Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Simple measurement structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machine vision-based ship hull six-degree-of-freedom measurement method

ActiveCN105809689AHigh-resolutionLift occupancyImage enhancementImage analysisRange of motionAngular degrees

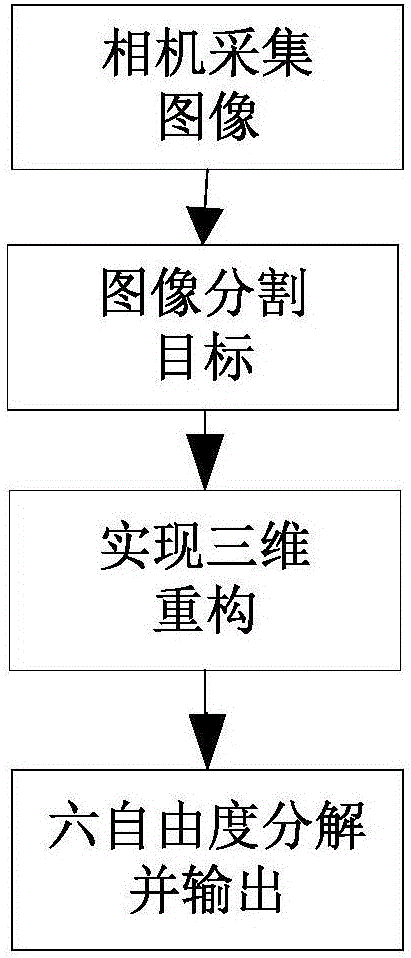

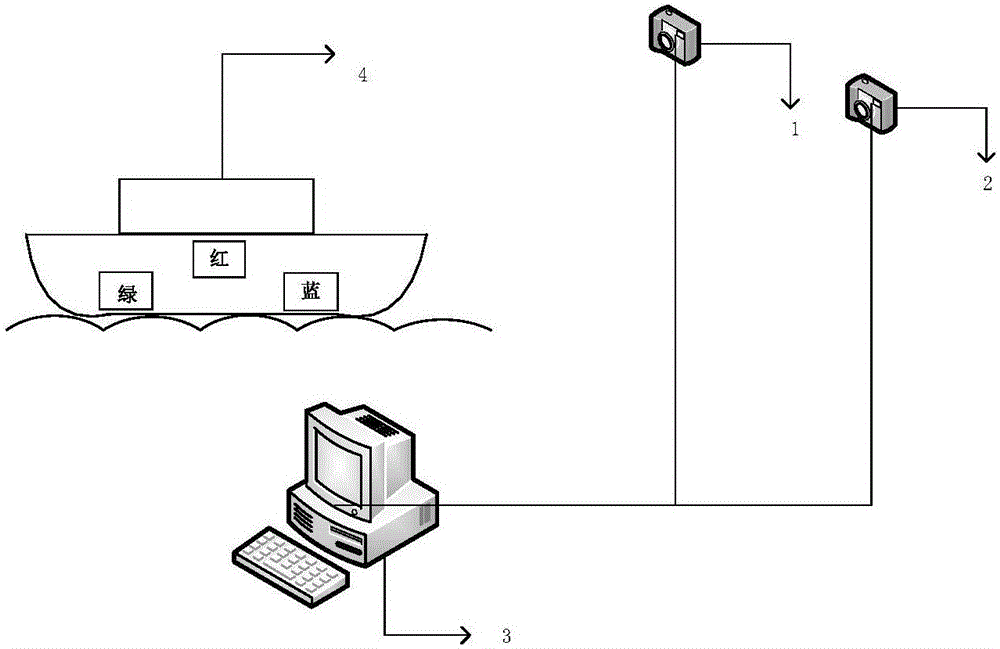

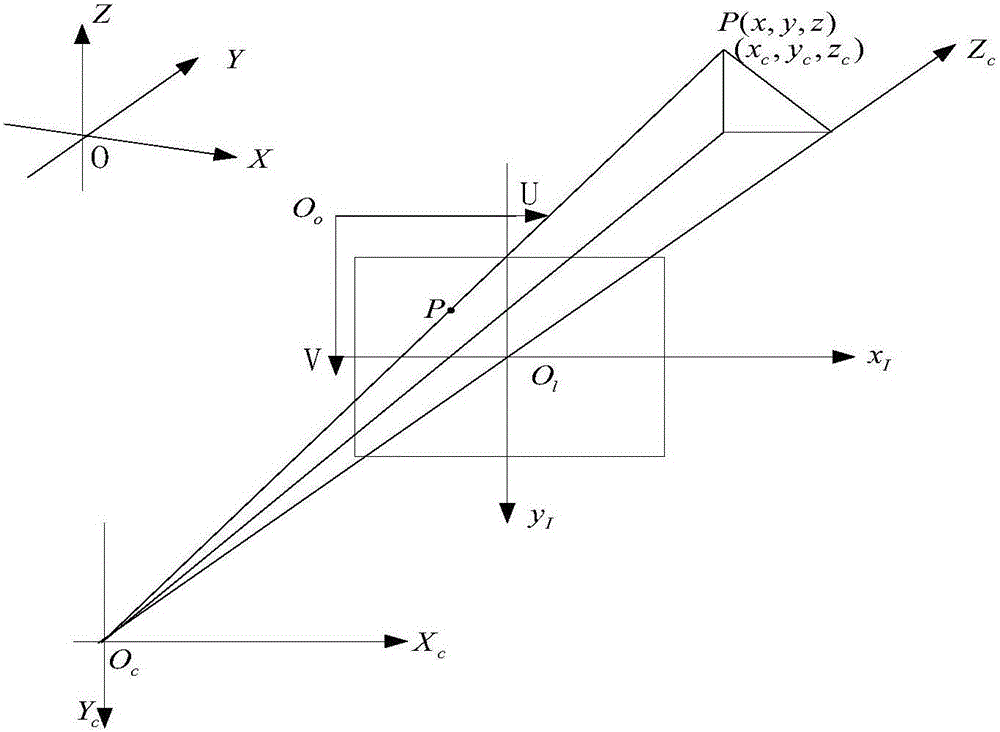

The invention discloses a machine vision-based ship hull six-degree-of-freedom measurement method. The method includes the following steps that: a RGB three-color marker is posted on a target ship, when the hull of the ship moves, the marker moves with the hull of the ship, two cameras are mounted at different positions, and the angles of the cameras are adjusted, so that the shooting range of the cameras can cover the movement range of the marker, and the cameras carry out image acquisition; images acquired by the cameras are preprocessed, and a RGB color occupancy volume-based segmentation algorithm is adopted to perform image segmentation operation, so that boundary parameters can be obtained, qualified feature points are made to be contained in a boundary range; and a binocular three-dimensional reconstruction method is adopted to obtain the three-dimensional coordinate values of the feature points; and the six degrees of freedom of the hull of the ship are decomposed, and the three-dimensional coordinates of P (x, y, z) at any one time point and the coordinates P'(x', y',z') of a next time point are known, so that a translation vector T(delta x, delta y, delta z) and a rotation vector R (alpha, beta, gamma) which are corresponding to the movement of the hull of the ship are obtained. With the machine vision-based ship hull six-degree-of-freedom measurement method of the invention adopted, real-time and non-contact measurement of six-degree-of-freedom movement of the hull of the ship in regular waves and irregular waves can be realized, and accuracy satisfies engineering requirements.

Owner:华研智兴(青岛)科技有限公司

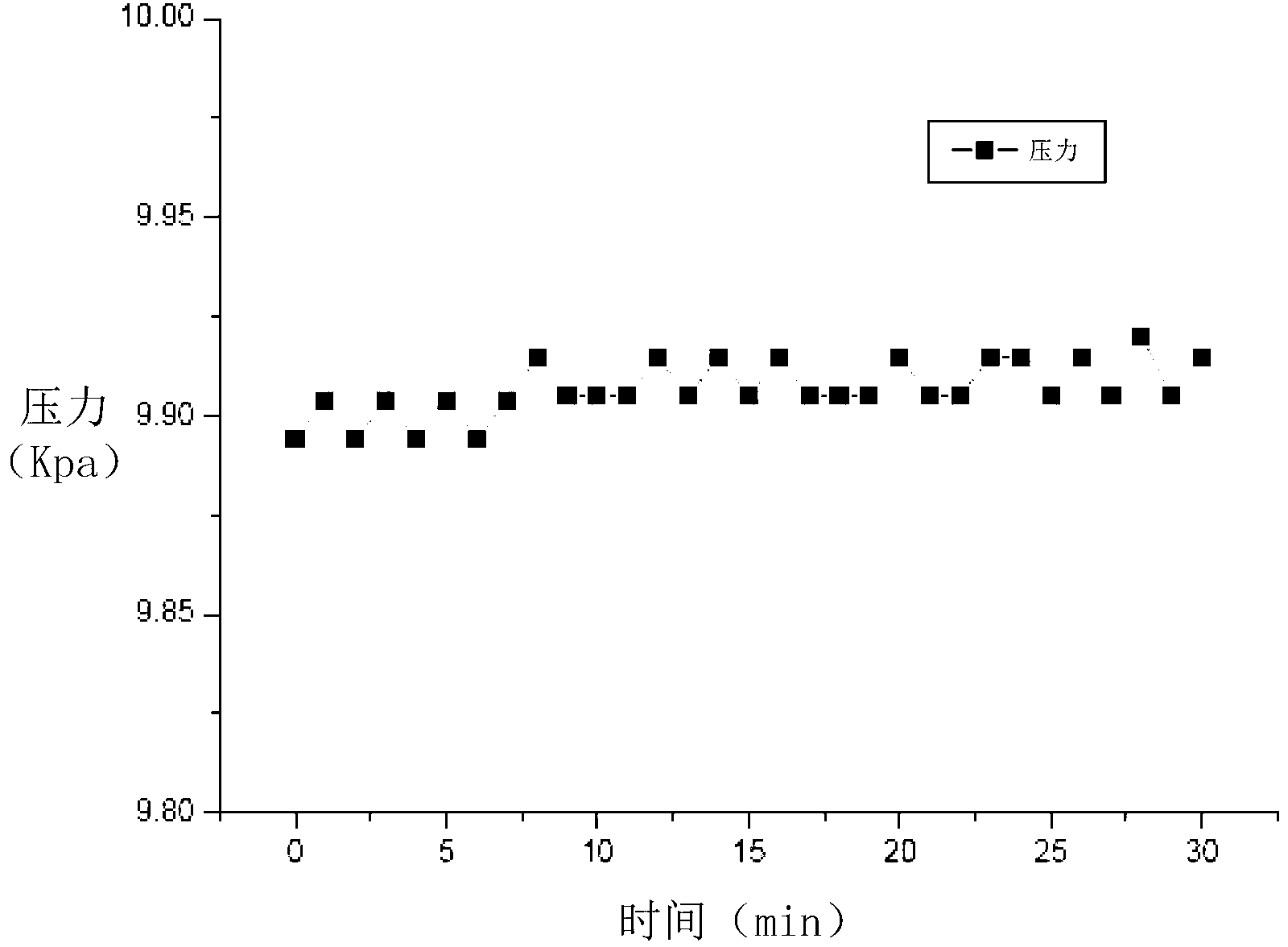

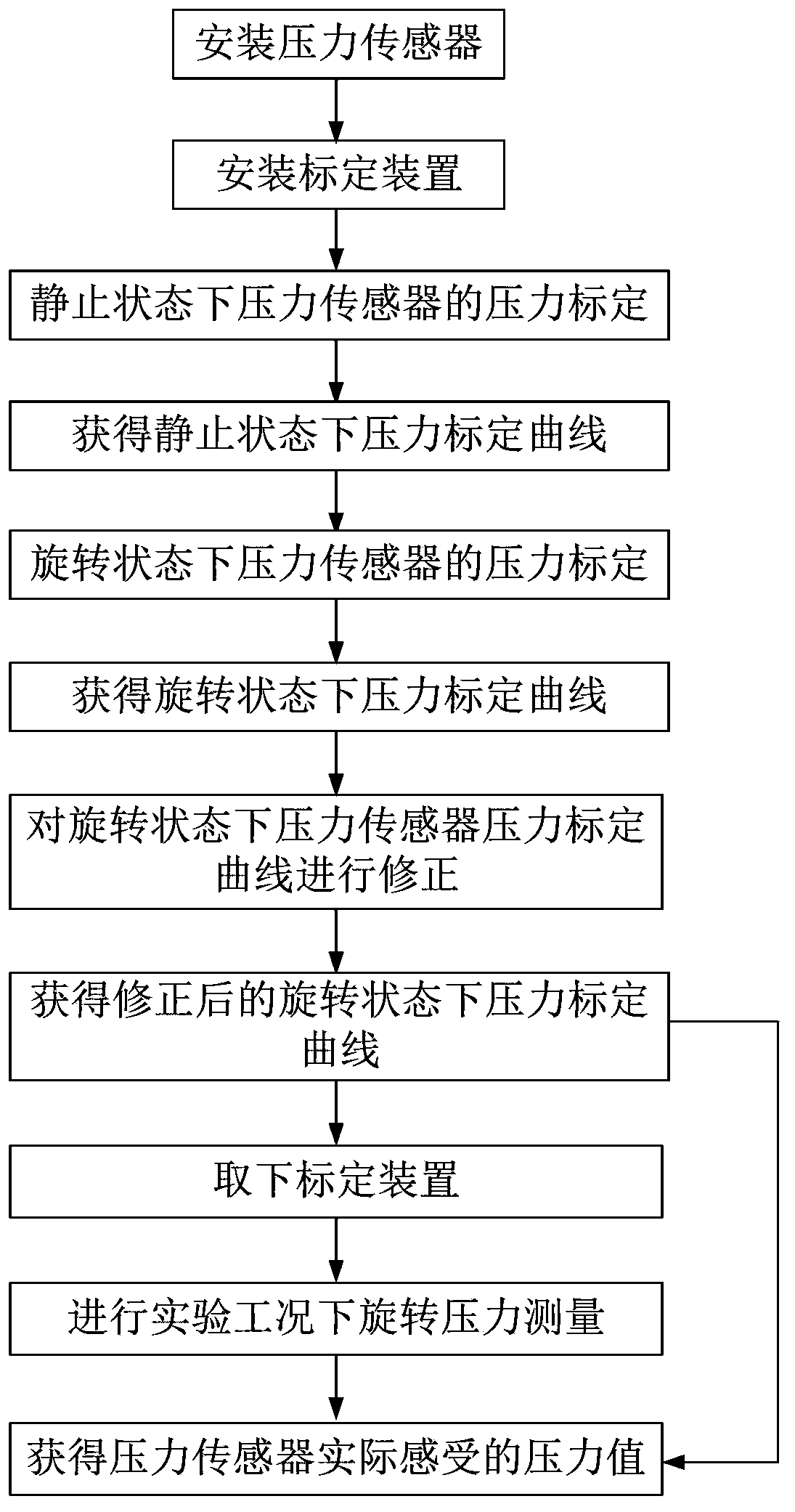

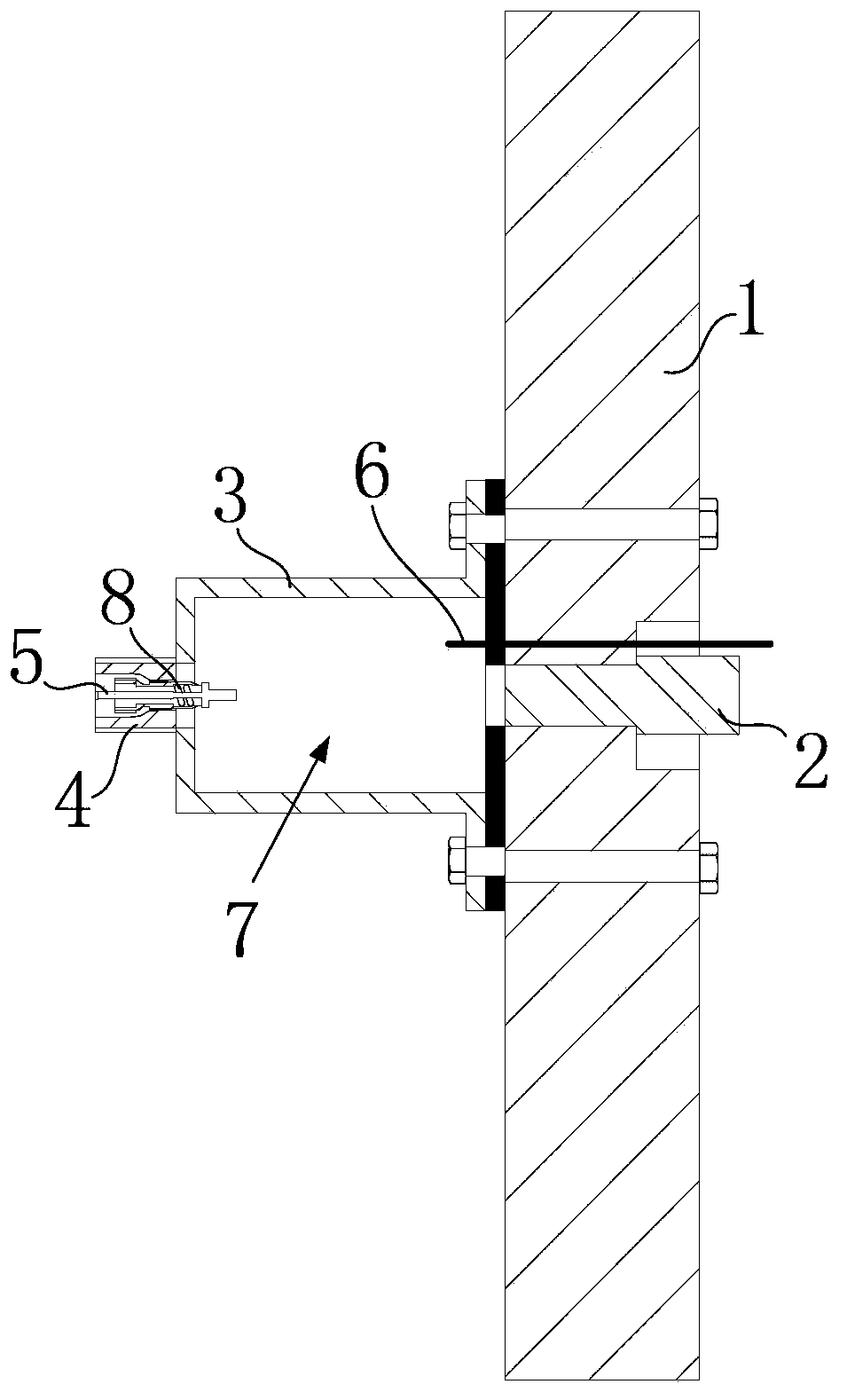

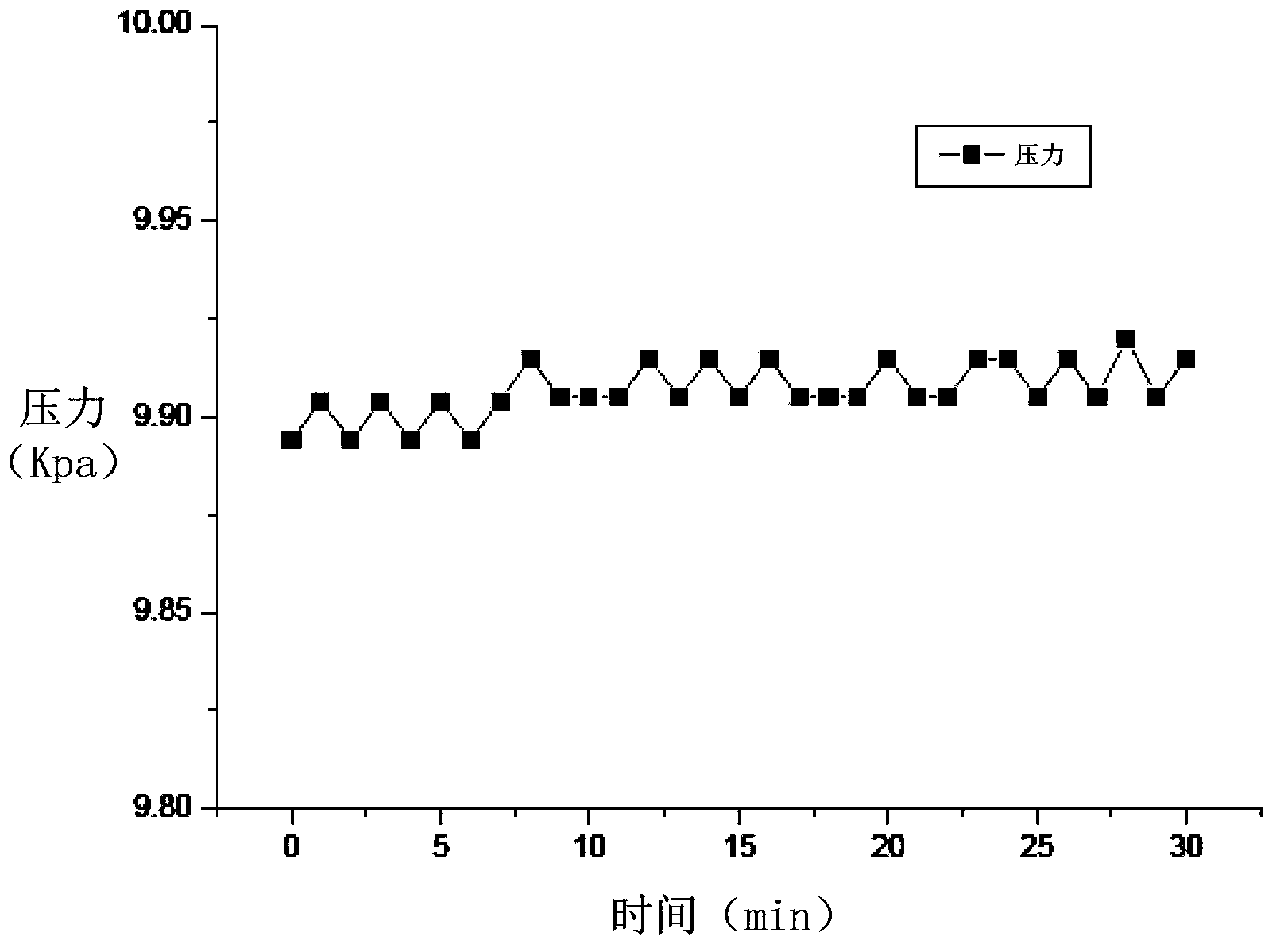

Method for measuring pressure in rotating state

InactiveCN102798496ASimple measurement structureAvoid experimental errorFluid pressure measurement by electric/magnetic elementsEngineeringStationary state

