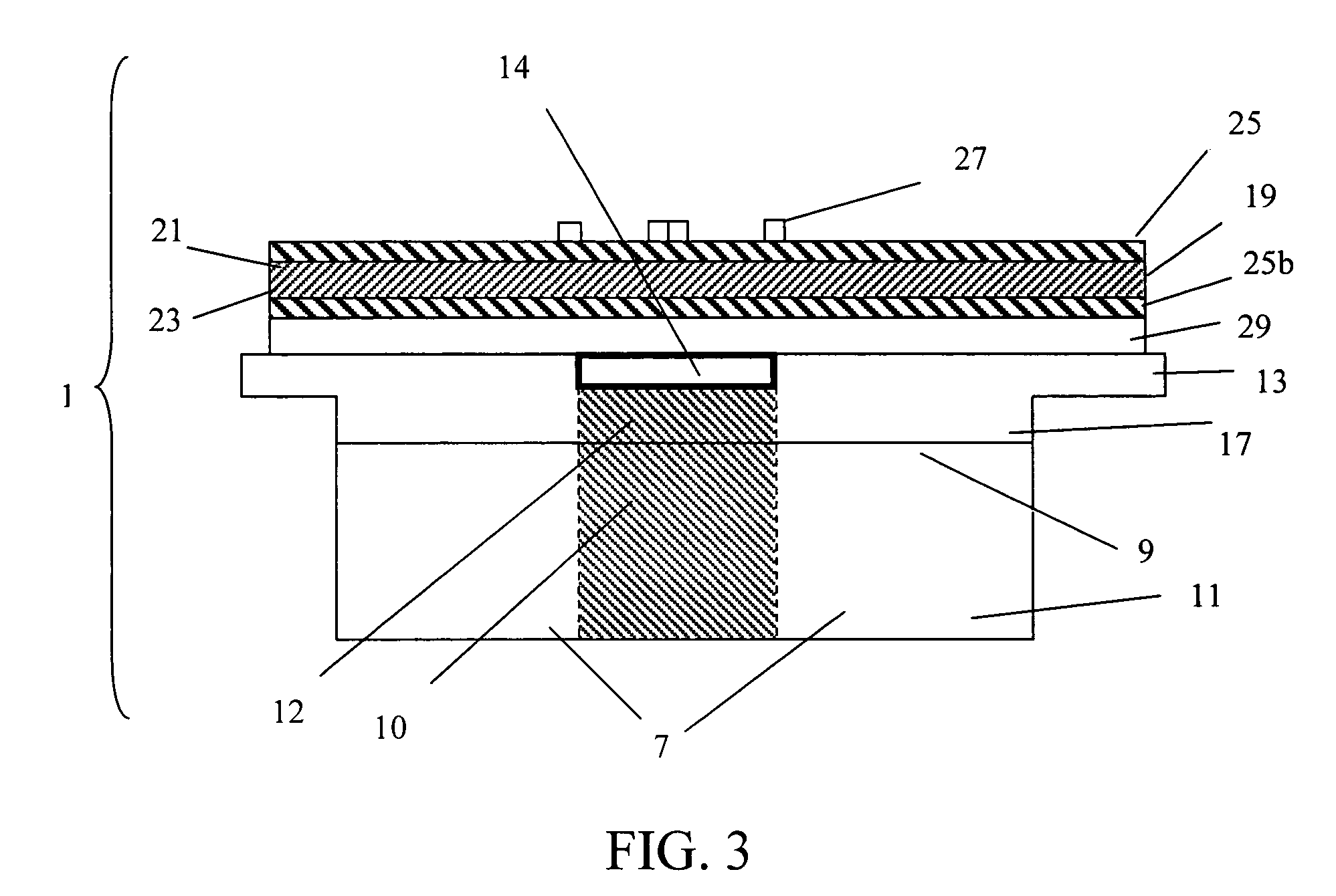

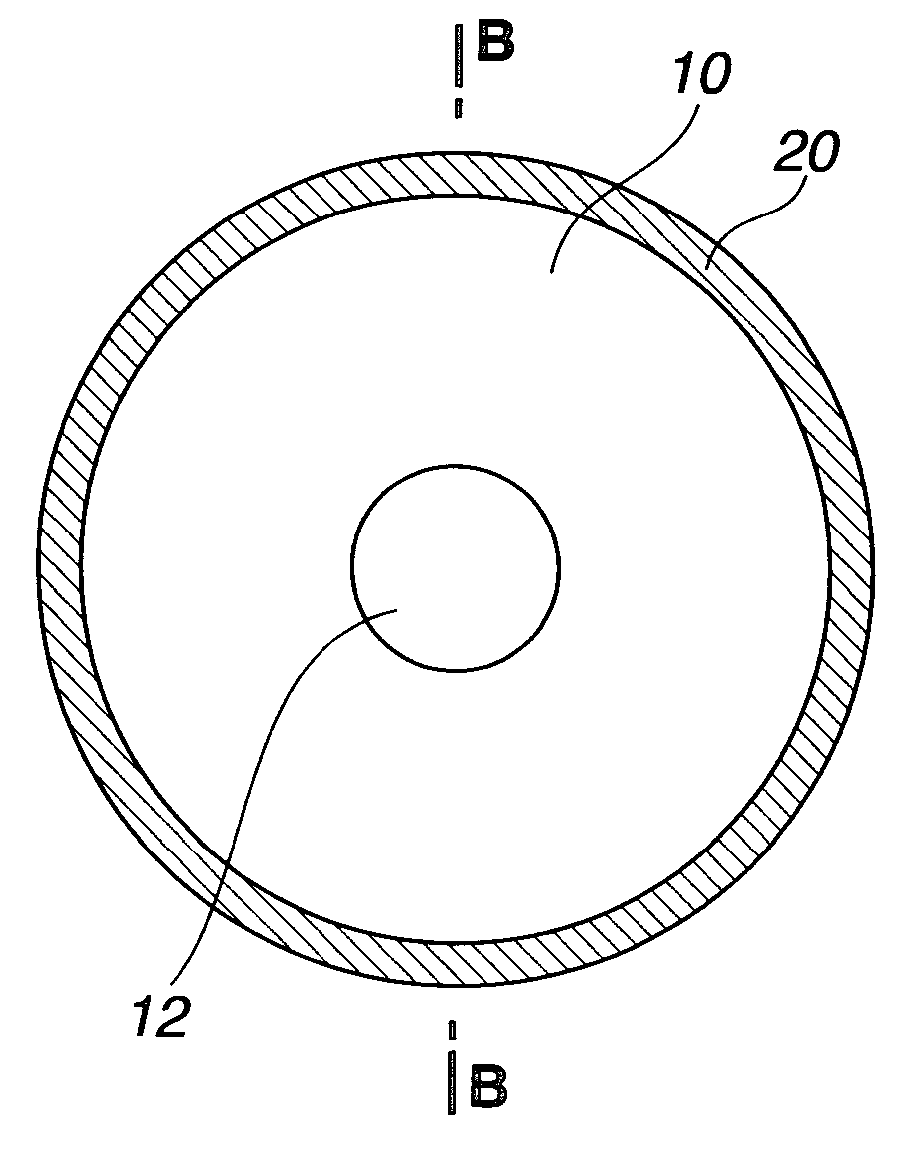

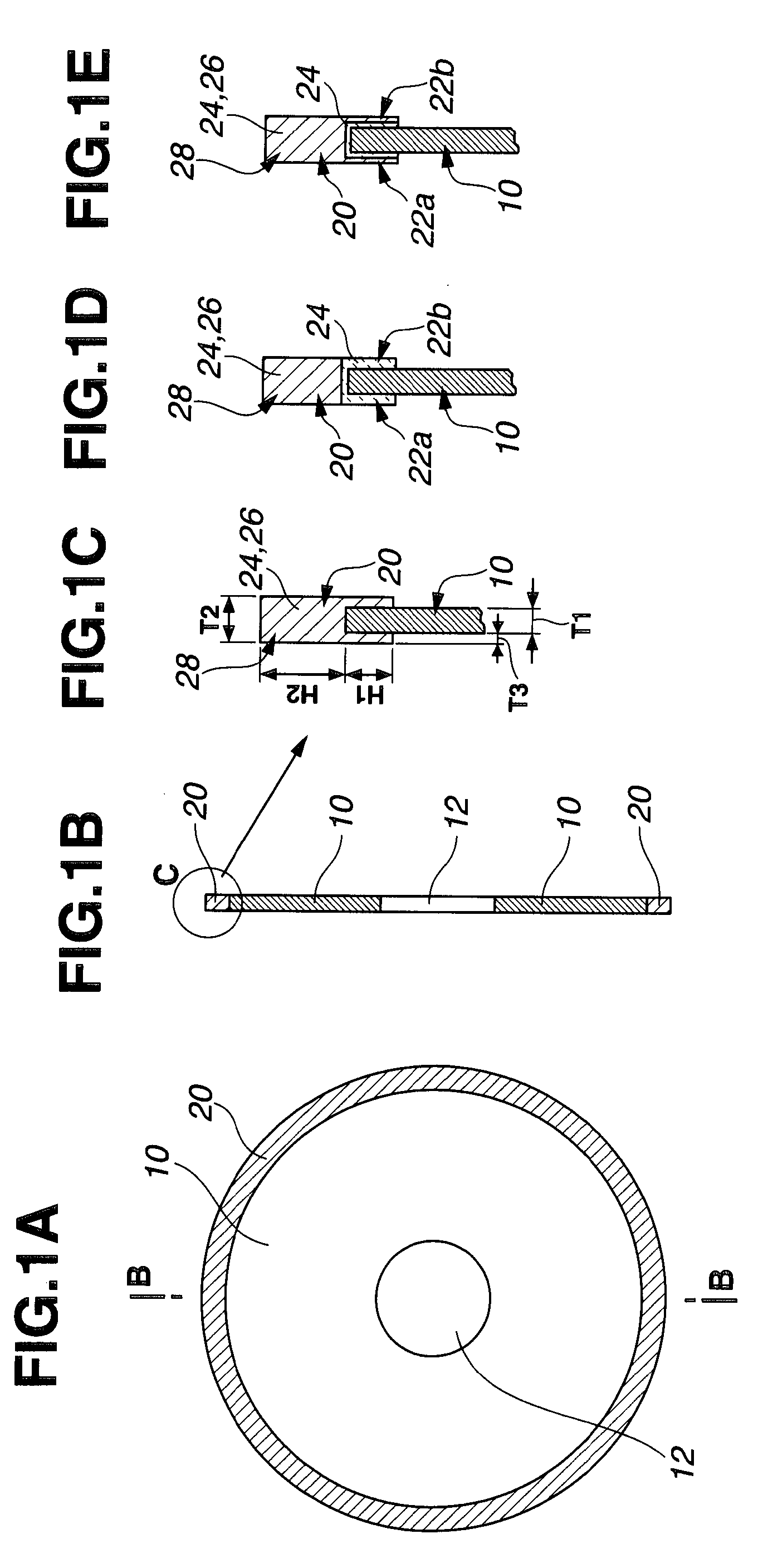

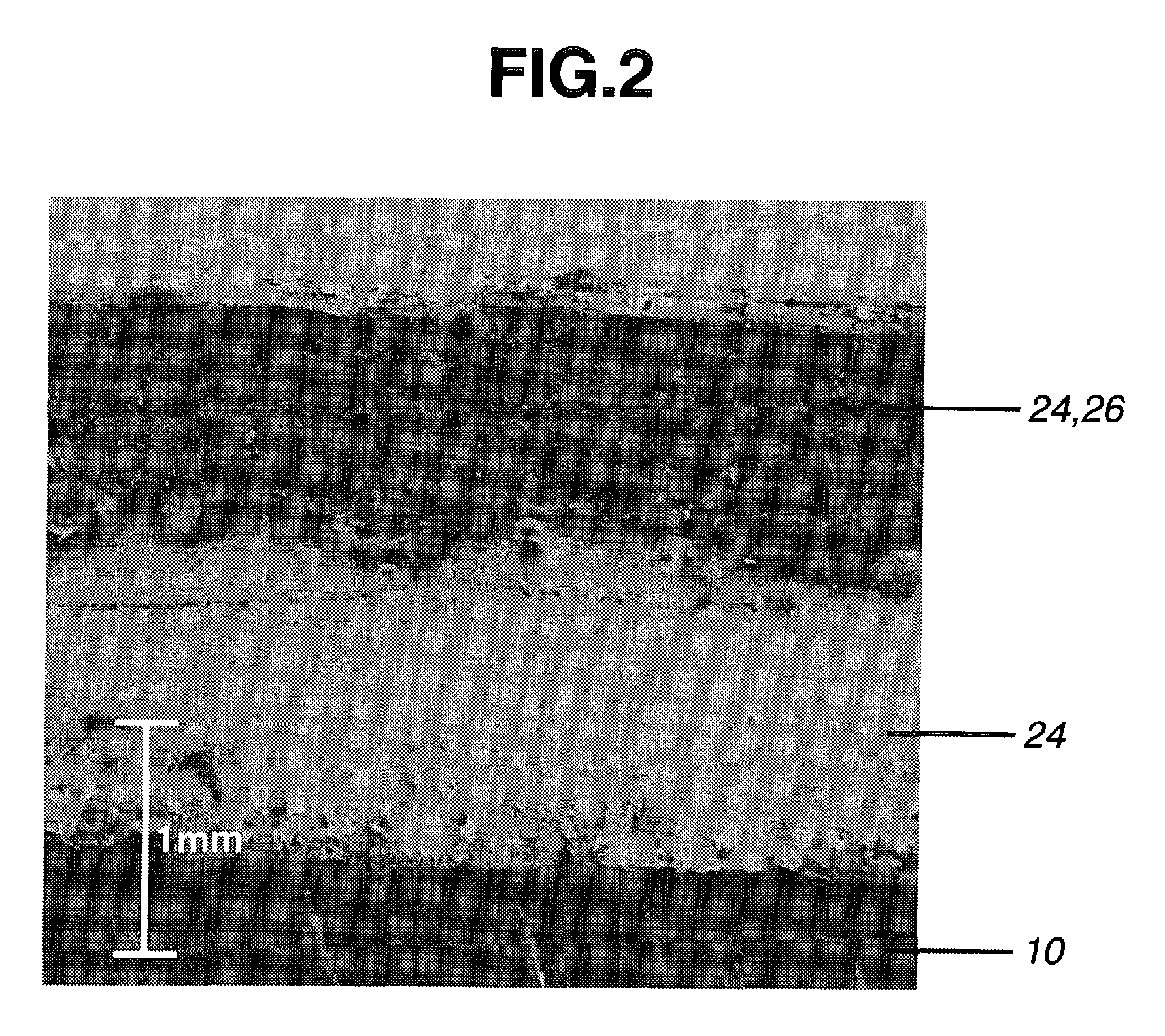

A pressure sensing apparatus including a thin disc of a metal having a ceramic material layer and piezoresistive elements formed thereon. A surface of the disc is bonded to a diaphragm assembly on a pressure port base constructed of a low cost metal. The bonding process is performed at low temperatures, (<700° C.), so that the diaphragm assembly and pressure port do not require high temperature corrosion resistance, and can thus be formed of less expensive materials. The inventive apparatus provides a lower cost alternative to conventional high pressure sensors since less material is used, less expensive materials are used, and fabrication is less complex. The inventive apparatus is also more reliable and exhibits greater thermal stability than conventional high pressure sensors.

Owner:HONEYWELL INT INC

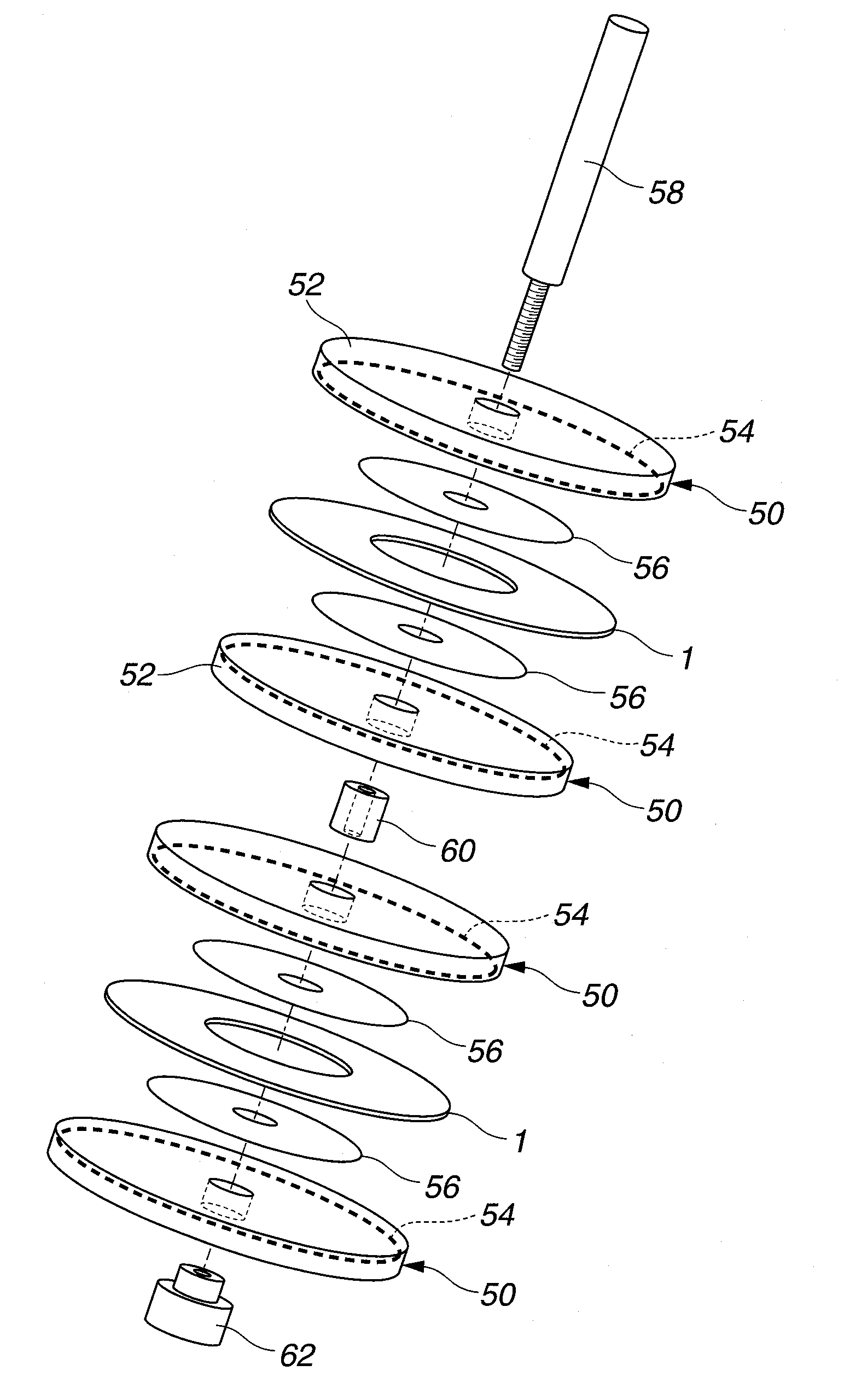

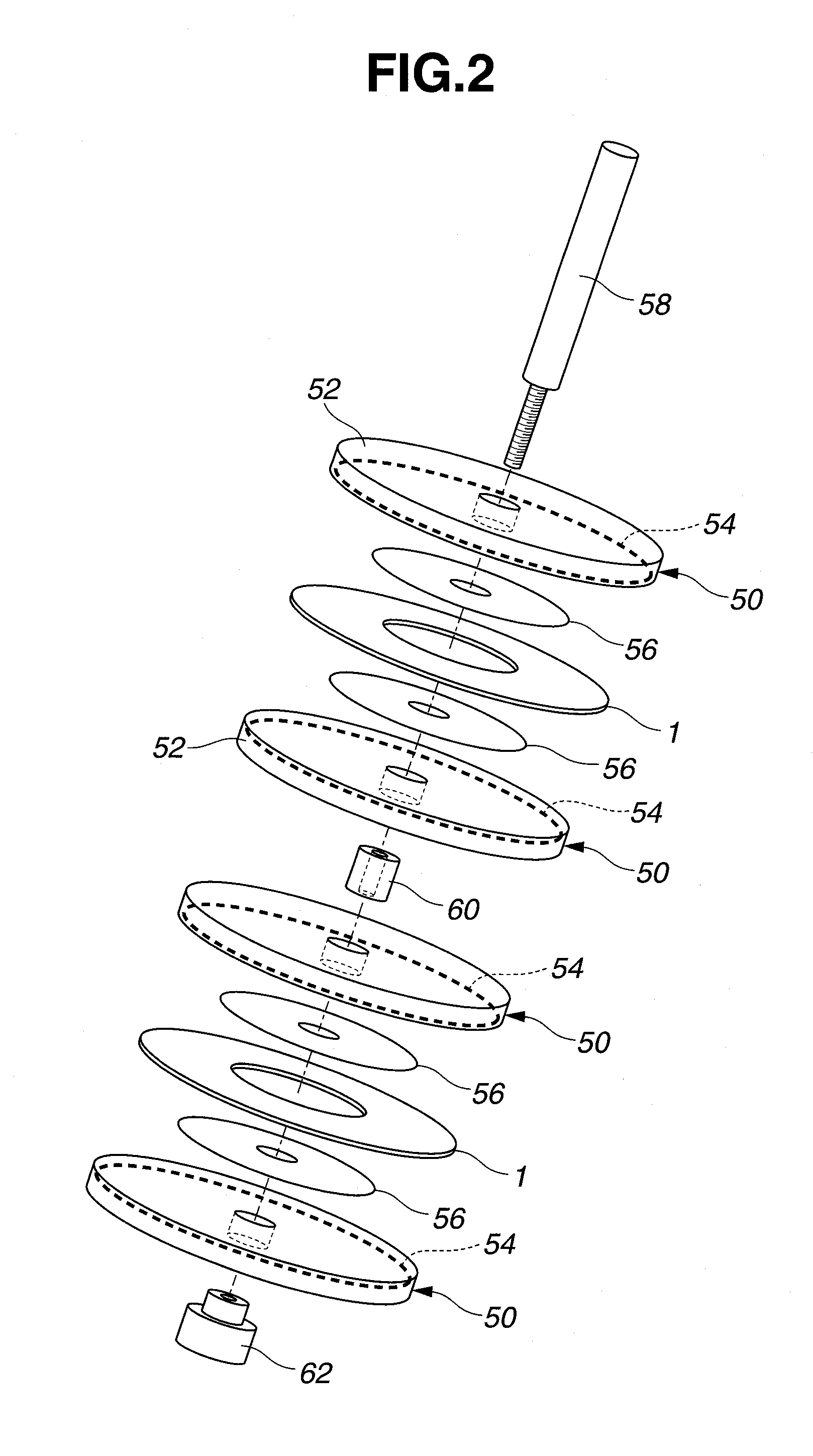

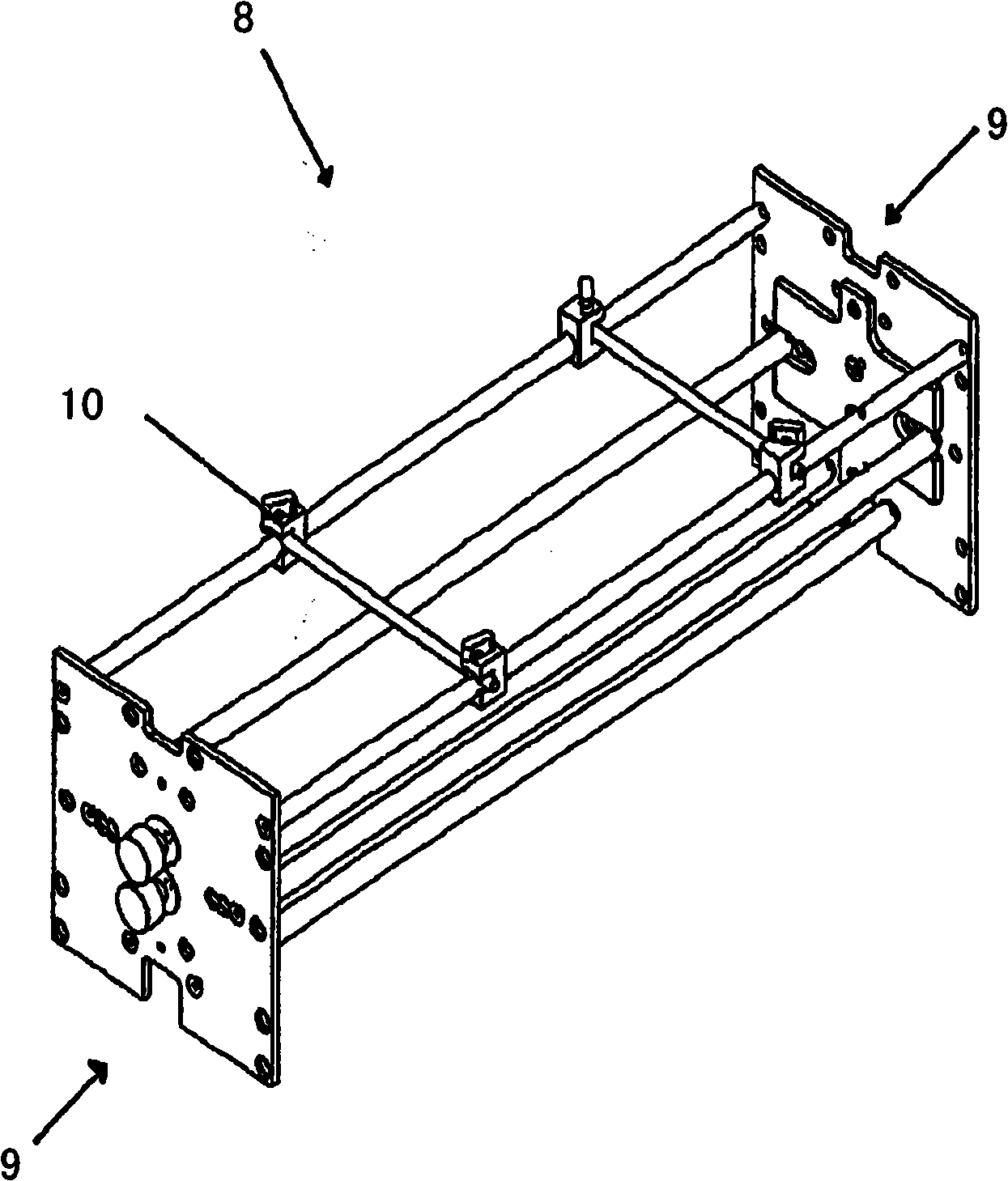

Method and jig assembly for manufacturing outer blade cutting wheel

ActiveUS20100275522A1Low costHigh yieldElectrolysis componentsElectrolytic coatingsCemented carbideElectroplating

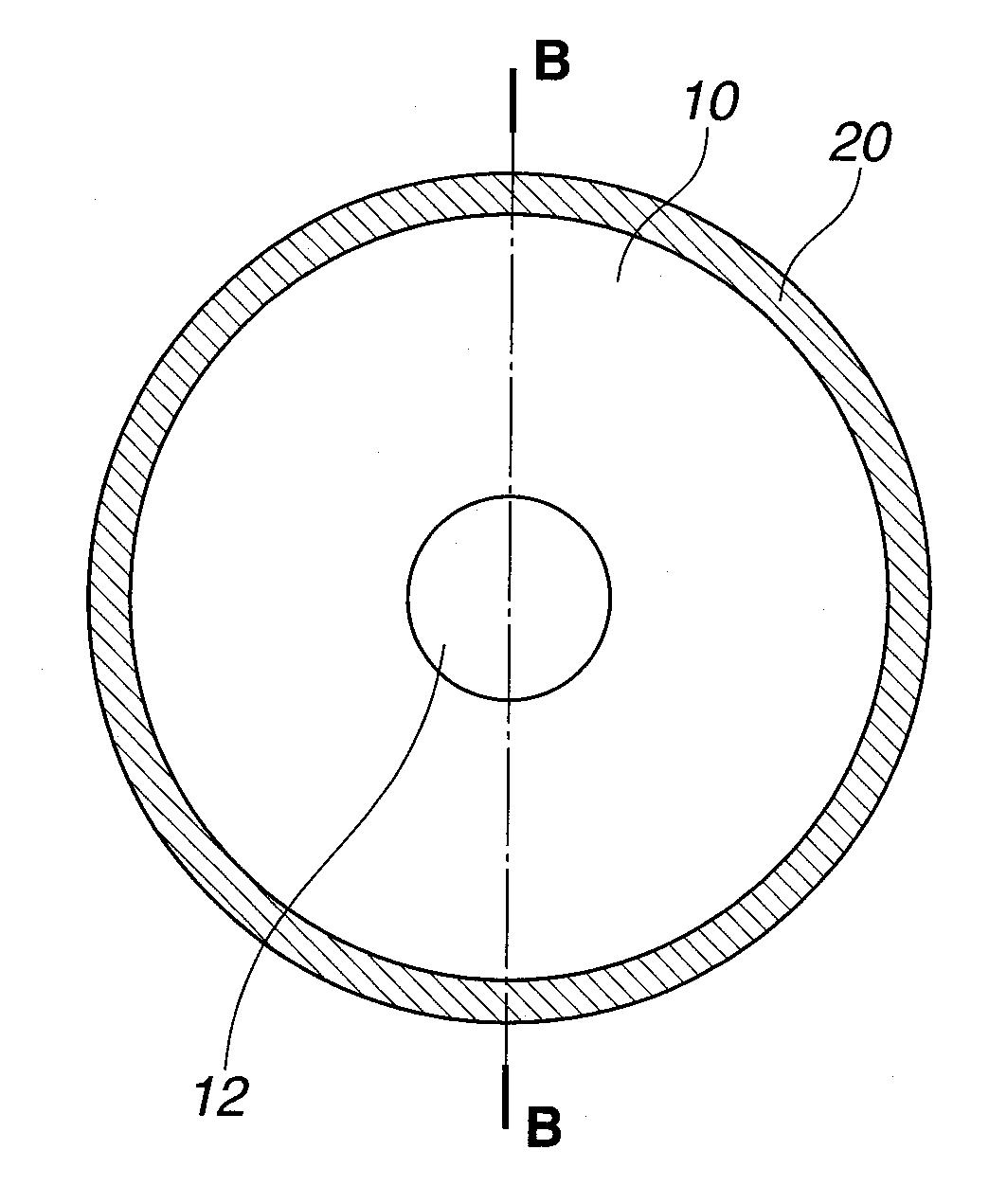

An outer blade cutting wheel comprising an annular thin disc base of cemented carbide and a blade section is manufactured by disposing permanent magnet pieces on the side surfaces and inward of the outer periphery of the base to produce a magnetic field, providing magnetic coated diamond and / or CBN abrasive grains such that the magnetic field may act on the grains, causing the grains to be magnetically attracted to the base outer periphery, and electroplating or electroless plating whereby the abrasive grains are bound to the base outer periphery to form the blade section.

