Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Surface heat flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

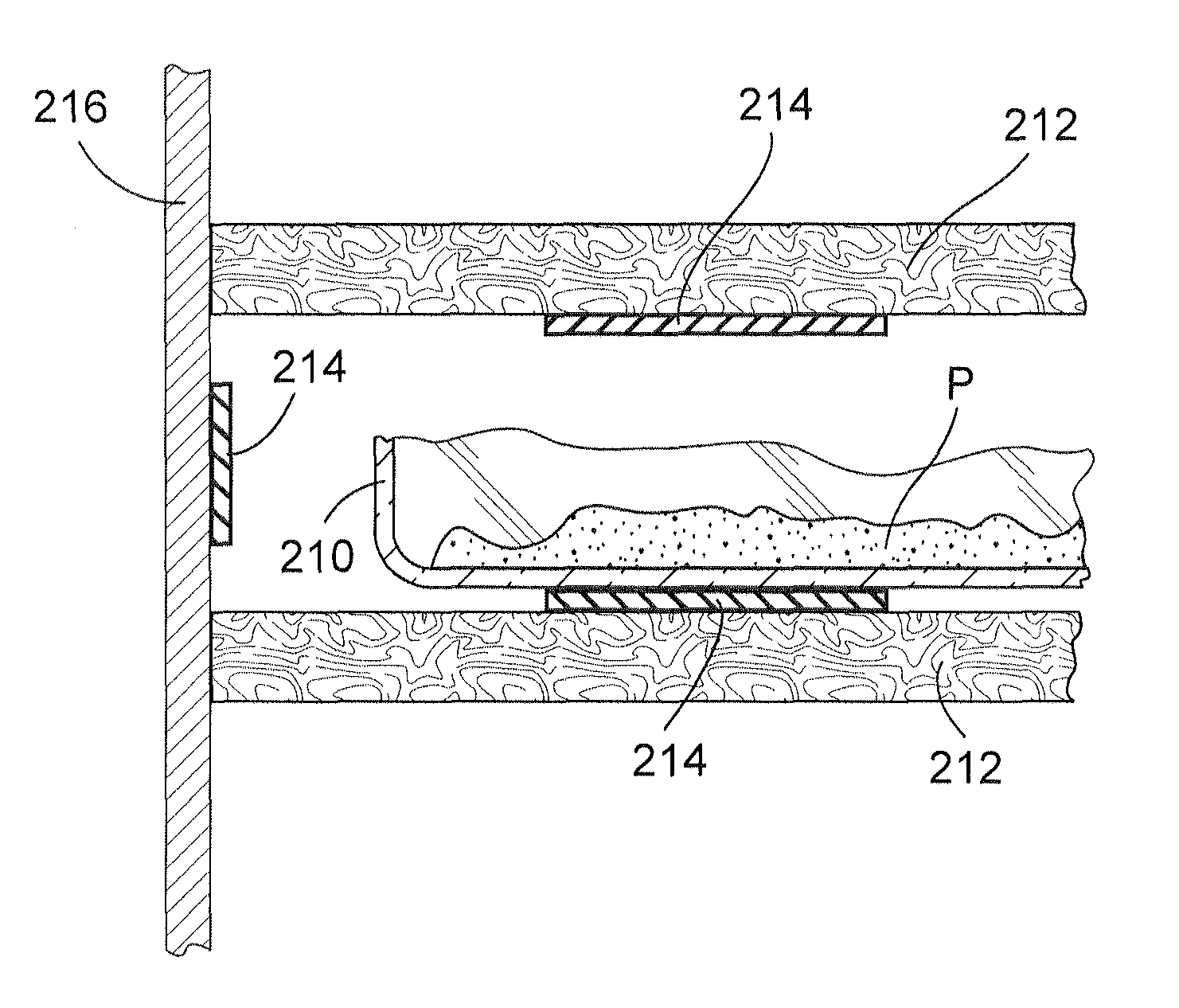

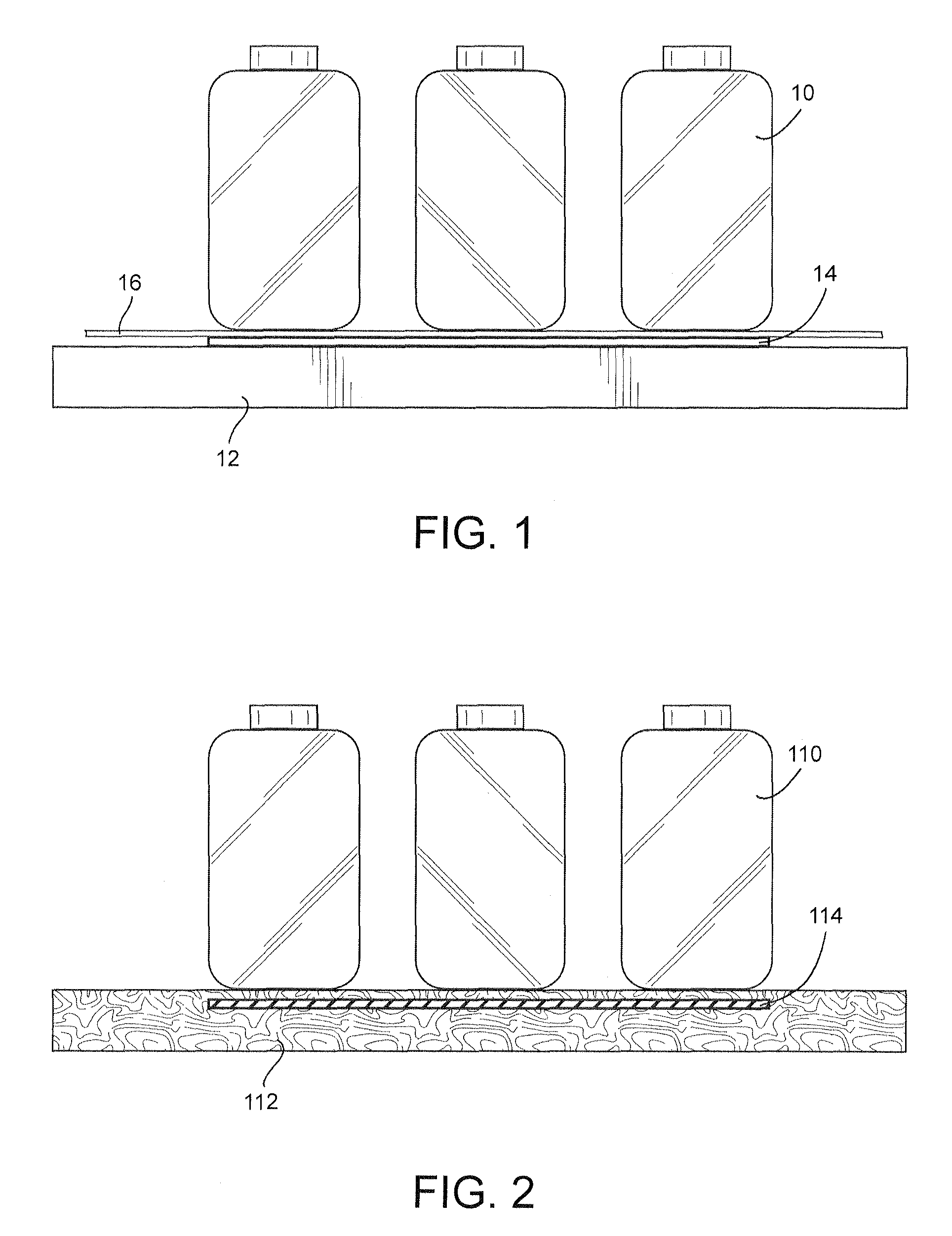

Using surface heat flux measurement to monitor and control a freeze drying process

ActiveUS9121637B2Shorten the timeSignificantly more consistent final productDrying solid materials without heatDrying machinesFreeze-dryingProcess engineering

A method of monitoring and controlling a freeze drying process in a freeze drying apparatus having walls, shelves and a number of vials or trays positioned on different areas of the shelves and containing product to be freeze dried. One or more vials or trays are selected that are representative of the positions of all of the vials or trays in different areas of the shelves. One or more heat flux sensors are positioned between the selected vials or trays and adjacent portions of the walls and / or shelves. The heat transfer between the selected vials or trays and the adjacent wall or shelf portions is measured during the freezing and drying stages of the freeze drying process.

Owner:MILLROCK TECH

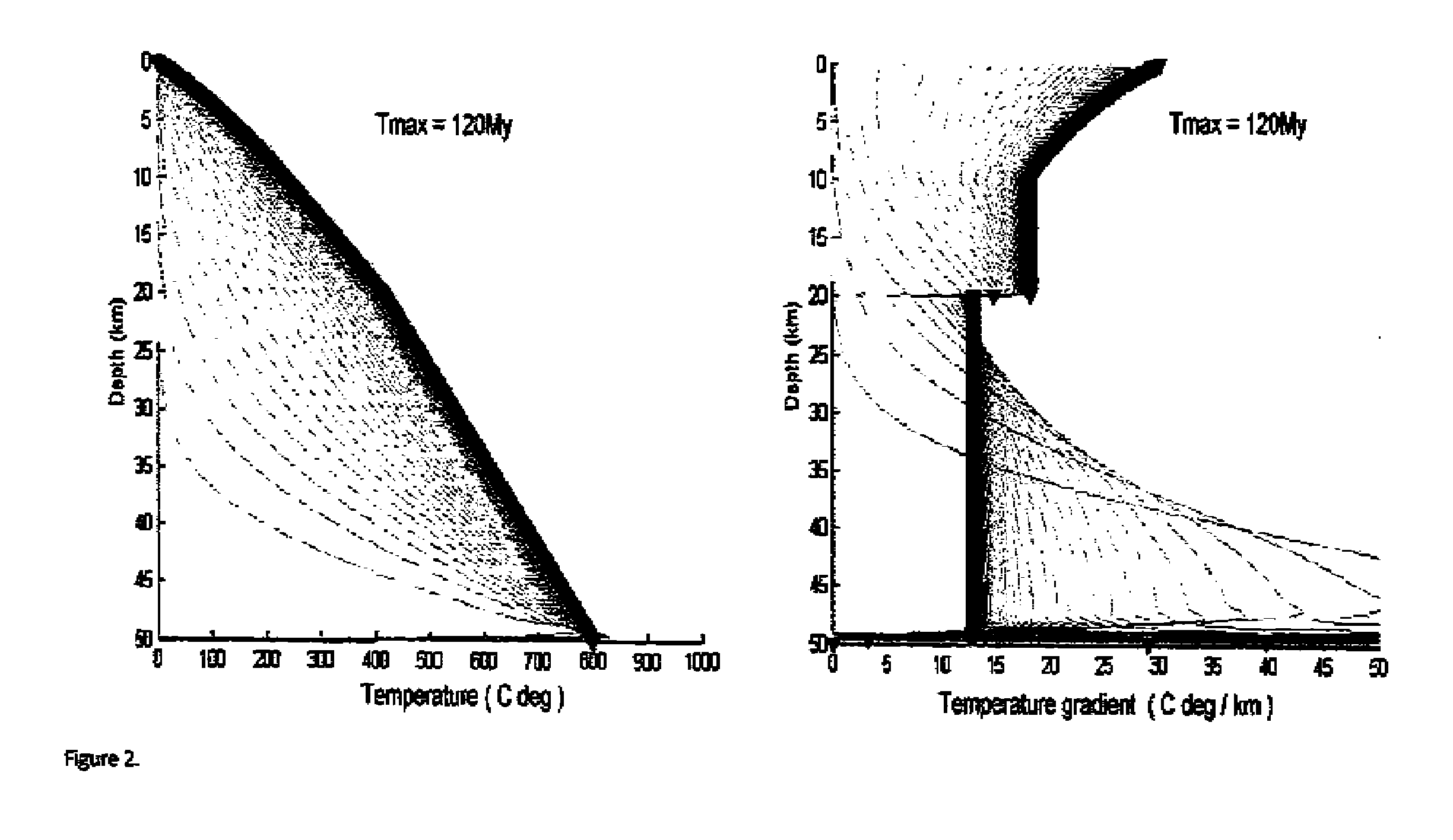

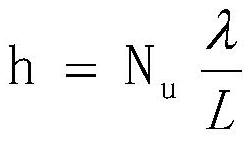

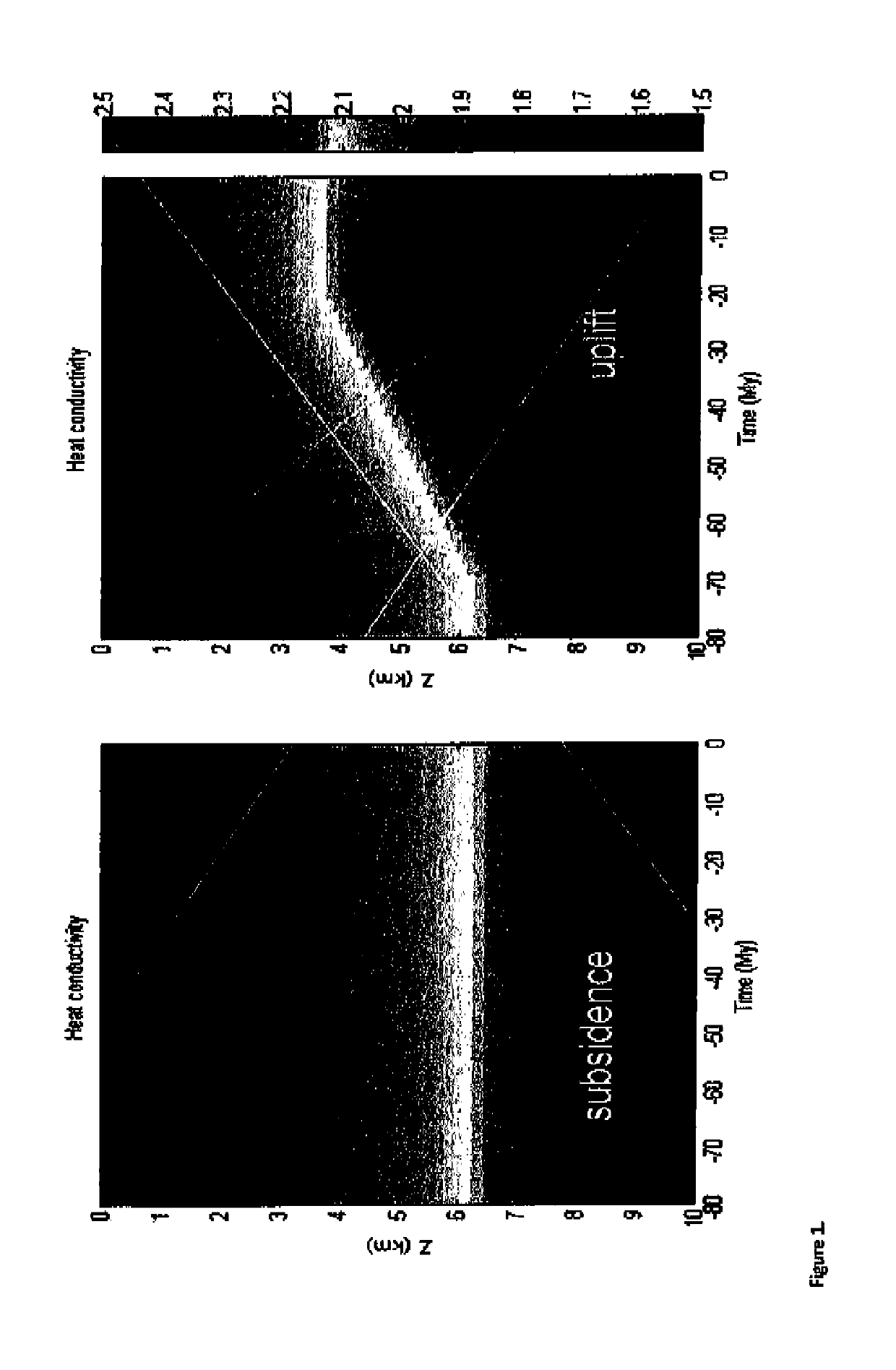

Temperature modeling constrained on geophysical data and kinematic restoration

ActiveUS20150242362A1Reduce uncertaintyAccurate kinematic restorationGeomodellingComputation using non-denominational number representationPorosityOcean bottom

A method is disclosed for the estimation of subsurface temperature distributions from a 3-dimensional heat conductivity model for a geological formation. The method may be characterized by the following steps: (a) obtaining measured data corresponding to a geological subsurface formation of interest including seismic survey data, in-well temperature, seafloor or surface heat flux measurements and laboratory-based measurements of core porosity, (b) estimating a relationship between seismic velocity and heat conductivity, wherein seismic velocity is linearly dependent on porosity and heat conductivity is exponentially or linearly dependent on porosity, and (c) calibrating the model to the measured in-well data and laboratory-based measurements of core porosity.