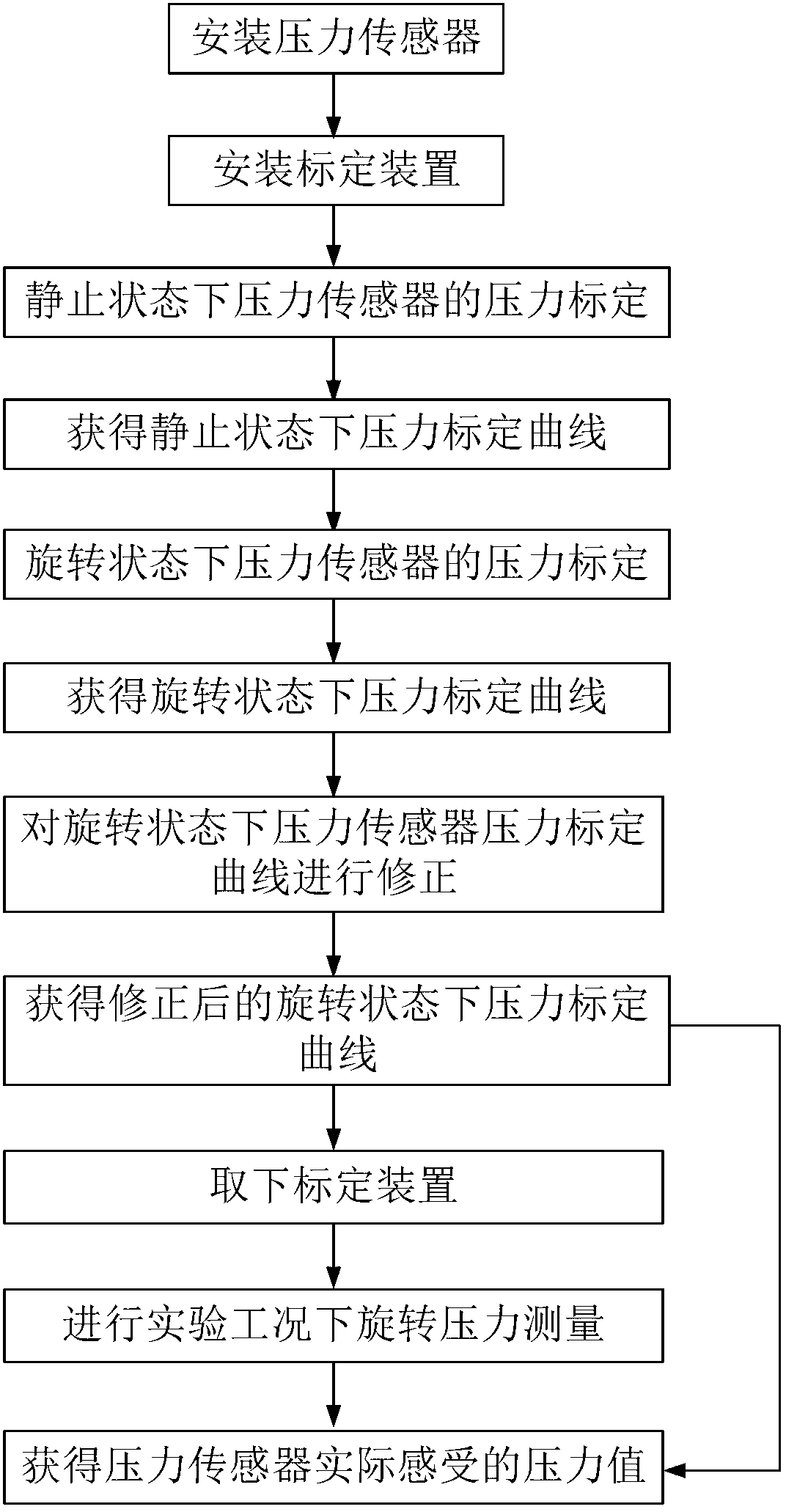

The invention discloses a method for measuring pressure in a rotating state. The method comprises: installing a demarcating device on a test piece to form a pressure-tight demarcating chamber, feeding gas into the demarcating chamber, measuring voltage signal values of a sensor and gas pressure values of the corresponding chamber, fitting a curve to obtain a pressure calibration curve in a stationary state; feeding gases with different pressures in the demarcating chamber and rotating the test piece at different rotating speed, measuring the voltage signal values of the sensor corresponding the gas pressure in the present demarcating chamber under each rotating speed, fitting a curve to obtain a pressure calibration curve in the rotating state; obtaining an actual pressure value of the demarcating chamber through temperature of the demarcating chamber under each rotating speed, and modifying the pressure calibration curve in the rotating state; and combining the modified calibration curve and the signal values under each rotating speed measured by the pressure sensor in a test condition to obtain an actual pressure value of the pressure sensor. The method for measuring pressure in the rotating state makes test results capable of being reference, and ensures measuring precision of the test at the same time.

Owner:BEIHANG UNIV

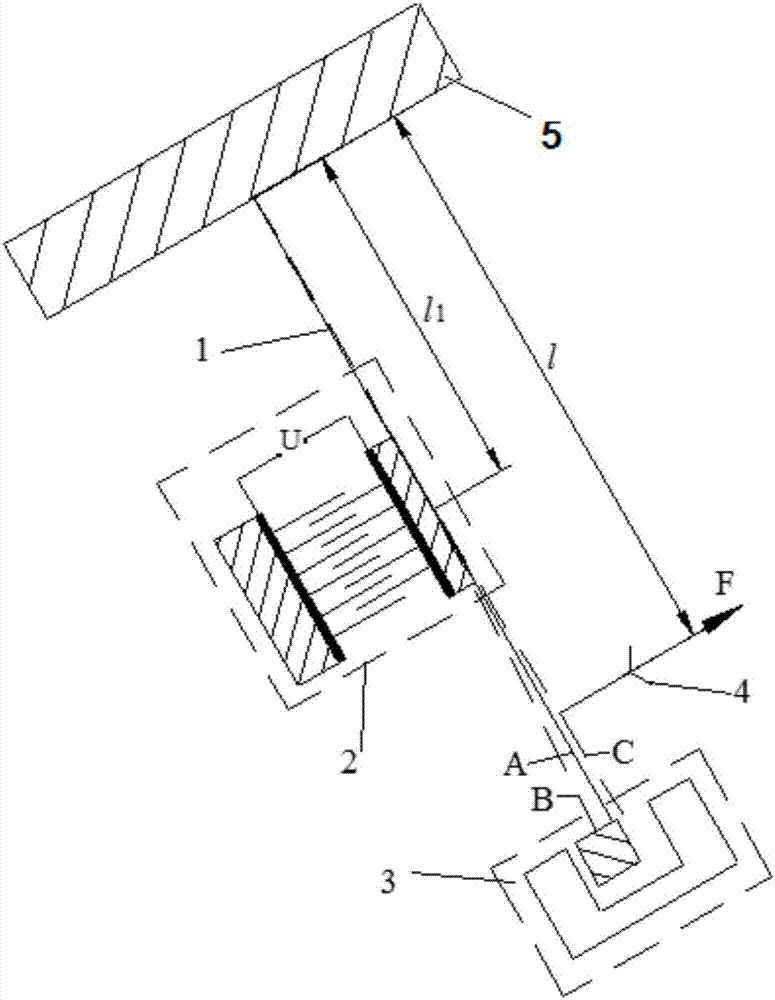

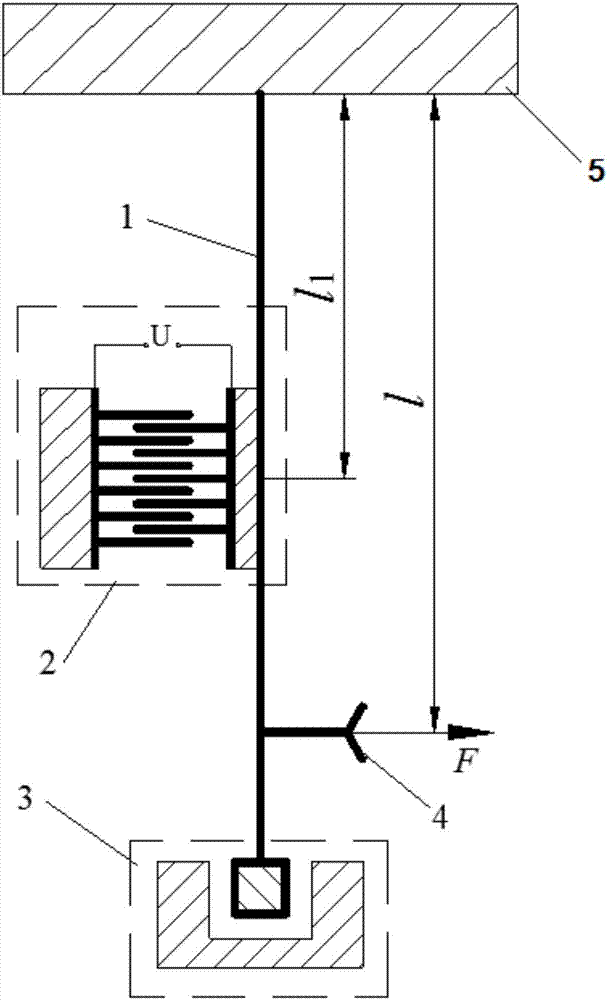

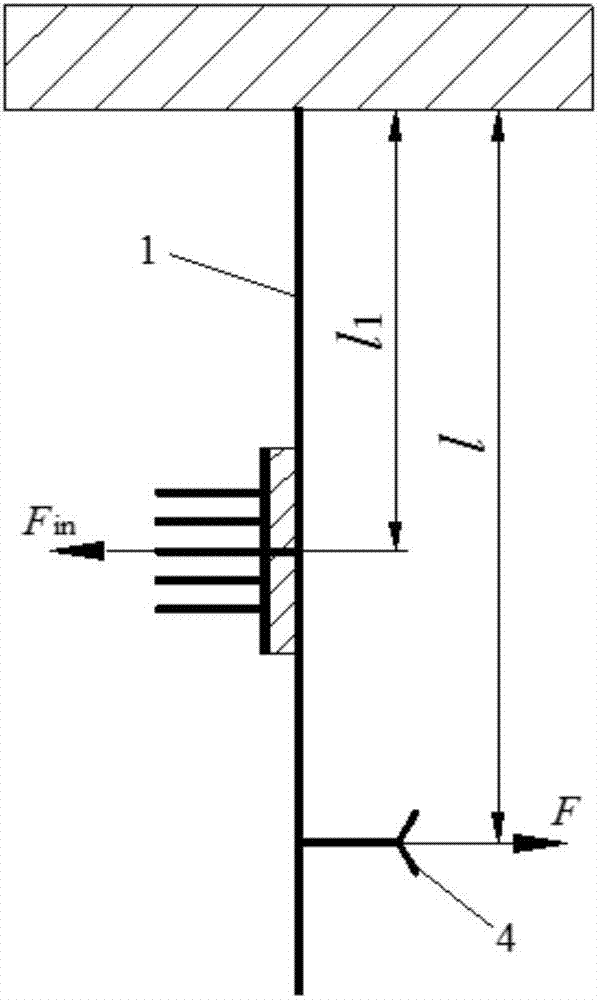

Multidirectional micro-nano force measurement device and method

PendingCN107219026ASimple measurement structureReduce cost of measurementForce measurementFluid pressure measurementMechanical engineeringPhysics

The invention discloses a multidirectional micro-nano force measurement device and method. The device comprises a loading mechanism, a standard micro-nano force value generation device, an elastic supporting mechanism and a position measurement device, wherein a tail end of the elastic supporting mechanism is connected with the position measurement device, and the standard micro-nano force value generation device and the loading device are mounted at two sides of the elastic supporting mechanism. The method comprises steps that the balance position of the elastic supporting mechanism is acquired; a measured micro-nano force value is applied to the elastic supporting mechanism through the loading mechanism to make the elastic supporting mechanism deviate from the balance position; magnitude of electrostatic force of the standard micro-nano force value generation device is adjusted to make the elastic supporting mechanism recover to the balance position from a position deviating from the balance position; the measured micro-nano force value is calculated according to magnitude of the electrostatic force of the standard micro-nano force value generation device during recovery to the balance position. The method is advantaged in that the method is independent of measurement directions of micro-nano force values, so the micro-nano force in any space direction can be measured, and the method can be widely applied to the force measurement field.

Owner:广东省计量科学研究院(华南国家计量测试中心)

