Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Surface recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

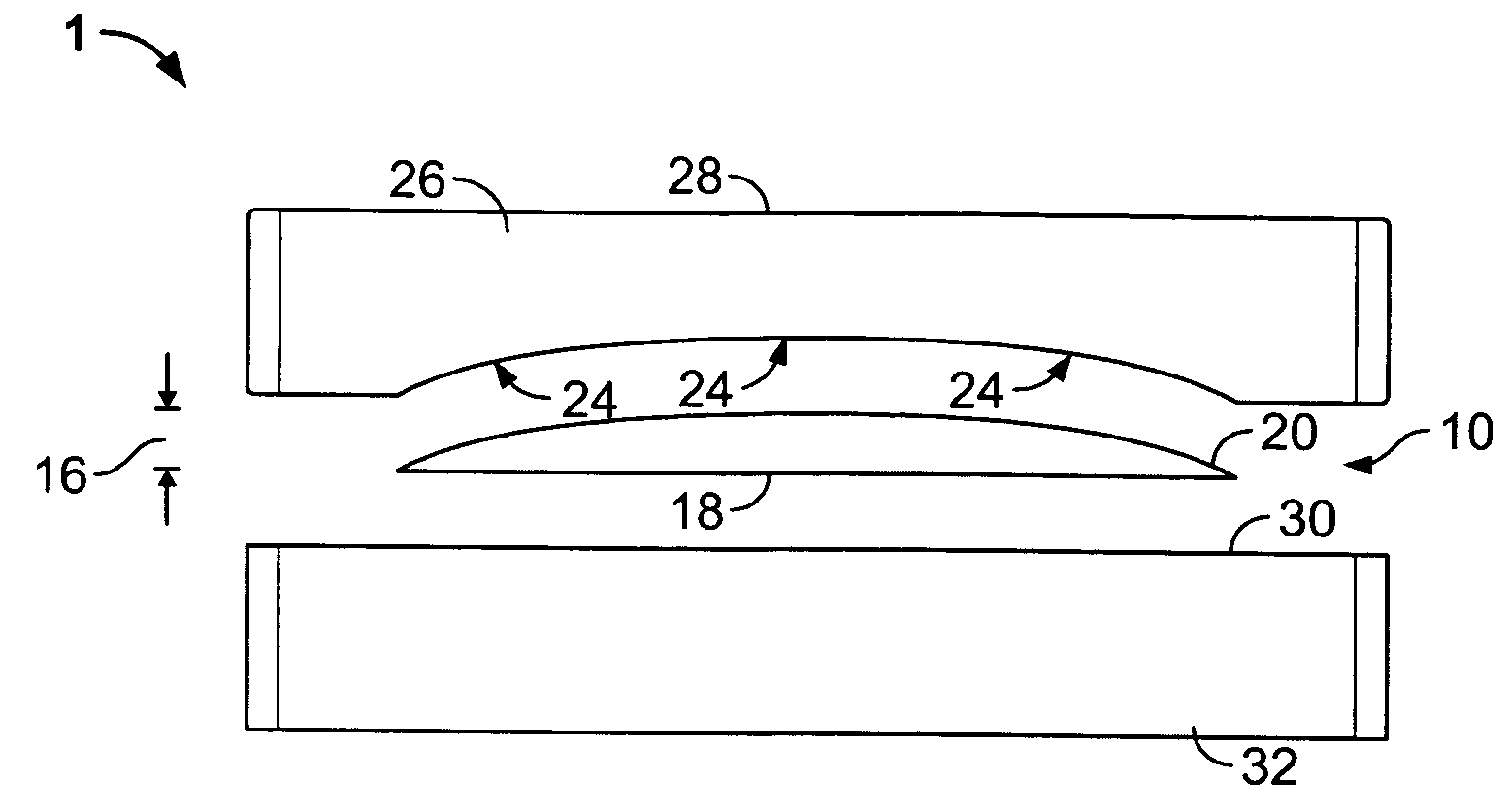

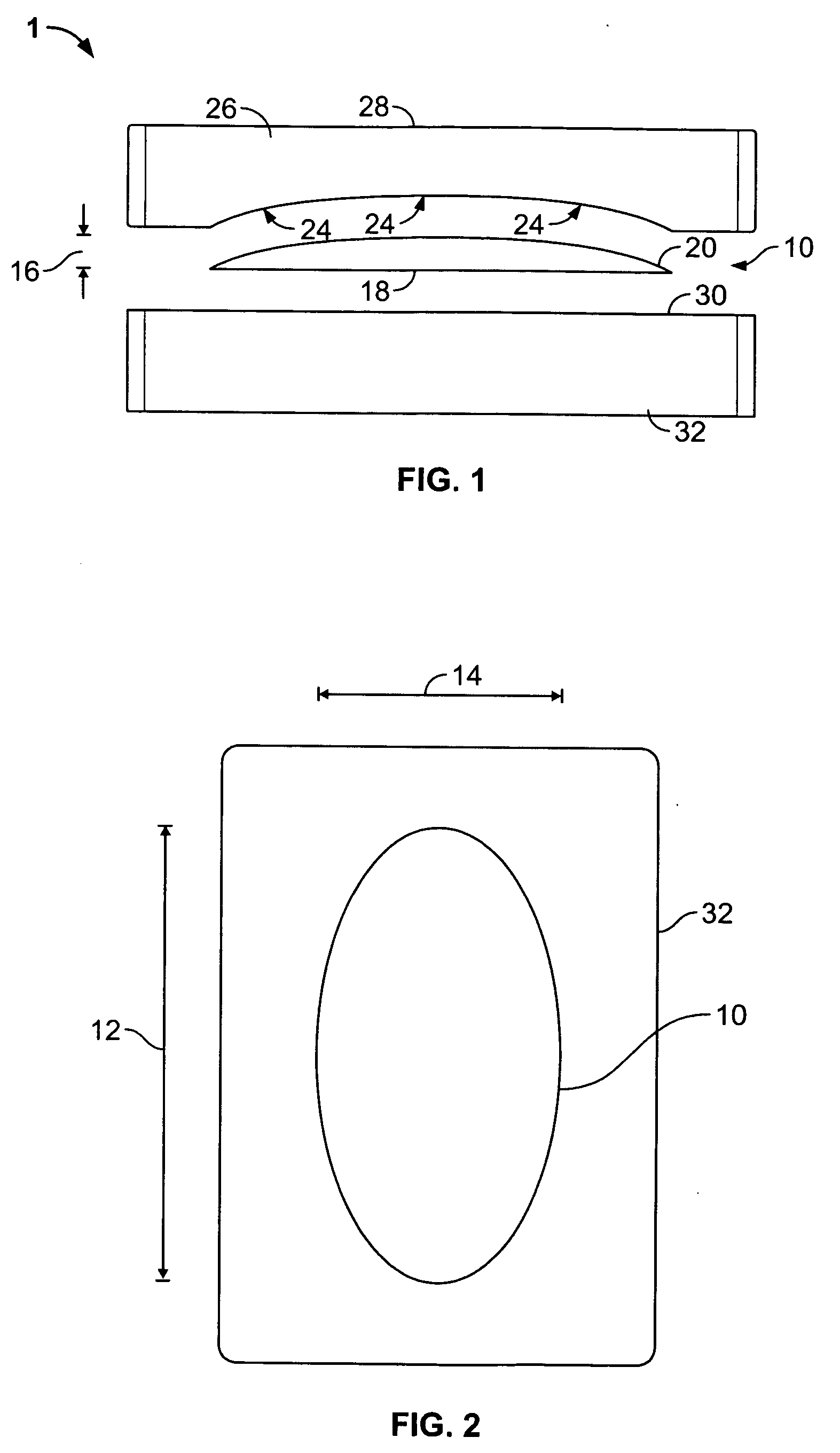

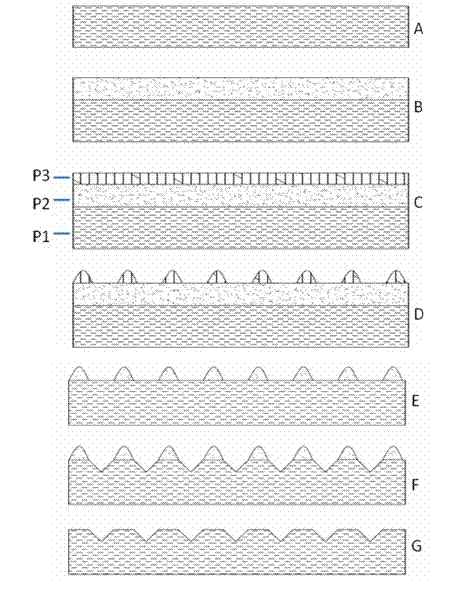

Sag stopper

InactiveUS20070000060A1Reduce manufacturing costEasy to useFluid mattressesBedsSurface recoveryThree dimensional shape

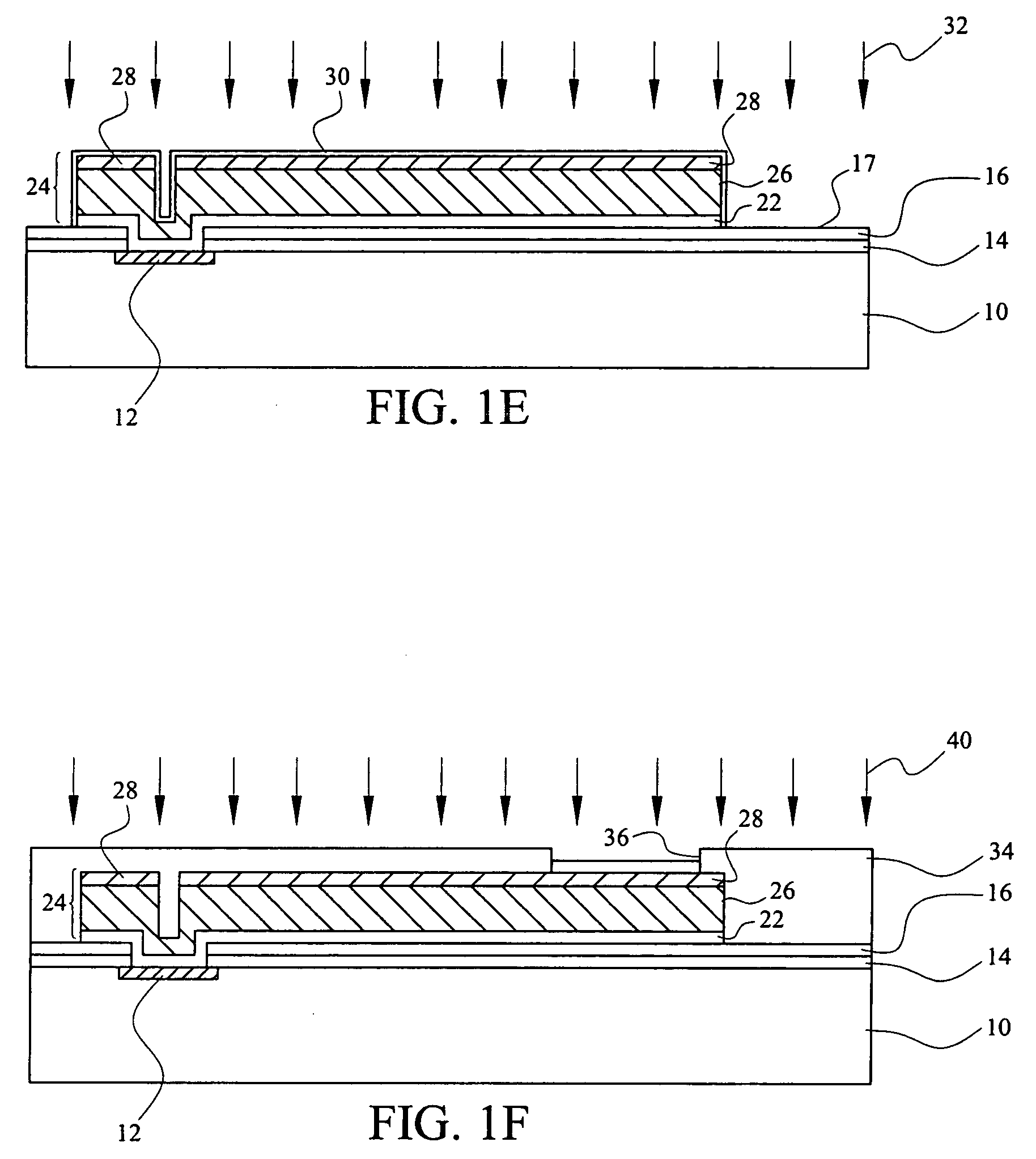

A mattress system comprising a body having a three dimensional shape; said body further having a first side and a second side, wherein said first side is configured and dimensioned to be in contact with a supportive surface, and said second side is configured and dimensioned to be in contact with the underside of a mattress and contoured to substantially match the volume of the concaveness of a mattress wherein the upper (sleeping or sitting) surface of the mattress is restored to a substantially planar surface.

Owner:FIRESTONE STEVEN

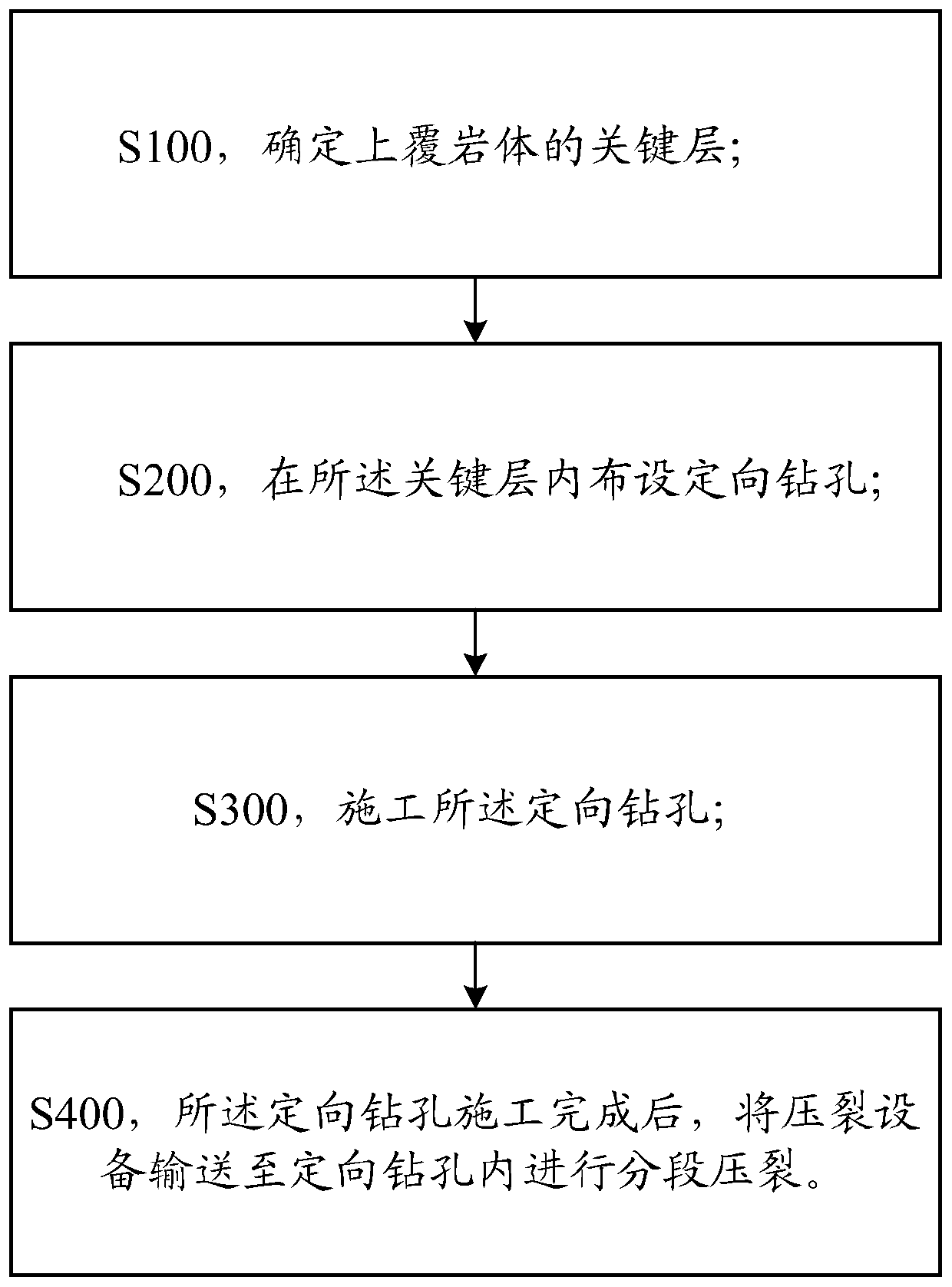

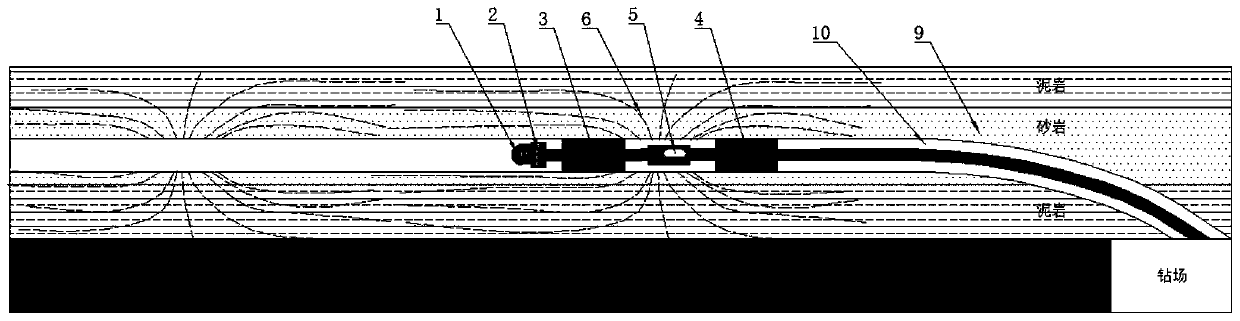

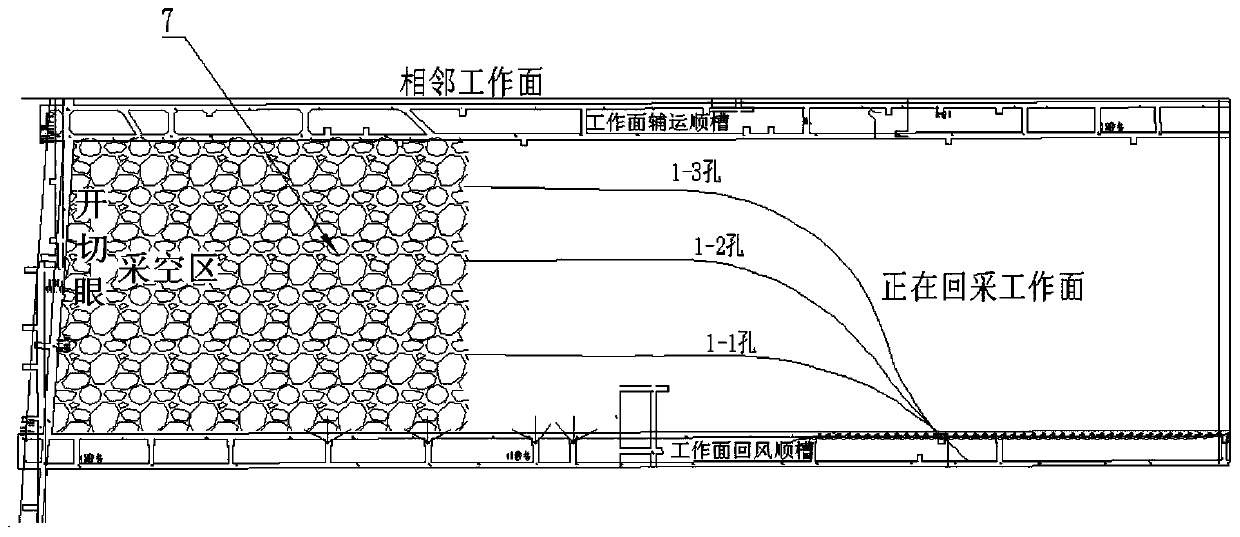

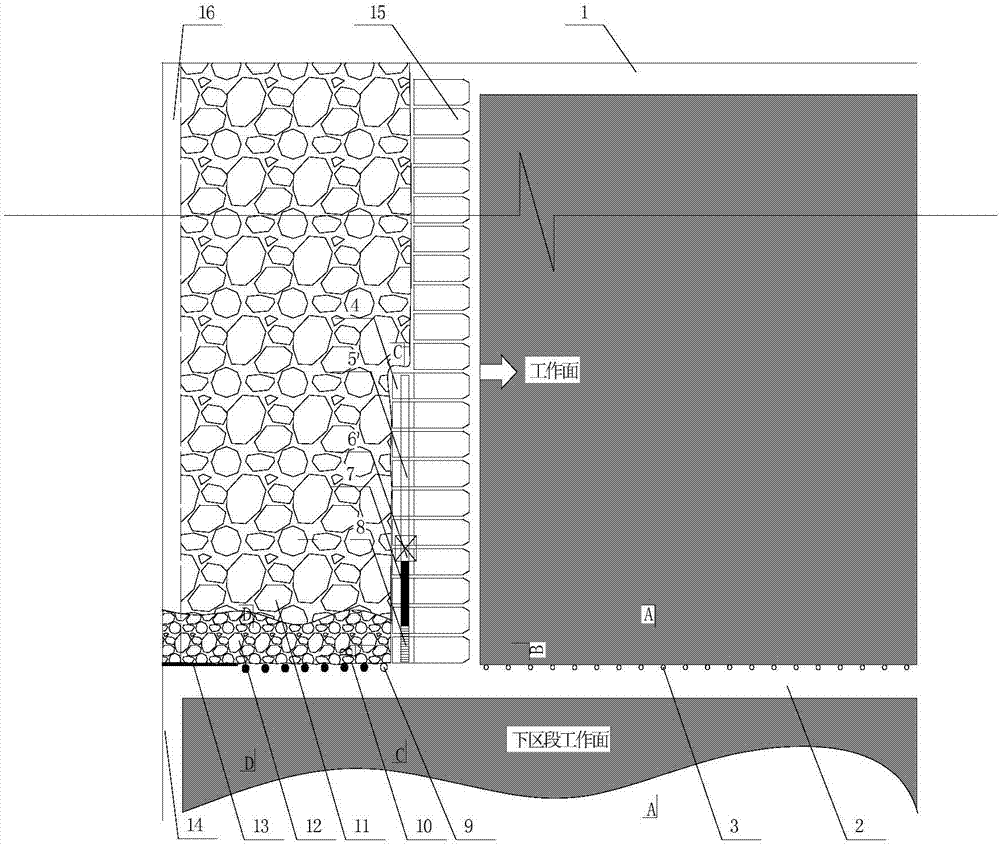

Top plate weaken danger removing method

InactiveCN110130897AWeaken effectiveEliminate or reduce overhang areaUnderground miningDirectional drillingSurface recoveryUltimate tensile strength

The embodiment of the invention discloses a top plate weaken danger removing method. The top plate weaken danger removing method comprises the steps that a critical layer of an overlying rock mass isdetermined; directional drilling holes are distributed in the critical layer; the directional drilling holes are constructed; and after constriction of the directional drilling holes are completed, staged fracturing is conducted on fracturing equipment by sending the fracturing equipment to the directional drilling holes. The directional drilling holes are accurately controlled in a hard top platerock layer by using the top plate weaken danger removing method, the rock intensity of the hard top plate can further be effectively reduced, the whole continuity of rock is destroyed, the top plateis effectively weakened, the top plate hanging arch area is eliminated or reduced, and the high mine pressure risk of working surface recovery is relieved in advance; and meanwhile, the pressure of anearby roadway rock layer can be lowered through effective collapsing of the whole working surface hard top plate, the supporting mode of a roadway is simplified, the repair work amount of the roadwayis reduced to great degree, and thus the maintenance cost of the roadway is lowered.

Owner:CHINA SHENHUA ENERGY CO LTD +2

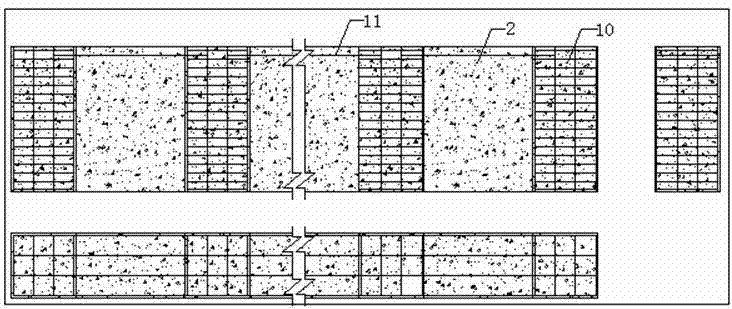

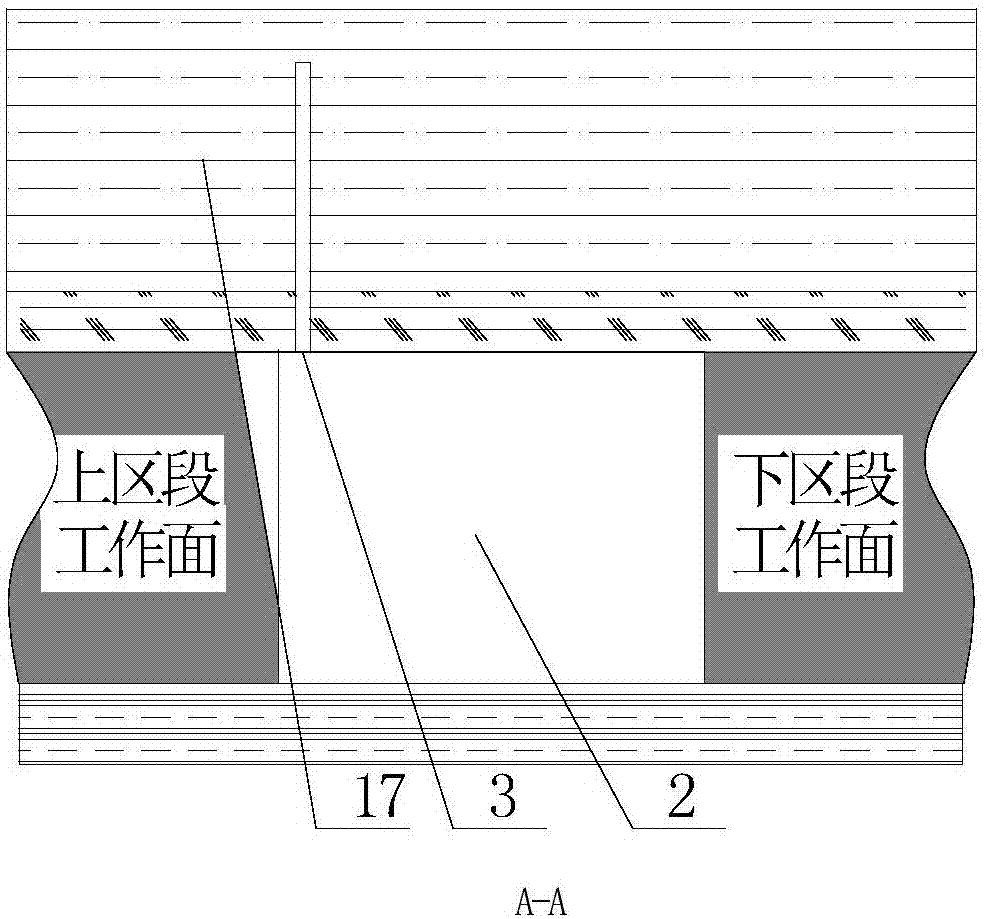

Non-coal-pillar double tunneling method

ActiveCN104763434AAvoid interferenceIncrease productivityUnderground chambersTunnel/mines ventillationSurface recoveryEngineering

The invention discloses a non-coal-pillar double tunneling method. The non-coal-pillar double tunneling method includes that retaining a separating wall width tunneling tail roadway when performing working surface air return way and tail roadway tunneling, after delaying a tail roadway tunneling working surface, constructing a concrete pier and a concrete separating wall with a connected channel at the inner coal wall of the tunneled roadway, pre-embedding a gas discharge pipe, after the wall body intensity reaches the standard, using the wall body as one coal wall of the working surface air return way and tunneling, temporarily closing the front channel after forming the next connected channel, wherein the double tunneling ventilation effect is formed between the tail roadway and air return way through the connected channels. The non-chain-pillar double tunneling method uses the isolating wall as the protection coal pillar, the bad influence of a traditional roadway retaining method to the working surface recovery is radically solved, the one-time tunneling section of the roadway is small, the tunneling construction and roadway support are easy to perform, the cost is low, and the operation is safe and effective.