Owner:SHIN ETSU CHEM IND CO LTD

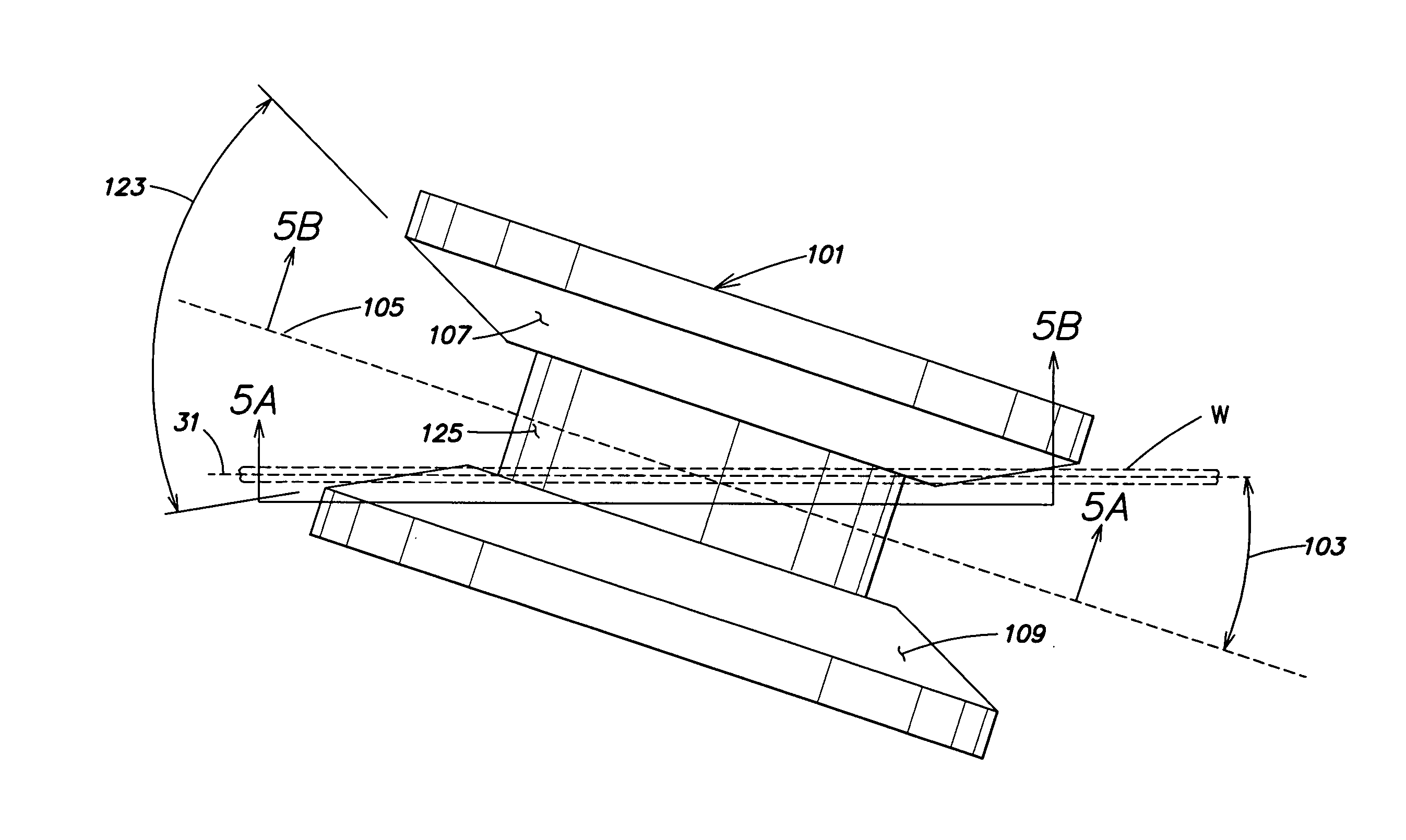

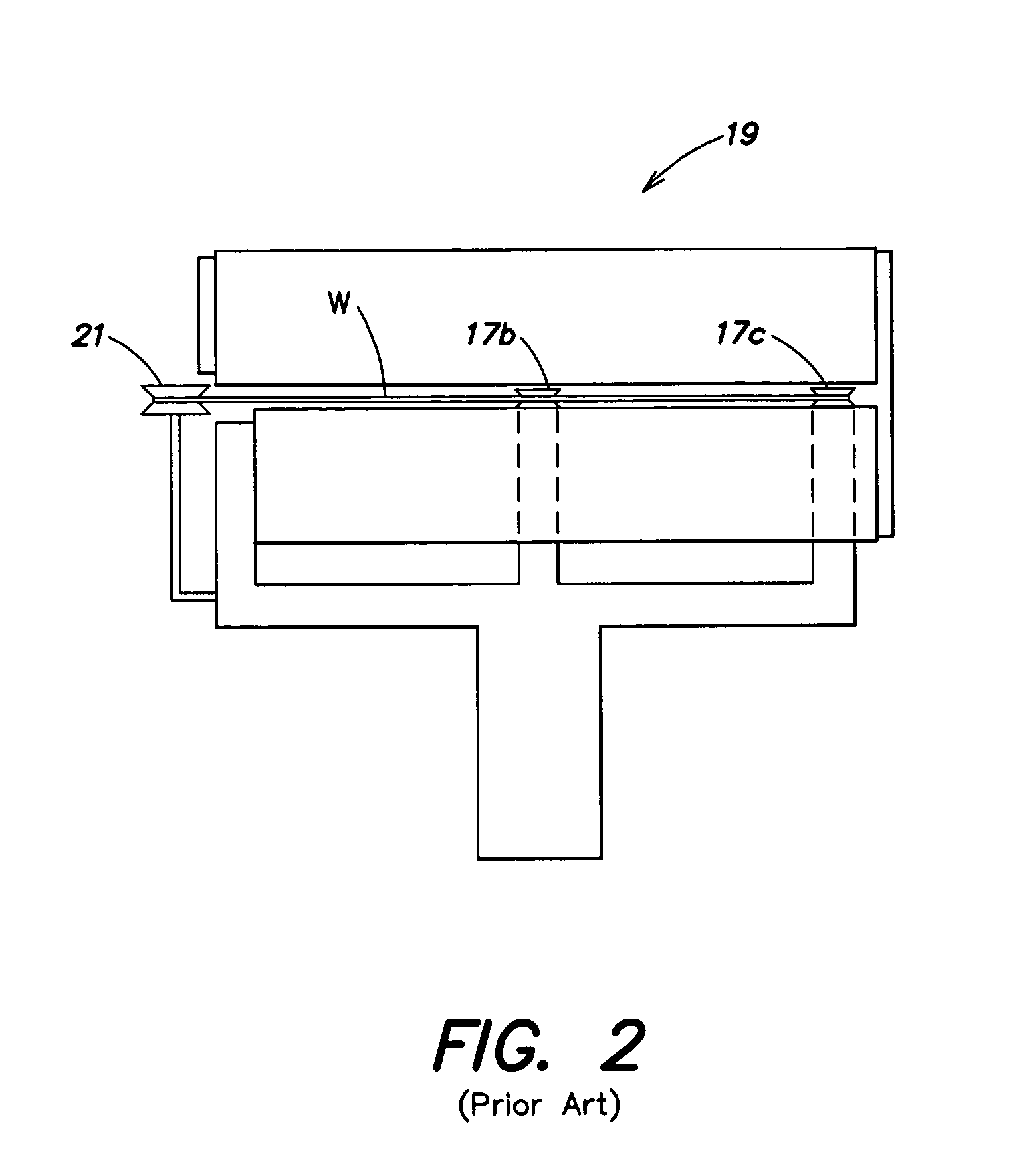

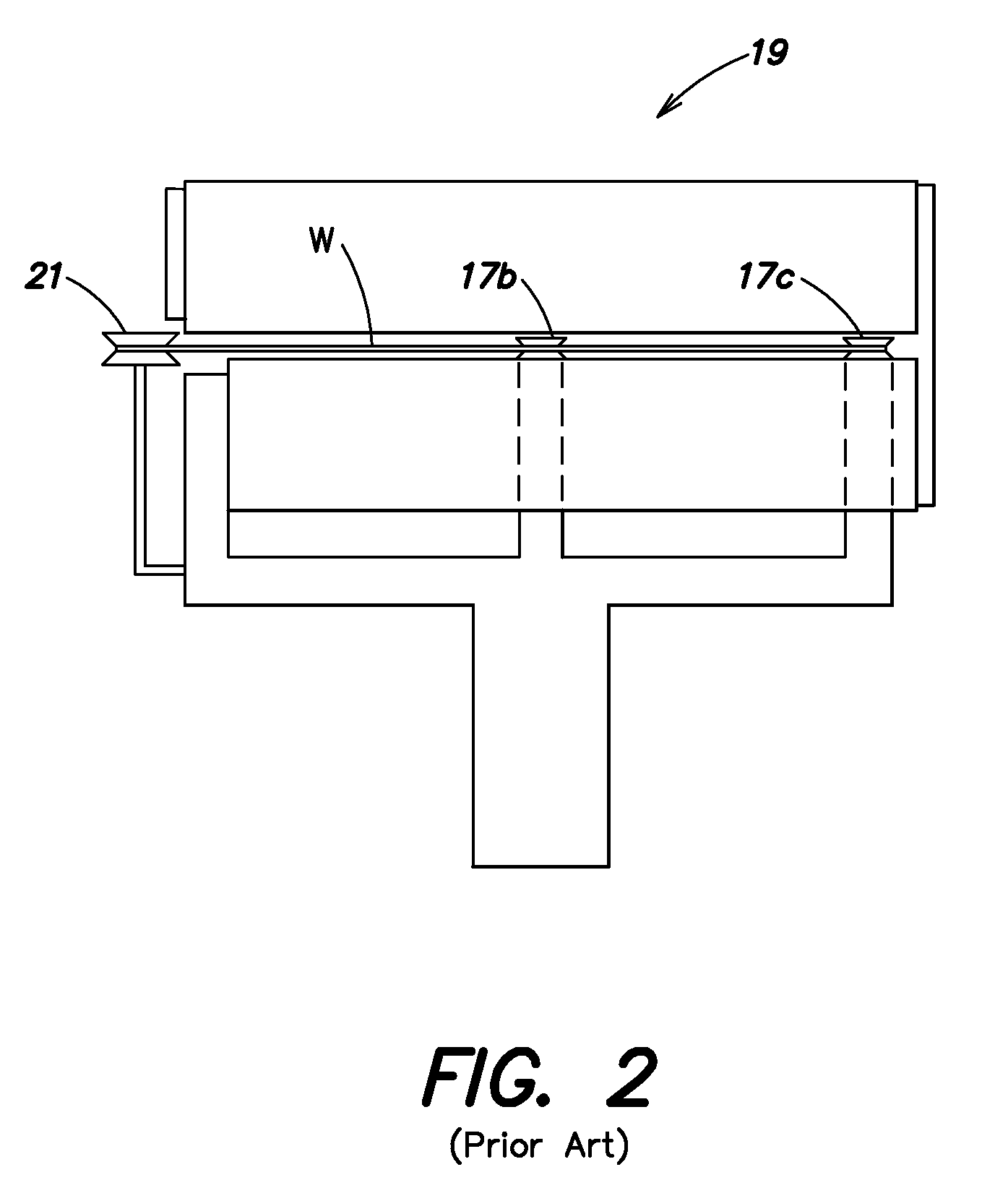

Wafer edge cleaning

InactiveUS20050172430A1Edge grinding machinesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:APPLIED MATERIALS INC

Low cost high-pressure sensor

InactiveUS7260994B2Low costLess materialFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesPressure senseBonding process

Owner:HONEYWELL INT INC

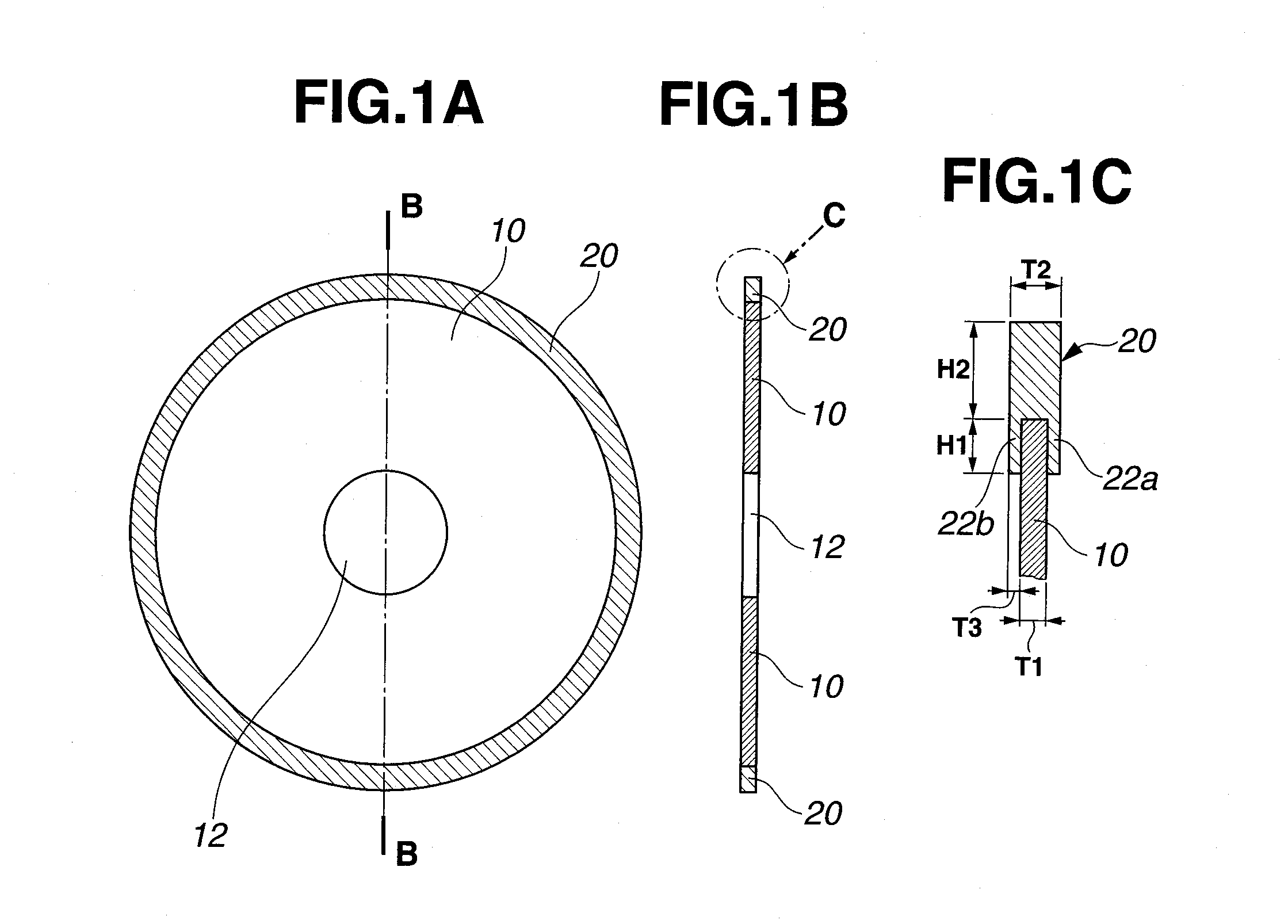

Outer blade cutting wheel and making method

ActiveUS20090165768A1High mechanical strengthImprove naturePigmenting treatmentRevolution surface grinding machinesYoung's modulusAlloy

In an outer blade cutting wheel comprising an annular thin disc base of cemented carbide having an outer diameter of 80-200 mm, an inner diameter of 30-80 mm, and a thickness of 0.1-1.0 mm, and a blade section disposed on an outer periphery of the base, the blade section comprises diamond grains and / or CBN grains bound with a metal bond having a Young's modulus of 0.7-4.0×1011 Pa and has a thickness which is greater than the thickness of the base by at least 0.01 mm. The outer blade cutting wheel is capable of cutting a workpiece at a high accuracy and a reduced allowance, improves machining yields, and reduces machining costs.