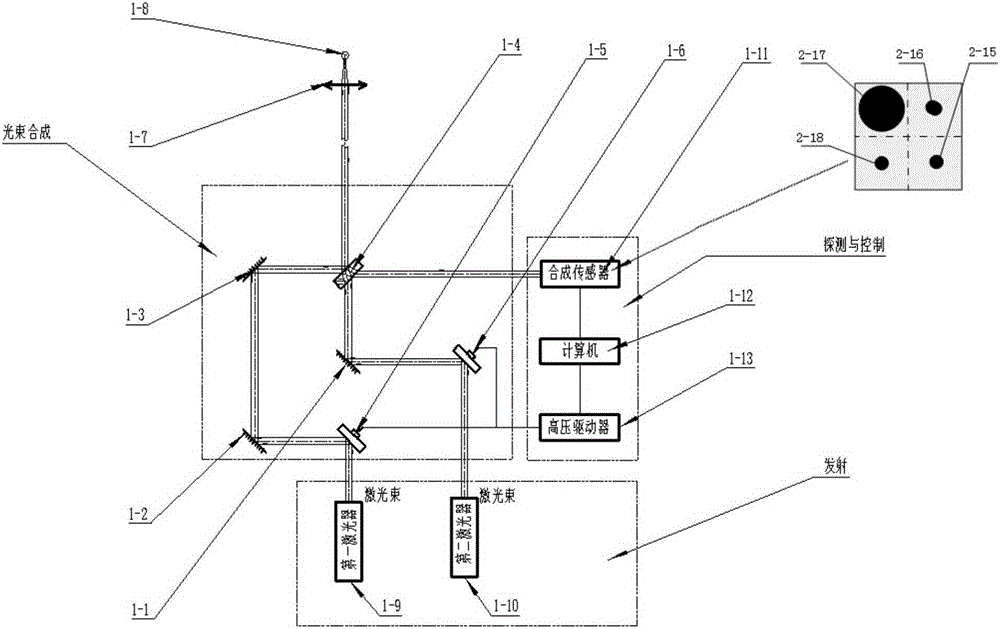

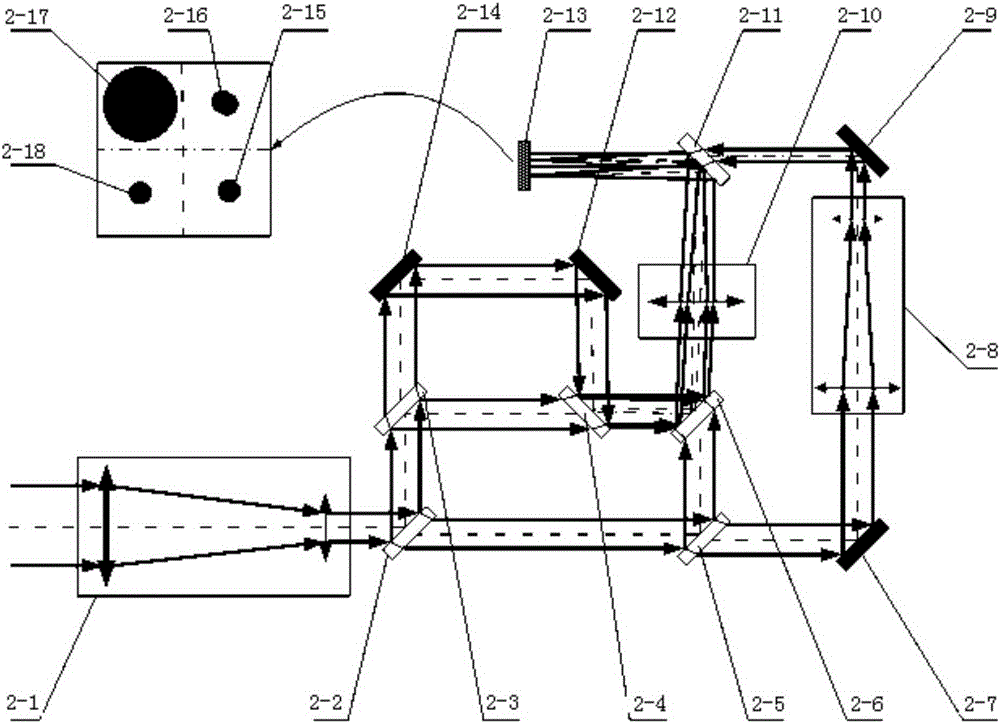

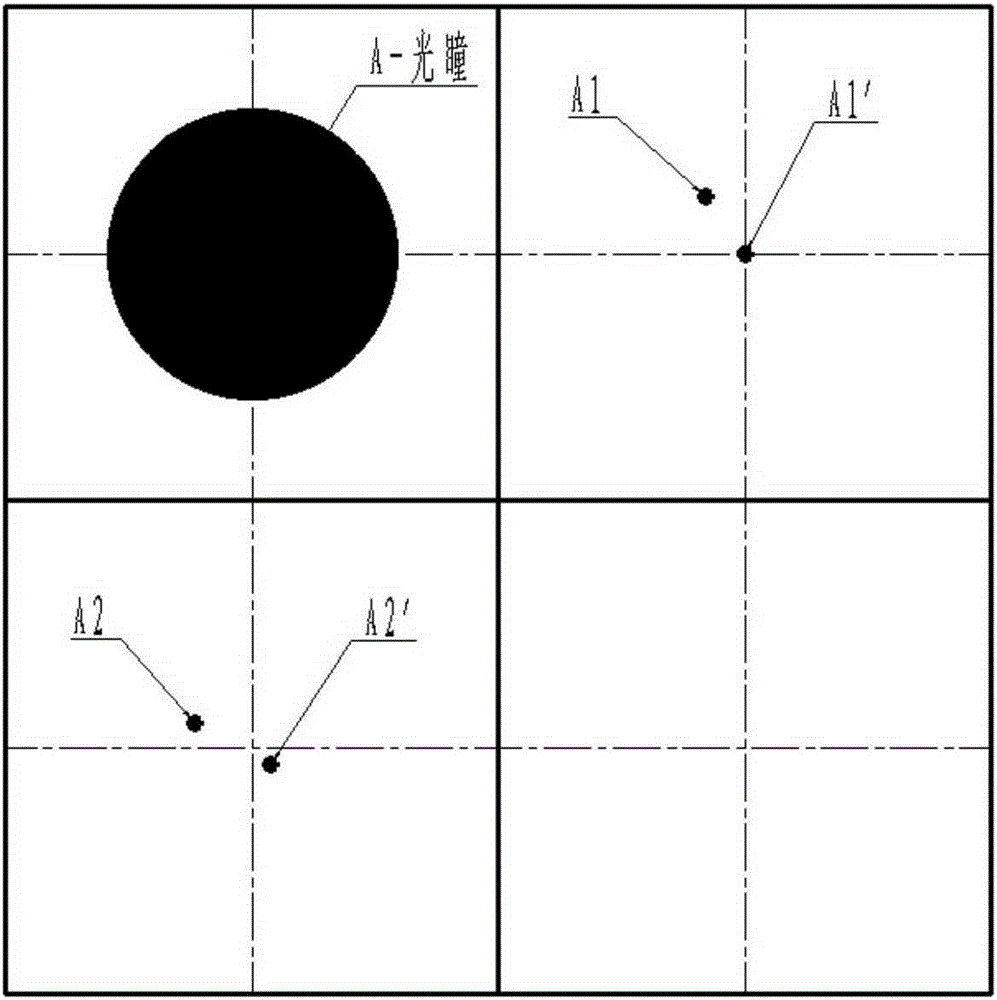

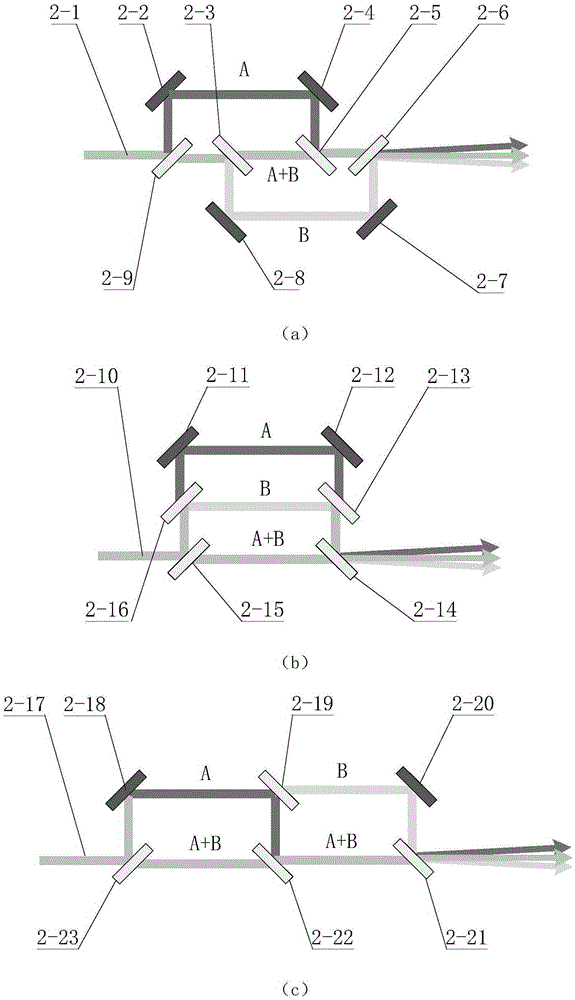

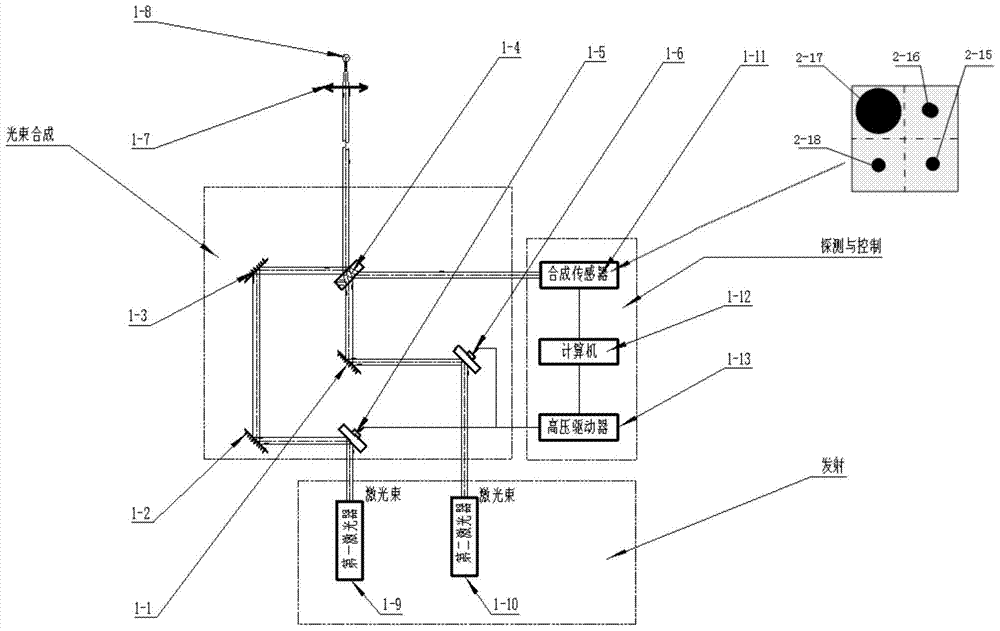

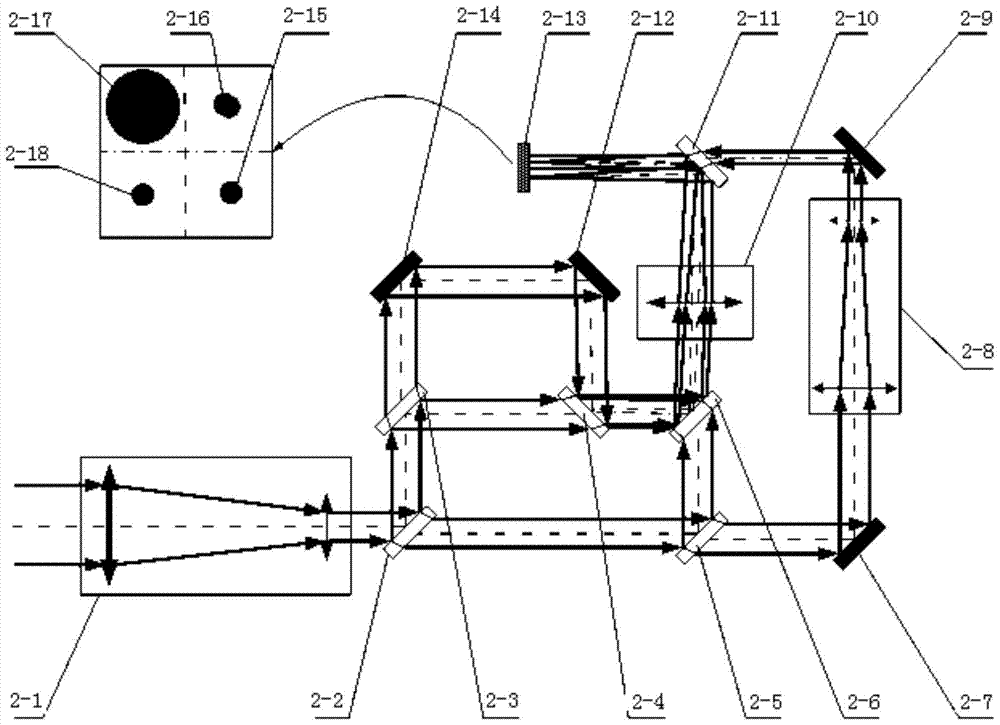

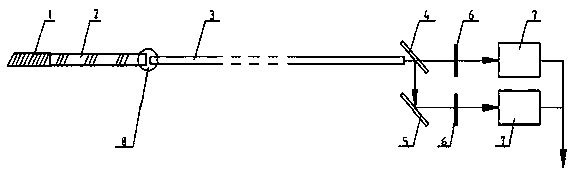

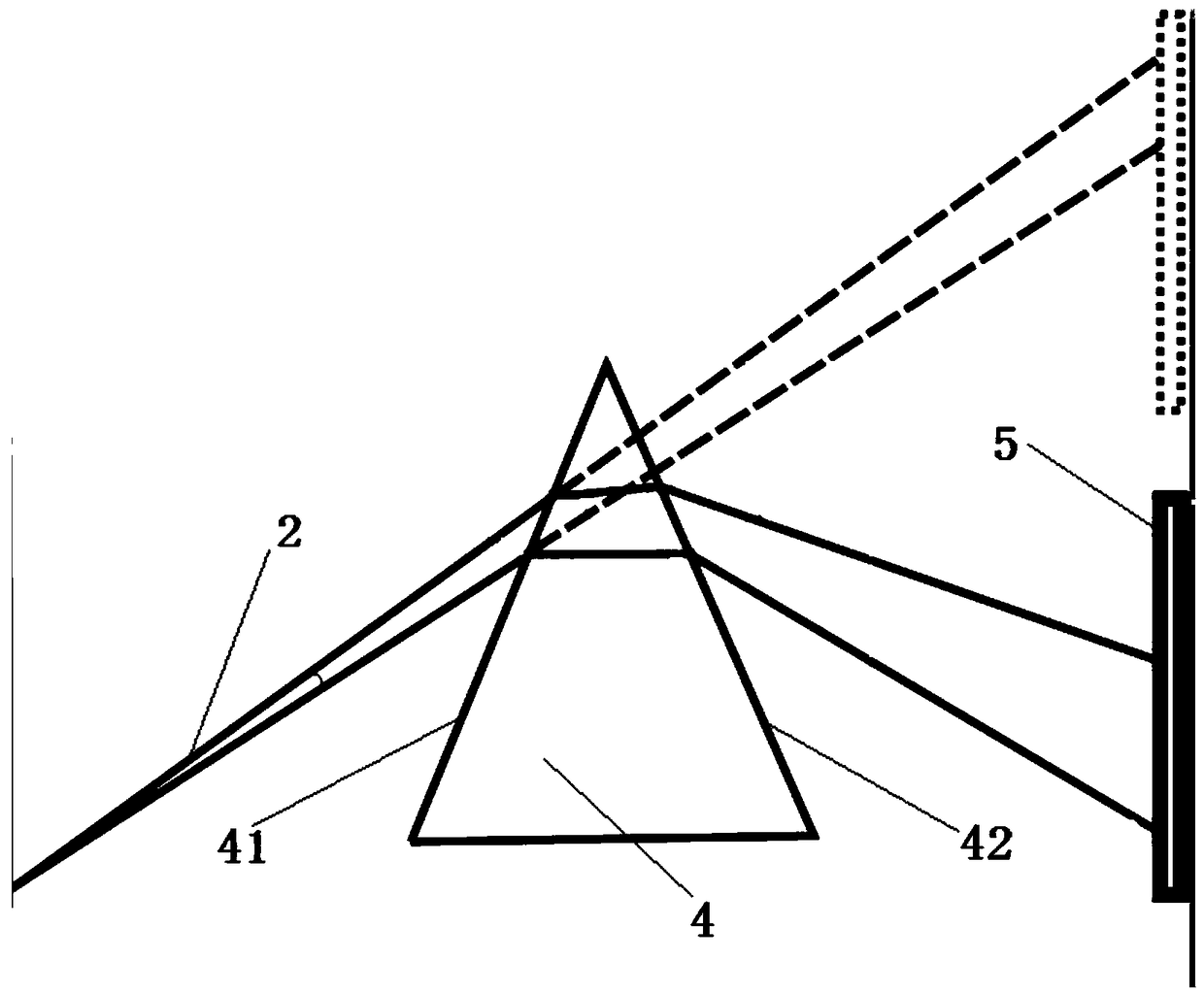

Calibration method for synthesizing far field through single detector to improve double-beam synthesis precision and pointing accuracy

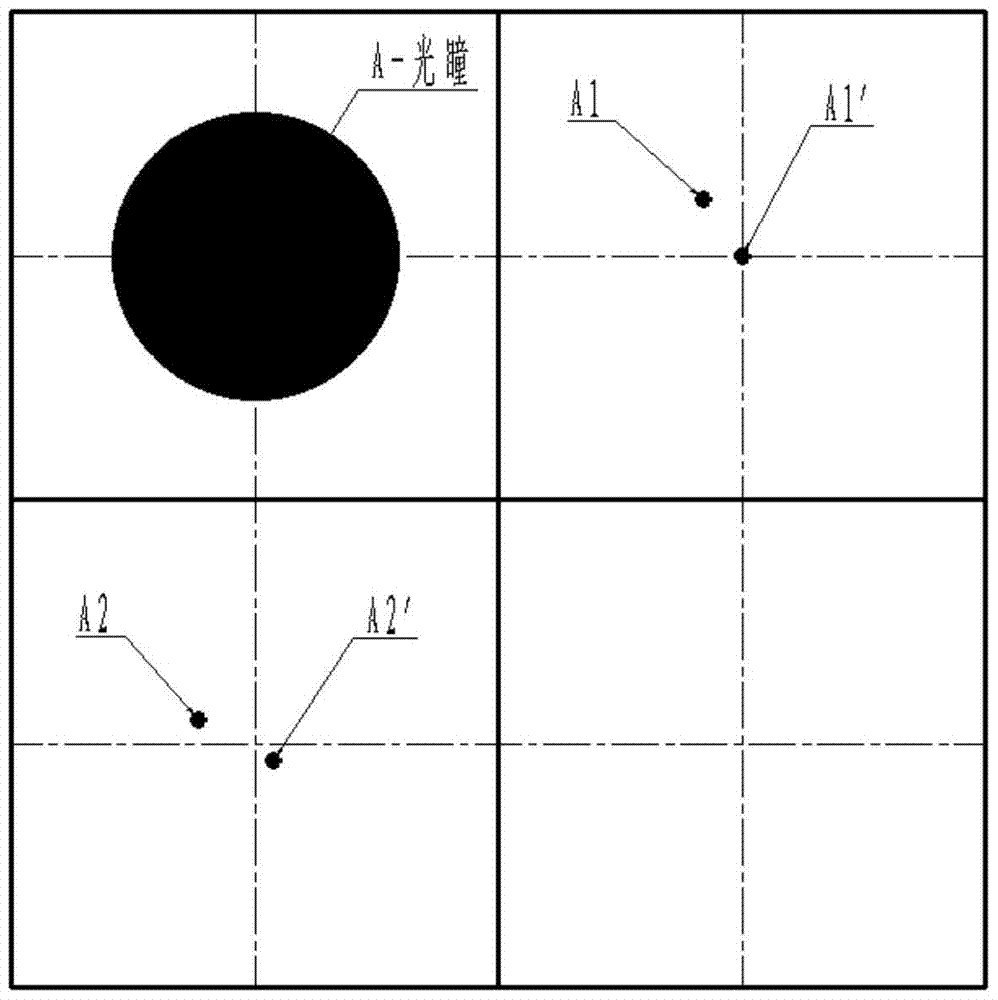

ActiveCN105334028AAvoid thermal driftGuaranteed identityTesting optical propertiesAbsolute zeroOptical axis

The invention discloses a calibration method for synthesizing a far field through a single detector to improve double-beam synthesis precision and pointing precision. According to the calibration method, the detection target surface of the same detector is subjected to area division, and four paths of measurement information are adjusted into four different areas which correspond to the real-time state information of a beam combination pupil, beam combination optical axes, a path A laser optical axis and a path B laser optical axis respectively. A path of laser and B path of laser are used for emitting light in the calibration process, the beam combination optical axes A1' and B1' are located on the absolute zero point of the center of the area in a closed loop mode, and after the coordinates of the beam combination optical axes A2' and B2' are respectively calculated, closed loop work is performed with the beam combination optical axes A2' and B2' as zero points. By means of the calibration method, calibration cost can be substantially reduced, a calibration structure is simplified, errors caused by equipment environment temperature and vibration are effectively eliminated, synthesis precision and stabilization precision of double beams on the target face of the detector are guaranteed, and therefore the synthesis precision and the pointing precision of output laser beams are improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

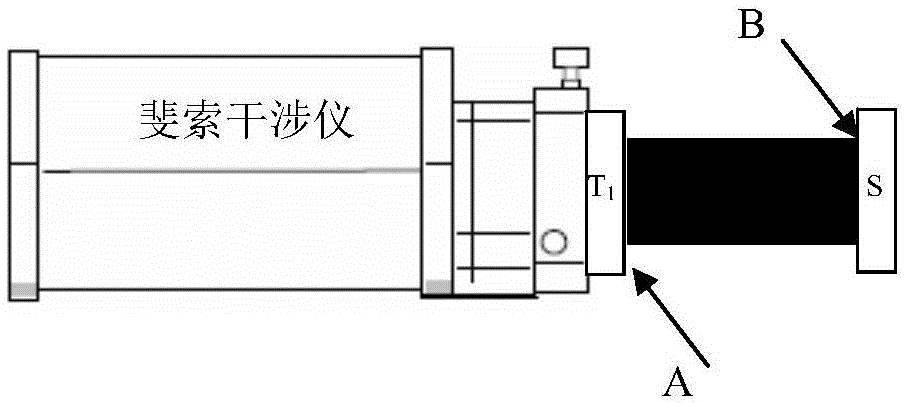

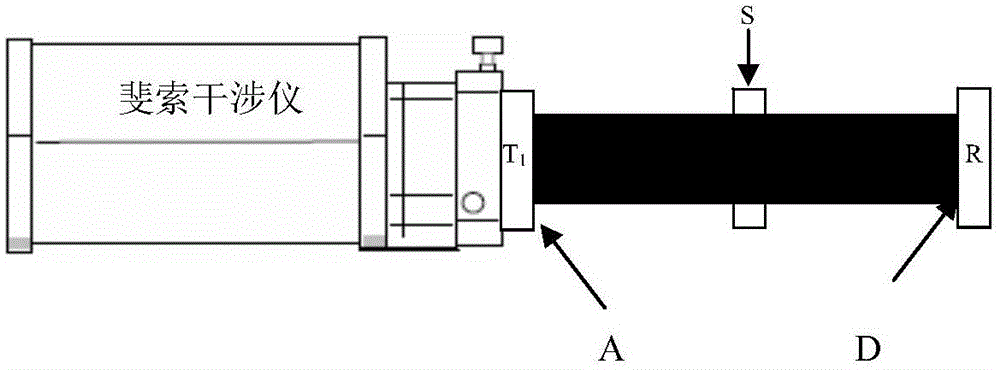

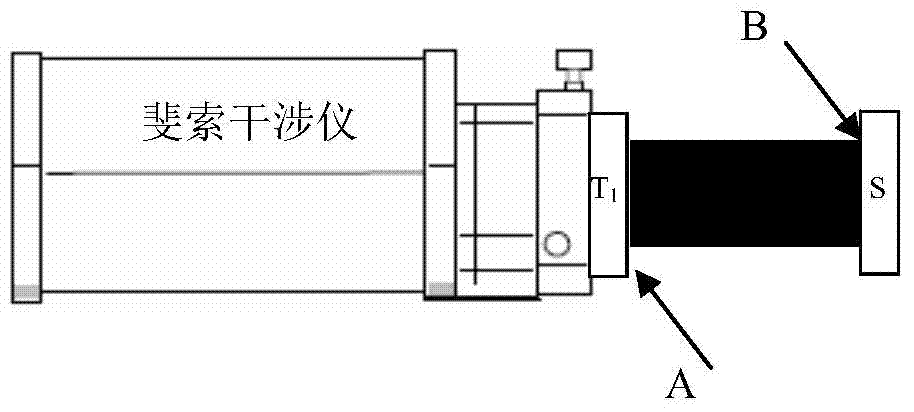

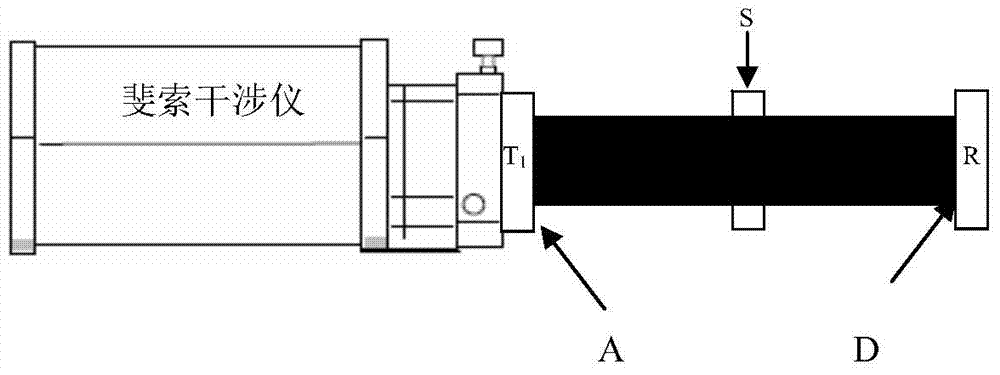

Parallel flat crystal optical inhomogeneity absolute measurement method

ActiveCN105092530AHigh measurement accuracyEasy to implementPhase-affecting property measurementsAbsolute measurementOptoelectronics

The invention discloses a parallel flat crystal optical inhomogeneity absolute measurement method. The method comprises the following steps: carrying out primary interference measurement on the working face of a first transmission reference flat crystal and a front surface of a to-be-measured parallel flat crystal; placing a reflective reference flat crystal behind the to-be-measured parallel flat crystal, and carrying out primary interference measurement on the working face of the first transmission reference flat crystal and the working face of the reflective reference flat crystal; carrying out primary interference measurement on the working face of the first transmission reference flat crystal and the rear surface of the to-be-measured parallel flat crystal; carrying out primary cavity interference measurement on the working face of the first transmission reference flat crystal and the working surface of the reflective reference flat crystal; replacing the first transmission reference flat crystal with a second transmission reference flat crystal, and carrying out primary interference measurement on the working face of the second transmission reference flat crystal and the working face of the first transmission reference flat crystal; carrying out primary interference measurement on the working face of the second transmission reference flat crystal and the working face of the reflective reference flat crystal; and synthesizing measurement results, to obtain the optical inhomogeneity of the to-be-measured parallel flat crystal. The method is simple, feasible, accurate and efficient, and the measured object is not restricted by the parallel degree of the front surface and the rear surface.

Owner:NANJING UNIV OF SCI & TECH

Method and apparatus for the detection of cracks in the teeth of generator rotors

InactiveCN101413924ASimple measurement structureEasy to useAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveWedge angle

Owner:ALSTOM TECH LTD

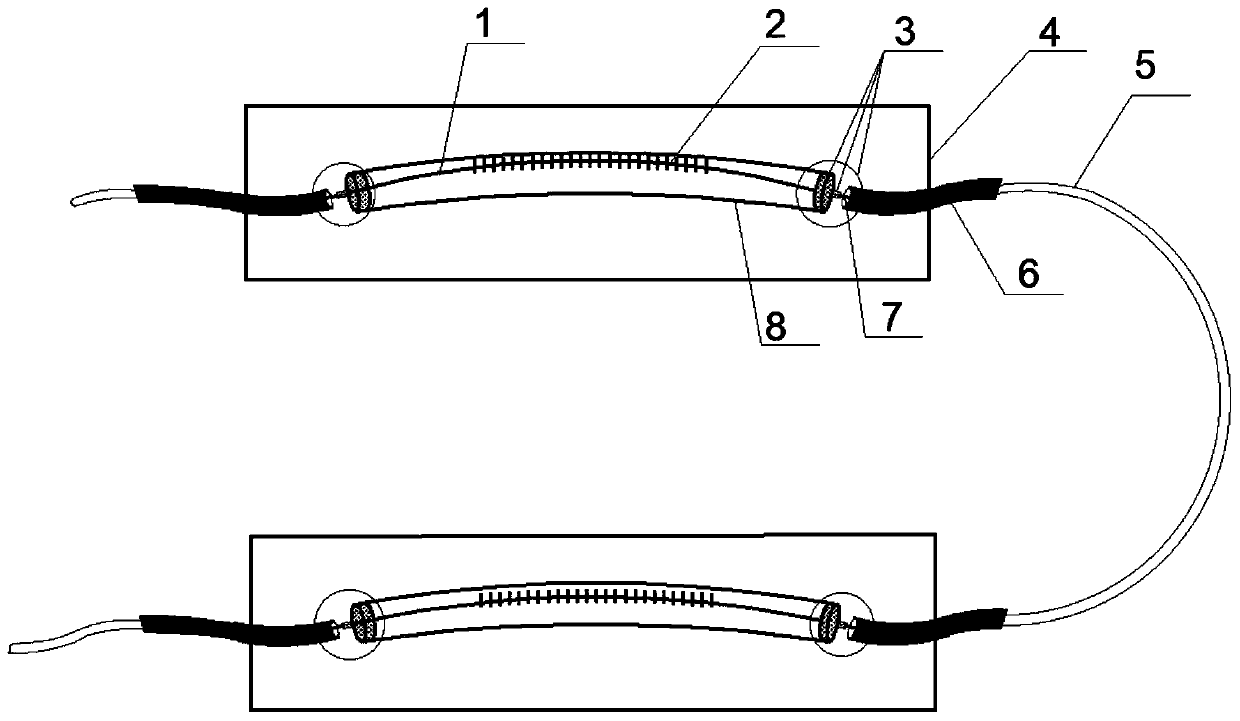

Distributed liquid temperature sensor based on fiber bragg grating

InactiveCN110954242ASimple measurement structureImprove long-term stabilityThermometer detailsThermometers using physical/chemical changesAdhesiveCapillary Tubing

The invention discloses a distributed liquid temperature sensor based on a fiber bragg grating. The sensor comprises a temperature measurement fiber grating, a stainless steel capillary tube, a substrate and a heat shrink tube, optical fiber jumper, the fiber bragg grating passes through the bent capillary tube after the coating layer is removed; the axis of the capillary steel pipe is not parallel; two ends of the stainless steel capillary tube respectively fix the optical fiber in the central area of the substrate through adhesives, the optical fiber area covered by the adhesives is not provided with a coating layer, and through the above packaging, the fiber bragg grating is ensured to resist external tension and optical fiber elongation caused by thermal expansion and cold contractionof the capillary tube, and the influence of thermal stress is isolated. The distributed liquid temperature sensor based on the fiber bragg grating has the advantages of being simple in structure, firmin installation and convenient to assemble and disassemble. The device has the characteristics of wide measurement range, high measurement precision and distributed measurement in function; and electromagnetic interference resistance and chemical corrosion resistance can be realized.

Owner:WUHAN UNIV OF TECH

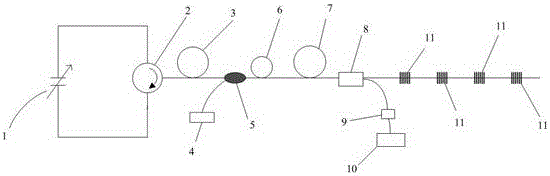

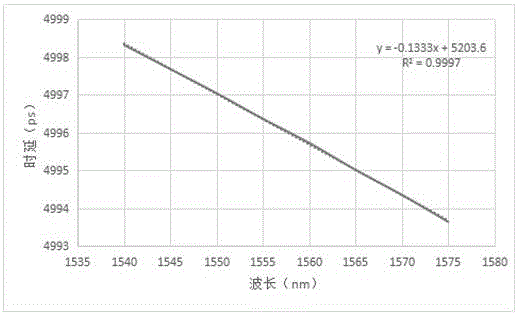

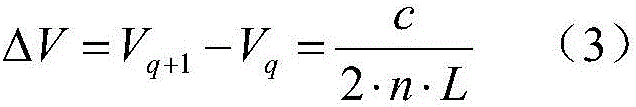

Fiber dispersion measuring method based on F-P adjustable filter

InactiveCN106596055ASimple measurement structureImprove stabilityTesting optical propertiesTesting fibre optics/optical waveguide devicesFrequency spectrumFiber chromatic dispersion

The invention discloses a fiber dispersion measuring method based on an F-P adjustable filter. The wavelength of a tunable laser can be scanned by changing the voltage of piezoelectric ceramics, fiber gratings of different central wavelengths are selected, change of the beat frequency in a fiber resonant cavity is realized, groups of different data are obtained in a spectrum analyzer, time delay without a fiber to be measured of different wavelengths is measured after wavelength scaling, time delay with the fiber to be measured is measured, a series of correspondences between the dispersion amounts of the fiber to be measured and the wavelengths under different wavelengths are obtained, and the dispersion of the fiber to be measured is measured accurately. The tunable fiber laser structure is used, the fiber to be measured in the fiber resonant cavity, a multi-longitudinal-mode beat frequency is used to measure the fiber dispersion, measurement of optical signals is converted into measurement of electric signals, convenience is provided for data processing, the method is not influenced by system loss and light source flucturation, and the fiber dispersion is measured successfully.