Owner:DEN NORSKE STATS OLJESELSKAP AS

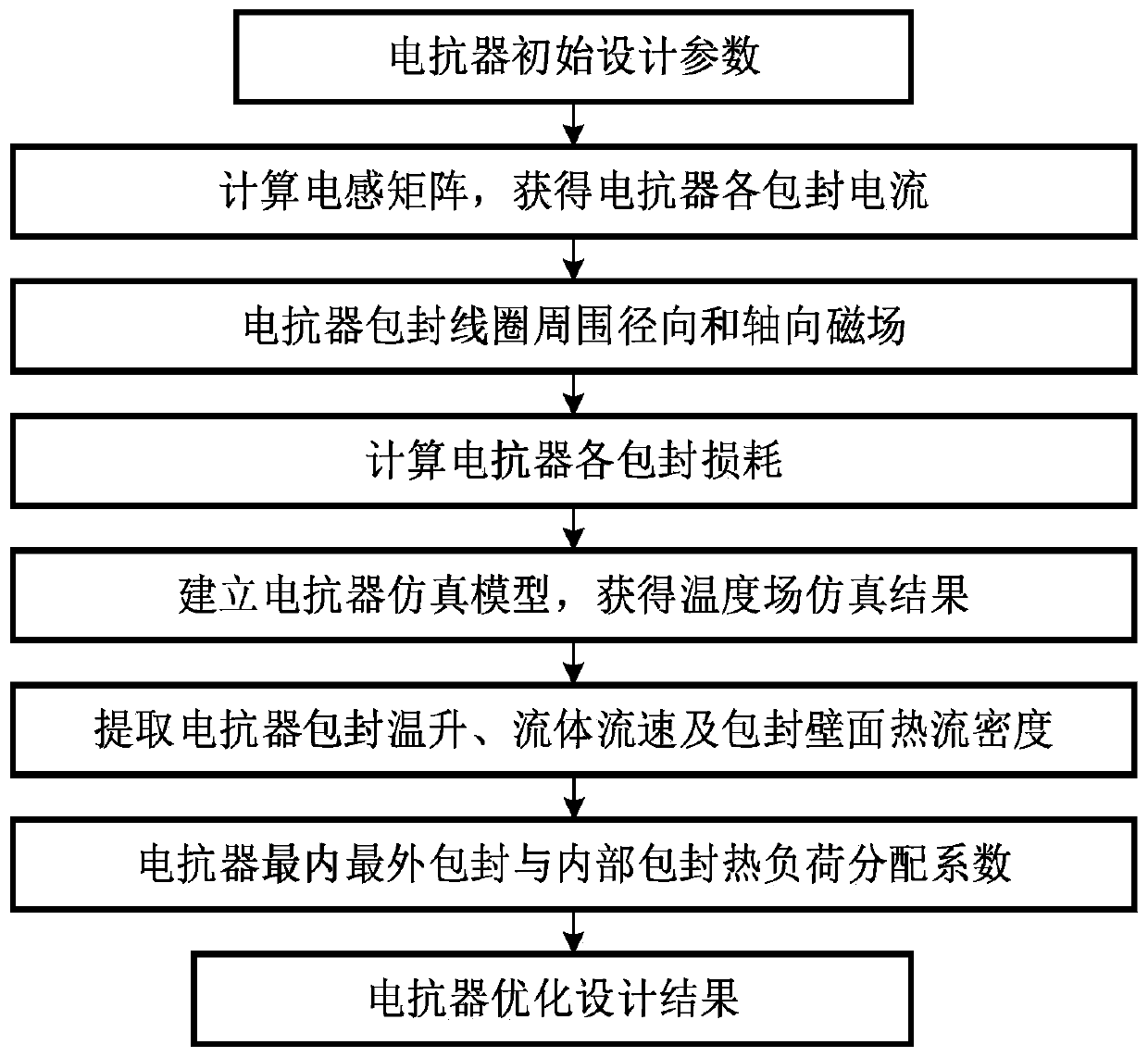

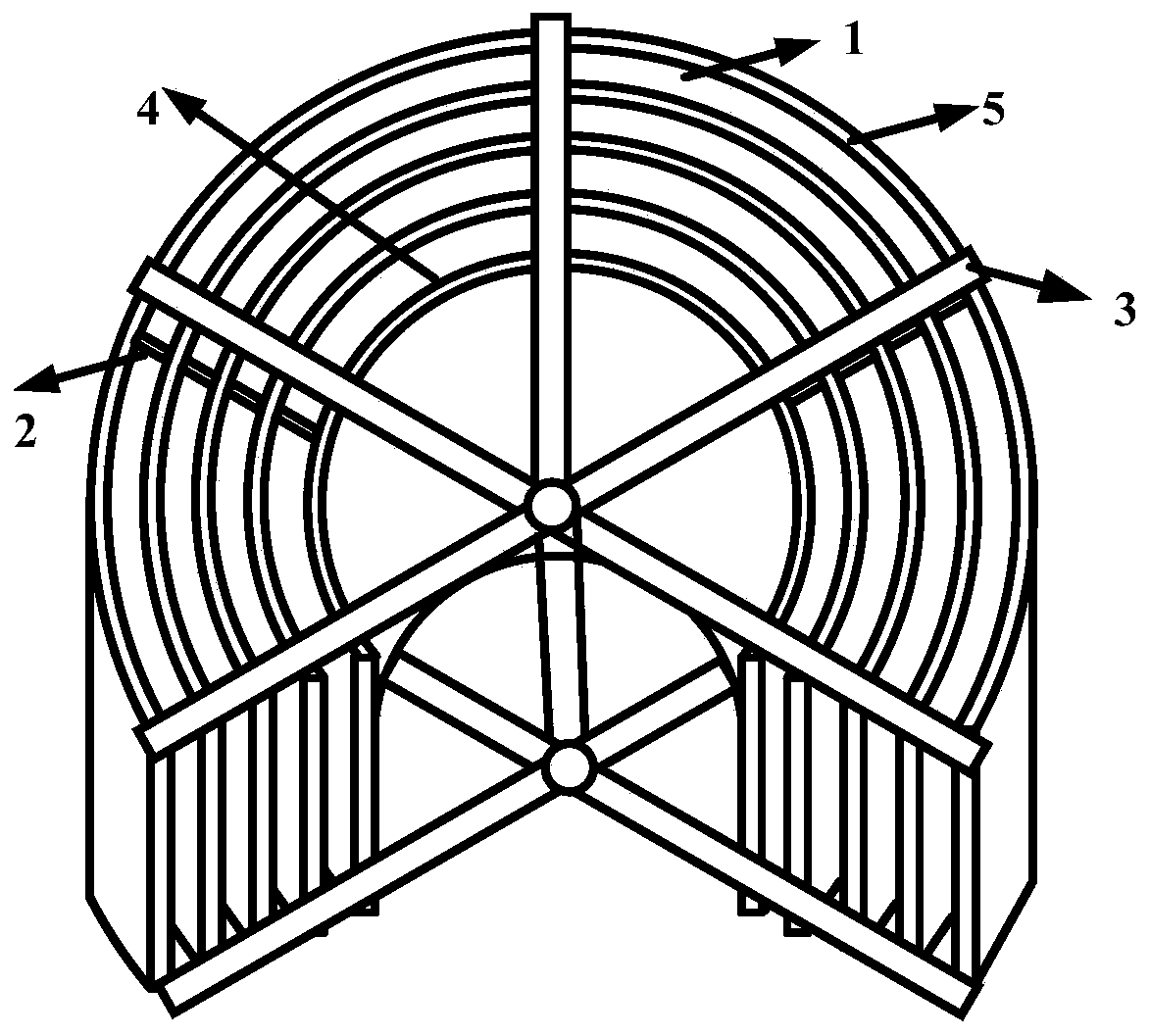

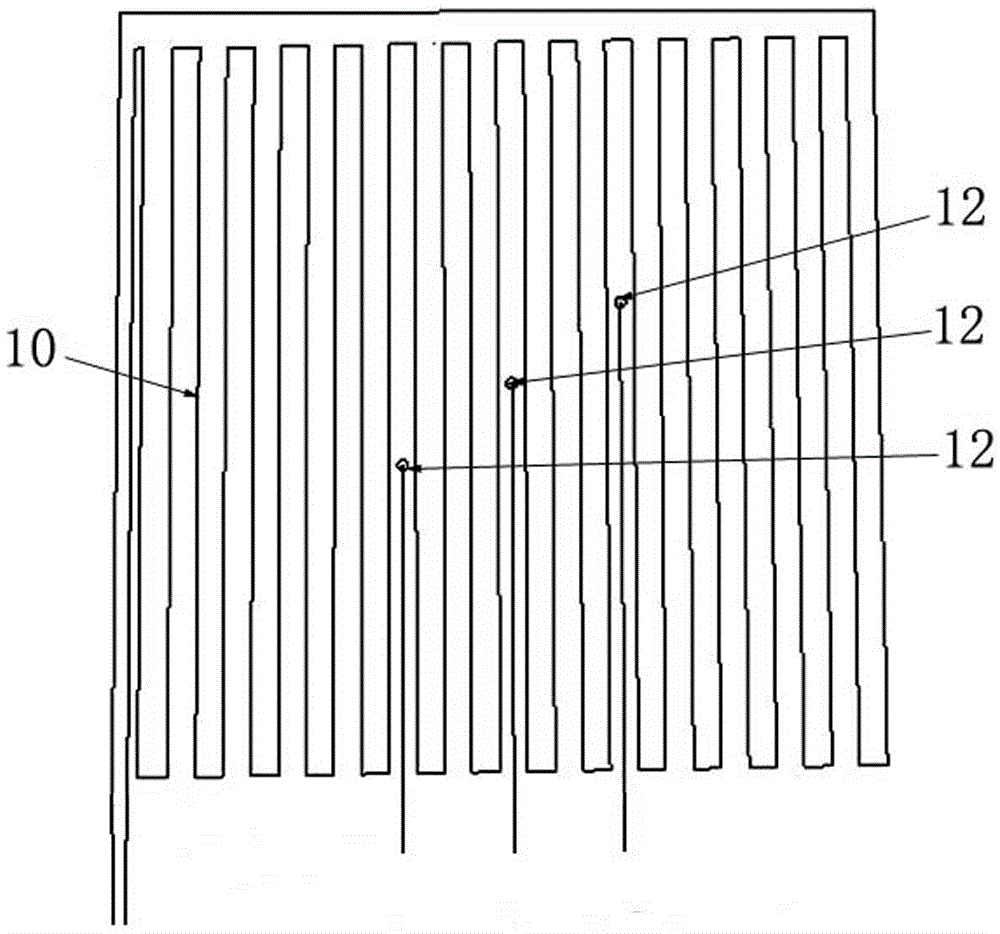

Design method for improving heat generation and heat dissipation capacity of each encapsulated coil of reactor

ActiveCN110414080AIncrease profitSame heat generationSpecial data processing applicationsElectrical conductorEngineering

The invention relates to a design method for improving the heat generation and heat dissipation capacity of each encapsulated coil of a reactor, which comprises the following steps of: obtaining initial design parameters of the reactor, calculating a mutual inductance matrix of the reactor, and obtaining current of each encapsulated coil by combining total current flowing through the reactor; obtaining the loss of each turn of coil in the encapsulation by adopting an analytical method, and calculating the total loss of each encapsulated coil of the reactor; building a model of the reactor, taking the calculated total loss of each encapsulated coil as a heat source condition in the model of the reactor, and obtaining a temperature field simulation result of the reactor through flow field-temperature field coupling; according to the temperature field simulation result, extracting temperatures, flow fields and encapsulation wall surface heat flux densities under different paths, and forming heat load distribution coefficients among the innermost encapsulation, the outermost encapsulation and the internal encapsulation in combination with a temperature rise calculation method; and obtaining an optimal design result of the reactor. According to the design method, by means of the flow field-temperature field coupling simulation technology of the electric reactor, the temperature risedistribution of all packages of the electric reactor is basically the same, and the utilization rate of metal conductors is increased.

Owner:CHINA THREE GORGES UNIV

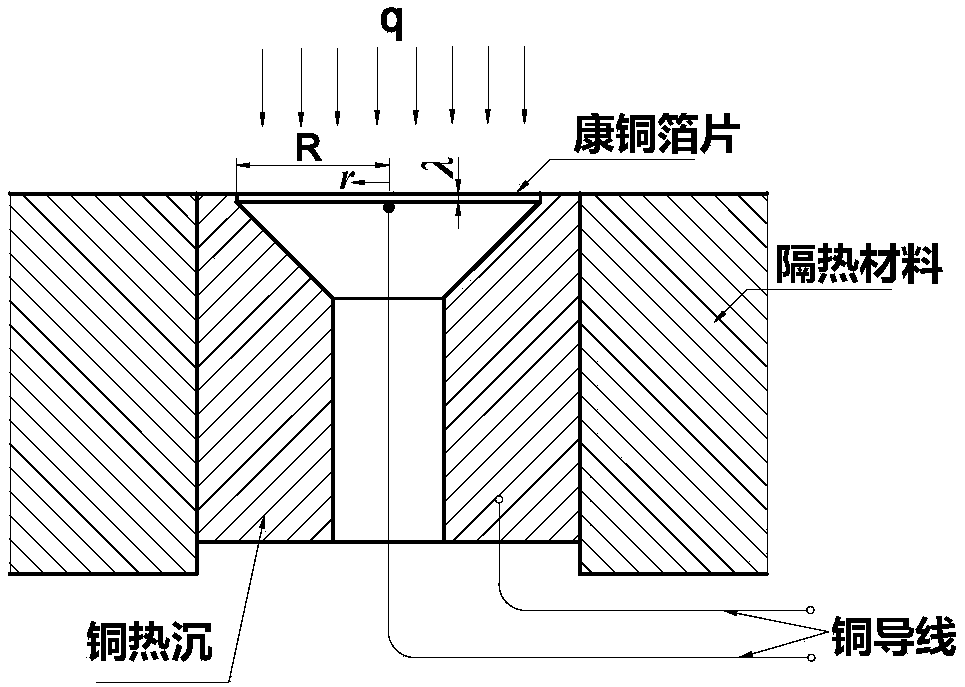

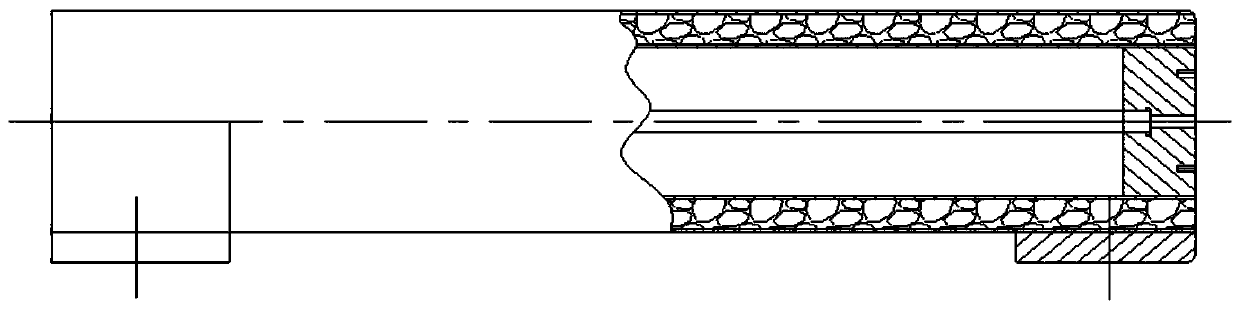

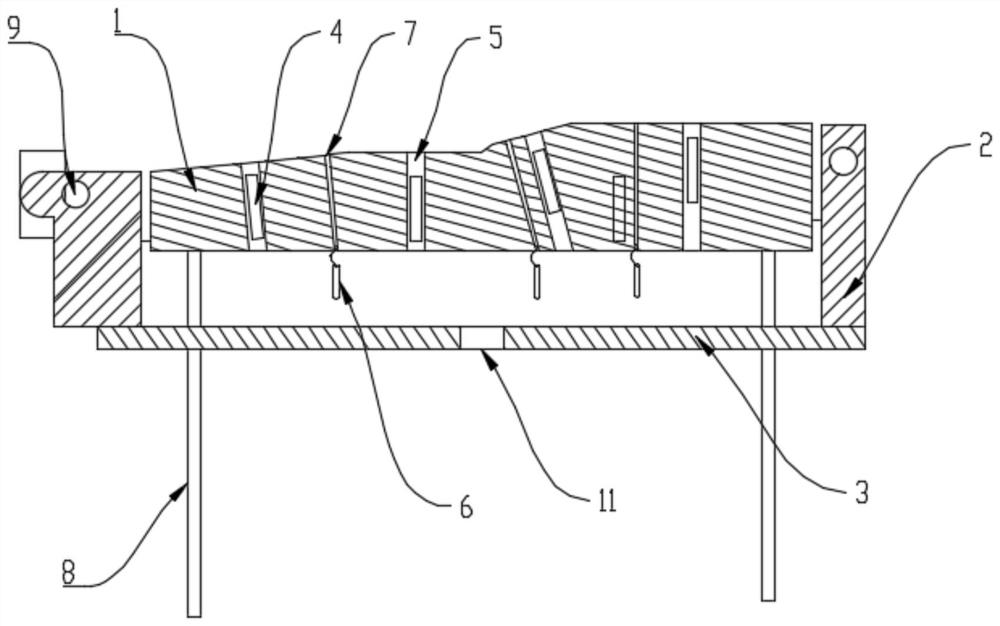

Ceramic wall surface composite plug type heat flux sensor applicable to high-enthalpy, medium and low heat flux environment

ActiveCN106706166ASmall difference in coefficient of linear expansionConducive to uniform temperatureCalorimeterThermal insulationCeramic coating

The invention provides a ceramic wall surface composite plug type heat flux sensor applicable to high-enthalpy, medium and low heat flux environments. The ceramic wall surface composite plug type heat flux sensor relates to the field of ceramic wall surface heat flux sensor design. The heat flux sensor comprises a graphene column, a rigid ceramic thermal insulation sleeve, a red copper column, a thermocouple and a ceramic coating, wherein one axial end of the graphene column is fixedly connected with the red copper column, and another axial end of the graphene column is coated with the ceramic coating; the outer side wall of the graphene column and the axial end surface (away from the graphene column) of the red copper column are coated with the rigid ceramic thermal insulation sleeve; and the end surface of the red copper column is provided with the thermocouple. The ceramic wall surface composite plug type heat flux sensor solves the problem that the ceramic coating cannot be prepared on the surface of the red copper column directly, alleviates the thermal diffusion in the plane direction, effectively avoids the problems of low thermal conductivity coefficients and slow thermal response of the ceramic material, and provides a more precise calorimetric sensor for hypersonic-speed aircraft ground thermal protection texts.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

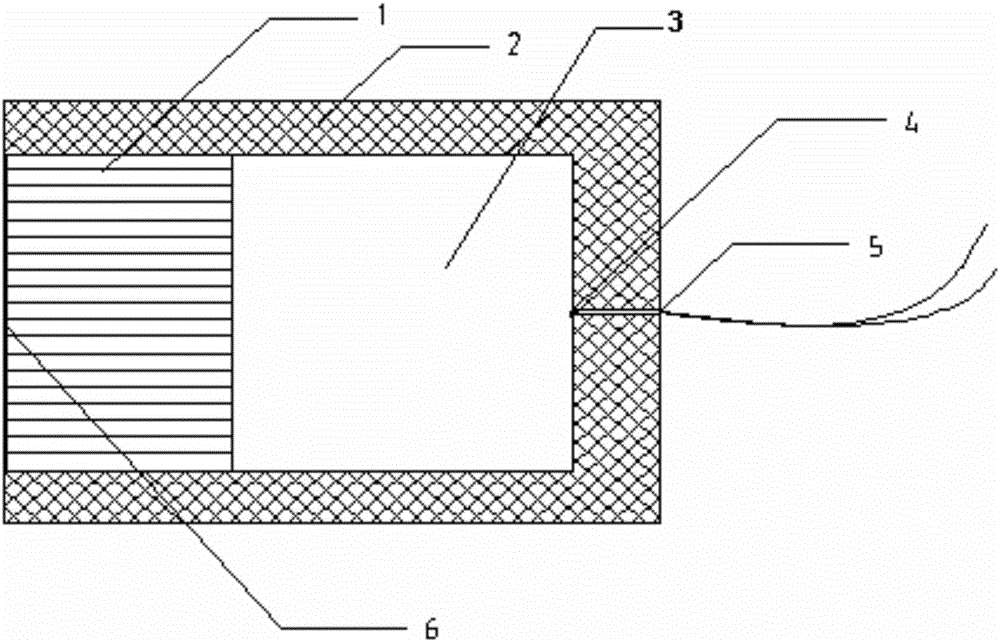

Testing device for heat conductivity coefficients of concrete in dry state

InactiveCN105572163AMaterial thermal conductivityMaterial heat developmentHeat transmissionStreamflow

The invention relates to a testing device for heat conductivity coefficients of concrete in a dry state. The device comprises a heat insulation test box, a test piece lower surface heating device, an upper surface heat flux testing device and a temperature collecting device. The heat conductivity coefficients of the massive concrete material in the dry state are obtained through calculation by measuring the average temperature of three points in a test piece lower surface heating area and an upper surface corresponding area in a stable heat transmission state and heat flux passing through a test piece. According to the device, interlayers are arranged in the bottom and the middle of the heat insulation test box, test piece carrying platforms are arranged on the two sides of the heat insulation test box, and a polymer nanomateiral-aerogel is fully utilized for the heat insulation function; existing concrete heat conductivity coefficient testing equipment is simplified to a great extent, and the heat insulation effects achieved when the different kinds of concrete serve as an enclosure structure can be intuitively observed and compared.