Owner:TAIYUAN UNIV OF TECH

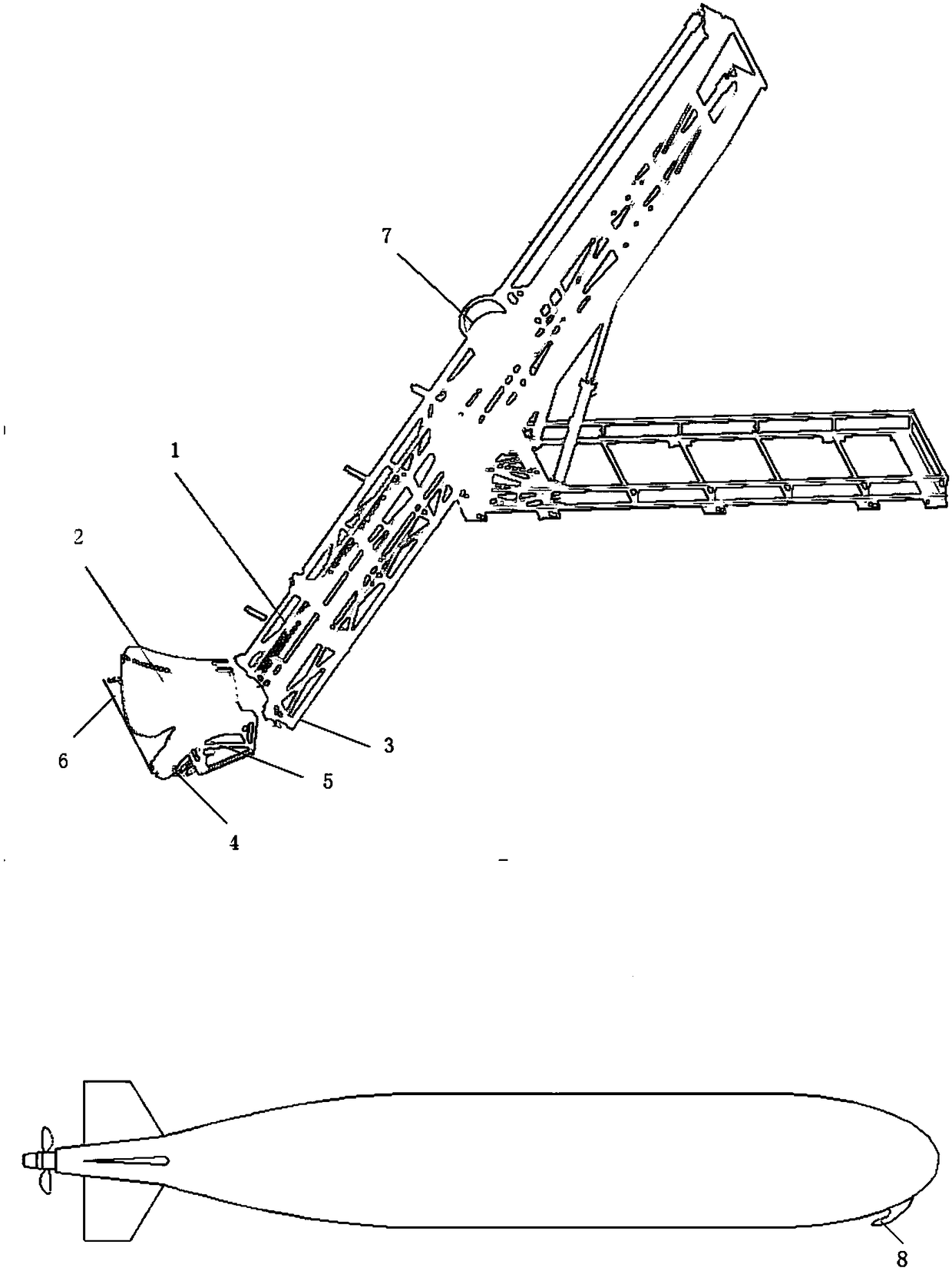

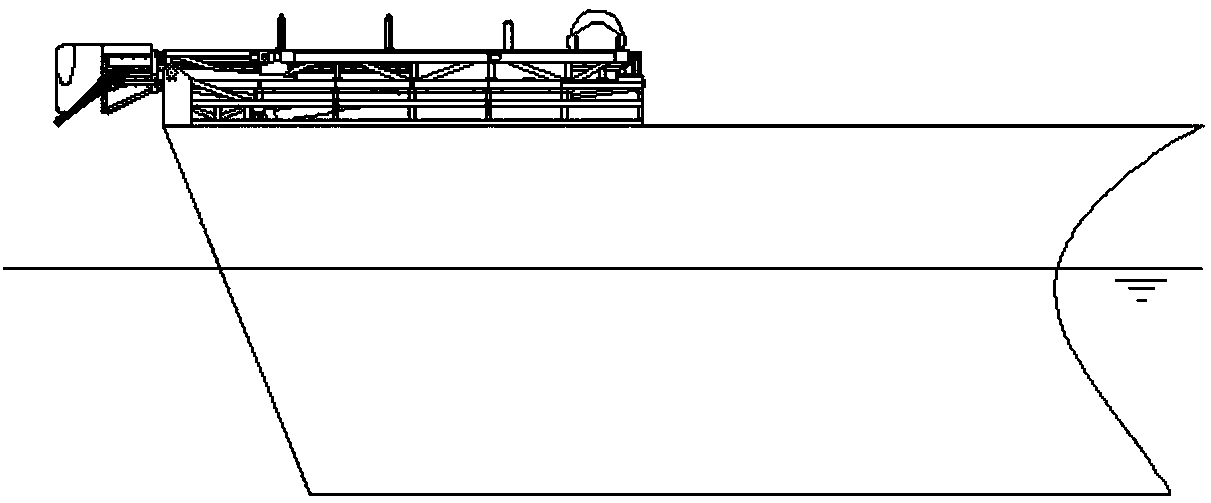

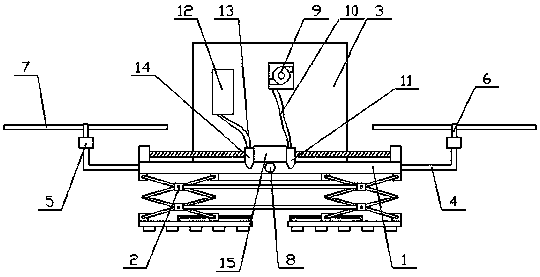

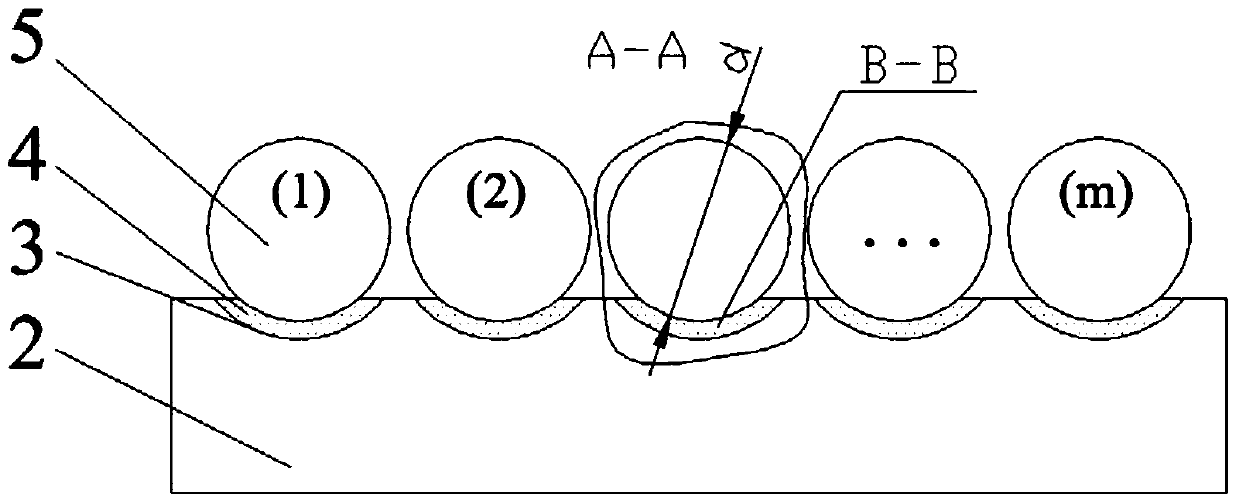

Arresting cable type automatic interfacing recovery device and method during UUV (Unmanned Underwater Vehicle) recovery based on slideway

ActiveCN108528640AImprove recycling efficiencySolving problems that require a lot of manpowerCargo handling apparatusPassenger handling apparatusRemote controlSurface recovery

The invention discloses an arresting cable type automatic interfacing recovery device and method during UUV (Unmanned Underwater Vehicle) recovery based on a slideway and belongs to the technology ofwater surface recovery of a UUV. The arresting cable type automatic interfacing recovery device and method adopt a specially designed extending-retracting slideway to perform work of full-automatic UUV recovery and has a main use of solving the problem of needing to consume a great quantity of manpower in traditional UUV recovery. The beneficial effects are concretely implemented through the following technical scheme, a water surface remote control device is utilized firstly to control the UUV to be recovered on the water surface to approach a water surface mother ship; in a next step, the extending-retracting slideway is controlled to unfold, so that the extending-retracting slideway and a floating type anticollision guide frame extend into water; then, a bow of the UUV is remotely controlled to be aligned to the floating type anticollision guide frame and rushes into the guide frame; then a rotatable mechanical arm carrying an arresting cable is controlled to rotate upward, so thatthe arresting cable is hooked with a recovery hook below the bow of the UUV; then a winch integrated on the extending-retracting slideway is utilized to drag the UUV onto the slideway; and finally, the slideway is controlled to swing and retract, and the UUV is recovered onto the water surface mother ship.

Owner:HARBIN ENG UNIV

Construction method capable of reducing roof cutting depth of gob-side entry retaining

ActiveCN107387084AReduce depthReduce dosageDisloding machinesUnderground miningSurface recoveryEngineering

The invention discloses a construction method capable of reducing the roof cutting depth of gob-side entry retaining, and belongs to the field of mine support. The method mainly comprises the following steps: (1) digging a working face tunnel to form a Y-shaped ventilation system; (2) directionally presplitting a top plate in an auxiliary intake airway construction blasthole; (3) changing all or parts of a working surface bracket into a top coal caving long tail beam bracket, and during working surface recovery, throwing inbreak gangues to an intake airway side by the top coal caving long tail beam bracket through a belt conveyor, a breaker and a downward-spreading conveyer; (4) along a tunnel edge, adopting a monomer hydraulic prop and a reinforcing mesh protection tunnel to form a lane with directional blasting gangues in a goaf; (5) after a working surface goaf is stable after collapse, carrying out guniting to seal the goaf; (6) repeating steps (2) to (5), thus forming a continuous roadside support to realize the mining of a Y-shaped ventilation no-coal pillar. After the method is adopted, roof cutting hole depth can be reduced, and explosion and construction cost is reduced; goaf gangues are adopted for supporting so as to improve a tunnel maintenance effect, and gob-side entry retaining cost and labor intensity are lowered.