Owner:HENAN NORMAL UNIV

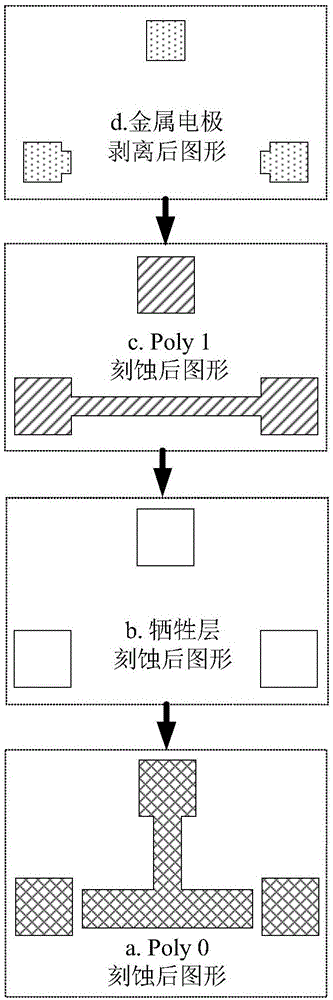

Online measurement method and measurement apparatus of residual stress of conductive thin film material

ActiveCN106248280ALower requirementEasy loadingMaterial strength using tensile/compressive forcesApparatus for force/torque/work measurementElectricityYoung's modulus

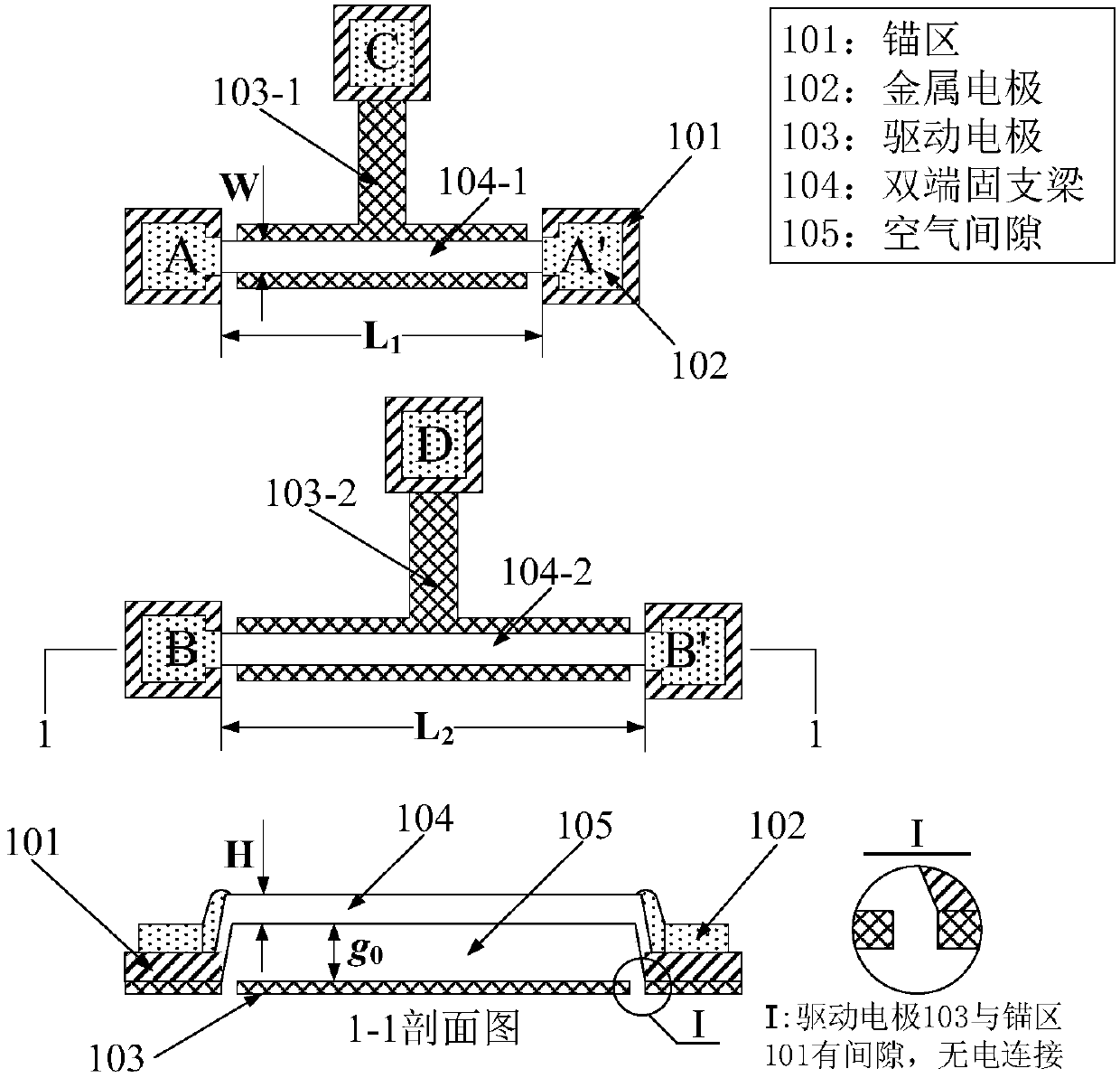

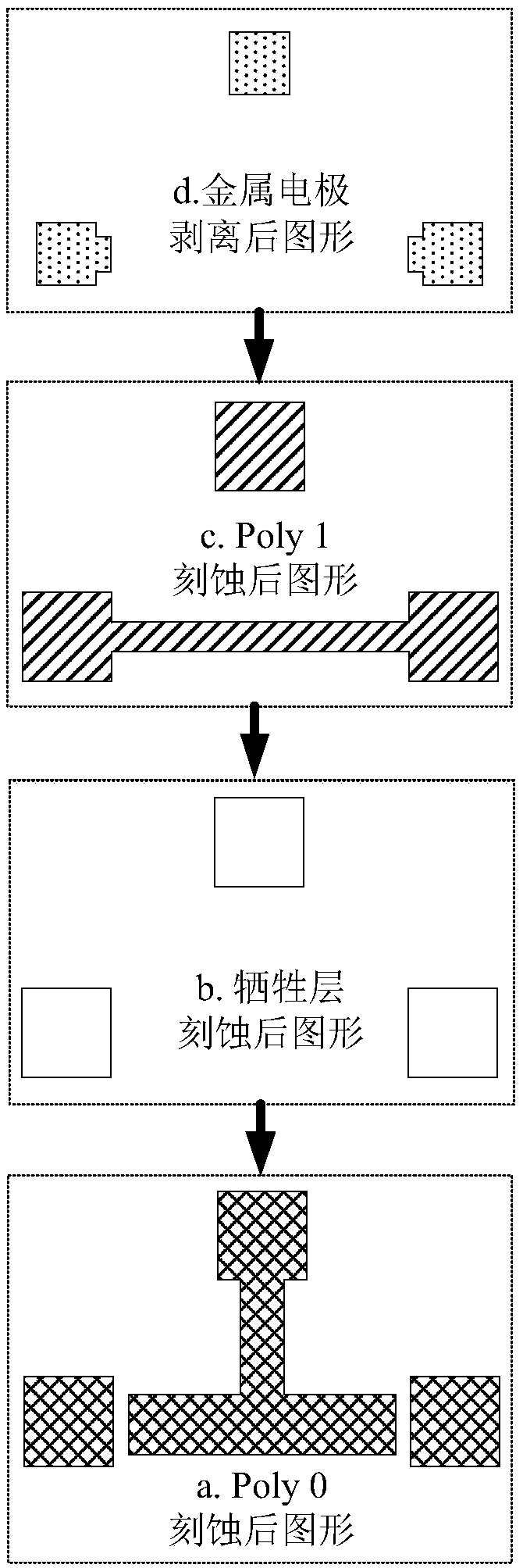

The invention brings forward an online measurement method of residual stress of a conductive thin film material, and a corresponding measurement apparatus. A measurement structure is designed by use of an electrostatic driving Pull-in principle, relevance of parameters of two measurement members is controlled through use of synchronous processing control, through limiting correlation parameters of total strain energy of the two measurement members, a partial differential equation set of the total strain energy is constrained accordingly, and values of unknown residual stress sigma 0 and a Young's modulus E of the two measurement members are obtained through a mode of solving the partial differential equation set. According to the invention, the problem of incapability of real-time measurement of the conductive thin film material under the condition of unknown material parameters, unknown residual stress size and unknown positivity and negativity (tensile stress or compression stress) is solved. The apparatus and method have the advantages of simple measurement structure, simple electric signal loading and measurement, stable calculation method and high measurement efficiency.

Owner:SOUTHEAST UNIV

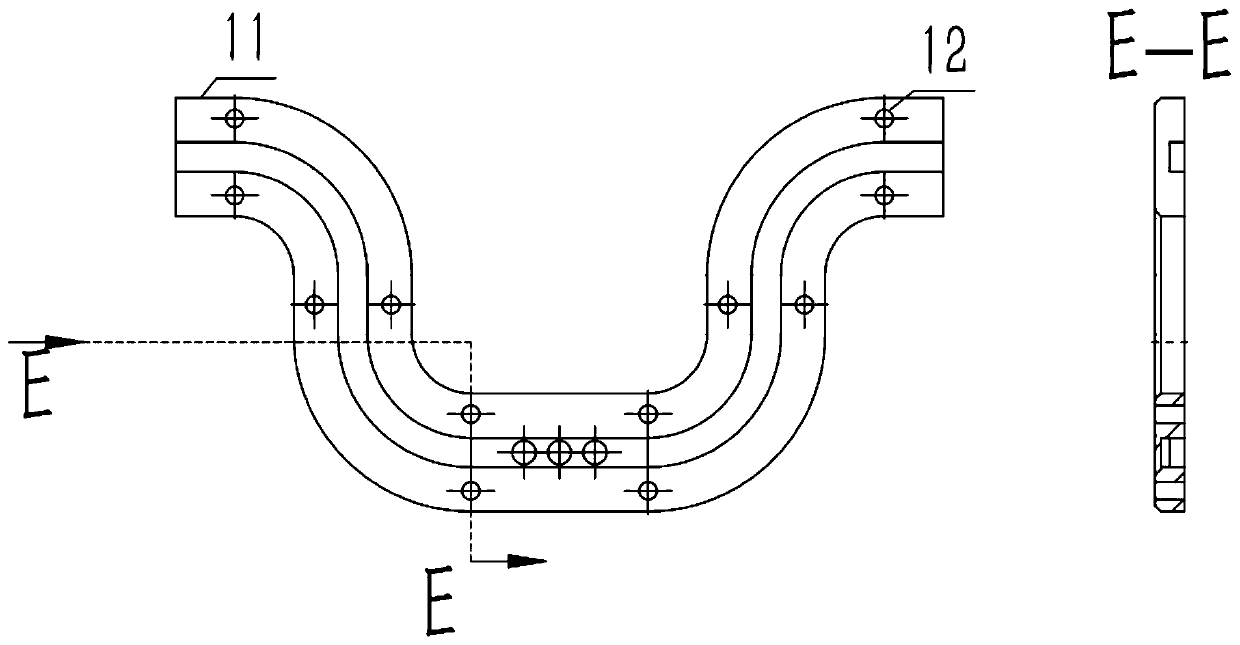

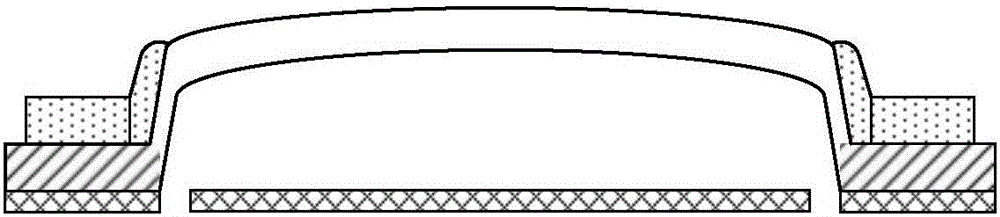

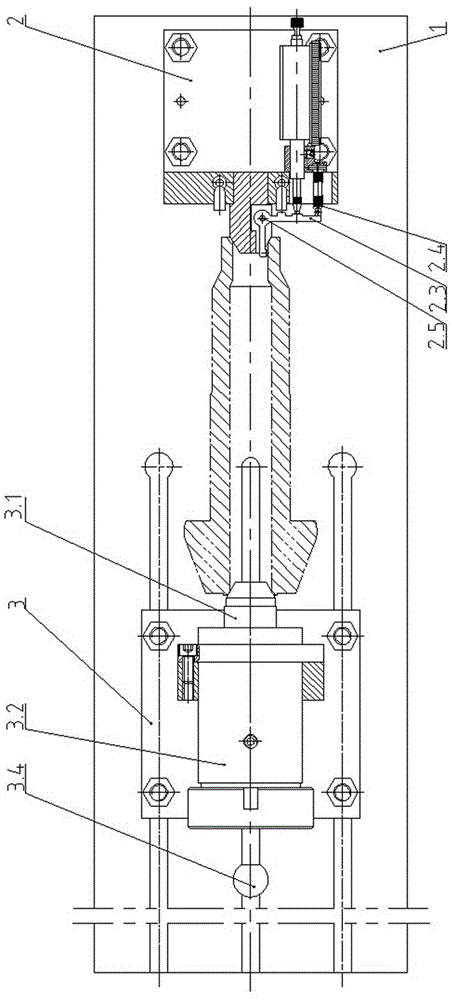

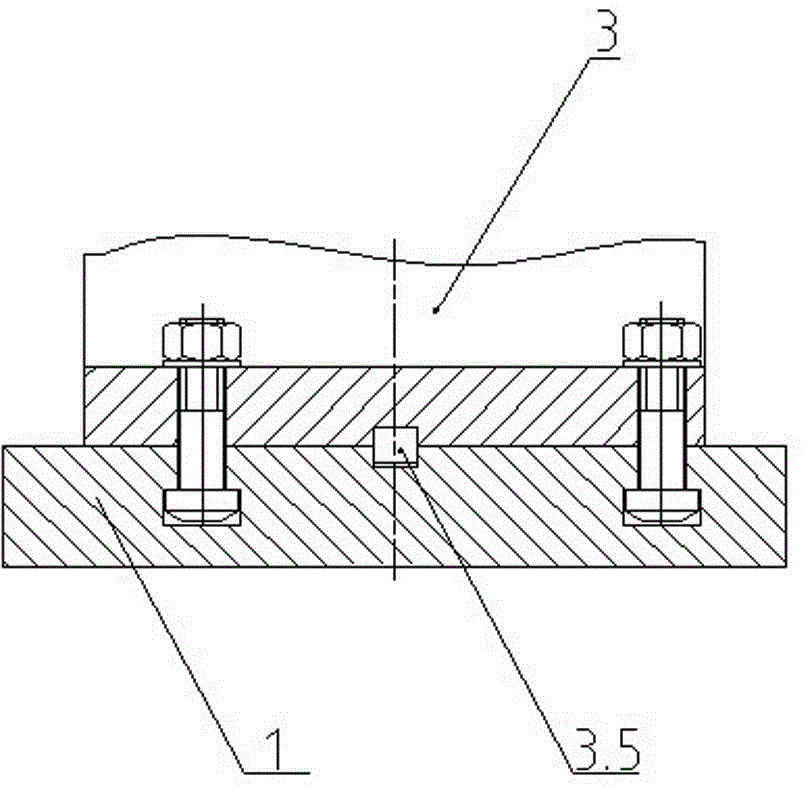

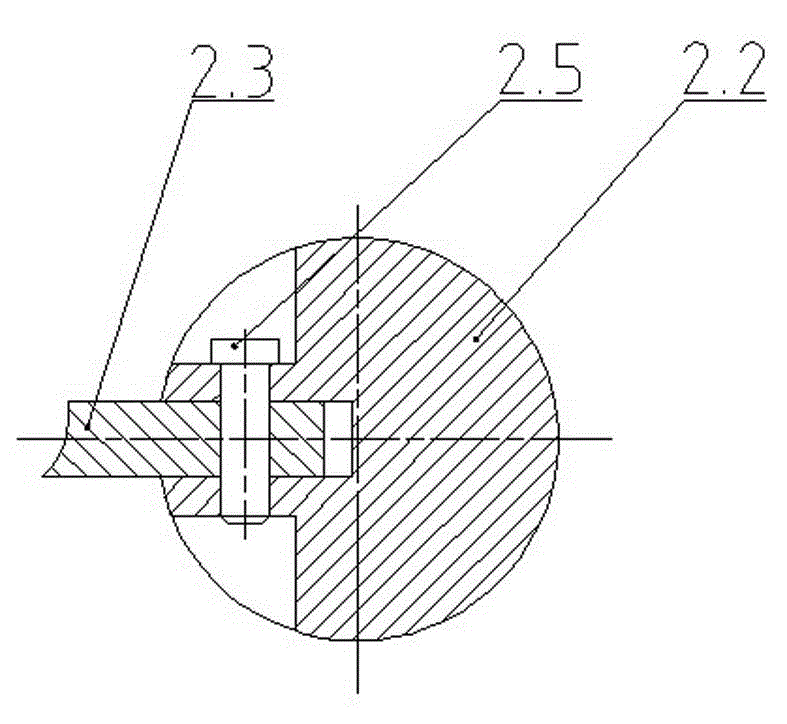

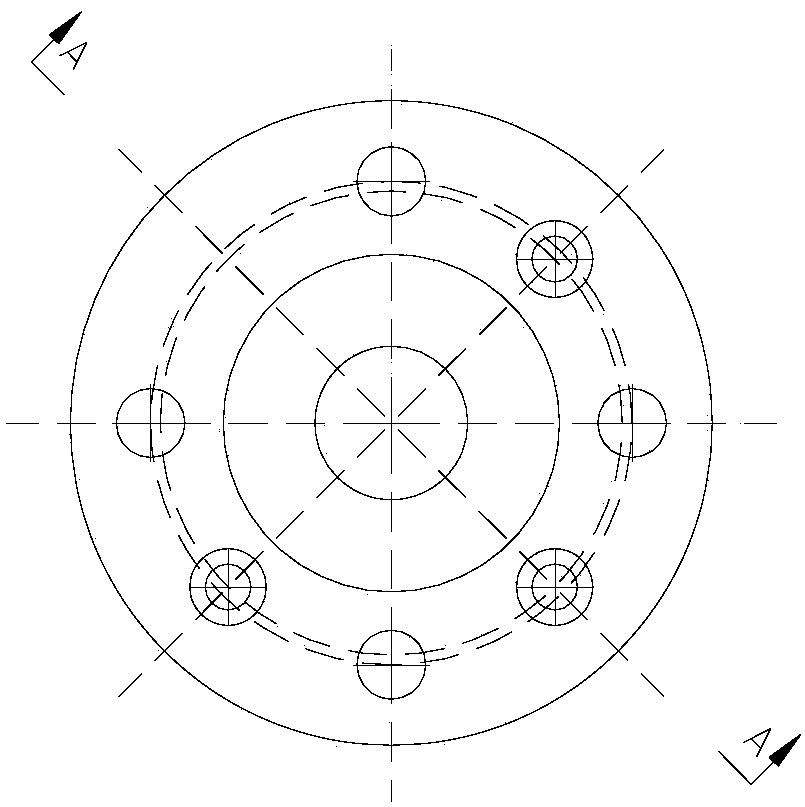

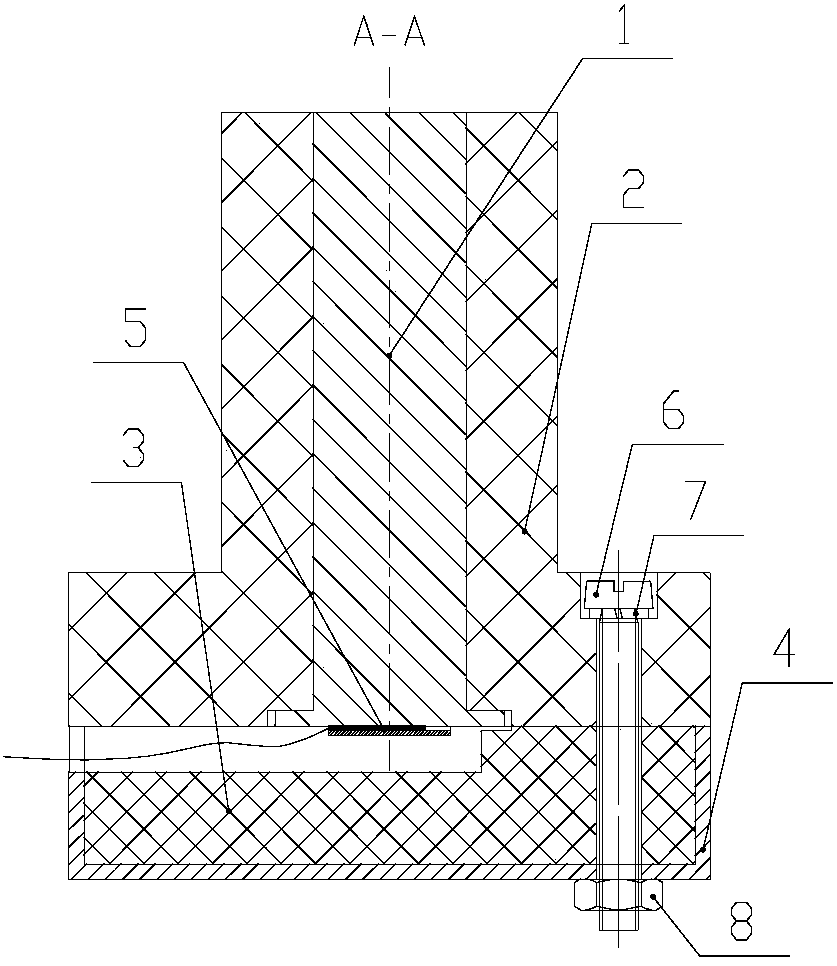

Gauge for radial run-out of inner bore walls at two ends of hollow shaft

InactiveCN104390543APrecise positioningEasy loading and unloadingMechanical measuring arrangementsEngineeringMechanical engineering

The invention discloses a gauge for radial run-out of inner bore walls at two ends of a hollow shaft. The gauge comprises a foundation bed, a fixed bracket and a movable bracket, wherein one end of the foundation bed is fixedly connected with the fixed bracket; the movable bracket is positioned and arranged at the other end of the foundation bed by virtue of three longitudinal slots which are parallel to one another and upwards open. An adjustable positioning structure which consists of a movable tip, a shaft sleeve, a spring and a fan-shaped gear is assembled on the top of the movable bracket. The tip arranged on the top of the fixed bracket at the other end of the foundation bed is coaxial with the movable tip in the movable bracket. A dial indicator arranged on the fixed bracket is positioned on the side surface of the tip, and the axes of the dial indicator and the fixed bracket are parallel to one another. According to the gauge for radial run-out of inner bore walls at the two ends of the hollow shaft, the groove is formed in one surface, facing towards one end of the workpiece, of the tip, and an angle-shaped measuring head inserted to the groove is in hinged connection by virtue of a pin roll, the radial side of the angle-shaped measuring rod in fixed-axis swinging is pulled by a tension spring on the fixed bracket, so that the contact point of the axial side is lean against the inner bore wall of the workpiece, and the linked radial side position changes are quantitatively displayed by the contacted dial indicator. The gauge for the radial run-out of the inner bore walls at the two ends of the hollow shaft is simple in structure, simple and convenient to operate, and especially suitable for quality detection on a production site.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

