Regular hexagon rotary cement kiln surface heat recovery device

A technology of heat recovery device and cement rotary kiln, which is applied in the field of waste heat recovery, can solve the problems of difficulty in manufacturing and installing water-cooled walls, short cold air travel, and short residence time, so as to reduce difficulty and cost, reduce equipment loss, and realize recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

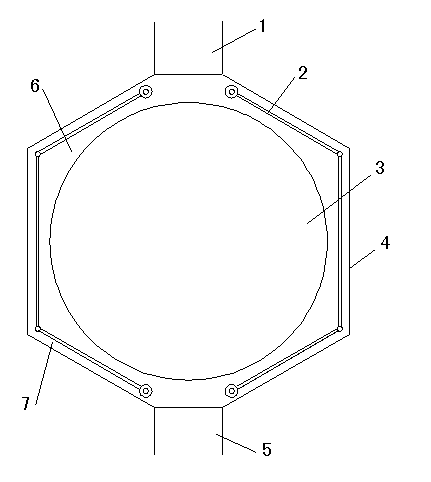

[0011] As shown in the drawings, the surface heat recovery device of the regular hexagonal cement rotary kiln of the present invention includes an outer cover 4 and a water cooling wall 2, both of which are regular hexagonal. The water-cooled wall 2 is arranged on the periphery of the cement rotary kiln 3 , and there is a gap between the water-cooled wall 2 and the cement rotary kiln 3 , forming an inner ventilation channel 6 . The outer cover 4 is arranged on the periphery of the water-cooled wall 2 , and there is a gap between the outer cover 4 and the water-cooled wall 2 to form an external air passage 7 . The inner ventilation channel 6 and the outer ventilation channel 7 are connected. An upper vent 1 and a lower vent 5 are respectively arranged on the upper and lower sides of the outer cover 4, and the two air passages can be connected to a fan respectively, and cold air is sucked in through the lower vent 5, and hot air is discharged through the upper vent 1. The water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com