Owner:SHIN ETSU CHEM IND CO LTD

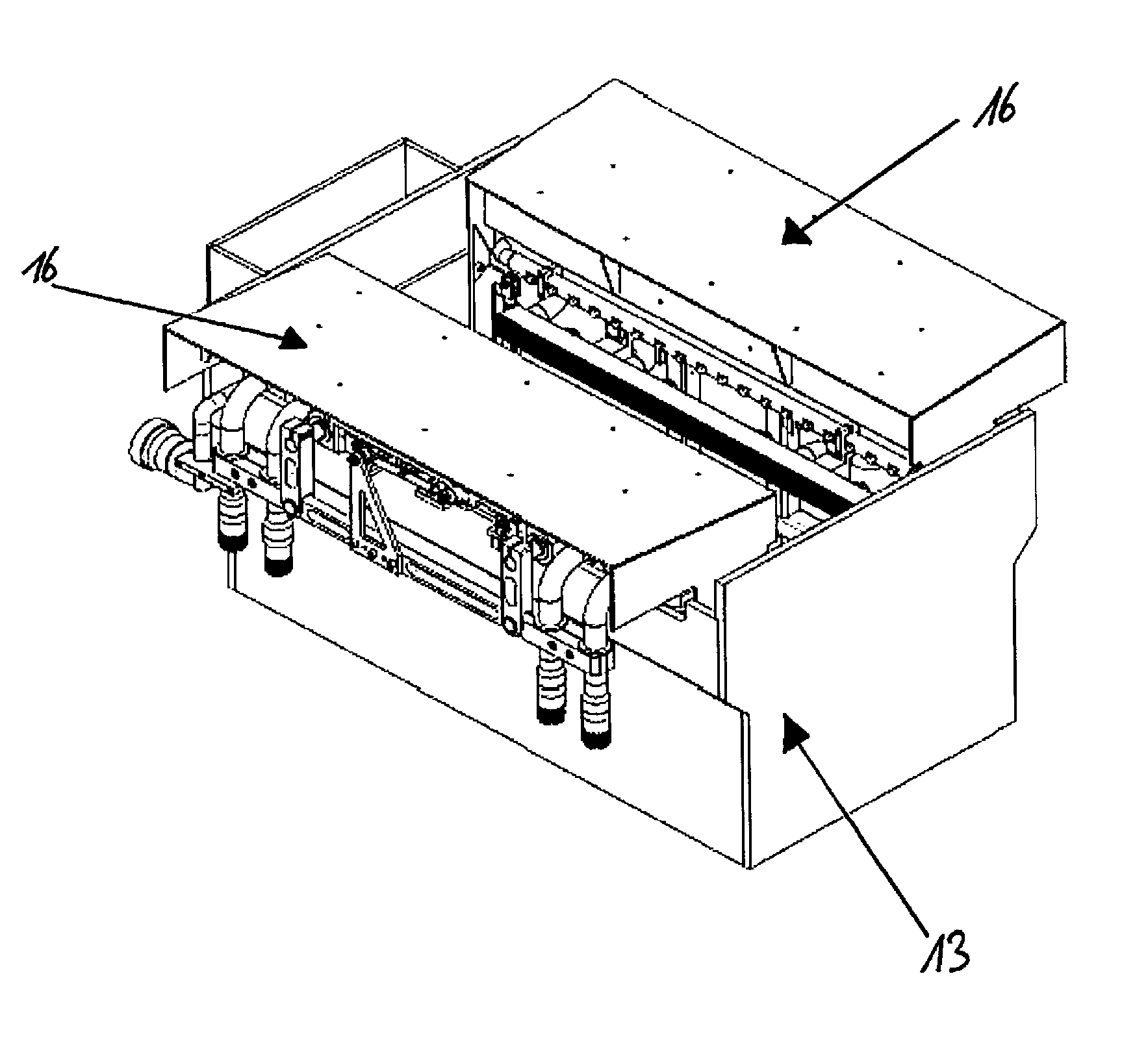

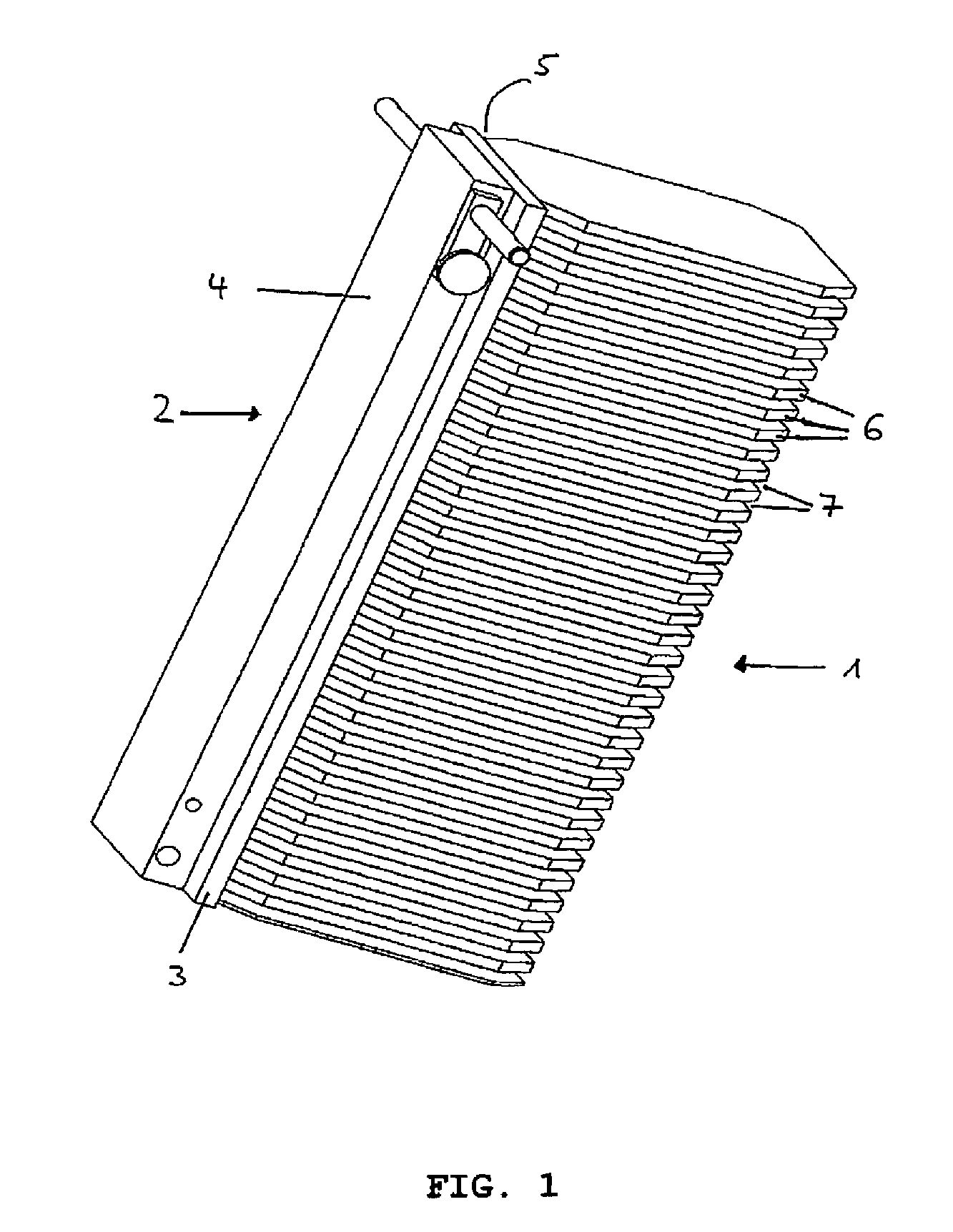

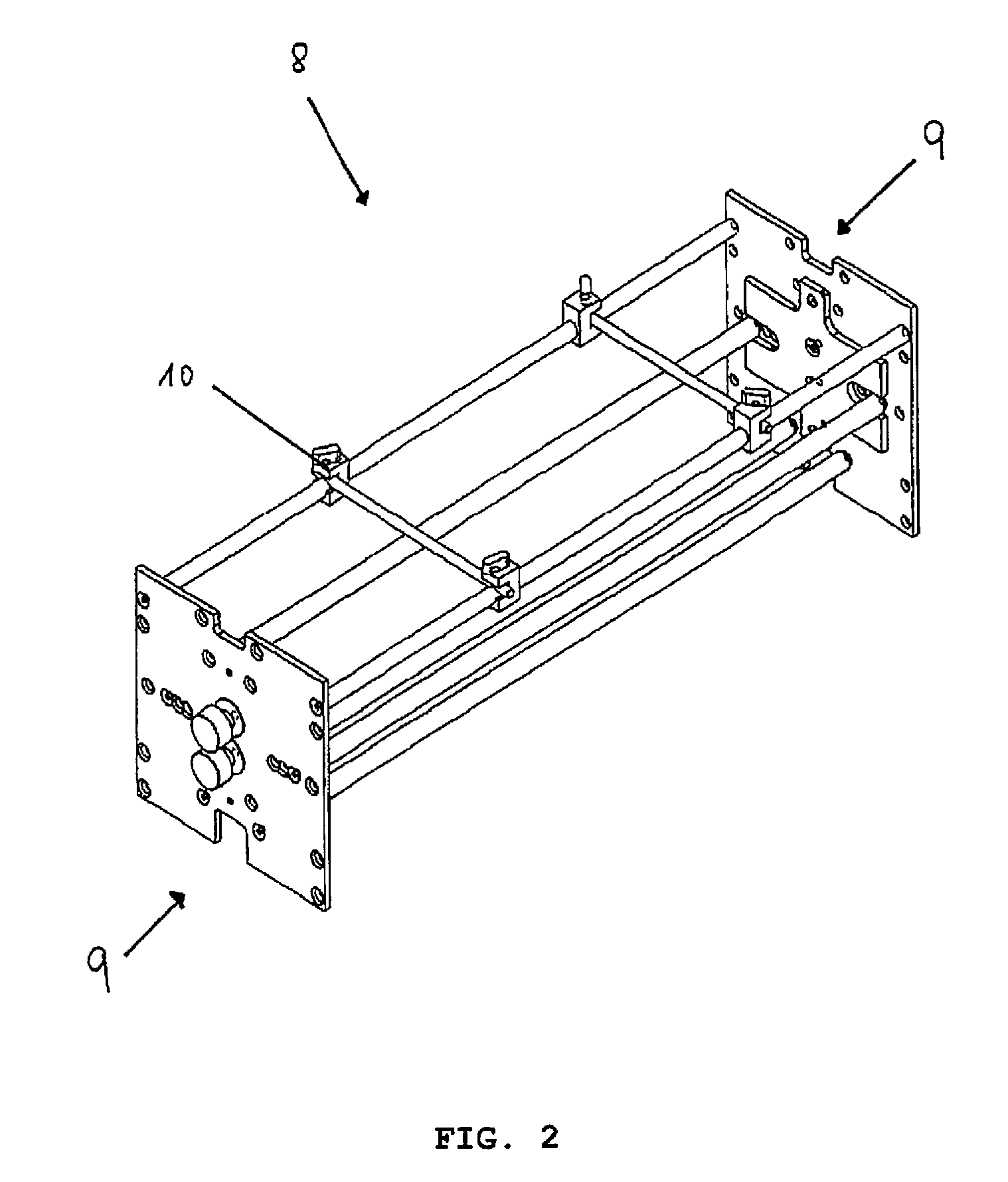

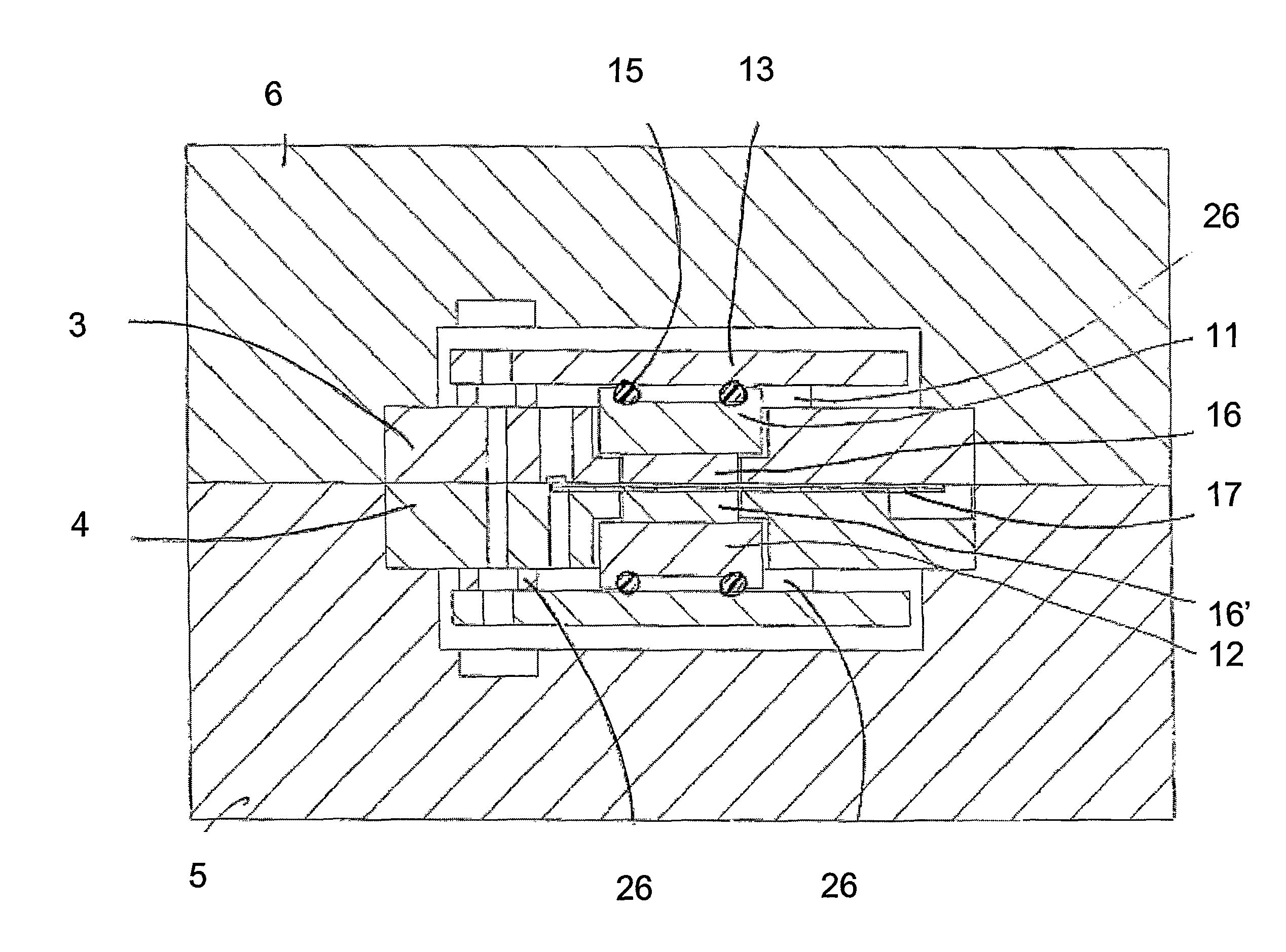

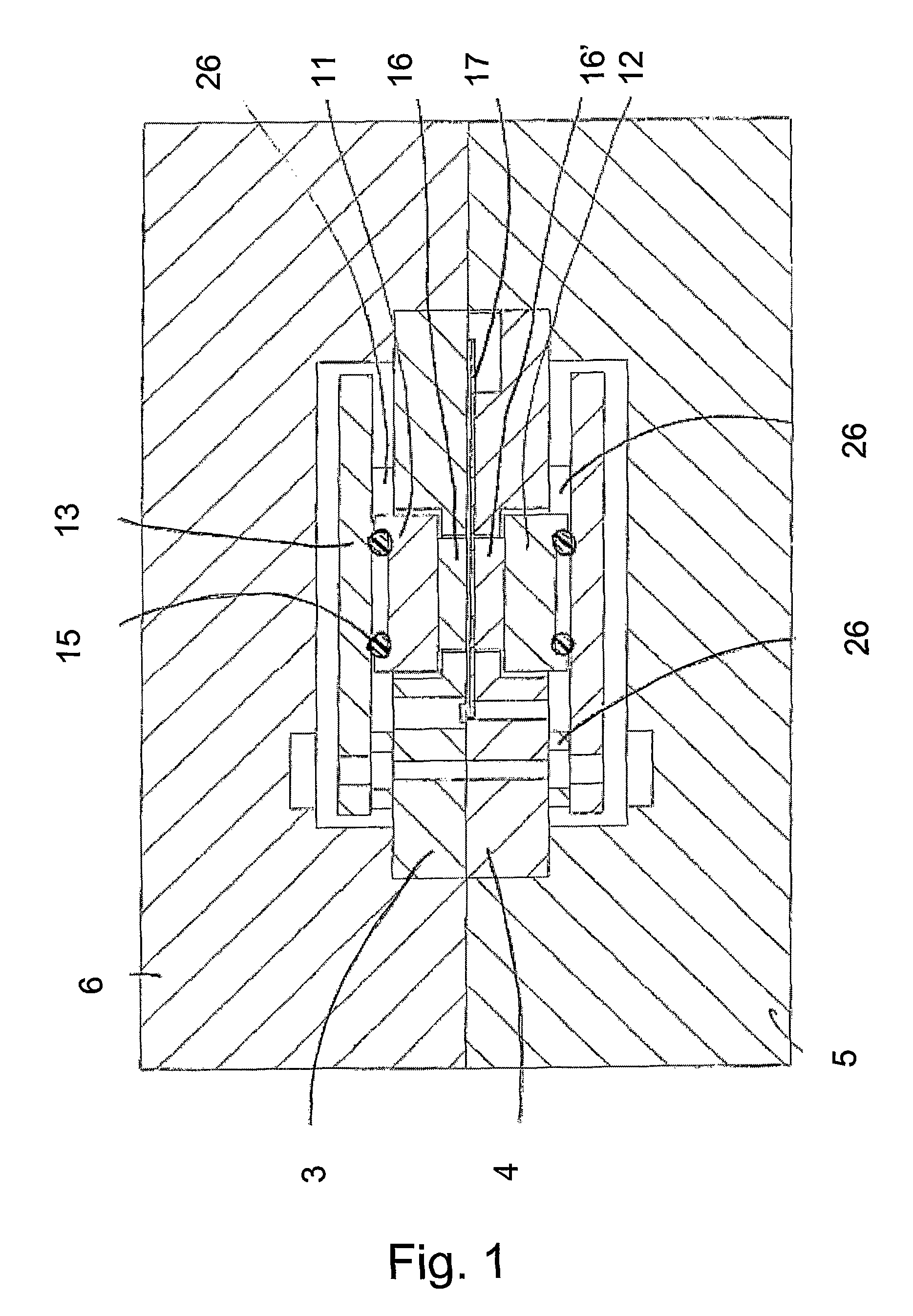

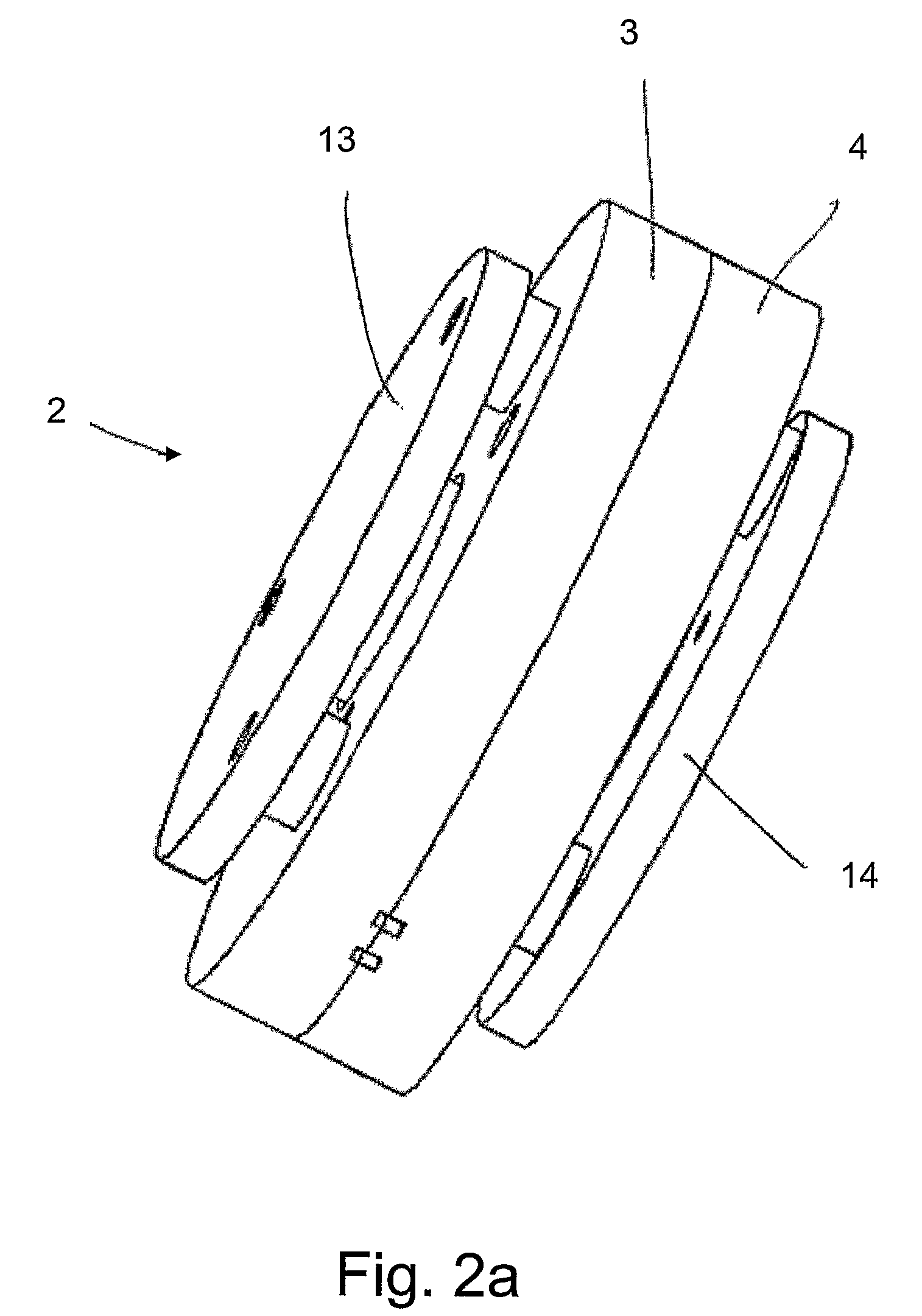

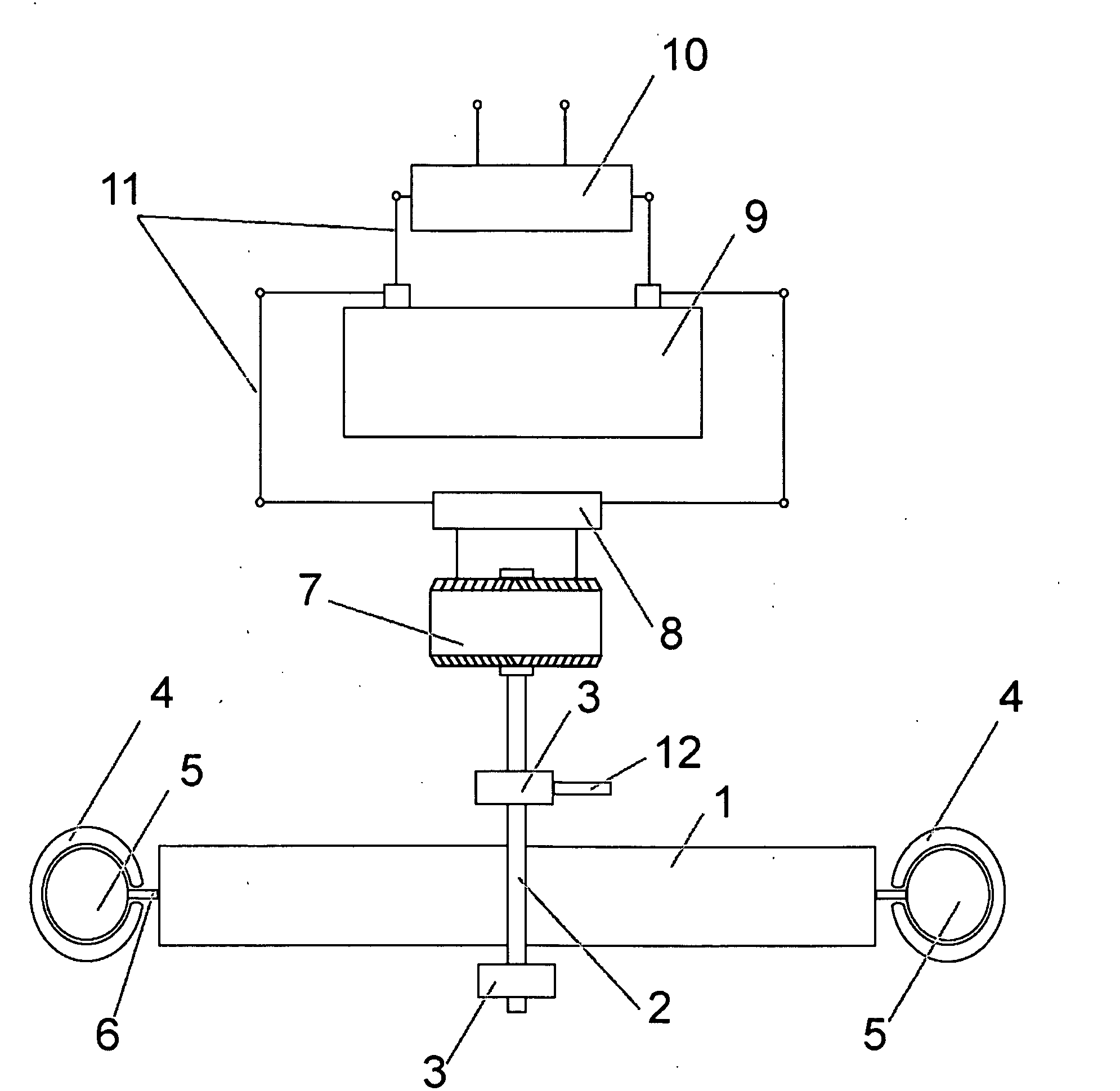

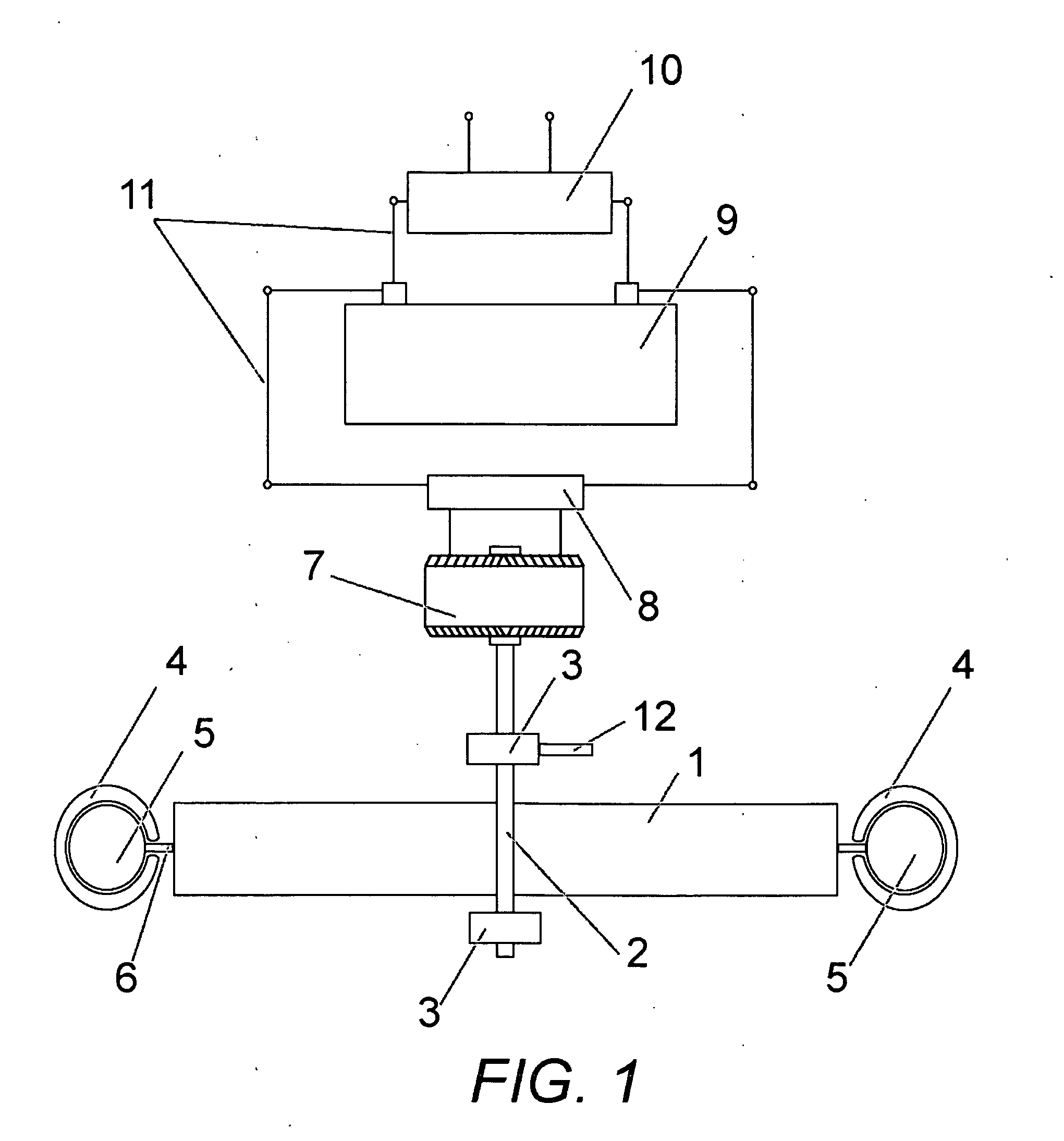

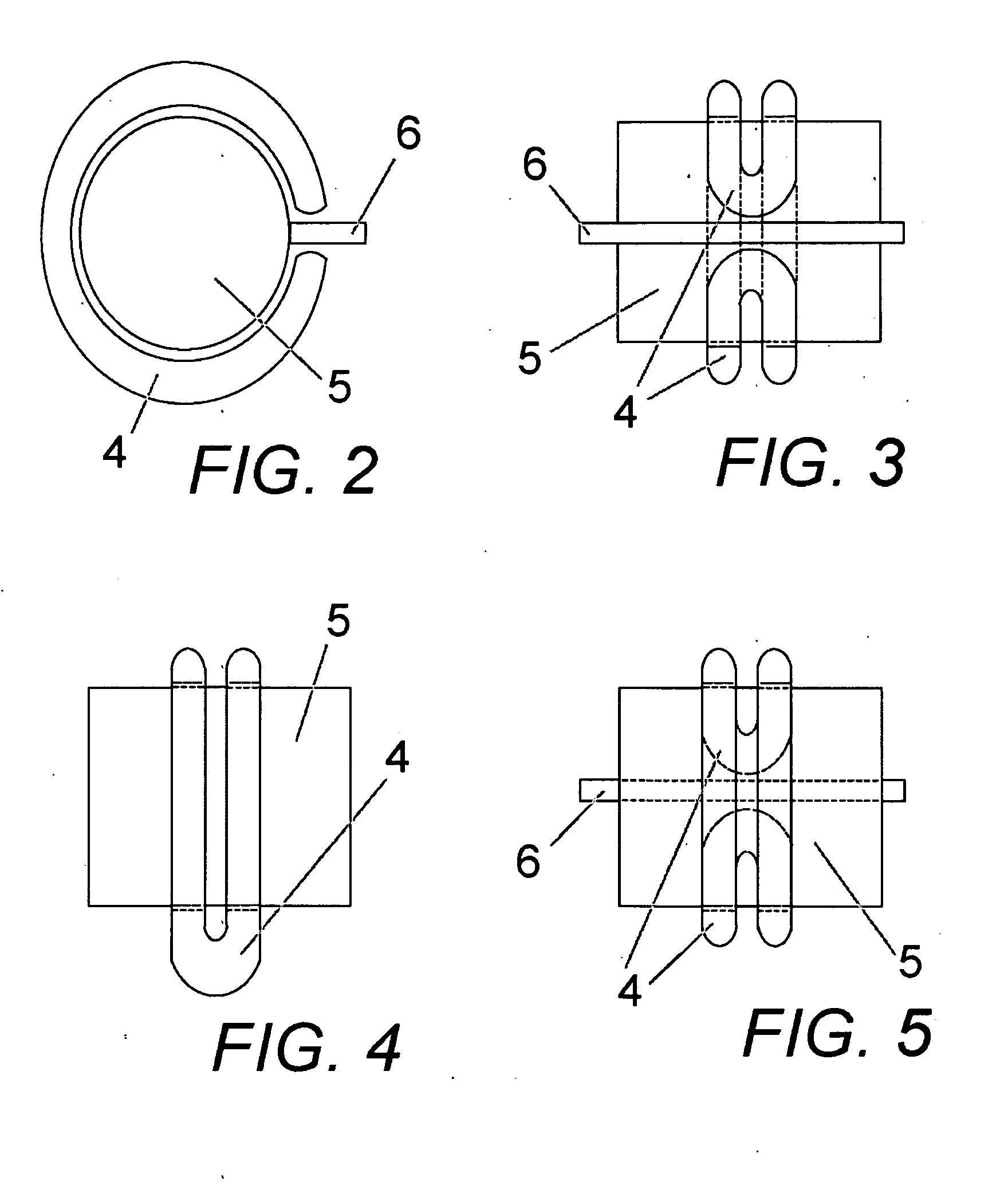

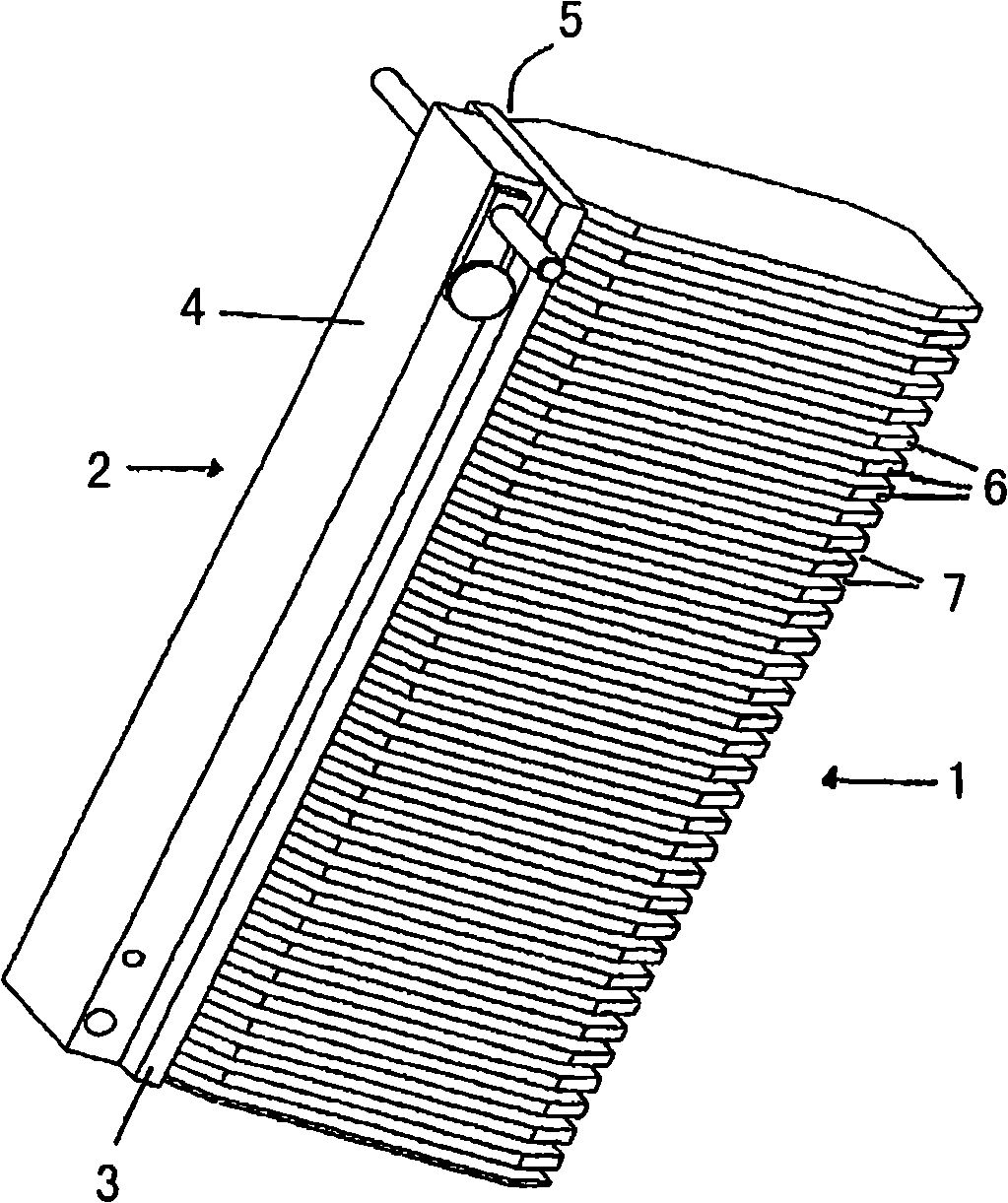

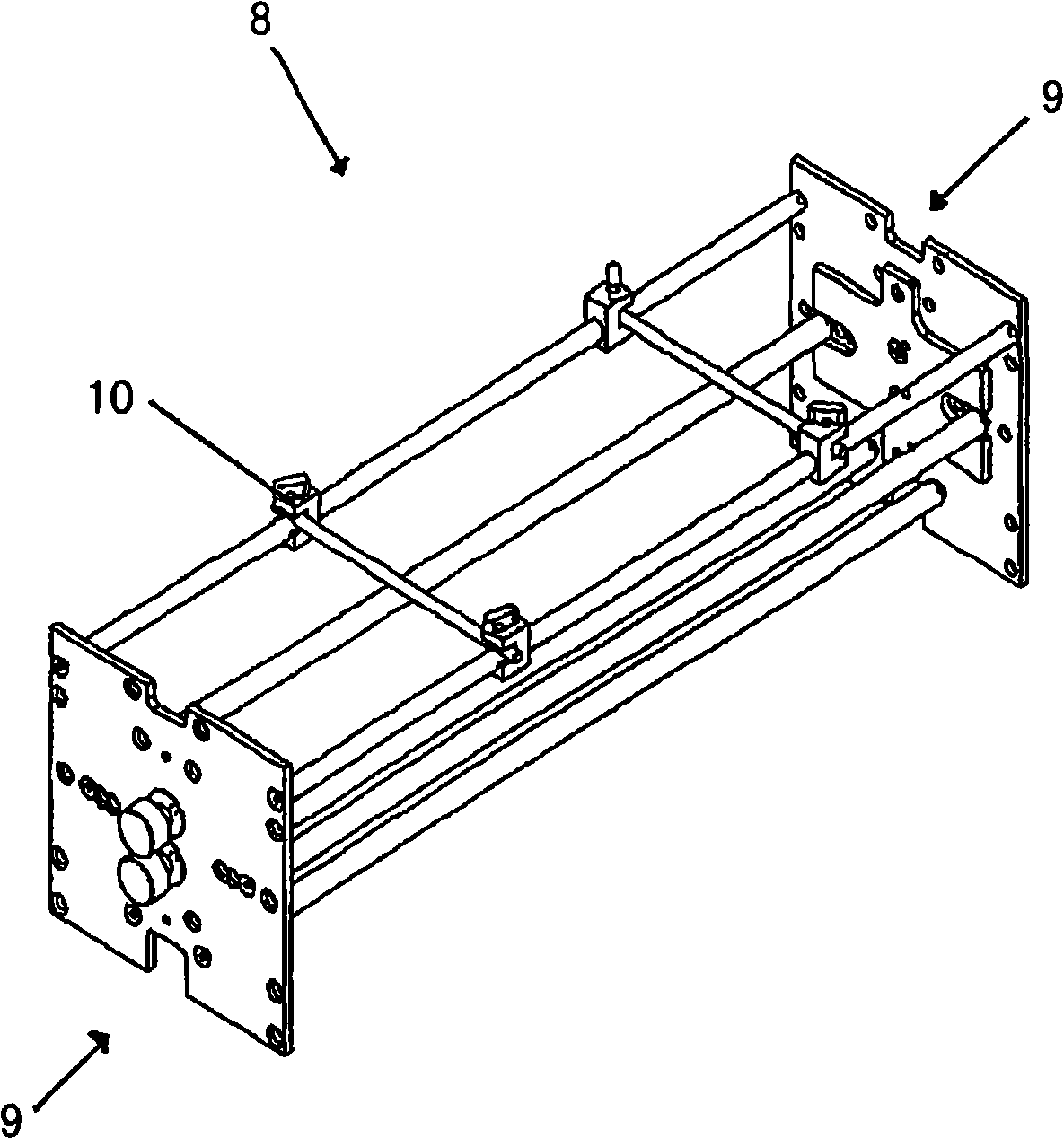

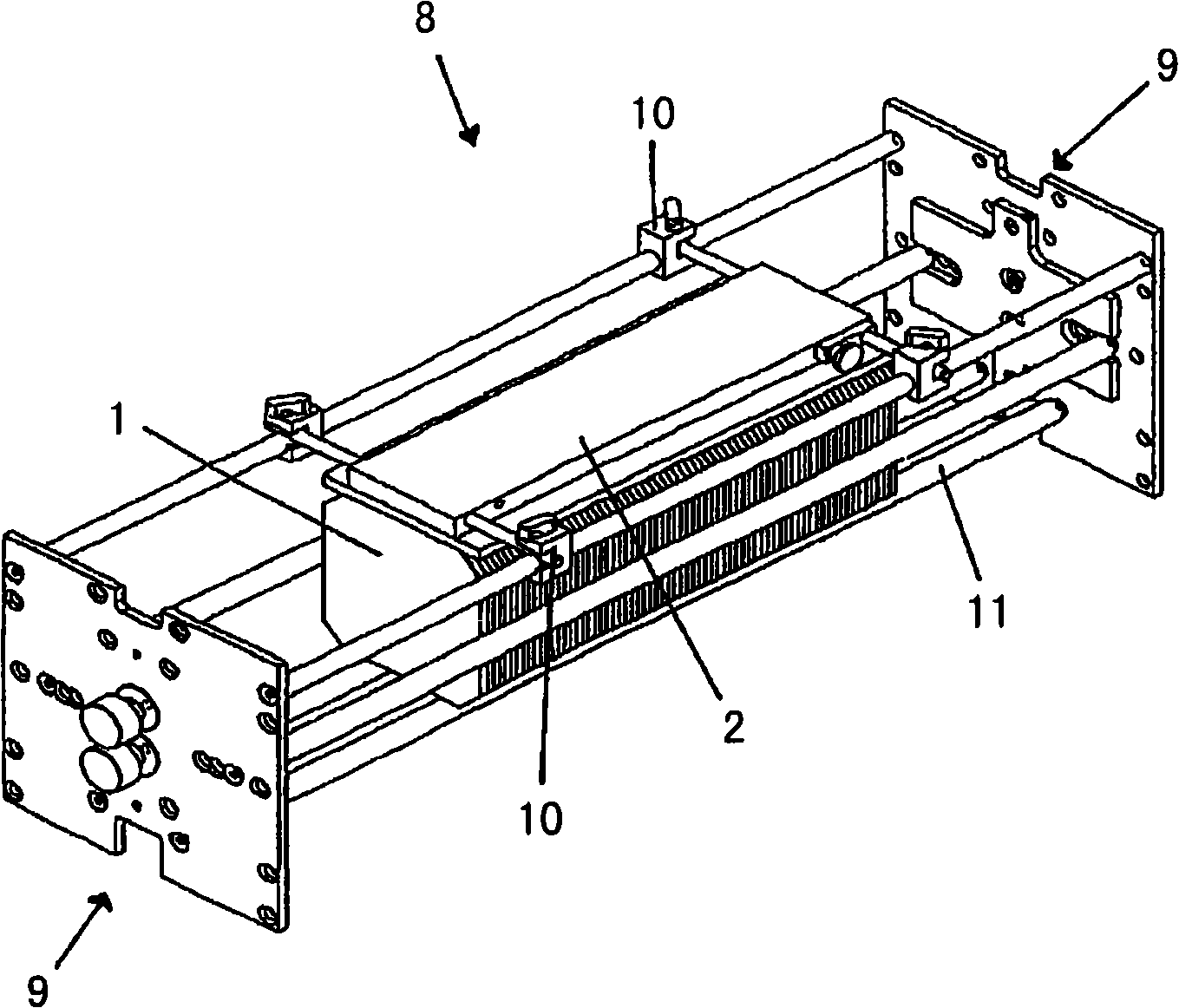

Apparatus and Method for Cleaning of Objects, in Particular of Thin Discs

InactiveUS20080295860A1Easy to integrateConstant quality levelSemiconductor/solid-state device manufacturingElectrostatic cleaningShowerElectrical and Electronics engineering

The invention relates to an apparatus for the cleaning of thin wafers (6), wherein the wafers (6) are fixed with one side to a carrier device (2), and wherein an interspace (7) is formed between two adjacent substrates, wherein the apparatus substantially consists of a shower device (15) by which fluid is injected into the respective interspaces (7), and a basin (14) that can be filled with fluid and that is dimensioned such that it houses the carrier device (2).According to the invention, optionally either the shower device (15) can be moved in relation to the immobile carrier device (2), or the carrier device (2) can be moved in relation to the immobile shower device (15), or both the carrier device (2) as well as the shower device (15) can be moved in relation to each other.The method stands out by the fact that in a preferred cleaning process, a shower with warm fluid takes place at first with the carrier device (2) being moved within the basin, followed by an ultrasonic cleaning in cold fluid and another shower with warm fluid.