Owner:TAIYUAN UNIV OF TECH

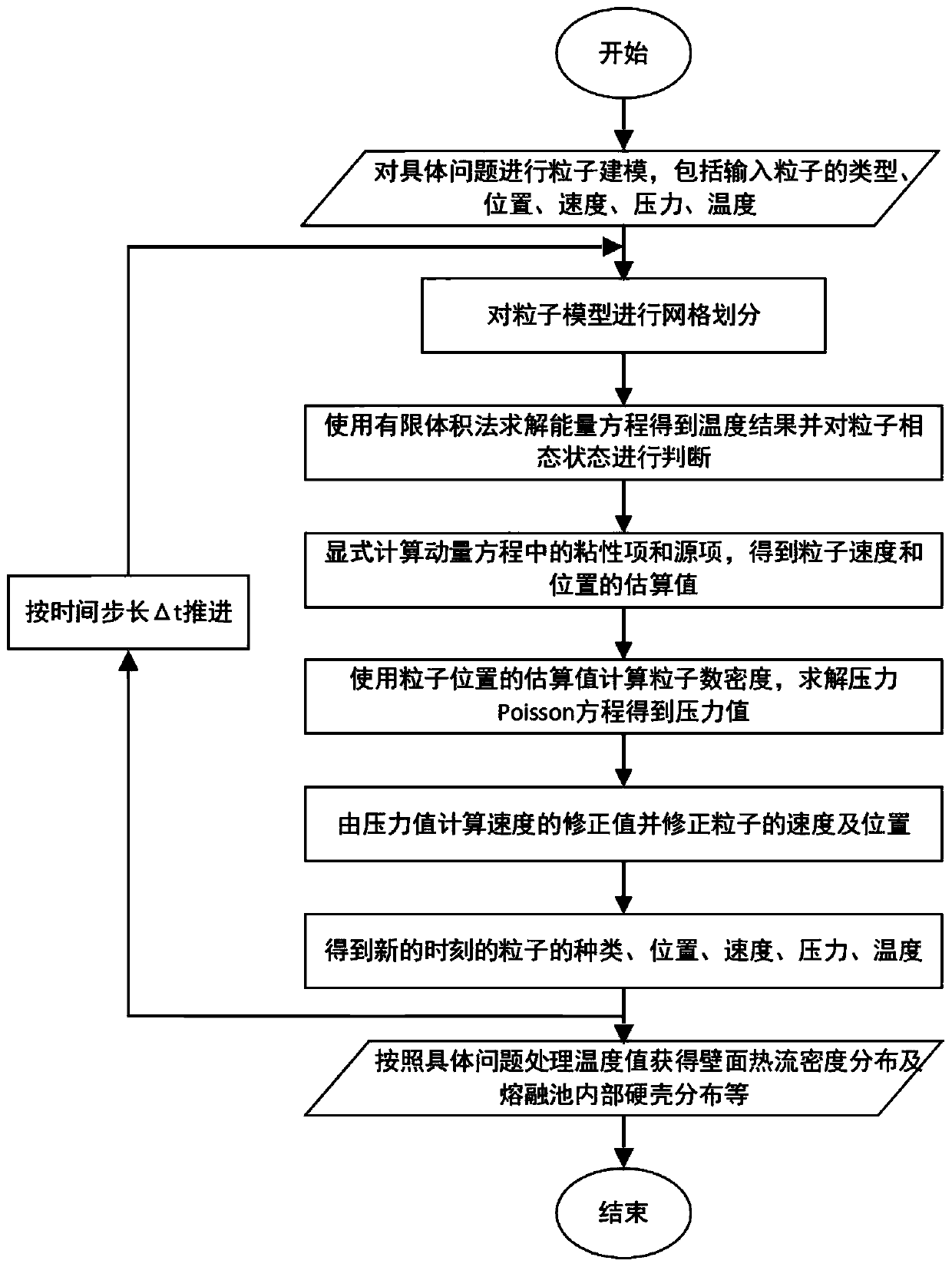

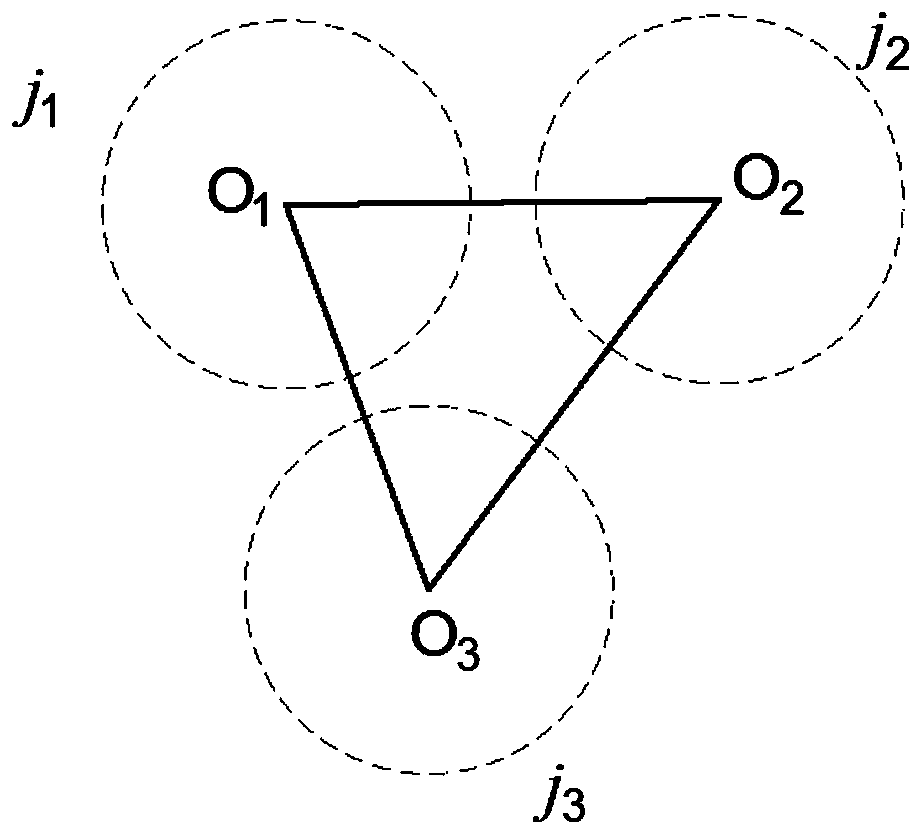

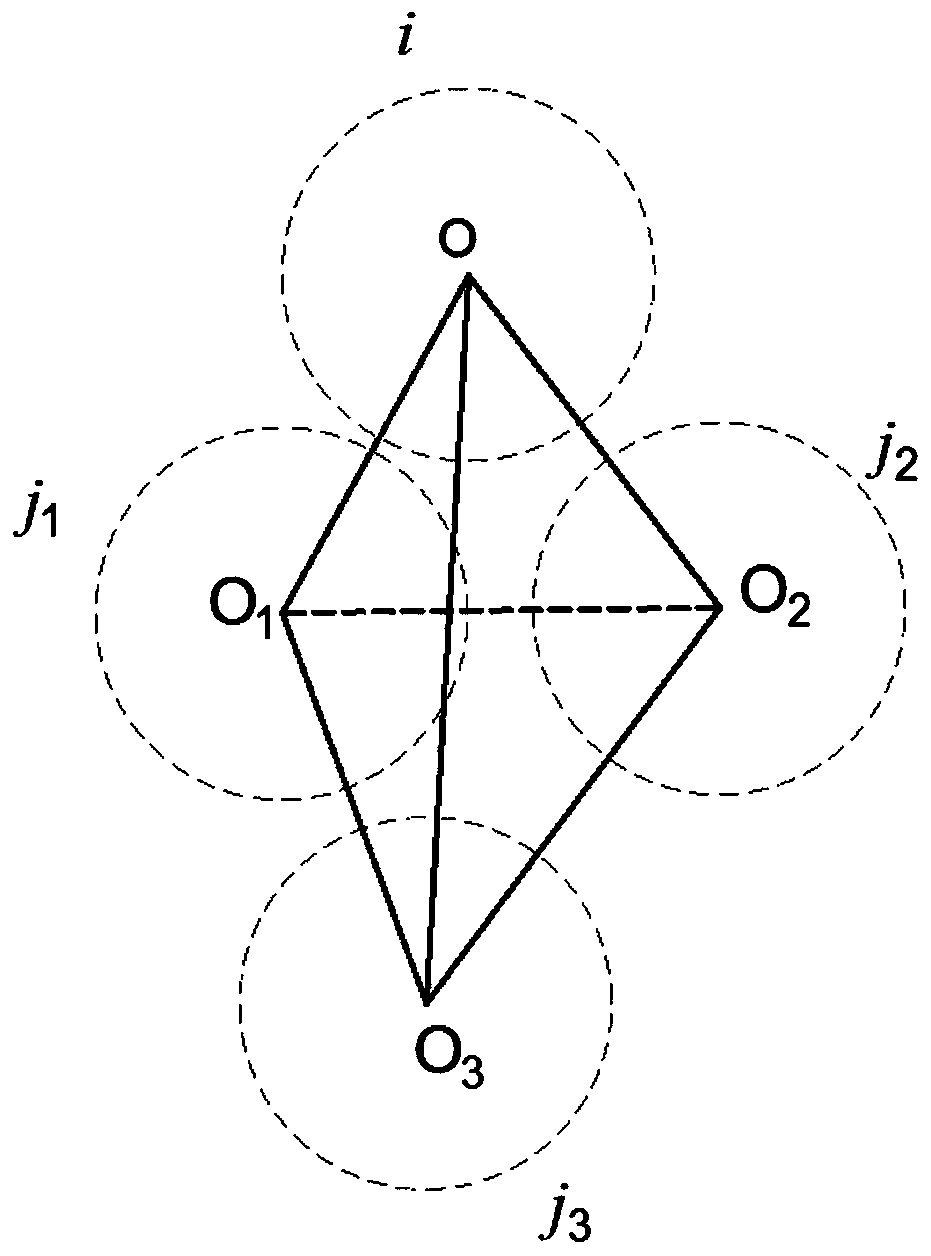

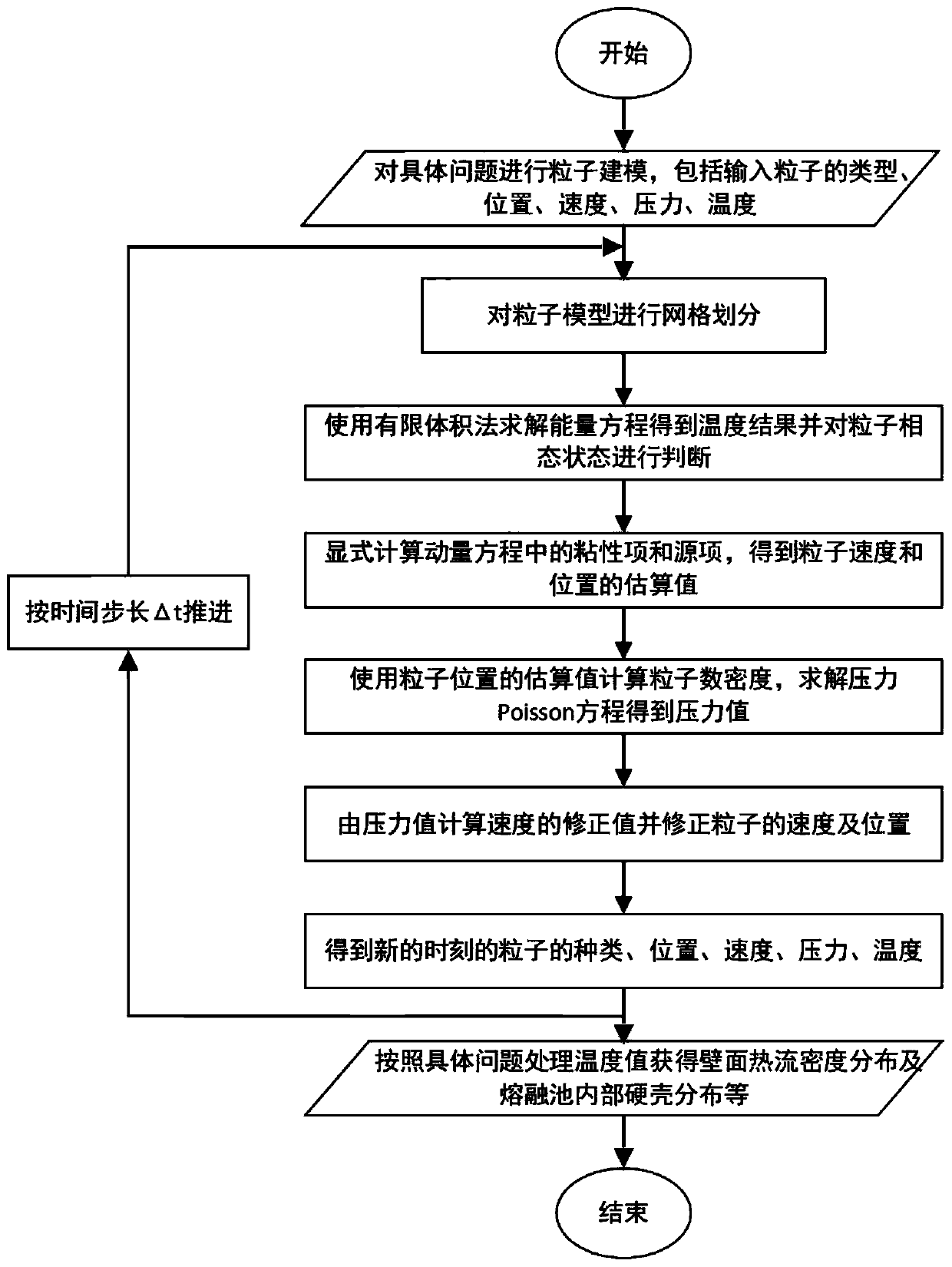

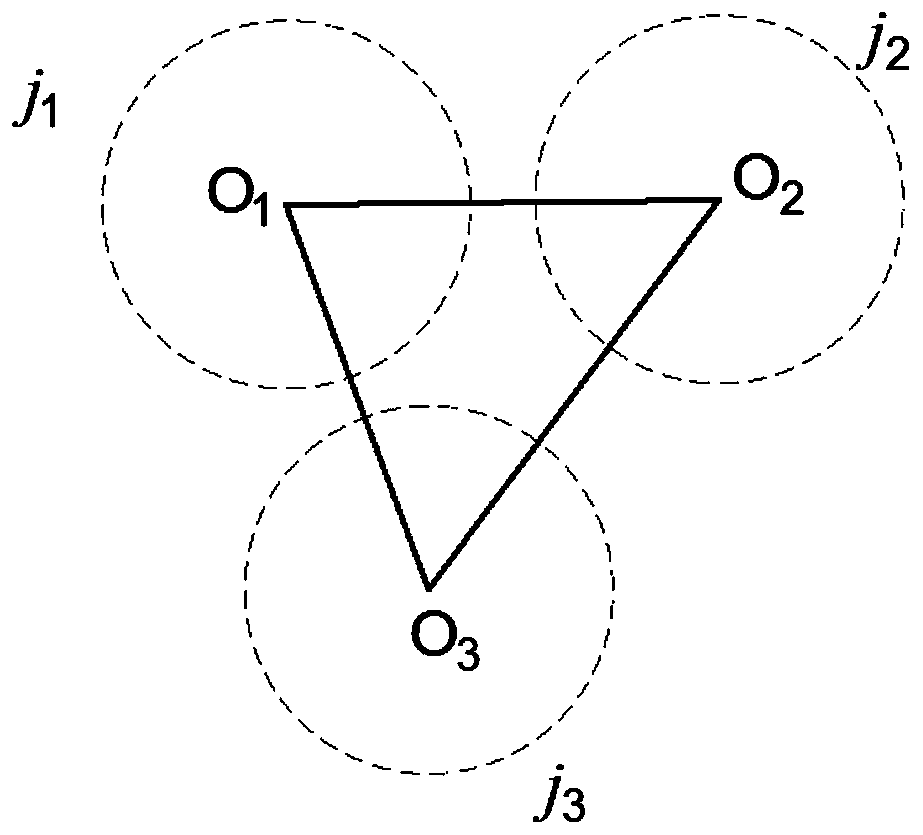

Method for researching high Rayleigh number fusion pool heat transfer characteristics by moving particle finite volume method

ActiveCN110044959AAccurate researchAccurate captureMaterial heat developmentPressure poisson equationLiquid surfaces

The invention discloses a method for researching high Rayleigh number fusion pool heat transfer characteristics by a moving particle finite volume method. The method comprises the following main stepsthat: 1: carrying out particle modeling by aiming at a specific problem, and setting a particle initial layout; 2: according to the position of each particle, dividing a grid; 3: after a time step length [Delta]t, using the finite volume method to solve an energy equation; 4: through a particle method, processing a viscosity term and a source term in an explicit calculation momentum equation, andestimating the speed and the position of the particle; 5: calculating particle number density, and solving a pressure Poisson equation; 6: calculating the correction value of the speed, and calculating the speed and the position of each particle in a next time level; and 7: outputting a calculation result, and according to a solved specific problem, outputting wall surface heat flux density and the phase state of substances in a fusion pool. The method has the advantages that a free liquid surface is accurately captured by a particle method and a phase change problem is simulated, and calculation accuracy is high. Through the method, the high Rayleigh number fusion pool heat transfer characteristics are researched, and an important basis is provided for researching the safety characteristics of the serious accident of a nuclear power plant reactor.

Owner:XI AN JIAOTONG UNIV

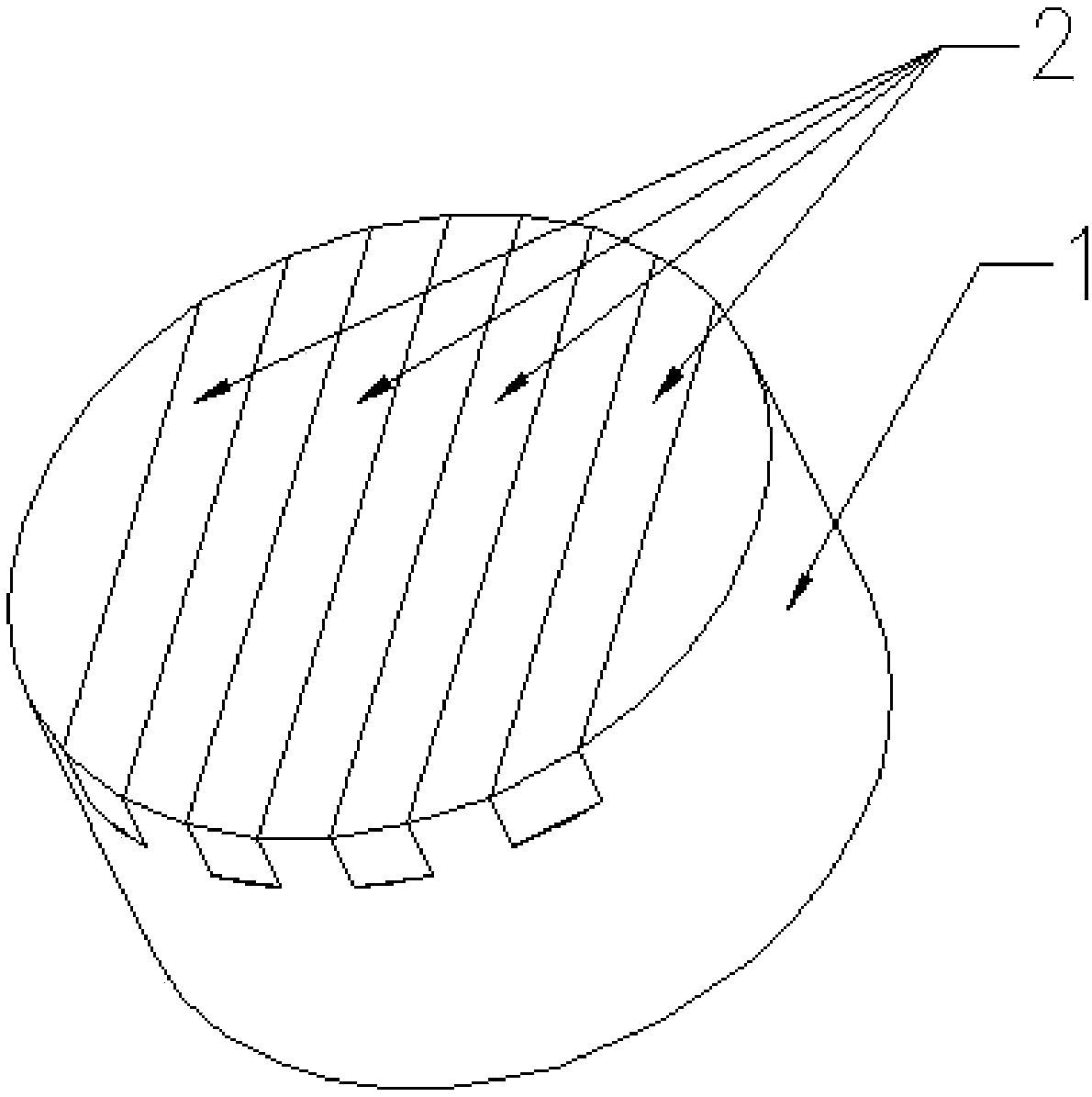

Thermopile principle based heat flux sensor

The invention discloses a thermopile principle based heat flux sensor which is used for measuring surface heat flux. The heat flux sensor is of a cylindrical structure. A cylindrical base is machinedfrom a to-be-measured material. One end face of the cylindrical base is used as a measurement surface. The measurement surface is designed to be conformal to the surface shape of the to-be-measured material. The measurement surface is provided with a plurality of grooves. The grooves are filled with a special material. The filled measurement surface has the same shape with the measurement surfacebefore the grooves are arranged. A sensitive element is attached to the surface of the measurement surface. Cold joints of the sensitive component are attached to the surface of the material with higher thermal conductivity between the cylindrical base material and the special material, and heat joints are attached to the surface of the material with lower thermal conductivity. The two ends of thesensitive element are connected to output lines. The output lines are drawn through line outlet holes on the cylindrical base. According to the invention, thermal interference caused by the heat fluxsensor can be minimized, the accuracy of measurement can be improved, and the sensitivity and response speed of the heat flux sensor are significantly improved.