Owner:CHINA UNIV OF MINING & TECH

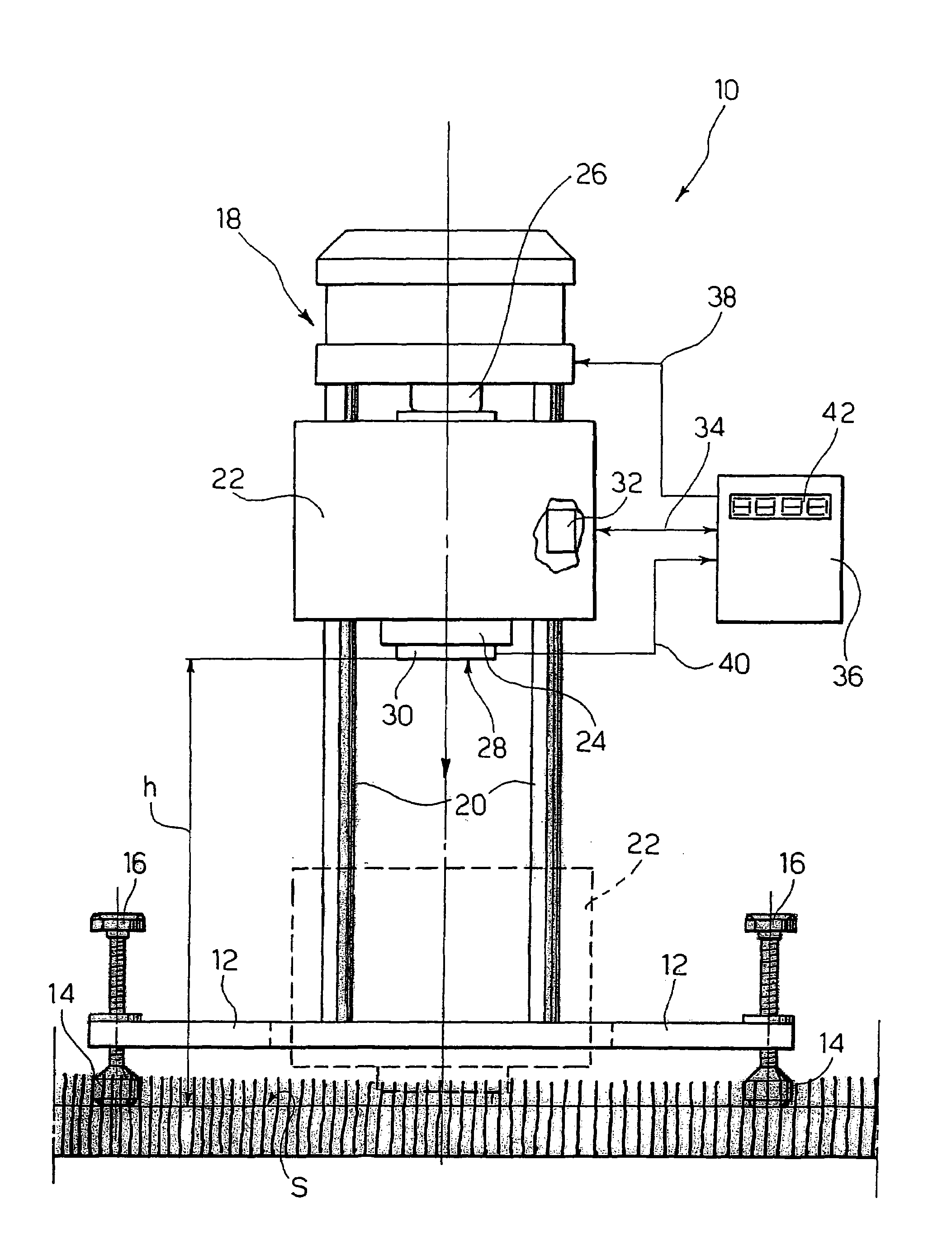

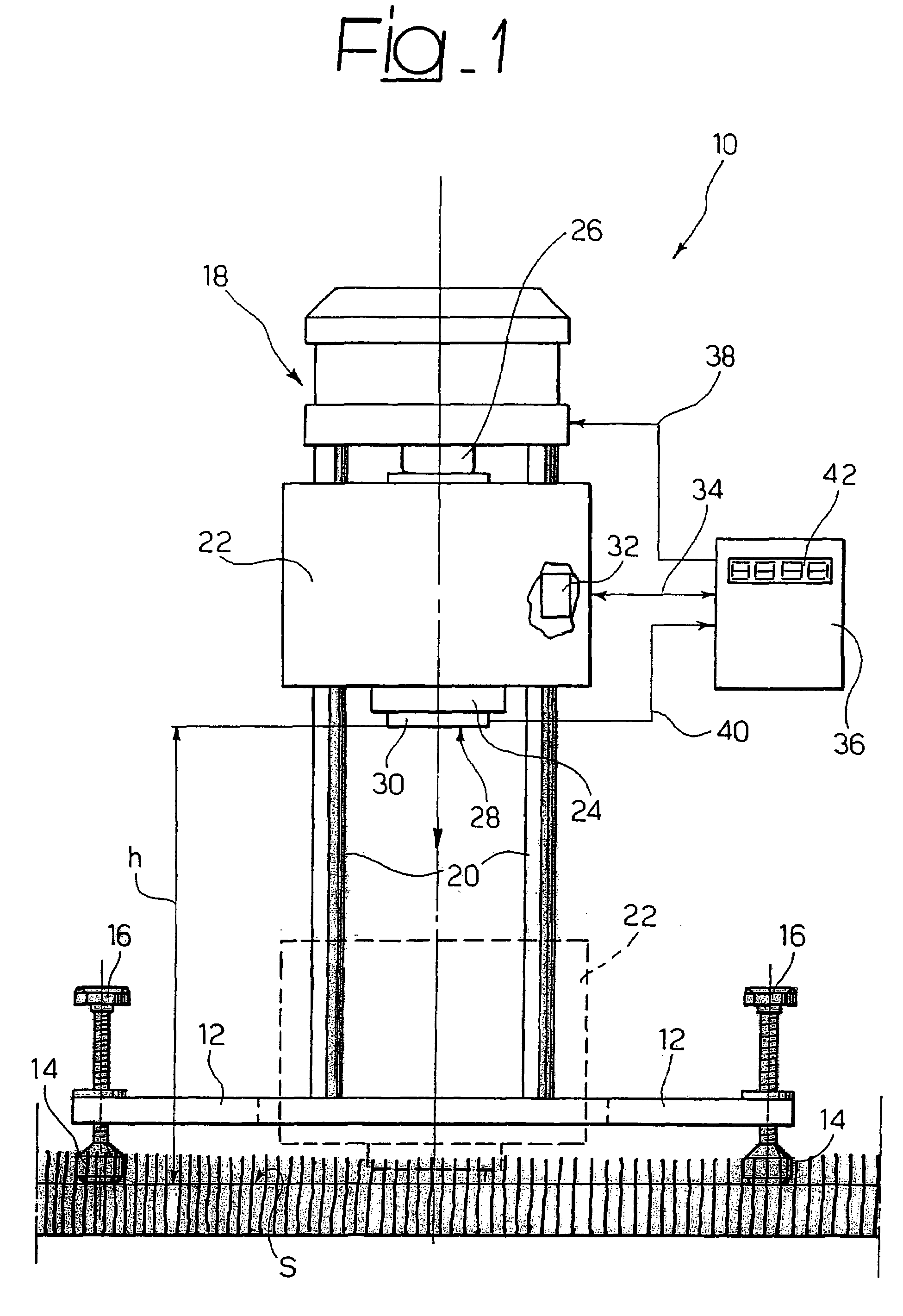

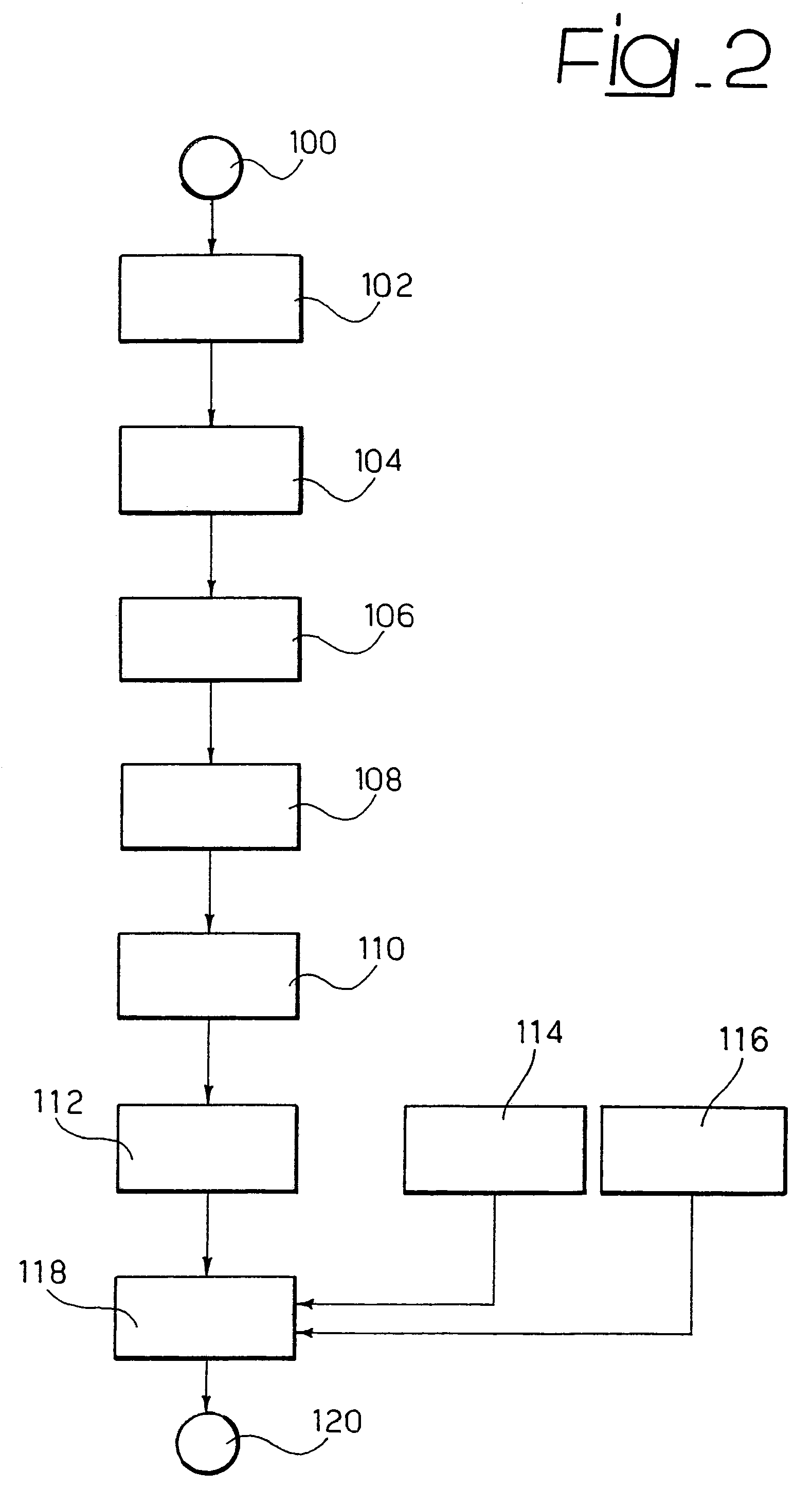

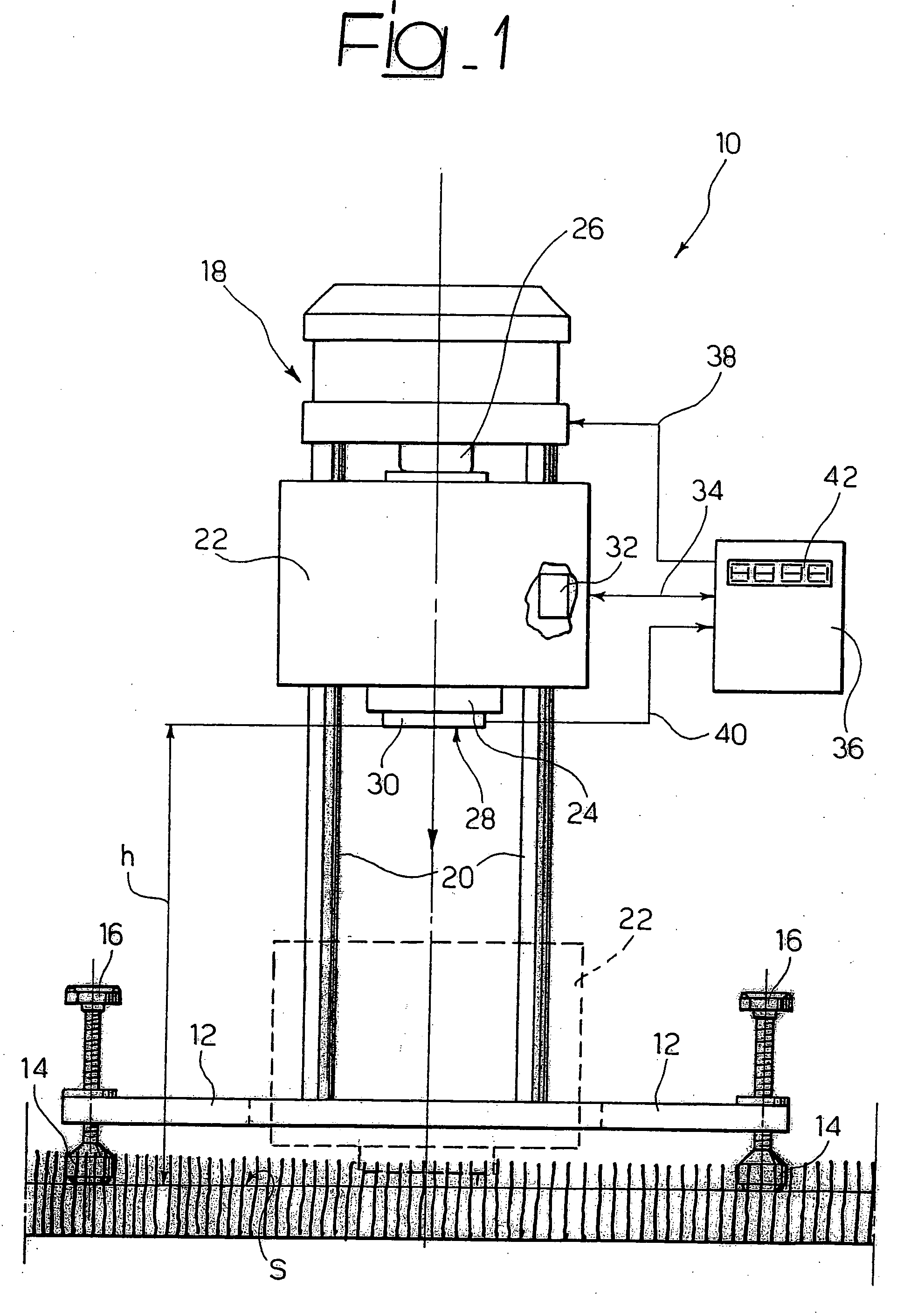

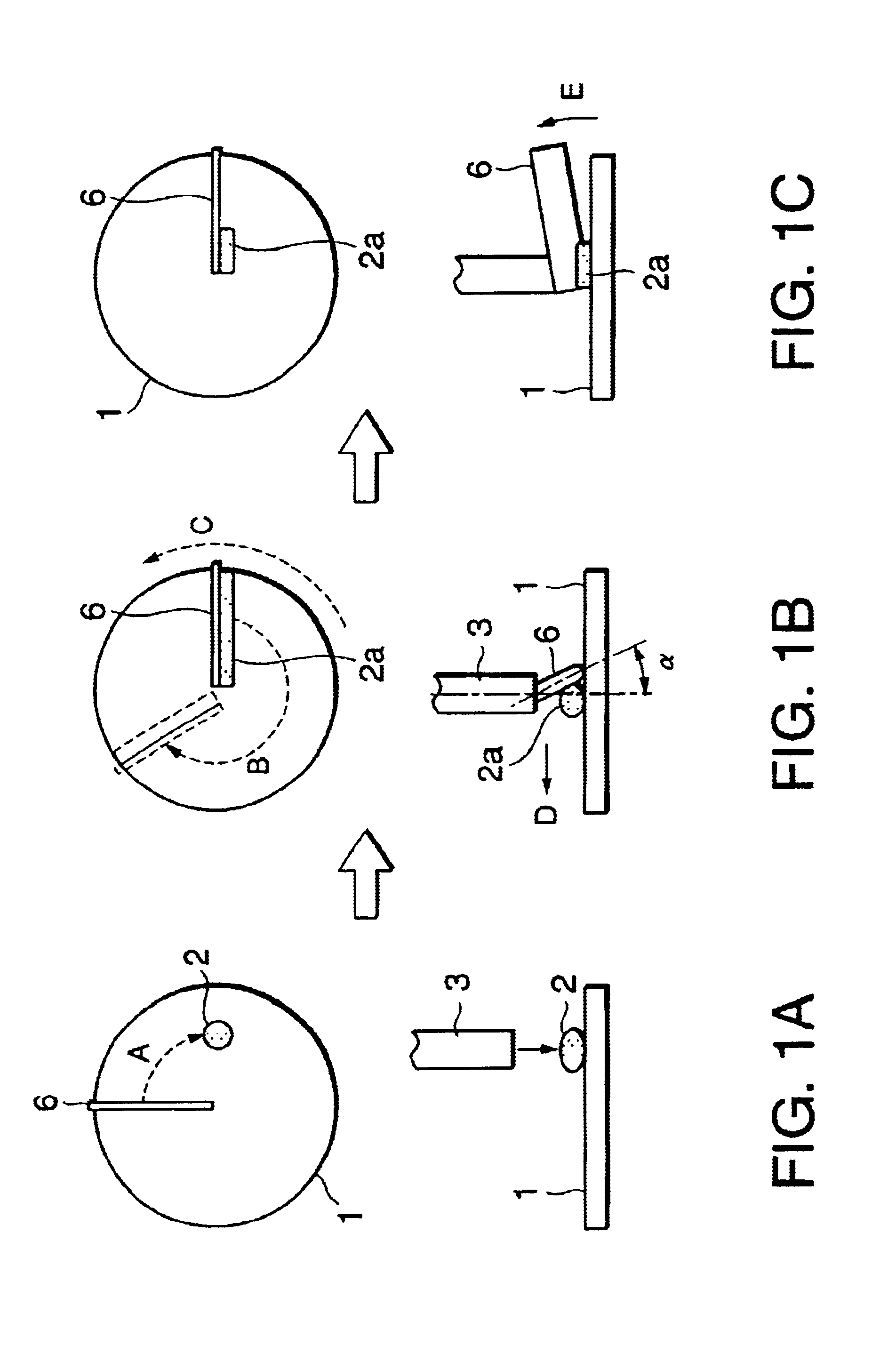

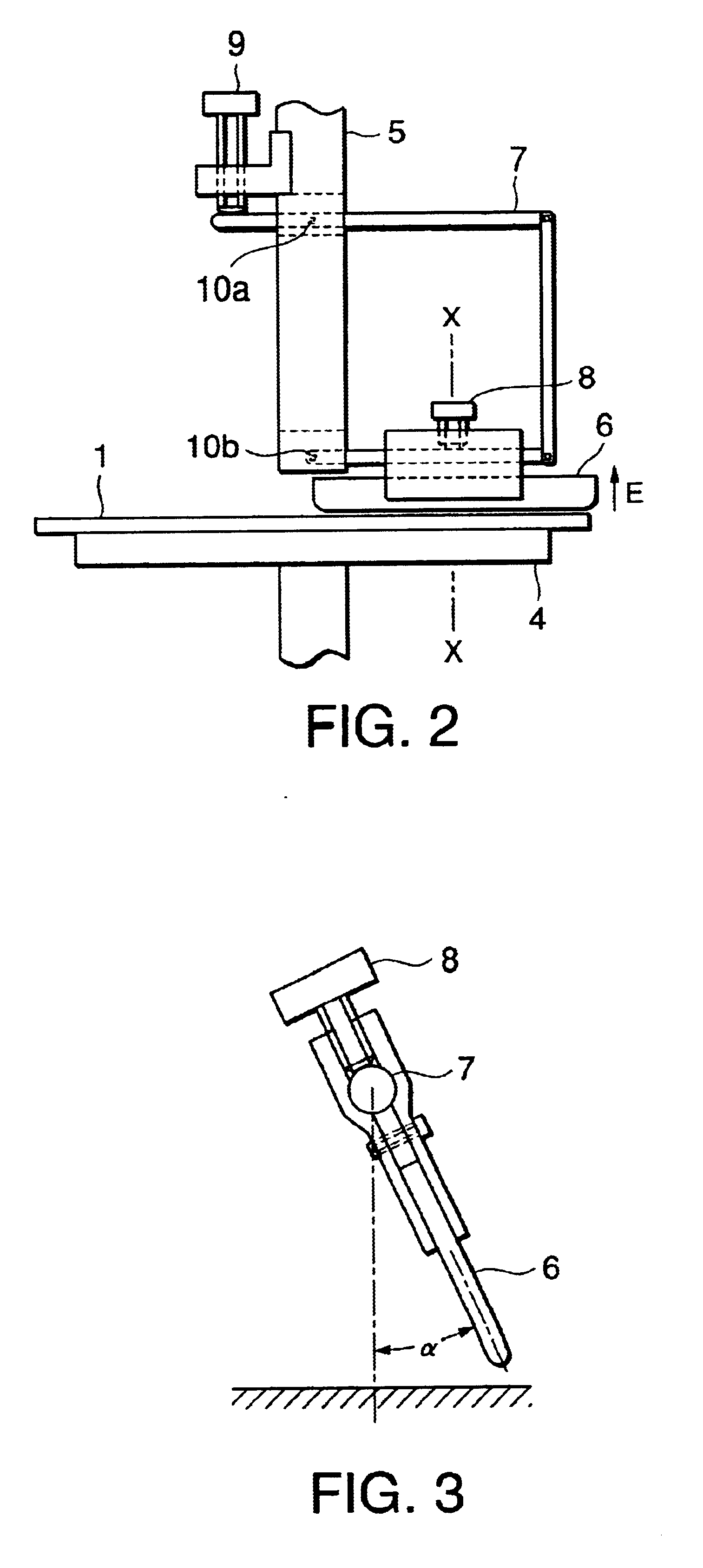

Method and instrument for characterizing treading surfaces, for instance for realizing synthetic turf surfaces

InactiveUS7137285B2Reliable characterizationEarth material testingMaterial strength using tensile/compressive forcesBiomechanicsSurface recovery

An instrument (“artificial athlete”) for characterizing, from the biomechanical standpoint, a treading surface, such as natural grass cover or synthetic grass flooring, is configured for: dropping a weight from a given height on the surface, producing the conversion of kinetic energy of falling of the weight into deformation energy of the surface, the deformation energy being able to be restored by the surface to the weight, bringing about its return / bouncing back upwards; and detecting at least one parameter representing the process of restitution of the deformation energy by the surface to the weight, the parameter identifying the characteristics of tread of the surface.

Owner:MONDO SPA

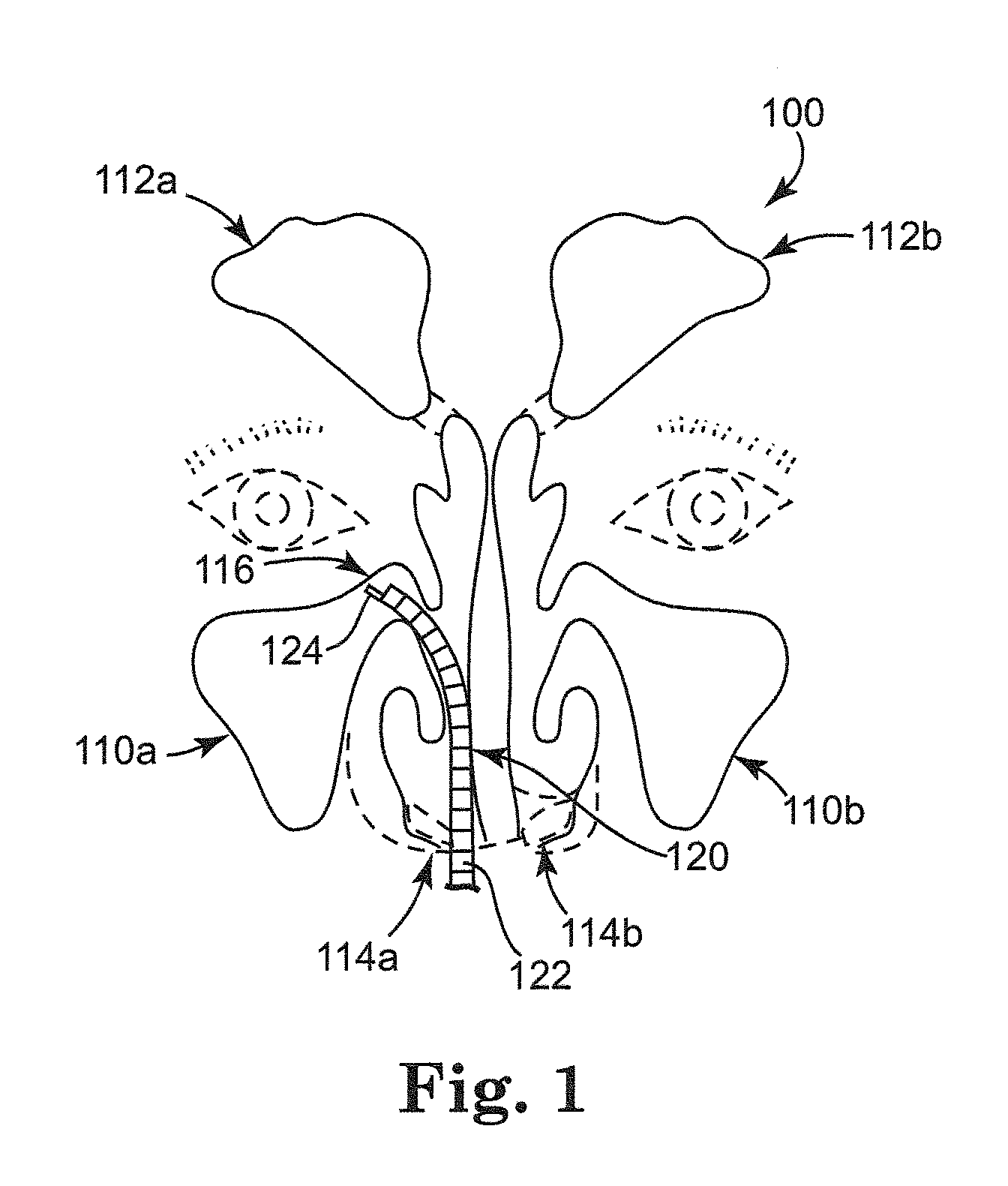

Rehydratable polysaccharide particles and sponge

ActiveUS20090291911A1Rapid and clump-free rehydrationHigh viscosityBiocideHydroxy compound active ingredientsSurface recoverySolvent

Tissue and other body structures may be protected using a hydrated composition made from free-flowing substantially collagen-free rehydratable polysaccharide particles and rehydratable polysaccharide sponges. Rehydration of the particles without clumping may be carried out be dispersing the particles in a biocompatible water-miscible polar dispersant such as ethanol and combining the dispersion with sufficient aqueous solvent for the particles to convert them to a cohesive hydrogel. The hydrated composition may assist in returning an injured, inflamed or surgically repaired surface to a normal state, e.g., through one or more healing mechanisms such as modulation of an inflammatory response, phagocytosis, mucosal remodeling, reciliation or other full or partial restoration of normal function.

Owner:MEDTRONIC INC +1

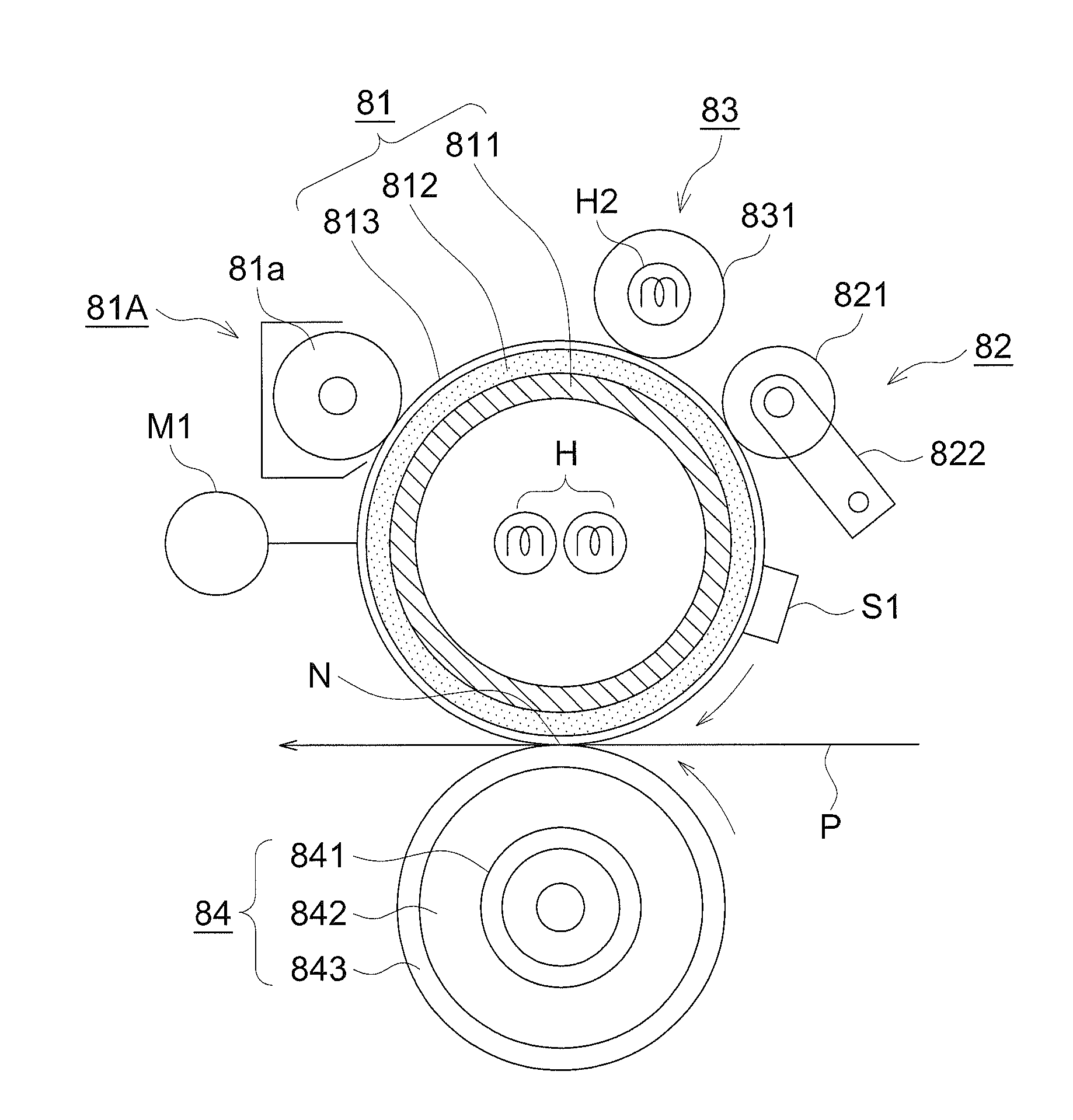

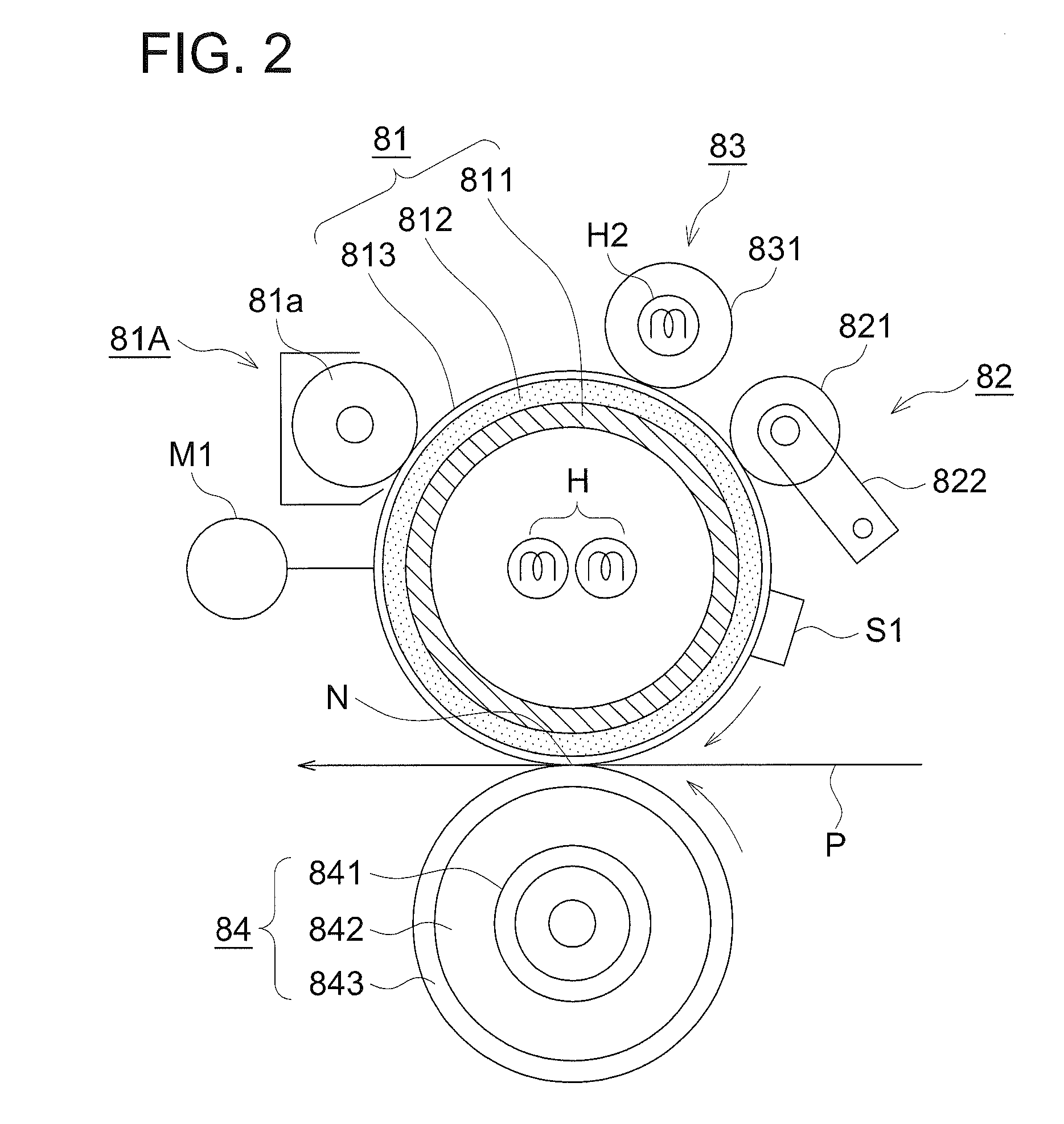

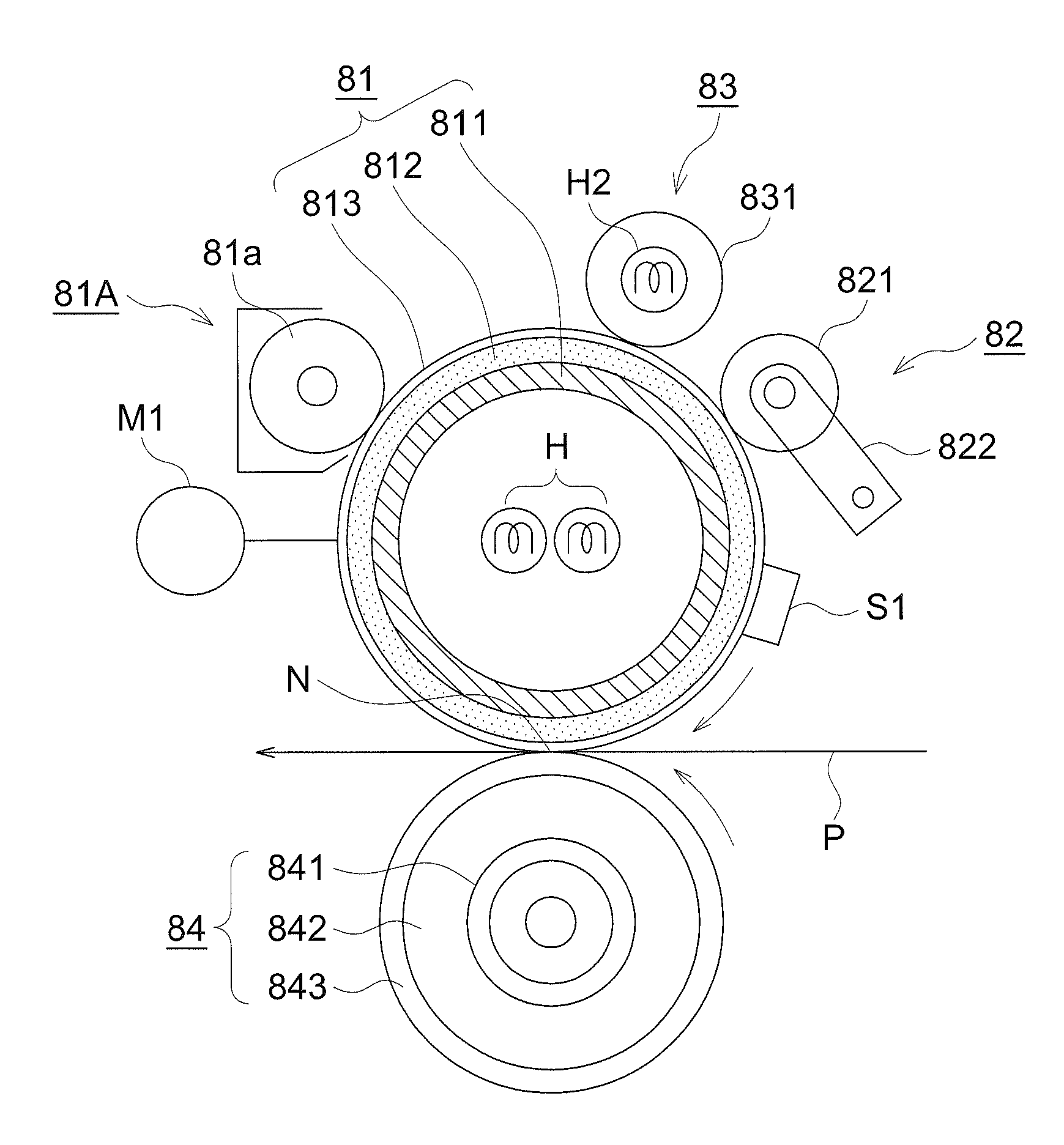

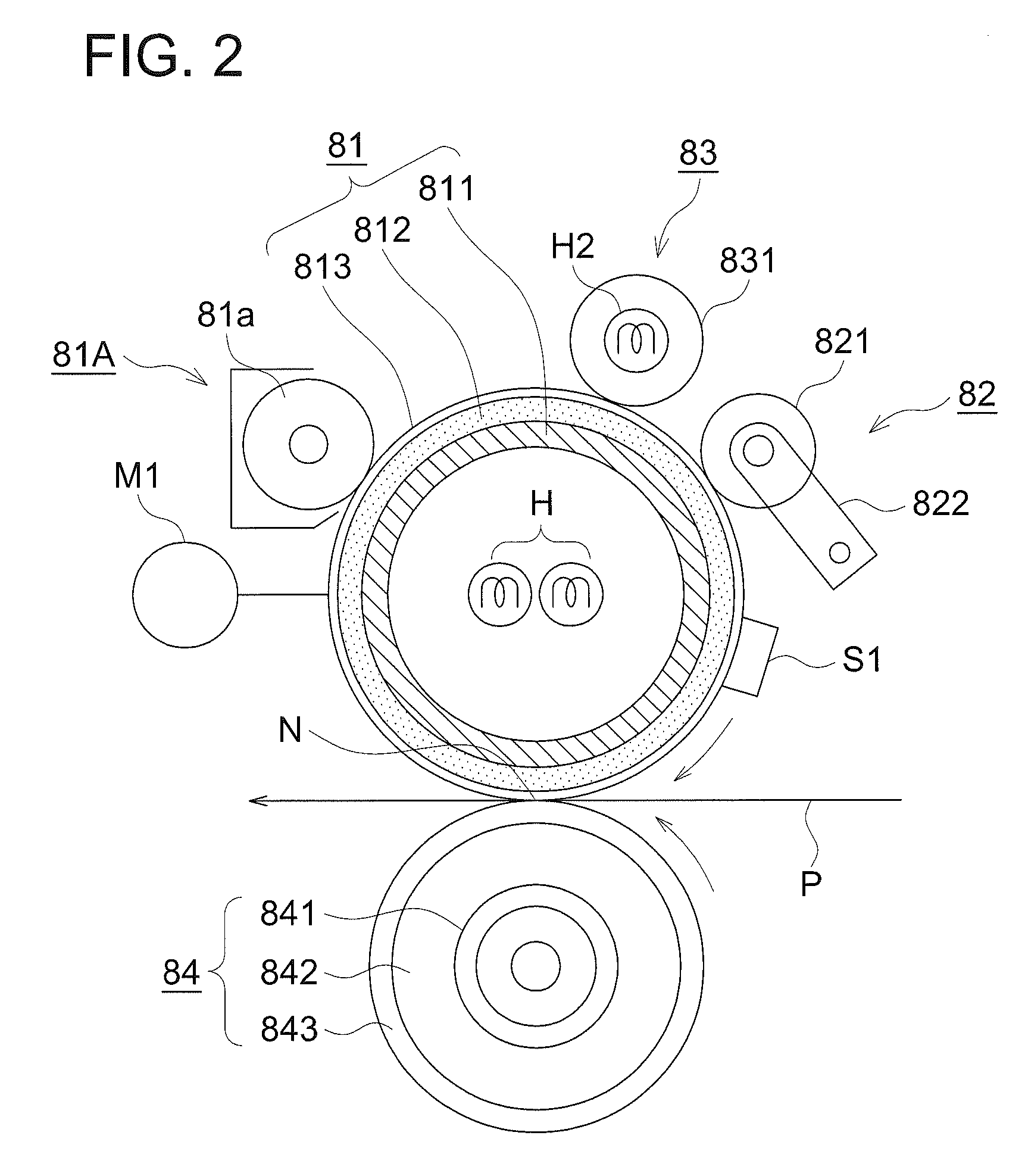

Fixing unit and image forming apparatus

InactiveUS20110129266A1Extended service lifeElectrographic process apparatusImage formationSurface recovery

A fixing unit is provided with a fixing member to heat a recoding medium and to fix a toner image on the recording medium; a pressure member to press the fixing member to form a nip portion in which a recording medium carrying a toner image is nipped; an auxiliary heating member to heat the surface of the fixing member; and a surface recovery member, arranged at a downstream side of the first auxiliary heating member in a rotational direction of the fixing member, for recovering damage to a surface of the fixing member by making contact with and sliding on the fixing member.

Owner:KONICA MINOLTA BUSINESS TECH INC

Method and instrument for characterizing treading surfaces, for instance for realizing synthetic turf surfaces

InactiveUS20050178184A1Reliable characterizationEarth material testingMeasurement/indication equipmentsBiomechanicsSurface recovery

Owner:MONDO

Epitaxial method for improving luminous efficiency of GaN-based LED (Light Emitting Diode)

InactiveCN102418146AReduce the impactFacilitated releasePolycrystalline material growthFrom chemically reactive gasesLuminous intensityQuantum well

The invention discloses an epitaxial growth method for improving the luminous efficiency of a GaN-based LED (Light Emitting Diode). The epitaxial growth method comprises the following steps of: adding a surface treating procedure between an n-type current diffusion layer and an n-type space layer on the basis of a buffer layer, a uGaN layer, an nGaN layer, an n-type current expansion layer, the n-type space layer, a quantum well active region, a p-type electronic blocking layer, a p-type GaN layer and a contact layer on a substrate of a traditional GaN-based LED structure; damaging and releasing the defect and the stress extending from the interface of the substrate and the GaN to the current diffusion layer; recovering the surface of a material to be flat by controlling growing conditions; and growing the quantum well active region. The result shows that a grown quantum well is less influenced by the defect and the stress compared with a traditional growing technology, so that the luminous intensity of a sample can be effectively improved. The epitaxial growth method disclosed by the invention is suitable for epitaxial growth of the GaN-based LED in a blue-green light waveband.