Owner:RENA SONDERMASCHINEN GMBH

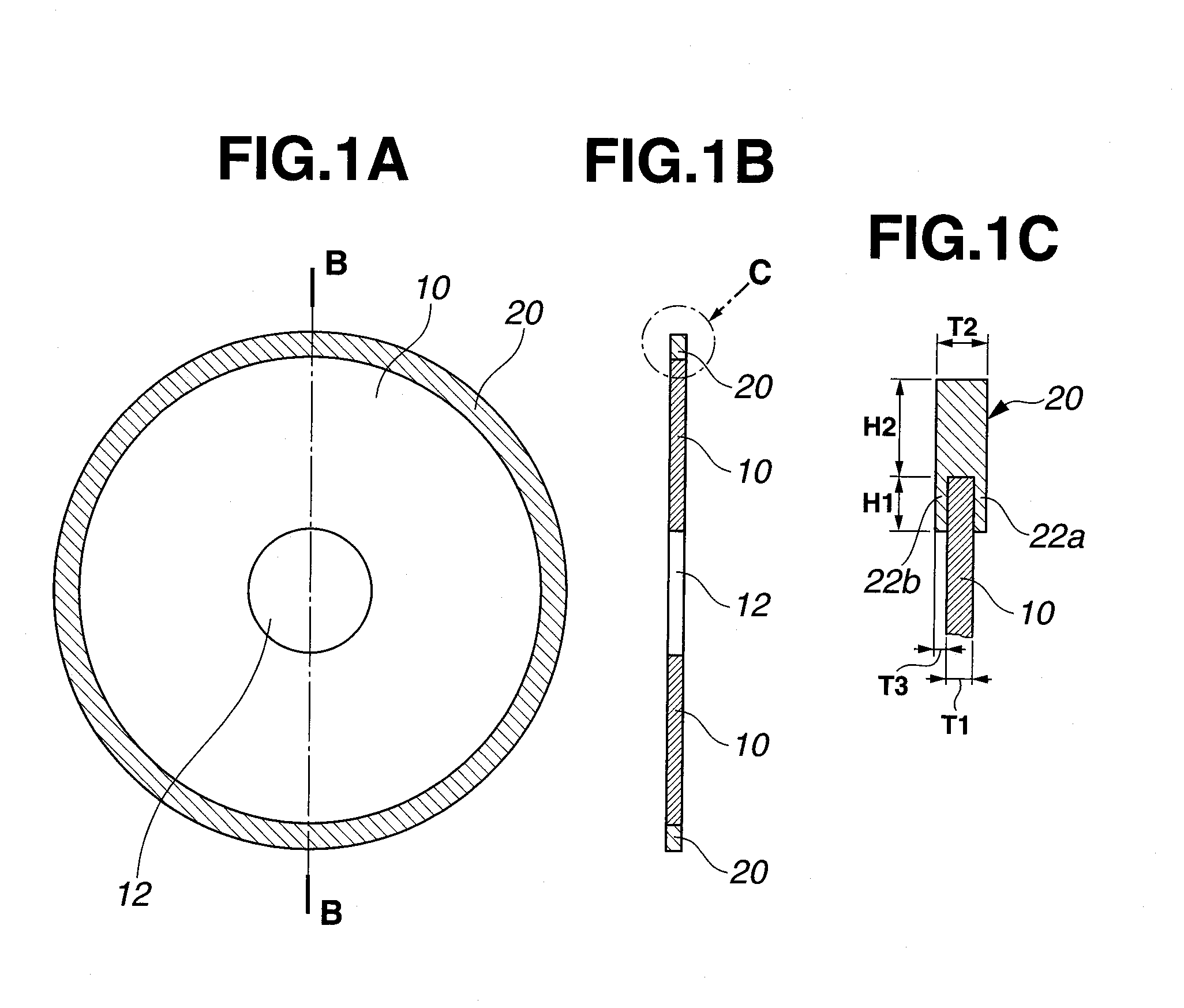

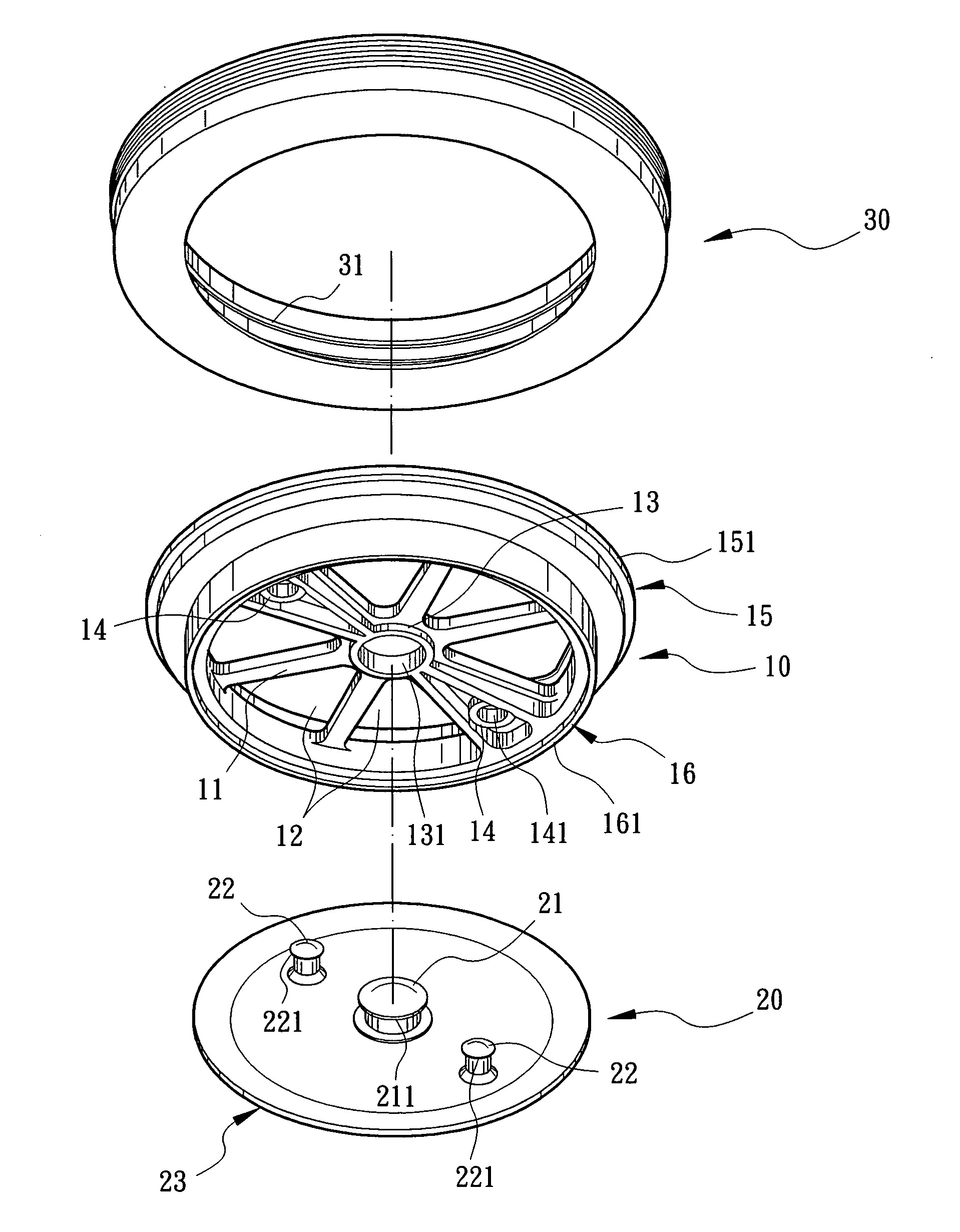

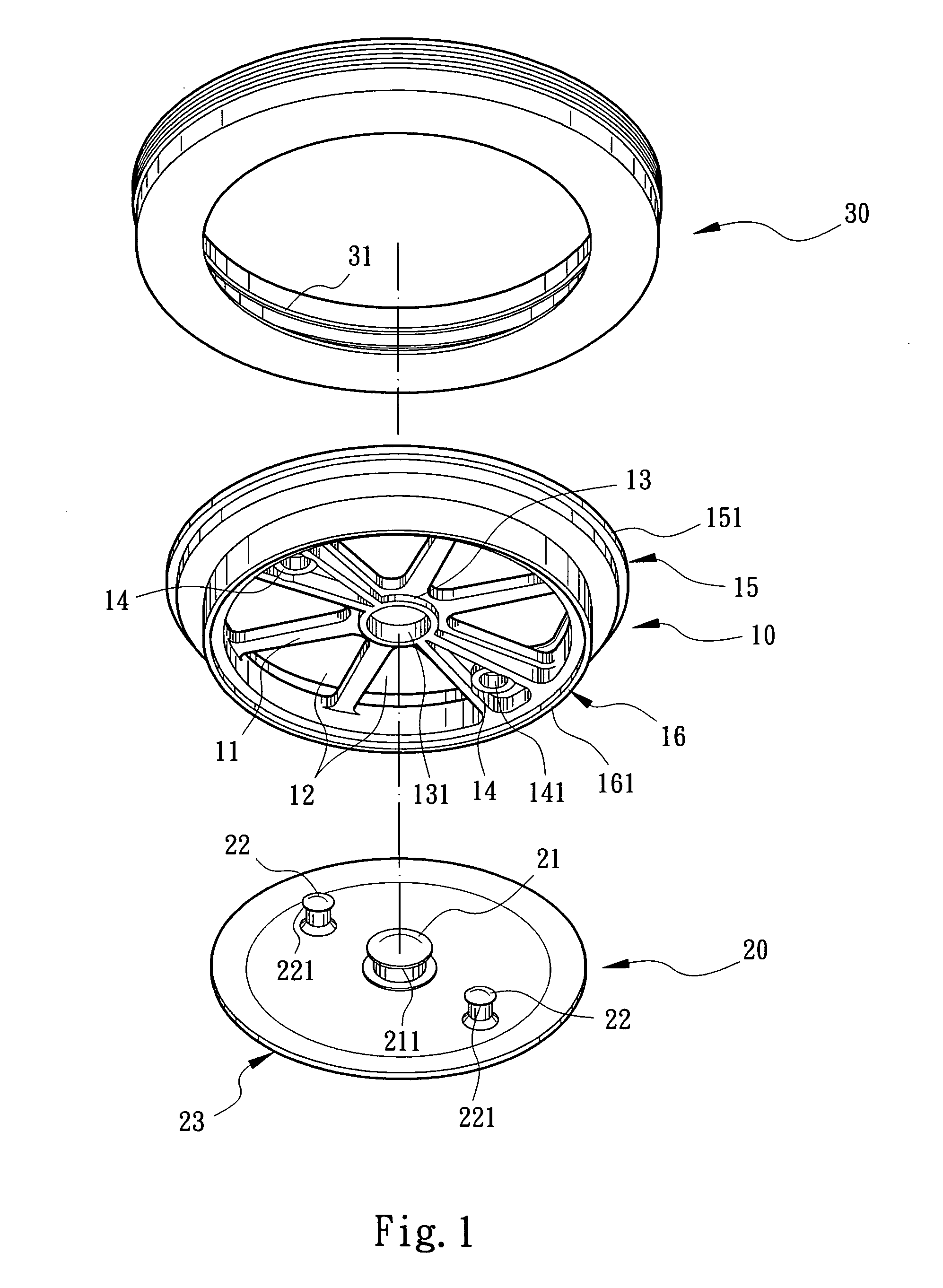

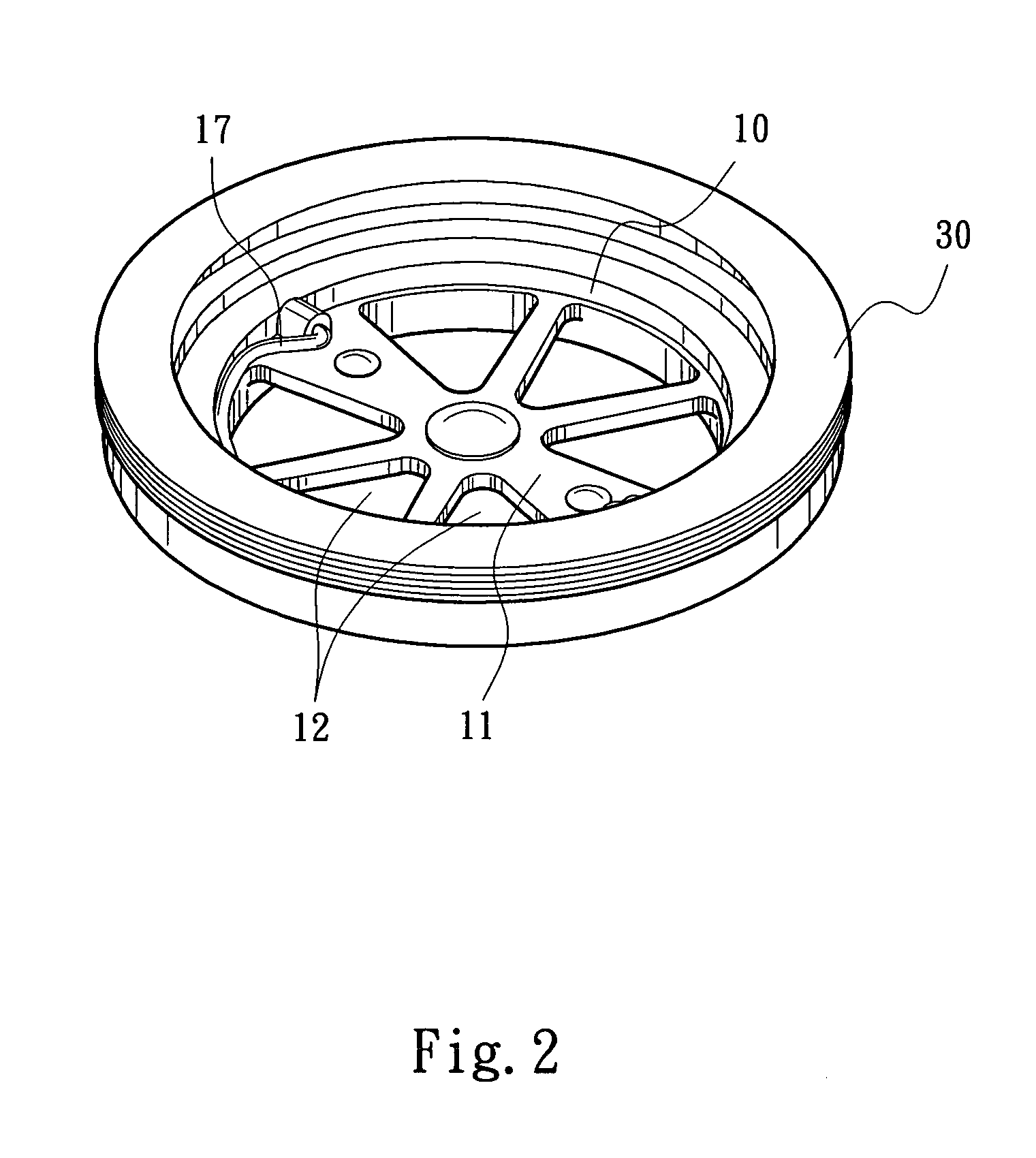

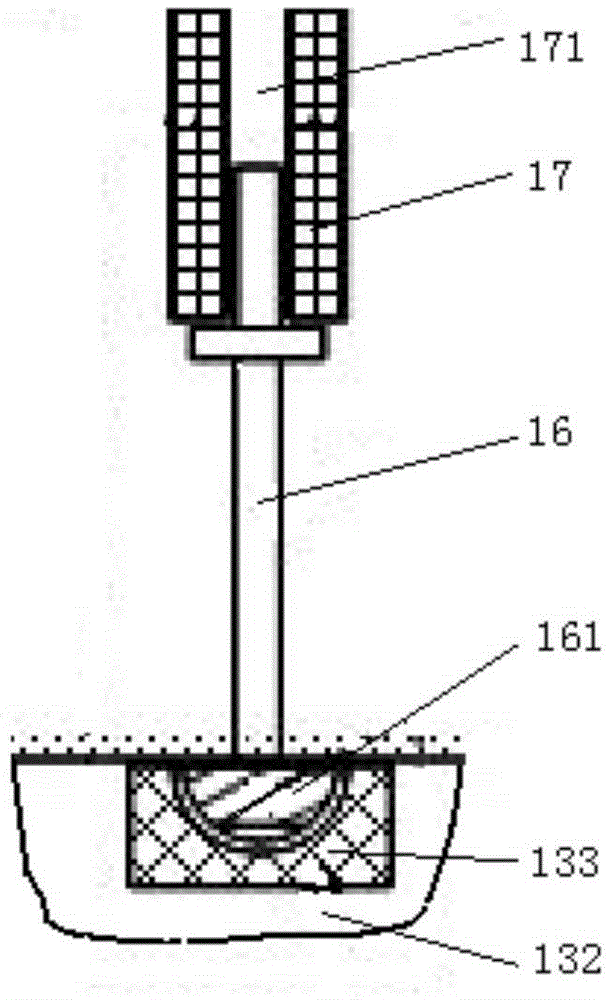

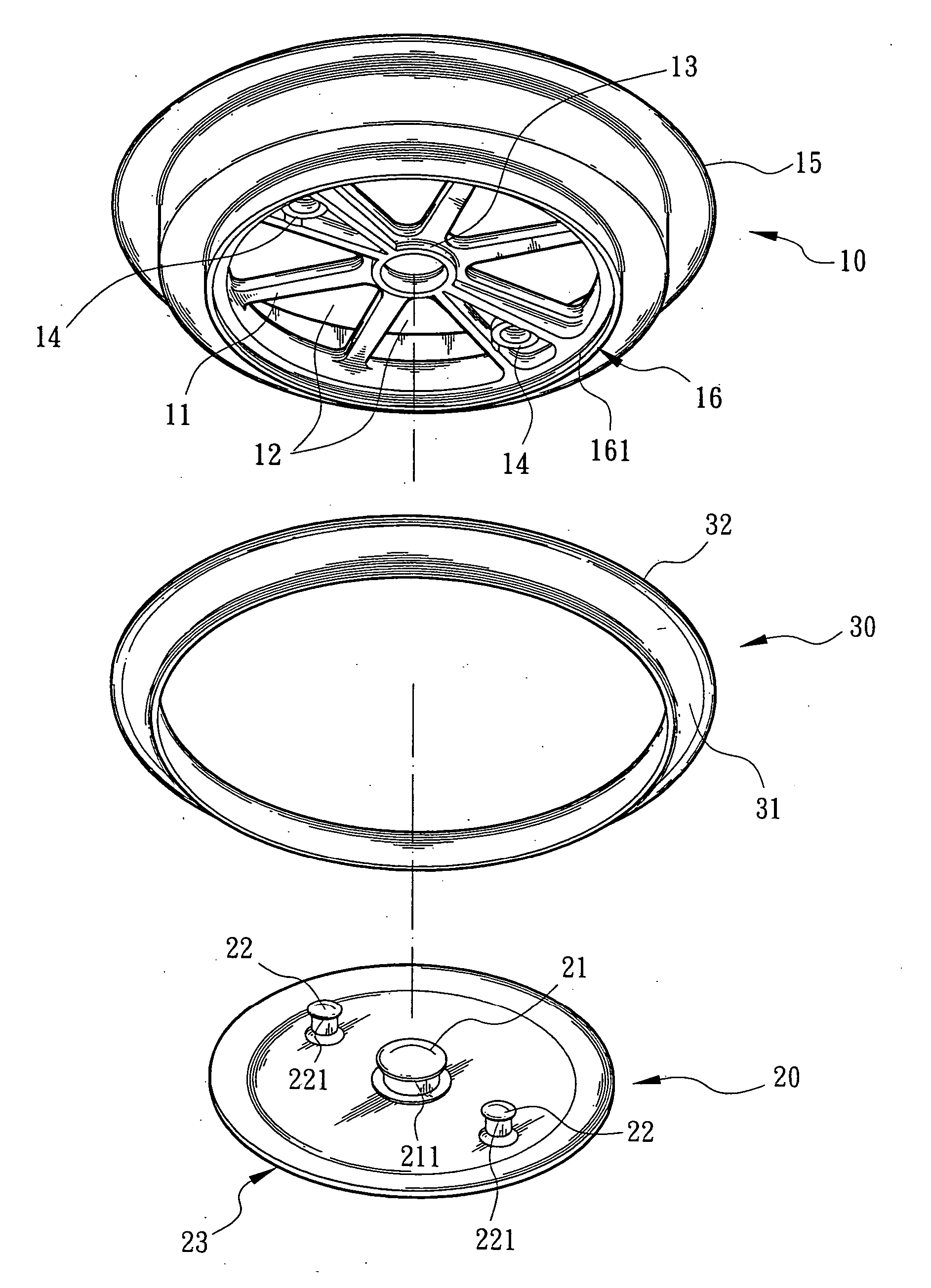

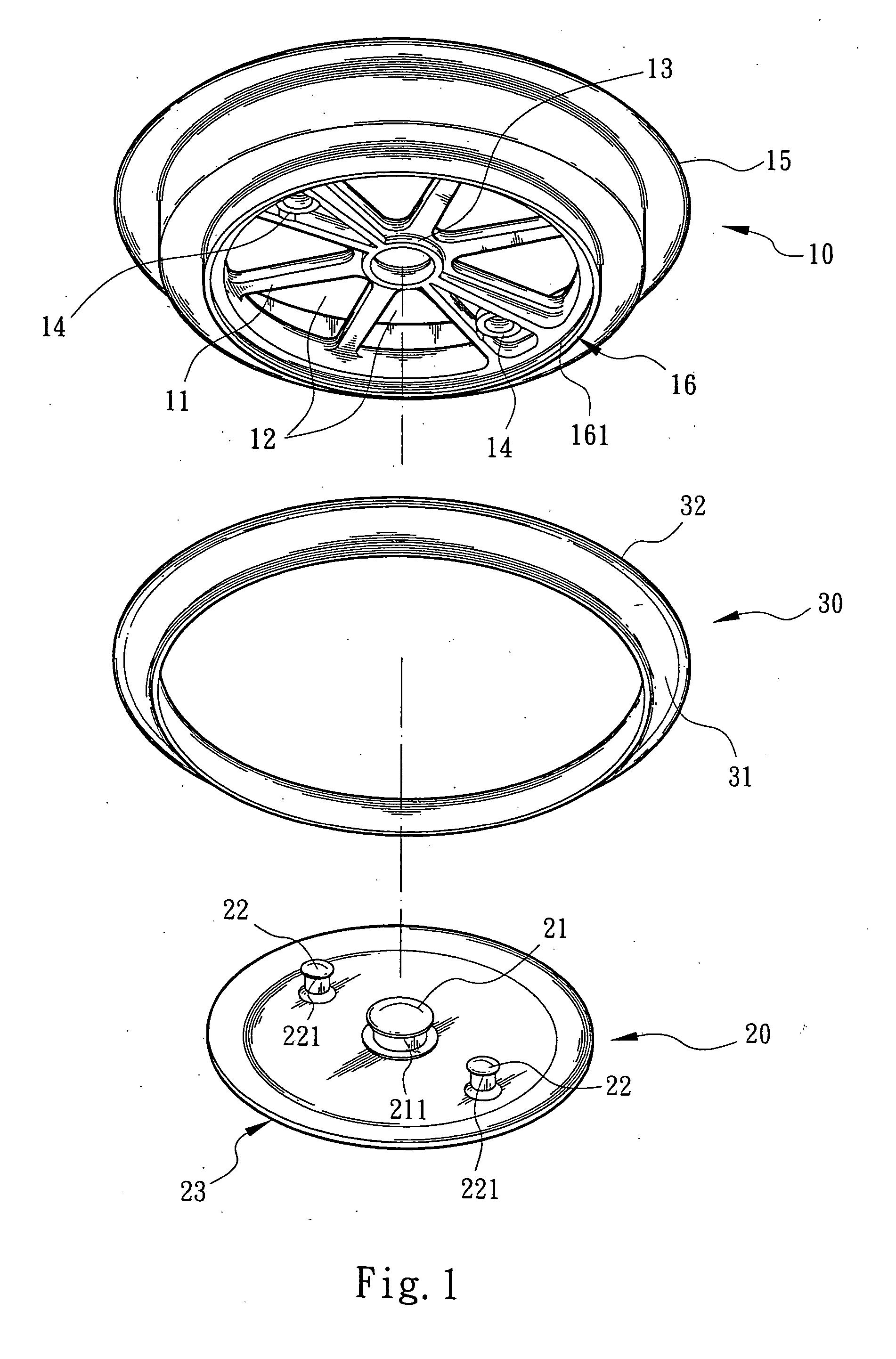

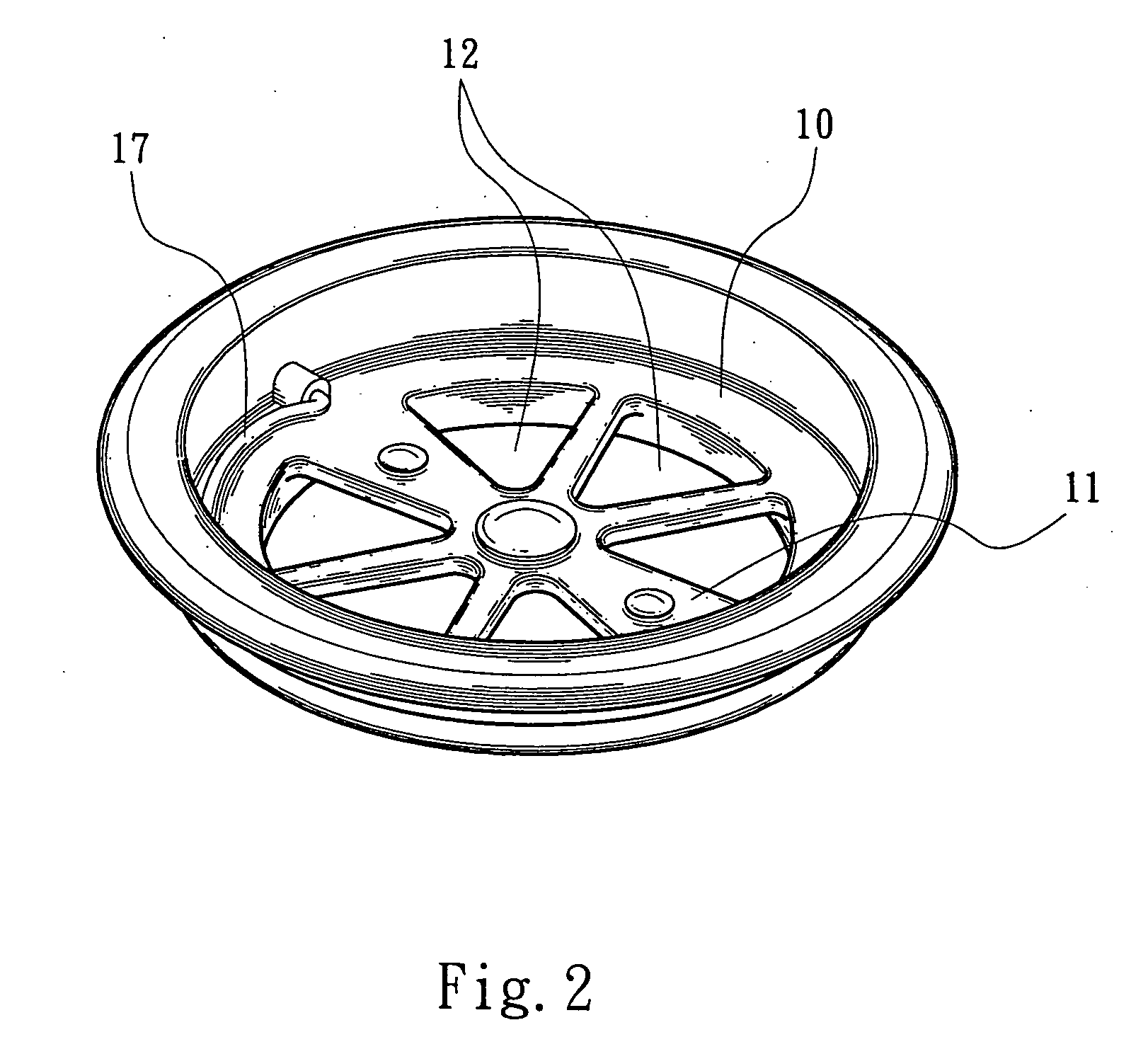

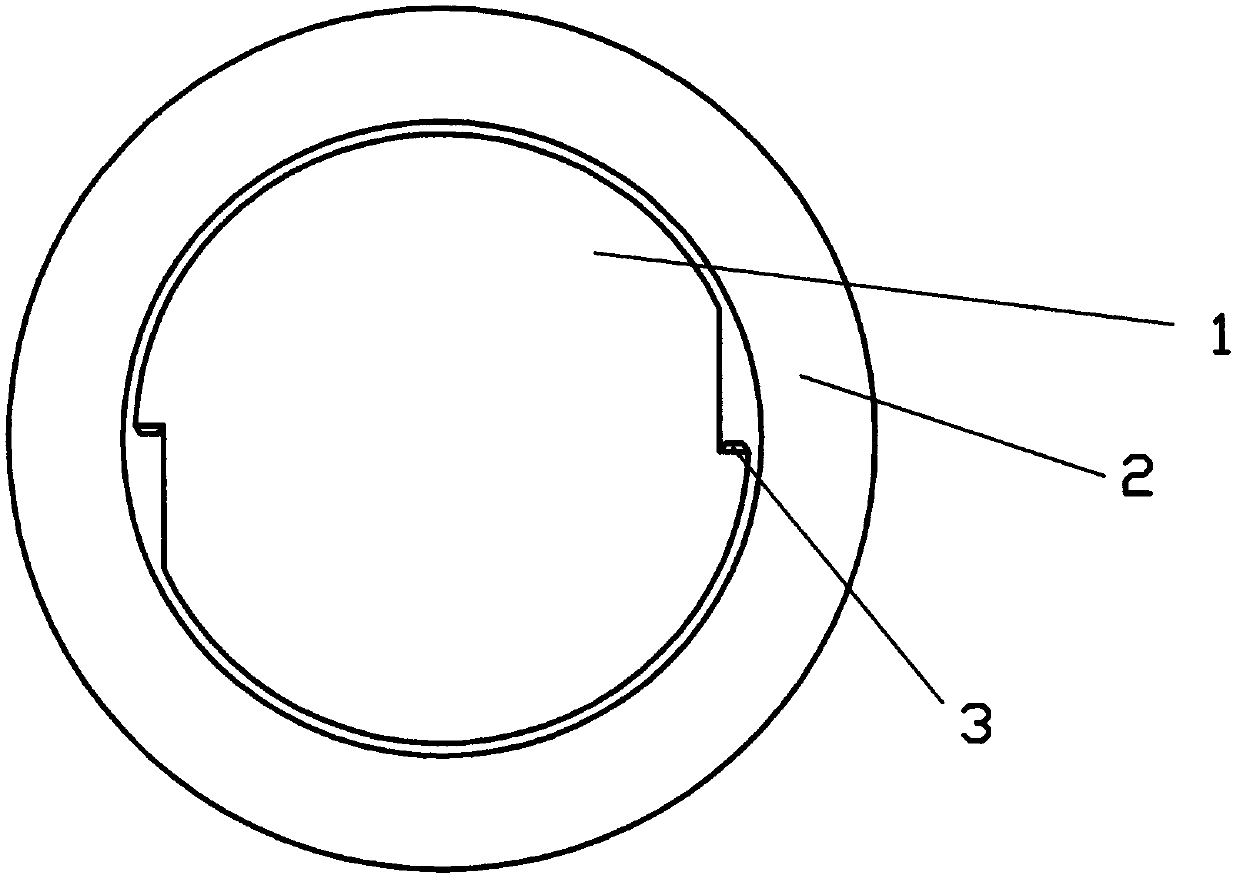

Bugproof and odorproof sealing ring structure of a sinkhole screen

A bugproof and odorproof sealing ring structure of a sinkhole screen, including a base seat, a diaphragm and a gum ring. The base is a ring body having a screen section formed with multiple perforations and holders. An upper end and a lower end of the base seat are respectively formed with a stepped flange and a stepped skirt. The diaphragm is a gum-made thin disc having chucking bosses inserted in the holders to connect the diaphragm under the base seat with outer circumference of the diaphragm tightly attaching to the stepped skirt of the base seat. The inner circumference of the gum ring is formed with a stepped annular groove adapted to the stepped flange of the base seat, whereby the gum ring can be snugly fitted around the stepped flange of the base seat. The sealing ring can be directly placed on a conventional sinkhole screen to achieve a bugproof and odorproof effect.

Owner:HUNG DEN LU

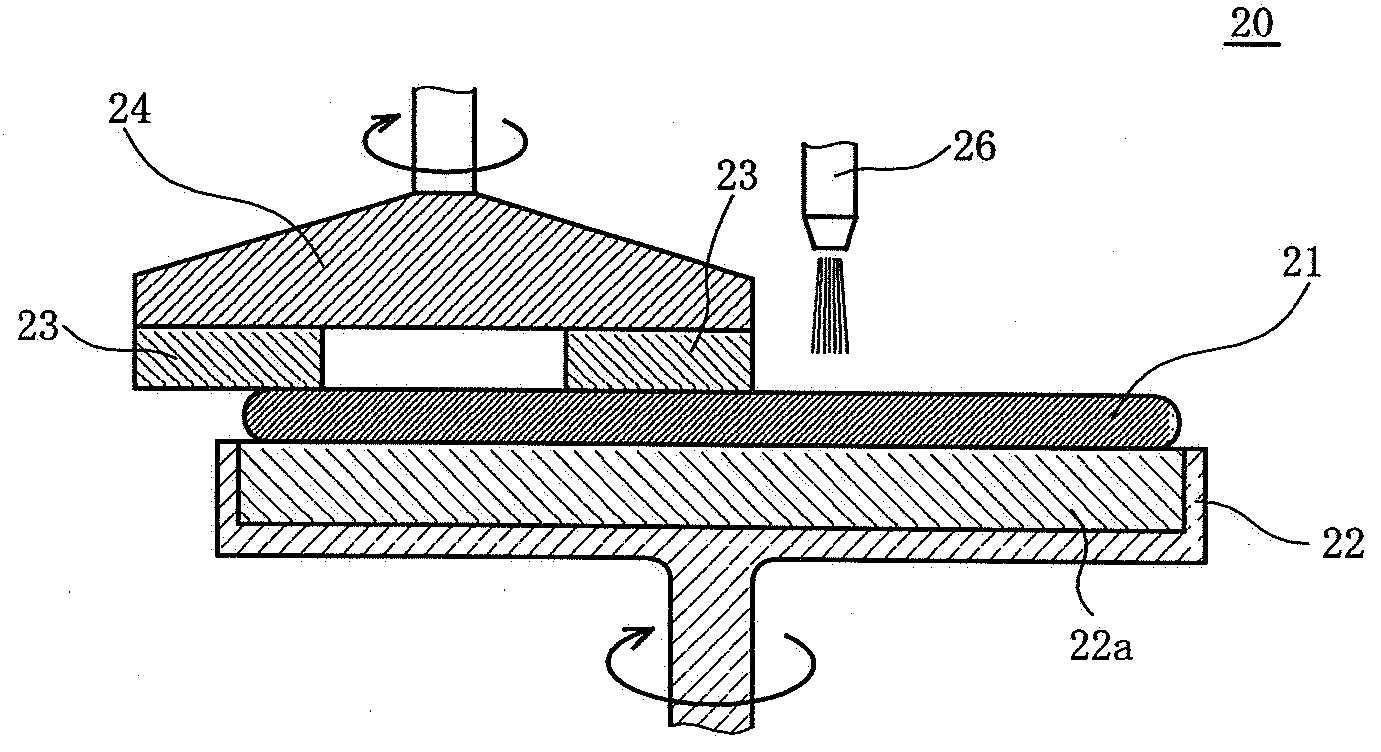

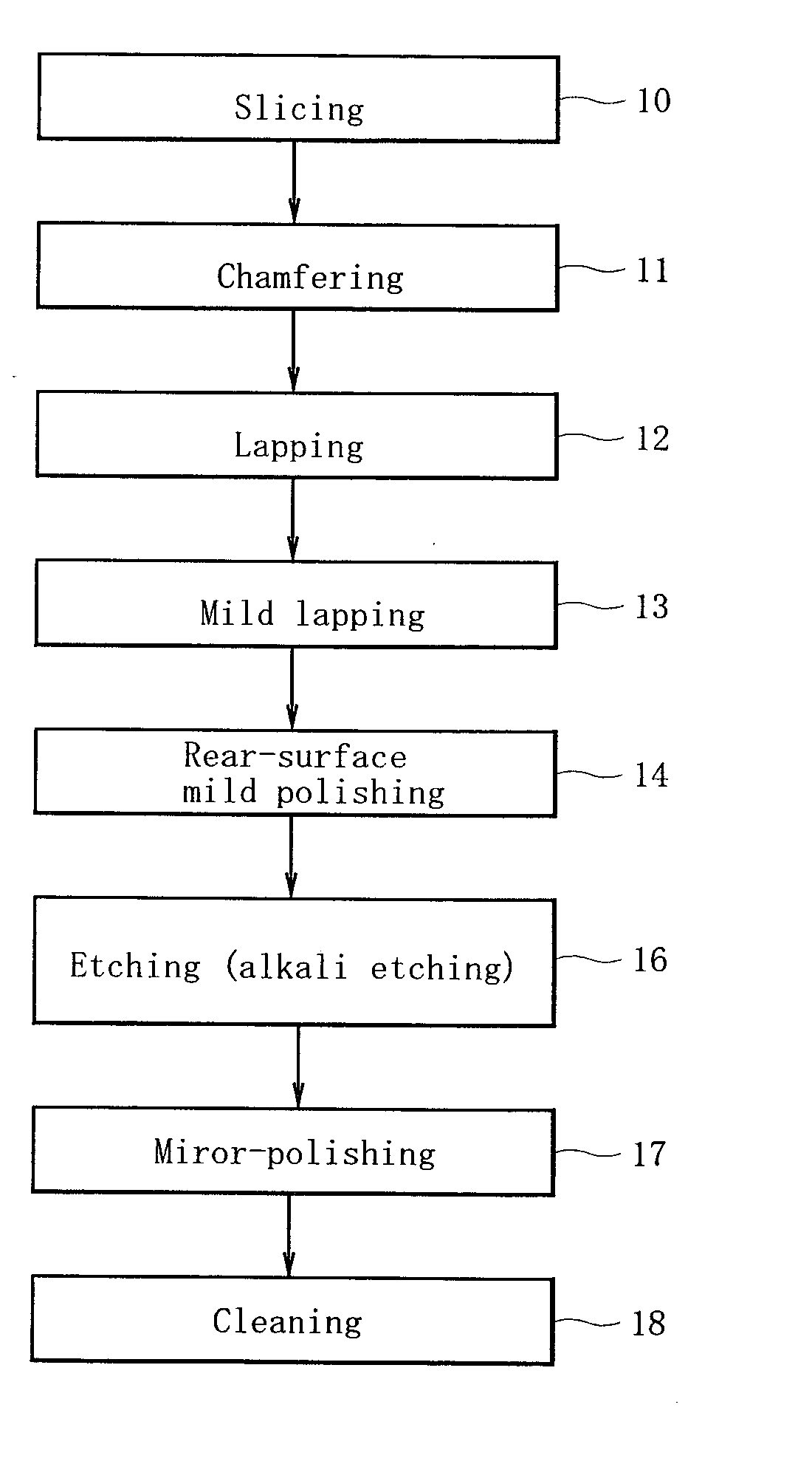

Method of processing silicon wafer

ActiveUS20060252272A1Reduce layeringSimple processDecorative surface effectsSemiconductor/solid-state device manufacturingHydrofluoric acidEdge surface

The inventive method for processing a silicon wafer is a method comprising step 11 in which a single crystal ingot is sliced into thin disc-like wafers; step 13 in which the surface of each wafer is lapped to be planar; step 14 in which the wafer is subjected to alkaline cleaning to be removed of contaminants resulting from preceding machining; and step 16 in which the wafer is alternately transferred between two groups of etching tanks one of which contain acidic etching solutions and the other alkaline etching solutions, wherein an additional step 12 is introduced between step 11 and step 13 in which a wafer is immersed in an acidic solution containing hydrofluoric acid (HF) and nitric acid (HNO3) at a volume ratio of ⅛ to ½ (HF / HNO3) so that degraded superficial layers occurring on the front and rear surfaces of the wafer as a result of machining can be removed and the edge surface of the wafer can be beveled. The inventive method simplifies the steps involved in the processing of a wafer, and reduces the intervention of alkaline cleaning accompanied with mechanical beveling, thereby reducing the risk of contamination due to metal impurities which may result from alkaline cleaning.