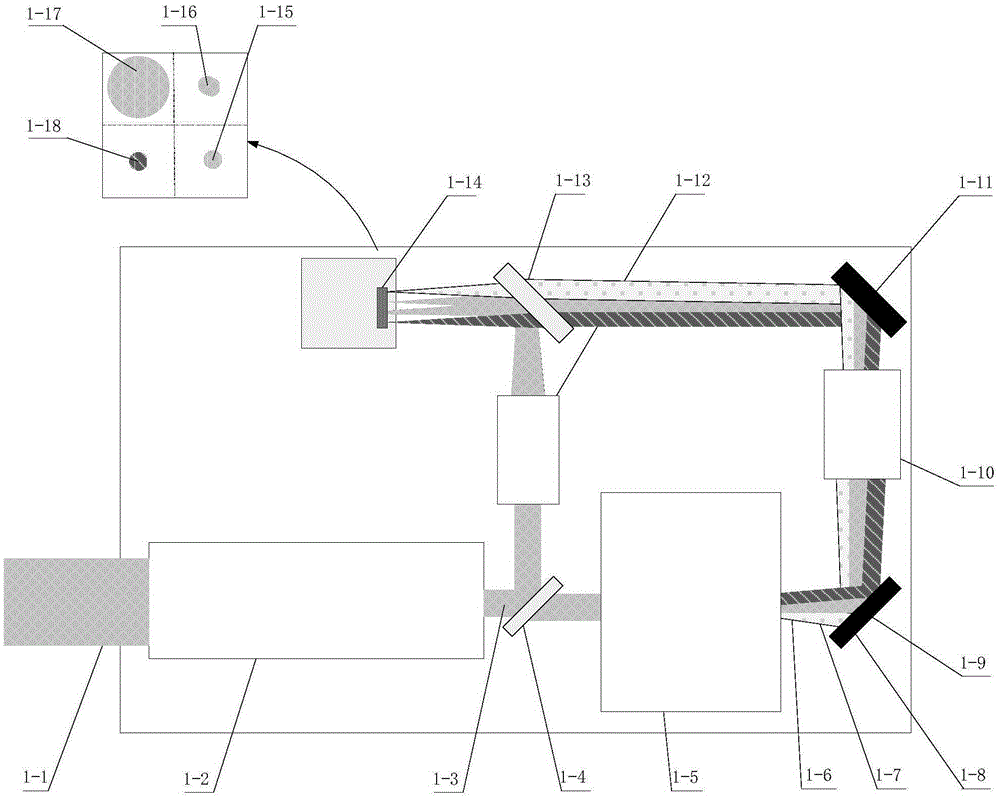

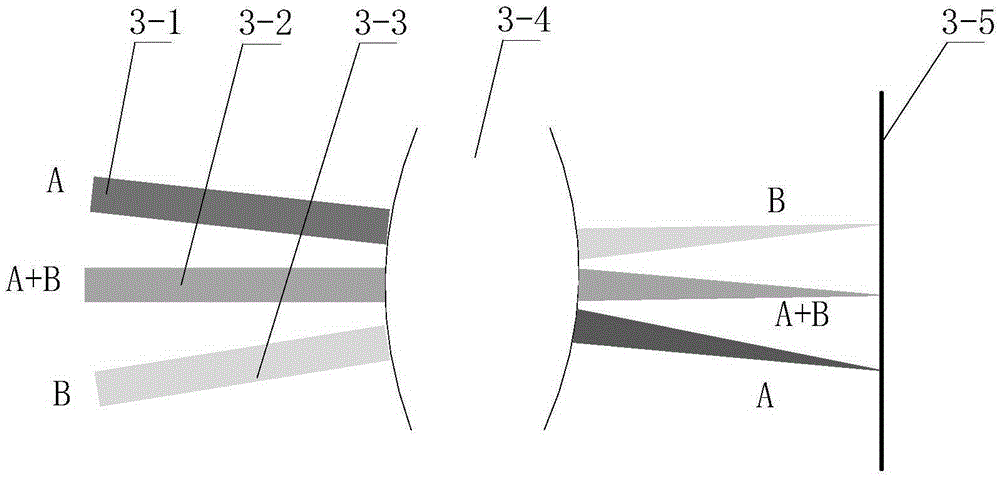

Double-light-beam synthesis sensor by utilizing single detector to perform optical pupil and optical axis regional imaging

The invention discloses a double-light-beam synthesis sensor by utilizing a single detector to perform optical pupil and optical axis regional imaging. The double-light-beam synthesis sensor aims to solve the technical problem: when the power synthesis is performed aiming at two paths of laser beams having different wavelengths, the double-light-beam synthesis sensor is adopted to detect a near field (optical pupil information) and a far field (optical axis information) of the two paths of the light beams so that a synthesis condition of the two paths of the light beams is measured, calculated and analyzed; and, in the double-light-beam synthesis sensor, through adoption of a special optical-path structure, the optical pupil image and optical axis imaging of the two paths of the light beams can be simultaneously performed by utilizing the same detector. By utilizing the double-light-beam synthesis sensor, light beam directional error information of various paths of light beams can be detected in real time, the measuring structure can be simplified, usage of the detection can be reduced, the thermal drift problem brought by separate detection of multiple detectors can be eliminated, measurement consistency and stability are improved, and far field and near field synthesis conditions when the two paths of the light beams are synthesized can be analyzed in real time.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

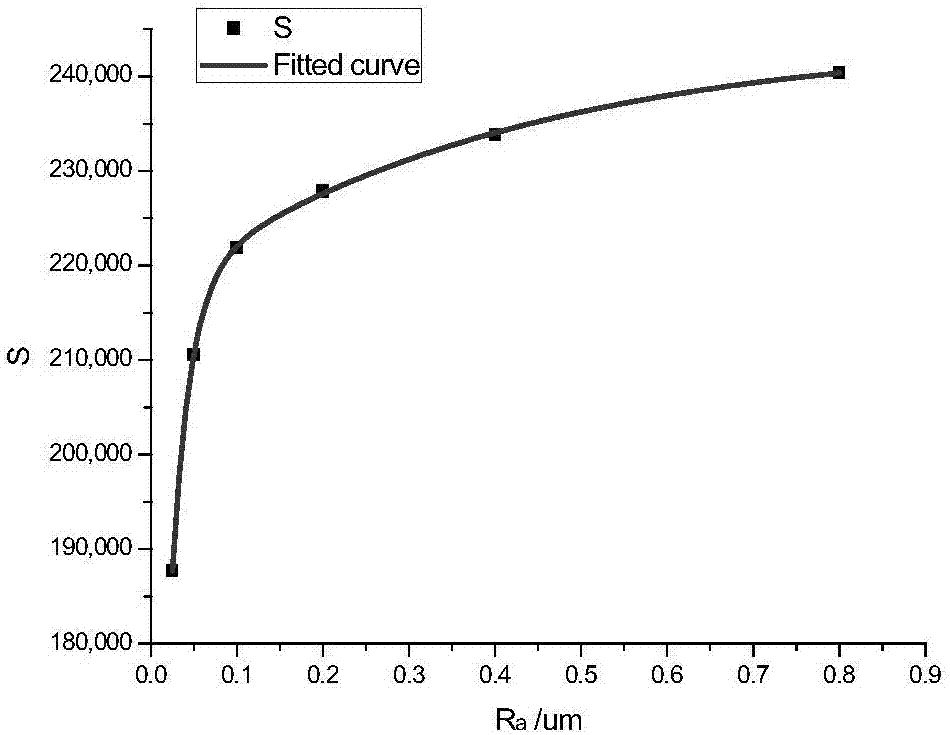

System and method for measuring surface roughness in online manner on basis of laser light scattering processes

InactiveCN107990850ADetermine accuracyAvoid secondary damageUsing optical meansProduction rateMicrometer

The invention provides a system and a method for measuring surface roughness in an online manner on the basis of laser light scattering processes. The method includes carrying out oblique incidence onlaser beams to the surfaces of measured objects at set angles; photographing scattered images on acquisition screens in reflection directions of the laser beams and extracting at least one of three feature parameters including a scattering feature parameter, a bright point ratio and a bright point gray ratio of each scattered image; computing roughness numerical values by the aid of relation curves between the feature parameters and the surface roughness. The heights of the acquisition screens are consistent with the heights of laser devices. Curve fitting is carried out on feature parametersof scattered images of standard roughness sample pieces and known roughness numerical values to obtain the relation curves. The system and the method have the advantages that the surface roughness ofmachined workpieces can be measured in the online manner by the aid of the method, accordingly, the quality of products can be guaranteed, and the productivity can be improved; the system and the method are combined with transparent window measurement modes, and accordingly the surface roughness (Ra ranging from 0.025 micrometer to 0.8 micrometer) of ground metal can be measured in the online manner under cooling liquid machining conditions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for measuring mining subsidence crack of mining area through low-altitude unmanned aerial vehicle photography

ActiveCN109631854AInterleaving is cheapThe method steps are simplePicture interpretationComputer visionLow altitude

The invention discloses a method for measuring a mining subsidence crack of a mining area through low-altitude unmanned aerial vehicle photography. The method comprises the following steps of 1, acquiring shooting parameters and arranging regular plates; 2, collecting and transmitting crack images; 3, establishing a coordinate system; 4, acquiring deformation coefficients of the crack images and acquiring object space coordinates; 5, acquiring conversion parameters of the object space coordinates to geographic coordinates; and 6, acquiring mining subsidence crack data of the mining area. The method has simple steps and reasonable design, the coordinate conversion parameters and the deformation coefficients are acquired through the regular plates, only and furthermore, an error of coordinate conversion accumulation is reduced, a processing process is simple, the accuracy of acquisition of the crack parameters is guaranteed, and the practicability is high.

Owner:XIAN UNIV OF SCI & TECH

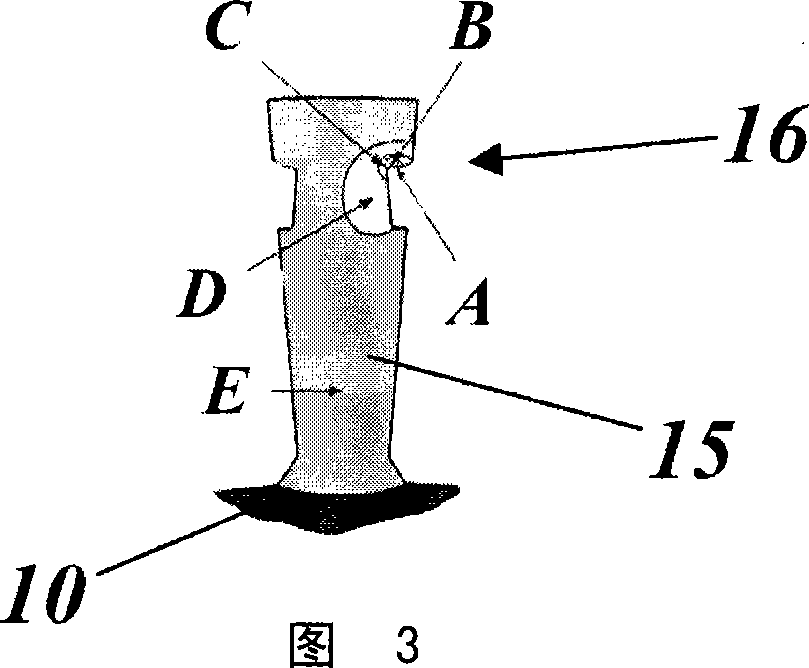

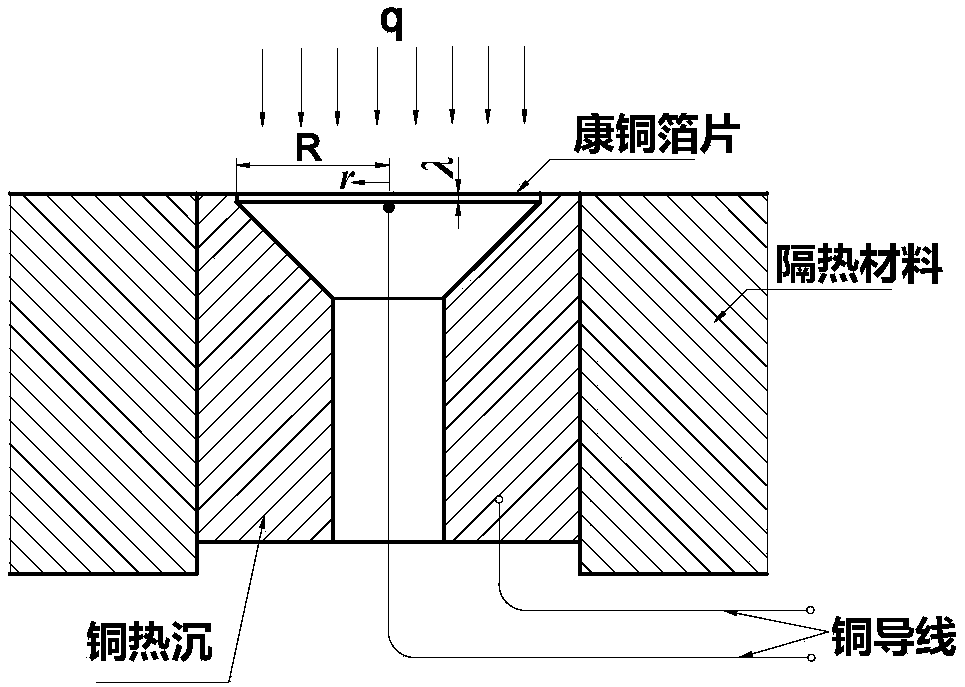

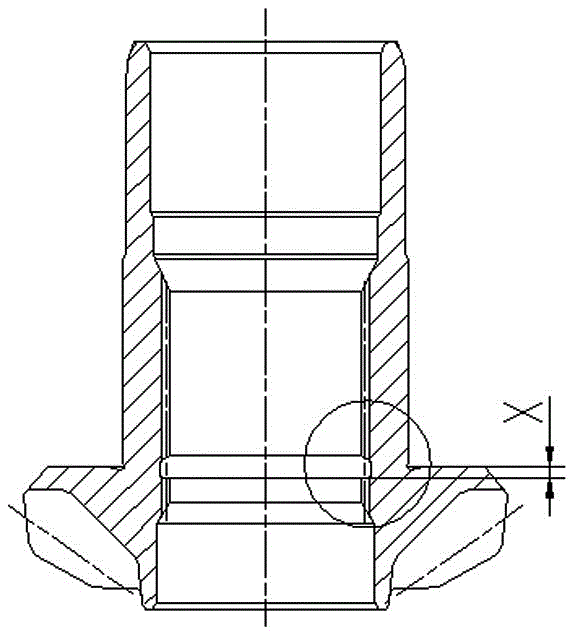

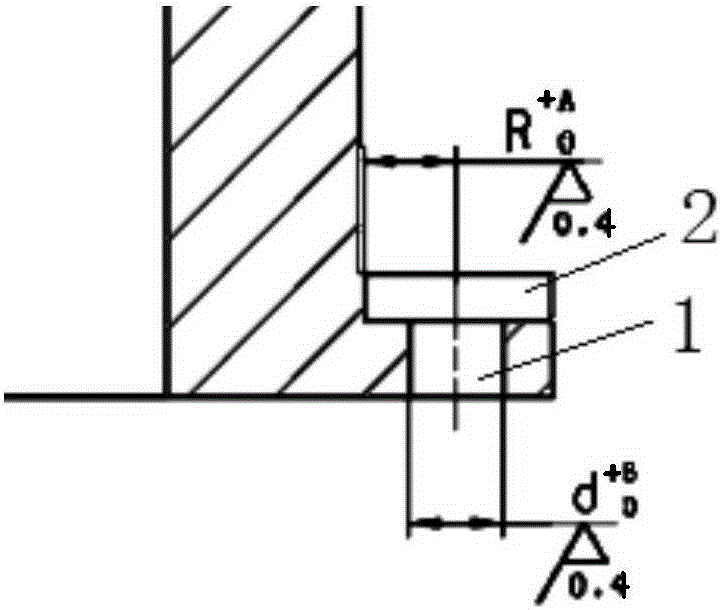

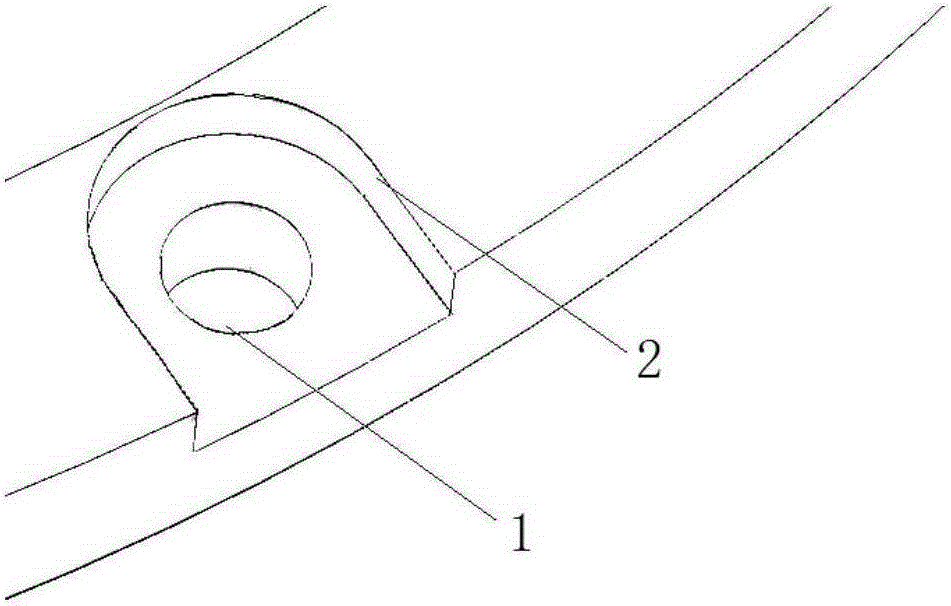

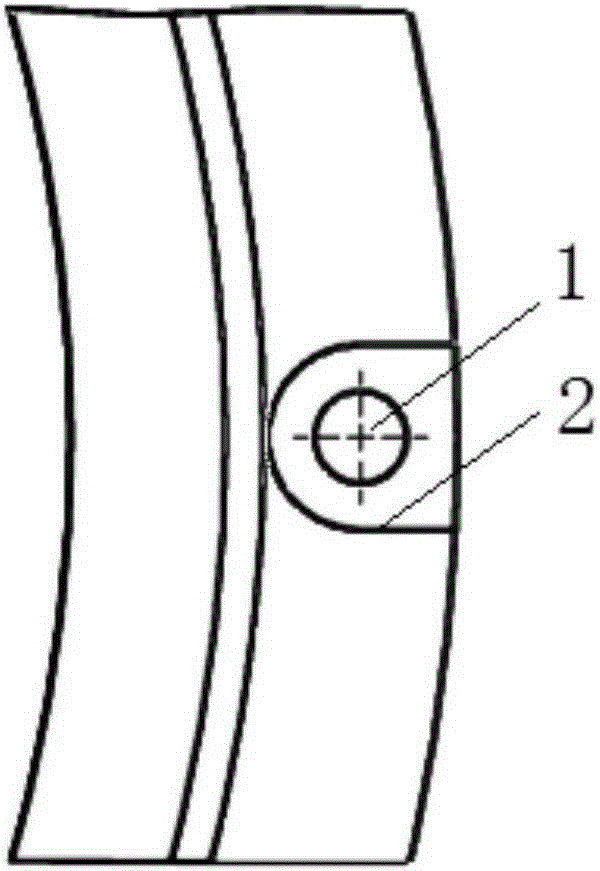

Identification apparatus for surface heat flux of hypersonic flight vehicle and design method thereof

ActiveCN108132112AHigh allowable temperatureSimple measurement structureThermometers using electric/magnetic elementsUsing electrical meansHeat flowFlight vehicle

The invention, which belongs to the technical field of thermal parameter measurement of a hypersonic flight vehicle, provides an identification apparatus for a surface heat flux of a hypersonic flightvehicle and a design method thereof. The apparatus is composed of a thermal-conduction sensitive element, a sensitive element insulating sleeve, a sensing element pressing plate, and a temperature sensor. The thermal-conduction sensitive element has a cylindrical structure. The sensitive element insulating sleeve has a cylindrical structure with a through hole. The thermal-conduction sensitive element is arranged in the through hole of the sensitive element insulating sleeve and is in a clearance fit with the sensitive element insulating sleeve. One side of the sensitive element is flush withthe outer surface of the insulating sleeve to form a measuring end surface and the temperature sensor is installed at the bottom of the other side of the sensitive element. The sensing element pressing plate presses the thermal-conduction sensitive element and is in a clearance fit with the sensitive element insulating sleeve; the sensitive element insulating sleeve, the gap between the sensitiveelement and the sensitive element insulating sleeve, and the sensing element pressing plate prevent the parts, except the measuring end surface, of the thermal-conduction sensitive element from carryout heat exchange with an external environment. Therefore, problems that the traditional heat flux sensor has the poor adaptability to the long-term high heat-flux measurement, the sensor size is large, the sensor is heavy, the installation difficulty is high, and intensive measurement can not be realized easily can be solved.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

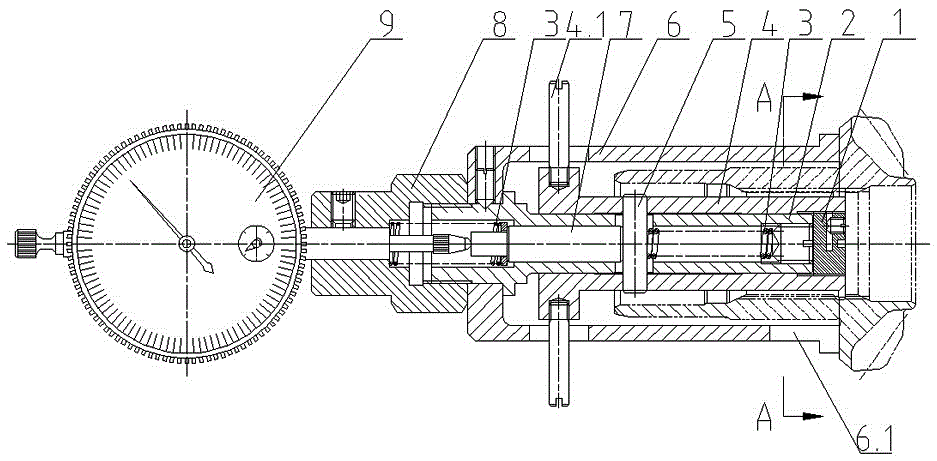

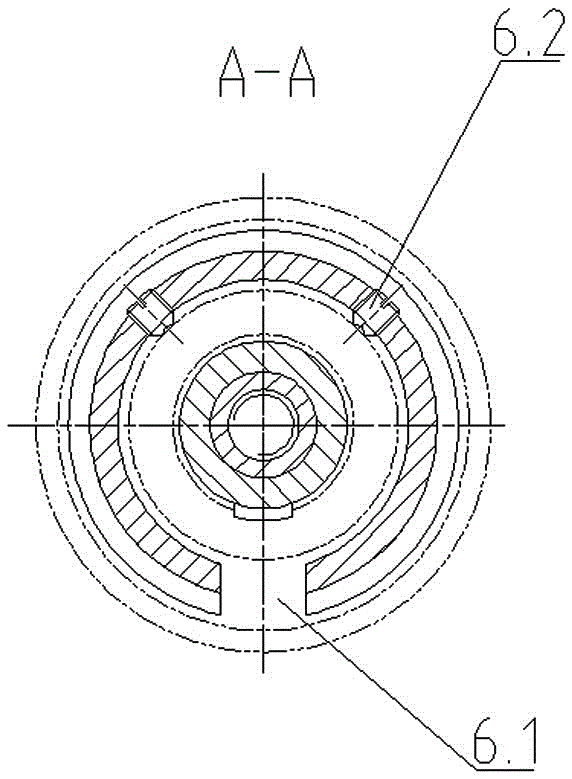

Tool for detecting linear distance between inner hole annular groove and outer end face of gear

InactiveCN106767317ASimple measurement structureEasy to makeMechanical clearance measurementsEngineeringLinear distance

The invention discloses a tool for detecting the linear distance between an inner hole annular groove and an outer end face of a gear. The tool comprises a pipe plug, an inner axle sleeve, springs, a measuring sleeve, a cylindrical pin, an outer sleeve, a push rod, a gauge stand and a dial indicator. An end, provided with external thread, of the inner axle sleeve is connected with the outer sleeve and the gauge stand. An indicator rod of the dial indicator is inserted into an inner hole of the gauge stand. An inner hole of the measuring sleeve is in clearance fit with the inner axle sleeve. Annular bosses are arranged on the outer walls of the two ends of the measuring sleeve correspondingly. The annular boss stretching into an inner hole of a workpiece is a measuring end. The annular boss at the other end is connected with two handles stretching out radially. The cylindrical pin is stuffed radially into the tube wall in the middle section of the measuring sleeve. The push rod is placed and inserted into one inner hole of the inner axle sleeve. One spring is axially arranged between the push rod and the gauge stand. One spring is also axially arranged in an inner hole in the other end of the inner axle sleeve and is adjusted and locked in position through the pipe plug. The to-be-measured workpiece is stuffed into the detecting tool for measurement, direct measuring is good in promptness and high in precision, and the detecting tool is suitable for being used in fields of production.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