Owner:BEIJING RES INST OF TELEMETRY +1

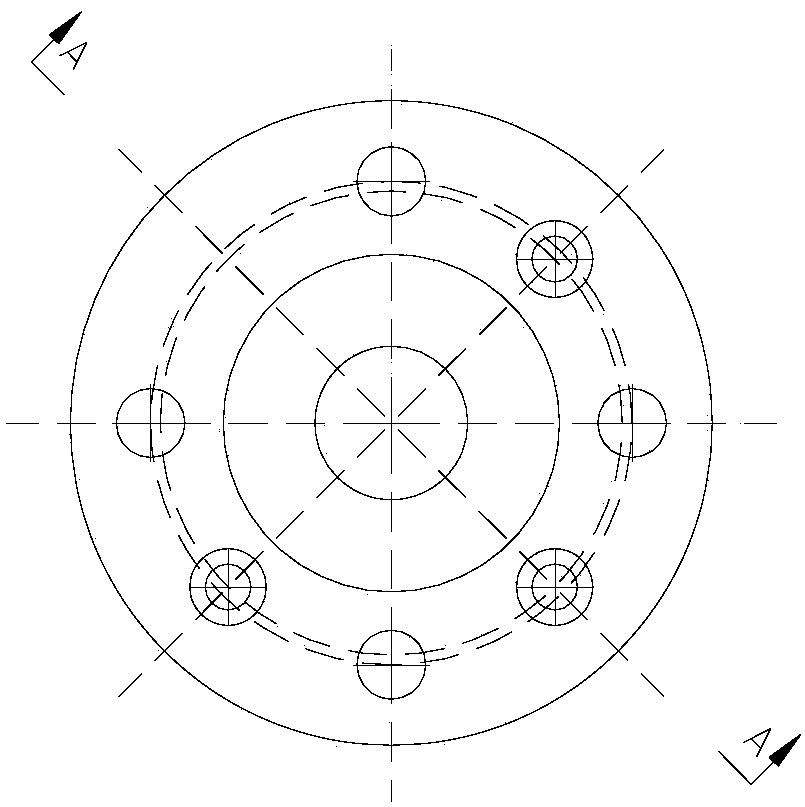

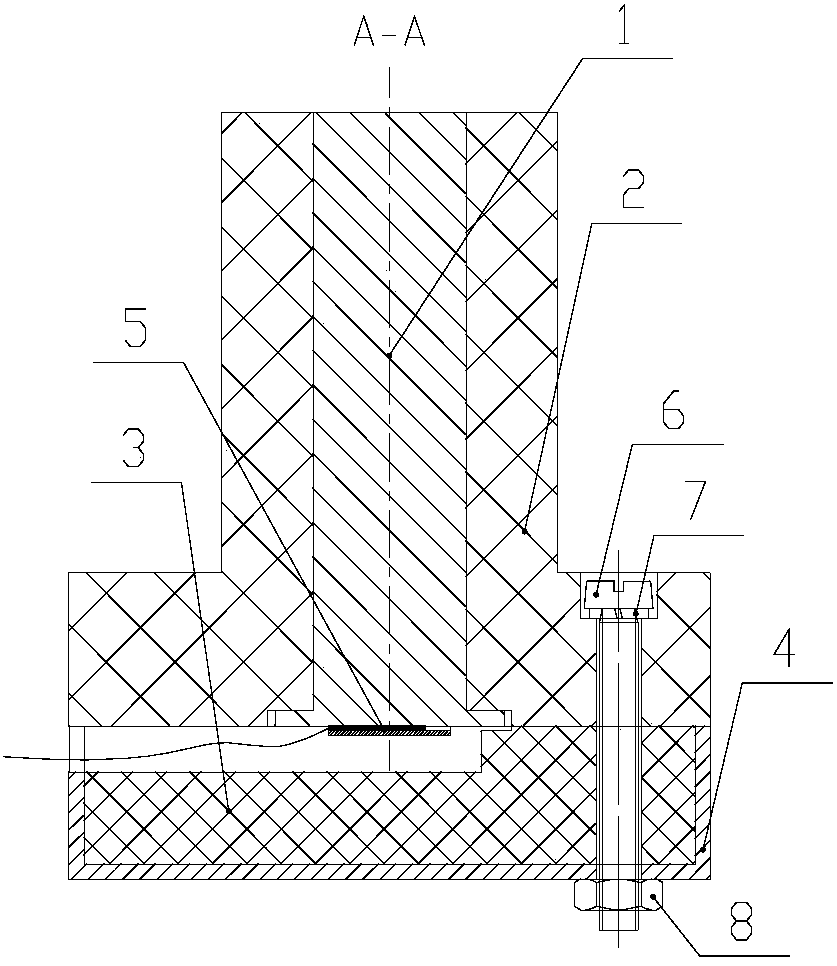

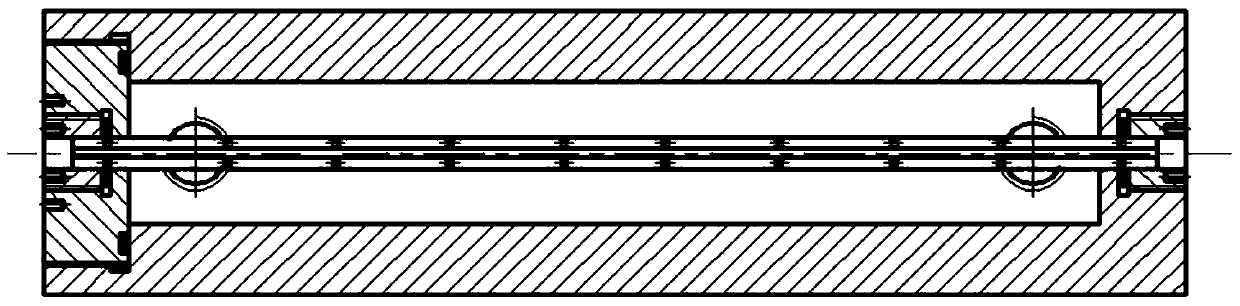

Identification apparatus for surface heat flux of hypersonic flight vehicle and design method thereof

ActiveCN108132112AHigh allowable temperatureSimple measurement structureThermometers using electric/magnetic elementsUsing electrical meansHeat flowFlight vehicle

The invention, which belongs to the technical field of thermal parameter measurement of a hypersonic flight vehicle, provides an identification apparatus for a surface heat flux of a hypersonic flightvehicle and a design method thereof. The apparatus is composed of a thermal-conduction sensitive element, a sensitive element insulating sleeve, a sensing element pressing plate, and a temperature sensor. The thermal-conduction sensitive element has a cylindrical structure. The sensitive element insulating sleeve has a cylindrical structure with a through hole. The thermal-conduction sensitive element is arranged in the through hole of the sensitive element insulating sleeve and is in a clearance fit with the sensitive element insulating sleeve. One side of the sensitive element is flush withthe outer surface of the insulating sleeve to form a measuring end surface and the temperature sensor is installed at the bottom of the other side of the sensitive element. The sensing element pressing plate presses the thermal-conduction sensitive element and is in a clearance fit with the sensitive element insulating sleeve; the sensitive element insulating sleeve, the gap between the sensitiveelement and the sensitive element insulating sleeve, and the sensing element pressing plate prevent the parts, except the measuring end surface, of the thermal-conduction sensitive element from carryout heat exchange with an external environment. Therefore, problems that the traditional heat flux sensor has the poor adaptability to the long-term high heat-flux measurement, the sensor size is large, the sensor is heavy, the installation difficulty is high, and intensive measurement can not be realized easily can be solved.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

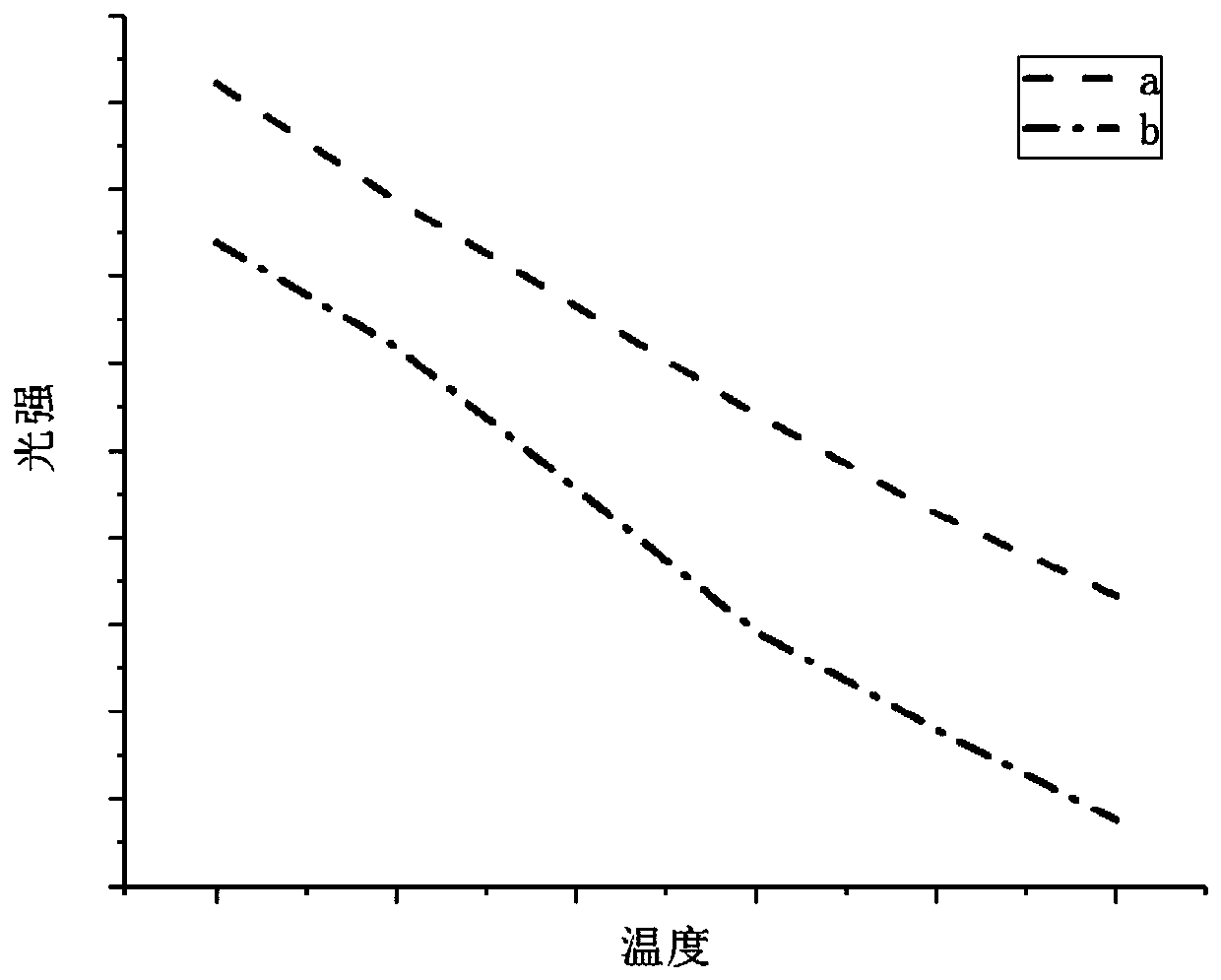

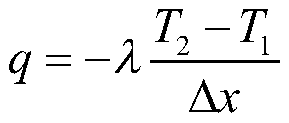

CdTe thin film-based wall surface heat flux density measurement method

ActiveCN110082326ARealize field measurementHigh sensitivityMaterial heat developmentFluorescence/phosphorescenceMeasurement testFluorescence

A CdTe thin film-based wall surface heat flux density measurement method comprises the following steps: firstly, preparing a measurement test piece containing two layers of CdTe thin films with different fluorescence emission wavelengths, and then calibrating the test piece to obtain peak wavelength-temperature calibration curve of the two layers of CdTe thin films respectively; placing the test piece on the wall surface to be measured, obtaining temperature fields of the two layers of CdTe films through high-speed camera shooting, image analysis and inversion calculation, and finally calculating the heat flux density field of the wall surface according to the Fourier heat conduction law. The field measurement of the heat flux density can be realized through the optical method, the measurement precision is high, the resolution is high, and the frequency response is fast.

Owner:XI AN JIAOTONG UNIV

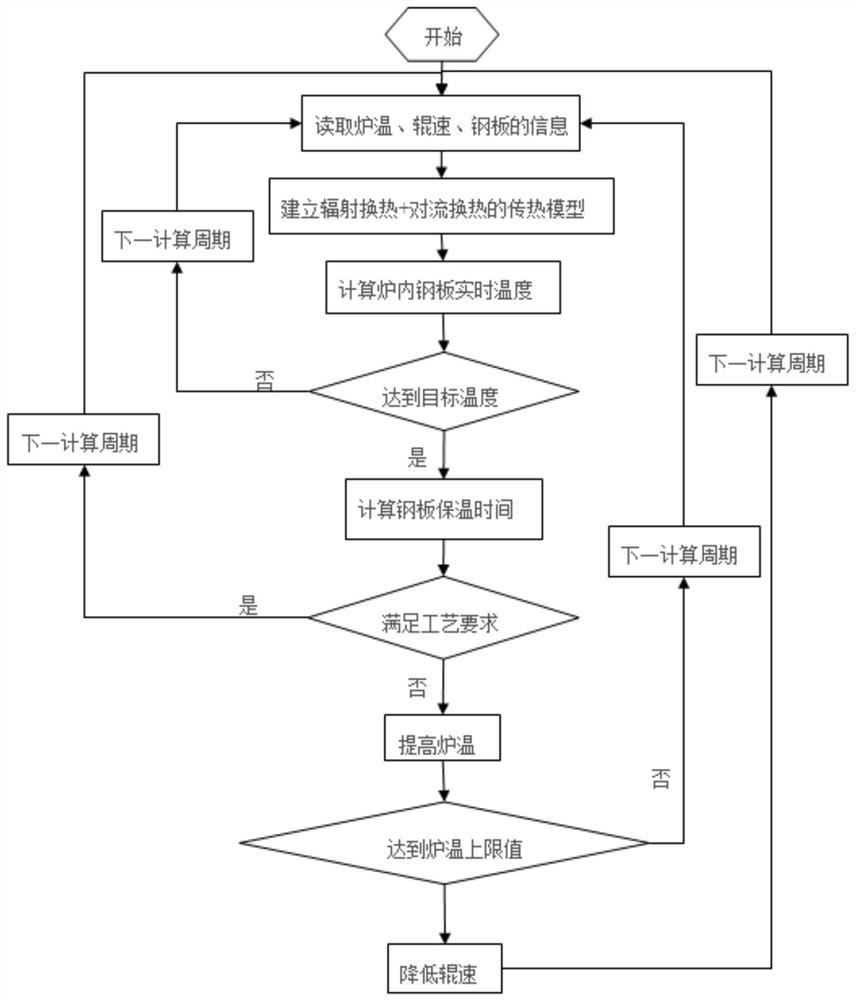

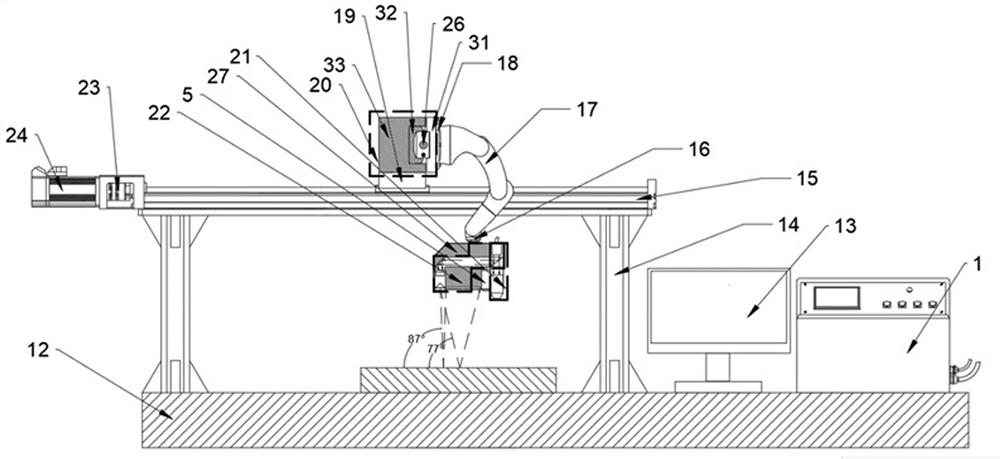

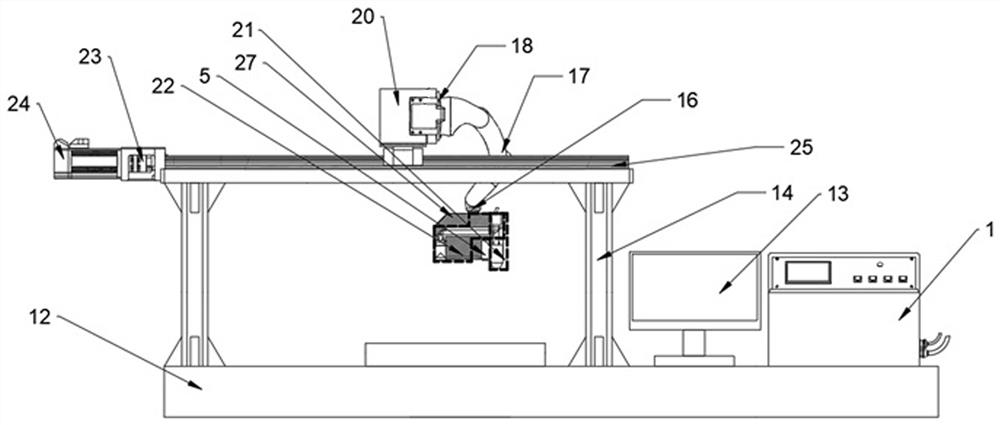

Control method for low-temperature roller hearth heat treatment furnace steel plate heating

InactiveCN111763819AAdded convective heat transfer calculationHigh control precisionFurnace typesHeat treatment process controlFurnace temperatureEngineering

The invention relates to a control method for low-temperature roller hearth heat treatment furnace steel plate heating, and belongs to the field of roller hearth heat treatment furnace optimized control. The control method comprises the following steps of 1, establishing a heat transfer model of radiation heat exchange and convection heat exchange, calculating the surface heat flux density of a steel plate, and calculating the real-time temperature of the steel plate in a furnace; 2, judging whether the steel plate reaches the heat treatment target temperature or not, if not, repeatedly carrying out the step 1, and entering the next calculation cycle to judge again; if yes, starting heat preservation, calculating the position of the steel plate in the furnace at the moment, and calculatingthe heat preservation time when the steel plate reaches an outlet of the heat treatment furnace; judging whether the heat preservation time of the steel plate reaching the outlet of the heat treatment furnace meets the process requirement of the shortest heat preservation time or not, if not, adjusting the furnace temperature and / or the roller speed, repeatedly carrying out the step 1 and step 2,and entering the next calculation period to judge again; and if yes, maintaining the current furnace temperature and roller speed. According to the heat transfer characteristic in the furnace, convection heat transfer calculation is added, reasonable modeling is carried out, and model control precision is improved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

Temperature modeling constrained on geophysical data and kinematic restoration

ActiveUS10261974B2Accurate kinematic restorationReduce uncertaintyGeomodellingComplex mathematical operationsOcean bottomPorosity

A method is disclosed for the estimation of subsurface temperature distributions from a 3-dimensional heat conductivity model for a geological formation. The method may be characterized by the following steps: (a) obtaining measured data corresponding to a geological subsurface formation of interest including seismic survey data, in-well temperature, seafloor or surface heat flux measurements and laboratory-based measurements of core porosity, (b) estimating a relationship between seismic velocity and heat conductivity, wherein seismic velocity is linearly dependent on porosity and heat conductivity is exponentially or linearly dependent on porosity, and (c) calibrating the model to the measured in-well data and laboratory-based measurements of core porosity.

Owner:DEN NORSKE STATS OLJESELSKAP AS

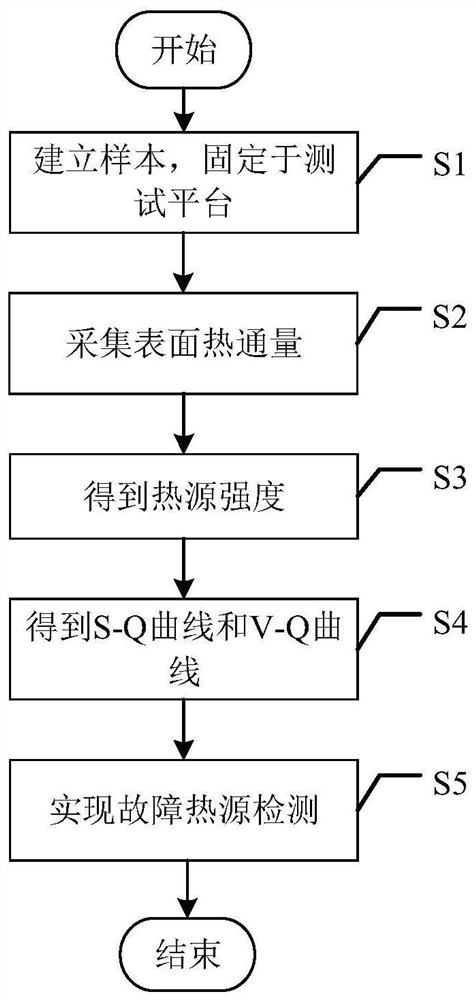

Fault heat source detection method for valve side bushing of extra-high voltage converter transformer

ActiveCN113237920AEfficient detectionReduce computational complexityMaterial flaws investigationCapacitanceThermodynamics

The invention discloses a fault heat source detection method for a valve side bushing of an extra-high voltage converter transformer, and the method comprises the steps: describing the internal defects of the valve side bushing of the extra-high voltage converter transformer through employing two physical geometric concepts: surface defects and body defects, wherein the defects of the extra-high voltage converter transformer valve side sleeve caused by the working conditions of metal particle mixing, bubble mixing, cracks in the pouring link and capacitive screen breakdown are summarized and approximated from thermal and geometric properties. The method comprises the following steps: by taking valve side sleeves with surface defects and body defects of different sizes as samples, calculating defect fault heat source intensity through surface heat flux obtained by actual measurement of a heat flow sensor through a valve side sleeve internal defect heat source equivalent model; and forming corresponding curve data of detailed defect faults and heating conditions, namely heat source intensity, providing data support for effectively preventing casing pipe faults, and therefore accurate fault heat source detection is achieved.