Owner:SUMCO CORP

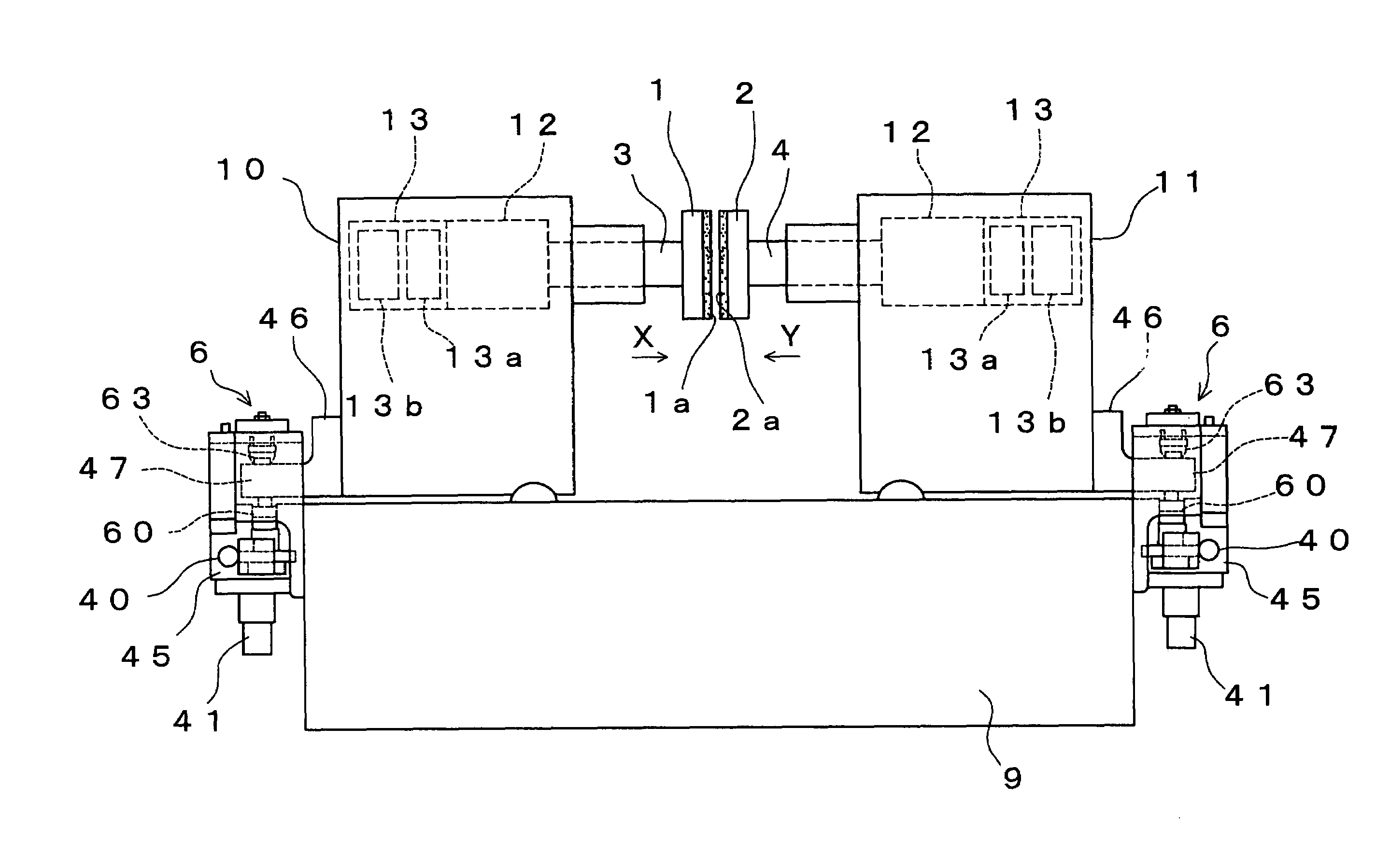

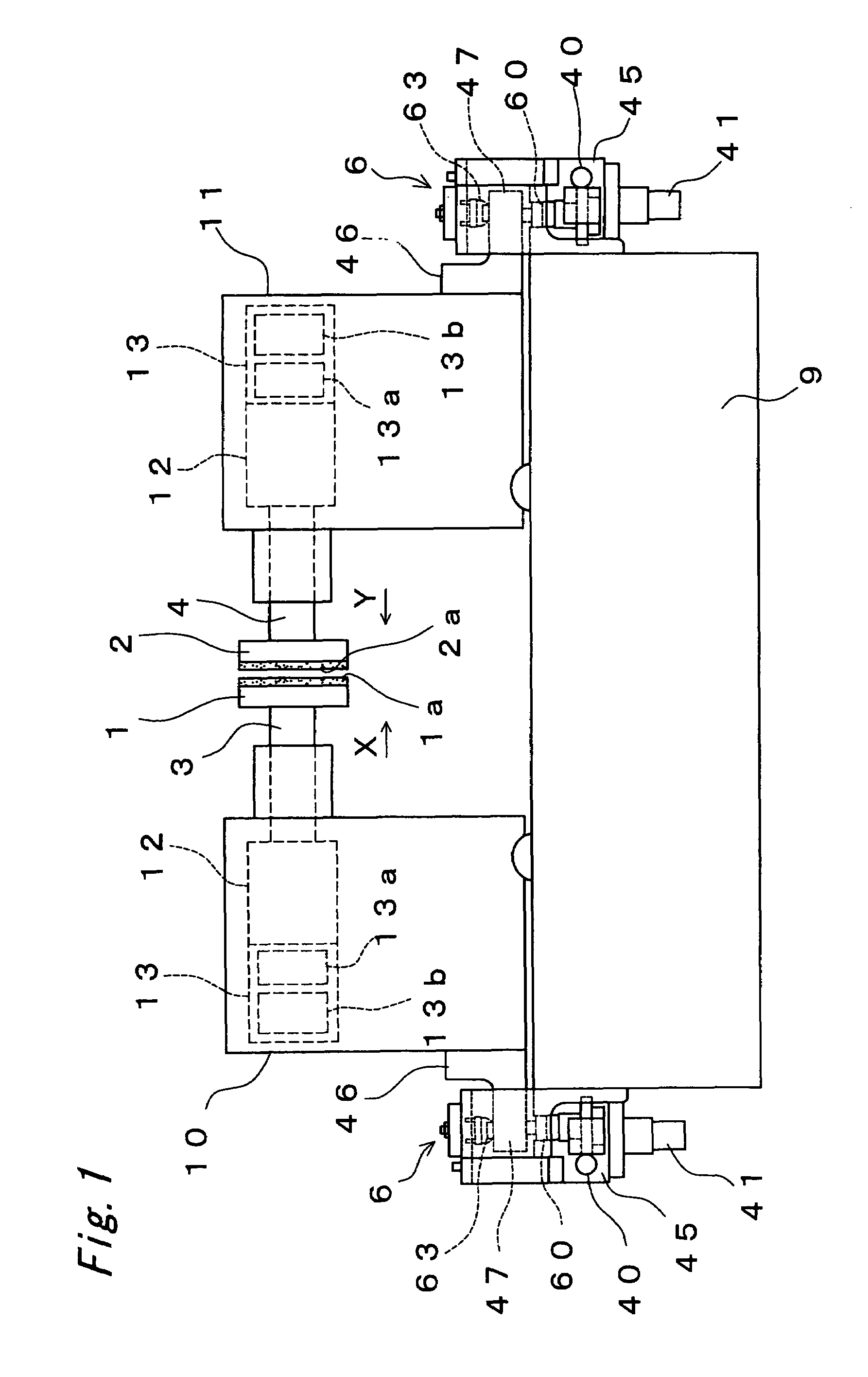

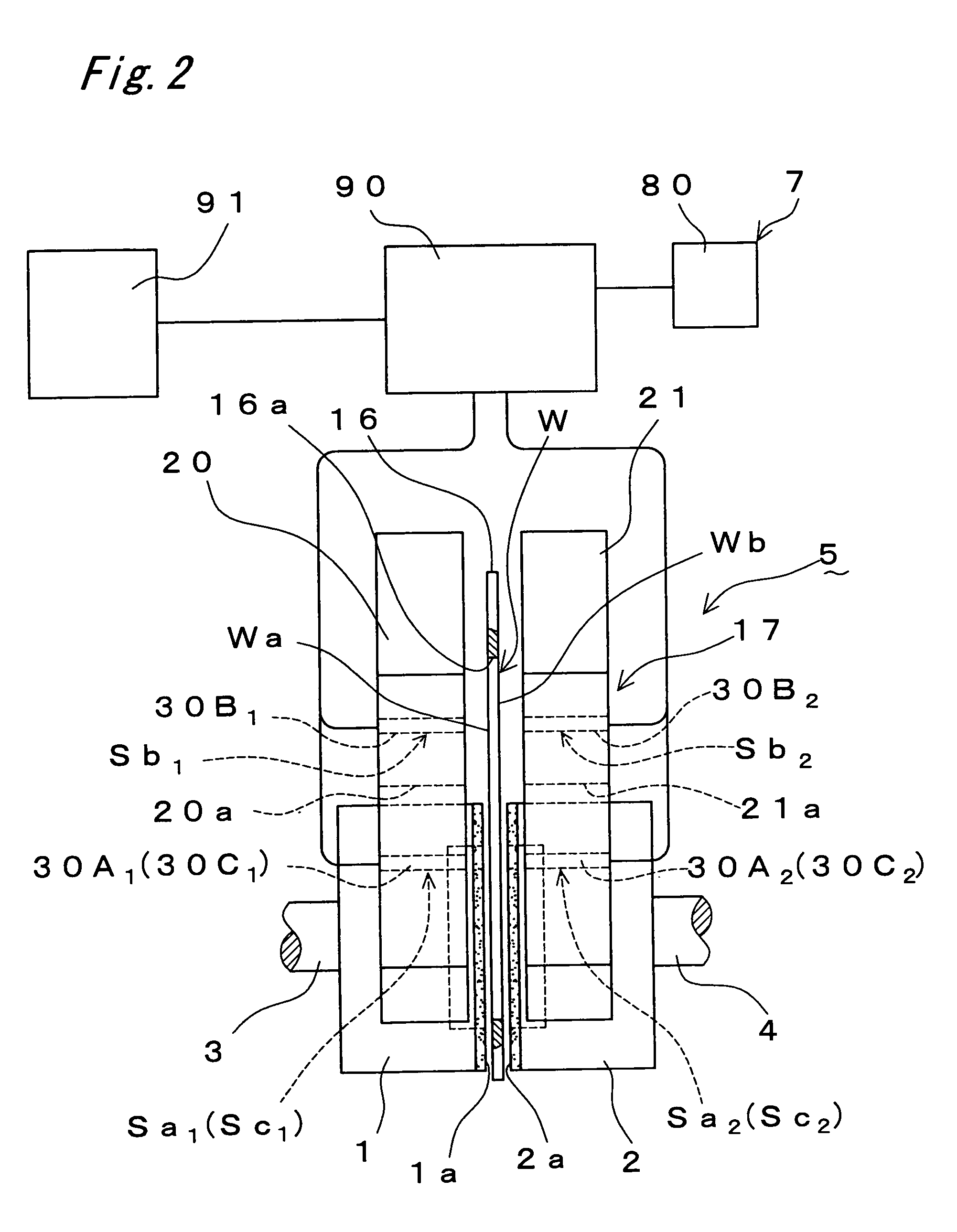

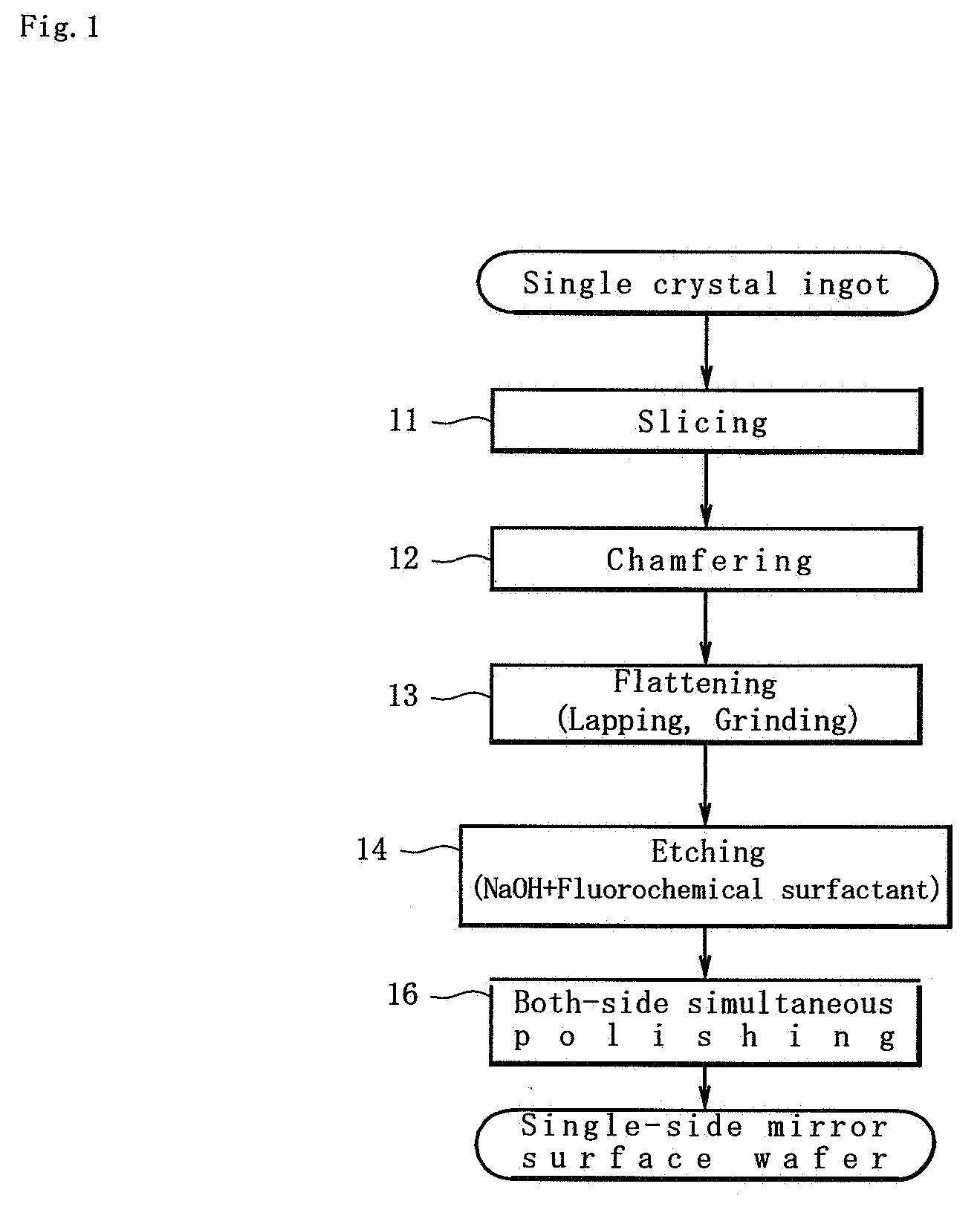

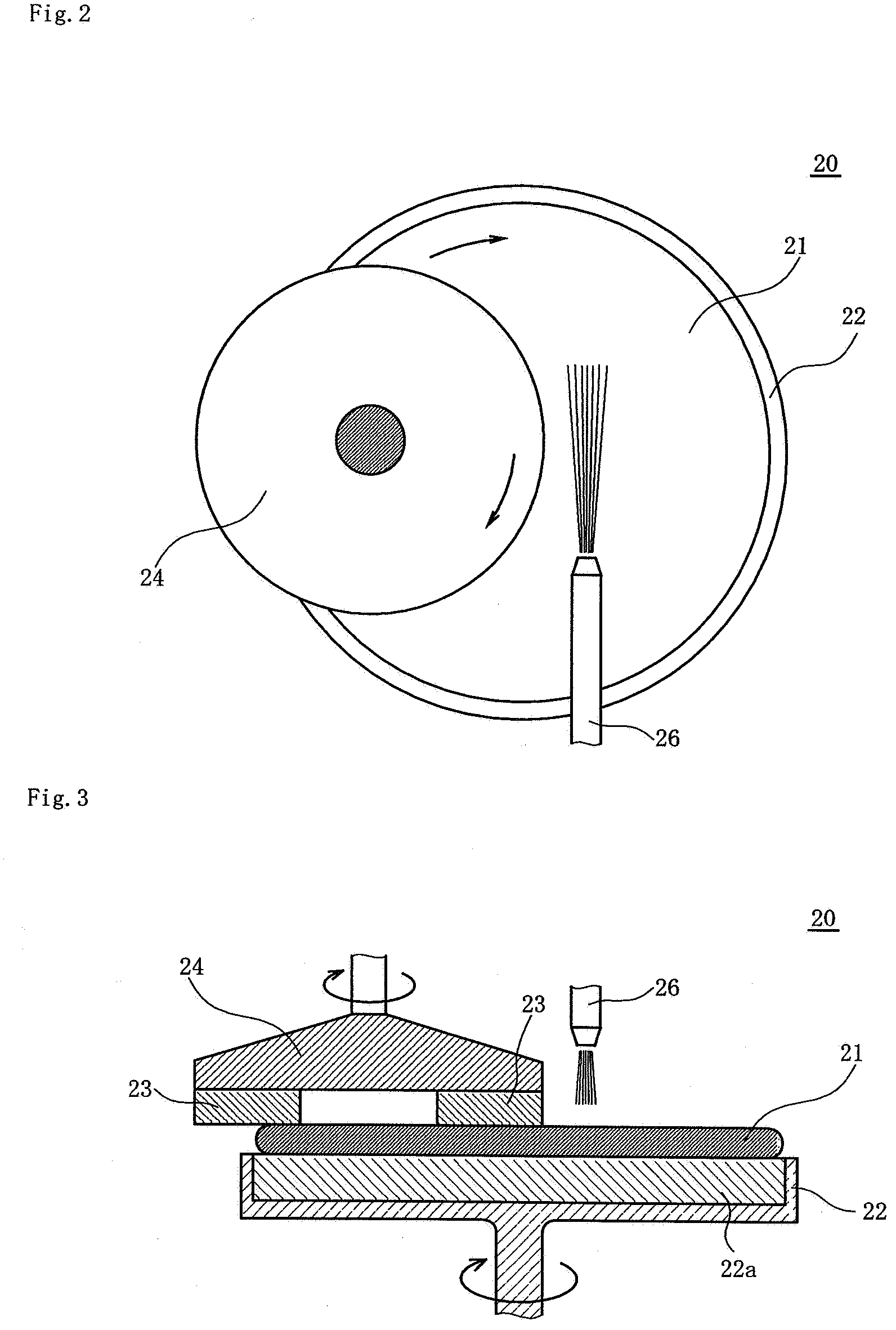

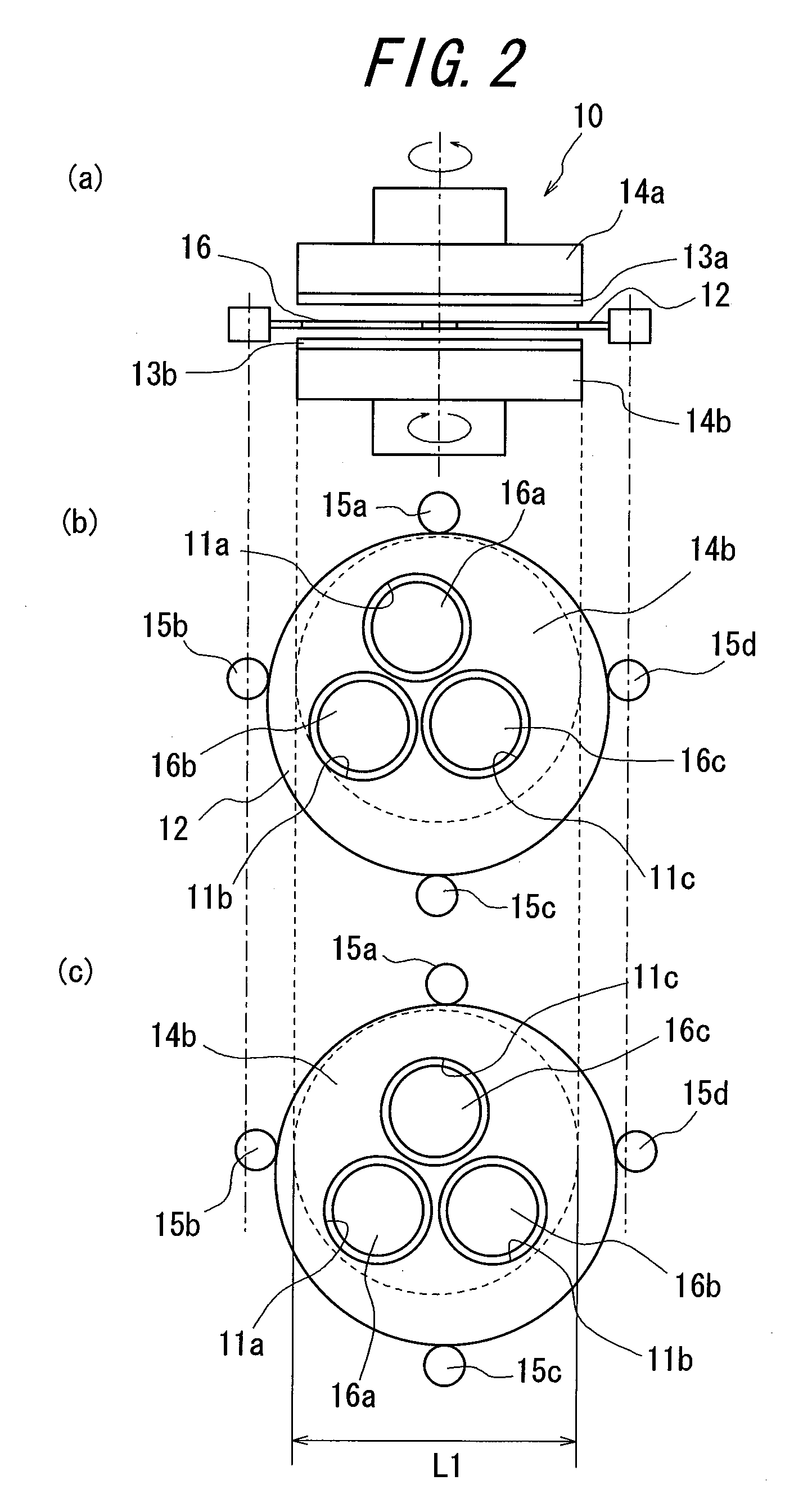

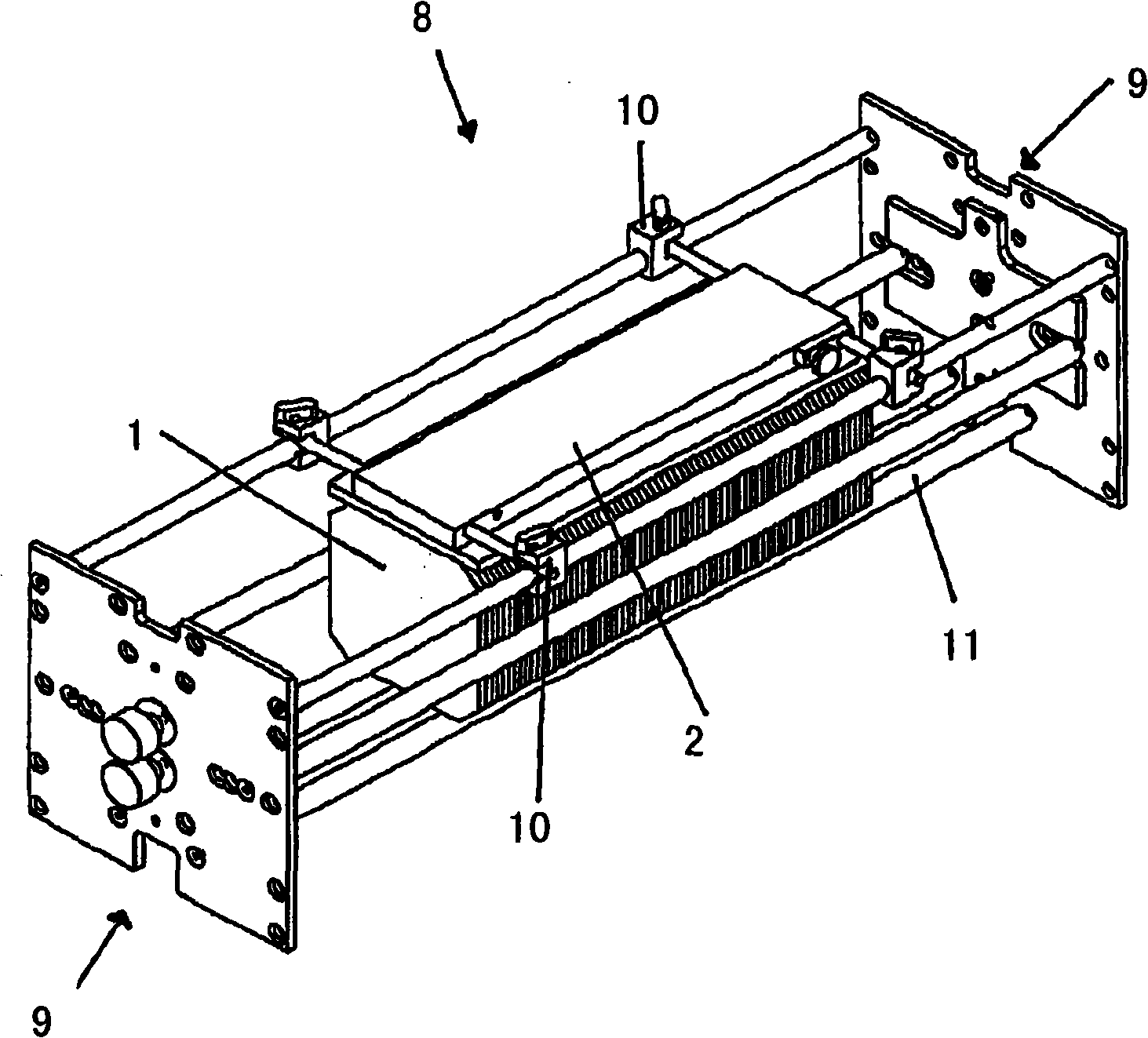

Both-side grinding method and both-side grinding machine for thin disc work

InactiveUS7150674B2Work being freeImprove flatnessEdge grinding machinesRevolution surface grinding machinesHydrostatic pressureEngineering

Owner:KOYO MASCH IND CO LTD

Etchant for silicon wafer surface shape control and method for manufacturing silicon wafers using the same

InactiveUS20090042390A1MaintenanceReduction in wafer front side roughnessSemiconductor/solid-state device manufacturingSurface treatment compositionsWaferingEngineering

It is possible to reduce workloads of a both-side simultaneous polishing process or a single-side polishing process, and to achieve both of the maintenance of the wafer flatness and the reduction in wafer front side roughness upon completing a flattening process. A method for manufacturing silicon wafers according to the present invention includes a flattening process 13 of grinding or lapping front and back sides of a thin disc-shaped silicon wafer obtained by slicing a silicon single crystal ingot, an etching process of immersing the silicon wafer in an etchant for controlling a silicon wafer surface shape in which a fluorochemical surfactant is uniformly mixed in an alkaline aqueous solution to etch the front and back sides of the silicon wafer, and a both-side simultaneous polishing process 16 of simultaneously polishing the front and back sides of the etched silicon wafer or a single-side polishing process of polishing the front and back sides of the etched wafer for every side, in this order.

Owner:SUMCO CORP

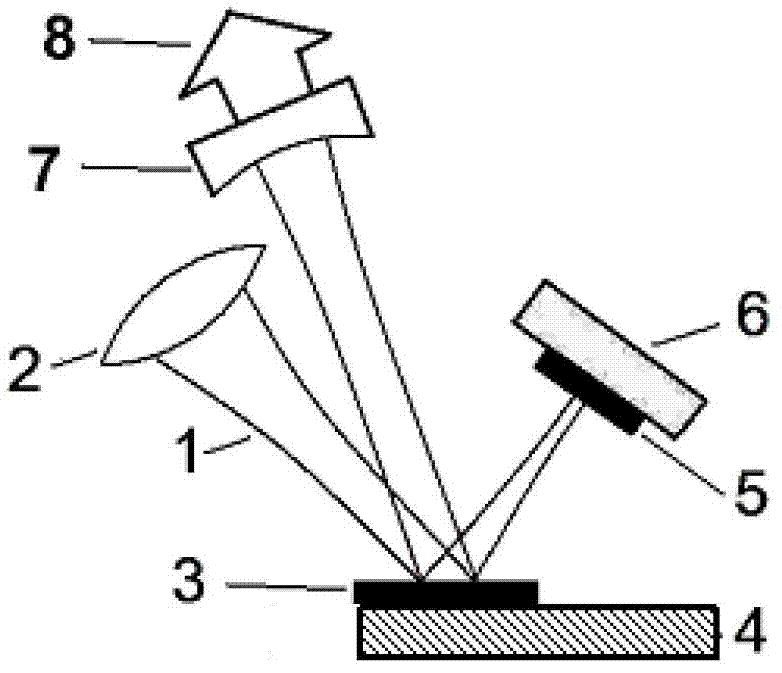

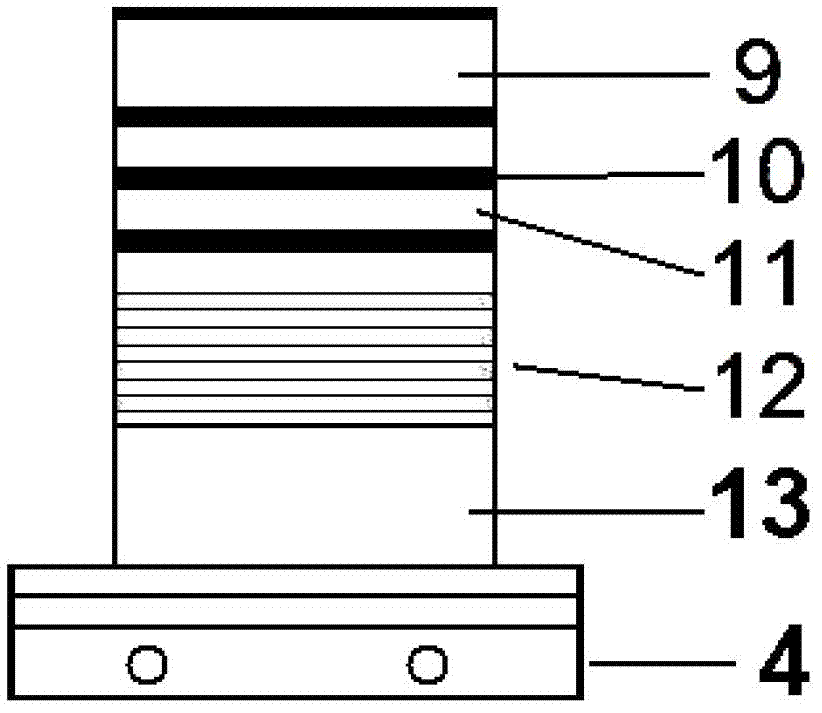

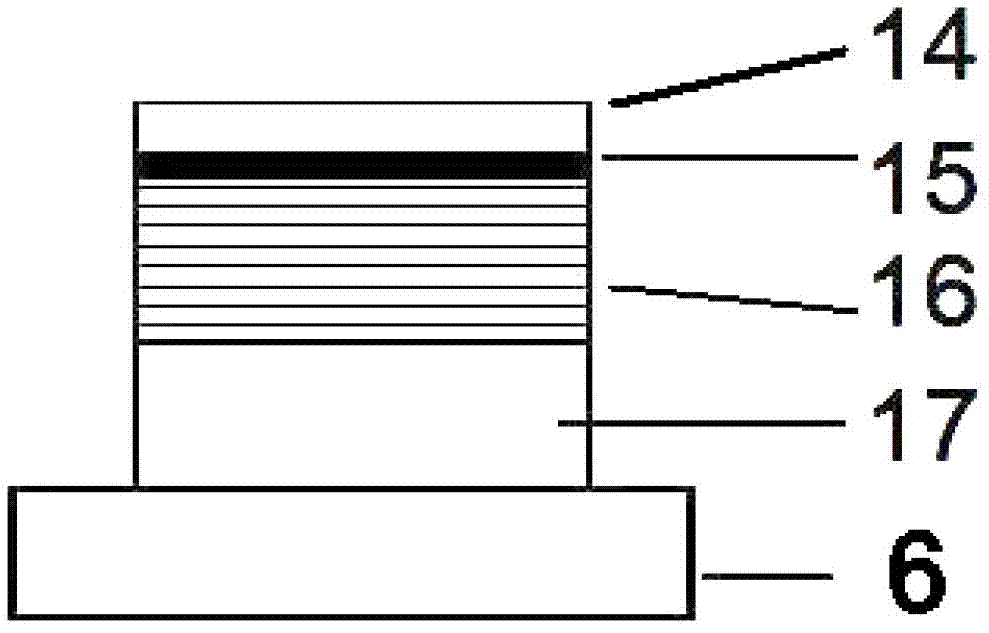

Graphene mode-locked optically pumped thin disc semiconductor laser

InactiveCN102769249ASimple structureShort recovery timeLaser detailsLaser output parameters controlResonant cavityCoupling

The invention relates to a graphene mode-locked optically pumped thin disc semiconductor laser, belonging to the technical field of semiconductor lasers. A V-shaped resonant cavity and a pump light source. The resonant cavity consists of an emergent end lens, a middle reflecting mirror and an end surface reflecting mirror, wherein the emergent end lens is an output coupling lens, the middle reflecting mirror adopts a semiconductor gain chip which is installed on a radiating device and the pump light source irradiates the semiconductor gain chip through a lens group. The graphene mode-locked optically pumped thin disc semiconductor laser is characterized in that the end surface reflecting mirror is a graphene saturable absorber mirror and the graphene saturable absorber mirror comprises a graphene saturable absorbing layer and a multilayer dielectric film reflecting mirror layer. Since the saturable absorber mirror uses a zero-band-gap graphene material for making an absorbing area, saturable absorbing bandwidth does not have wavelength selectivity, the saturable restoration time is very short and ultrashort pulse output of self-starting picoseconds or femtoseconds is easy to produce. The entire system is proved to have the advantages of simple structure, easiness in adjustment, narrow output pulse width and high repeating frequency.

Owner:BEIJING UNIV OF TECH

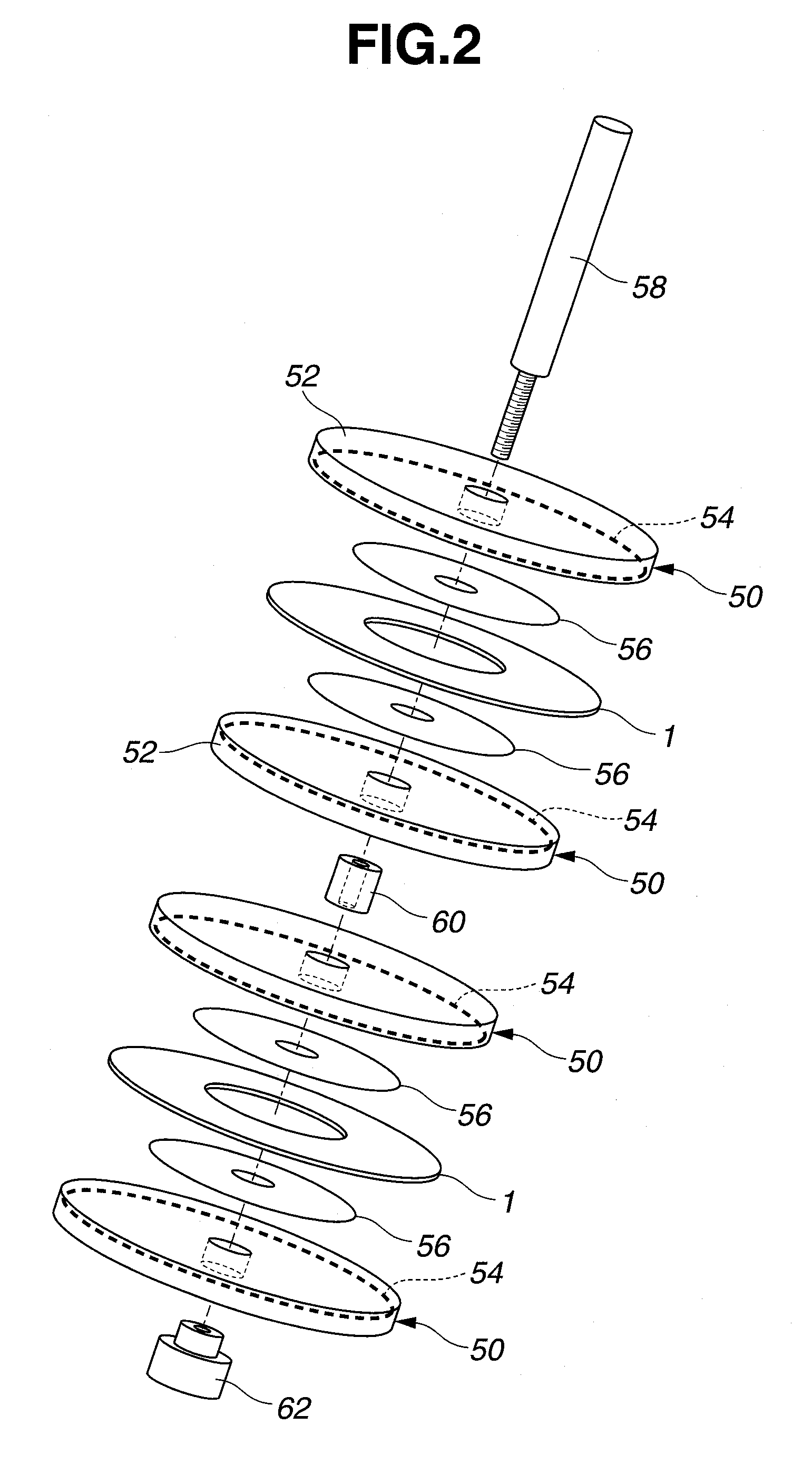

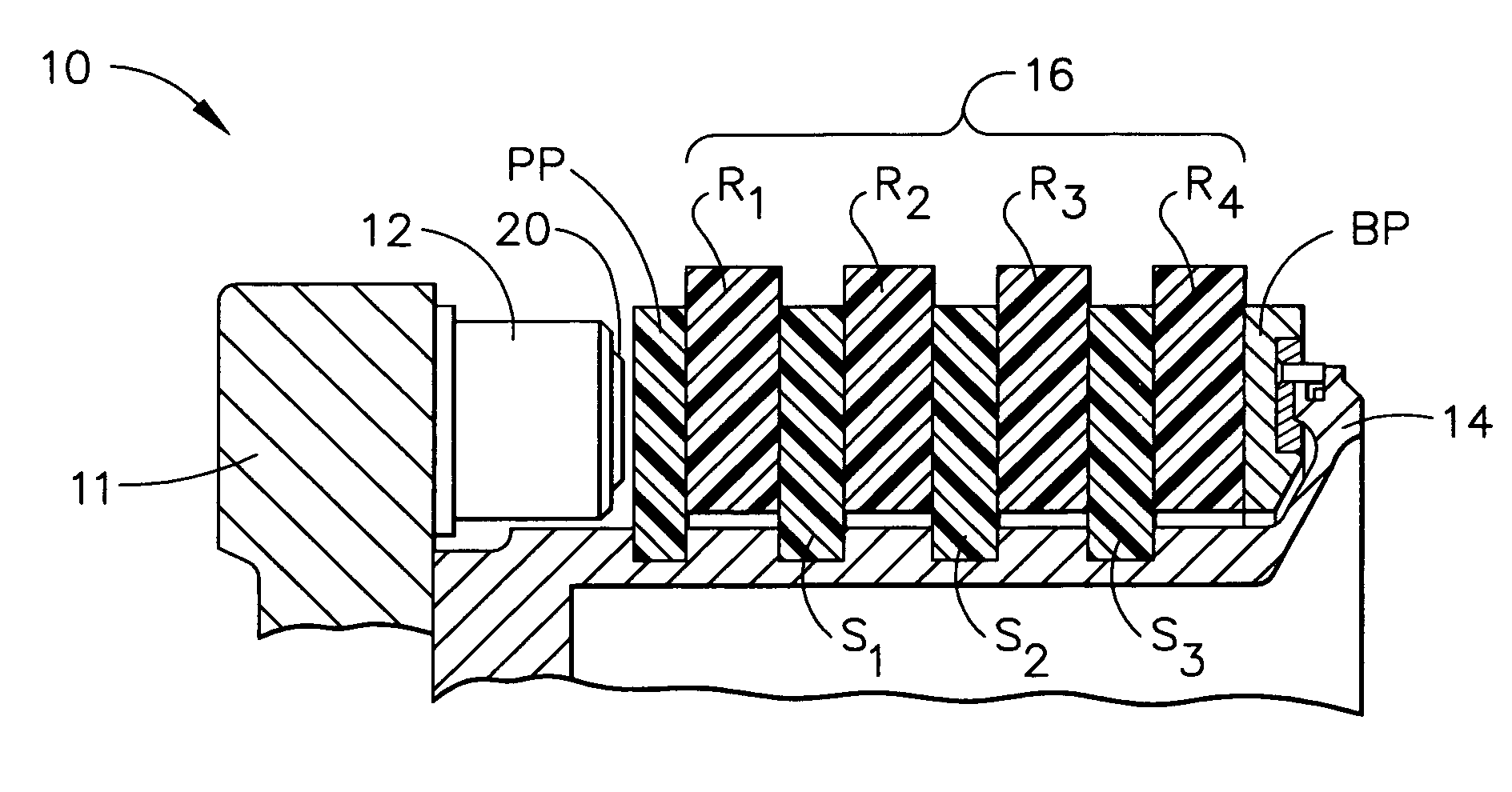

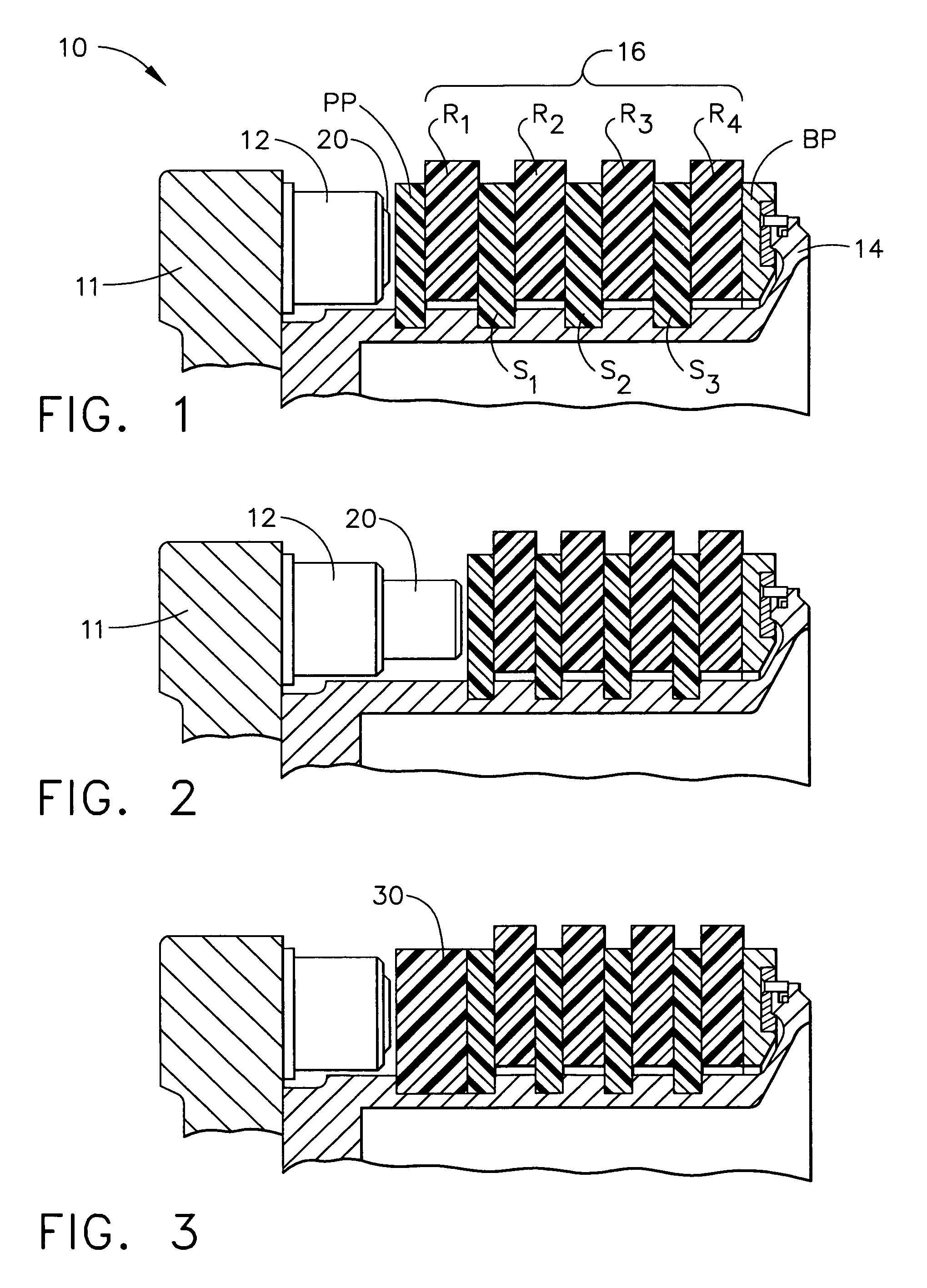

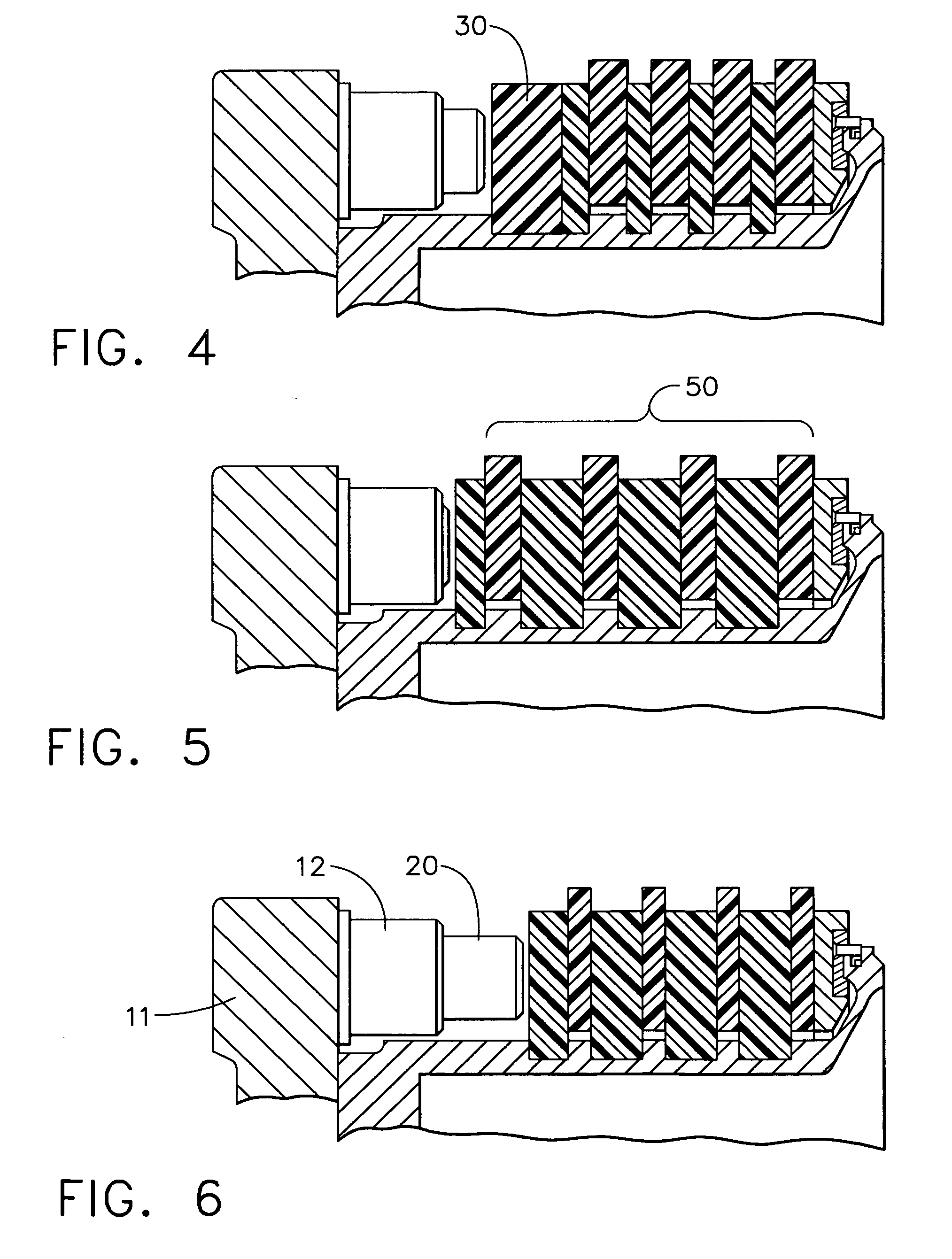

Method of increasing friction material utilization for carbon brakes

A method of increasing carbon disc utilization in aircraft carbon brakes. A brake (10) is initially assembled with a heat stack (16) of alternating thick rotors (R1–R4) and thin stators (S1–S3). When the piston (20) is fully extended, it is retracted and a spacer (30) is inserted between the piston (20) and the original heat stack (16). The brake (10) is then subjected to a another half tour. After this half tour, the brake (10) is overhauled, and the now-thin discs (S1–S3, PP and BP) are replaced with thick discs to form another heat stack (50). For the next half tour, no spacer is used between the piston (20) and the heat stack (50). At the end of this half tour and the piston (20) is fully extended, a spacer (70) is inserted between the piston (20) and the heat stack (50). The heat stack (50) remains unchanged. For the next half tour, it is accomplished with the spacer (70). When this half tour is completed, the worn out rotors are replaced with new thick rotors and the process can be repeated.