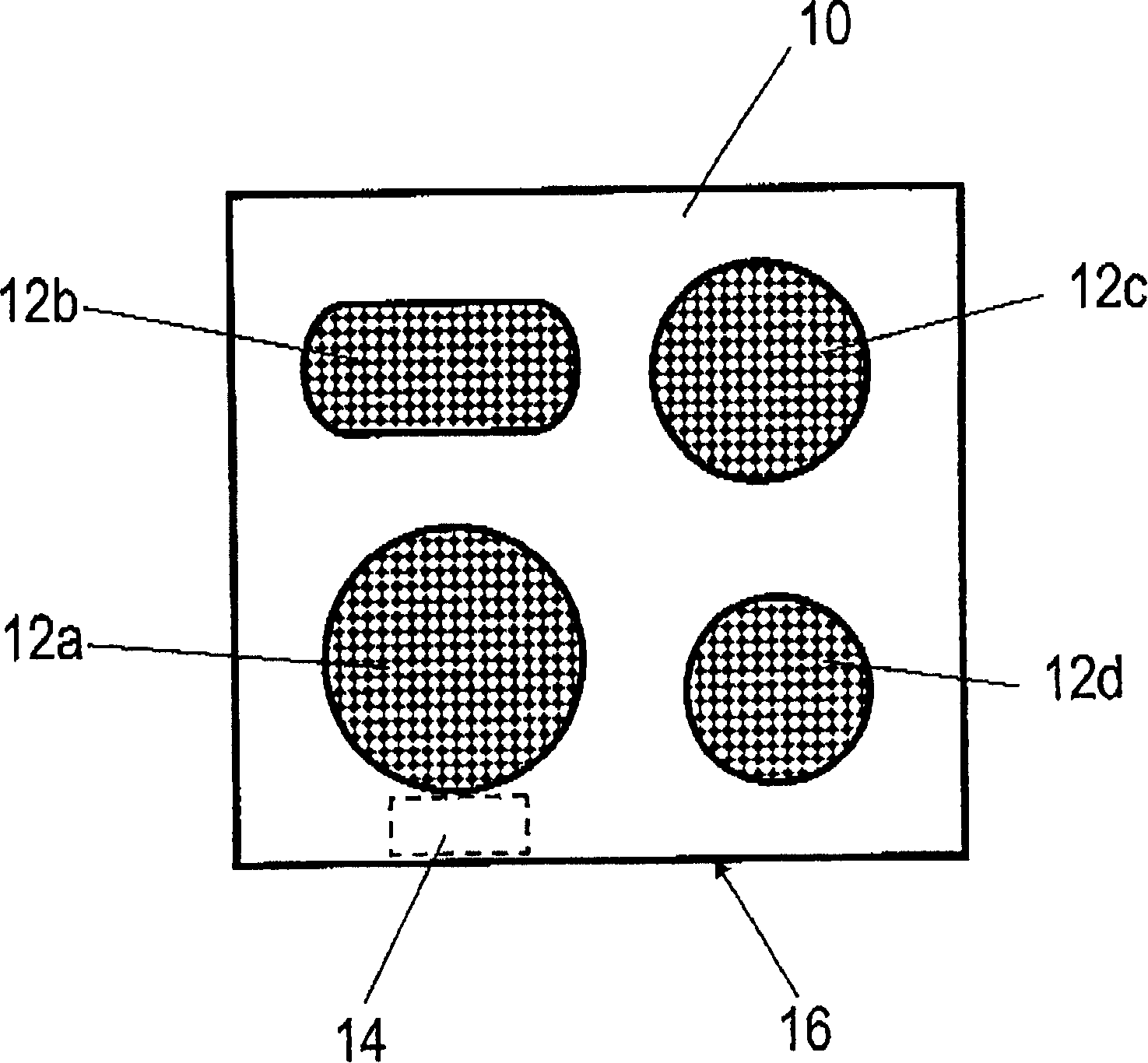

Method for monitoring the risk of damage in a cooking plate or glass plate

InactiveCN1590995ASimple measurement structureIncrease heat loadDomestic stoves or rangesLighting and heating apparatusEngineeringProcess engineering

To provide a method of monitoring the risk of damaging a cooking surface or a glass surface for a cooking device, which makes it possible to use a material having a higher thermal expansivity than that of a conventionally-used material. A method of monitoring the risk of damaging a cooling surface for a cooking device, having at least one cooking area 12a, 12b, 12c and 12d which are arranged on the cooking surface 10 and can be heated by an electrically-operated heating device, and monitoring a damage of the cooking surface 10 based on the heating efficiency, wherein a mechanical stress of the cooking surface 10 induced by heat is directly detected.

Owner:SCHOTT AG

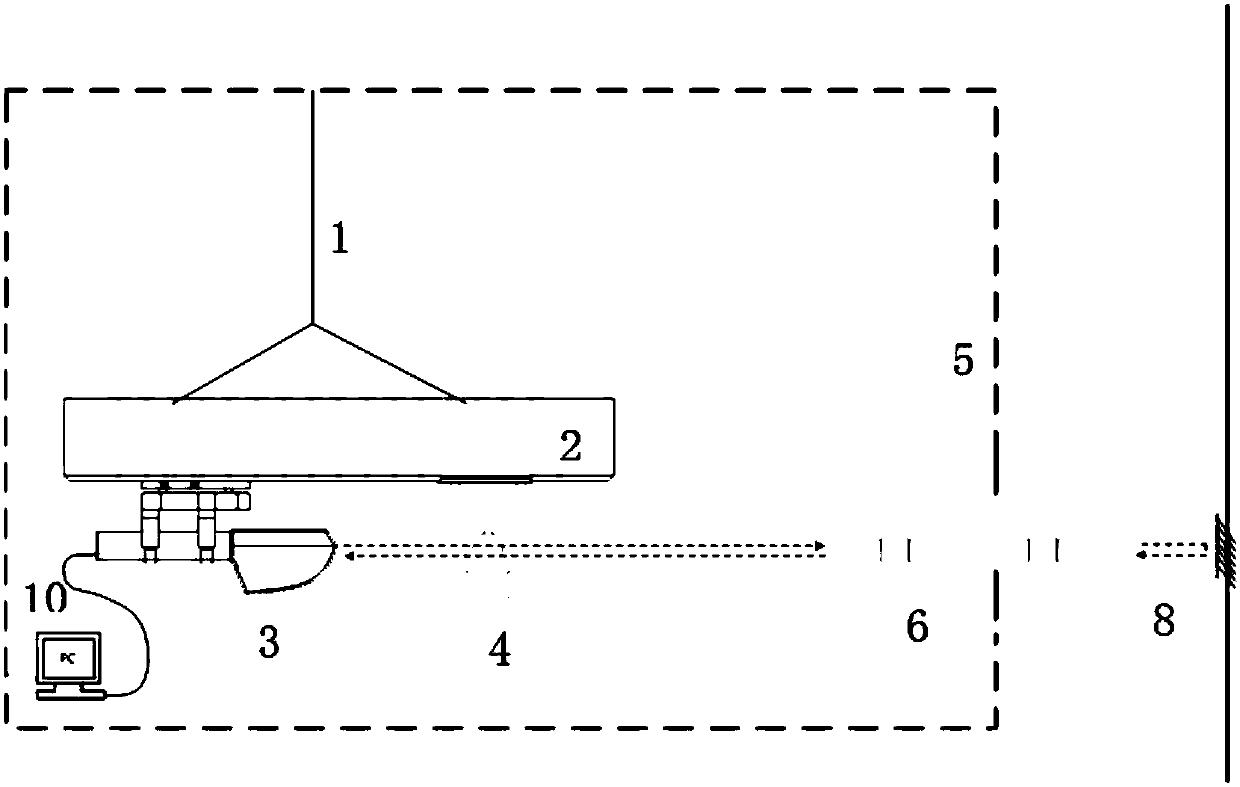

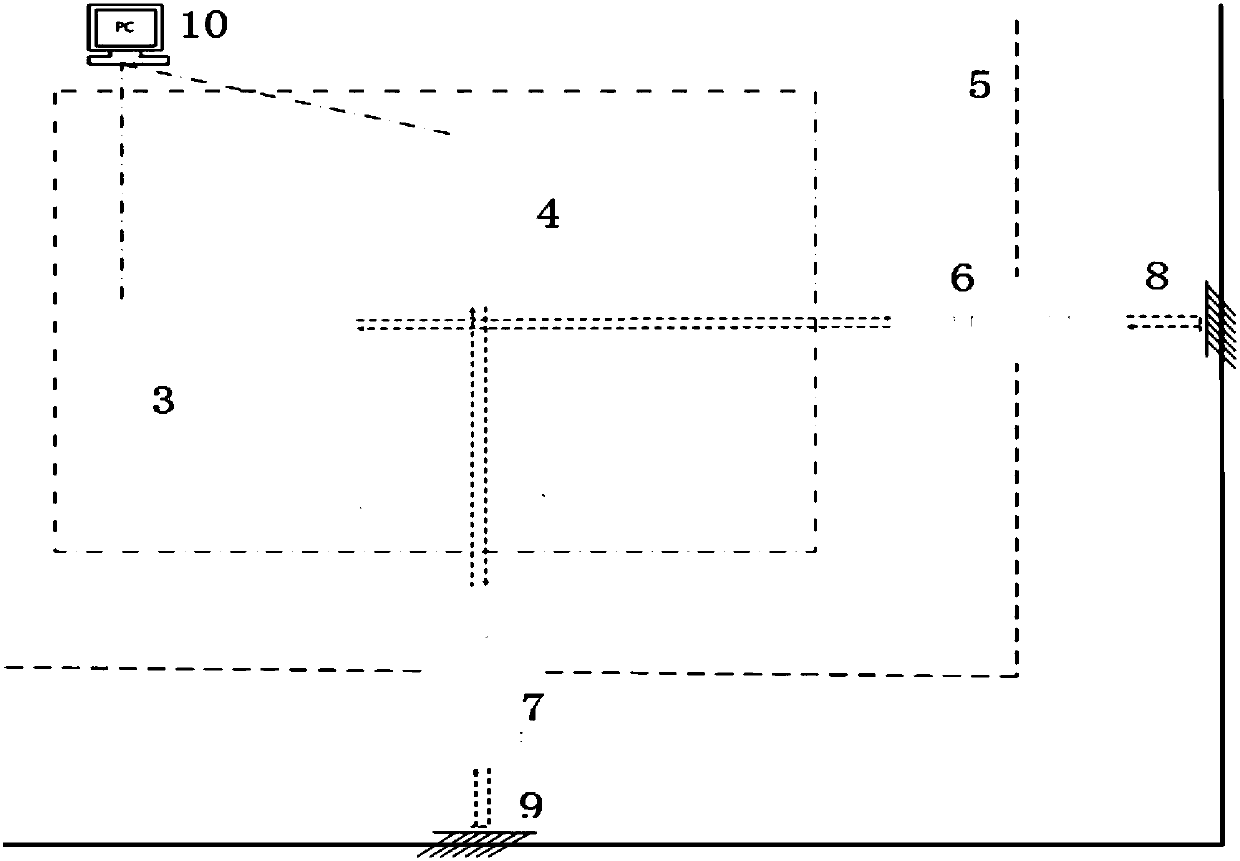

Attitude angle detection apparatus for suspension platforms

ActiveCN107747945AHigh-precision real-time measurement of platform attitudeSimple measurement structureNavigational calculation instrumentsRolling angleLight beam

The invention discloses an attitude angle detection apparatus for suspension platforms. The attitude angle detection apparatus comprises two vertically-arranged optical autocollimators fixed under anexperimental platform, wherein the two optical autocollimators are respectively arranged opposite to light through holes in the outer wall of a laboratory and reflection mirrors on a building wall, the two optical autocollimators emit light beams and real-timely receive the reflected light beams passing through the light through holes and the reflection mirrors, and the attitude angle changes of the two optical autocollimators are detected and analyzed through a communication host computer according to the relative movement between the two groups of the reflection light spot positions detectedby the two optical autocollimators and the incident light spot position so as to indirectly reflect the course angle, pitch angle and roll angle changes of the suspension experimental platform. The attitude angle detection apparatus of the present invention has advantages of high detection precision, good real-time performance and simple detection structure.

Owner:ZHEJIANG UNIV

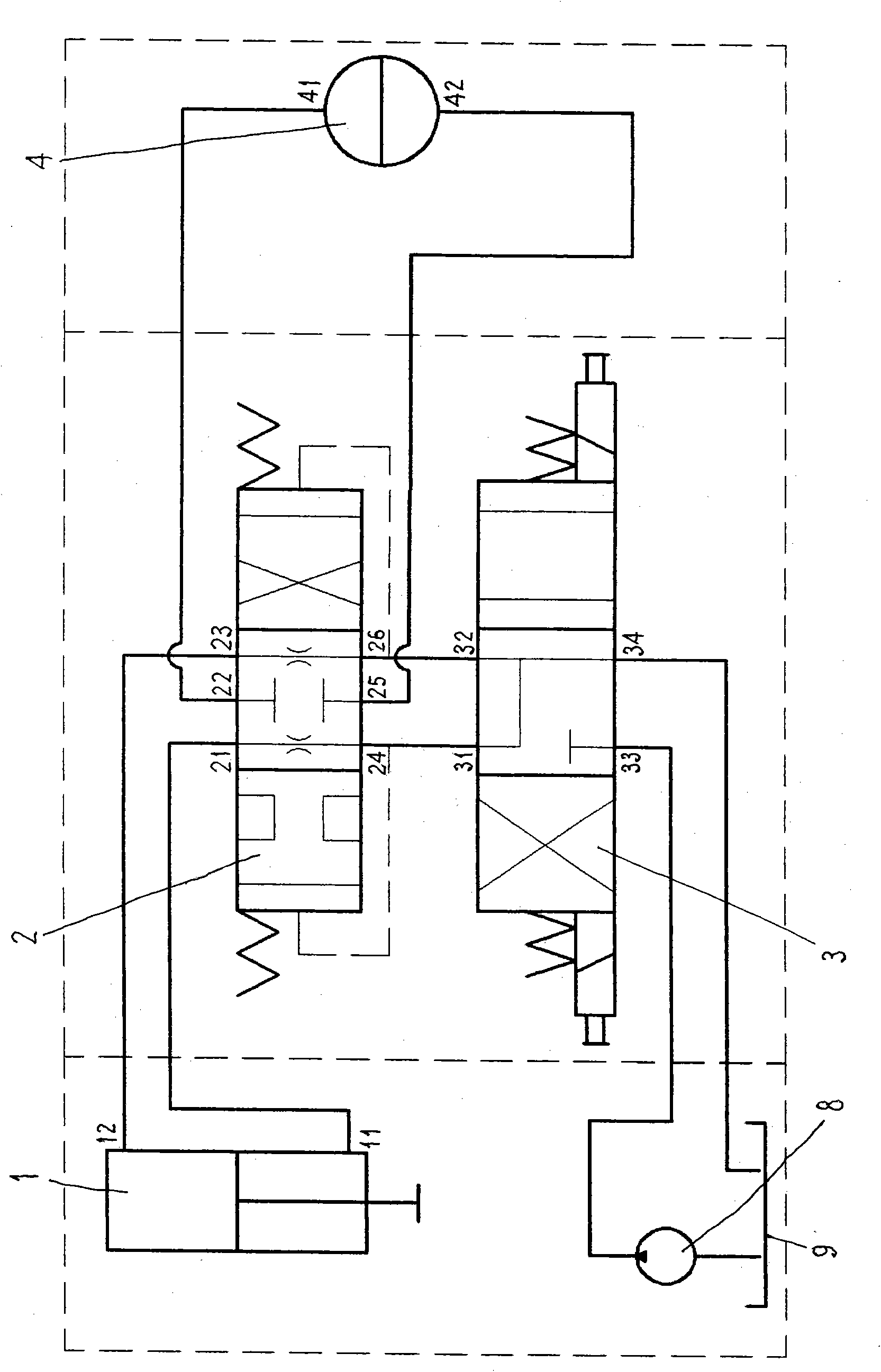

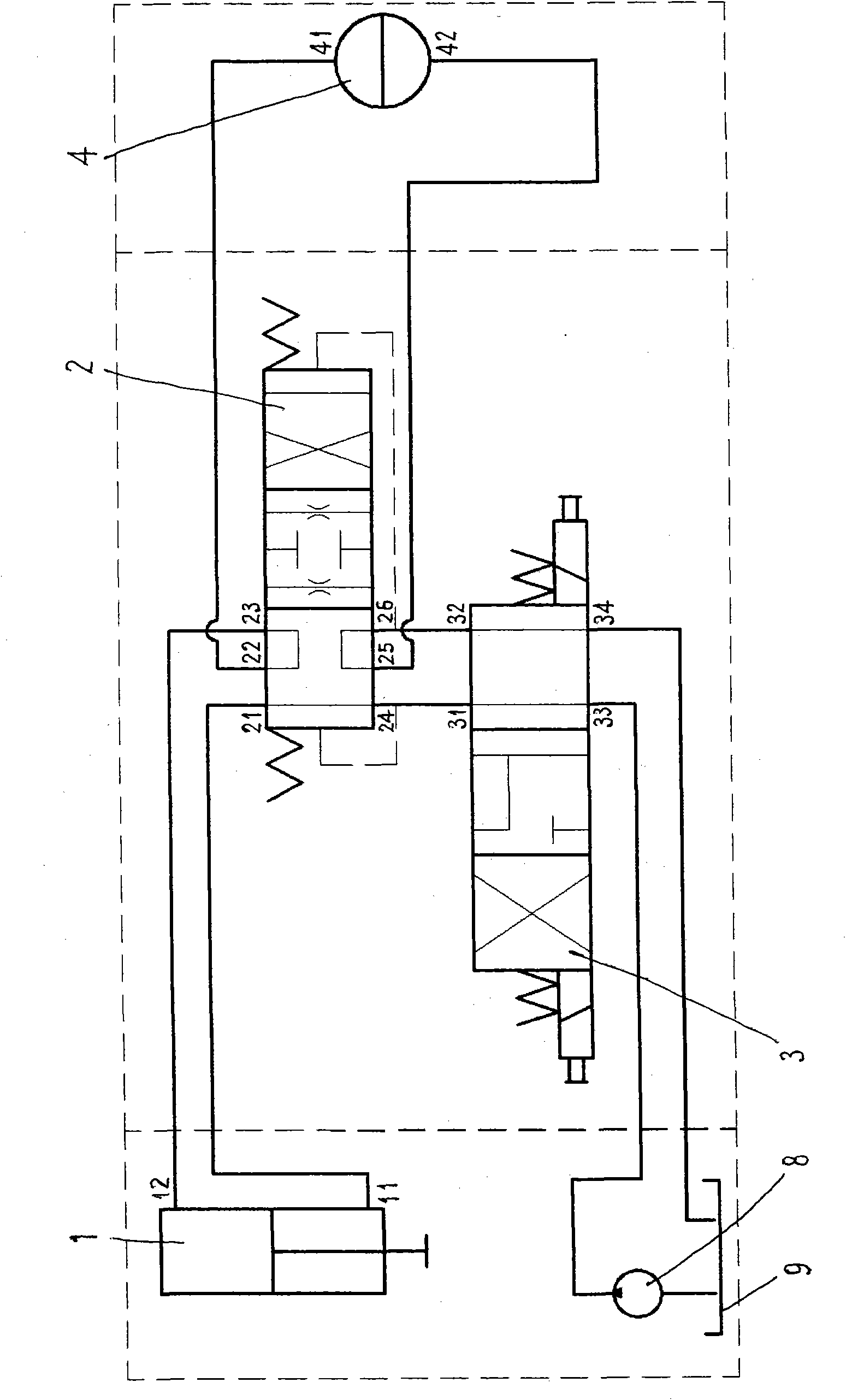

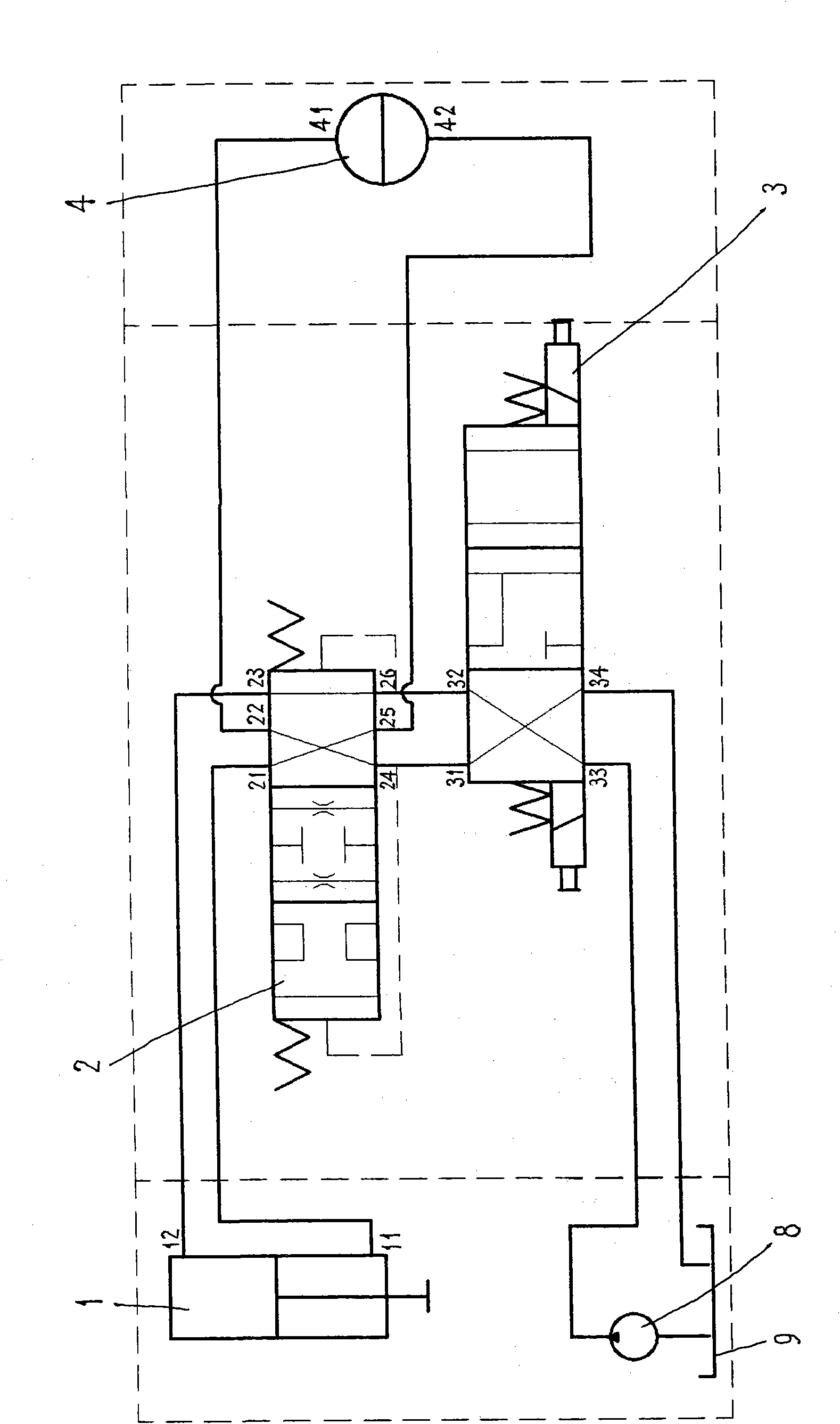

Hydraulic system indirect measurement temperature pressure compensating device

InactiveCN102141061AHigh measurement accuracyHighly integratedFluid-pressure actuator testingElectricityMeasurement device

The invention relates to a hydraulic system indirect measurement temperature pressure compensating device, mainly used for improving measurement accuracy. In the technical scheme, the device is provided with a three-position six-way valve; the three-position six-way valve is respectively connected with a hydraulic executive element, an electromagnetic valve and a valve position indicator; when the electricity of the electromagnetic valve is cut off, the three-position six-way valve is at the middle position, all oil ways are cut off, and two working chambers of the hydraulic executive element are at an oil return end; one side of the electromagnetic valve is energized, the three-position six-way valve shifts right, and one working chamber of the hydraulic executive element is at the low pressure and gets connected with the valve position indicator to form a first measurement loop; and when the other side of the electromagnetic valve is energized, a valve plug of the three-position six-way valve shifts left, the other working chamber of the hydraulic executive element is at low pressure and gets connected with the valve position indicator to form a second measurement loop. The device is suitable for all types of hydraulic system indirect measurement devices.