Owner:SOUTHWEST JIAOTONG UNIV +1

Airborne integrated air-cooled optical fiber cladding power stripper

PendingCN111431024AAvoid radiationReal-time heat dissipationActive medium shape and constructionLaser cooling arrangementsOptical radiationEngineering

The invention discloses an airborne integrated air-cooled optical fiber cladding power stripper, which comprises a total reflection parabolic mirror and a laser full-absorption surface layer. The total reflection parabolic mirror is arranged in a fuselage; and the laser full-absorption surface layer and the fuselage skin are integrally formed. According to the invention, the cladding power stripper and the fuselage skin are integrally designed, and the design principle of a parabolic mirror is combined, and stray light is directly scattered to the inner wall of the cavity through a quartz glass tube, so that the surface heat flux density of stray light radiated to the inner wall absorption surface is greatly reduced; the generated waste heat is completely concentrated on the inner surfaceof the skin, then, is transferred to the outer surface and is subjected to real-time heat dissipation by utilizing an airborne environment natural cold source-high-altitude low-temperature high-speedairflow, so that a large amount of waste heat generated by stray light stripped from an optical fiber cladding can be efficiently dissipated in real time to meet the temperature control requirement ofthe cladding power stripper; and the cladding power stripper is simple in structure, the overall weight is greatly reduced, and the lightweight design requirement can be met.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

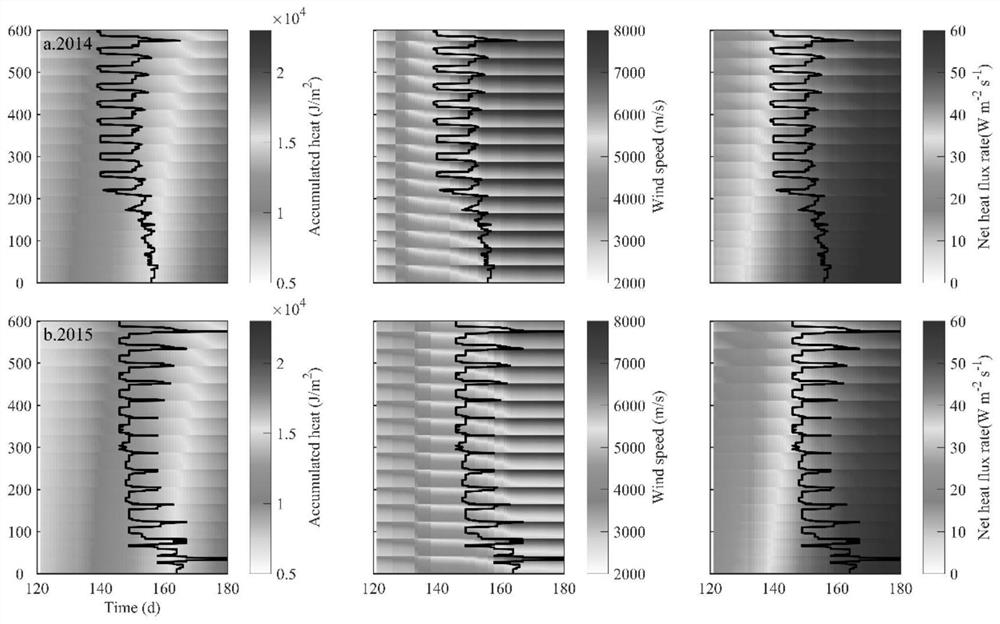

Method for calculating water body stratification starting moment based on sea surface heat flux

PendingCN113642142AThe result is accurateDesign optimisation/simulationSpecial data processing applicationsMoving averageAnalysis data

The invention relates to a method for calculating a water body stratification starting moment based on sea surface heat flux. The method comprises the following steps: carrying out data acquisition, i.e., acquiring atmosphere reanalysis data information about a wind field and reanalysis data information about heat flux; according to net heat flux data obtained in real time, after moving average, determining ocean heat absorption time t0; setting that a certain linear relationship exists between time [delta]t required between the starting moment of water stratification and the starting of heat absorption and the accumulated wind energy action, the accumulated net heat flux and the net heat flux growth rate, and establishing a regression model through a multivariate linear fitting method; selecting sample data of a certain number of grid points to perform regression analysis to obtain a regression equation, and performing standardization processing on the obtained linear regression equation; and by calculating the accumulated net heat flux and the net heat flux growth rate of each day, determining the [delta]t required between the water body stratification starting moment and the heat absorption starting moment, and calculating the water body stratification starting moment.

Owner:TIANJIN UNIV

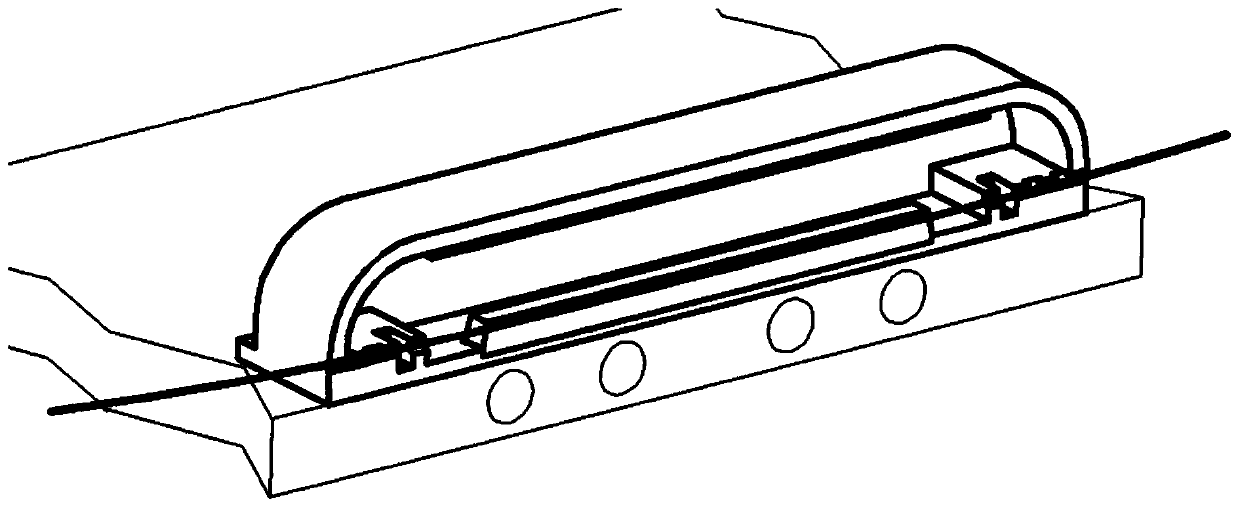

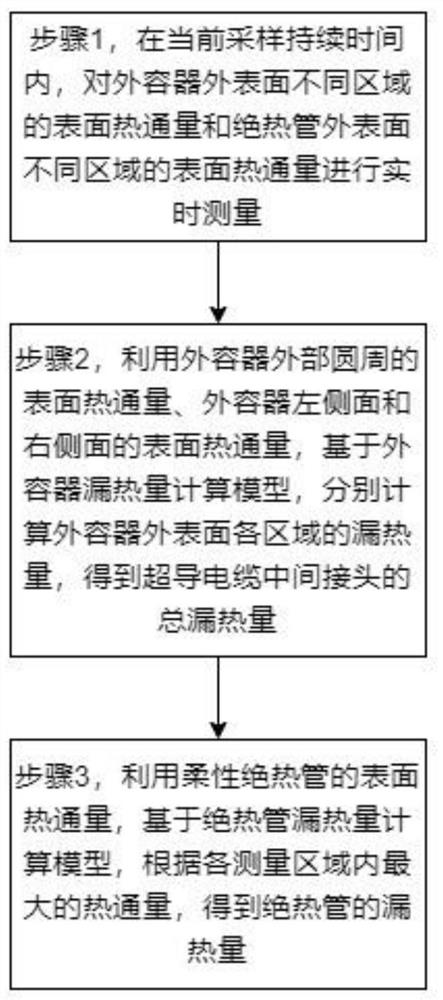

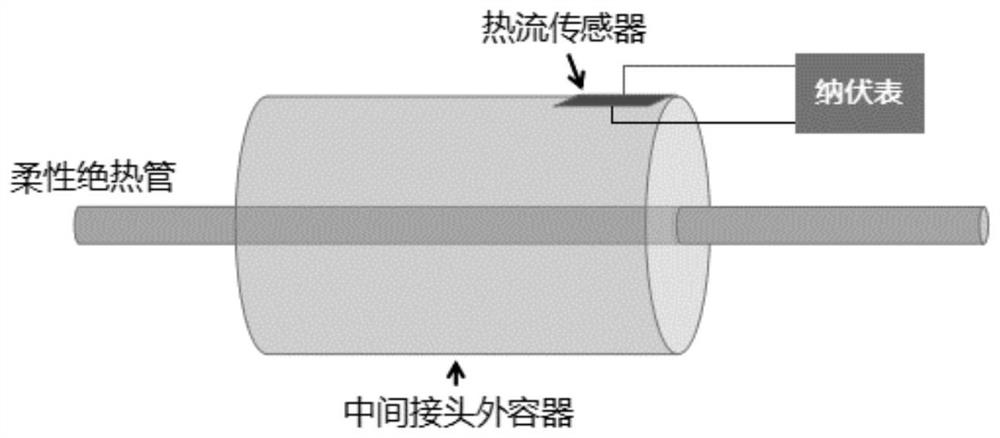

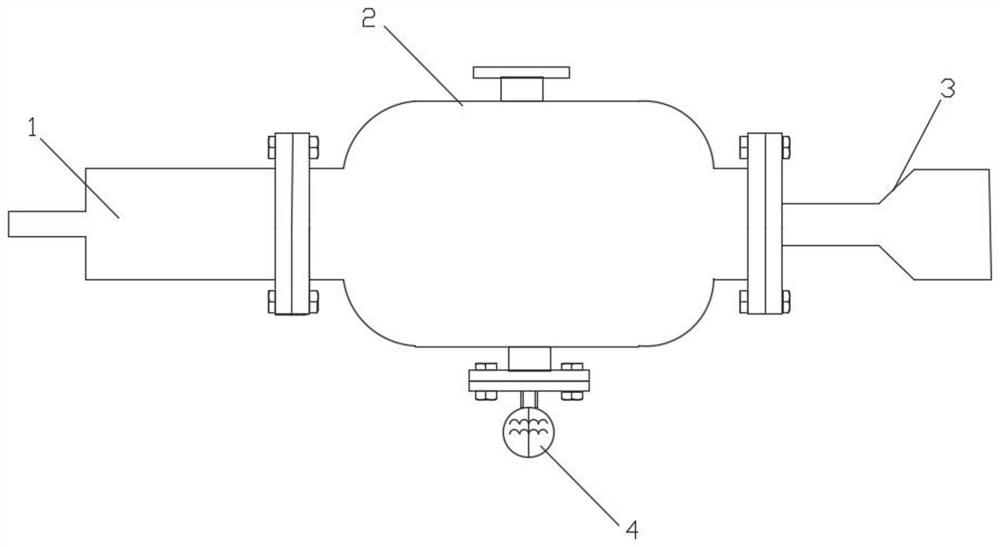

Method and device for measuring and calculating heat leakage of intermediate joint of superconducting cable

ActiveCN113340472AEconomical and reliable operationDelivery capacity dropsDesign optimisation/simulationSpecial data processing applicationsThermodynamicsElectric cables

The invention relates to a method and device for measuring and calculating the heat leakage of the intermediate joint of a superconducting cable.Surface heat flux of an outer container is collected from the left side face to the right side face of the outer container in a low-temperature constant-temperature container along the outer circumference of the outer container in the axis direction of the outer container, and surface heat flux of the left side face and the right side face of the outer container is collected; from one end of a flexible heat insulation pipe to the other end of the flexible heat insulation pipe, the surface heat flux of the flexible heat insulation pipe is collected along the outer circumference of the flexible heat insulation pipe in the axis direction of the flexible heat insulation pipe; based on an outer container heat leakage calculation model, the total heat leakage of the intermediate joint of the superconducting cable is obtained; and the heat leakage amount of the heat insulation pipe is obtained based on a heat insulation pipe heat leakage amount calculation model. Measurement and calculation of the heat leakage of the outer container and the heat insulation pipe of the intermediate joint of the superconducting cable are achieved, the total heat leakage of the intermediate joint and the heat leakage of the heat insulation pipe of the superconducting cable are obtained, and data support is provided for manufacturing of the intermediate joint of the superconducting cable and the heat insulation pipe based on heat leakage data.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Polluted waste liquid treatment device

InactiveCN103011316ALarge surface heat fluxHigh surface heat fluxWater/sewage treatment by heatingLiquid wasteHigh concentration

The invention discloses a polluted waste liquid treatment device comprising a spiral scraper, a first inlet, a planar scraper, a jacket, a vertical scraping barrel, a rotary shaft, a cavity, a first outlet, a second outlet, a second inlet, a third outlet, a flange and a shaft seal. The polluted waste liquid treatment device is high in operable flexibility, solves the problems that the inner contact wall surface of other film scrapers is easy to scale and high-concentration liquid is insufficiently evaporated, is high in evaporation performance due to the fact that a heating surface has high surface heat flux by the aid of characteristics of the film scrapers, is heat-sensitive in treatment due to short stop time and low evaporation temperature therein, capable of completely separating severely polluted liquid into distilled water, solid-state and semi-solid state residues discharged up to standard, and thoroughly effectively treating the high-concentration liquid. Besides, the polluted waste liquid treatment device is simple in structure and convenient to operate, over-concentrated liquid in sewage is efficiently treated, sewage treatment effect is improved, and the environment is protected.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

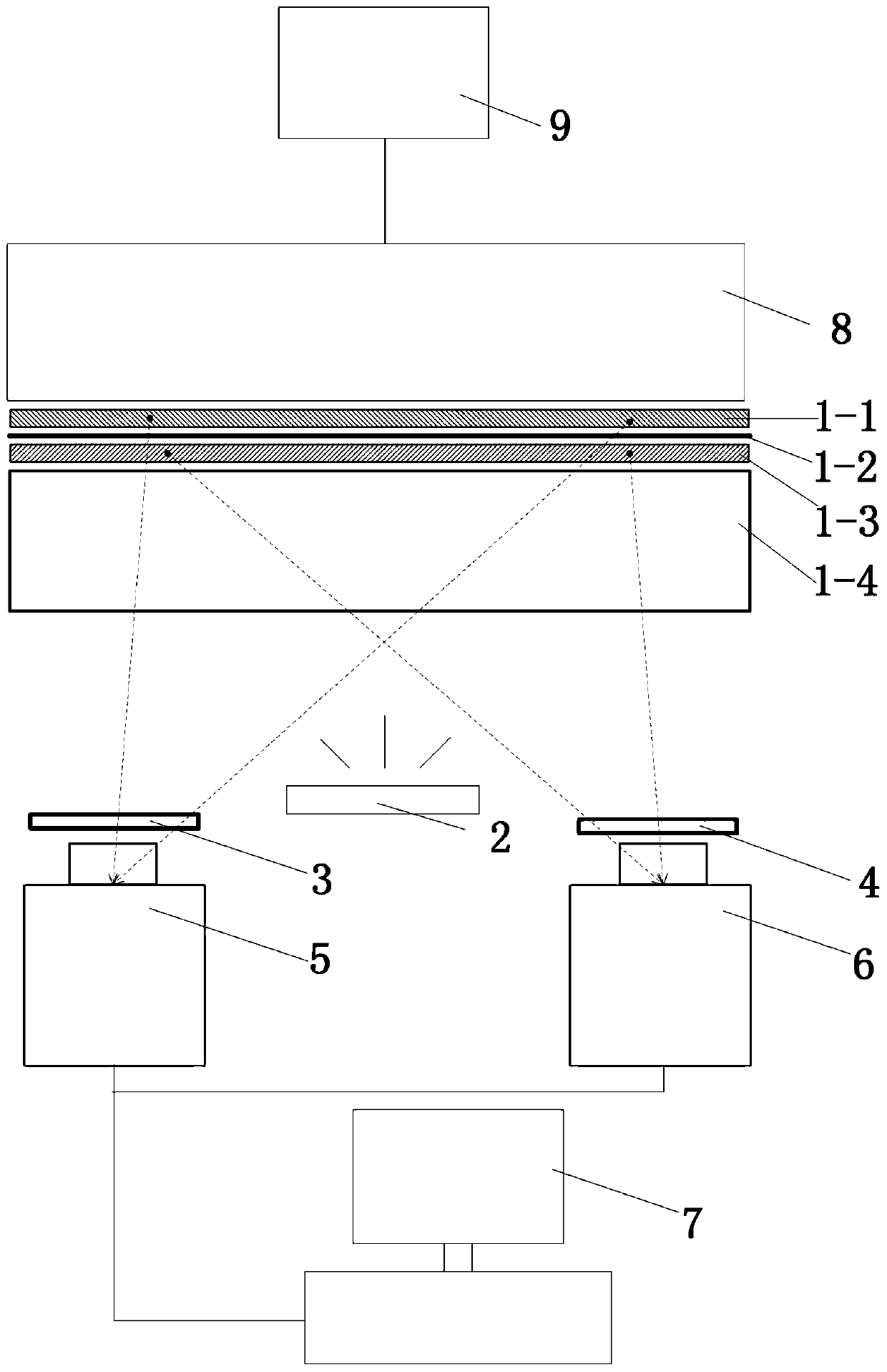

Two-dimensional surface heat flux density real-time online measuring device and method

ActiveCN111735847AQuick responseGuaranteed repeatabilityMaterial heat developmentCalorimeterHeat flowData acquisition

The invention relates to a real-time online measuring device and method, in particular to a two-dimensional surface heat flux density real-time online measuring device and method. According to the technical scheme provided by the invention, the two-dimensional surface heat flux density real-time online measuring device comprises a base body and a base body temperature sensor capable of monitoringthe temperatures of multiple points of the base body, the base body temperature sensor is electrically connected with a measurement control calculation device through a data acquisition board card, and the measurement control calculation device can synchronously acquire the temperatures of multiple points of the base body monitored by the base body temperature sensor through the data acquisition board card; and the measurement control calculation device calculates and determines the surface multi-point heat flux density of the base body by adopting a two-dimensional filtering method after obtaining the multi-point temperature values of the base body. The online monitoring and measuring problems of the surface heat flux density of thermal conversion equipment such as boilers and internal combustion engines can be solved, and therefore optimization and development of related industrial processes are promoted.