Owner:HONEYWELL INT INC

Method for making substrate wafers for low-defect semiconductor components, obtained thereby and uses thereof

InactiveUS20050193942A1Reduces anisotropic stress statePolycrystalline material growthAfter-treatment detailsSingle crystalPartial pressure

A method for making a substrate wafer for a low-defect semiconductor component is described. In this method a single crystal having a [0001] surface perpendicular to a c-axis thereof is formed, subdivided into thin disks each with at least one disk surface to be coated, the at least one disk surface is smoothed and the thin disks are tempered at a temperature above 1770 K. Preferably the tempering occurs for at least 10 minutes at temperatures greater than 1770 K in a dust-poor atmosphere with a reduced oxygen partial pressure. Al2O3 is a preferred material for the single crystal.

Owner:SCHOTT AG

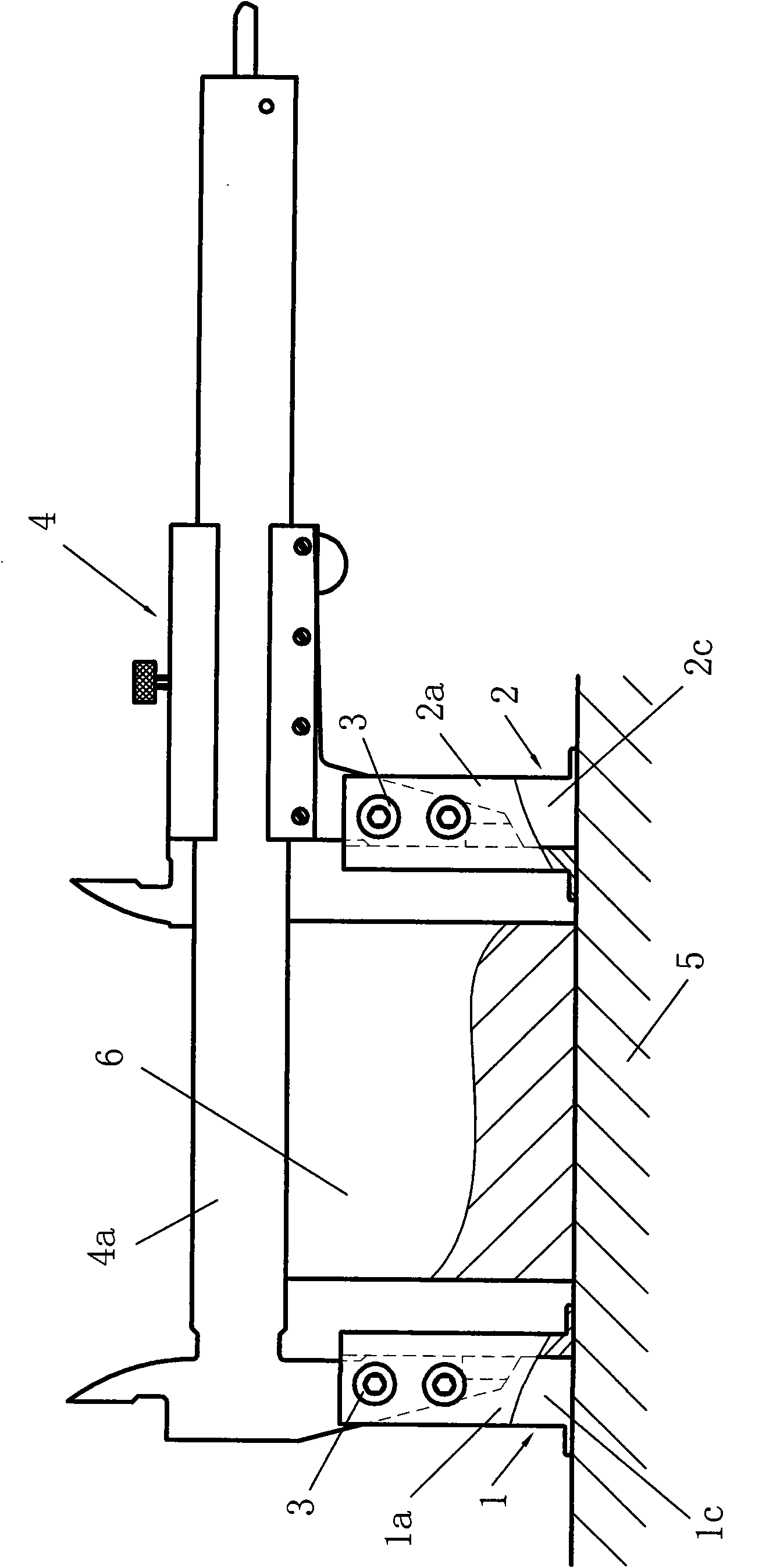

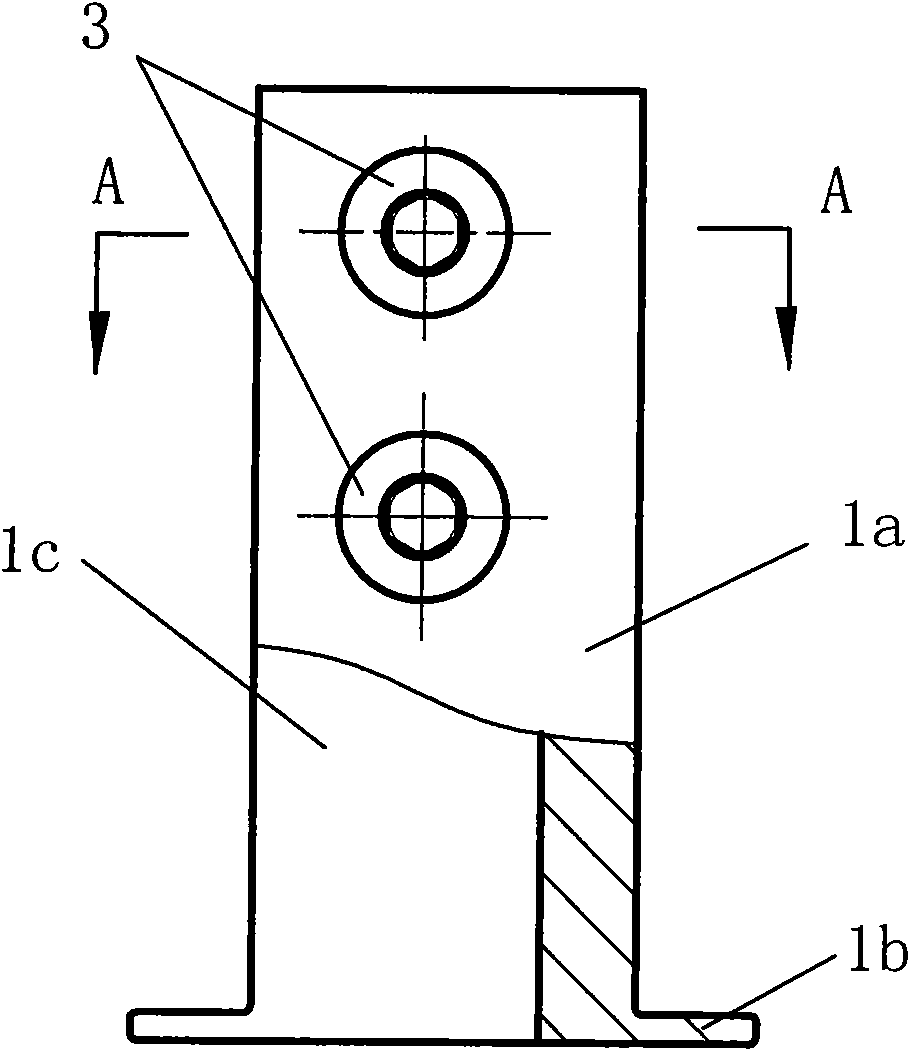

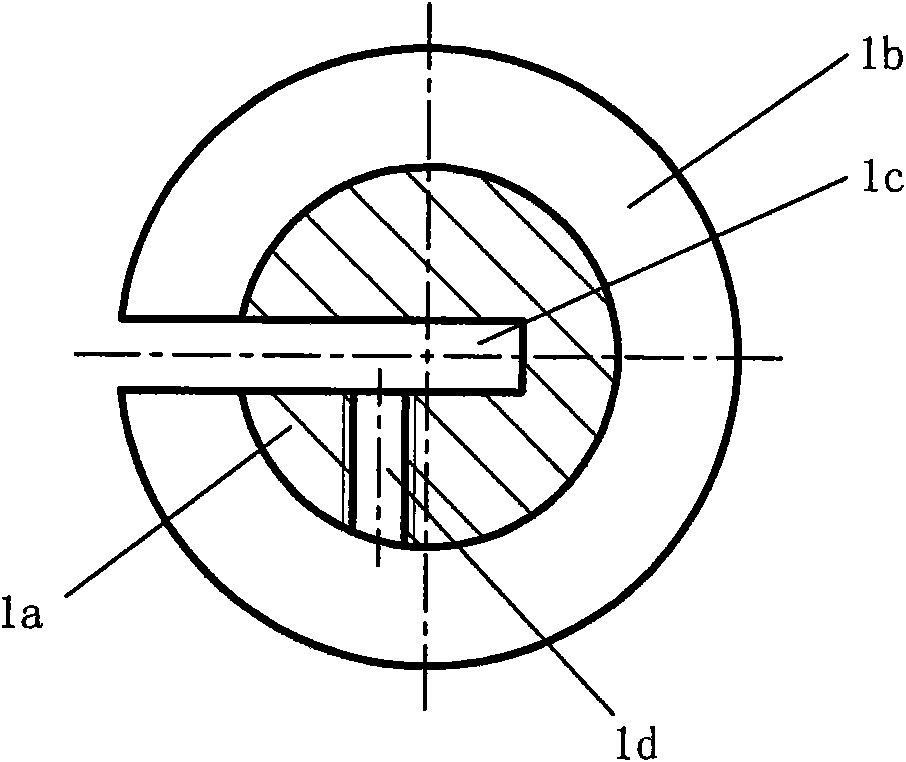

Method for measuring diameter of ring groove

InactiveCN101551222AAccurate detectionEasy to detectMechanical diameter measurementsVernier scaleTolerance limit

The invention relates to a method for measuring the diameter of a ring groove, which comprises an installing method and a detecting method. The measuring method comprises the following steps: placing the lower surface of the body of a vernier caliper on the top surface of a sizing block positioned on a flat plate, and making two outside tips vertically hang at two sides of the sizing block; fitting the bottom surface of the lower flanges of the measuring tips sleeved on the tips with the flat plate, and tightly screwing fastening bolts; when detecting, inserting the flanges of the two measuring tips from two sides of a measured ring groove until the flanges touch the bottom of the groove; finding the maximum value D2 generated when the shaft axis of the two measuring tips and the shaft axis of the measured ring groove are in the same plane; comparing the reading D2 with the standard value D1 of a block gage which is previously measured; and then, judging whether the measured value is within the tolerance limit or not. Each measuring tip comprises a column shaft provided with an axial through groove, and a coaxial thin disc-shaped flange positioned at the bottom end of the column shaft. The invention can accurately and conveniently detect the diameters of inner ring grooves and outer ring grooves of different sizes to meet the detection requirements of various workpieces.

Owner:力帆科技(集团)股份有限公司

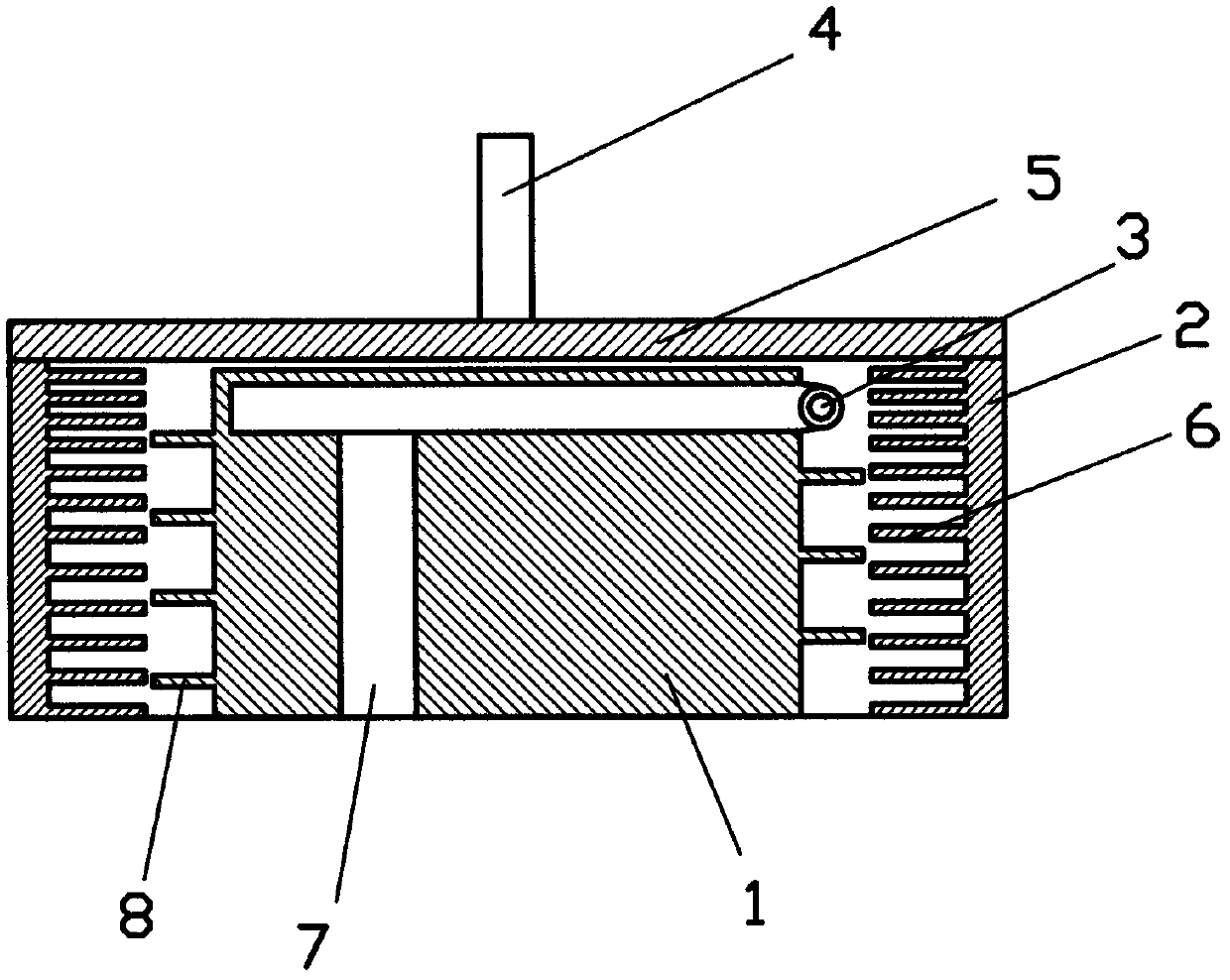

Biosensor apparatus for detection of thermal flow

ActiveUS7947223B2Eliminate needFirmly connectedMaterial heat developmentBiological testingHeat flowLow emissivity

Owner:SENZIME

Method for producing a silicon wafer

ActiveUS20050148181A1High precision flatnessMinute surface roughnessPolycrystalline material growthAfter-treatment detailsWaferingSurface roughness

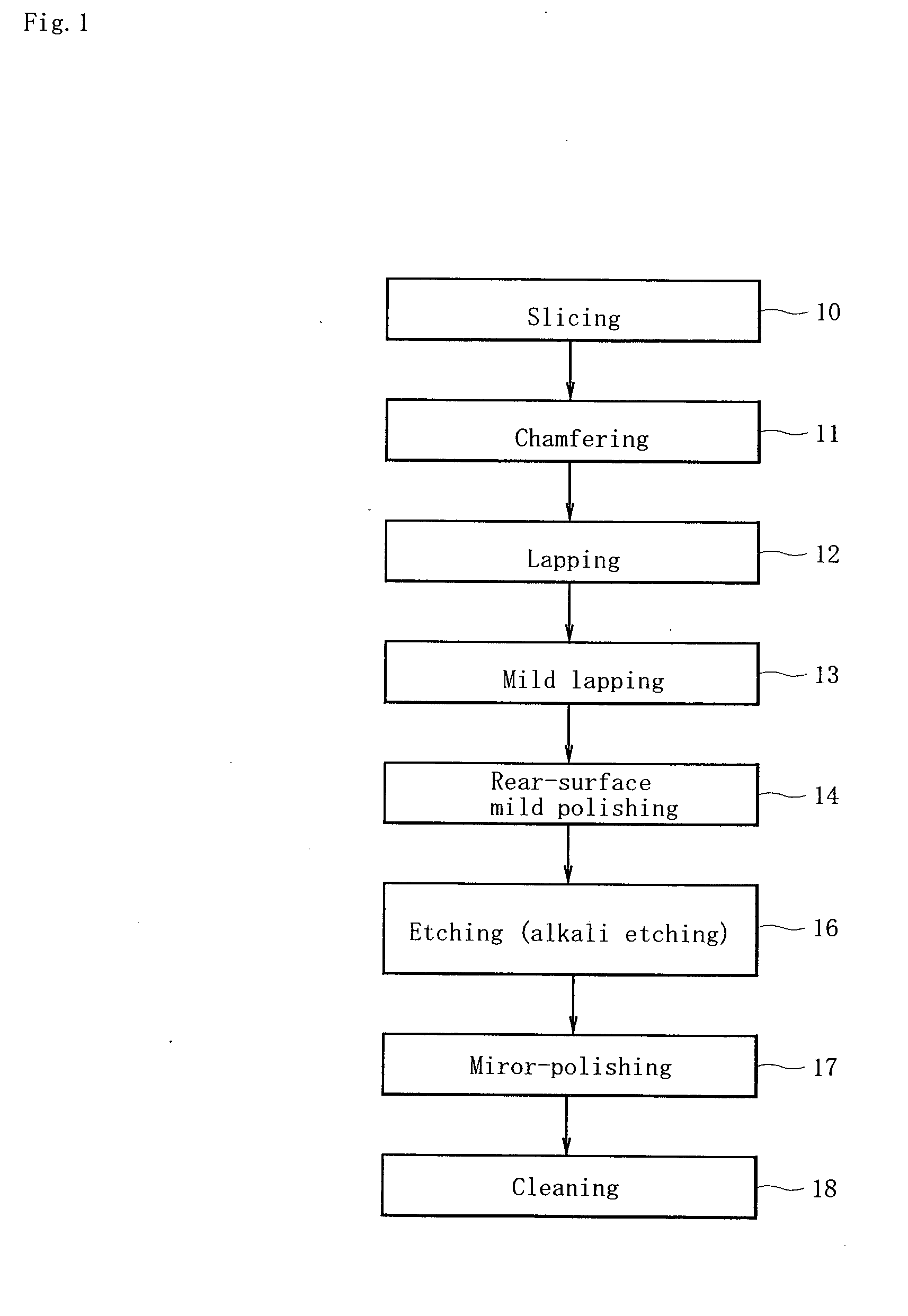

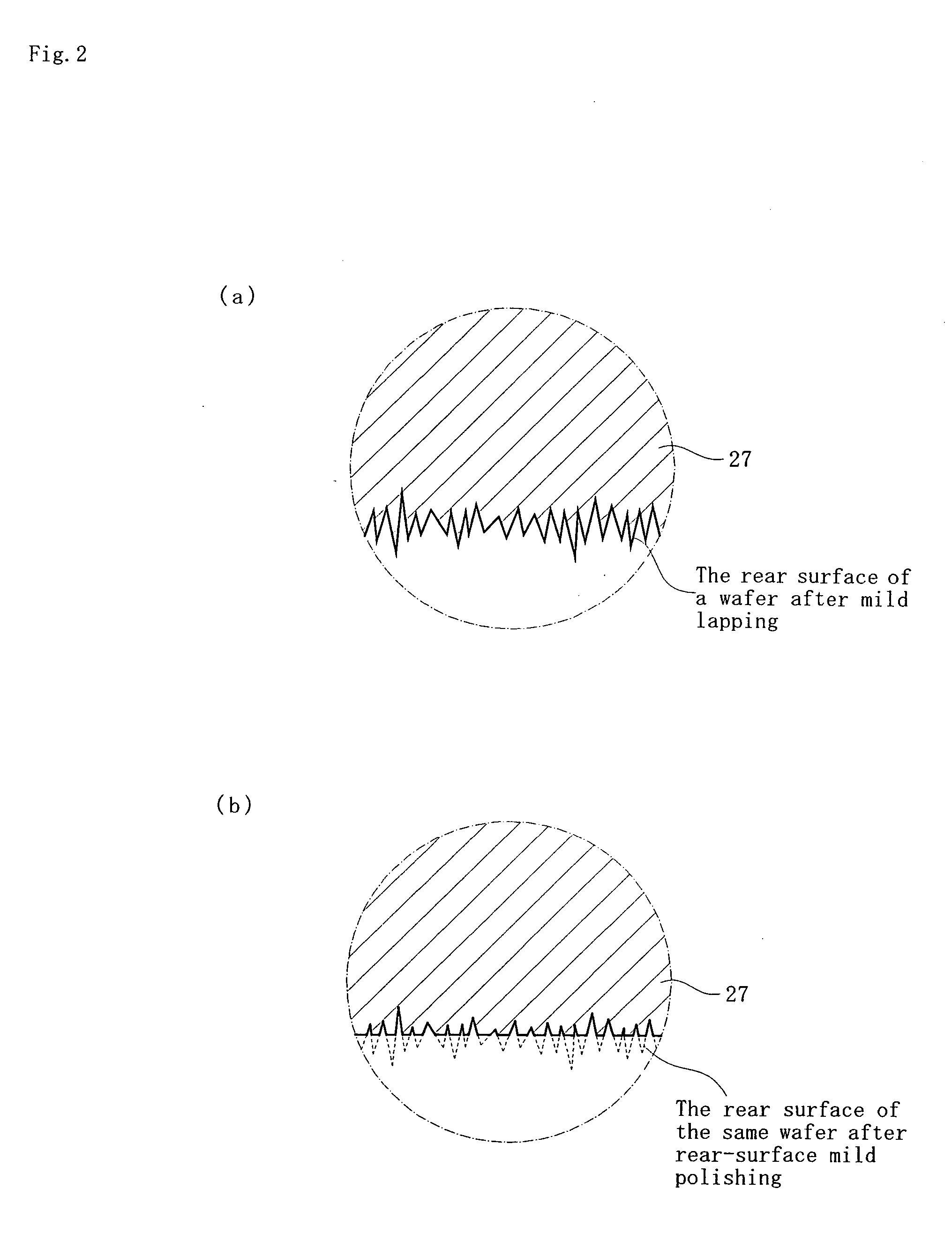

Provided is a method for producing a silicon wafer those surfaces exhibit precise flatness and minute surface roughness, and which allows one to visually discriminate between the front and rear surfaces, the method comprising a slicing step of slicing a single-crystal ingot into thin disc-like wafers, a chamfering step of chamfering the wafer, a lapping step for flattening the chamfered wafer, a mild lapping step for abrading away part of processing distortions on the rear surface of the wafer left after chamfering and lapping, a rear-surface mild polishing step for abrading away part of roughness on the rear surface of the wafer, an etching step for alkali-etching the remains of processing distortions on the front and rear surfaces of the wafer, a mirror-polishing step for mirror-polishing the surface of the etched wafer, and a cleaning step for cleaning the mirror-polished wafer.

Owner:SUMCO CORP

Optical measuring method and apparatus for deformation and strain of high speed rotating structural member

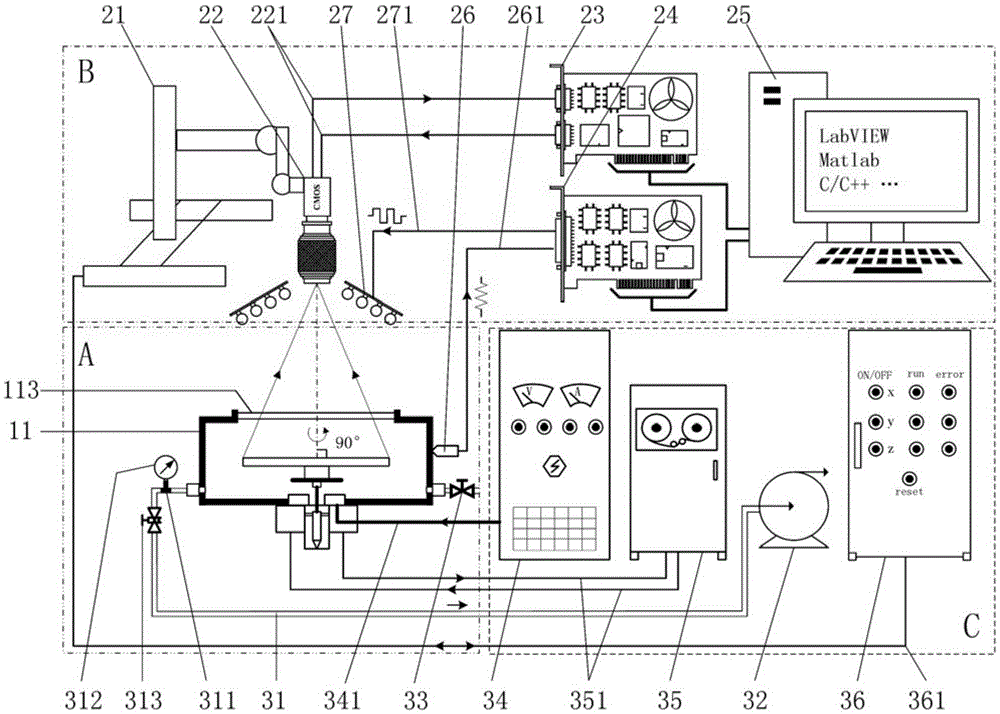

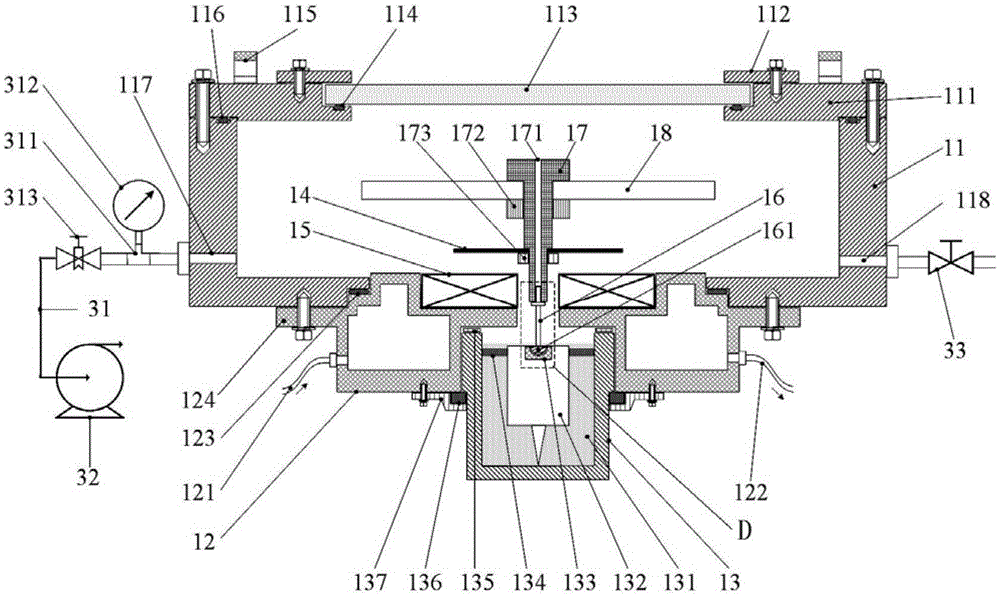

ActiveCN105333832ARealize variable frequency driveQuality improvementUsing optical meansSurface patternLow speed

The invention belongs to the field of rotating machinery experimental mechanics, and specifically relates to an optical measuring method and apparatus for deformation and strain of a high speed rotating structural member. The optical measuring apparatus comprises a high speed rotating system for a thin disk-shaped axisymmetric structural member, an image acquisition and signal processing system and an auxiliary test system, wherein the surface of a test member of the thin disk-shaped axisymmetric structure is coated with a pattern of concentric circles and a vertical ultra high-speed rotating axis is formed; a disk type variable frequency motor is used to drive the single-point supported vertical ultra high-speed rotating axis in a vacuum chamber; a common low-speed digital camera is used to acquire the surface pattern of concentric circles of the high-speed rotating thin disc-shaped axisymmetric structure test member under the irradiation of a stroboscopic light source; and the image identification technology is used to acquire the pattern change information and obtain deformation and strain of the high speed rotating test member after processing the pattern change information. The optical measuring method and apparatus for deformation and strain of a high speed rotating structural member can acquire the stress information by measuring changes of the radius of the concentric circles, and are suitable for the mechanical robustness testing field of high speed and ultra high-speed rotating structural member, wherein the rotating speed is greater than 10000rpm.

Owner:TSINGHUA UNIV

Sealing ring structure of a sinkhole

A sealing ring structure of a sinkhole, which is inlaid in the sinkhole to achieve bugproof and odorproof effects. The sealing ring structure includes a base seat, a diaphragm and a gum ring. The base is a ring body having a screen section formed with multiple perforations. The center and other portions of the screen section are respectively formed with holders. An upper end and a lower end of the base seat are respectively formed with a flange and a stepped skirt. The diaphragm is a gum-made thin disc having chucking bosses inserted in the holders to connect the diaphragm under the base seat with outer circumference of the diaphragm tightly attaching to the stepped skirt of the base seat. The gum ring is fitted around the base seat under the flange thereof. A middle portion of the gum ring is formed with a bight section. When the base seat is placed in the sinkhole, the gum ring is snugly watertight fitted in the sinkhole. The sealing ring can be directly placed in the sinkhole on a stepped shoulder section thereof instead of the conventional petal-type plastic ring to achieve a bugproof and odorproof effect.