Owner:HC SEMITEK CORP

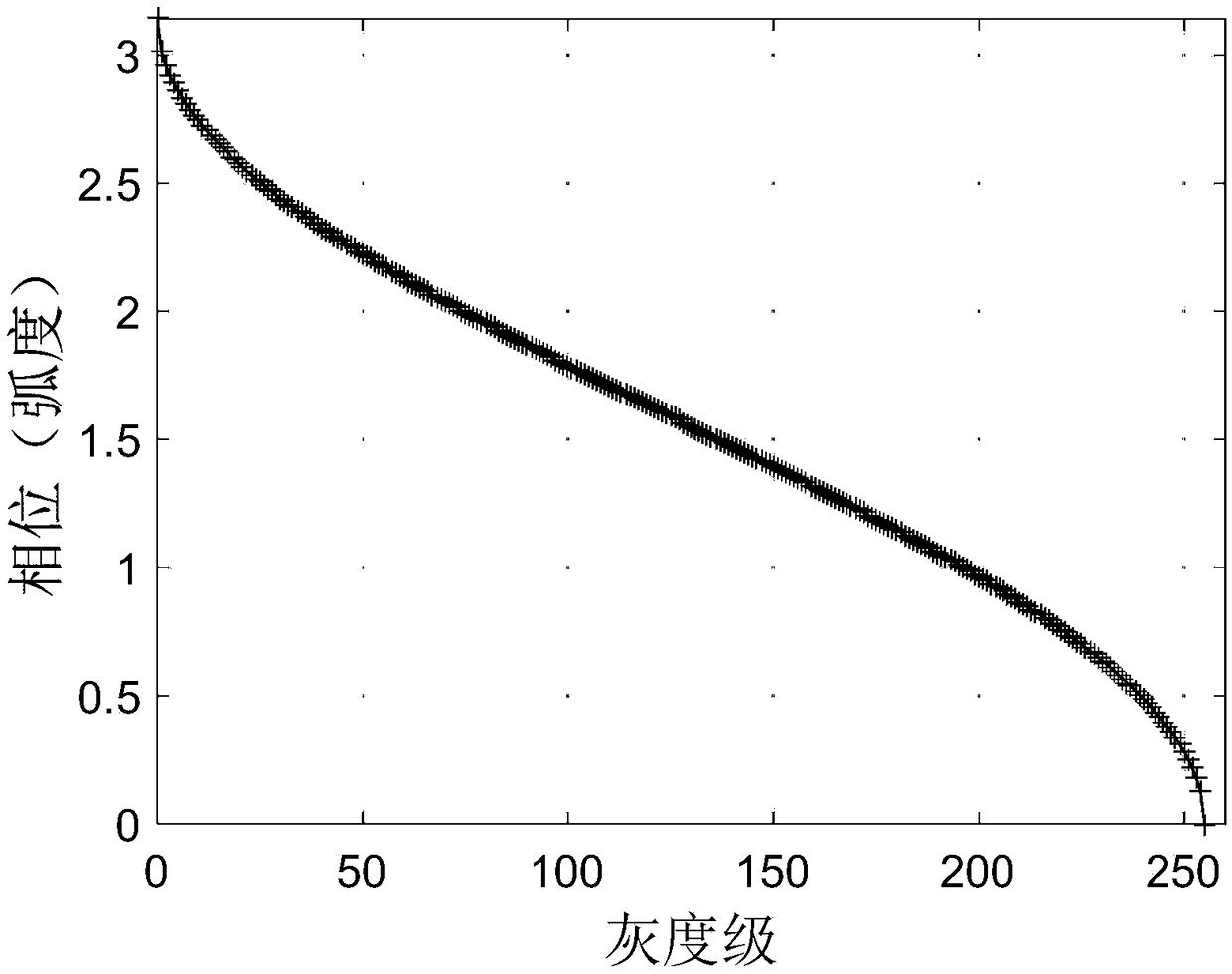

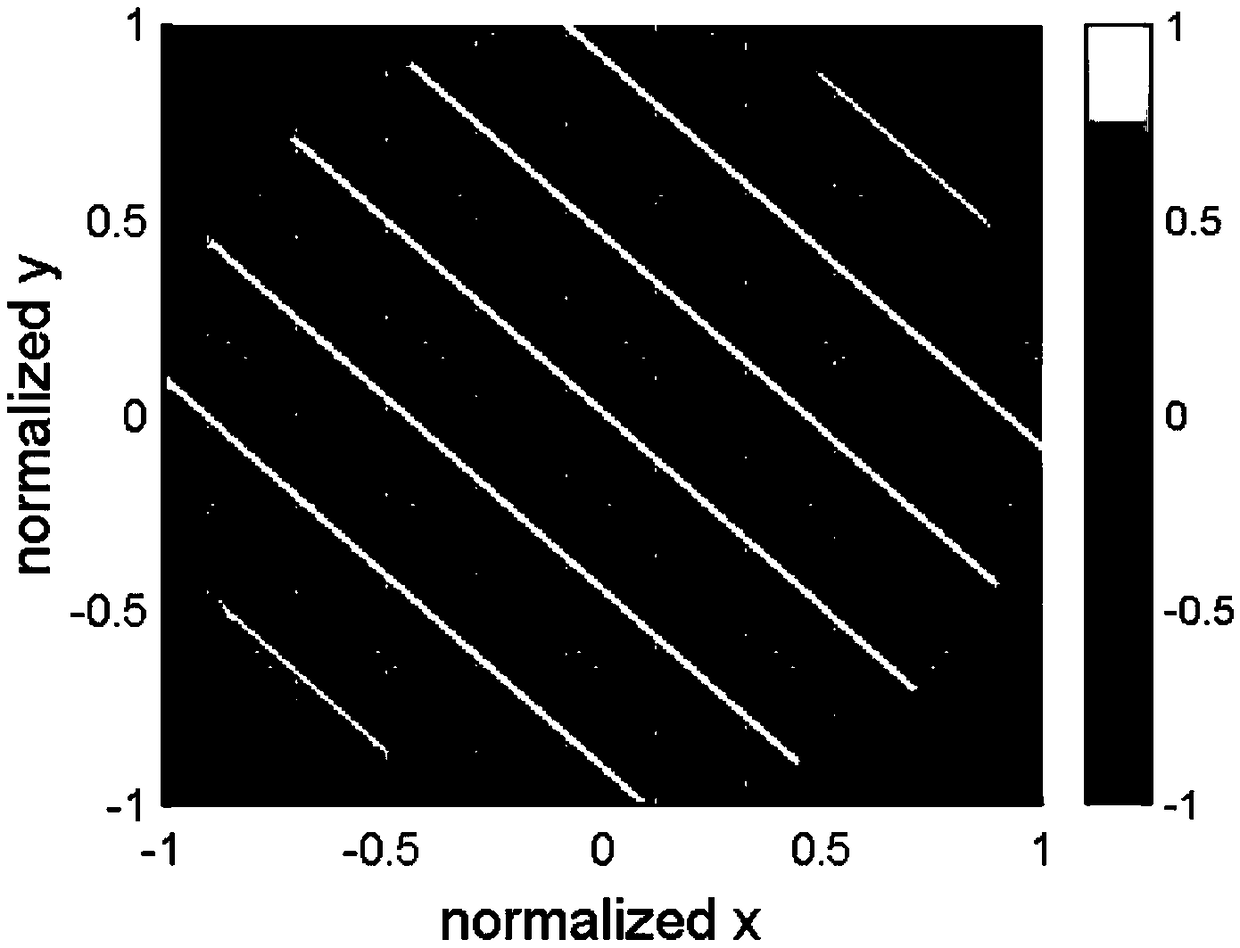

Method for recovering wave surface with high precision based on single width interference fringe

ActiveCN108955575AAccurate Phase ExtractionHigh precision wave surface recoveryUsing optical meansSurface recoveryFrequency function

The invention discloses a method for recovering a wave surface with high precision based on a single width interference fringe and belongs to the field of surface shape measurement of optical components. The method includes the following steps: peak values and valley values are assigned in an interference region so as to convert the same into phases, the interference fringe is divided into regions, pixels of interferometer cameras in the same region are enabled to be the same in parity, and accurate phase extraction is performed to achieve high-precision wave surface recovery. According to themethod disclosed in the invention, the peak values and the valley values are assigned in the interference region so as to convert the same into phases, the interference fringe is divided into the regions, the pixels of the interferometer cameras in the same region are enabled to be the same in parity, and accurate phase extraction is performed to achieve high-precision wave surface recovery. Themethod is simple and efficient in calculation, no carrier frequency function is needed, and neither Fourier transform nor Hilbert transform is required.

Owner:JIANGNAN UNIV

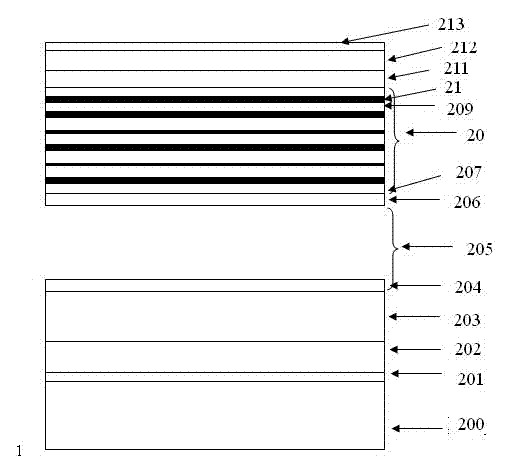

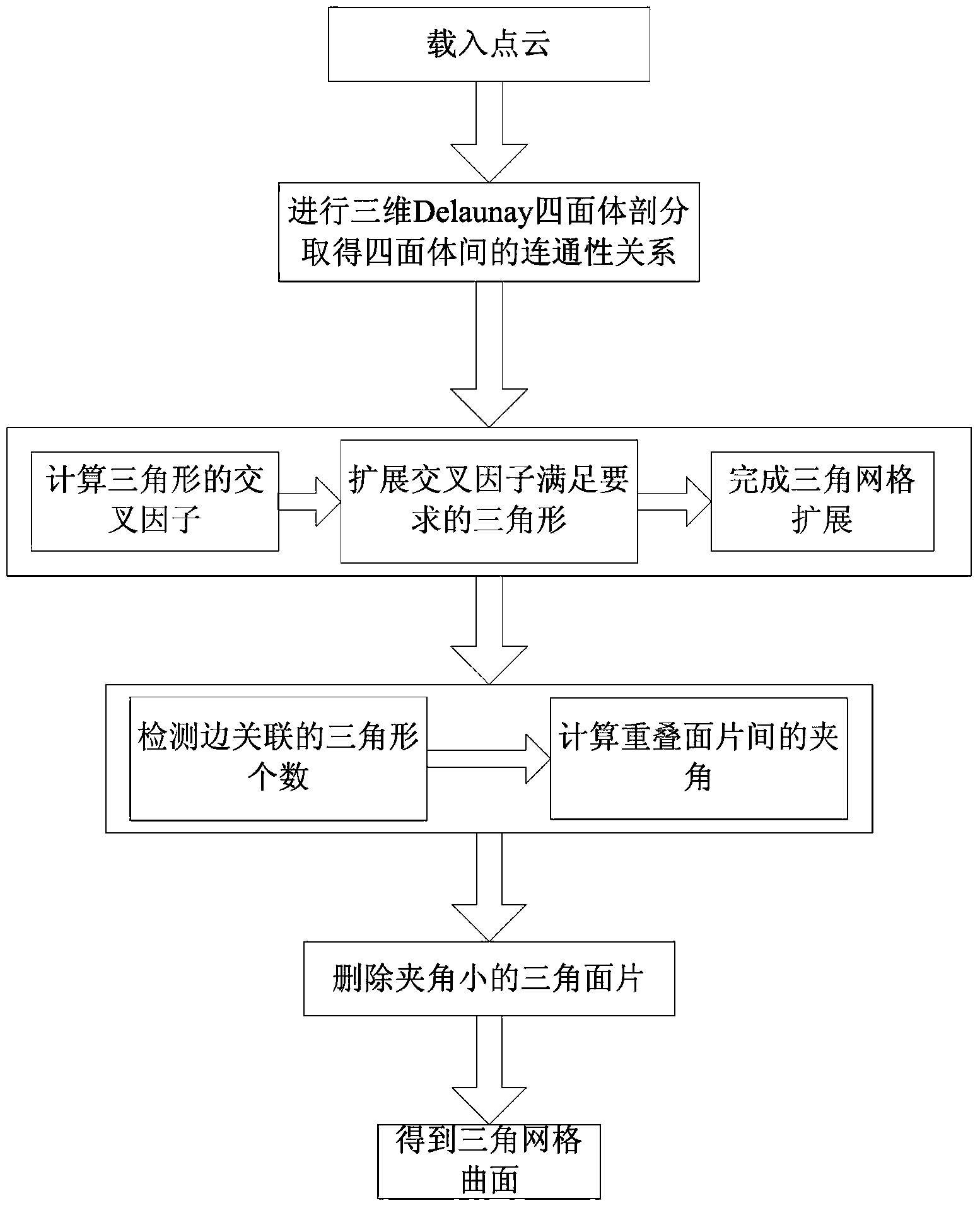

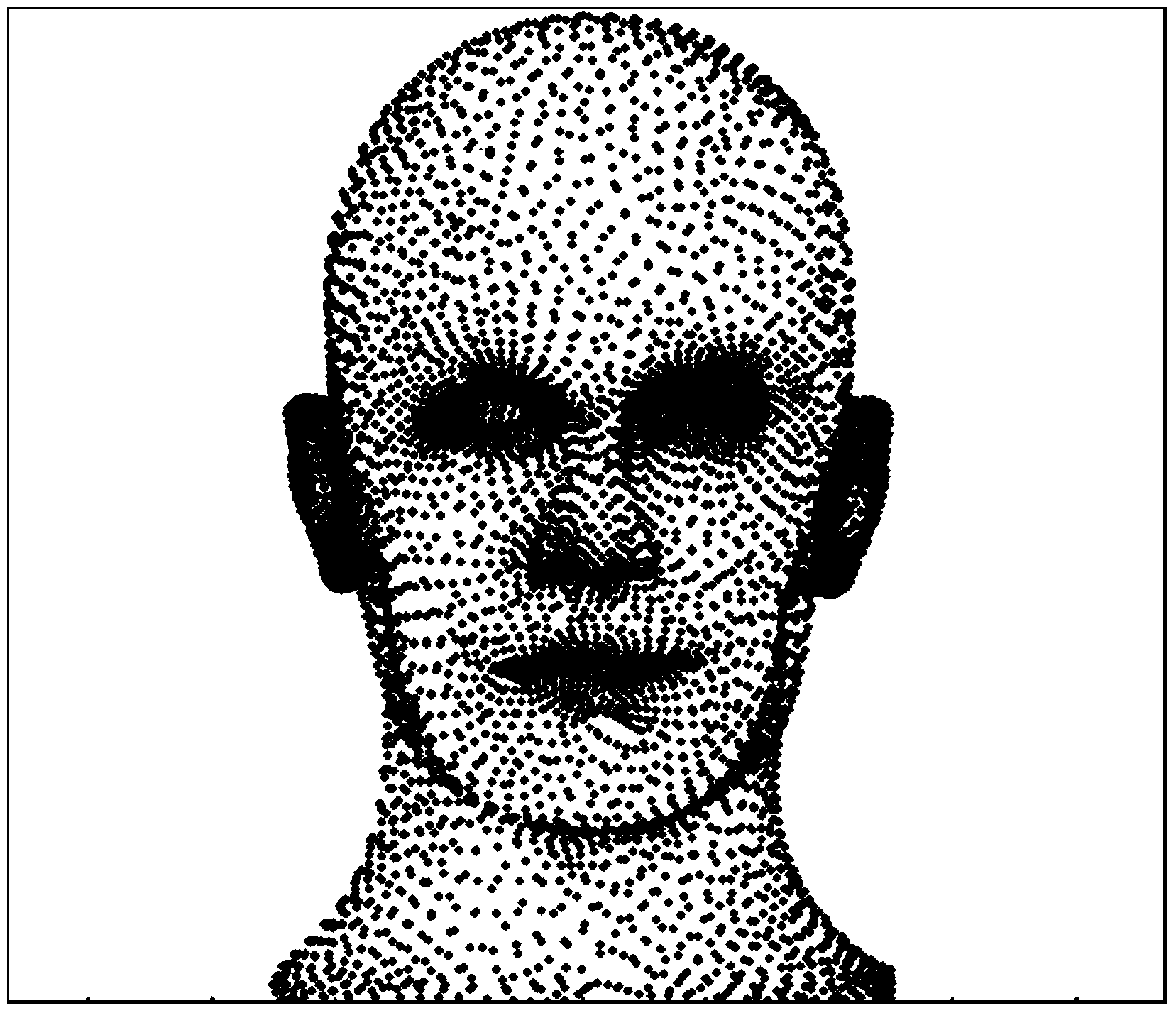

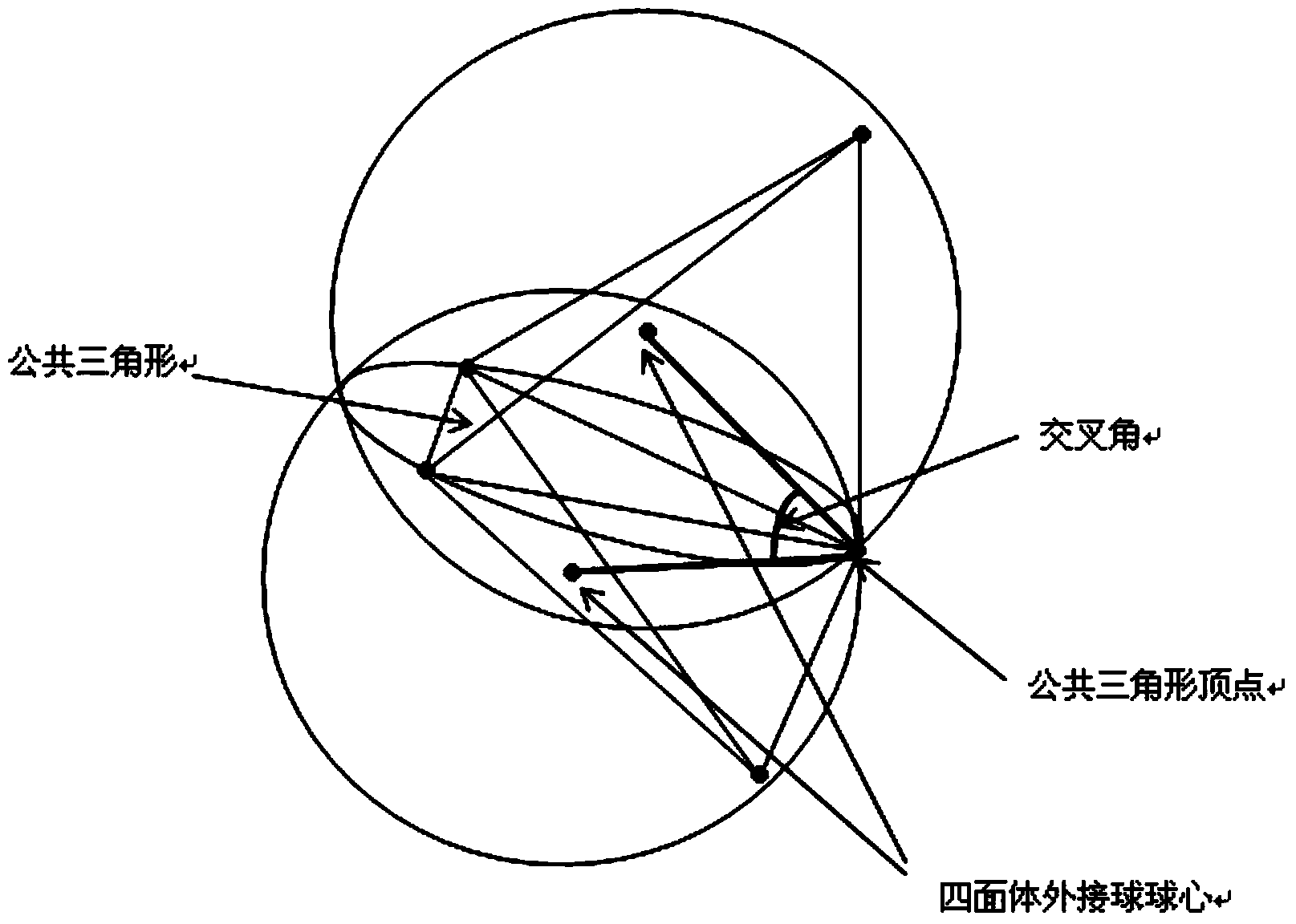

Triangular mesh curve surface recovery post-treatment method based on removal of overlapped patches with included angles

InactiveCN104392477AReduce reconstruction errorHigh industrial requirements3D-image rendering3D modellingPoint cloudAlgorithm

The invention discloses a three-dimensional scattered point cloud-oriented post-treatment method for removing overlapped patches based on three-dimensional Delaunay tetrahedral partition and triangular mesh curve surface reconstruction methods and theoretical basis of the reconstruction method. The theory is based on further optimization of a triangular mesh reconstruction algorithm Crust theory. According to the post-treatment method, triangular patches overlapped in the surface of an object recovered by point clouds are removed by detecting the number of edge-related triangular patches and calculating the included angles between the overlapped patches; the problem of overlapped triangular patches at the detail part of a conventional triangular mesh model is emphatically solved, so that the quality of the recovered model is improved, the recovered curve surface is relatively close to the model, and relatively high industrial requirements are met.

Owner:DALIAN UNIV

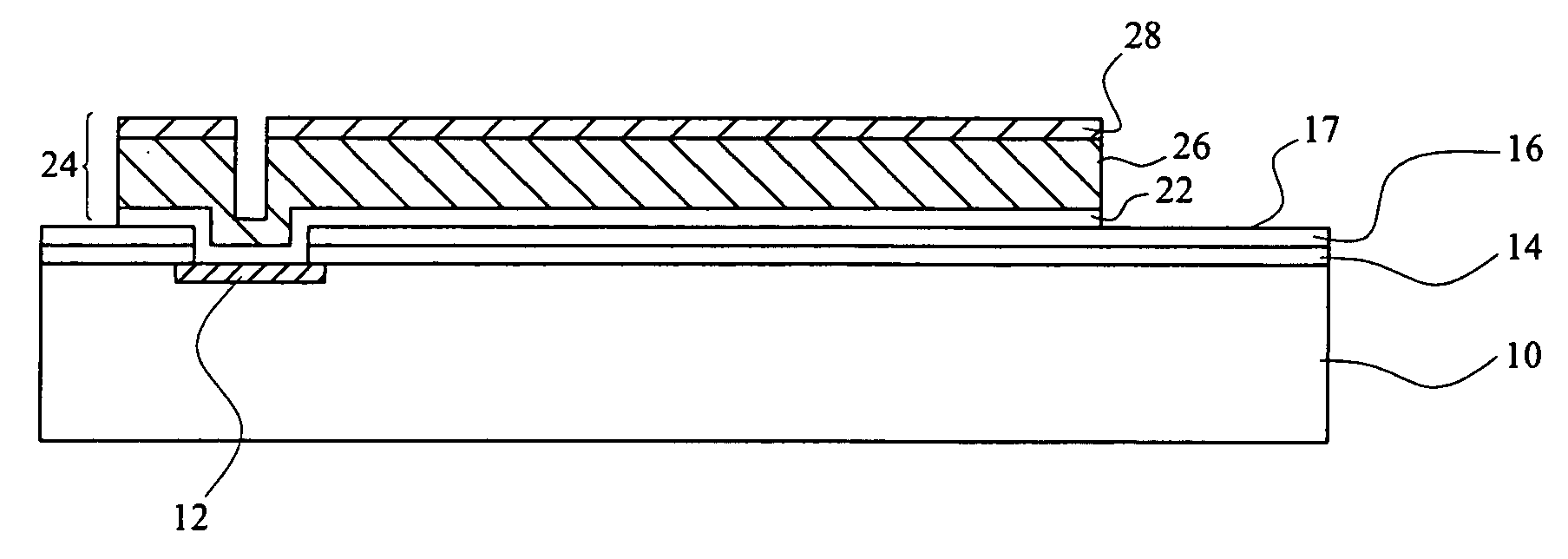

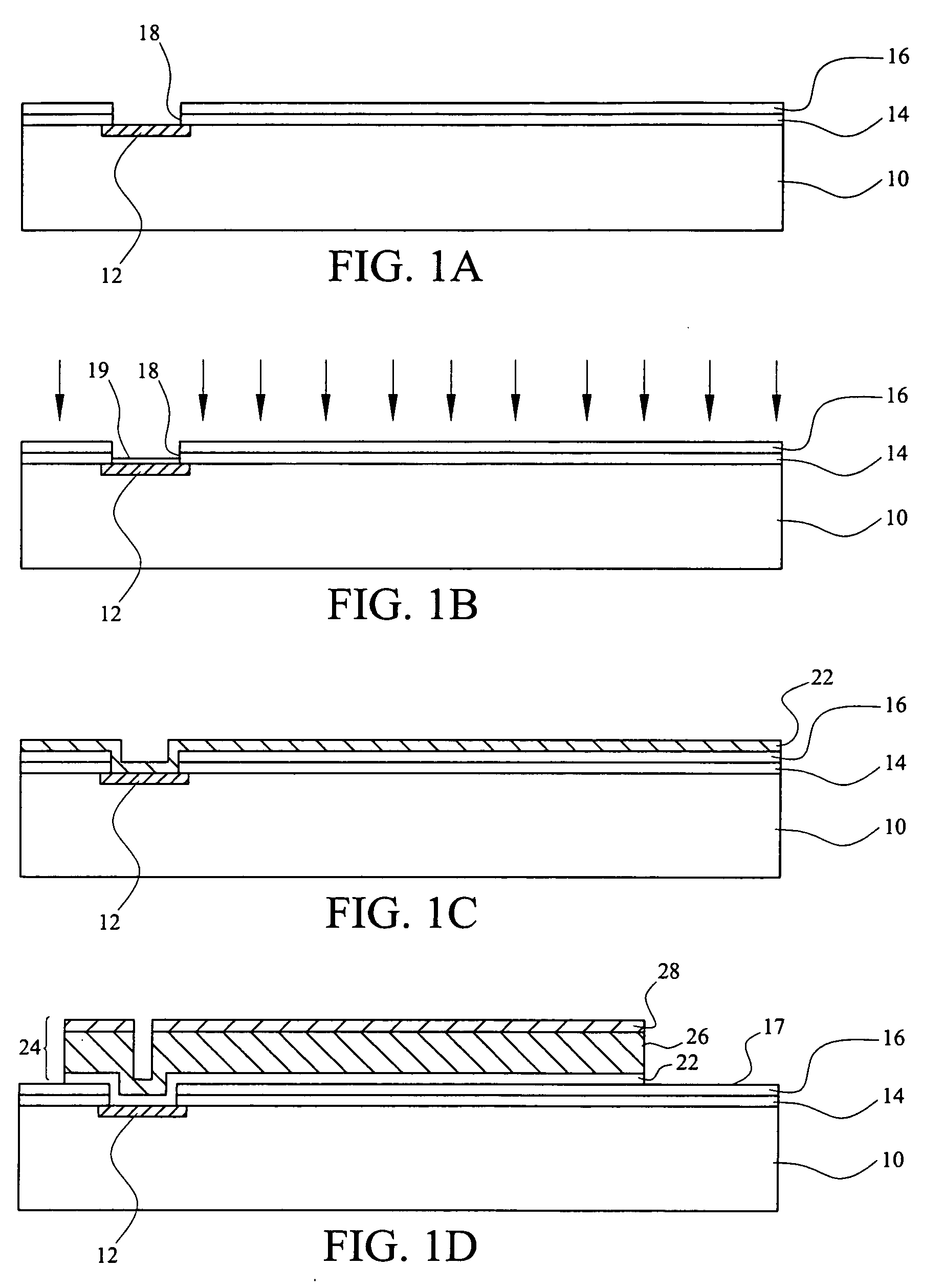

Method and apparatus for polymer dielectric surface recovery by ion implantation

InactiveUS20060113640A1Semiconductor/solid-state device detailsSolid-state devicesInsulation layerPolymer dielectrics

In one embodiment, the disclosure relates to a method and apparatus for surface recovery of a polymer insulation layer through implantation. The method includes providing a substrate having thereon a conductive pad and an insulation layer, optionally processing the conductive pad to remove oxide layer formed on the conductive pad and conducting ion implantation to recover dielectric properties of the insulation layer.