Owner:704TH RES INST OF CHINA SHIPBUILDING IND CORP

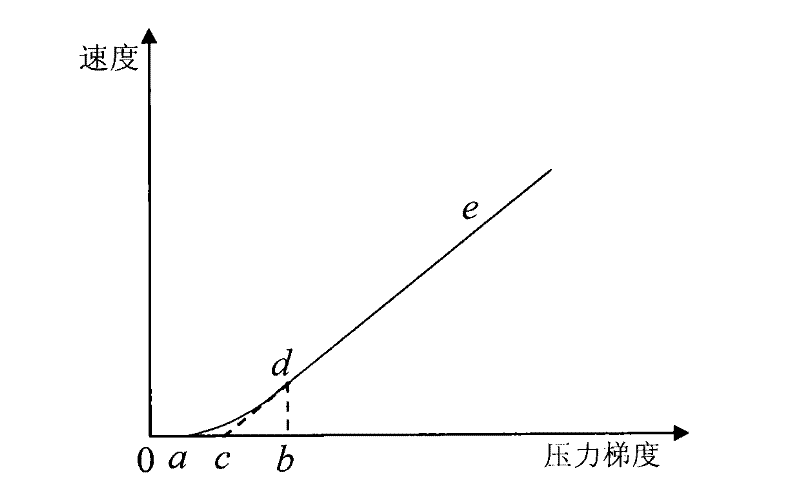

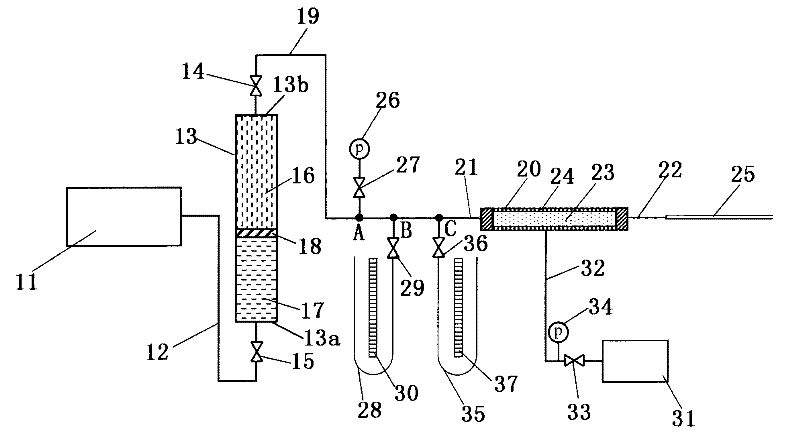

Measuring system and method of low-speed non-linear seepage parameters

InactiveCN101852714BNot easy to damageWill not be damagedPermeability/surface area analysisLow speedHeight difference

The embodiment of the invention provides measuring system and method of low-speed non-linear seepage parameters. The system comprises a power output device, a pressure measuring device and a flow measuring device, wherein the power output device is connected with a first opening of an intermediate container through a pipeline and is used for outputting different drive pressures so as to displace a displacing fluid in the intermediate container to be transmitted to a core of a core holder by the pipeline; the pressure measuring device comprises a pressure gage and a U-shaped pipe pressure gagewhich are respectively connected with a third opening of the core holder through pipelines and is used for measuring the pressure of the third opening of the core holder under different drive pressures; the U-shaped pipe pressure gage can display the level height difference so as to acquire the starting pressure of the core when the drive pressure is reduced to the minimum value, a switching partis in a closed state and the self level is stable; and the flow measuring device is connected with a fourth opening of the core holder through a pipeline and is used for measuring the volume of the displacing fluid seeped from the core under the different pressures of the third opening. The system can accurately measure the pressure, the starting pressure and the fluid volume under the low-speed non-linear seepage conditions.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

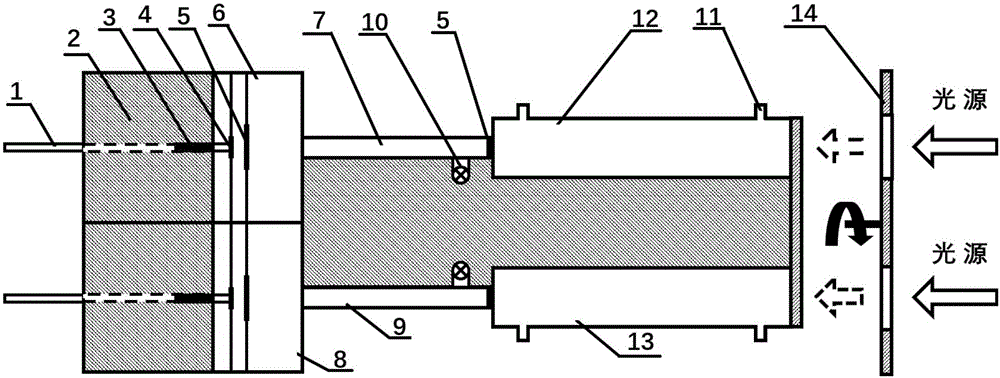

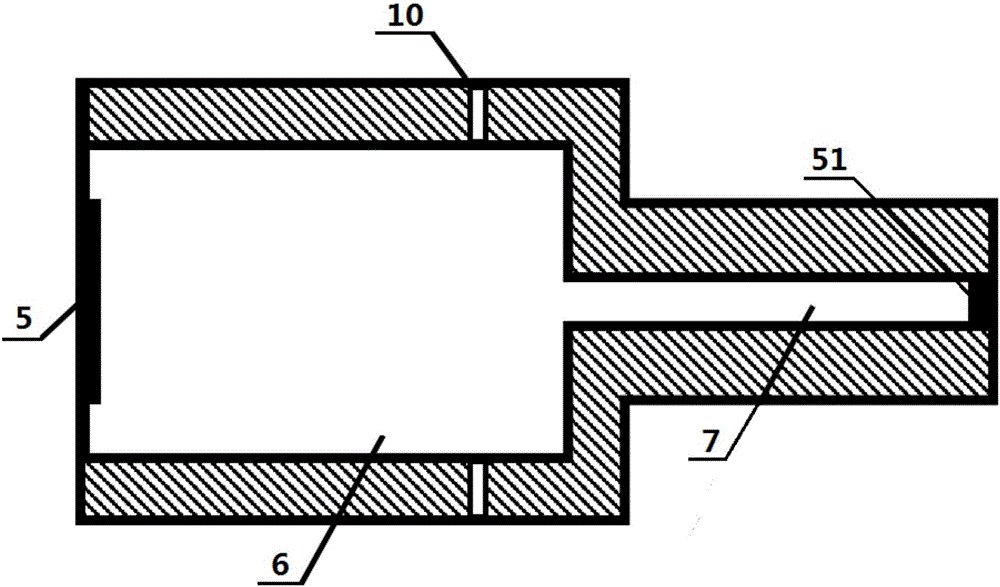

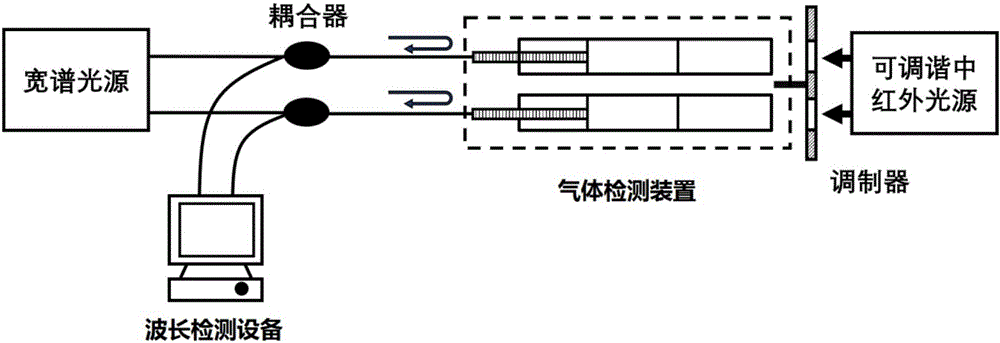

Photoacoustic spectrum gas detection device and system based on fiber Bragg grating

ActiveCN105910994ASimple measurement structureReduce electromagnetic interferenceMaterial analysis by optical meansPhysicsBroadband light source

The invention belongs to the technical field of gas detection and discloses a photoacoustic spectrum gas detection device based on fiber Bragg grating. The device is characterized by comprising a detection structure, the detection structure is used for containing to-be-detected samples, and the detection structure is matched with an upper wavelength detection device, a broadband light source and a detection light source to detect the concentration of a certain to-be-detected component in mixed gas according to the photoacoustic spectrum principle; the detection structure comprises a detection gas bin and a detection fiber Bragg grating (FBG); the detection FBG is connected with the detection gas bin; when gas detection is conducted, the to-be-detected samples are placed in the detection gas bin, detection light enters the detection gas bin, the detection FBG senses pressure intensity in the detection gas bin, the wavelength shift of the detected FBG is obtained through the upper wavelength detection device, and the concentration of the to-be-detected component in the to-be-detected samples is obtained. The photoacoustic spectrum gas detection device based on fiber Bragg grating has good electromagnetic interference resistance and is reliable in detection precision and low in cost.

Owner:HUAZHONG UNIV OF SCI & TECH

On-line measurement method and measurement device for residual stress of conductive thin film material

ActiveCN106248280BLower requirementEasy loadingMaterial strength using tensile/compressive forcesApparatus for force/torque/work measurementElectricityMeasurement device

Owner:SOUTHEAST UNIV

A Calibration Method Using Single Detector Combining Far Field to Improve Double-beam Combining Accuracy and Pointing Accuracy

ActiveCN105334028BAvoid thermal driftGuaranteed identityTesting optical propertiesTarget surfaceOptical axis

The invention discloses a calibration method for synthesizing a far field through a single detector to improve double-beam synthesis precision and pointing precision. According to the calibration method, the detection target surface of the same detector is subjected to area division, and four paths of measurement information are adjusted into four different areas which correspond to the real-time state information of a beam combination pupil, beam combination optical axes, a path A laser optical axis and a path B laser optical axis respectively. A path of laser and B path of laser are used for emitting light in the calibration process, the beam combination optical axes A1' and B1' are located on the absolute zero point of the center of the area in a closed loop mode, and after the coordinates of the beam combination optical axes A2' and B2' are respectively calculated, closed loop work is performed with the beam combination optical axes A2' and B2' as zero points. By means of the calibration method, calibration cost can be substantially reduced, a calibration structure is simplified, errors caused by equipment environment temperature and vibration are effectively eliminated, synthesis precision and stabilization precision of double beams on the target face of the detector are guaranteed, and therefore the synthesis precision and the pointing precision of output laser beams are improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Absolute measurement method for optical non-uniformity of parallel flat crystals

ActiveCN105092530BHigh measurement accuracyEasy to implementPhase-affecting property measurementsTransmittanceAbsolute measurement

The invention discloses an absolute measurement method for the optical non-uniformity of parallel flat crystals. The steps are: perform an interferometric measurement on the working surface of the first transmission reference flat and the front surface of the parallel flat to be tested; place a reflection reference flat behind the parallel flat to be tested, and perform an interferometric measurement on the first transmission reference flat and the reflection reference flat An interferometric measurement is performed on the working surface; an interferometric measurement is performed on the first transmission reference flat crystal working surface and the back surface of the parallel flat crystal to be measured; a cavity interferometric measurement is performed on the first transmission reference flat crystal and the reflection reference flat crystal working surface; Replace the first transmission reference flat with the second transmission reference flat, and perform an interferometric measurement on the second transmission reference flat and the first transmission reference flat working surface; An interferometric measurement is carried out; the measurement results are integrated to obtain the optical non-uniformity of the parallel flat crystal to be measured. The invention is simple and easy to implement, accurate and efficient, and the measuring object is not limited by the parallelism of the front and rear surfaces.

Owner:NANJING UNIV OF SCI & TECH

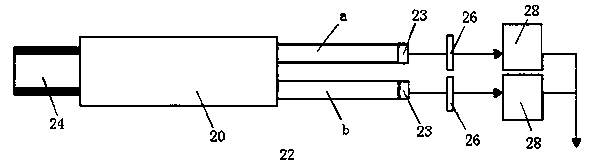

Optical fiber sensor for temperature measurement

InactiveCN103743499ASimple measurement structureSimple structureThermometers using physical/chemical changesOxidation resistantFiber optic sensor

The invention discloses an optical fiber sensor for temperature measurement. The optical fiber sensor is characterized by comprising an optical fiber beam (20), wherein the optical fiber beam (20) comprises a plurality of unit optical fibers (22), an oxidation-resistance metal coating is coated on the surface of one end of each unit optical fiber (22), the ends, with the oxidation-resistance metal coating, of all unit optical fibers (22) are gathered for forming a probe (24), the other ends of all unit optical fibers (22) form two strands of branch optical fiber beams (a and b), the two strands of branch optical fiber beams (a and b) are respectively connected with a filtering plate (26), and the filtering plate (26) is connected with a photoelectric detector (28). The probe of the optical fiber sensor is directly formed at one ends of the optical fiber beams, in addition, through the composition structure, the errors caused by heat expansion and cold contraction effects can be eliminated, the temperature sensing area of the optical fiber is further increased, and the signal picking capability is greatly enhanced. Meanwhile, the optical fiber sensor has the advantages that the structure is stable and reliable, the size is small, the cost is low, and the measuring precision is high.

Owner:NANJING INST OF TECH

Method for measuring pressure in rotating state

InactiveCN102798496BSimple measurement structureAvoid experimental errorFluid pressure measurement by electric/magnetic elementsEngineeringStationary state

The invention discloses a method for measuring pressure in a rotating state. The method comprises: installing a demarcating device on a test piece to form a pressure-tight demarcating chamber, feeding gas into the demarcating chamber, measuring voltage signal values of a sensor and gas pressure values of the corresponding chamber, fitting a curve to obtain a pressure calibration curve in a stationary state; feeding gases with different pressures in the demarcating chamber and rotating the test piece at different rotating speed, measuring the voltage signal values of the sensor corresponding the gas pressure in the present demarcating chamber under each rotating speed, fitting a curve to obtain a pressure calibration curve in the rotating state; obtaining an actual pressure value of the demarcating chamber through temperature of the demarcating chamber under each rotating speed, and modifying the pressure calibration curve in the rotating state; and combining the modified calibration curve and the signal values under each rotating speed measured by the pressure sensor in a test condition to obtain an actual pressure value of the pressure sensor. The method for measuring pressure in the rotating state makes test results capable of being reference, and ensures measuring precision of the test at the same time.

Owner:BEIHANG UNIV

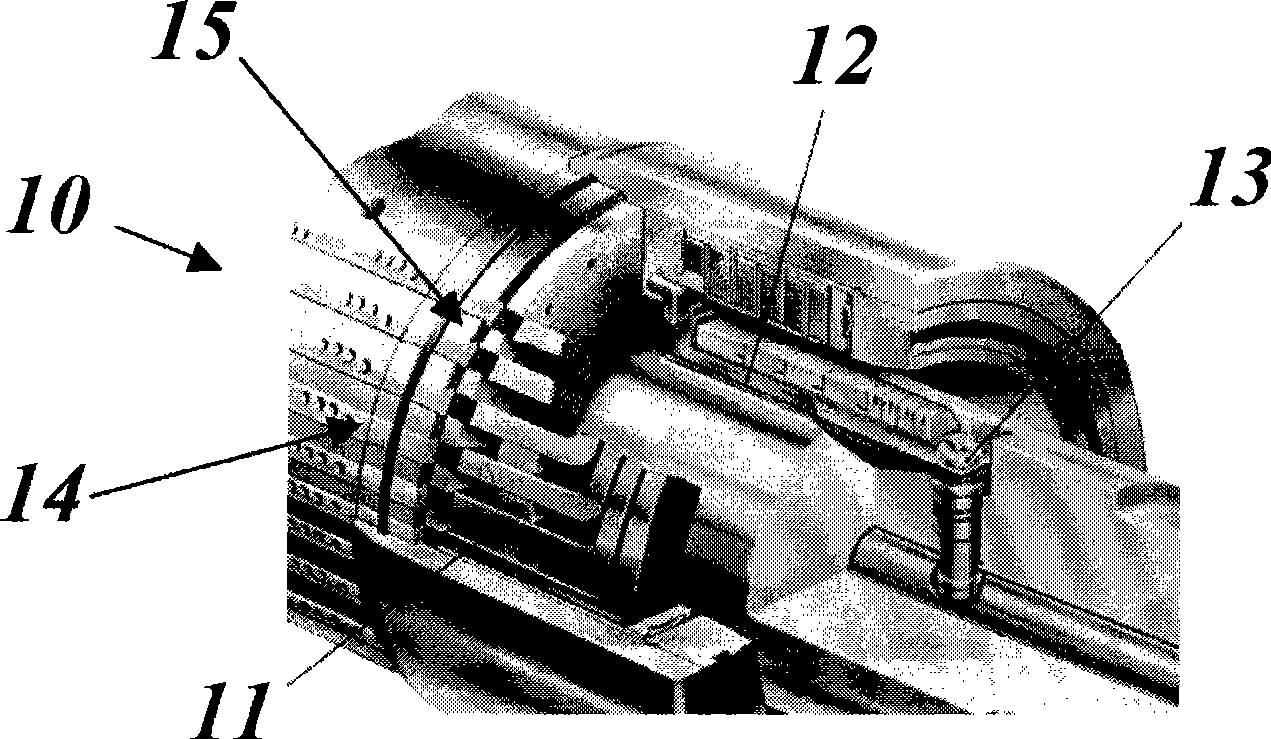

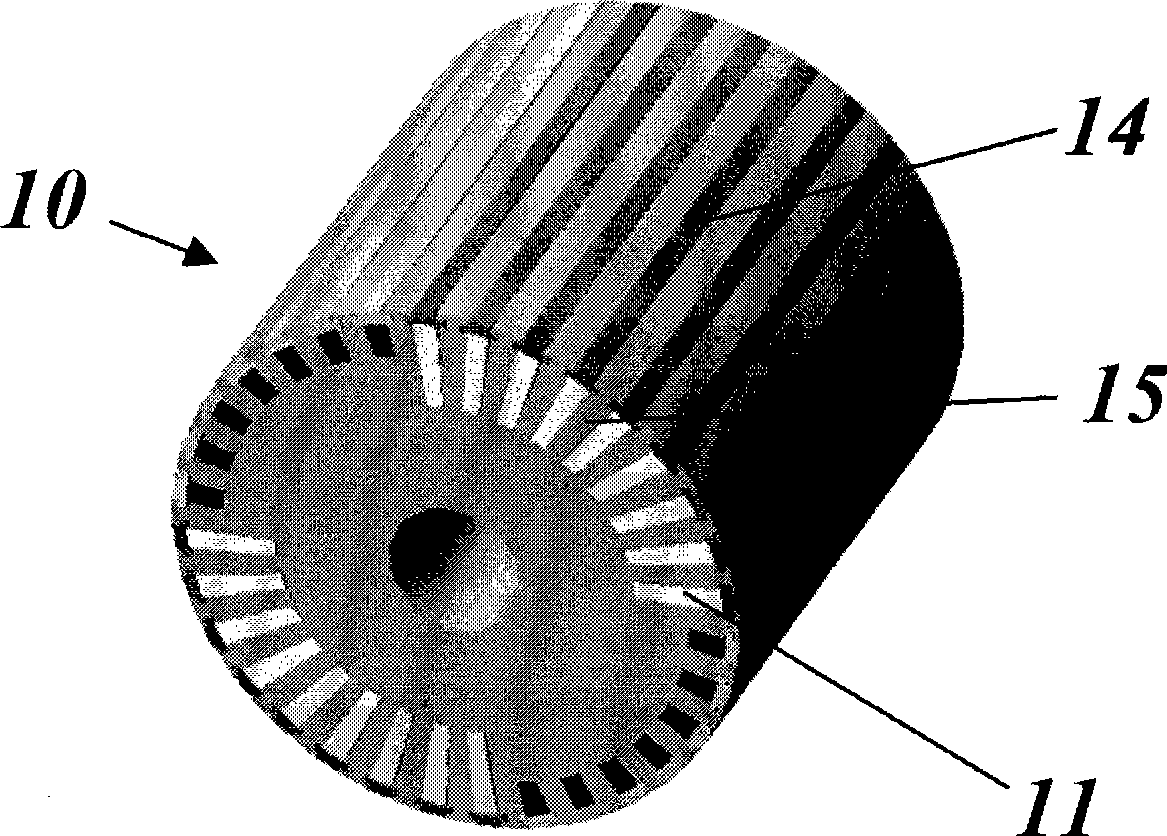

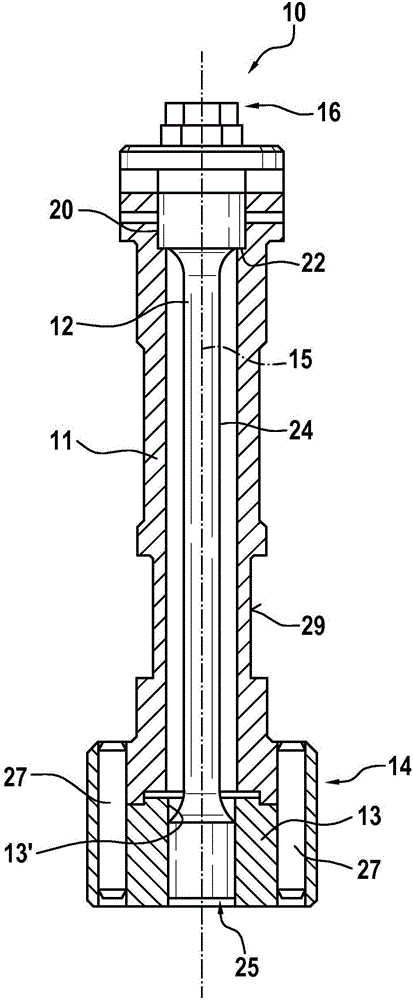

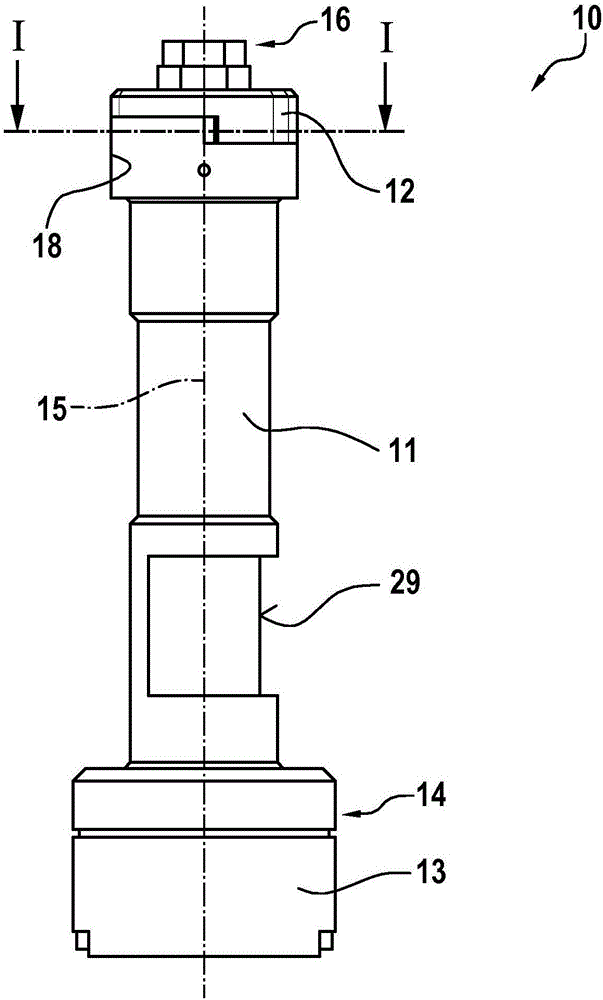

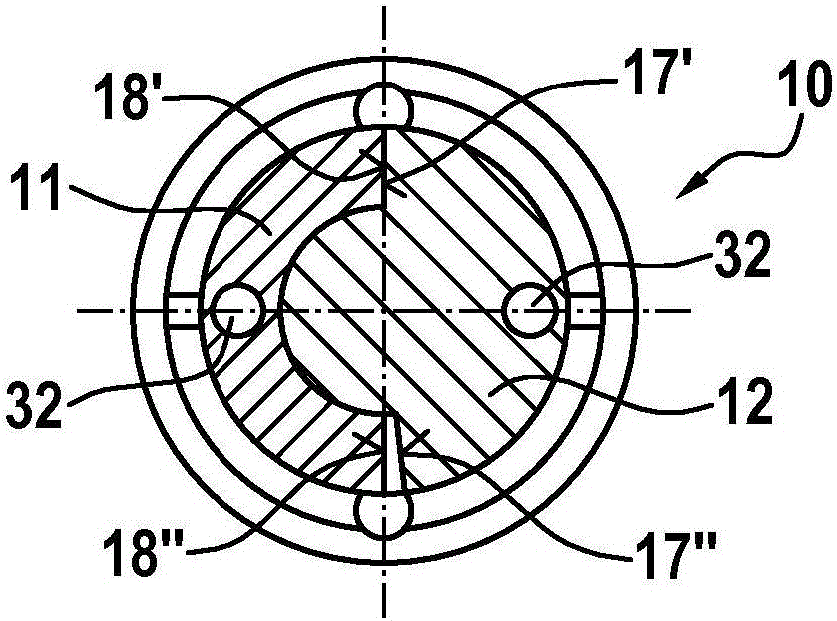

Testing device for testing screw systems, and testing method for this purpose

ActiveCN106662494ASimple measurement structureImprove accuracyMeasurement of torque/twisting force while tighteningSpannersPre stressScrew system