Owner:HUNG DEN LU

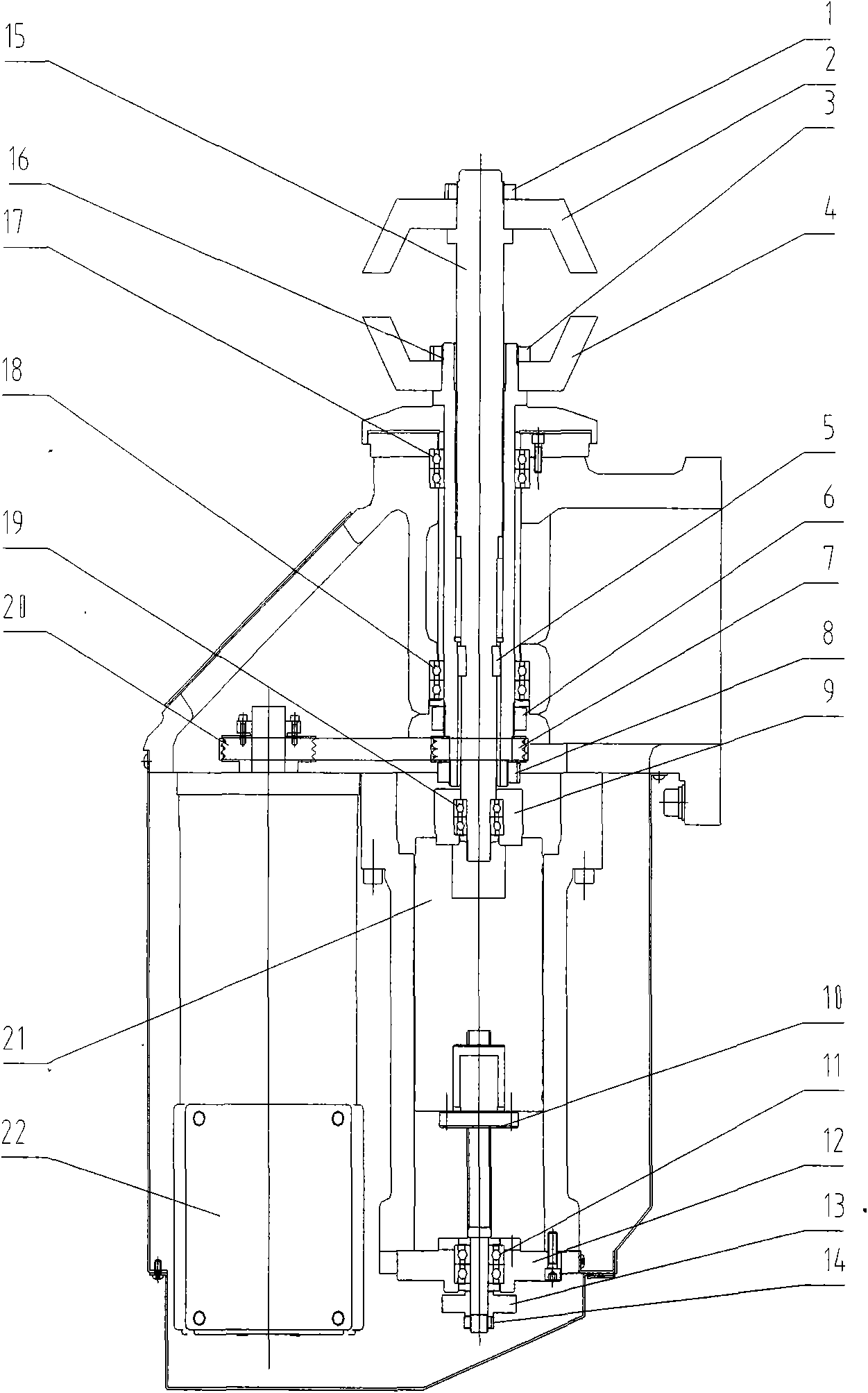

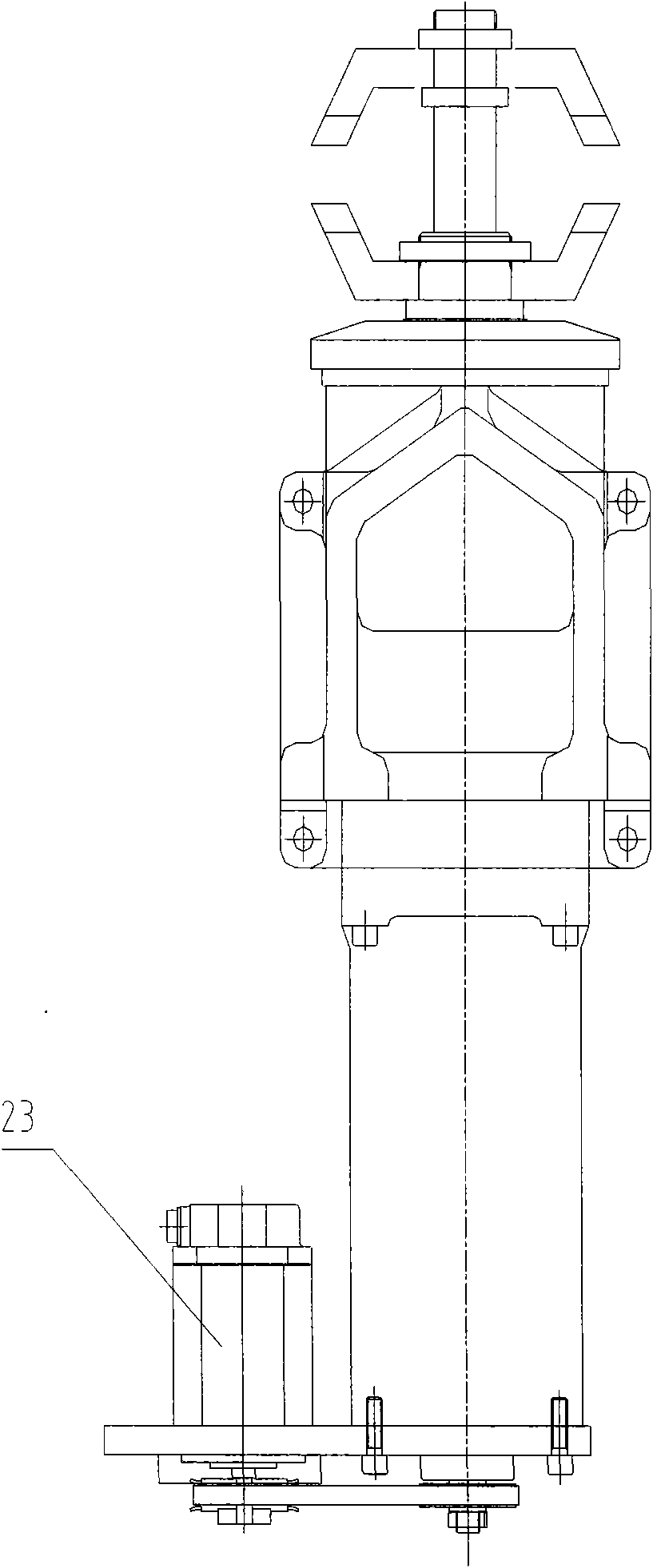

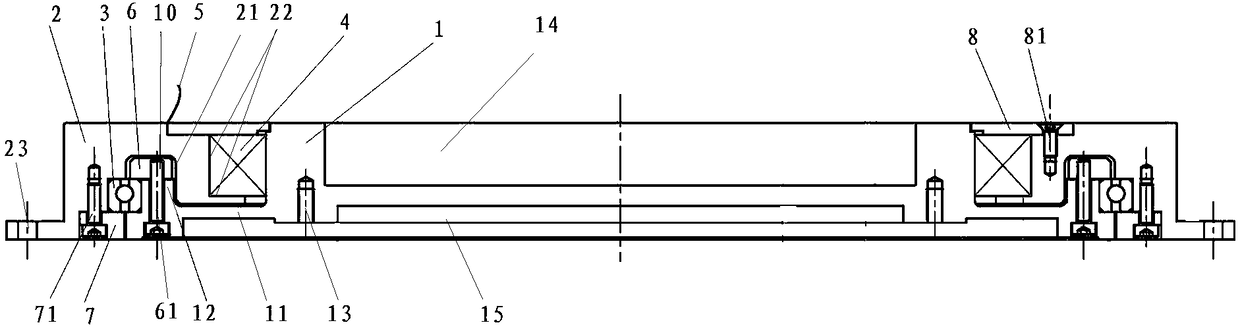

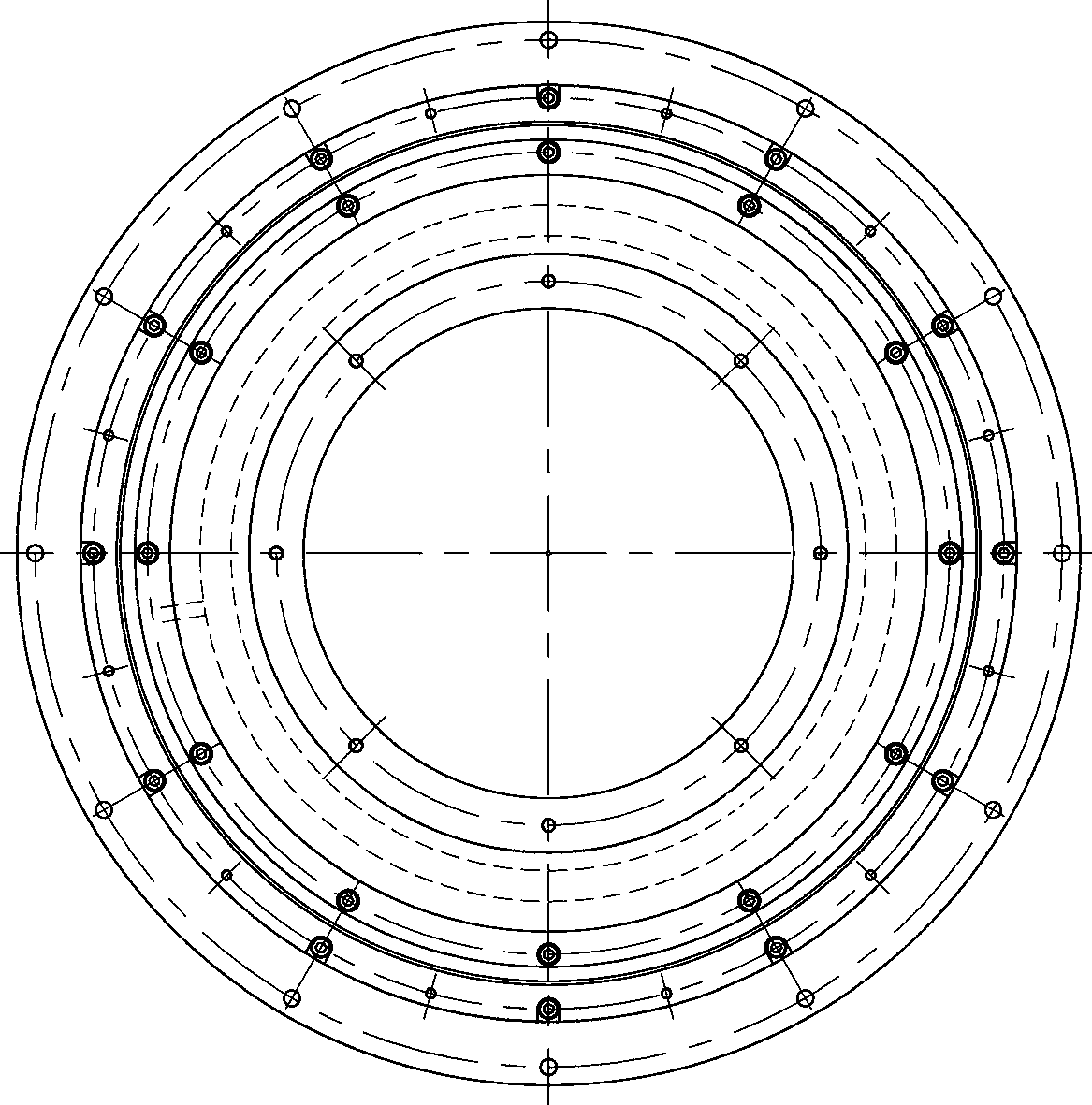

Method and system for grinding double sides of disc type rotary work piece, and vertical double-sided grinding machine with numerical control synchronous double-sided grinding head

ActiveCN101612715AImprove performanceImprove efficiencyPlane surface grinding machinesNumerical controlTransfer system

The invention relates to a method for grinding double sides of a disc type rotary work piece, a double-sided grinding system and a vertical double-sided grinding machine. The method is to grip a work piece on a transfer system through an inverted rotary gripping mechanism, and feed the work piece into a vertical double-sided grinding device to grind double sides of the work piece. The system grinds the work piece by adopting the vertical double-sided grinding machine. The grinding machine is provided with a double-sided grinding head consisting of an upper grinding wheel and a lower grinding wheel which are oppositely arranged; the two grinding wheels are parallel to each other, are positioned on the top of the grinding head device, and are connected with a grinding wheel rotary drive system which can lead the two grinding wheels to rotate synchronously, wherein at least one of the grinding wheels is connected with a grinding wheel vertical motion drive system. The method, the system and the grinding machine are beneficial to improvement of the manufacturing efficiency, ensure that the horizontally placed work piece is uneasily deformed in grinding, guarantee high precision processing of the thin-disc type work pieces, have stable system performance, easily realized structure, convenient installation and small occupied space, can be widely applied to double-sided synchronous grinding of various parts, and are mainly used for processing of the disc type rotary work piece and other disc shaped work pieces.

Owner:北京北一机床有限责任公司

Annular Tesla turbine

InactiveCN103306738ASmall sizeIncrease powerBlade accessoriesNon-positive displacement enginesCircular discTesla turbine

The invention provides an annular Tesla turbine which is characterized in that a rotor is in a ring shape, a stator is cylindrical and is arranged in the rotor, airflow rings are fully distributed inside the rotor, the space between the airflow rings adjacent to a nozzle is smaller, the space between the airflow rings far away from the nozzle is larger, and the nozzle is used for spraying air to the rotor along the tangential direction of the ring of the rotor. Since the airflow rings fully distributed inside the ring can be used for greatly increasing the contact area between the ring of the rotor and airflow; according to a boundary layer effect, the ring of the rotor can be driven to rotate by the airflow, so that the rotation of the rotor is realized; the airflow rings inside the ring of the rotor of the annular Tesla turbine are used for replacing the thin disc of a traditional Tesla turbine, the airflow rings and the ring of the rotor can be manufactured into a whole, or the airflow rings are supported and fixed on the ring, so that the airflow rings have rigidity better than that of the thin disc and have less possibility of deformation, and thus the rotor with a greater diameter and less possibility of deformation can be manufactured; and the power is increased, the efficiency is improved, and the operation is stable and reliable.

Owner:时剑

Flywheel generator system having open shaped loop coils

InactiveUS20100283350A1Save electricityGenerate efficientlySynchronous machinesAsynchronous induction motorsElectricityEngineering

A series of elongated oval wire windings bent into open C-shaped or other loop shape coils are positioned around a flywheel. Magnets, mating the loop opening shape, extend from the outer edge of the flywheel on a thin disc to pass through the coils to generate electricity with the spin of the flywheel. With no magnetic material is the coils there is no magnetic resistance created thereby providing more efficient electricity generation.

Owner:SURODIN EDUARD G

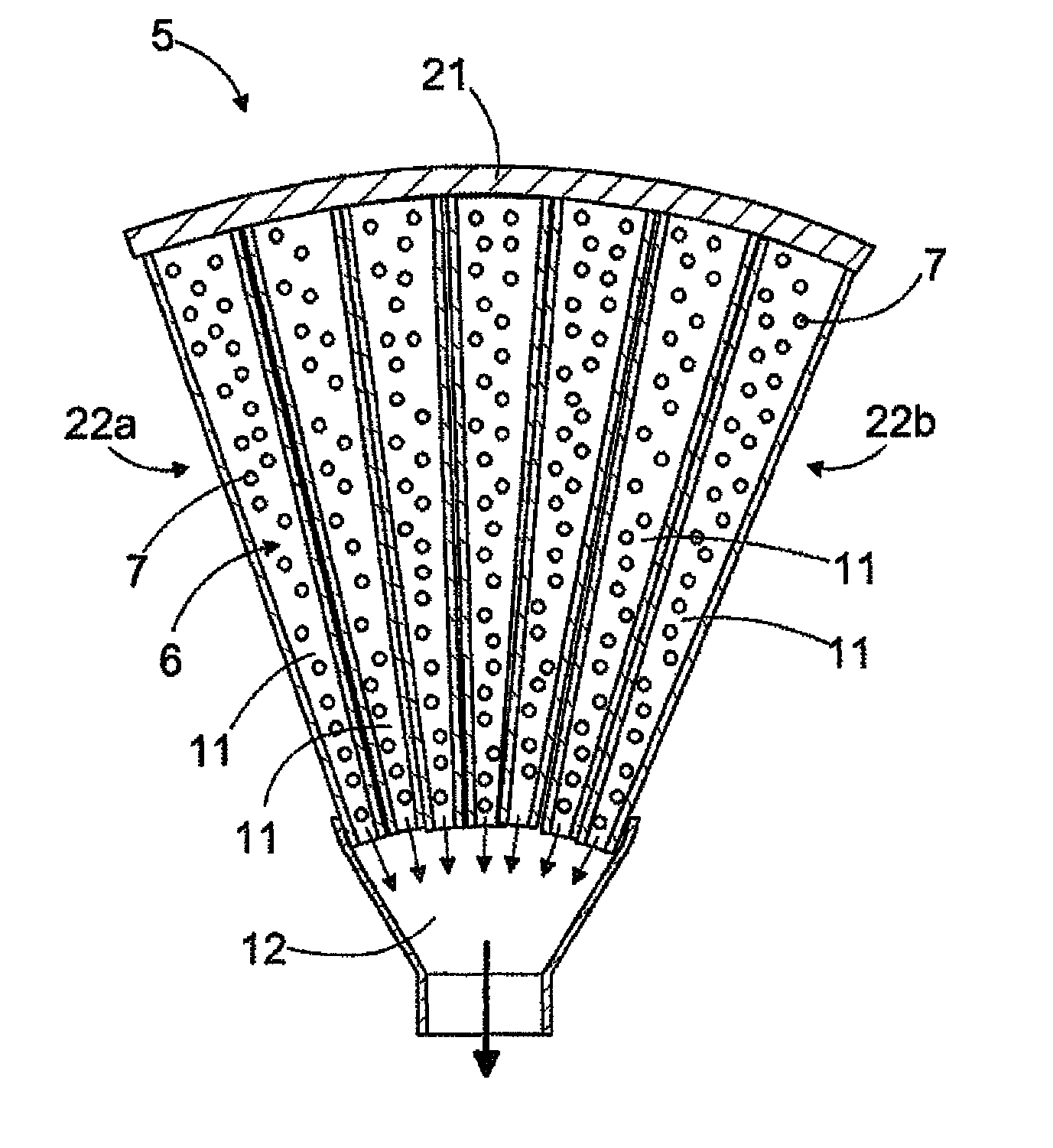

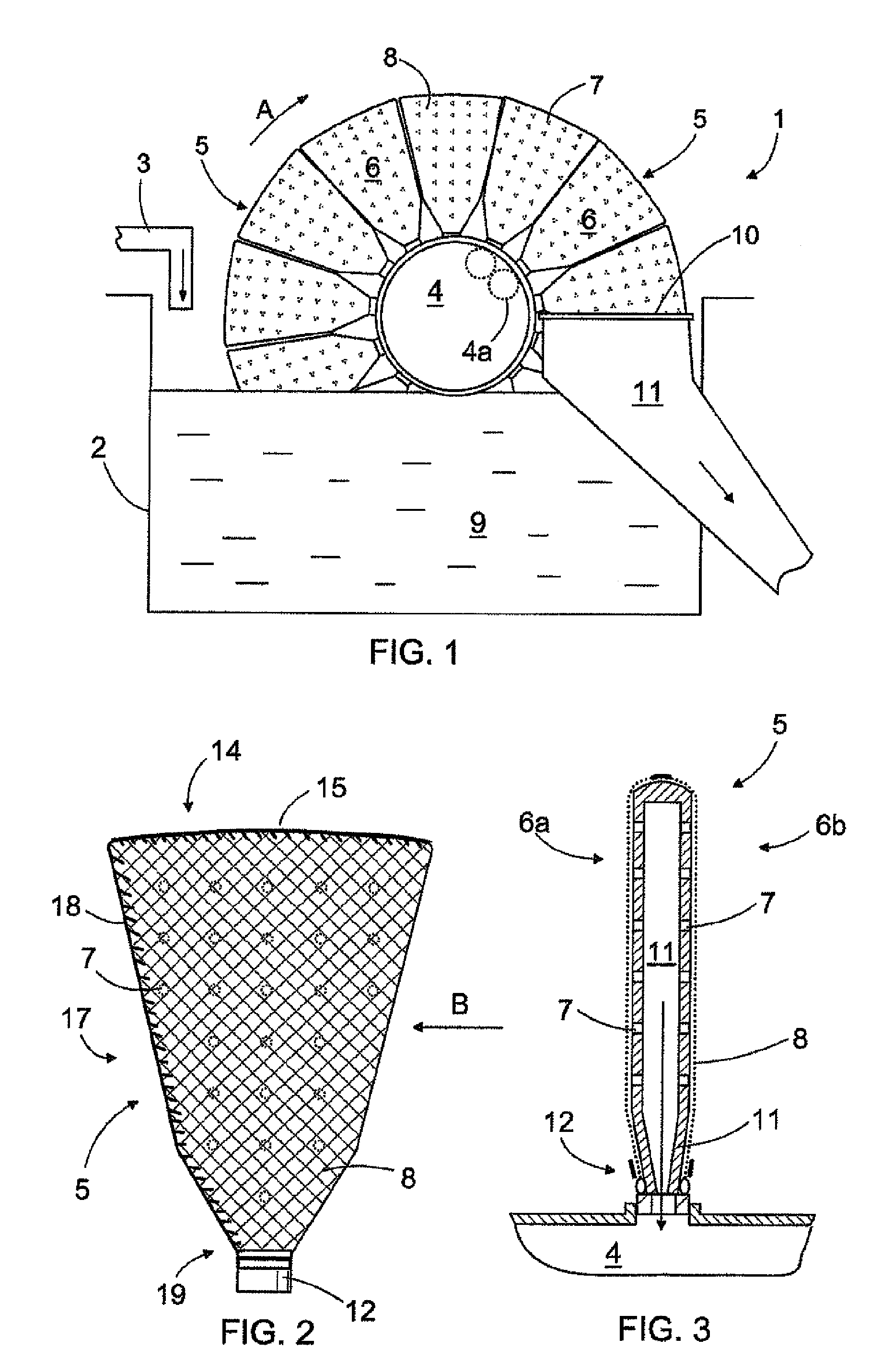

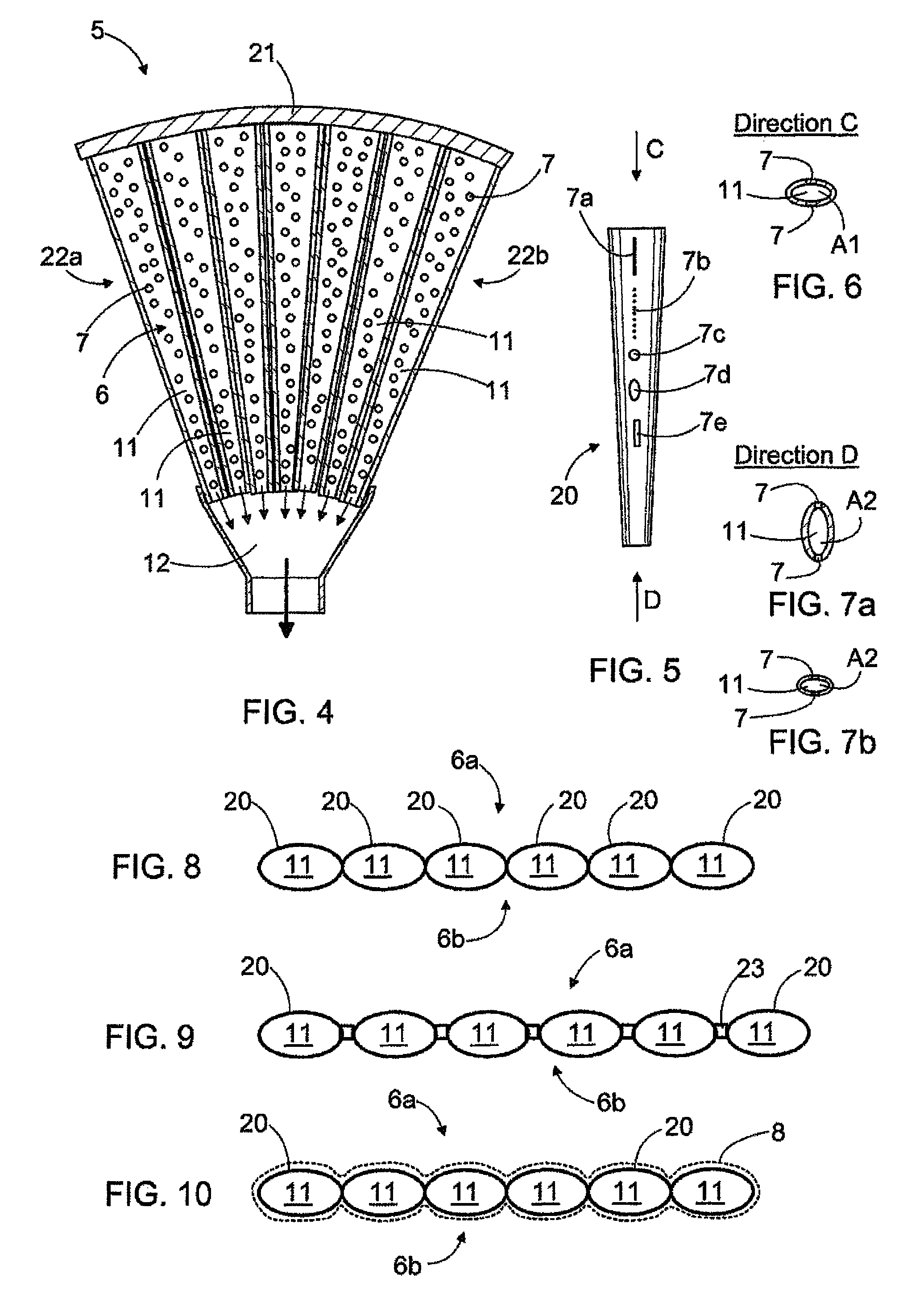

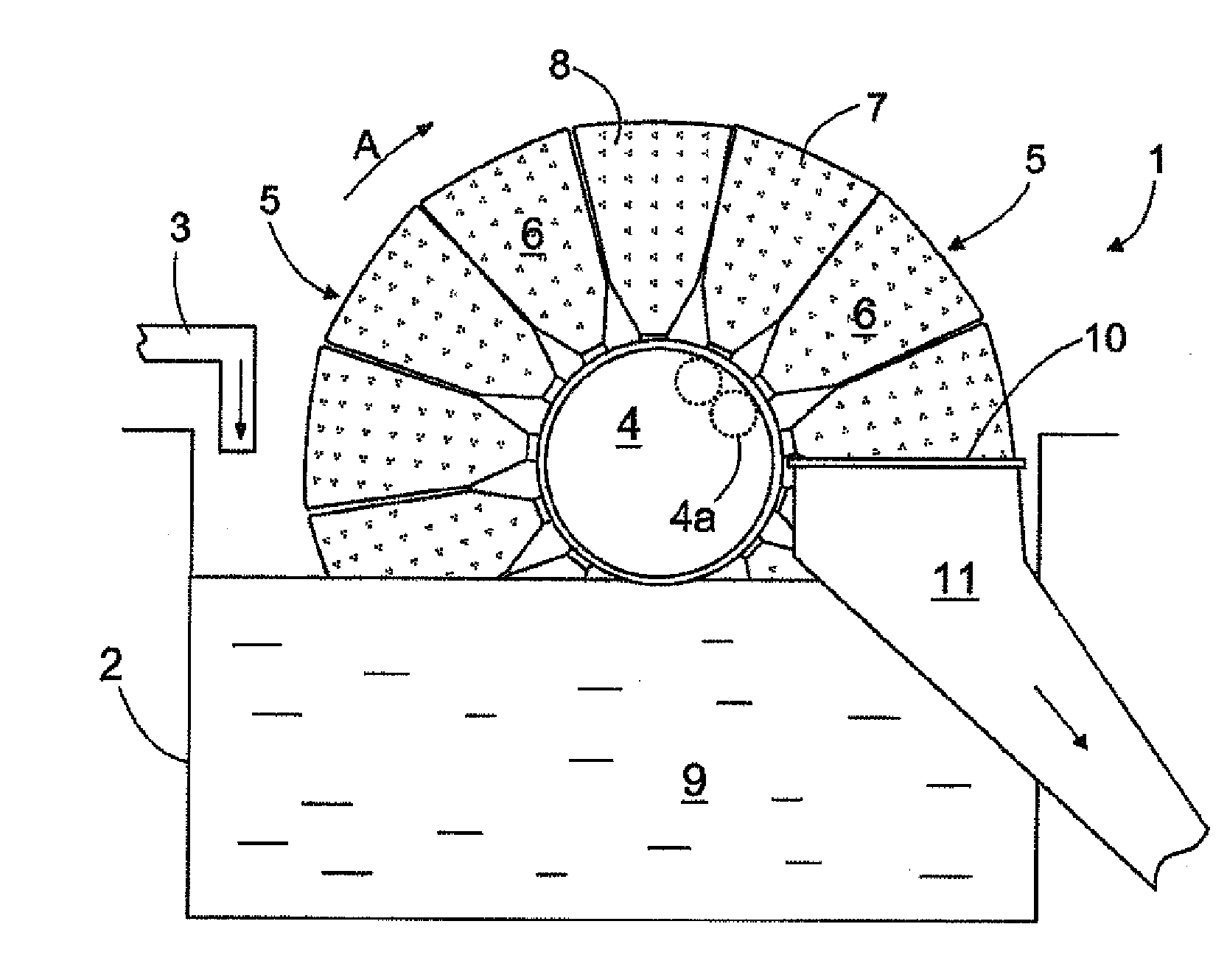

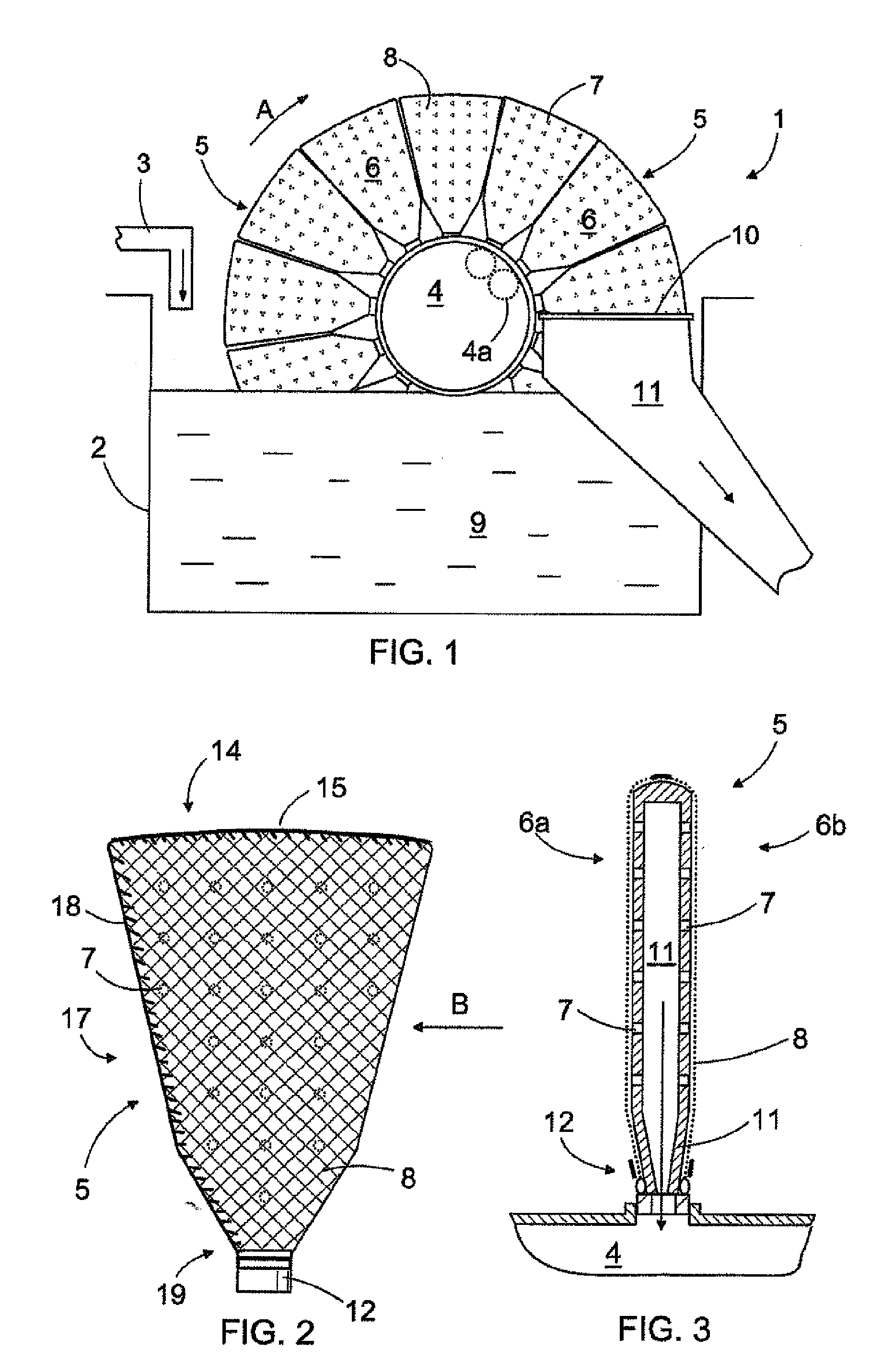

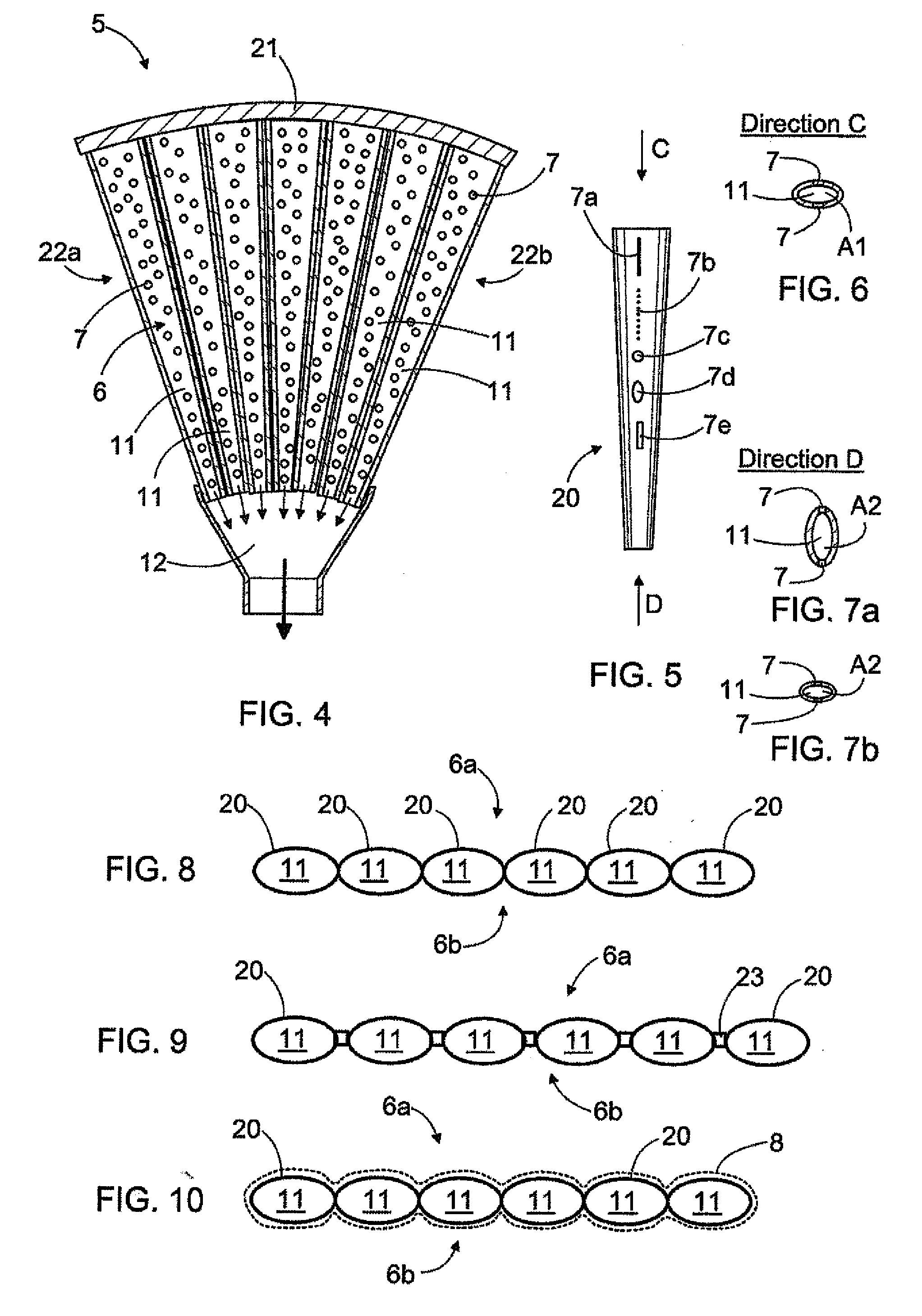

Disc filter sector and disc filter

ActiveUS8414769B2Improve filtration efficiencySpeed up the flowMembrane filtersLoose filtering material filtersCircular discFiltration

A disc filter includes several triangular sectors that are connected from their neck section to the body of the disc filter. The sectors form a relatively thin disc that is rotated during filtration in a basin that contains a suspension to be filtered. The side surfaces of the sector have openings through which liquid in the suspension passes into several essentially radial flow channels inside the sector to flow on to the neck section and away from the sector. A separating wall is formed between two adjacent radial flow channels. Furthermore, the sector is made of two side elements, which are of plastic material and the mating surfaces of which are placed against each other.