Owner:TAIWAN SEMICON MFG CO LTD

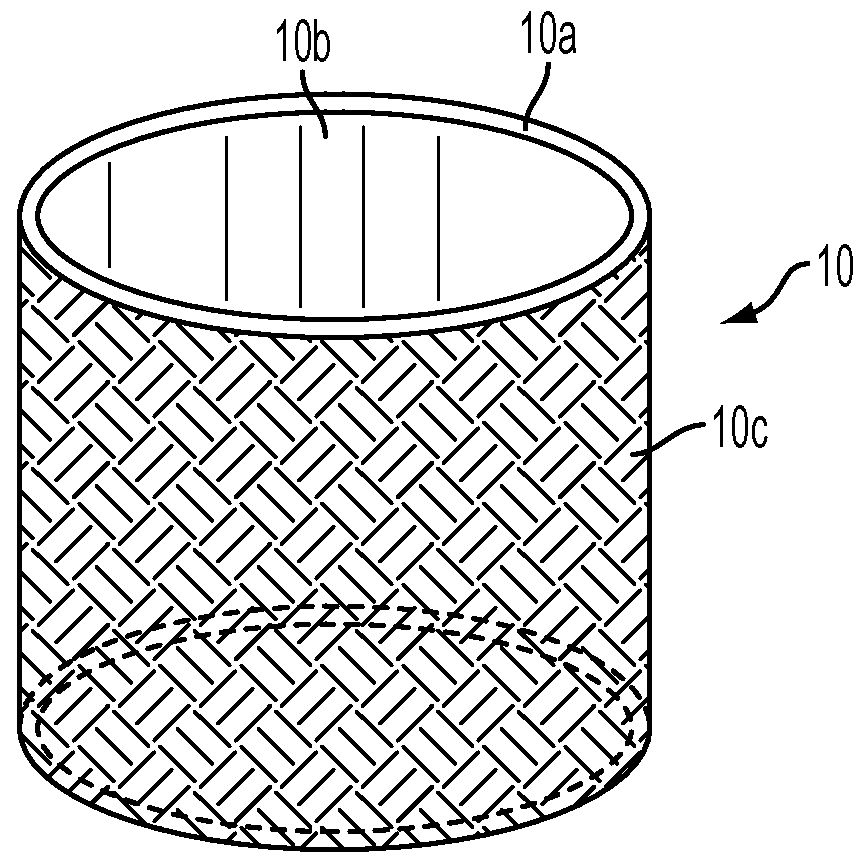

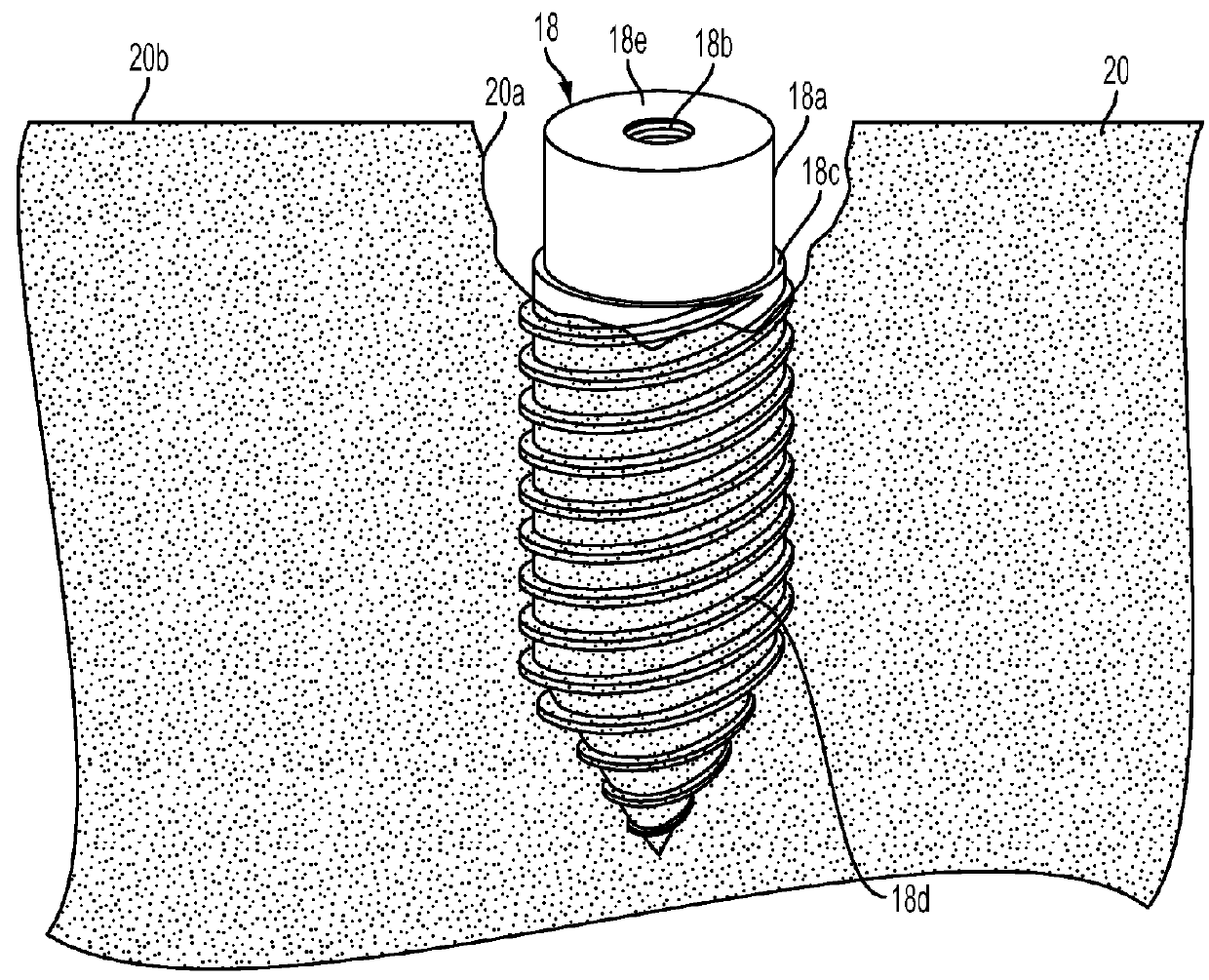

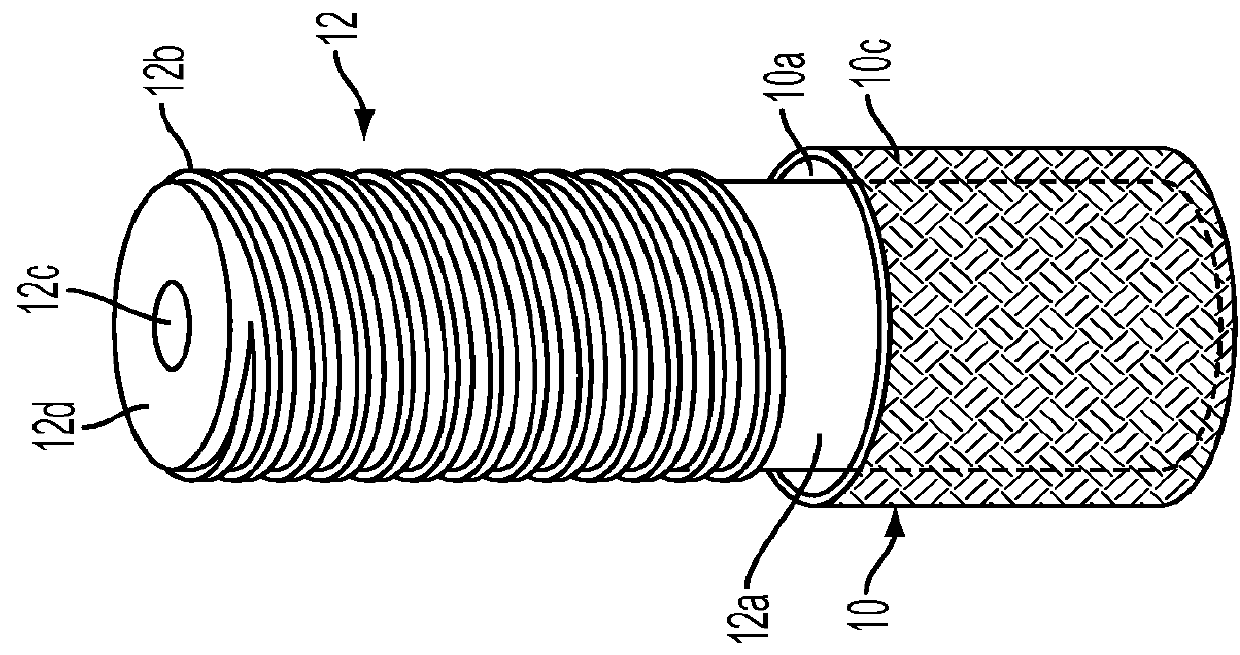

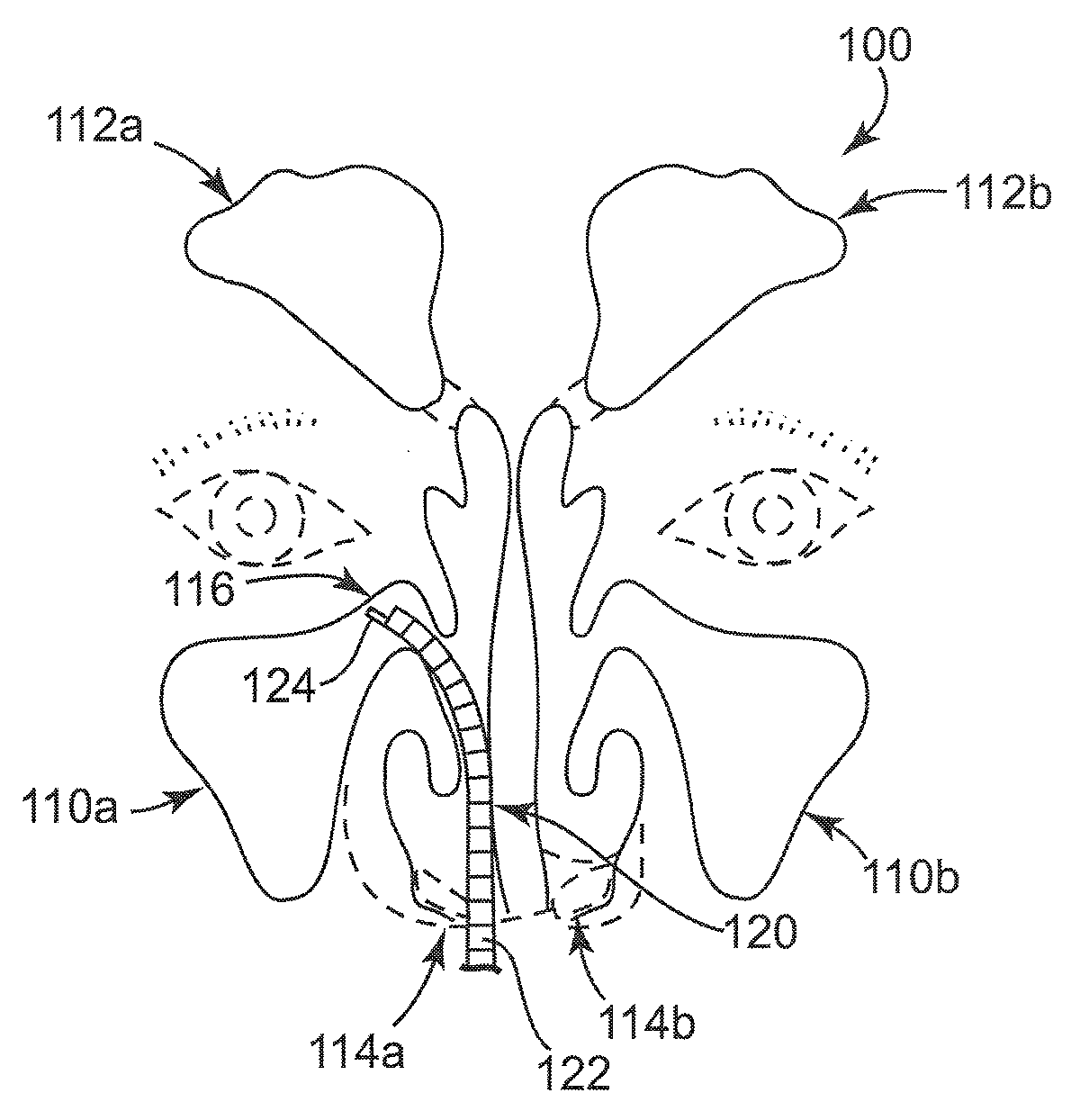

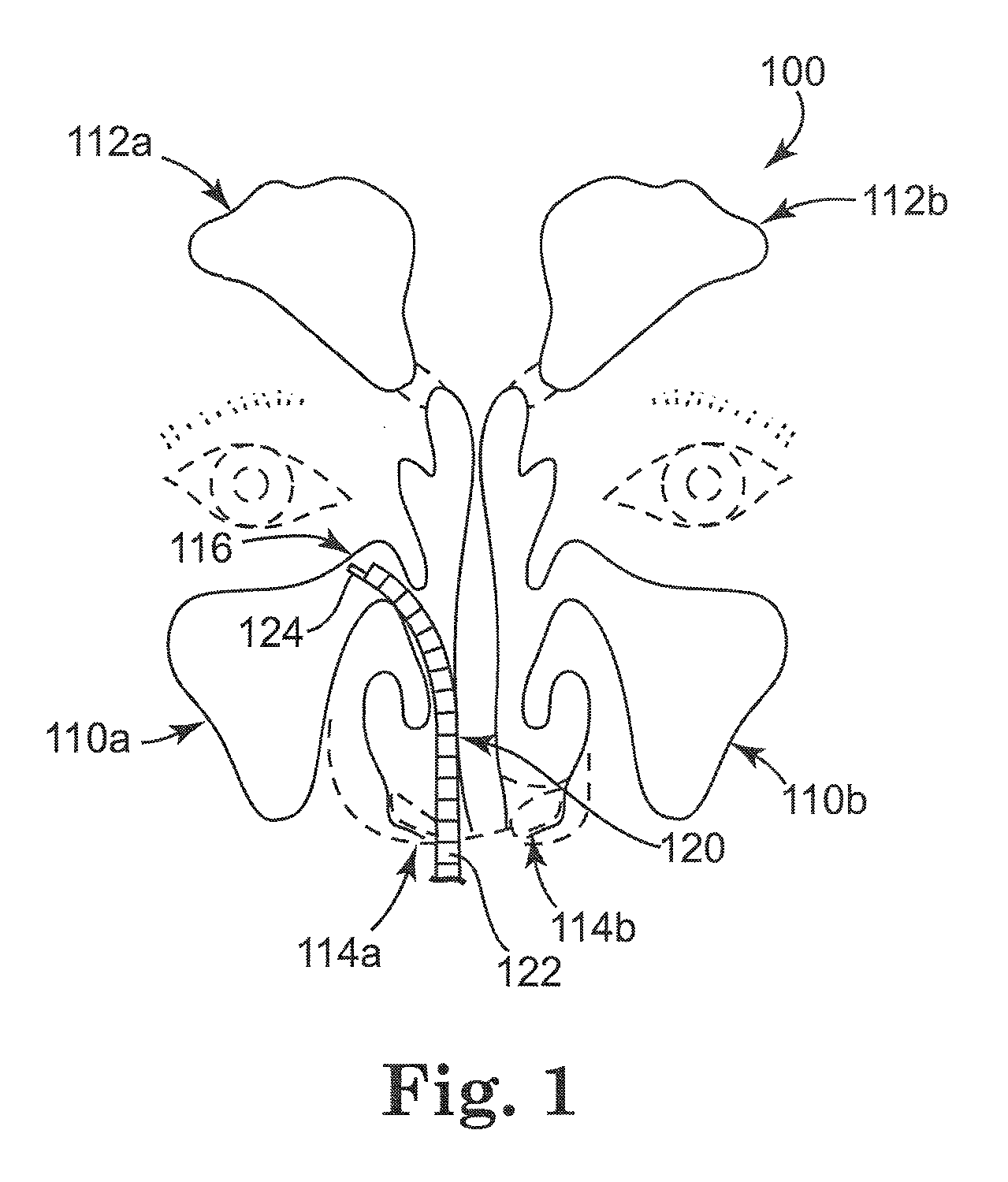

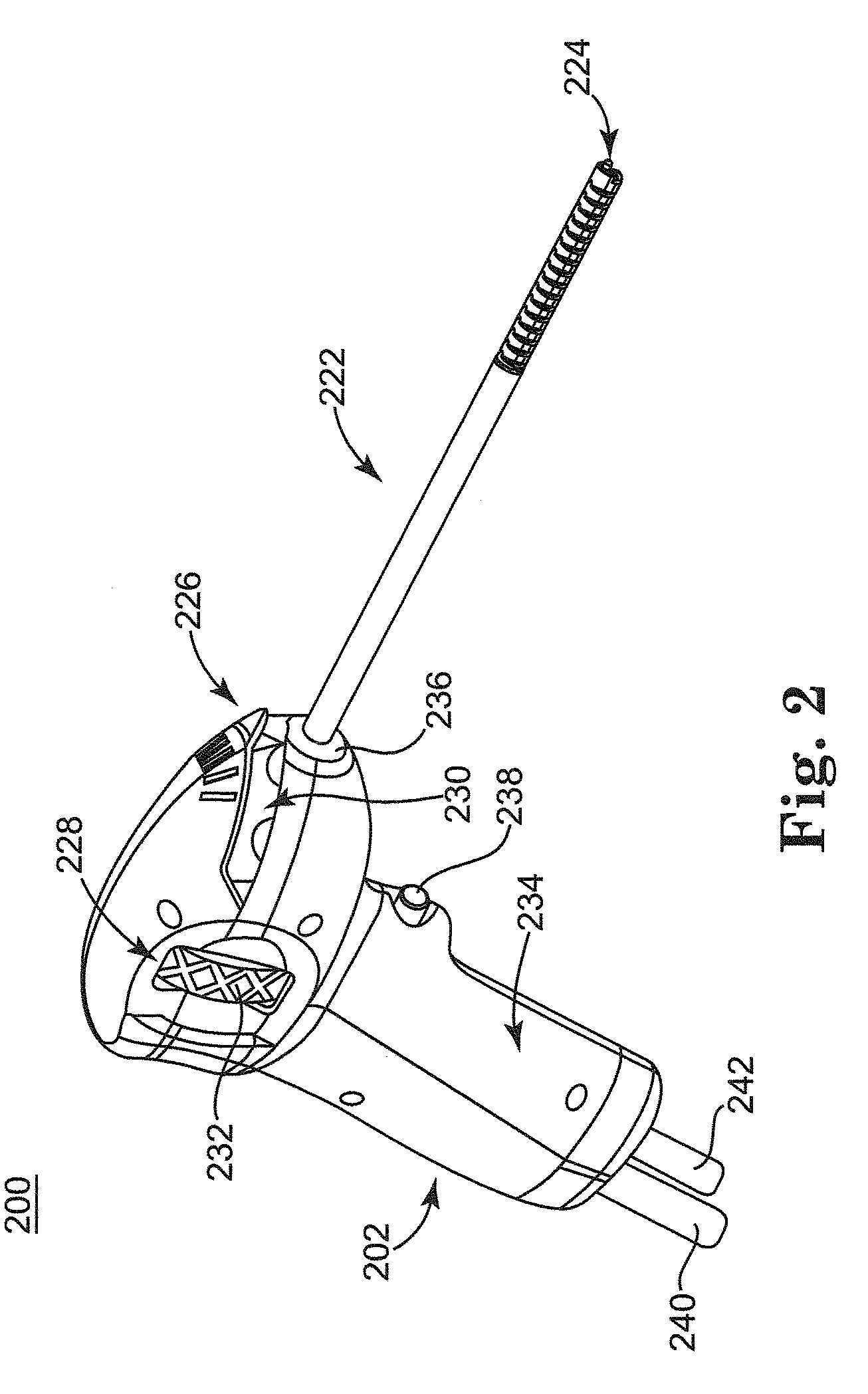

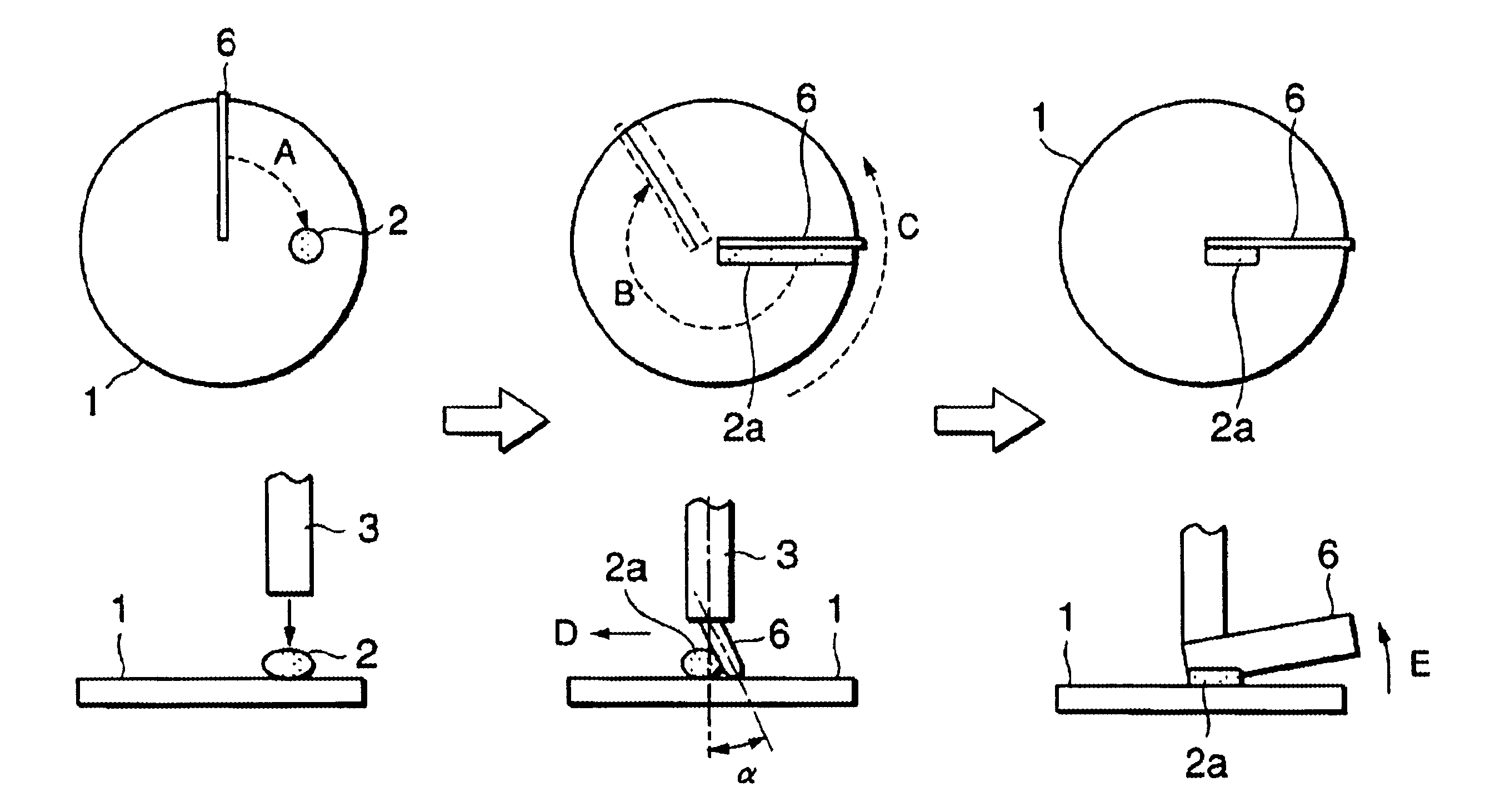

Method and apparatus to restore a tooth implant impaired by peri-implantitis

The invention is for the repair of a traditional implant previously installed, the implant being of the kind currently manufactured by many implant companies. The invention includes a method and apparatus used to repair a diseased tooth implant having peri-implantitis. A soft thin titanium alloy sleeve having an exterior treated surface for enhancing osseo-integration is used for implant surface restoration. The sleeve is initially installed on a dowel. The dowel is necessary to support the thin soft deformable sleeve at all times to prevent its collapse or being crushed. The dowel is also necessary to accomplish the transfer of the sleeve onto the implant surface. The diseased implant is restored by a new surface that enhances osseo-integration provided by the surface restoration sleeve.

Owner:GARFINKEL LEONARD M

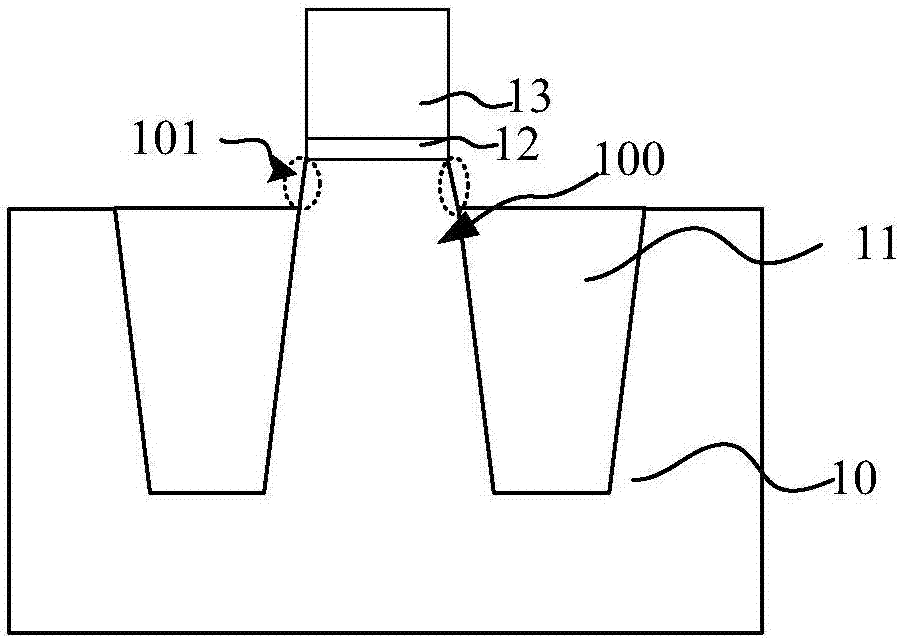

Manufacturing method of flash memory

ActiveCN107221533ARepair damageSolve the problem of poor isolationSolid-state devicesSemiconductor devicesMarine engineeringSurface recovery

The invention provides a manufacturing method of a flash memory. A step of surface recovery processing on a floating grid, which is exposed due to sunken of an active region, at a junction of the active region and a shallow groove isolation region is added after a source region or a drain region is formed in a semiconductor substrate at the bottom of an opening and before a second side wall material is deposited in the opening, the opening is formed after a floating grid layer and a floating grid oxide layer are etched, thus, the damage to a side wall of the floating grid on a sunken region of the active region of the opening can be recovered, a favorable process surface is provided for material deposition of a second side wall, the problem of relatively poor isolation between the floating grid and a source line caused by that the active region at a boundary of a shallow groove isolation structure is sunken can be further solved, and the data maintaining ability of the flash memory is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Rehydratable thiolated polysaccharide particles and sponge

ActiveUS20090285897A1Rapid and clump-free rehydrationHigh viscosityOrganic active ingredientsBiocideSurface recoverySolvent

Tissue and other body structures may be protected using a hydrated composition made from free-flowing rehydratable particles or a rehydratable sponge comprising substantially collagen-free dehydrothermally crosslinked thiolated polysaccharide. Rehydration of crosslinked or uncrosslinked polysaccharide particles may be carried out without clumping by dispersing the particles in a biocompatible water-miscible polar dispersant such as ethanol and combining the dispersion with sufficient aqueous solvent for the particles to convert them to a cohesive hydrogel. The hydrated particles or sponge may assist in returning an injured, inflamed or surgically repaired surface to a normal state, e.g., through one or more healing mechanisms such as modulation of an inflammatory response, phagocytosis, mucosal remodeling, reciliation or other full or partial restoration of normal function.