Owner:常州江苏大学工程技术研究院

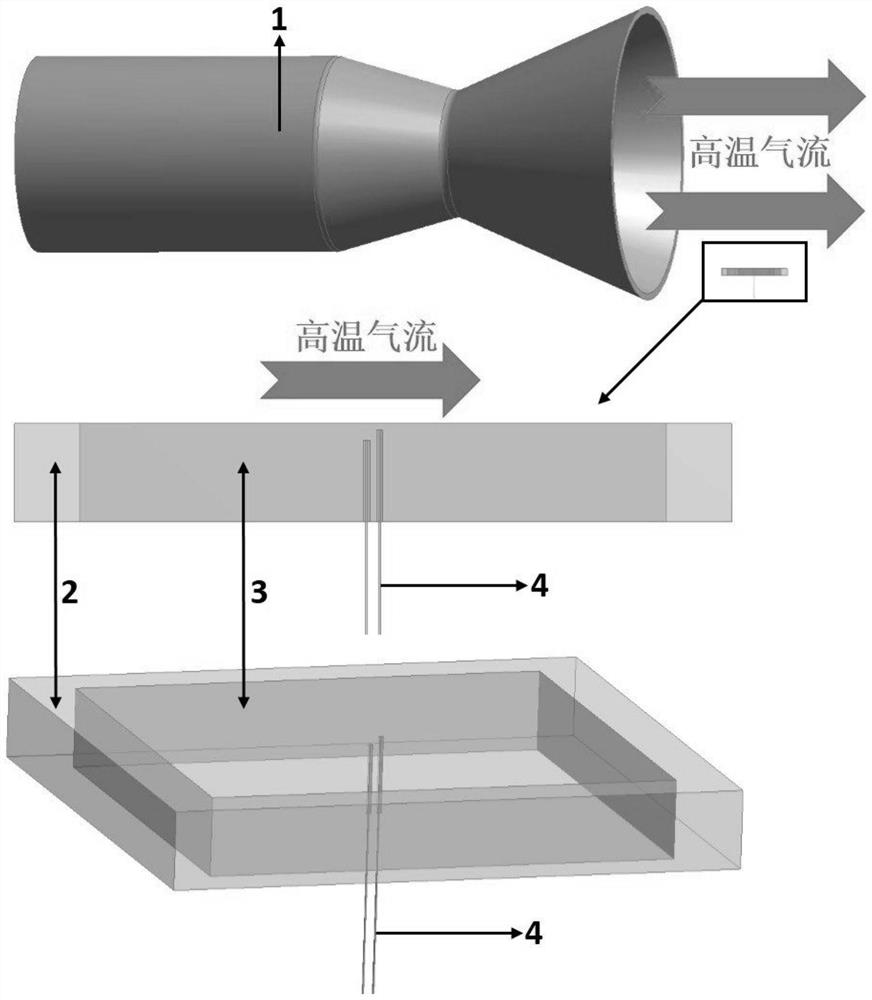

Temperature acquisition assembly and electric arc wind tunnel flat plate test piece surface heat flux density measurement method

PendingCN114593835AResistance to scourImprove reliabilityAerodynamic testingThermometers using electric/magnetic elementsThermodynamicsHeat flow

The invention provides a temperature acquisition device and an arc wind tunnel flat plate test piece surface heat flux density measurement method, the device comprises a metal flat plate, a heat insulation frame and thermocouples, the heat insulation frame surrounds the metal flat plate, the two thermocouples are installed at the center of the lower surface of the metal flat plate, and the distances between probes of the two thermocouples and the upper surface of the metal flat plate are different. The temperature acquisition assembly is arranged at a to-be-measured position of an arc wind tunnel nozzle outlet. The temperature acquisition assembly can measure temperature repeatedly for a long time and calculate the heat flux density through temperature data, and in combination with the heat flux density measurement method, the change process of the transient heat flux density can be measured in a short time, and the steady-state heat flux density and the radiation equilibrium temperature can be measured for a long time.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

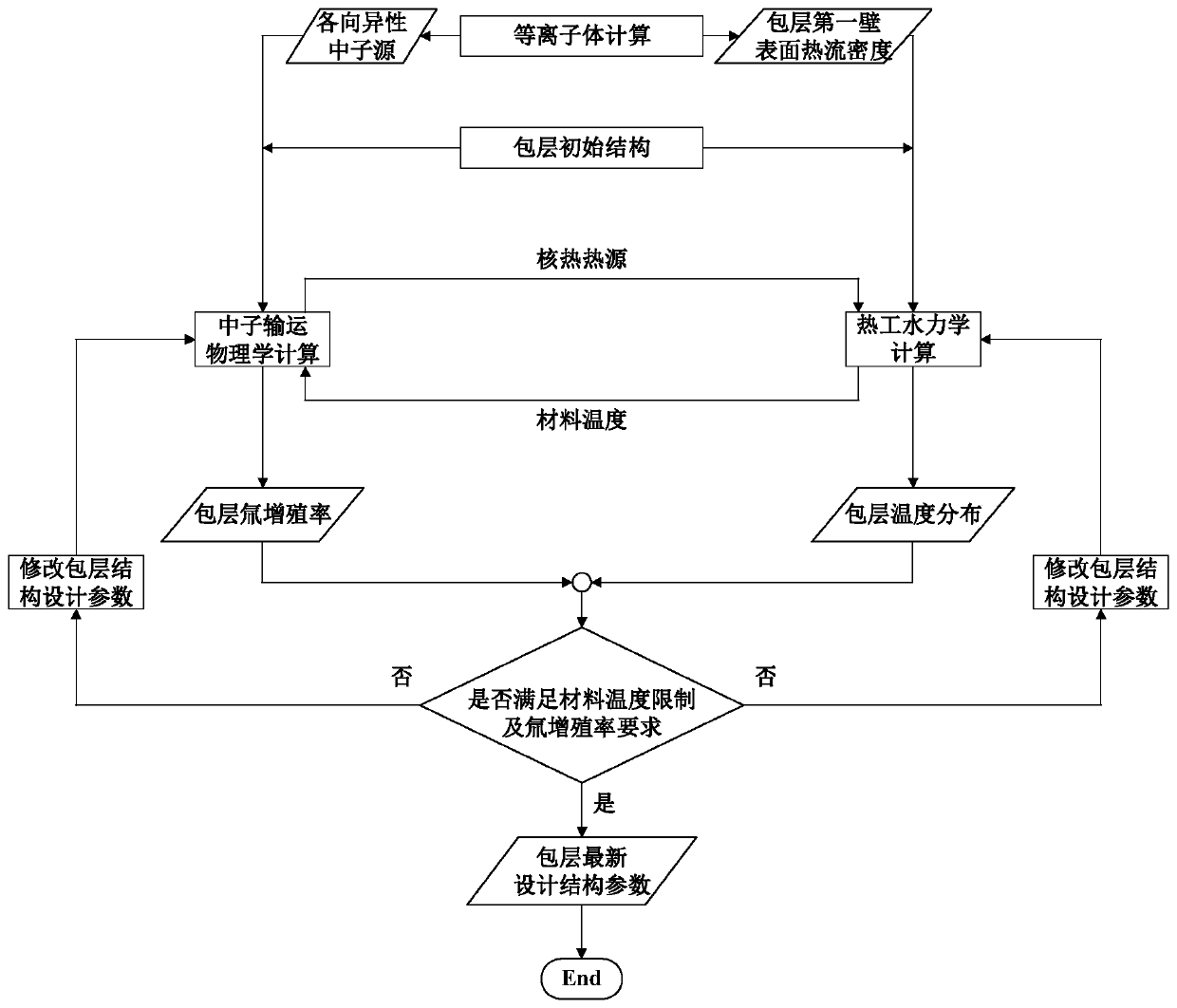

A method for precise engineering of fusion reactor cladding

ActiveCN110569613BGet security featuresGain Thermal Safety FeaturesCAD circuit designFusion reactor blanketNuclear engineering

The invention discloses a method applied to fusion reactor cladding accurate engineering design. The method comprises the following steps: firstly, performing plasma calculation to obtain anisotropicneutron source distribution and cladding first wall surface heat flux density distribution; combining anisotropic neutron source distribution obtained through plasma calculation in neutron transport physics calculation with material temperature distribution obtained through thermohydraulics calculation, and obtaining cladding core heat source distribution and cladding tritium propagation rate; obtaining material temperature distribution of different areas in the cladding by utilizing cladding first wall surface heat flux density distribution provided by plasma calculation and nuclear heat source distribution provided by neutron transport calculation in thermal hydraulics calculation; neutron transport calculation and thermal hydraulics calculation needing to be mutually iterated until therequirements of material temperature safe operation limitation and cladding tritium propagation rate are met. According to the method, engineering design can be carried out on the fusion reactor cladding in the real service environment of the cladding, the defect that in a traditional method, an isotropic neutron source and the surface heat flux of the first wall of the uniform cladding are adopted is overcome, and accurate engineering design of the cladding is achieved.

Owner:XI AN JIAOTONG UNIV

A Method for Studying the Heat Transfer Characteristics of Melting Pool by Using the Moving Particle Finite Volume Method

ActiveCN110044959BAccurate researchAccurate captureMaterial heat developmentEngineeringPressure poisson equation

The invention discloses a method for researching high Rayleigh number fusion pool heat transfer characteristics by a moving particle finite volume method. The method comprises the following main stepsthat: 1: carrying out particle modeling by aiming at a specific problem, and setting a particle initial layout; 2: according to the position of each particle, dividing a grid; 3: after a time step length [Delta]t, using the finite volume method to solve an energy equation; 4: through a particle method, processing a viscosity term and a source term in an explicit calculation momentum equation, andestimating the speed and the position of the particle; 5: calculating particle number density, and solving a pressure Poisson equation; 6: calculating the correction value of the speed, and calculating the speed and the position of each particle in a next time level; and 7: outputting a calculation result, and according to a solved specific problem, outputting wall surface heat flux density and the phase state of substances in a fusion pool. The method has the advantages that a free liquid surface is accurately captured by a particle method and a phase change problem is simulated, and calculation accuracy is high. Through the method, the high Rayleigh number fusion pool heat transfer characteristics are researched, and an important basis is provided for researching the safety characteristics of the serious accident of a nuclear power plant reactor.

Owner:XI AN JIAOTONG UNIV

Method for controlling triangular area cracks of continuous casting plain carbon steel slab

PendingCN114523081AReduce the incidence of cracksReduce incidenceCasting parameters measurement/indication devicesEngineeringMechanics

The invention discloses a method for controlling a triangular area crack of a continuous casting plain carbon steel slab, which belongs to the technical field of continuous casting slabs, and comprises the following steps: S1, keeping the wide surface water flow of a crystallizer at 3200L / min, controlling the narrow surface water flow of the crystallizer at 510L / min-600L / min, calculating the narrow side and wide surface heat flux according to a heat flux formula of the crystallizer in combination with the water inlet and outlet temperature difference of the crystallizer, meanwhile, the cooling water flow of the foot roller section of the crystallizer is increased by 10-30 L / min, a database is established, and data with the heat flux density ratio of the narrow side to the wide side being 0.8-1.0 MW / m < 2 > is selected; s2, measuring the surface temperature of an inlet and an outlet of the straightening section of the casting blank, firstly, establishing a database according to the measured temperature and the optimized secondary cooling water specific water flow, and selecting data of the straightening section at the temperature of 910-930 DEG C from the database; secondly, an arc-shaped section nozzle of the casting machine is changed into a backwashing nozzle, so that the temperature return amount is less than 20 DEG C;

Owner:天铁热轧板有限公司

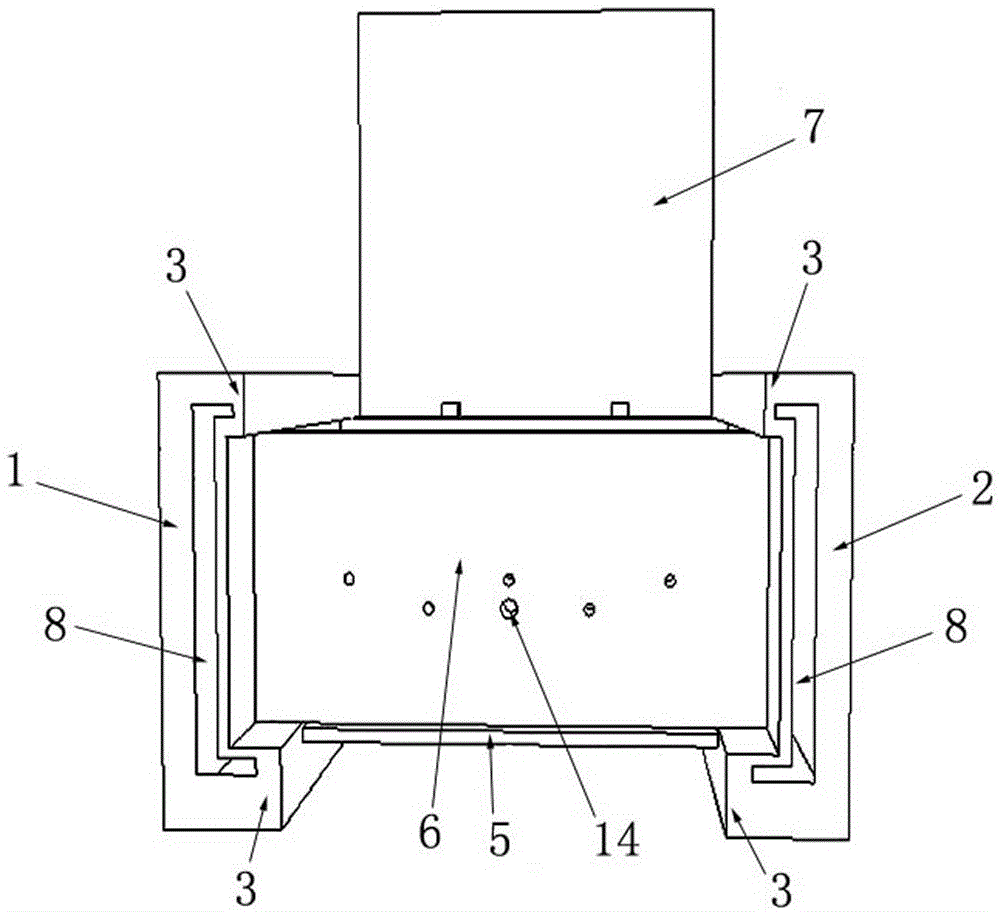

Electromagnetic induction heating gas heat exchange experimental device

InactiveCN113112895AAvoid electrificationReduce air velocityEducational modelsThermodynamicsInsulation layer

The invention discloses an electromagnetic induction heating gas heat exchange experimental device. The device comprises a gas injection pipe; a device main body, an experiment tube, a heat insulation layer and an induction coil are arranged in the device main body; one end of the experiment tube is communicated with the gas injection tube; the heat insulation layer is arranged outside the experiment tube in a sleeving manner; the induction coil is arranged outside the heat insulation layer in a sleeving manner; an exhaust pipe which is communicated with the other end of the experiment tube; and an induction heating power supply which is electrically connected with the induction coil. Non-contact induction heating is carried out on the experiment tube through the induction coil, the phenomenon that the experiment tube is powered on is avoided, therefore, personnel safety is ensured, and the device is more stable in operation, more uniform in wall surface heat flux density, better in air tightness and higher in experiment precision.

Owner:XI AN JIAOTONG UNIV

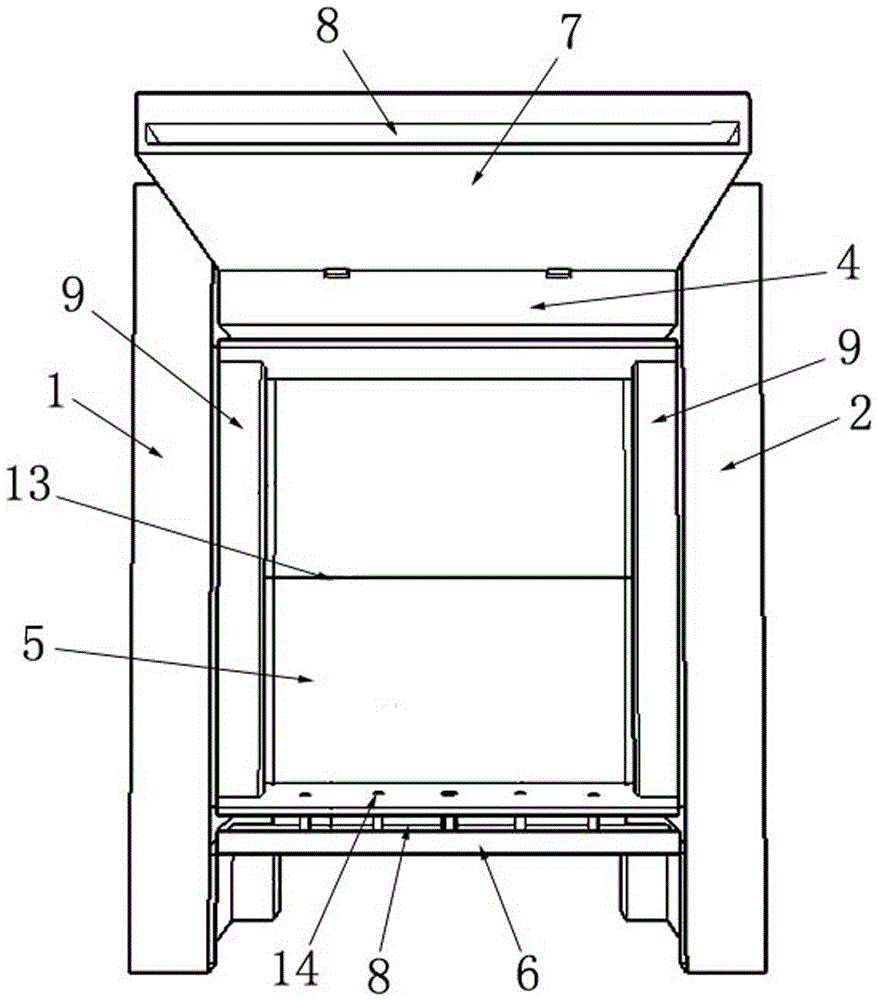

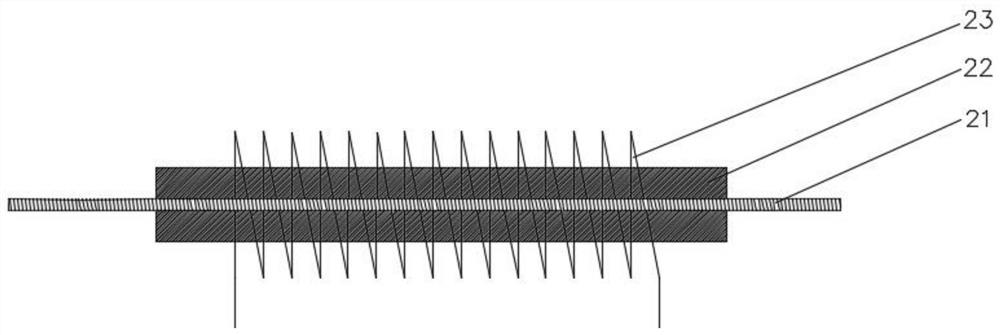

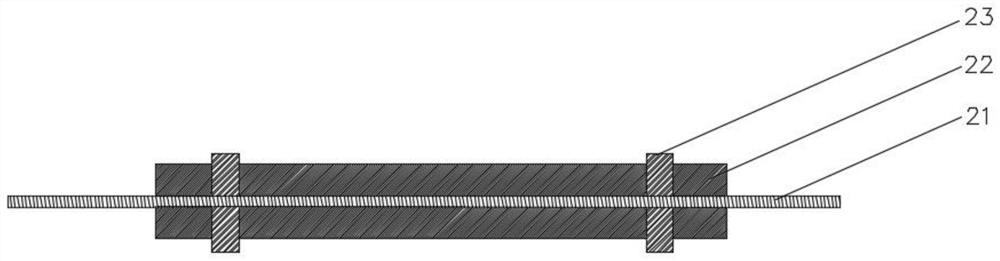

Direct-current heating single-channel gas heat exchange experimental device

InactiveCN113125498AImprove insulation performanceAvoid high temperature oxidationMaterial heat developmentEducational modelsThermodynamicsHeat flow

The invention discloses a direct-current heating single-channel gas heat exchange experimental device which comprises a gas inlet cylinder, an experimental device main body, a gas outlet cylinder and a direct-current power supply, the air inlet cylinder and the air outlet cylinder are tightly connected to the two ends of the experimental device main body; an experiment pipe, a heat insulation sleeve and two electrodes are arranged in the experiment device main body; two ends of the experiment tube are respectively communicated with the air inlet cylinder and the experiment device main body; the heat insulation sleeve is arranged outside the experiment tube in a sleeving manner; the two electrodes are arranged outside the experiment tube in a sleeving manner, and the two electrodes are both embedded into the heat insulation sleeve; and the two electrodes are electrically connected with the direct-current power supply. According to the invention, high-precision, stable and uniform wall surface heat flux density distribution can be realized, the air tightness is better, and the experiment precision is higher.