The invention relates to a testing device (10) for testing screw spindles or screw systems, said testing device being provided for installing between an output of a screw spindle to be tested and a screwing location. The testing device has a torsion element (12) which is received in a main part (11) such that the torsion element is provided with a specified pretension and is used to apply a spring characteristic to a screw spindle torque curve, which is produced by a screw spindle to be tested, when the torque curve influences the torsion element (12). The spring characteristic is determined by two stop positions of the torsion element, and means are provided in order to analyze measured data which characterizes the torque curve of the screw spindle in that torque curve interpolation nodes which correspond to the stop positions and which determine the spring characteristic are used as a measure in order to evaluate a screw spindle behavior which deviates from the norm using the analyzed measured data and the spring characteristic impressed in the measured data.

Owner:ROBERT BOSCH GMBH

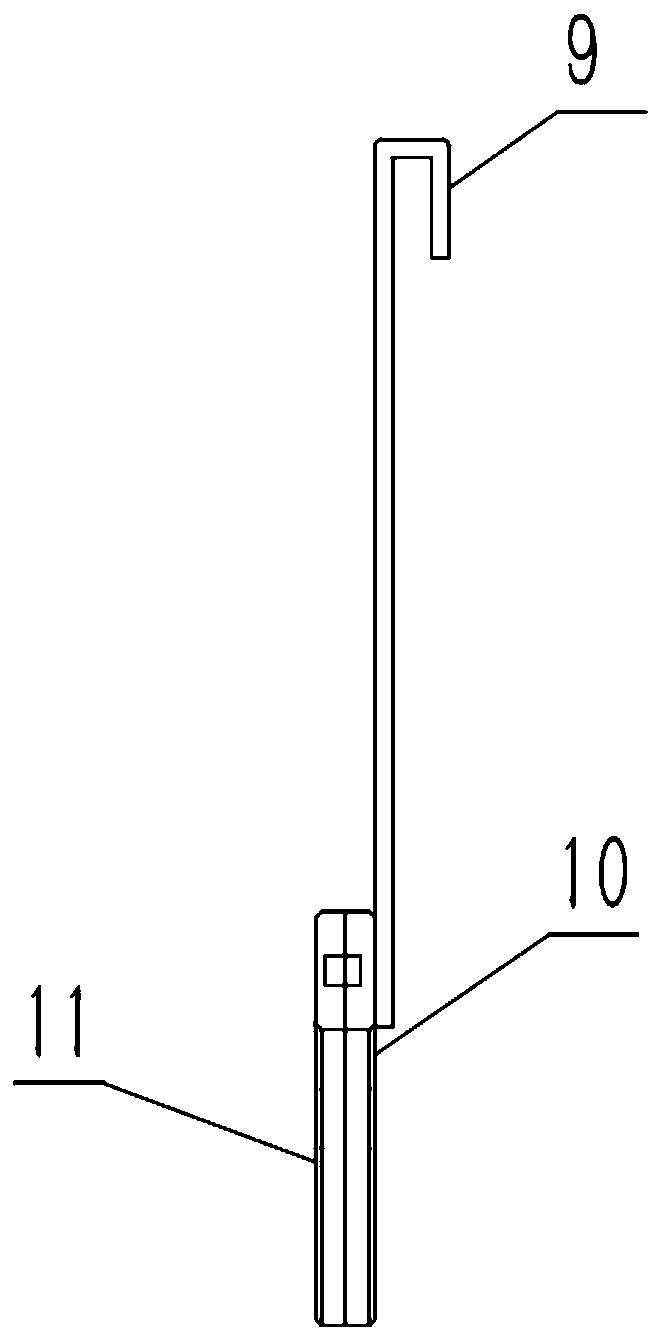

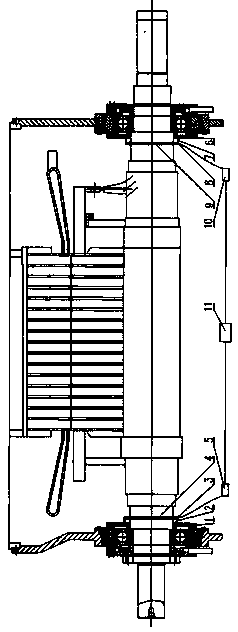

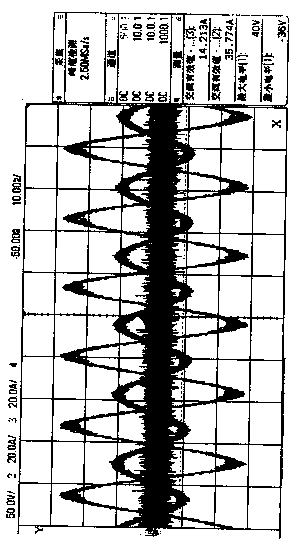

Bearing electric corrosion wind driven generator structure defect detection mechanism and bearing electric corrosion wind driven generator structure defect detection method

PendingCN109239598ASimple measurement structureAccurate measurementDynamo-electric machine testingWind drivenElectricity

The invention discloses a bearing electric corrosion wind driven generator structure defect detection mechanism and a bearing electric corrosion wind driven generator structure defect detection method, which solve a difficult problem of how to measure a shaft current numerical value of a wind driven generator subjected to bearing electric erosion. An AS end insulating support frame (2) is arrangedon an inner side face of an AS end bearing inner cover (1), an AS end Rogowski detection coil (4) is arranged on the AS end insulating support frame (2), the AS end Rogowski detection coil (4) encircles a rotating shaft of the bearing electric corrosion wind driven generator, the AS end Rogowski detection coil (4) and the AS end insulating support frame (2) are fixed together through being strapped by an AS end insulating strapping tape (3), and the AS end Rogowski detection coil (4) is electrically connected with an oscilloscope (11) through an AS end decoder (5). The detection mechanism provided by the invention has simple measurement structures, is easy to operate and can accurately obtain the numerical value of the shaft current through measurement.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

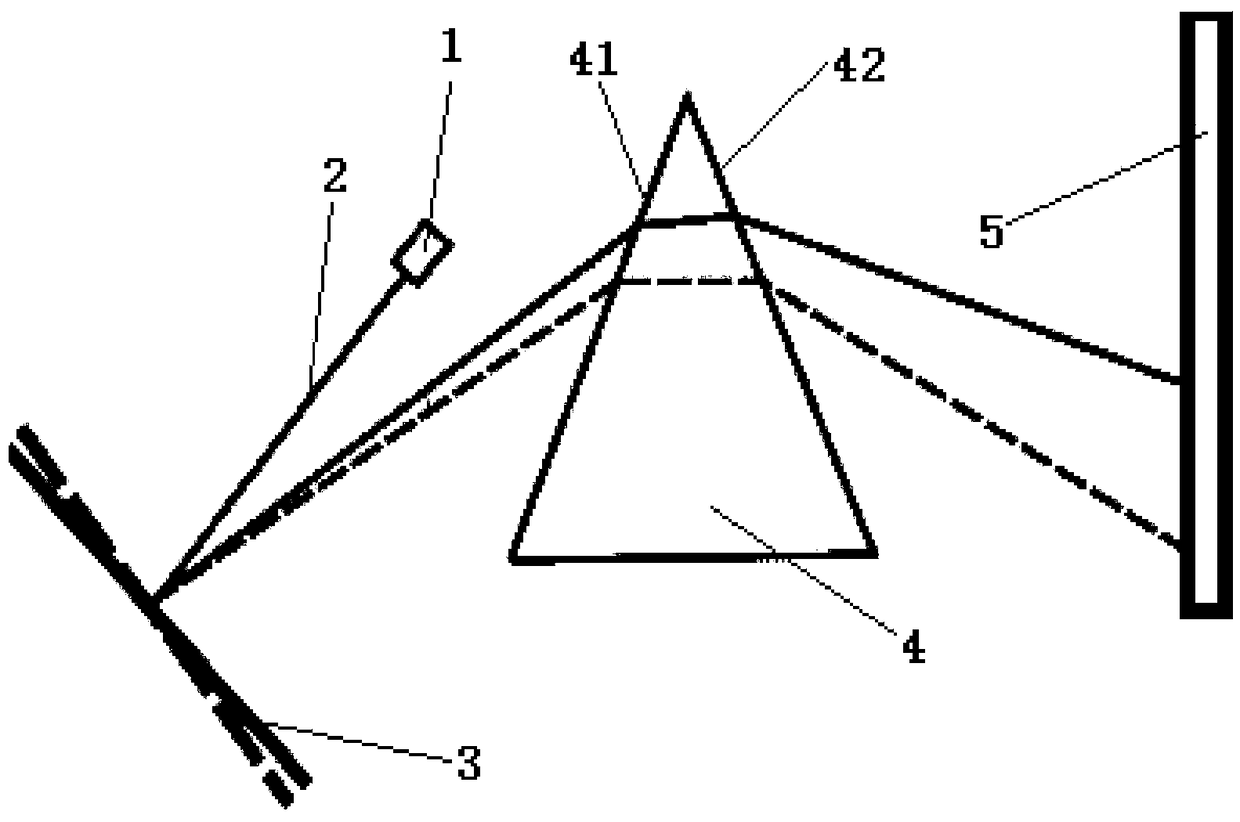

Angle measurement sensor and calibration method thereof, and calibration method of angle measurement sensor

PendingCN109141294ASimple measurement structureLow costUsing optical meansPhotovoltaic detectorsLaser beams

The present invention relates to an angle measurement sensor and a calibration method thereof, and a calibration method of an angle measurement sensor. The angle measurement sensor comprises: a laserconfigured to emit out a laser beam; a reflector capable of synchronous rotation with a measured object and configured to receive the laser beam emitted by the laser and reflect the laser beam to a refractor; the refractor configured to generate refraction of the laser beam reflected by the reflector and emit out the laser beam; a photoelectric detector configured to receive the laser beam refracted from the refractor and measure the incident position; and a processing system configured to calculate the rotation angle of the measured object according to the incident position variation of the laser beam received by the photoelectric detector. The sensor performs refraction for the reflected laser beam by the refractor so as to amplify the change of the reflection angles before and after rotation, and calculates the rotation angle of the measured angle through the change of the incident angle of the laser on the photoelectric detector.

Owner:BEIFANG UNIV OF NATITIES

Plain plug gauge for measuring incomplete holes and design method thereof

ActiveCN105222663ASimple Size CalculationEasy to understand size calculationPlug gaugesSEMI-CIRCLEHand held

The invention provides a plain plug gauge for measuring incomplete holes and a design method thereof. The plain plug gauge comprises a plug gage body. The plug gage body is of a stepped cylindrical structure, and is composed of a positioning part at one end thereof, an intermediate measurement part and a hand-held part at the other end thereof. The measurement part comprises a go end and a not-go end. The go end and the not-go end are respectively of a small semi-circle cylindrical-surface structure and a large semi-circle cylindrical-surface structure, and are concentrically arranged. The radius of the go end is larger than the radius of the positioning part. The plain plug gauge is simple and straightforward in dimension calculation, simple in structure, easy to manufacture and convenient to use.

Owner:AECC AVIATION POWER CO LTD

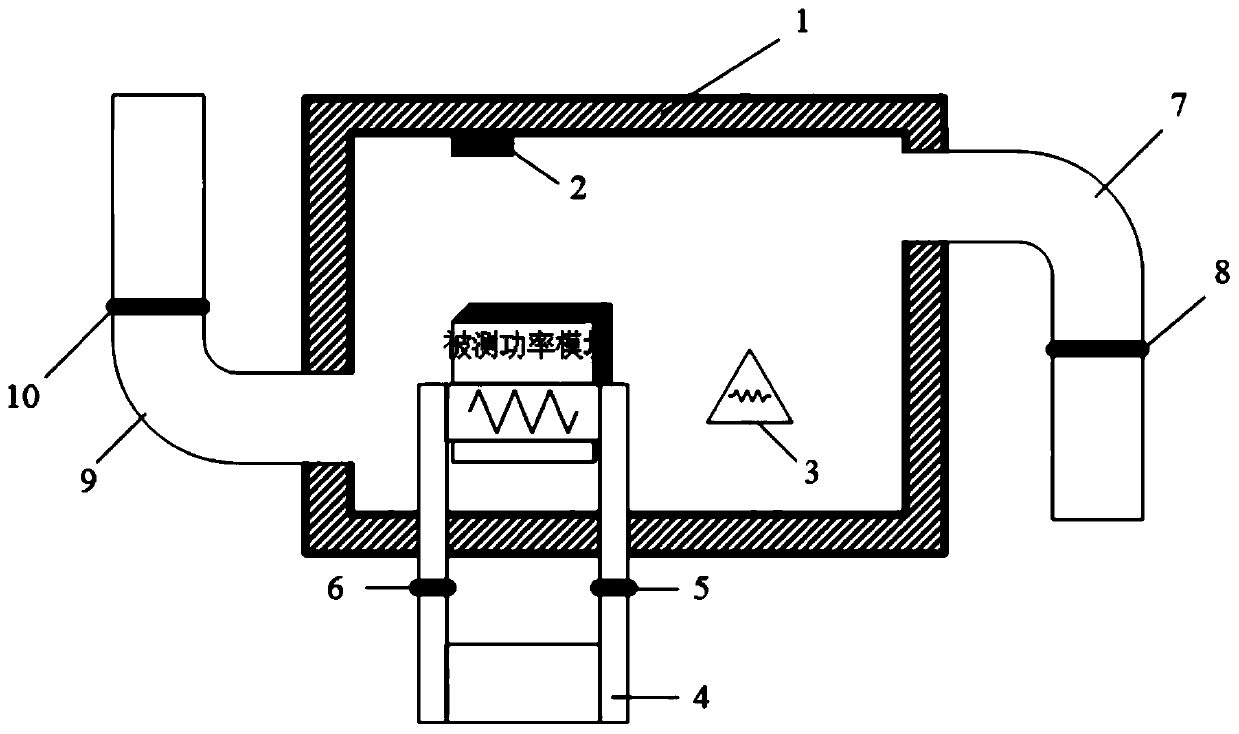

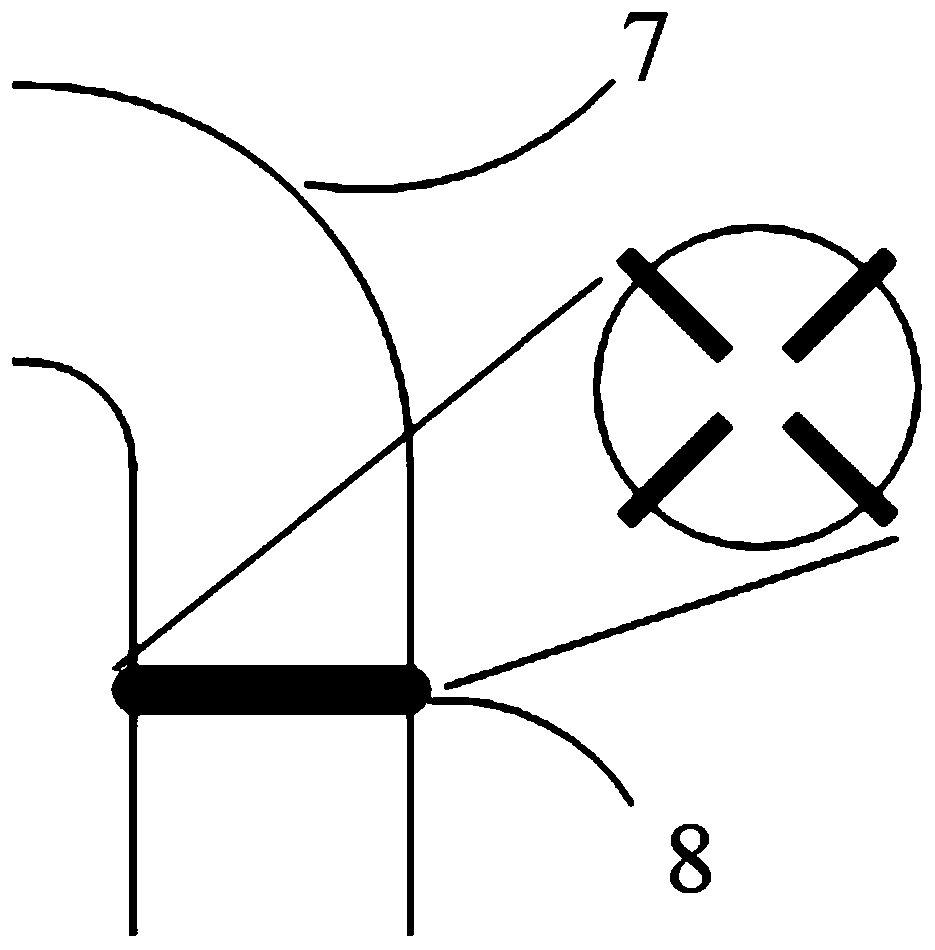

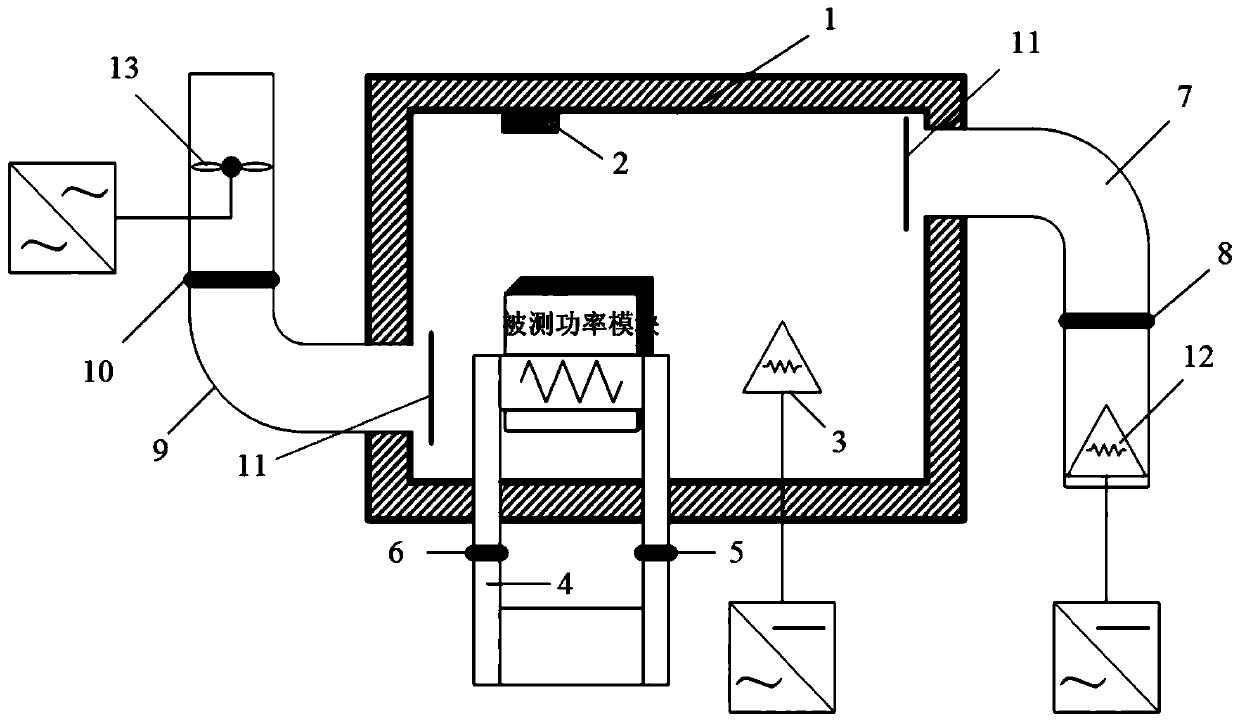

Loss measurement system of flexible DC converter valve power module

InactiveCN110412369APrevent escapeHigh Loss Measurement ResultsDielectric property measurementsElectrical testingComputer moduleEngineering

The invention discloses a loss measurement system of a flexible DC converter valve power module. The system comprises a heat insulation box, a temperature measurement module, a heater, a water coolingmodule, an inlet water temperature measuring module, an outlet water temperature measuring module, an air inlet module, an inlet air temperature measuring module, an air outlet module and an outlet air temperature measuring module; the temperature measurement module, the heater and the water cooling module are arranged in the heat insulation box, the inlet water temperature measuring module and the outlet water temperature measuring module are arranged in the water cooling module, the inlet air temperature measuring module is arranged in the air inlet module, and the outlet air temperature measuring module is arranged in the air outlet module; the heater is used to heat the internal of the heat insulation box; the water cooling device is used to carry out water cooling on a measured powermodule arranged in the heat insulation box; and the wall of the heat insulation box is provided with an air inlet and an air outlet connected with the air inlet module and the air outlet module respectively. The system can obtain a more accurate loss measurement result via a simpler measurement structure, and the measuring efficiency is improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com