Owner:MEDTRONIC INC

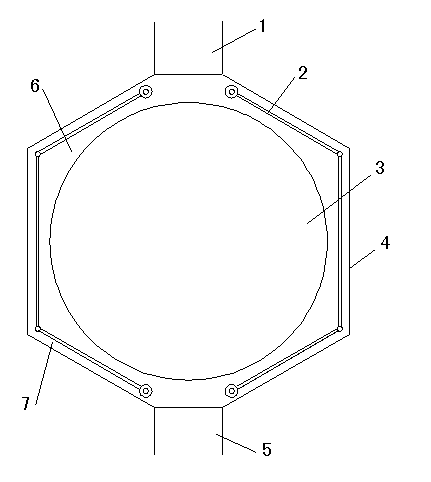

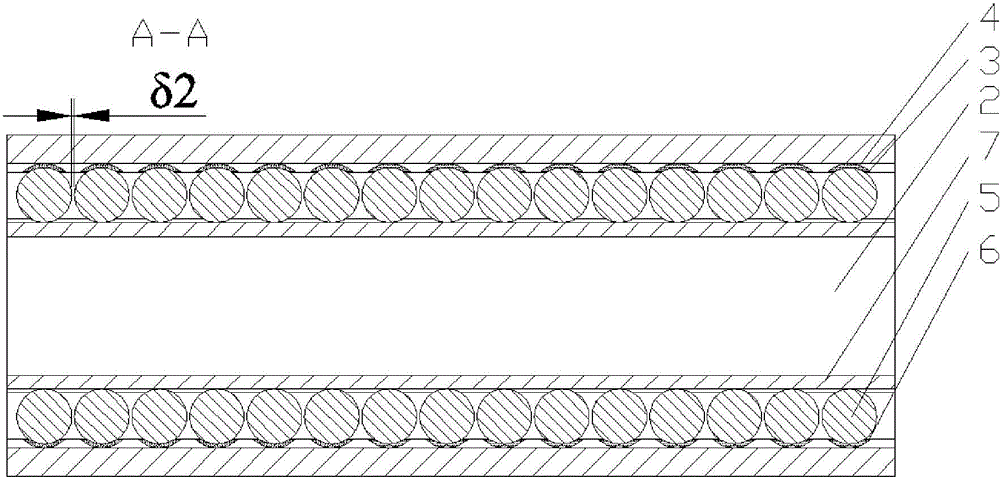

Regular hexagon rotary cement kiln surface heat recovery device

InactiveCN103123219AAchieve recyclingReduce wear and tearRotary drum furnacesIncreasing energy efficiencySurface recoveryEngineering

The invention discloses a regular hexagon rotary cement kiln surface heat recovery device. The regular hexagon rotary cement kiln surface recovery device comprises a water-cooling wall and an outer cover, and is characterized in that the water-cooling wall and the outer cover are regular-hexagon-shaped, the water-cooling wall is arranged on the periphery of a rotary cement kiln, the outer cover is arranged on the periphery of the water-cooling wall, gaps are remained between the outer cover and the water-cooling wall and between the water-cooling wall and the surface of the rotary cement kiln to form an inner ventilating duct and an outer ventilating duct which are communicated, and the upper portion and the lower portion of the outer cover are respectively provided with a ventilating opening. Because the regular-hexagon-shaped outer cover and the regular-hexagon-shaped water-cooling wall are adopted, difficulties and costs are greatly reduced in the manufacturing and installment process. Air entering ventilating ducts forms backflow because of geometry reasons, not only ensures that heat-exchanging effects on the surfaces of the water-cooling wall and the rotary cement kiln are enhanced, stay time of the air inside the ventilating ducts is longer, and accordingly heat recovery effects are strengthened, and more heat is recovered, but also facilitates regular operations of the rotary cement kiln.

Owner:山东省能源与环境研究院

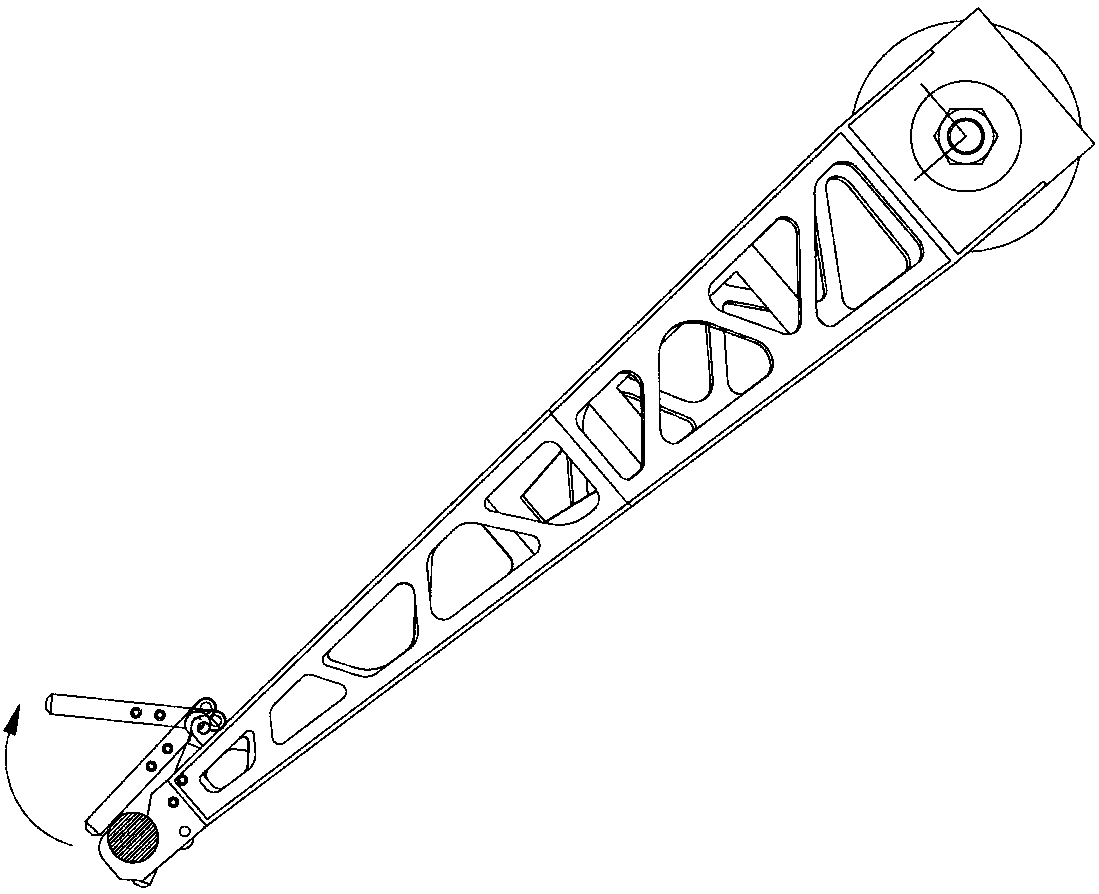

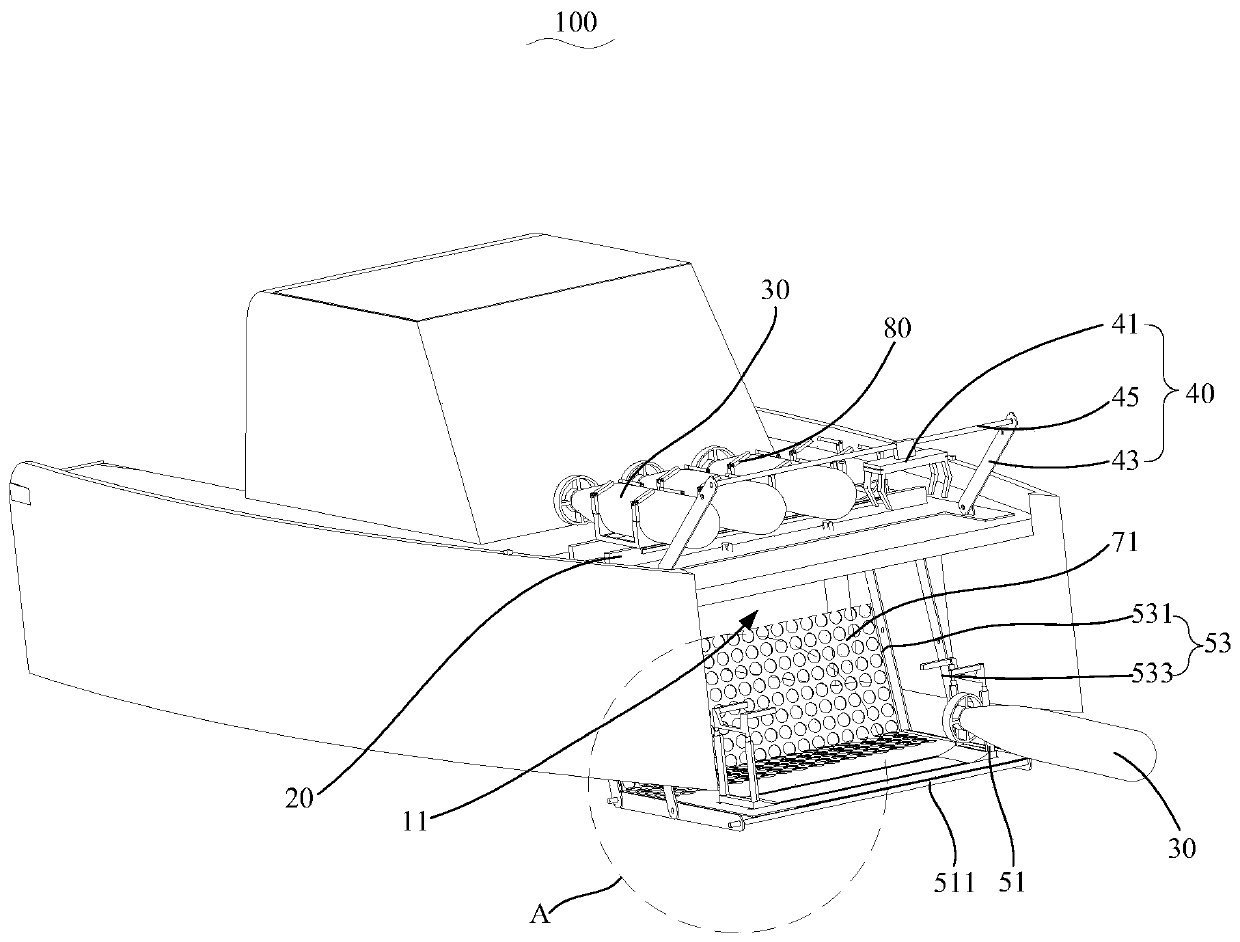

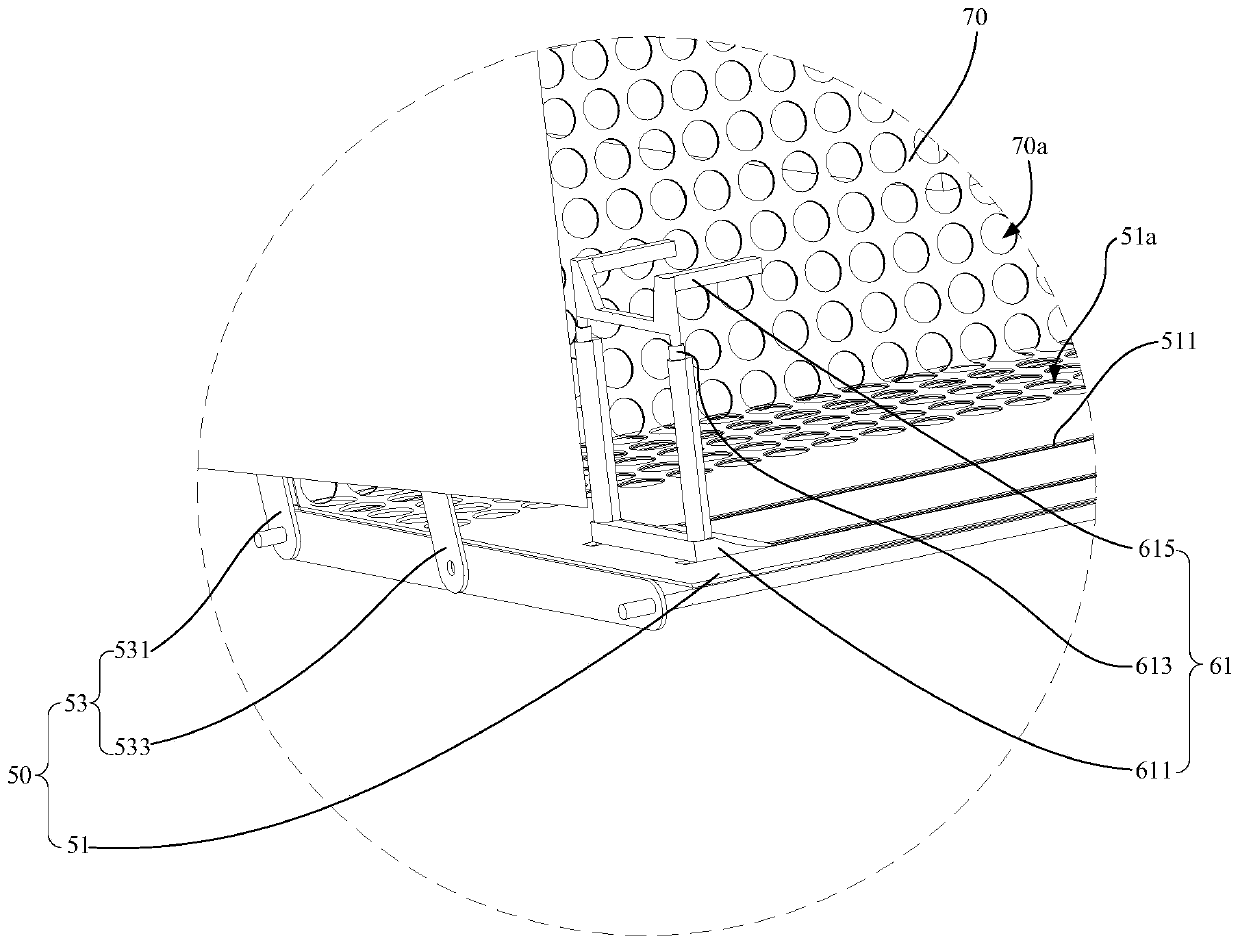

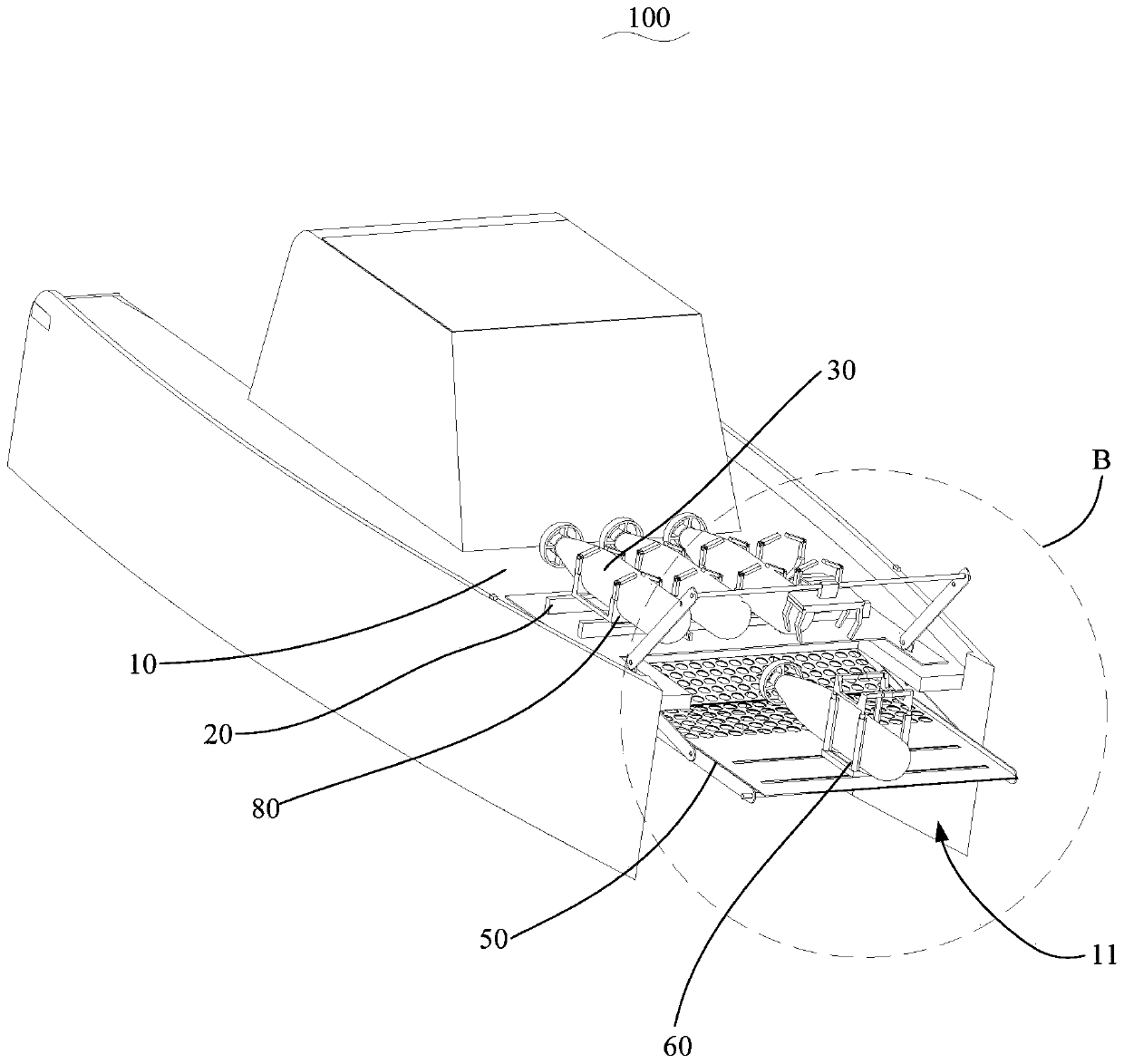

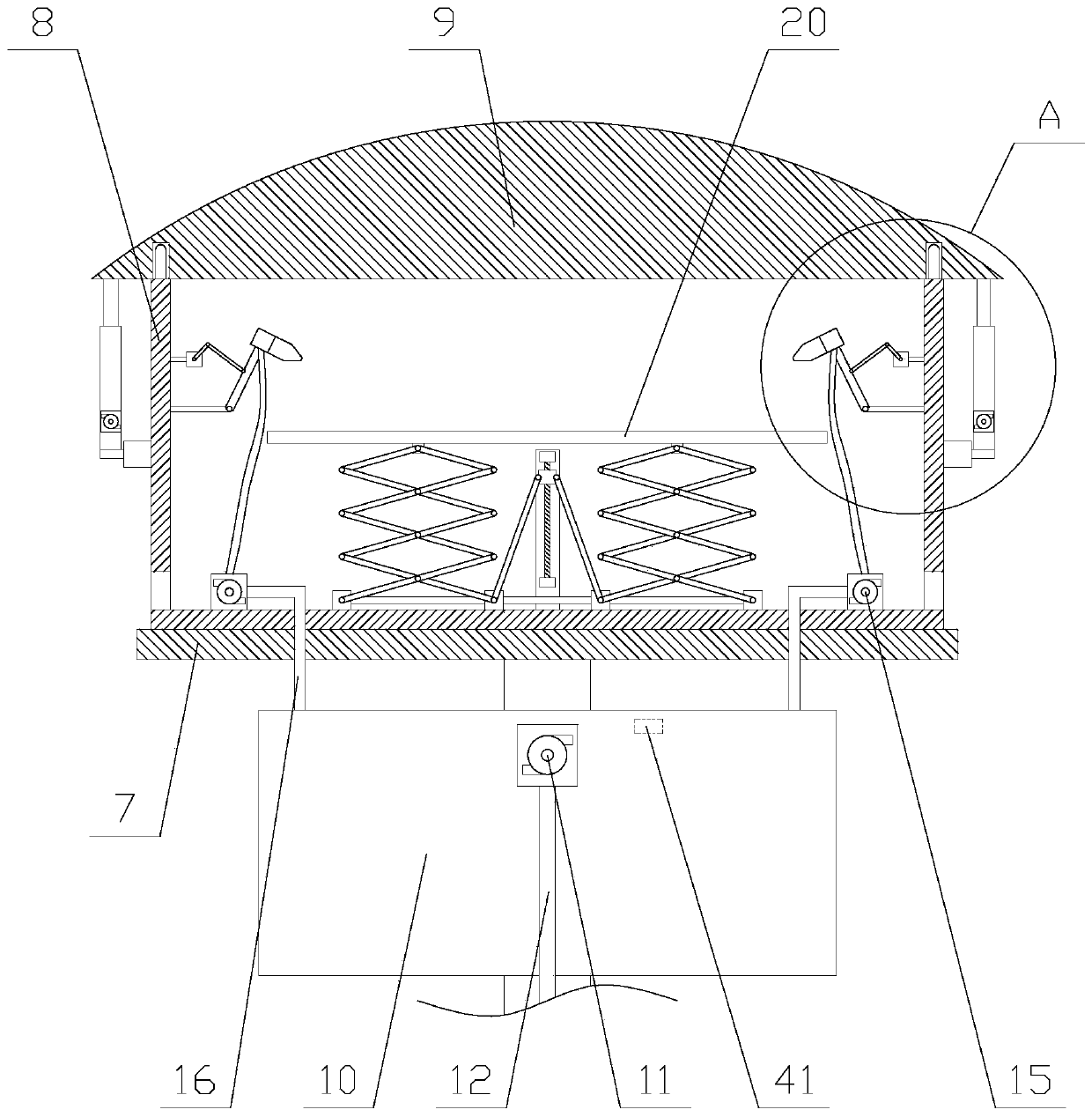

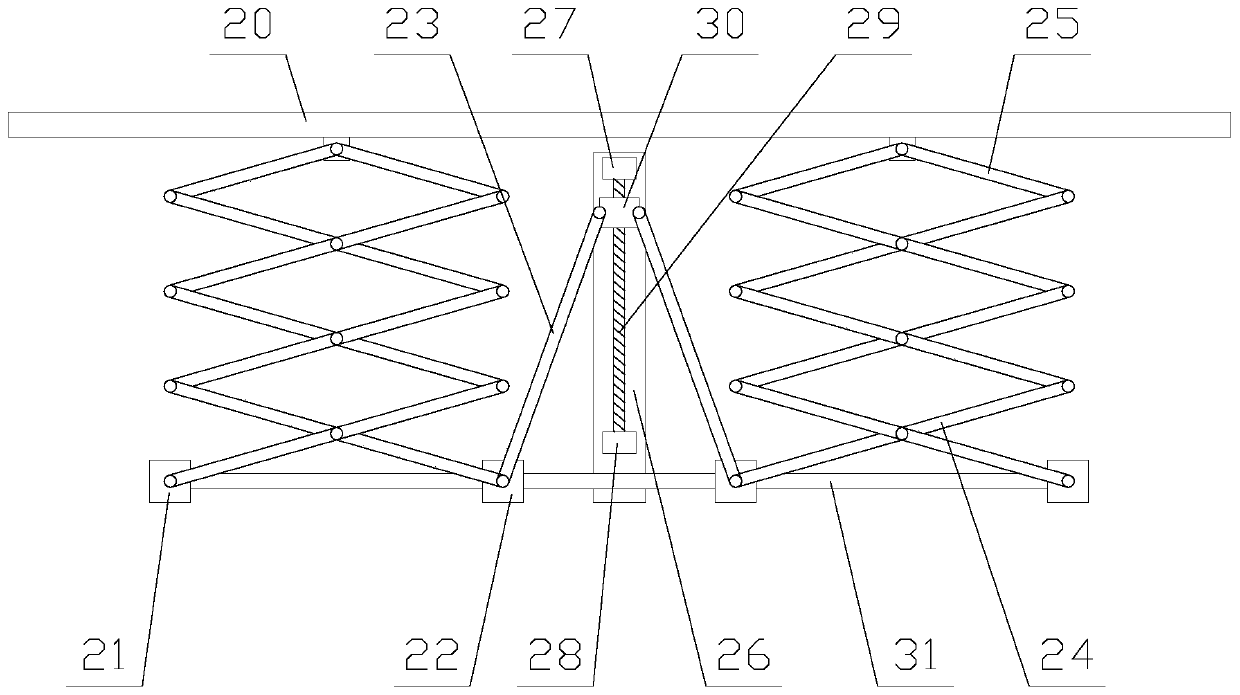

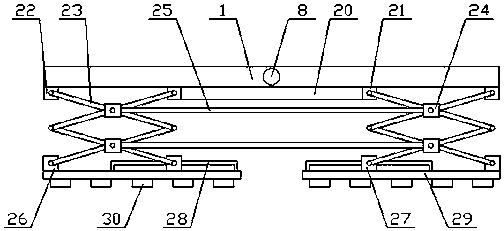

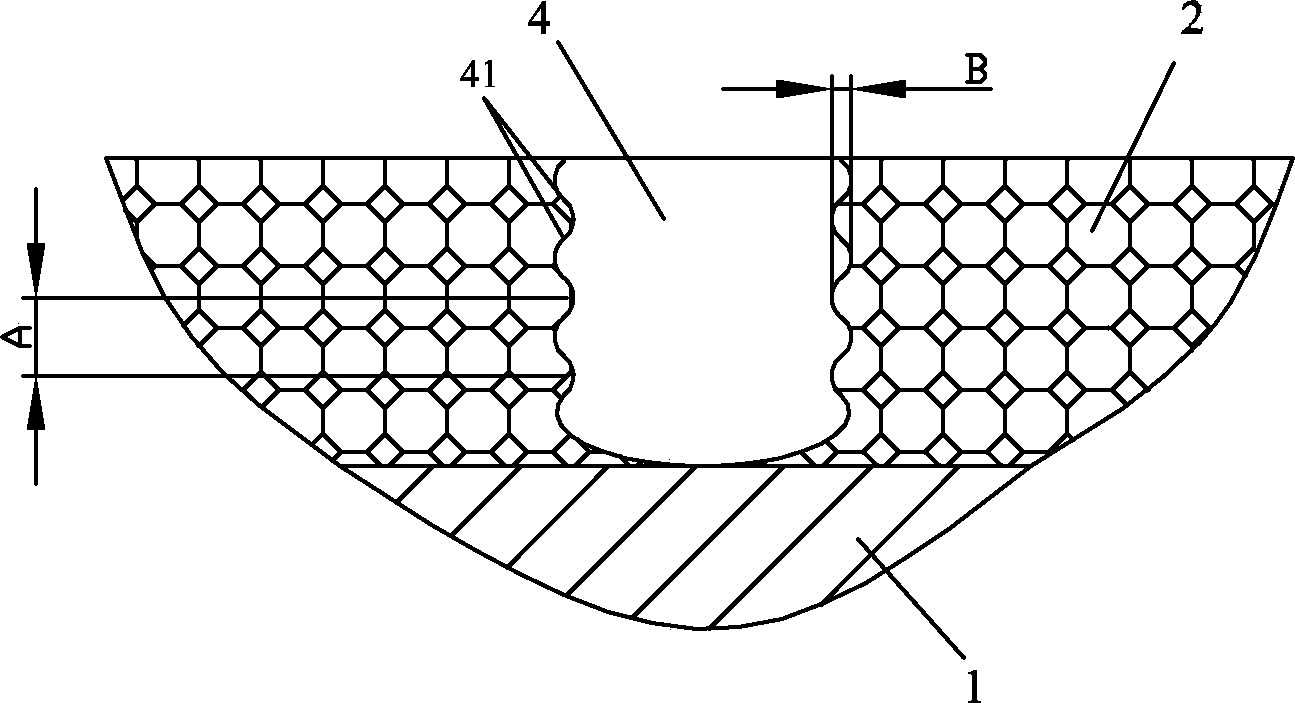

AUV cluster water surface recovery device

ActiveCN110901858ANo need for manual recyclingImprove efficiencyVessel salvagingUnderwater equipmentMarine engineeringSurface recovery

The invention discloses an AUV cluster water surface recovery device. The AUV cluster water surface recovery device comprises a recovery platform; a base, wherein the base is arranged on the recyclingplatform, and the base is used for placing the AUV; a portal frame, wherein the portal frame is erected on the recycling platform, and the portal frame is provided with a grabbing piece; a lifting mechanism, wherein the lifting mechanism is arranged at one end of the recycling platform and moves up and down relative to the recycling platform to have a capturing position and a lifting position; afixing mechanism, wherein the fixing mechanism is arranged on the lifting mechanism, the fixing mechanism is provided with an accommodating space which can be folded and unfolded and has a variable cross-sectional area, and at the capturing position, the AUV enters the accommodating space, and the accommodating space is folded to fix the AUV to the lifting mechanism, and at the lifting position, the accommodating space is opened, and the grabbing piece grabs the AUV and places the AUV on the base. The AUV cluster water surface recovery device is high in AUV recovery efficiency.

