Identification apparatus for surface heat flux of hypersonic flight vehicle and design method thereof

A hypersonic, aircraft technology, applied in measurement devices, thermometers using electrical devices, and directly sensitive electrical/magnetic components, etc., can solve the problems of large sensor size, difficulty in intensive measurement, and limited installation, etc. Achieve the effect of simple measurement structure, good environmental adaptability and small product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

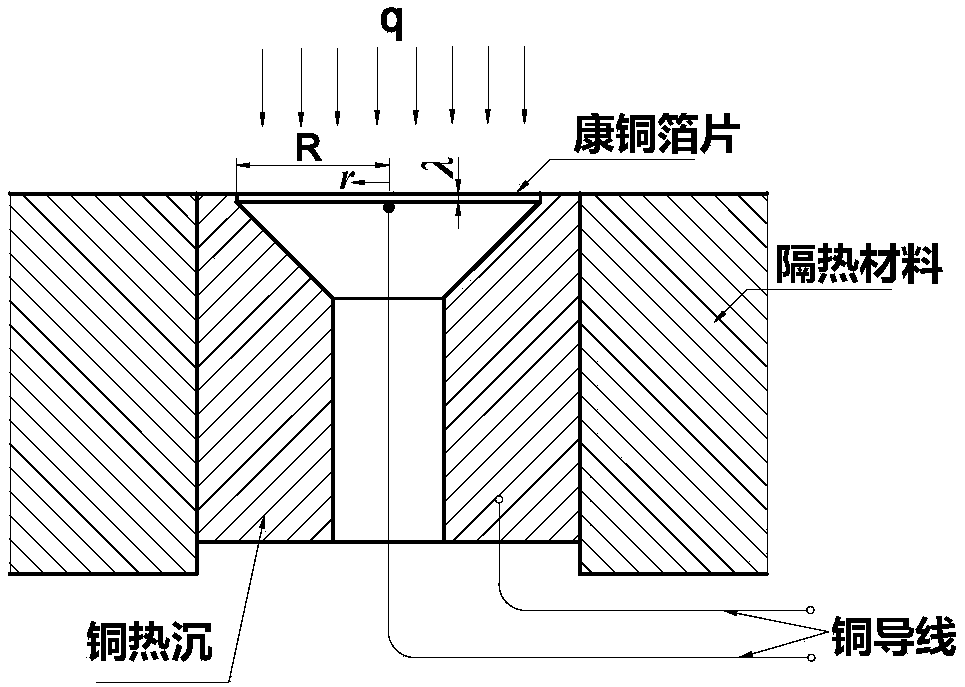

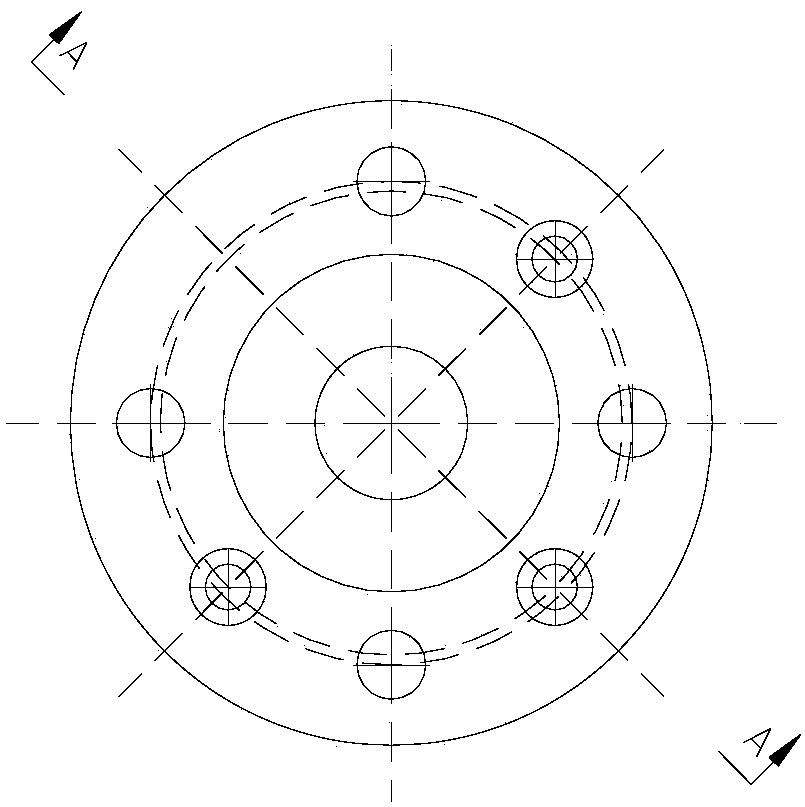

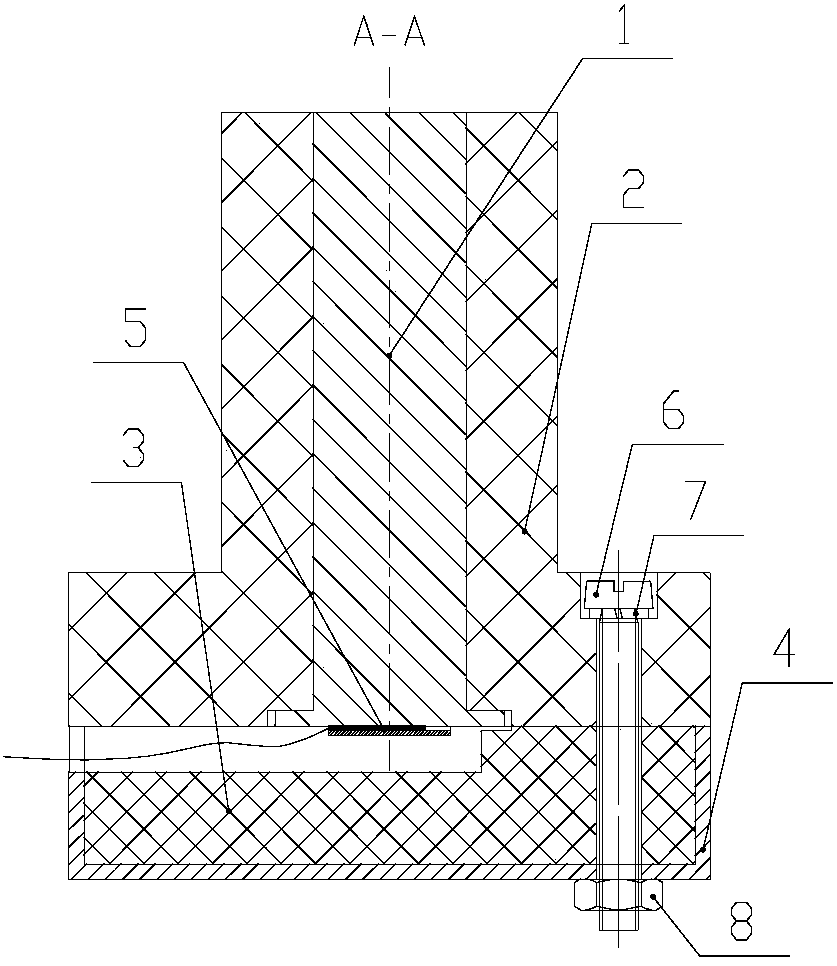

[0037] Aiming at the existing problems of heat flow sensors in the measurement of heat flow on the surface of hypersonic vehicles, the present invention provides an identification device and design method for heat flow on the surface of hypersonic vehicles, which is suitable for intensive measurement of long-term high heat flow. The technical characteristics of the device are: the heat flow identification device contains sensitive elements made of high thermal conductivity materials (such as copper), which can respond to the aerodynamic heating on the surface of the aircraft relatively quickly; by measuring the temperature change of the sensitive elements inside the heat flow identification device The temperature information is used to invert the heat flow on the surface of the measured position through the heat flow identification method based on inverse problem solving. Since the heat flow identification method in the present invention has no special requirements on the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com