Owner:XI AN JIAOTONG UNIV

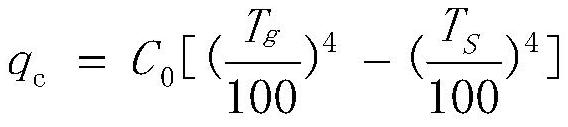

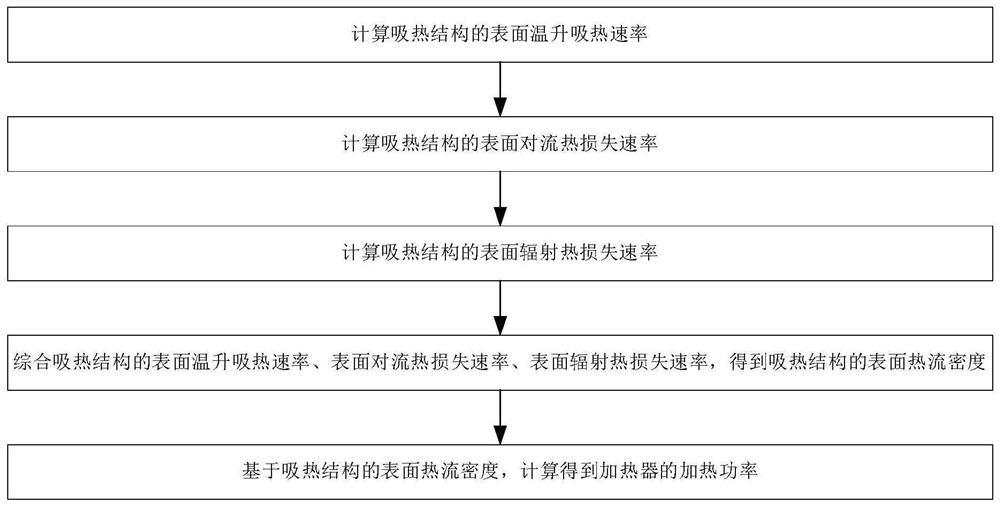

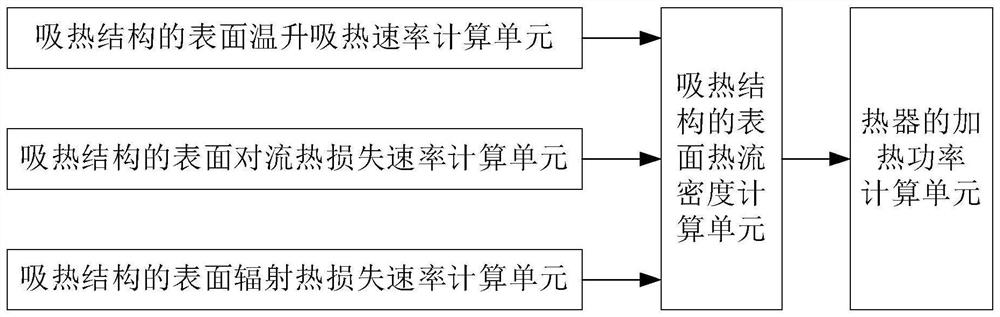

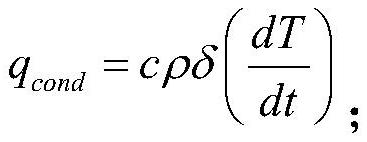

Method, system and equipment for determining heating power of heater for heat absorption structure and medium

PendingCN114878631ARealize the heating power determination methodMaterial heat developmentCalorimeterRadiative heat lossThermodynamics

The invention belongs to the technical field of heater heating, and particularly relates to a method for determining the heating power of a heater for a heat absorption structure. Calculating the surface convective heat loss rate of the heat absorption structure; calculating the surface radiation heat loss rate of the heat absorption structure; integrating the surface temperature rise heat absorption rate, the surface convection heat loss rate and the surface radiation heat loss rate of the heat absorption structure to obtain the surface heat flux density of the heat absorption structure; and calculating the heating power of the heater based on the surface heat flux density of the heat absorption structure. In addition, the invention relates to a heater heating power determining system for a heat absorption structure, equipment and a medium thereof.

Owner:CHINA AIRPLANT STRENGTH RES INST

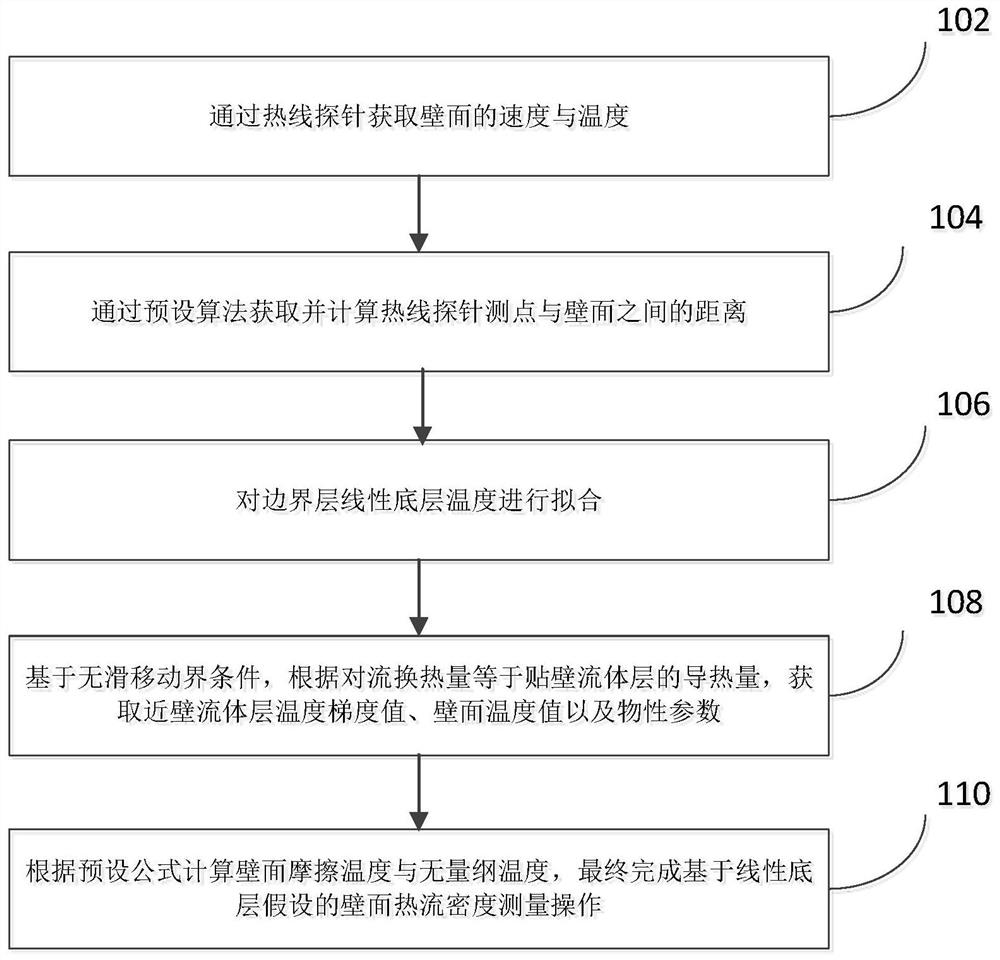

Method and device for measuring wall heat flux density based on linear bottom layer assumption

This disclosure provides a method for measuring wall heat flux density based on the assumption of a linear bottom layer. The method uses two parallel boundary layer hot wire probes, a stepping motor displacement mechanism, a small CTA module, a small digital-to-analog conversion module, a slip ring lead and The computer measures the boundary layer velocity and temperature under rotating conditions, and finally calculates the wall heat flux density through the verification of the linear bottom layer assumption and the turbulent standard temperature wall rate, and has the accuracy and ease of use of the measurement. The present disclosure also provides a wall surface heat flux measurement device based on the assumption of a linear bottom layer.

Owner:BEIHANG UNIV

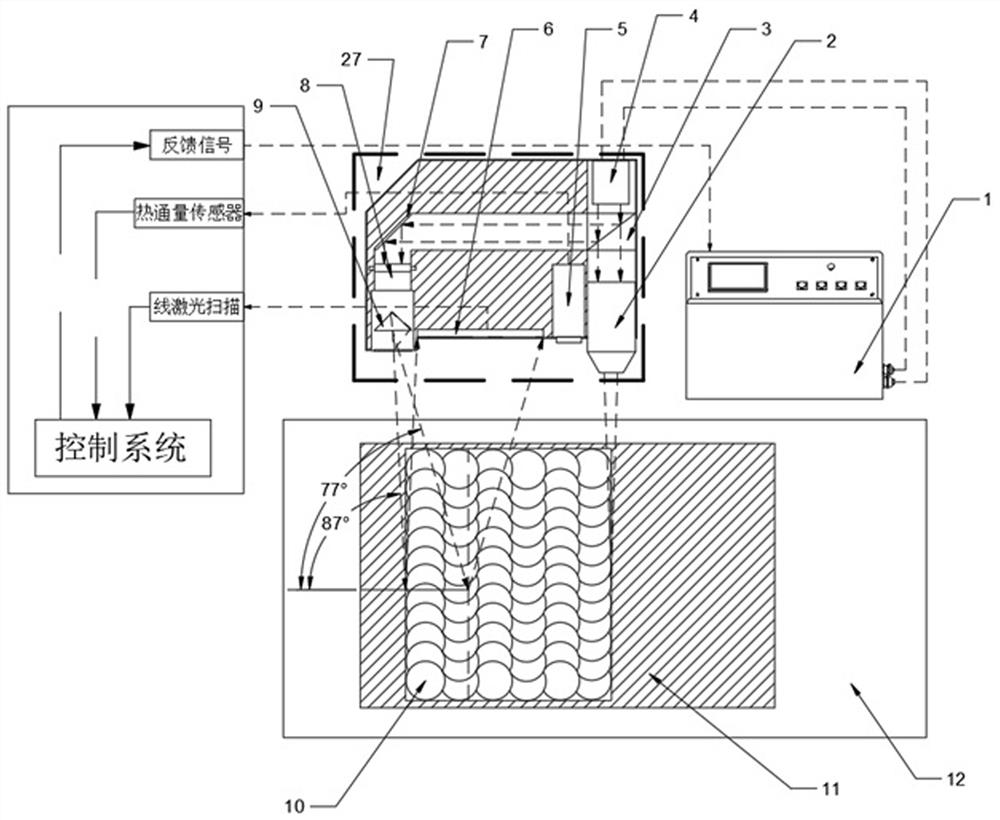

Heat flux based laser cleaning quality online detection system and method

ActiveCN113649361AAffect performanceImprove detection accuracyMaterial heat developmentMaterial flaws investigationPhysicsSurface heat flux

The invention relates to a heat flux based laser cleaning quality online detection system and a method. A supporting structure of the system is connected with a laser cleaning detection device through a sliding connecting piece. The method comprises the steps that a heat flux sensor is started to correct the cleaning environment temperature, and a laser cleaning module is started to carry out laser cleaning on a workpiece; and a scanning laser detection module is started, when the heat flux, detected by the heat flux sensor, of the workpiece surface is equal to the heat flux of a workpiece base material, a linear scanning laser detection module determines that the workpiece surface is free of areas where protrusions and pits are located, and cleaning is finished. The air hole defect generated by workpiece cleaning is detected by utilizing different convection heat conduction coefficients between different materials on the workpiece surface and the atmosphere and different convection heat conduction coefficients between different shapes of the workpiece surface and the atmosphere, and the problems that only one of cleaning quality and workpiece flaw detection of the previous laser cleaning detection technology is considered, and cleaning quality and workpiece flaw detection cannot be considered at the same time are solved.

Owner:SHENYANG POLYTECHNIC UNIV

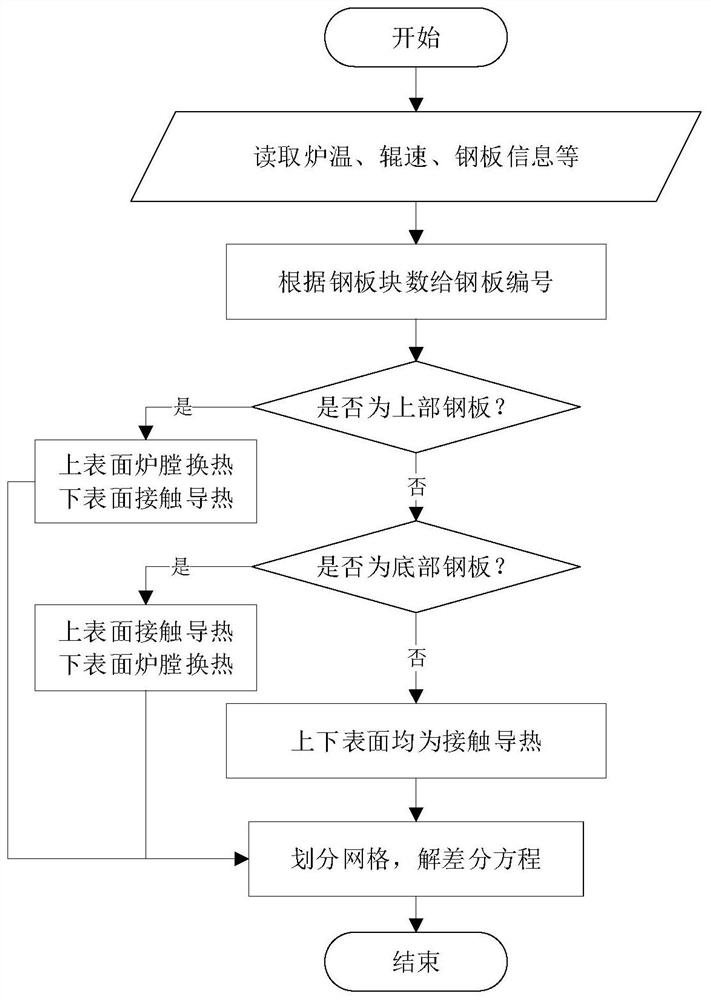

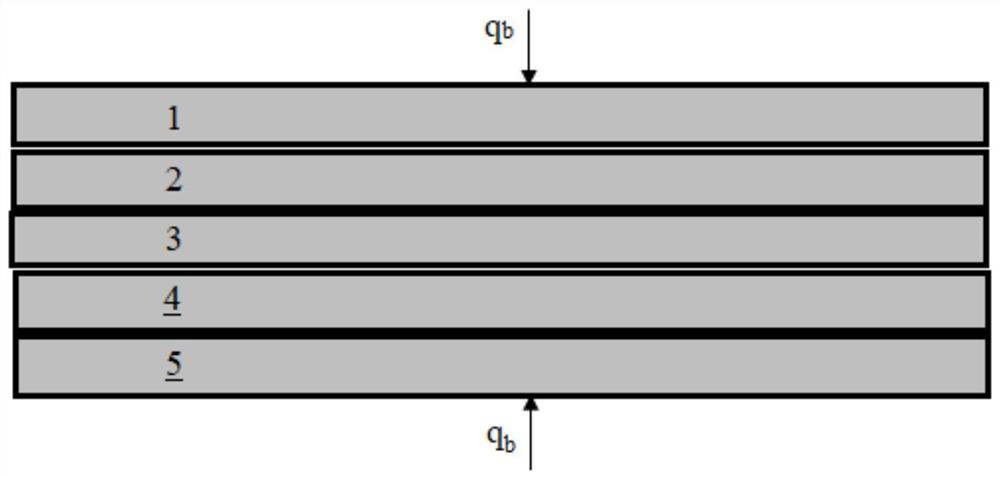

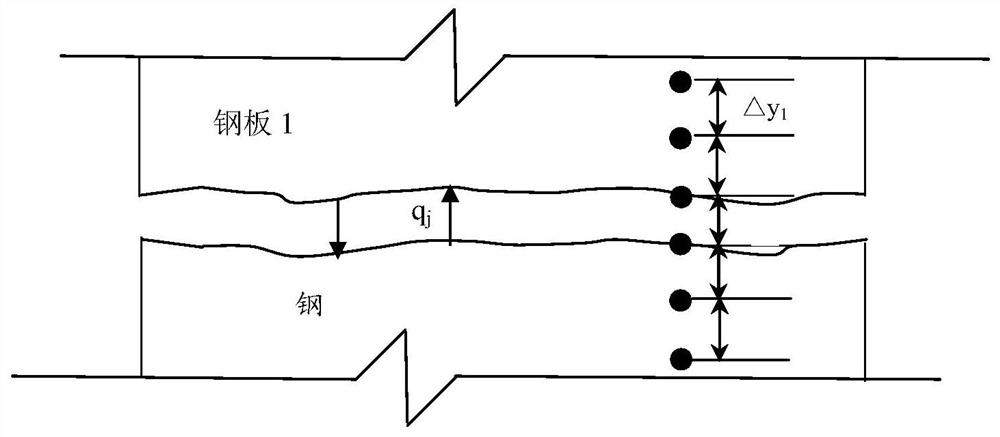

Temperature calculation method during stacking of steel plates

PendingCN113850004ASolving Heat Transfer Calculation ProblemsImprove calculation accuracyFurnace typesDesign optimisation/simulationHeat flowThin slab

The invention relates to a temperature calculation method during stacking of steel plates, and belongs to the technical field of roller hearth type heat treatment furnace model control. The method includes: S1, reading the number n of steel plate blocks stacked into a furnace; S2, dividing the steel plates into an upper steel plate, a middle steel plate and a bottom steel plate according to the positions of the steel plates, and respectively calculating the surface heat flux density of each steel plate; enabling the upper surface of the upper steel plate to exchange heat with the hearth, and enabling the lower surface of the upper steel plate to be in contact with the other steel plate for heat conduction; enabling the upper and lower surfaces of the middle steel plate to be in contact with other steel plates for heat conduction; enabling the upper surface of the bottom steel plate to be contacted with the other steel plate for heat conduction, and enabling the lower surface ofthe bottom steel plateto exchange heat with the hearth; and S3, after obtaining the surface heat flux density of the steel plate, dividing grids, and calculating the section temperature distribution of each steel plate according to a steel plate difference equation. The method for calculating the temperature of the steel plates is provided according to the stacking production condition during heat treatment of the thin plates, and the production efficiency and the model calculation precision of the thin plate stacking heat treatment furnace are improved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