Owner:METSO FABRICS INC

Disc filter sector and disc filter

ActiveUS20100032364A1Quick installationSimple and fast assemblyMembrane filtersLoose filtering material filtersCircular discPlastic materials

A disc filter includes several triangular sectors that are connected from their neck section to the body of the disc filter. The sectors form a relatively thin disc that is rotated during filtration in a basin that contains a suspension to be filtered. The side surfaces of the sector have openings through which liquid in the suspension passes into several essentially radial flow channels inside the sector to flow on to the neck section and away from the sector. A separating wall is formed between two adjacent radial flow channels. Furthermore, the sector is made of two side elements which are of plastic material and the mating surfaces of which are placed against each other.

Owner:METSO FABRICS INC

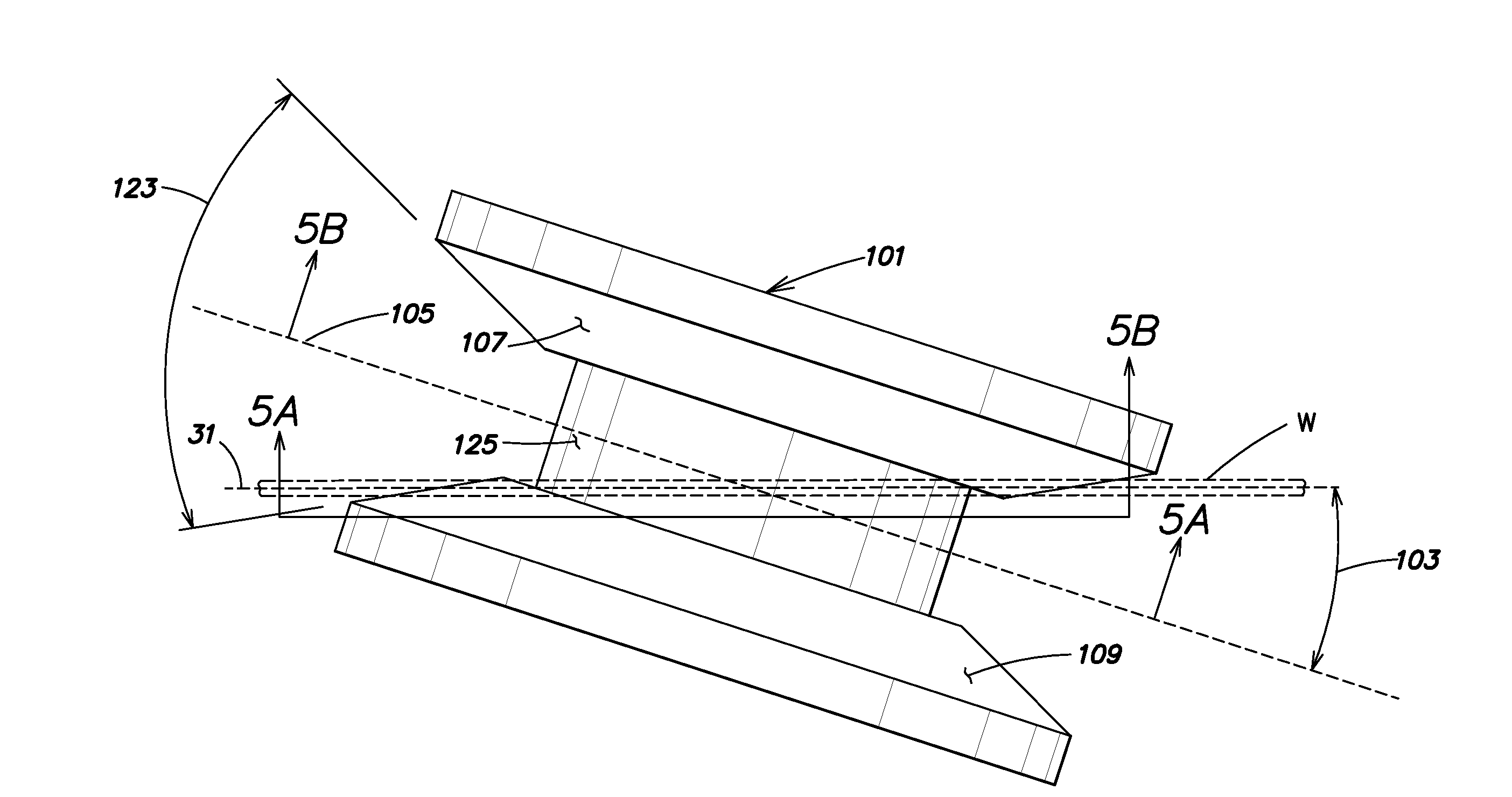

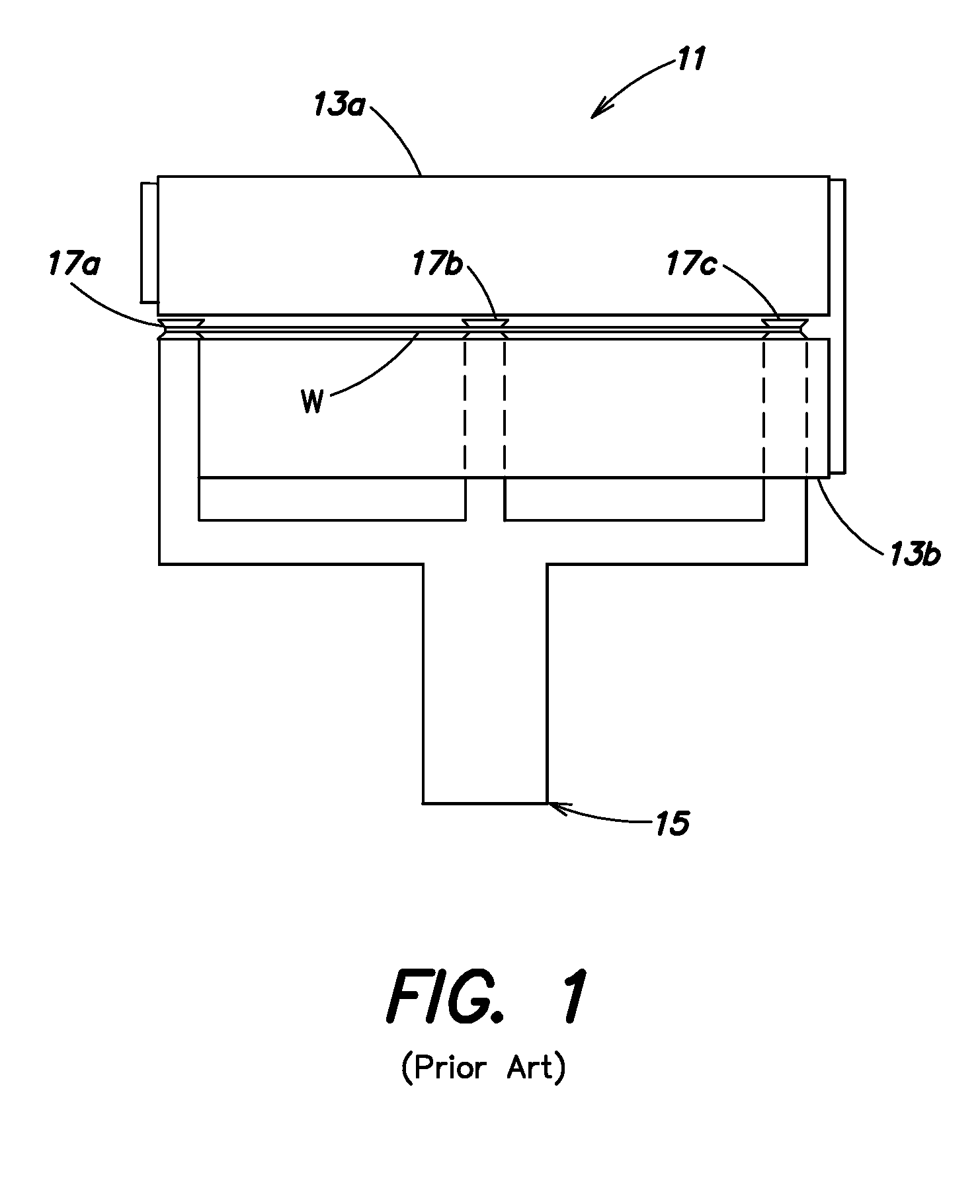

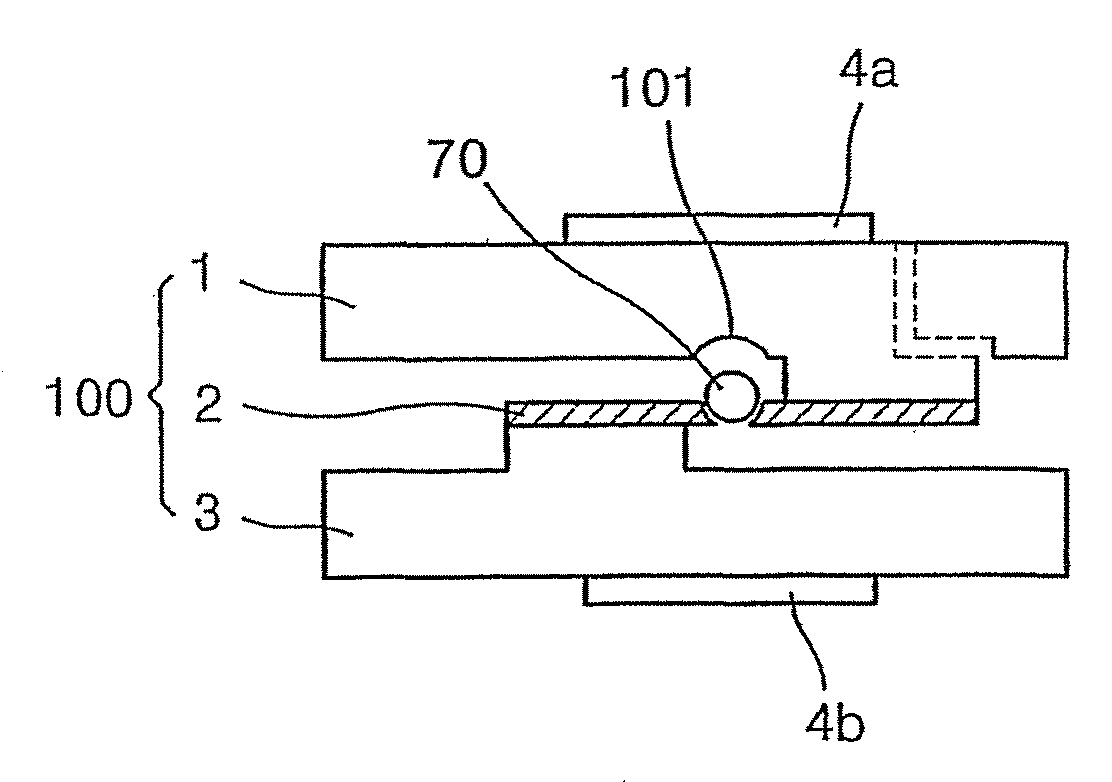

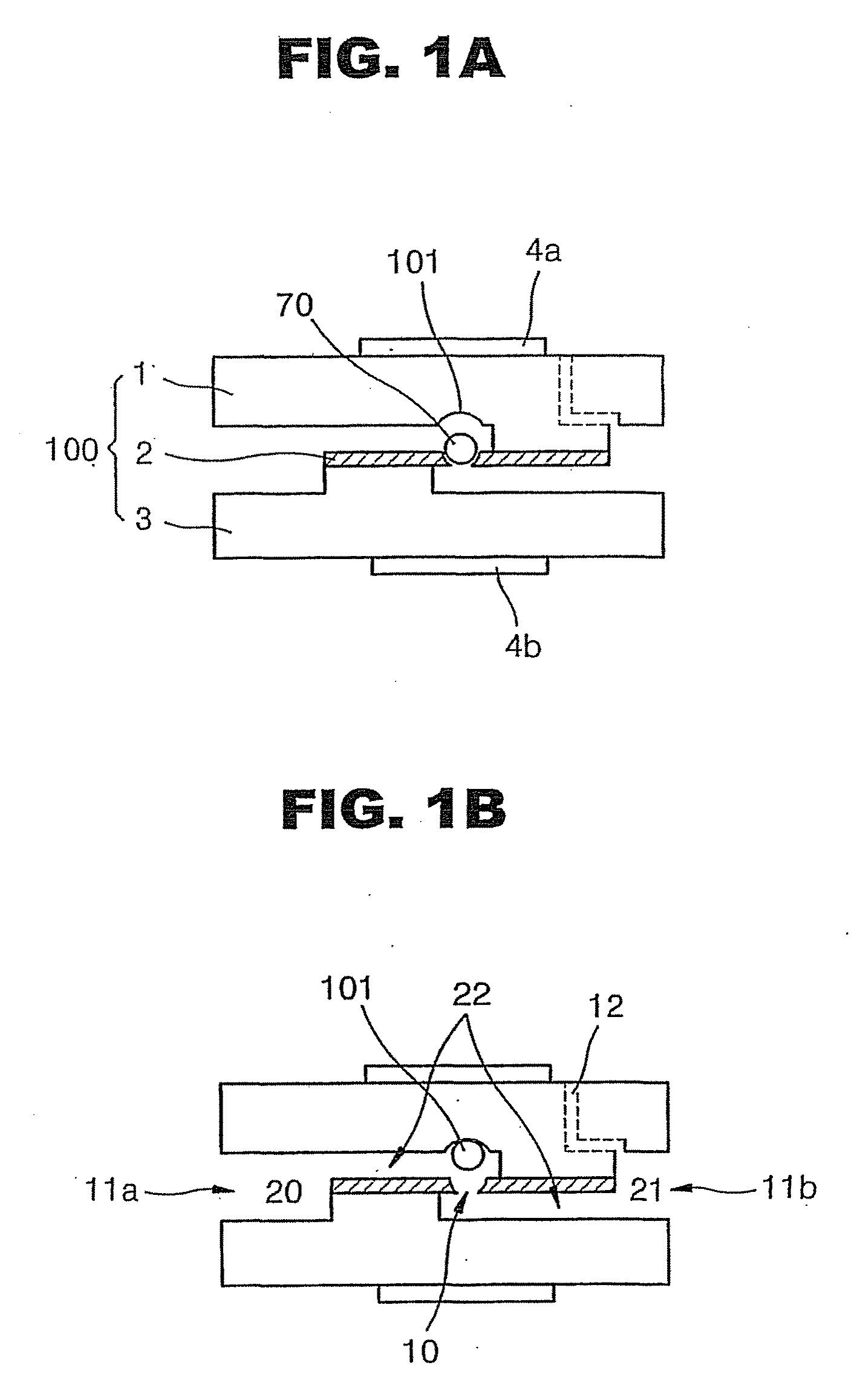

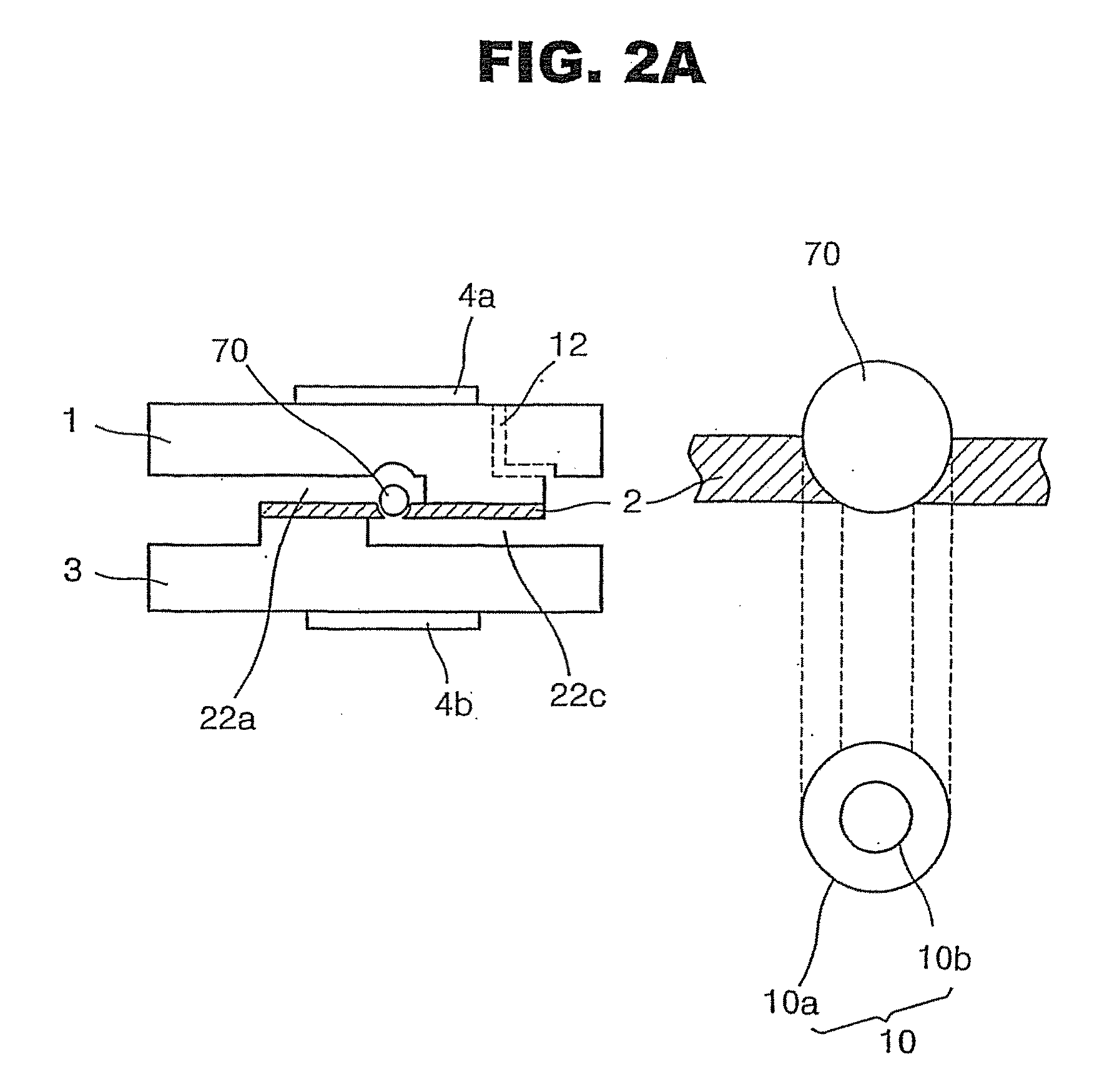

Wafer edge cleaning

In a first aspect, an apparatus for cleaning a thin disk is provided. The apparatus includes a support roller for supporting a rotating wafer within a wafer cleaner. The support roller comprises a guide portion, for receiving an edge of a wafer, having an inclined surface comprising a low-friction material and adapted to allow the wafer edge to slide thereagainst; and an edge-trap portion for retaining the edge of the wafer and having a transverse surface comprising a high-friction material and adapted, when in communication with the edge of the wafer, to resist sliding thereagainst. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

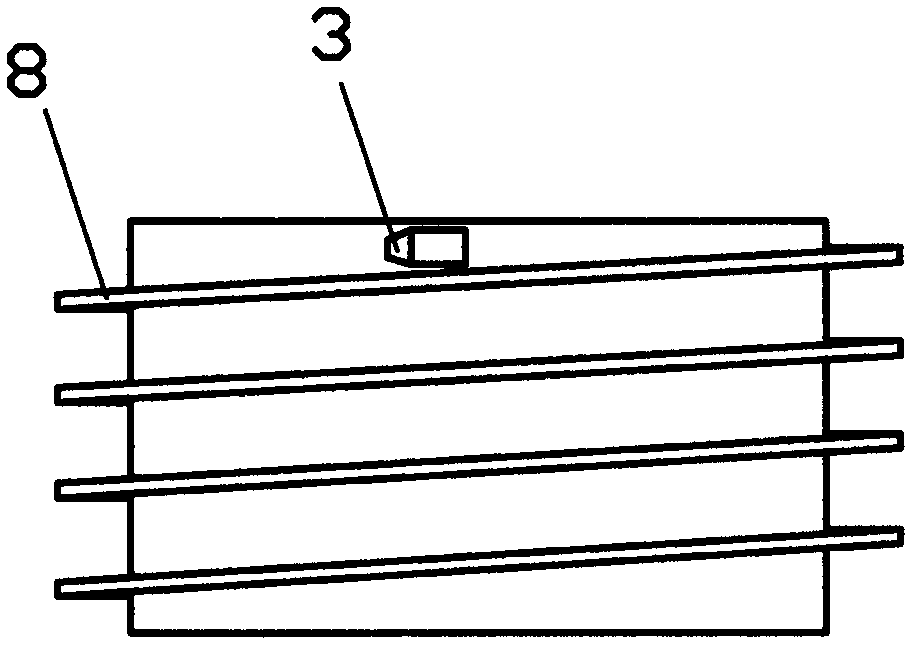

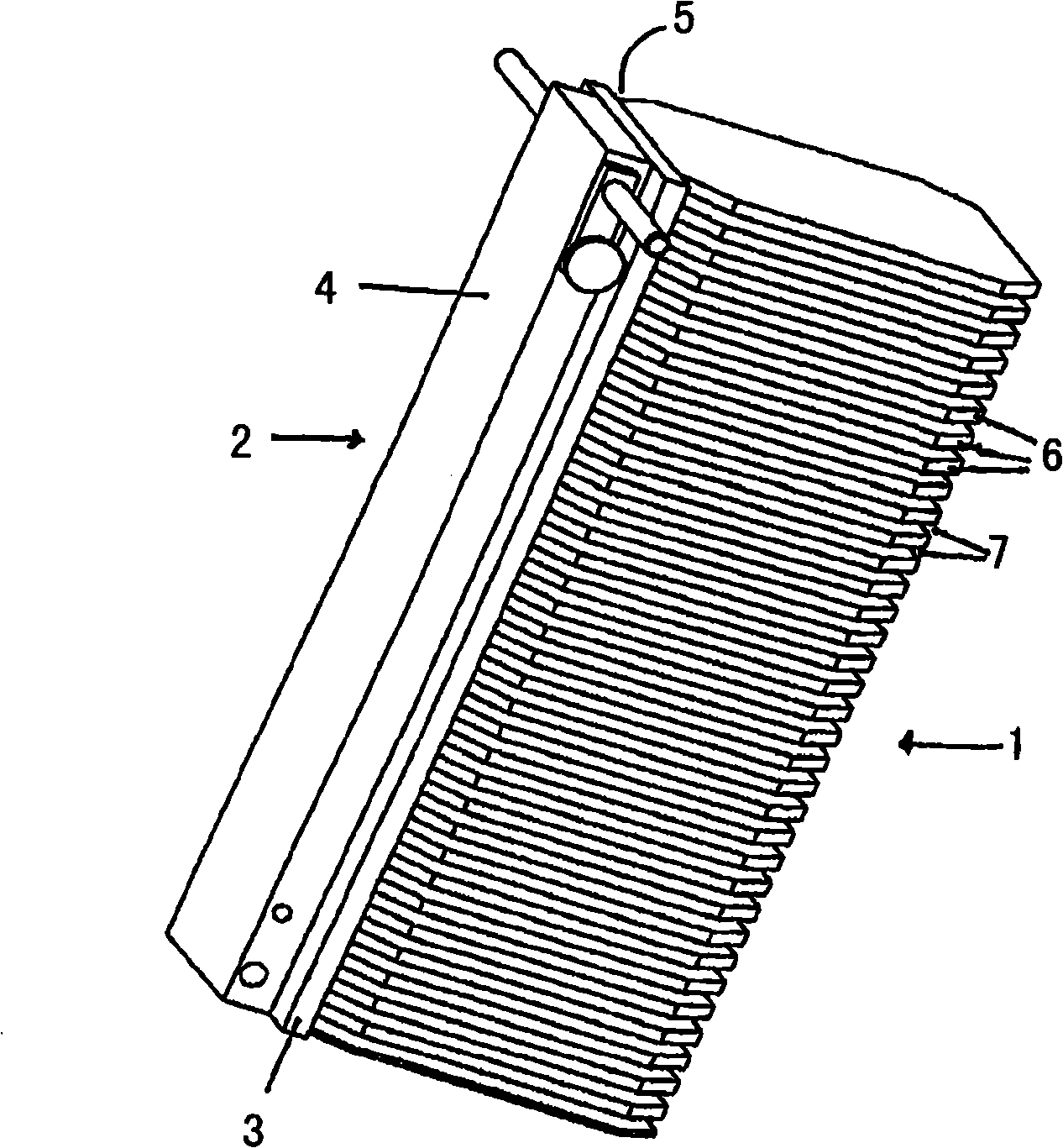

Apparatus and method for cleaning of objects, in particular of thin discs

InactiveCN101361166ASemiconductor/solid-state device manufacturingFlexible article cleaningBiomedical engineeringShower

The invention relates to a device for cleaning thin wafers (6), said wafers (6) being immobilized with one side on a support device (2) and an interspace (7) being defined between two respective adjoining substrates. The device essentially consists of a shower device (15) which is used to introduce a fluid between the interspaces (7), and a tank (14) that can be filled with the fluid and is dimensioned to receive the support device (2). The invention is characterized in that optionally either the shower device (15) can be displaced relative to the stationary support device (2), or the support device (2) relative to the stationary shower device (15), or both the support device (2) and the shower device (15) can be displaced relative each other. The method according to the invention is characterized by showering, preferably in a cleaning step, the wafers with warm fluid, the support device (2) being displaced inside the tank, then ultrasound-cleaning them in cold fluid and again showering them with warm fluid.

Owner:RENA有限责任公司

Method and jig assembly for manufacturing outer blade cutting wheel

ActiveUS20130009353A1Low costHigh yieldElectrolysis componentsElectrolytic coatingsAdamiteCemented carbide

An outer blade cutting wheel comprising an annular thin disc base of cemented carbide and a blade section is manufactured by disposing permanent magnet pieces on the side surfaces and inward of the outer periphery of the base to produce a magnetic field, providing magnetic coated diamond and / or CBN abrasive grains such that the magnetic field may act on the grains, causing the grains to be magnetically attracted to the base outer periphery, and electroplating or electroless plating whereby the abrasive grains are bound to the base outer periphery to form the blade section.

Owner:SHIN ETSU CHEM CO LTD

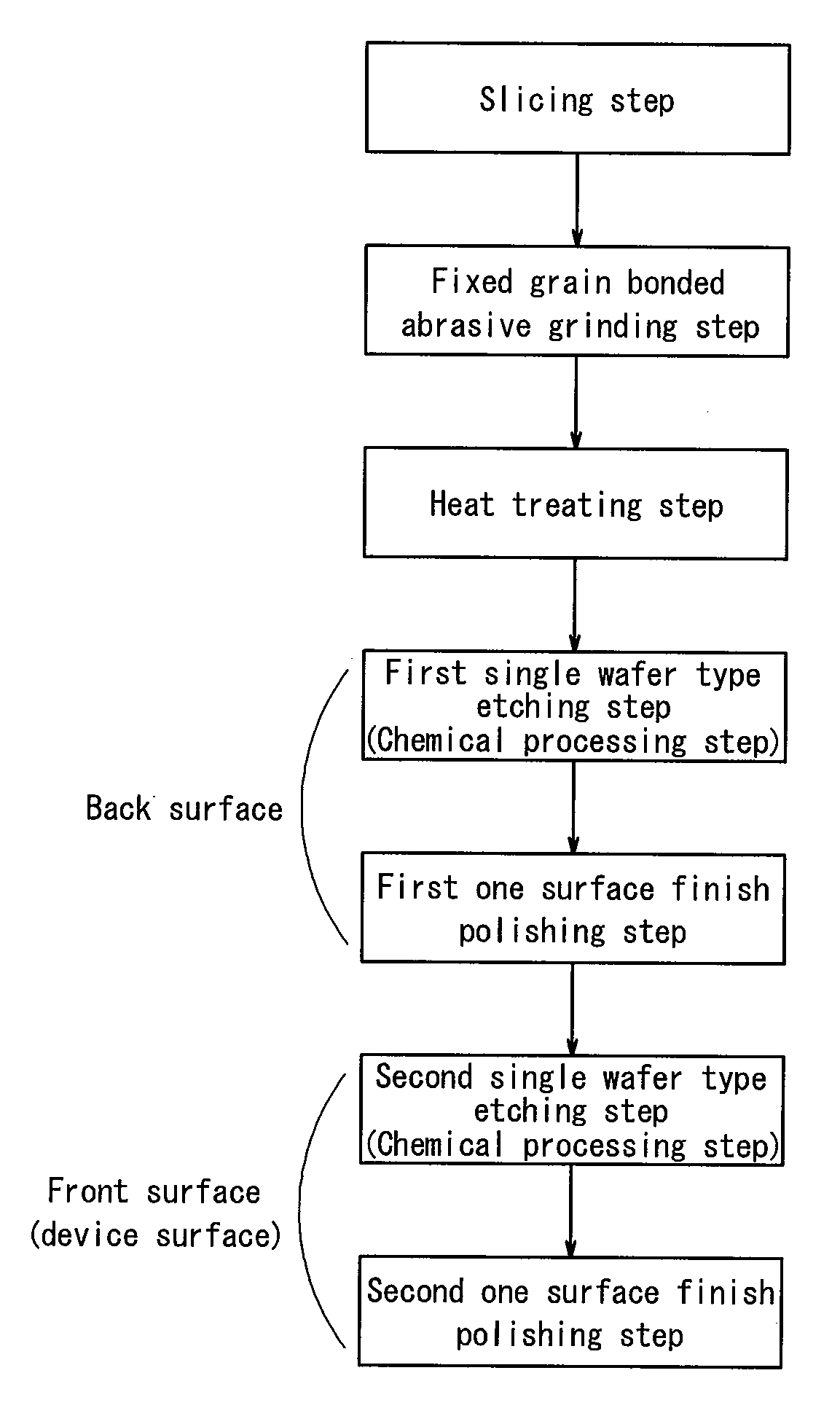

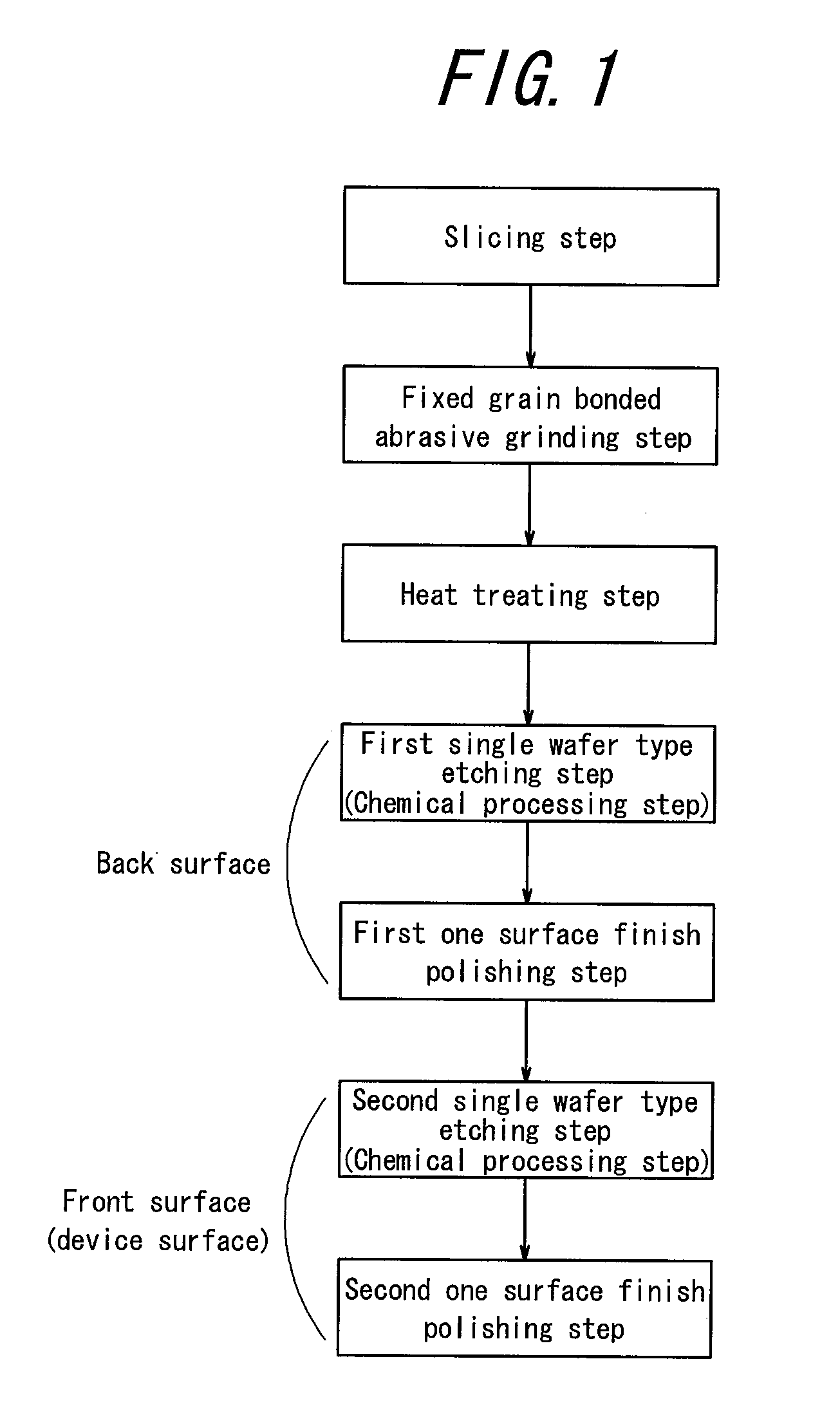

Method of producing semiconductor wafer

InactiveUS20100009521A1Reducing production step numberDecreasing machining allowanceSemiconductor/solid-state device manufacturingWaferingSemiconductor materials

There is provided a production method in which the beveling step conducted for preventing the cracking or chipping in a raw wafer during the grinding can be omitted when the raw wafer cut out from a crystalline ingot is processed into a double-side mirror-finished semiconductor wafer and a semiconductor wafer can be obtained cheaply by shortening the whole of the production steps for the semiconductor wafer and decreasing the machining allowance of silicon material in the semiconductor wafer to reduce the kerf loss of the semiconductor material as compared with the conventional method.The method is characterized by comprising a slicing step of cutting out a thin disc-shaped raw wafer from a crystalline ingot; a fixed grain bonded abrasive grinding step of sandwiching the raw wafer between a pair of upper and lower platens each having a pad of fixed grain bonded abrasive to simultaneously grind both surfaces of the raw wafer; a heat treating step of subjecting the raw wafer to a given heat treatment after the fixed grain bonded abrasive grinding step; and a one-side polishing step of polishing each of the both surfaces of the raw wafer after the heat treating step.

Owner:SUMCO CORP

Apparatus and method for cleaning of objects, in particular of thin discs

InactiveCN101361167ASemiconductor/solid-state device manufacturingFlexible article cleaningMegasonic cleaningBiomedical engineering

The invention relates to a device for cleaning thin wafers (6), said wafers (6) being immobilized with one side on a support device (2) and an interspace (7) being defined between two respective adjoining substrates. The device essentially consists of a shower device (15) which is used to introduce a fluid between the interspaces (7), and a tank (14) that can be filled with the fluid and is dimensioned to receive the support device (2). The invention is characterized in that optionally either the shower device (15) can be displaced relative to the stationary support device (2), or the support device (2) relative to the stationary shower device (15), or both the support device (2) and the shower device (15) can be displaced relative each other. The method according to the invention is characterized by showering, preferably in a cleaning step, the wafers with warm fluid, the support device (2) being displaced inside the tank, then ultrasound-cleaning them in cold fluid and again showering them with warm fluid.

Owner:RENA SONDERMASCHINEN GMBH

Micro valve apparatus using micro bead and method for controlling the same

InactiveUS20100055771A1Bioreactor/fermenter combinationsBiological substance pretreatmentsLab-on-a-chipCD-ROM

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com