Owner:PENG CHENG LAB

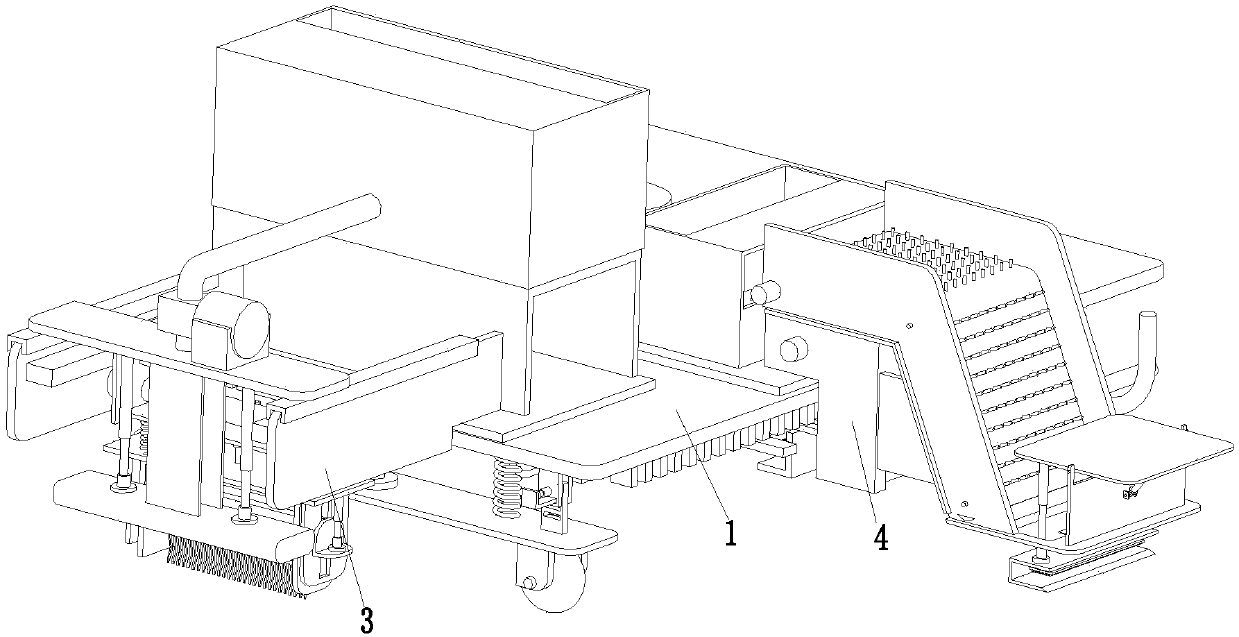

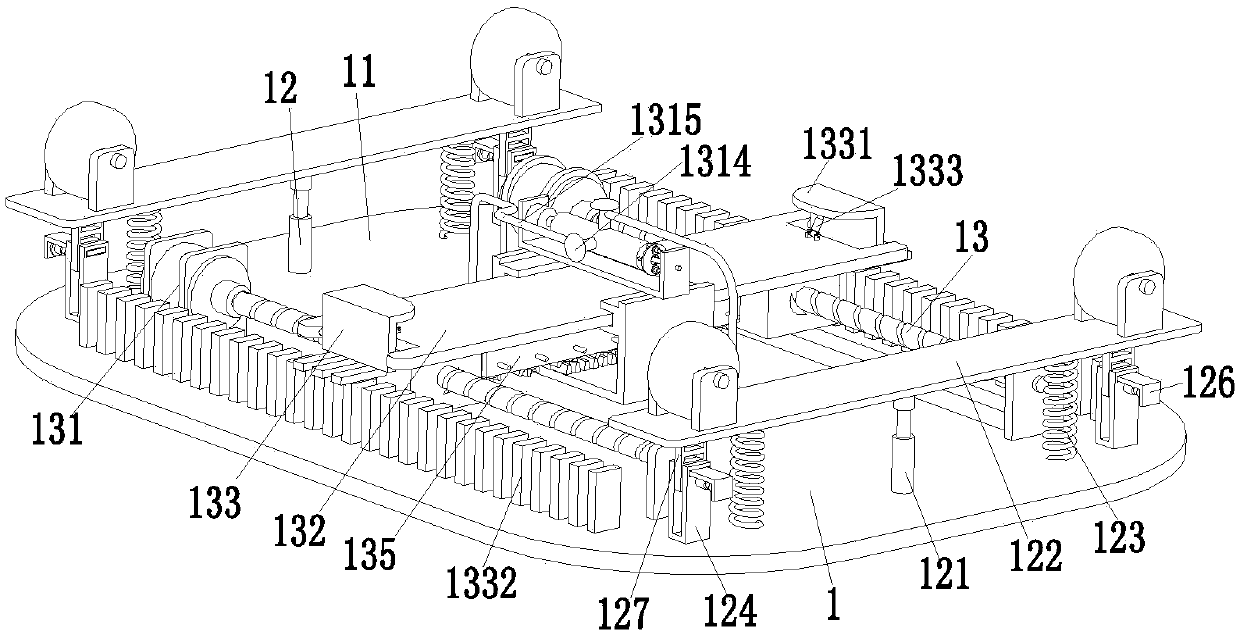

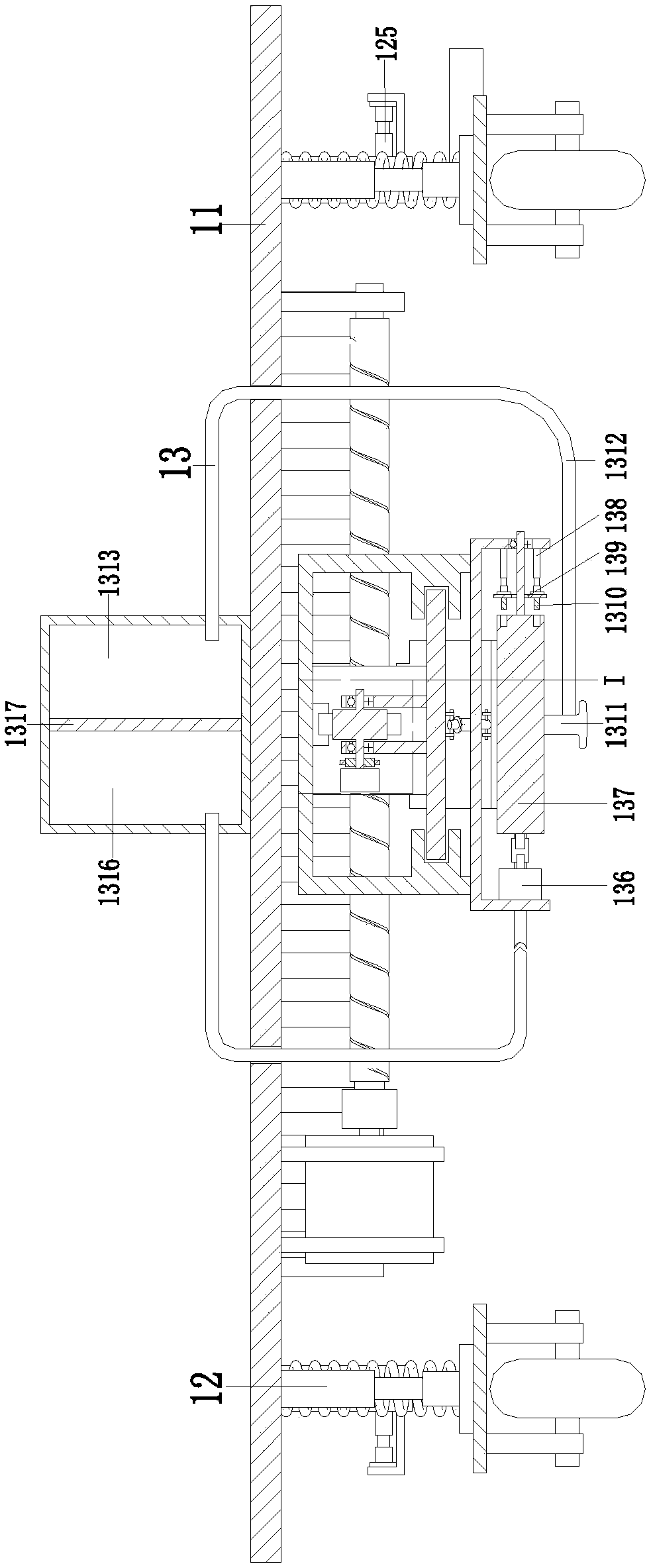

Intelligent repairing robot for high-magnesium cement concrete road surface

InactiveCN107905077AWill not affect the use effectReduce contact areaRoads maintainenceHigh magnesiumSurface recovery

The invention relates to an intelligent repairing robot for a high-magnesium cement concrete road surface. The intelligent repairing robot comprises a moving device. The rear end of the moving deviceis provided with a repairing device, and the right end of the moving device is provided with a spreading and rolling device. The moving device comprises a moving bottom plate, and the lower end of themoving bottom plate is provided with two moving auxiliary mechanisms which are symmetrically located on the front side and the rear side of the bottom plate. The lower end of the moving bottom plateis provided with a line marking mechanism. According to the intelligent repairing robot, the problems that moving on the road surface needs to be manually achieved through an existing device, concreteslurry needs to be manually coated multiple times through tools, scratching and trowelling treatment is conducted repeatedly, a protective cloth needs to be manually laid on the repaired concrete road surface, and the consumed time for manual laying of the protective cloth is long can be solved, and the function of integrated construction on the repairing and laying working procedures of concreteroad surface recovery can be achieved.

Owner:黄正秀

Method of collecting impurities on surface of semiconductor wafer

ActiveUS6911096B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSurface recoveryEngineering

A method of collecting impurities existing on the surface of a semiconductor wafer and in a thin film formed on the semiconductor wafer is provided with a process for dripping collecting liquid on the surface of the semiconductor wafer to which hydrophobic processing is applied, a process for elongating the collecting liquid dripped and turned spherical by surface tension in a direction of the radius of the semiconductor wafer with the surface tension kept, a process for relatively rolling and scanning the elongated collecting liquid, touching the collecting liquid to the surface of the semiconductor wafer and incorporating impurities into the collecting liquid, a process for restoring the elongated collecting liquid to the original spherical shape after the impurities are incorporated and a process for withdrawing the collecting liquid restored to the spherical shape from the surface of the semiconductor wafer.

Owner:RENESAS ELECTRONICS CORP

Solar street lamp with protection function

InactiveCN109945117AFlexible structureGuaranteed uptimeElectric circuit arrangementsPhotovoltaicsDrive shaftProtection mechanism

The invention relates to a solar street lamp with a protection function. The solar street lamp comprises a base, a lamp pole, a side pole, a lamp tube, a processor and a photovoltaic device, wherein the photovoltaic device comprises a supporting plate, a protection shell, a protection cover, a water tank, a first water pump, a water pumping pipe, a power generation mechanism, two cleaning mechanisms and two protection mechanisms, wherein the protection mechanisms comprise first motors, first driving shafts and telescopic components; the cleaning mechanisms comprise second water pumps, clean water pipes, water conveying pipes, water spray pipes, direction change components, water outlets and a plurality of spray nozzles. The solar street lamp with the protection function can drive the protection cover to rotate through the protection mechanisms; in an emergency case, the protection cover rotates to a position above the protection shell to seal and protect a solar panel to prevent the solar panel from being damaged; furthermore, the cleaning mechanisms can pump clean water in the water tank to clean the solar panel, so that the surface of the solar panel can be recovered to be cleaned; therefore, the power generation efficiency is improved, and the practicability of equipment is improved.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

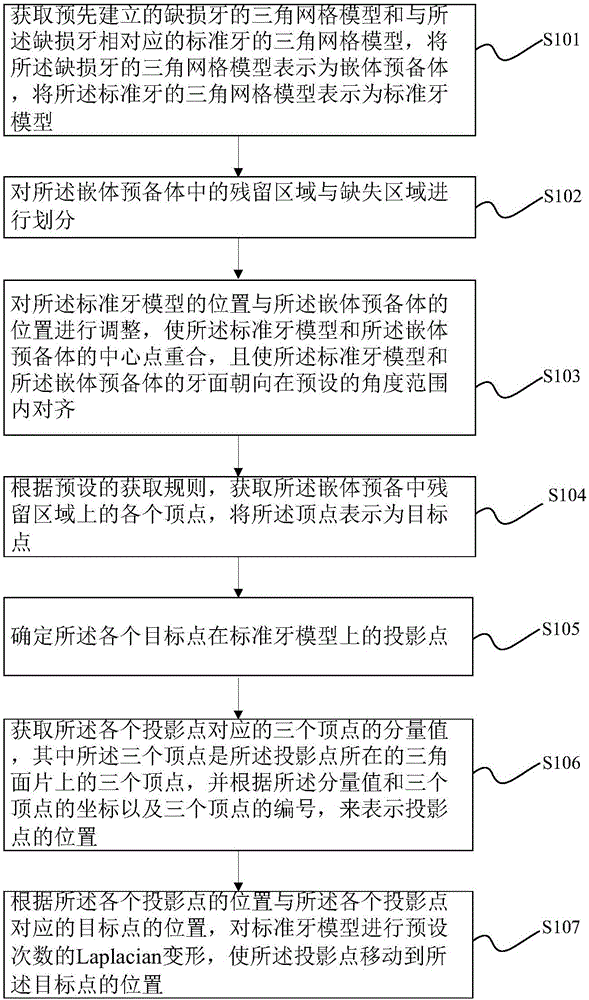

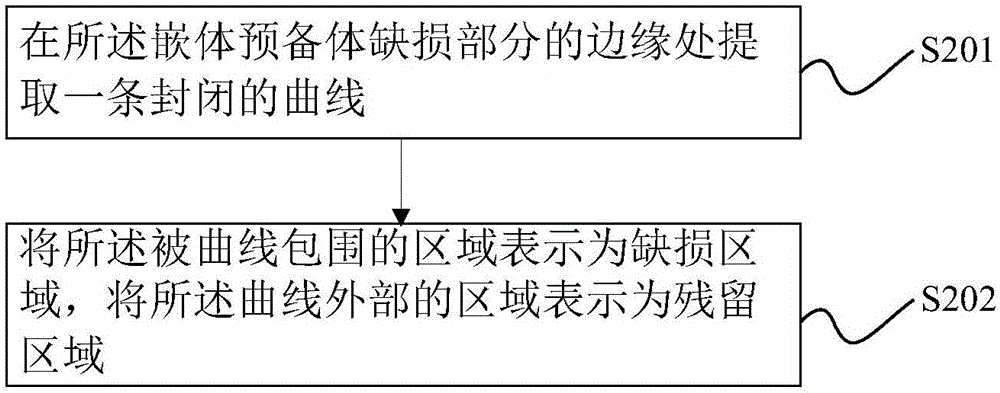

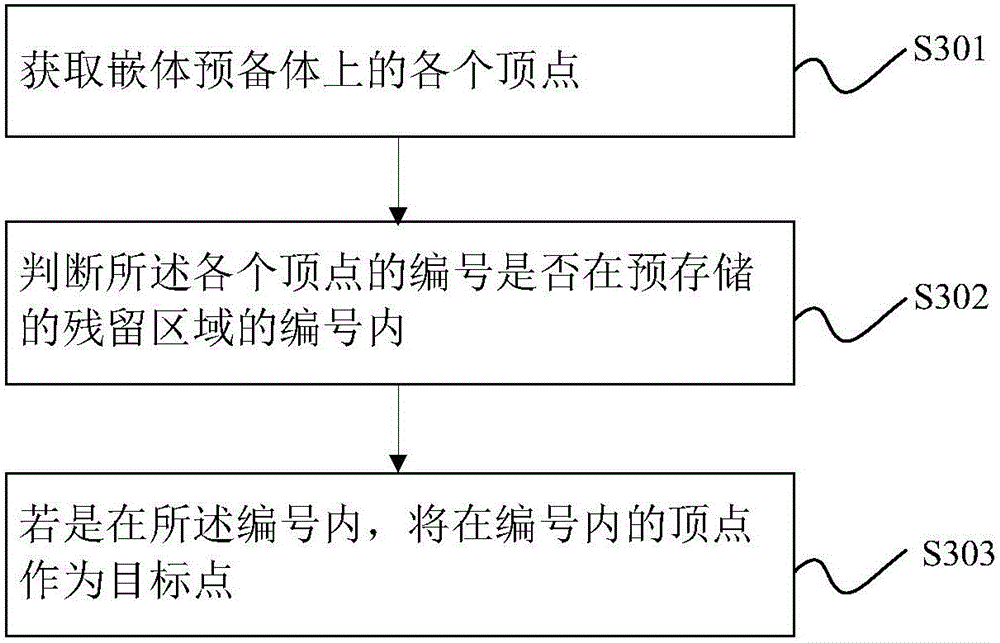

Dental occlusion surface recovering method and system

The invention provides a dental occlusion surface recovering method. The method includes the steps that the vertexes on the residual occlusion surface of an inlay preparation and projection points, on a standard tooth model, of the vertexes are obtained, the projection points are dispersed to the corresponding vertexes, and the projection points are moved to a standard tooth by carrying out Laplacian deformation on the standard tooth so that the standard tooth can be tightly attached to the inlay preparation; as Laplacian deformation is carried out multiple times, model self-crosslinking can be prevented, and moreover key information of fossa, groove, cusp and ridge on the residual occlusion surface is retained.