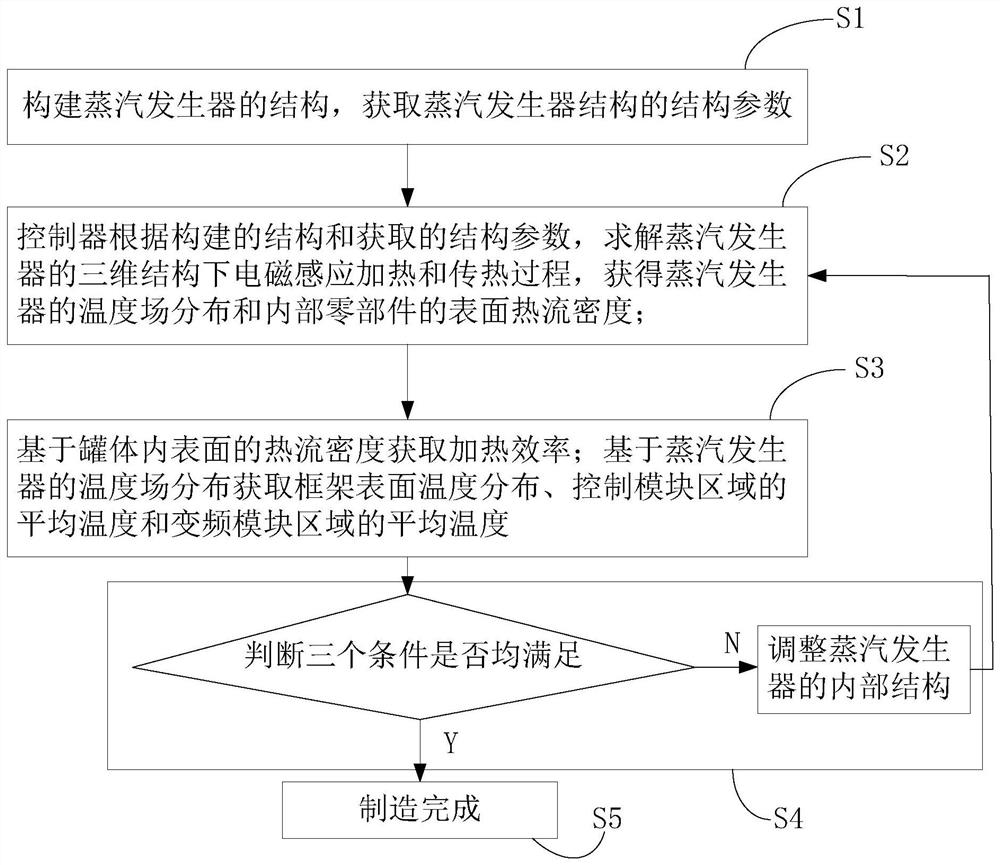

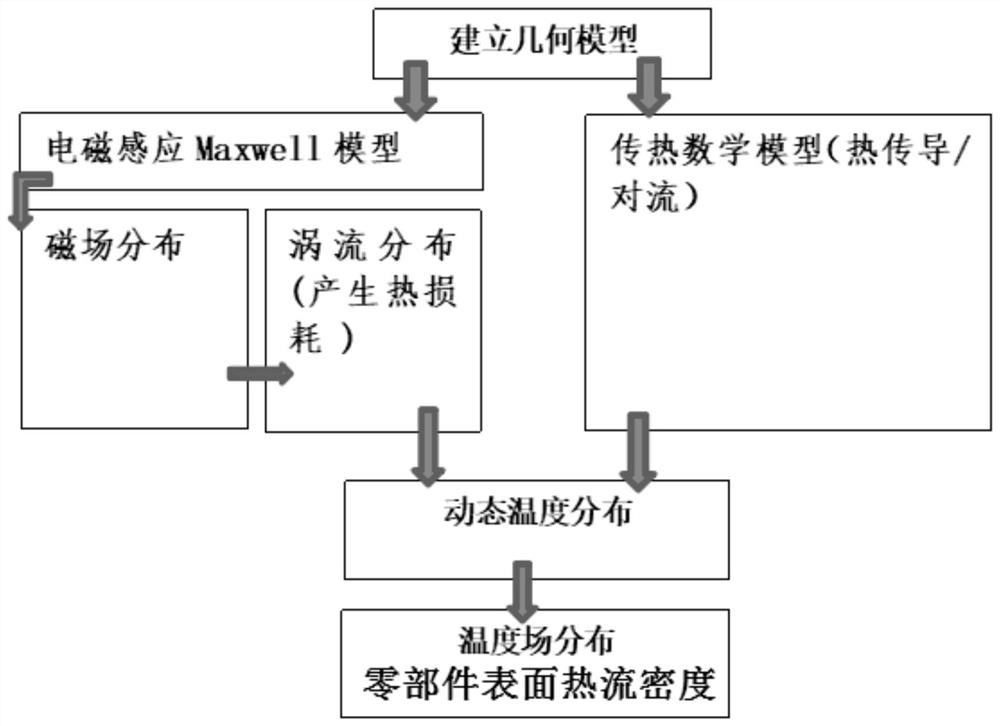

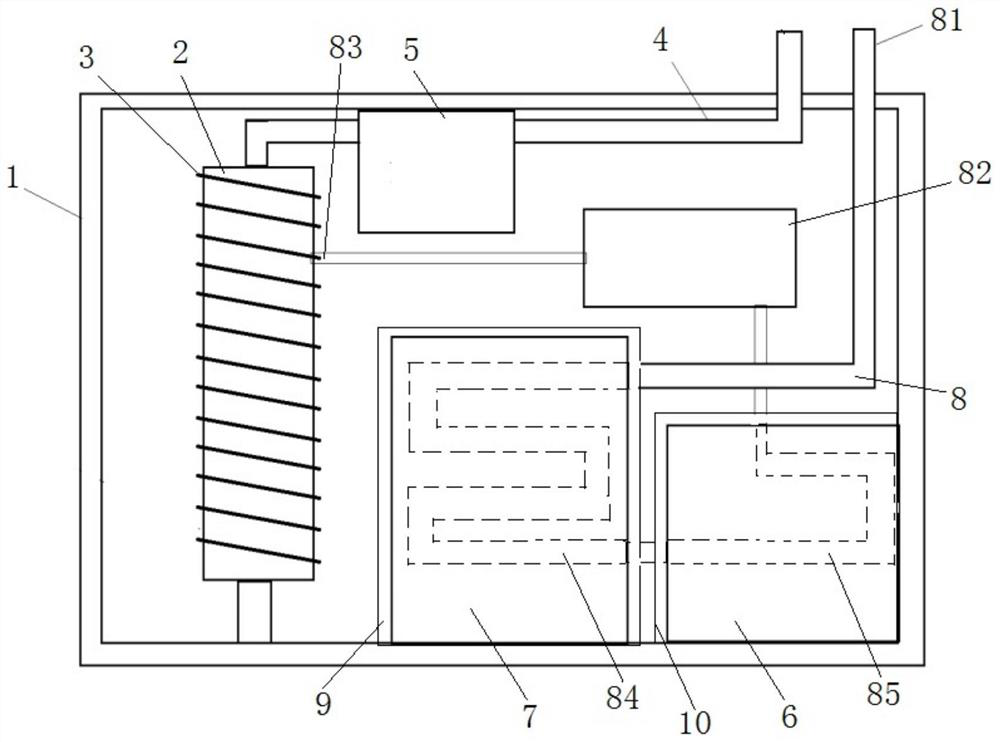

Manufacturing method of electromagnetic induction steam generator and steam generator

ActiveCN110953565BImprove the problem of local high temperatureIncrease temperatureSteam generation heating methodsDesign optimisation/simulationHeat flowFrequency conversion

The invention discloses a manufacturing method of an electromagnetic induction steam generator and the steam generator. The method includes: S1, constructing the structure of the steam generator, and obtaining structural parameters; S2, solving the process of electromagnetic induction heating and heat transfer according to the constructed structure and obtained structural parameters, and obtaining the temperature field distribution and internal components of the steam generator surface heat flux density; S3, obtain heating efficiency, frame surface temperature distribution, average temperature of control module area and frequency conversion module area; S4, if all three conditions are satisfied, complete manufacturing; if at least one of the three conditions is not satisfied , adjust the internal structure of the steam generator and return to S2. This method adjusts the internal structure to ensure heating efficiency, reduces energy loss, avoids local high temperature on the surface of the frame that is not good for user experience, makes the control module and frequency conversion module work within the allowable temperature range, and improves operation stability and reliability. and security.

Owner:HUBEI UNIV FOR NATITIES +1

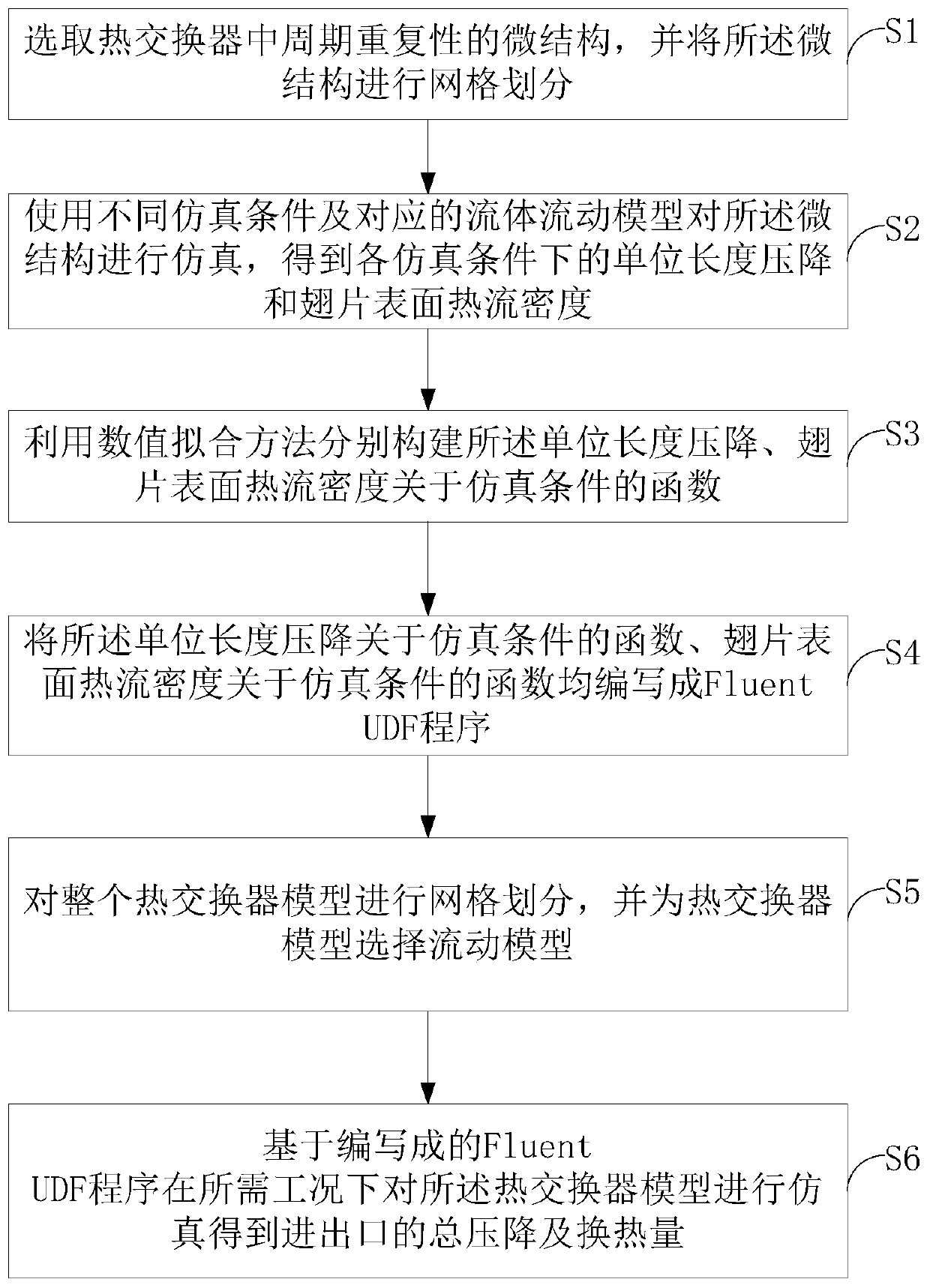

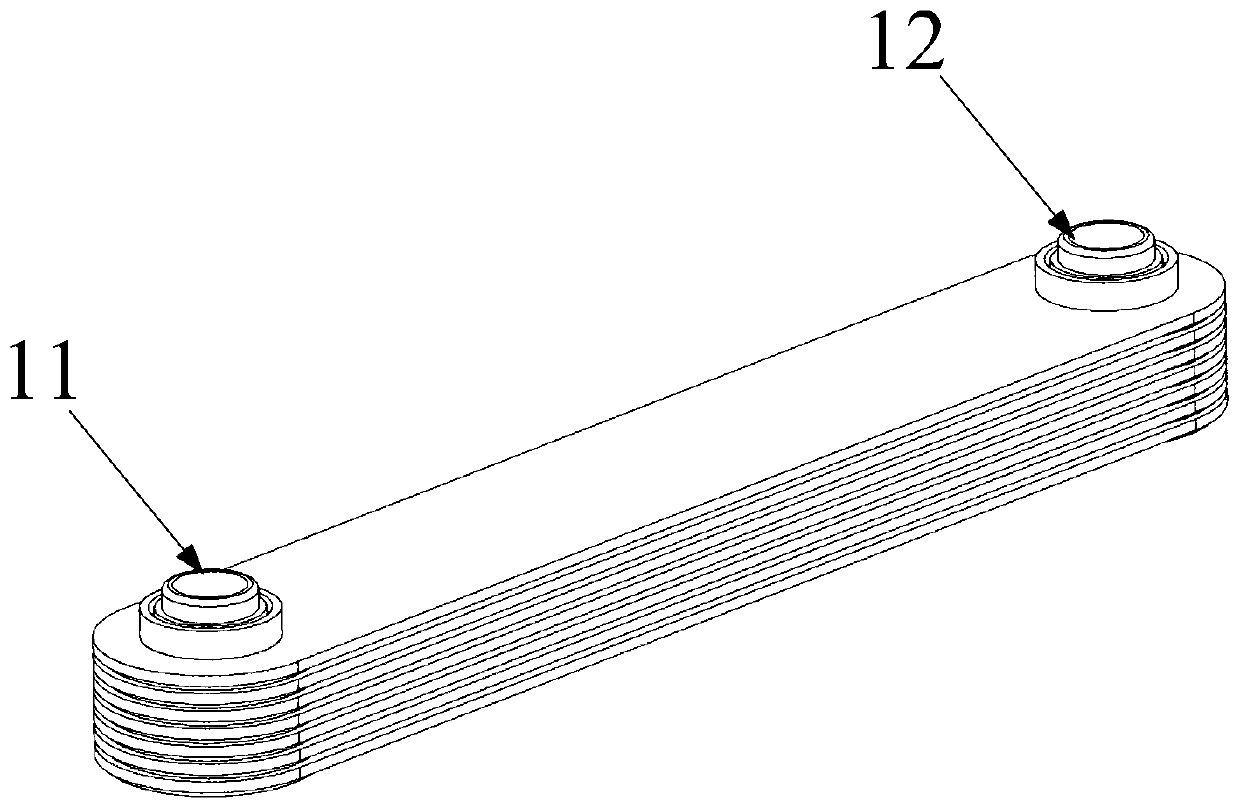

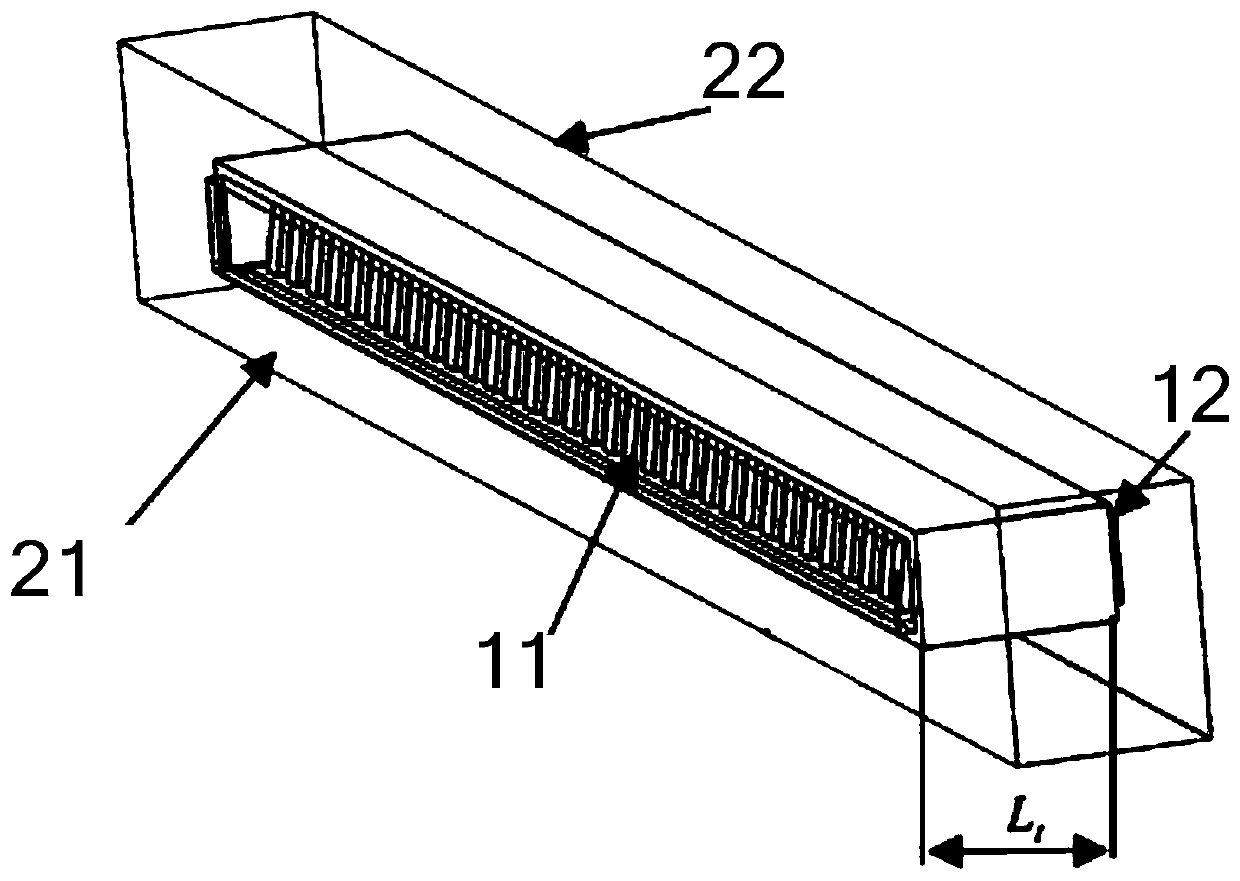

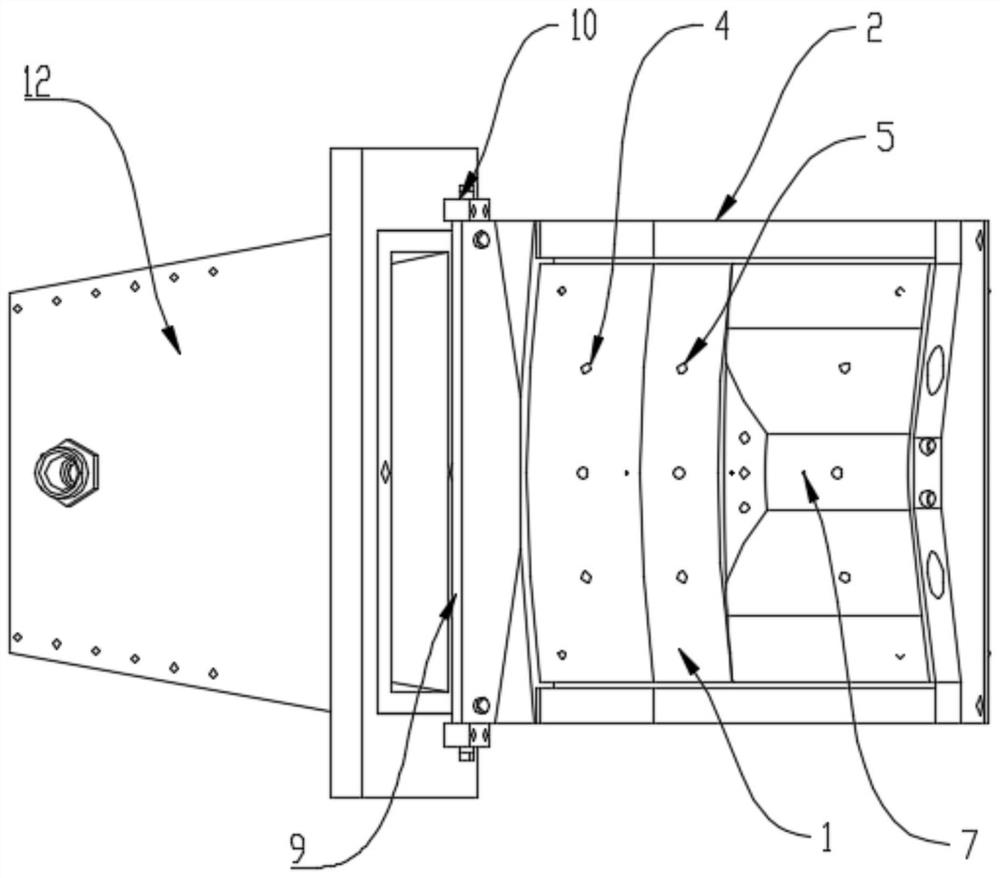

Simulation method of plate-fin heat exchanger

The invention relates to a simulation method for a plate-fin heat exchanger, and the method comprises the steps: S1, selecting a periodic repetitive microstructure in the heat exchanger, and carryingout the mesh generation of the microstructure; s2, simulating the microstructure by using different simulation conditions and corresponding fluid flow models to obtain unit length pressure drop and fin surface heat flux density under each simulation condition; s3, respectively constructing functions of the unit length pressure drop and the fin surface heat flux density relative to simulation conditions by utilizing a numerical fitting method; and based on the written Fluent UDF program, simulating the heat exchanger model under the required working condition to obtain the total pressure drop and the heat exchange amount of the inlet and the outlet. According to the invention, the influence of changes of fluid flow rates and temperatures in different heat dissipation flow channels on pressure drop and heat transfer is comprehensively considered, and compared with experimental data of a plurality of plate-fin heat exchangers, the simulation result has higher precision.

Owner:SOUTH CHINA UNIV OF TECH +1

Cable cover surface heat flux density and pressure measuring device and application method thereof

PendingCN114235220ASolve for Heat FluxSolve stressApparatus for force/torque/work measurementCalorimeterHeat flowFlight vehicle

The invention provides a cable cover surface heat flux density and pressure measuring device and a use method thereof, the structure comprises a cambered surface projection probe, a support and a bottom plate, the cambered surface projection probe, the support and the bottom plate are connected in sequence to form a closed housing; the cambered surface of the upper surface of the cambered surface protruding probe is consistent with the cambered surface of an aircraft provided with a cable cover, and the cambered surface protruding probe is provided with a plurality of connecting holes used for being connected with a heat flow sensor or a pressure sensor. The bottom plate is provided with wiring holes, and tail wires of the heat flow sensor and the pressure sensor penetrate through the wiring holes to be connected with external testing equipment. The cable cover surface cold wall heat flux density and pressure measuring device solves the problem of cable cover surface cold wall heat flux density and pressure measurement in a wind tunnel test, and is reasonable in structure, simple to mount and dismount, high in measurement precision, wide in measurement range and reusable.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com