Owner:GUANGDONG UNIV OF TECH

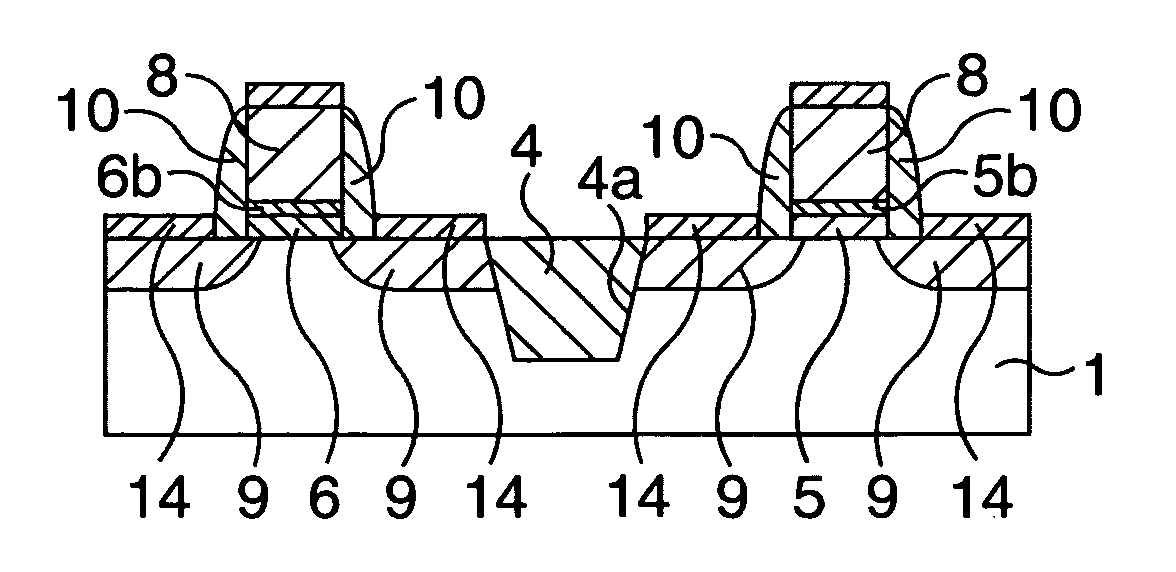

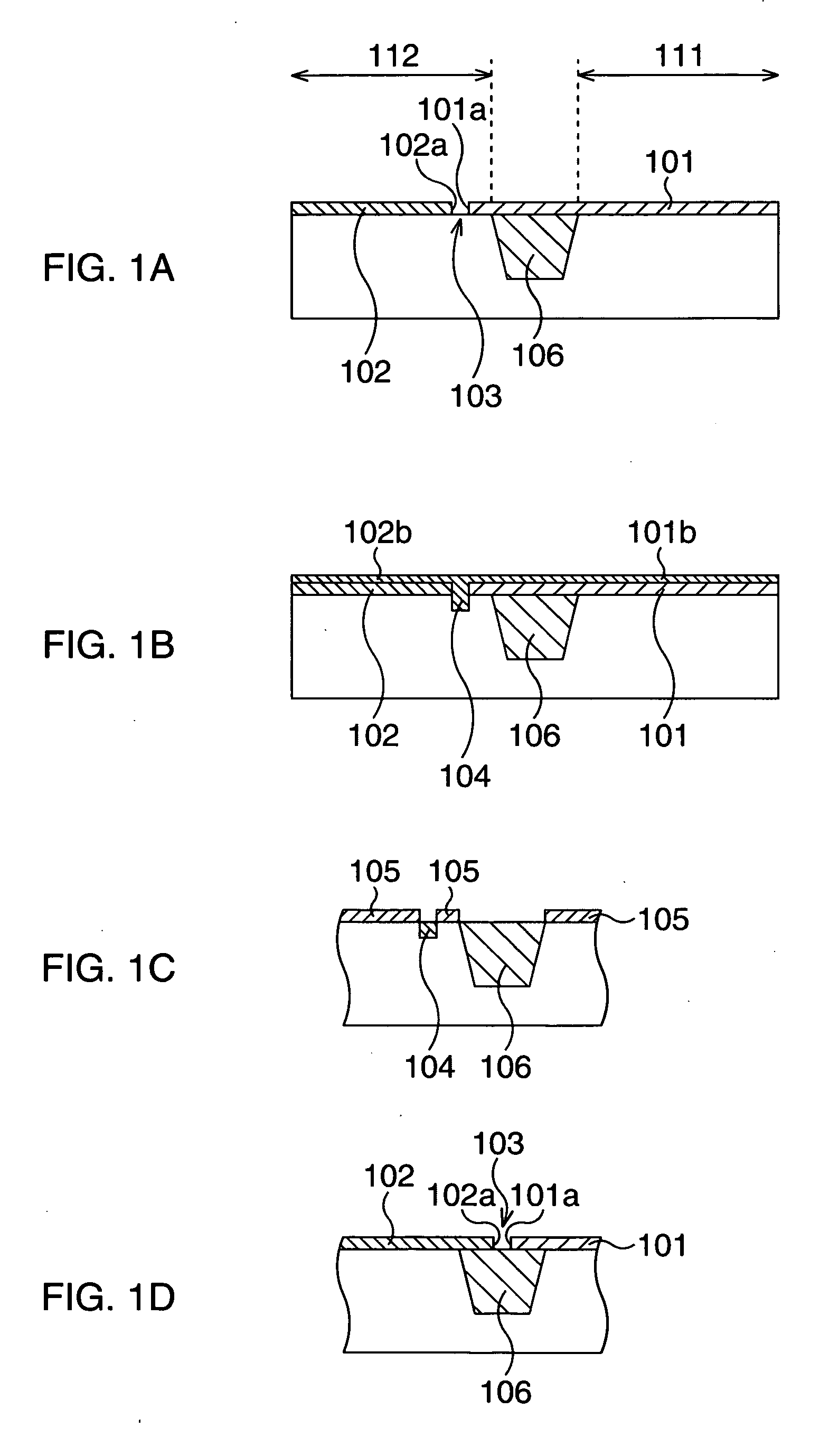

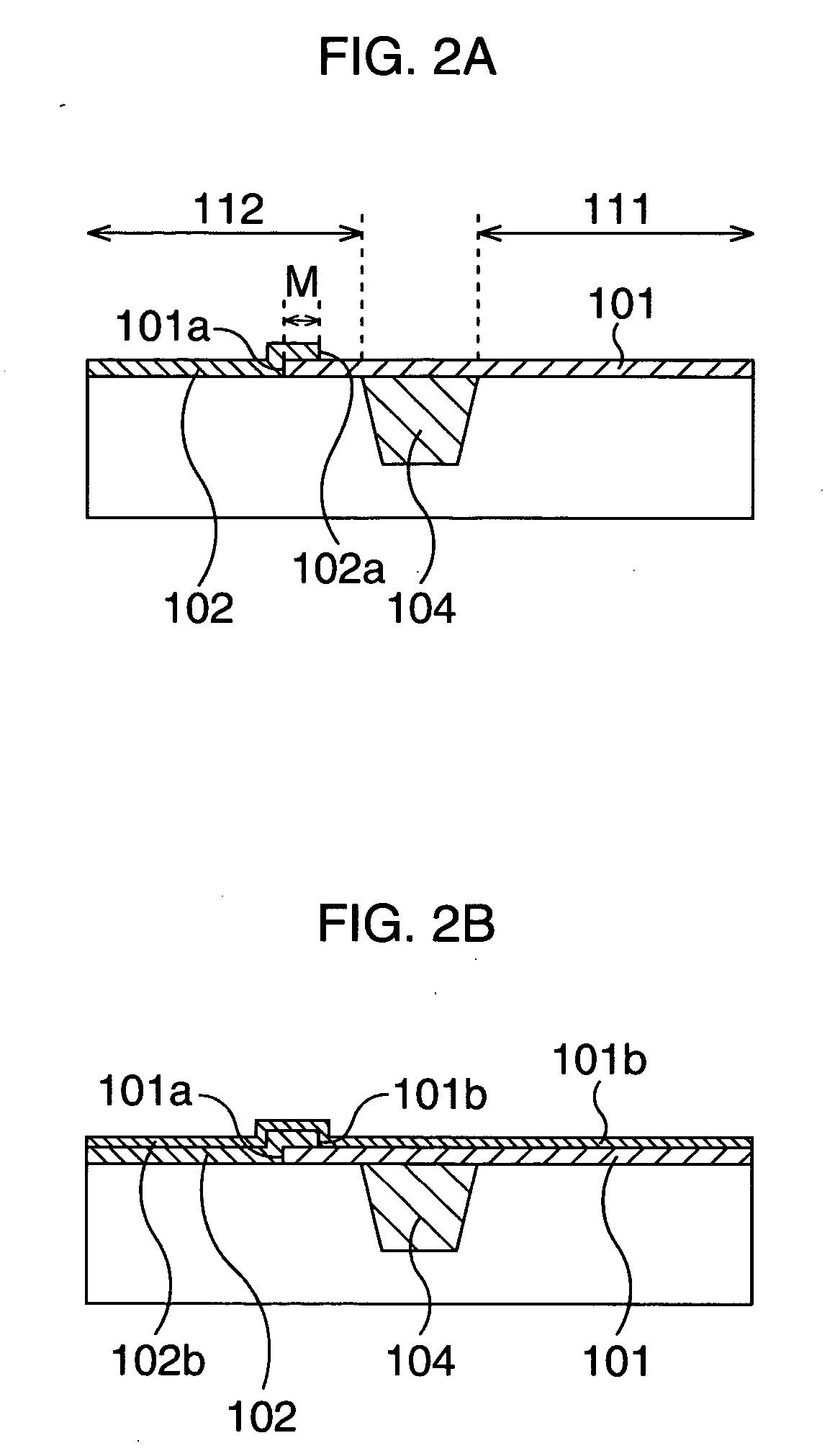

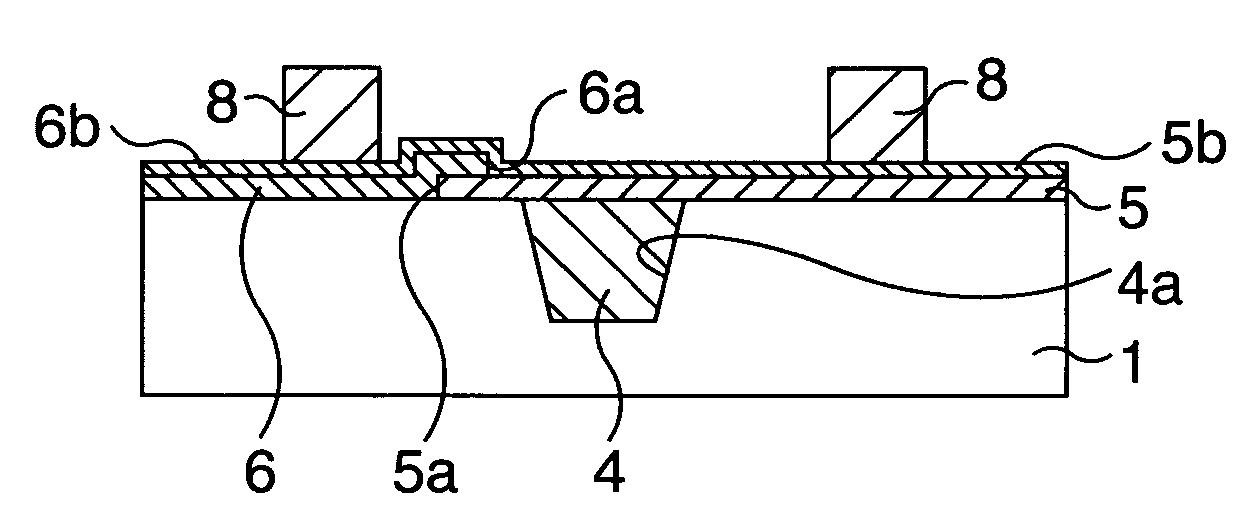

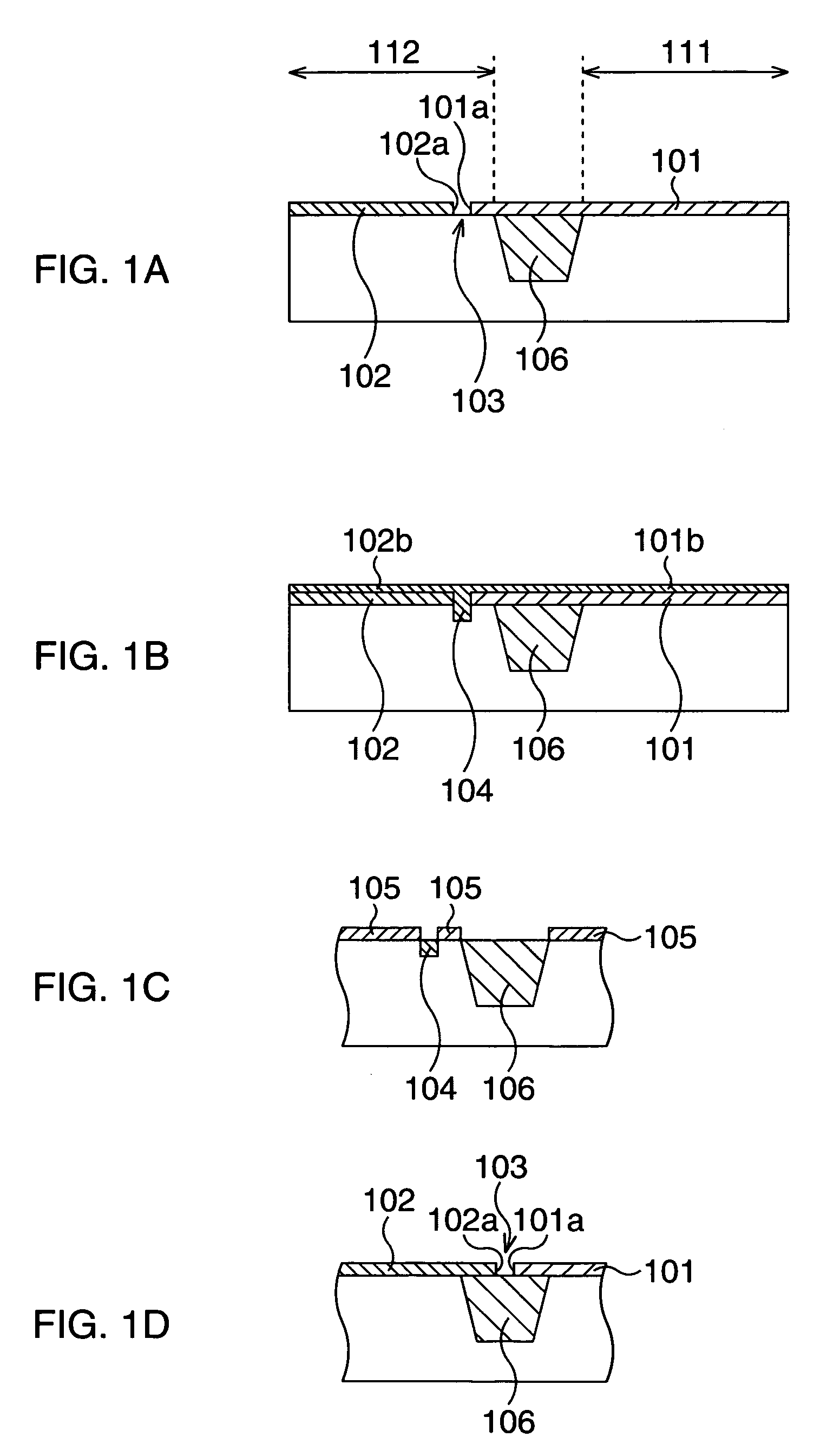

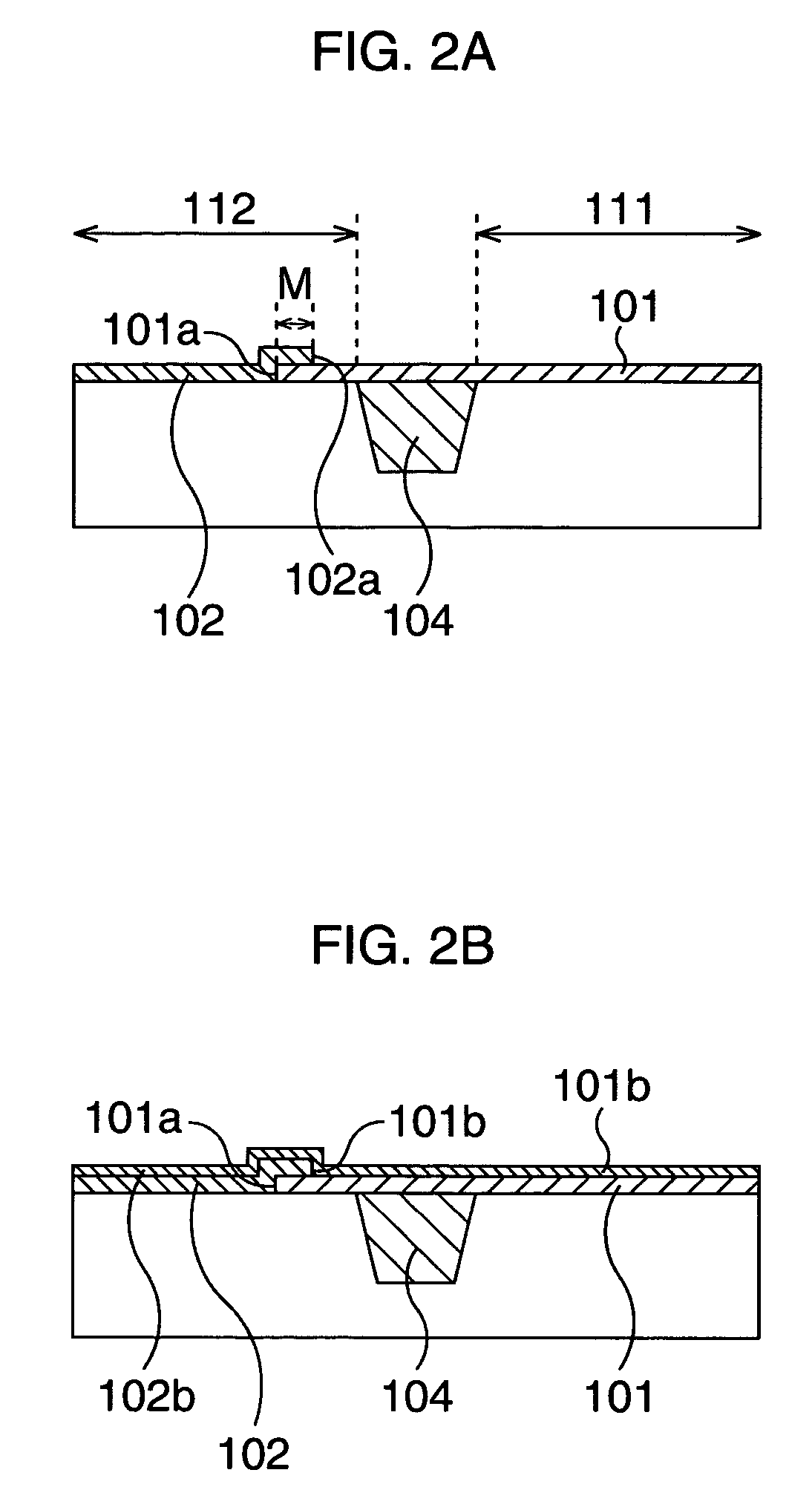

Semiconductor device and manufacturing method of the same

InactiveUS20060220143A1Satisfactory electrical propertyHigh equipment integrationSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSurface recovery

Patterning is performed in such a manner that an end portion fabricated of a second gate insulating film partially overlaps an end portion fabricated of a first gate insulating film. Then, a surface recovery treatment is performed in the aforementioned state where the first and second gate insulating films partially overlap each other.

Owner:FUJITSU SEMICON LTD

Semiconductor device and manufacturing method of the same

InactiveUS7396715B2Satisfactory electrical propertyHigh equipment integrationSemiconductor/solid-state device manufacturingSemiconductor devicesSurface recoveryEngineering

Patterning is performed in such a manner that an end portion fabricated of a second gate insulating film partially overlaps an end portion fabricated of a first gate insulating film. Then, a surface recovery treatment is performed in the aforementioned state where the first and second gate insulating films partially overlap each other.

Owner:FUJITSU SEMICON LTD

Inelastic collision and rolling viscous resistance particle coupling energy consumption low-noise gear

ActiveCN104141768ACircumferential vibration suppressionSuppress axial vibrationPortable liftingGearing elementsLow noiseInelastic collision

The invention discloses an inelastic collision and rolling viscous resistance particle coupling energy consumption low-noise gear and relates to gears. The gear is provided with a gear body, gear lightening holes, lightening hole grooves, high surface viscous resistance high polymer particles, low surface recovery coefficient particles, high polymer films, low surface recovery coefficient particle holders and a lightening hole sealing plate, wherein the lightening hole grooves are formed in the gear lightening holes; one low surface recovery coefficient particle and at least two high surface viscous resistance high polymer particles are placed in the lightening hole grooves; one low surface recovery coefficient particle holder is arranged in each gear lightening hole; the gear lightening holes are sealed by the lightening hole sealing plate; the high surface viscous resistance high polymer particles are coated with the high polymer films; a gap theta 1 is reserved between adjacent low surface recovery coefficient particles in the circumferential direction; a gap theta 2 is reserved between adjacent low surface recovery coefficient particles in the axial direction.

Owner:厦门环寂高科有限公司

Intelligent unmanned aerial vehicle for maintaining photovoltaic power generation device based on Internet of Things

InactiveCN109693798AEasy to washImprove practicalityAircraft componentsEnergy efficient board measuresMarine engineeringWater storage tank

The invention relates to an intelligent unmanned aerial vehicle for maintaining photovoltaic power generation device based on the Internet of Things. The intelligent unmanned aerial vehicle comprisesa main body, a supporting mechanism, a washing mechanism and a translation mechanism. The flushing mechanism comprises a water storage tank. The supporting mechanism comprises a driving mechanism, twotelescopic mechanisms and two clamping plates. Each telescopic mechanism comprises a first sliding block, a first fixing block, a telescopic frame, a hinge block, a second fixing block, a second sliding block, a sliding rail and a supporting plate. A flow guide pipe and a speed regulating mechanism are arranged in the water storage tank. The intelligent unmanned aerial vehicle for maintaining photovoltaic power generation device based on the Internet of Things has the advantages that: a driving mechanism in the supporting mechanism drives the two first sliding blocks to get close, so that a solar panel is clamped by the two clamping plates for cleaning and cleaning can be performed without consuming flight energy; the water flow speed in a backflow pipe is increased through the speed regulating mechanism, and high-speed water flow is sprayed out through a first spray head, so that flushing of firmly-attached dirt is facilitated, the surface of a solar panel is made clean, and therefore the practicability of the equipment is improved.

Owner:NANJING LINGYA AUTOMOBILE TECH RES INST

Fixing unit with auxiliary heating member and surface recovery member, and image forming apparatus

InactiveUS8422928B2Extended service lifeElectrographic process apparatusSurface recoveryImaging equipment

A fixing unit is provided with a fixing member to heat a recoding medium and to fix a toner image on the recording medium; a pressure member to press the fixing member to form a nip portion in which a recording medium carrying a toner image is nipped; an auxiliary heating member to heat the surface of the fixing member; and a surface recovery member, arranged at a downstream side of the first auxiliary heating member in a rotational direction of the fixing member, for recovering damage to a surface of the fixing member by making contact with and sliding on the fixing member.

Owner:KONICA MINOLTA BUSINESS TECH INC

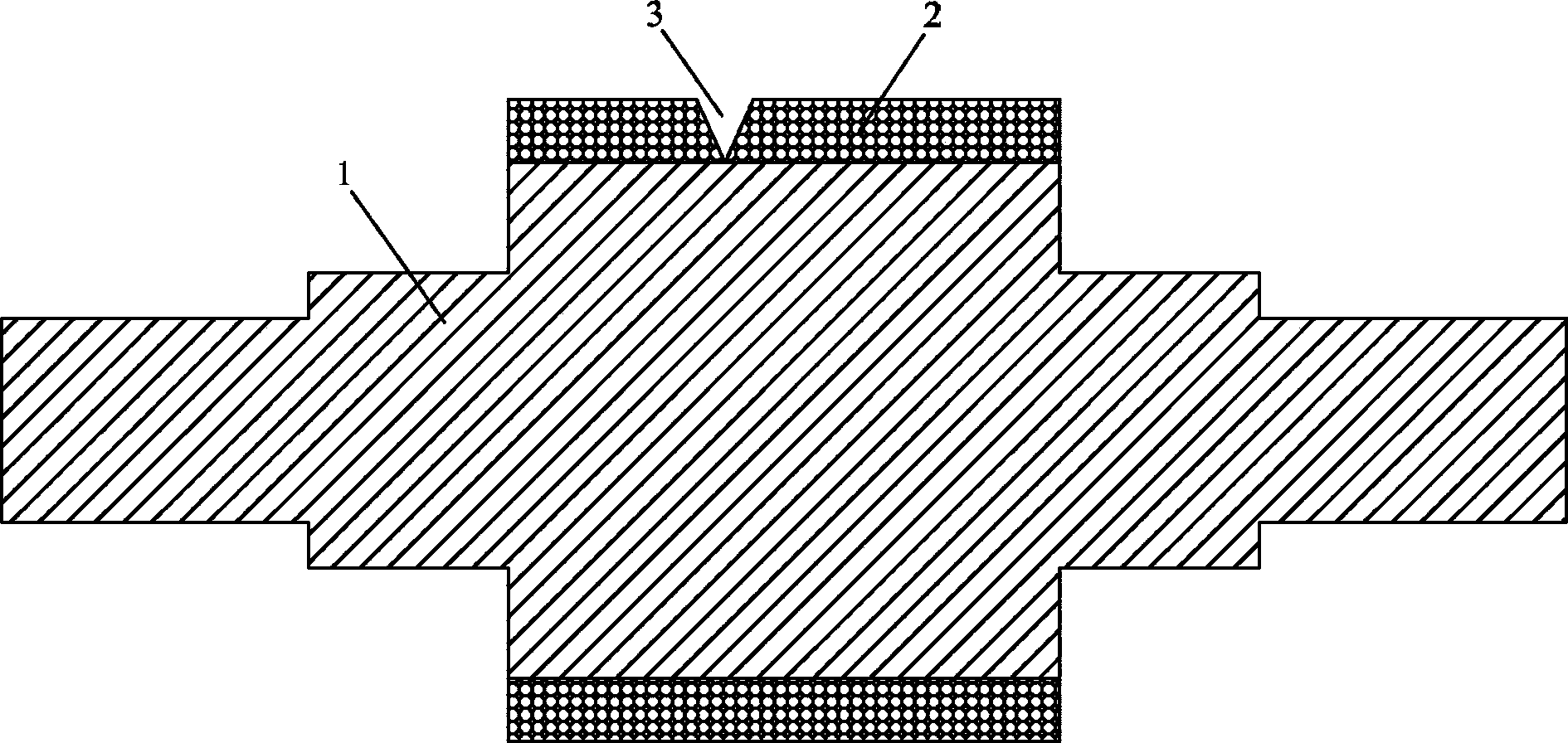

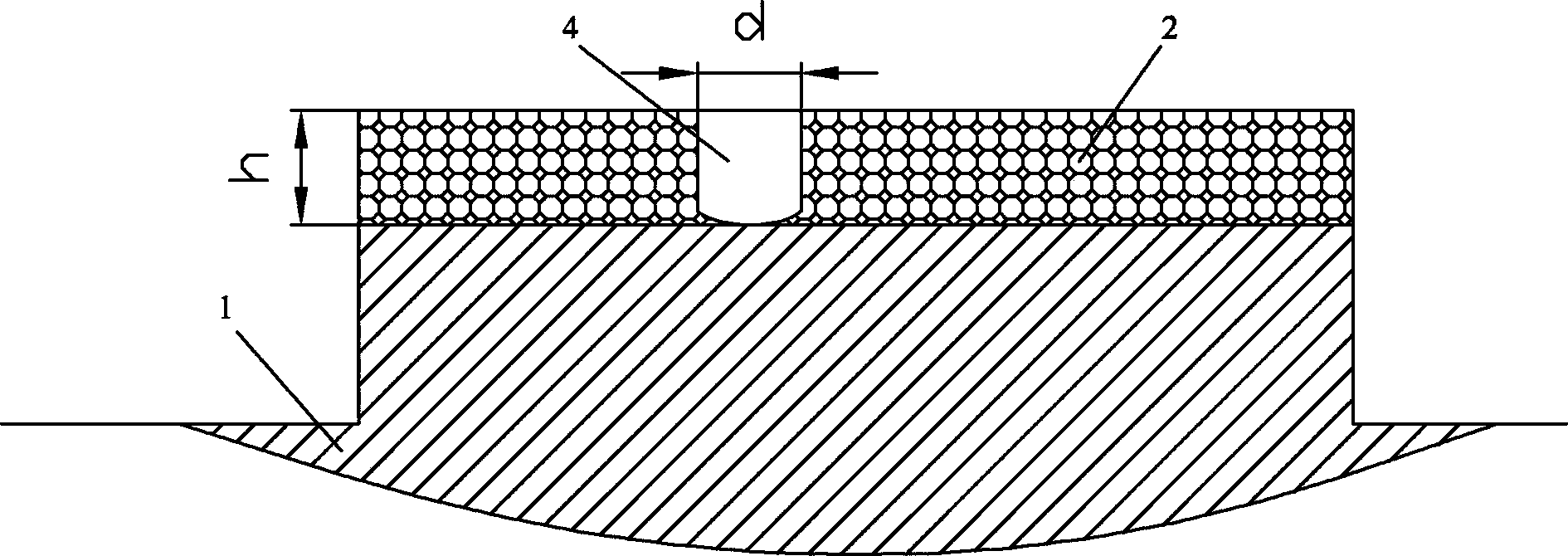

Crystallization roller surface taper hole defect online recovery method

ActiveCN104178761AHigh bonding strengthImprove thermal fatigue strengthPressure inorganic powder coatingRecovery methodSurface recovery

A crystallization roller surface taper hole defect online recovery method comprises the following steps: processing a crystallization roller surface taper hole defect inner wall to form a cylindrical flat-bottom hole inner wall, and processing the inner wall to have equidistantly distributed wave texture structures; carrying out smoothing and frosting treatment on the wave texture structure by using a high pressure gas and ceramic particles; and bumping the bottom and the inner wall of the cylindrical flat-bottom holes by using metal particles having a same recovery layer with the surface of the above crystallization roller in order to realize online rapid recovery. The whole recovery process basically has no thermal influences on the crystallization roller, and the microstructure of a taper hole defect recovery area is consistent to that of the crystallization roller surface recovery layer, so the generation of extra stress is effectively avoided, the bonding strength of the taper hole defect recovery area and the crystallization roller surface recovery layer is improved by above 30%, and the thermal fatigue strength is improved by above 25%; and the method has the advantages of online implementation in the whole process, simple technology, realization of the zero removal of the crystallization roller surface recovery layer, increase of the crystallization roller surface recovery rate by above 30%, great shortening of the recovery cycle, and recovery cost reduction.

Owner:BAOSHAN IRON & STEEL CO LTD

Inelastic collision and rolling viscous resistance particle coupling energy consumption numerical control machine tool

ActiveCN104175169AImprove stabilityImprove machining accuracyLarge fixed membersMaintainance and safety accessoriesNumerical controlSurface recovery

An inelastic collision and rolling viscous resistance particle coupling energy consumption numerical control machine tool relates to a numerical control machine tool and is provided with a numerical control machine tool body, upright posts, a crossbeam, a top beam, a stiffening beam, a ram, an electric spindle and a worktable, wherein at least two coupling energy consumption boards are arranged in at least one structural part of the numerical control machine tool, and the structural part comprises at least one of the numerical control machine tool body, the upright posts, the crossbeam, the top beam, the stiffening beam, the ram and the like; a groove array is arranged on each of the coupling energy consumption boards; at least two high-surface-viscous-resistance polymer particles are arranged in each groove of the groove arrays; a low-surface-recovery-coefficient particle is placed in each of the grooves. When the machine tool is in high-speed heavy cutting, the coupling energy consumption boards can quickly dissipate unidirectional and multi-directional vibration energy generated by the cutting force step by step, the energy consumption factor is high, the vibration suppression effect is obvious, and the stability and the machining precision of the machine tool are effectively improved.

Owner:厦门环寂高科有限公司

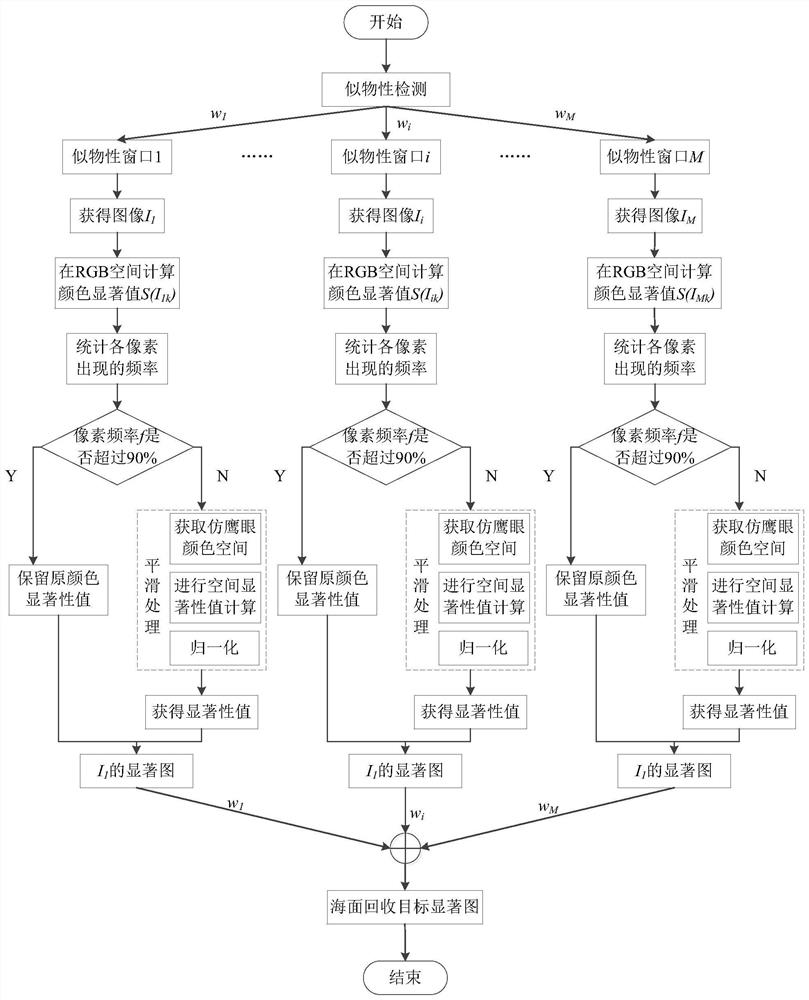

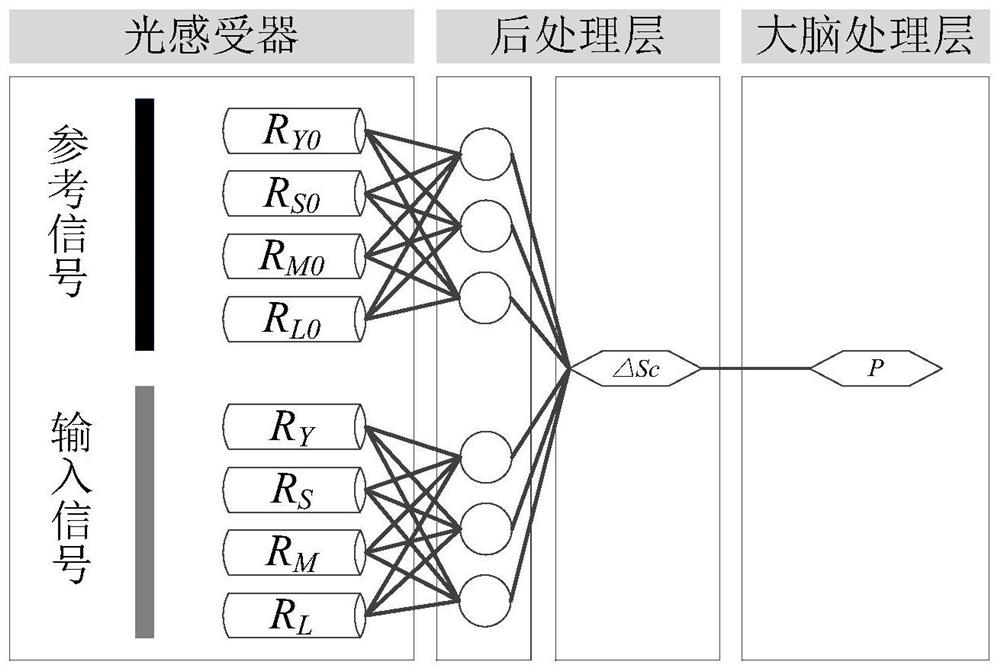

Sea surface recovery target detection method based on eagle-eye-imitating vision and objectness

PendingCN114758119AReduce complexitySignificance Detection ImplementationCharacter and pattern recognitionPattern recognitionRadiology

The invention discloses a sea surface recovery target detection method based on eagle-eye-imitating vision and objectness. The sea surface recovery target detection method comprises the following steps: step 1, acquiring an objectness window image; 2, establishing an eagle-eye-imitating color space; 3, selecting an image with a relatively high score for subsequent processing; 4, calculating significance values of the same color; 5, eagle-eye-imitating color space smoothing processing is carried out; step 6, summing saliency results of the object-like window; and step 7, outputting a saliency detection result of the offshore recovery device. According to the invention, saliency detection is carried out on a window result of likelihood detection, so that the algorithm complexity of saliency detection is greatly reduced; according to the method, the eagle-eye-imitating color space is introduced into the process of detecting the saliency features of the object-like window, and the distance relation between pixels of a real image can be closer in the process of evaluating the image color space distance.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com