Optical fiber sensor for temperature measurement

An optical fiber sensor, temperature measurement technology, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of places that cannot be used in harsh environments, complex sensor device structures, complex processing systems, etc., to improve the efficiency of optical transmission and measurement. The effect of high precision and simplified measurement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

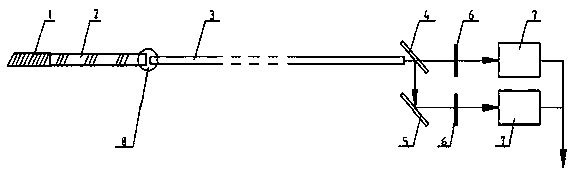

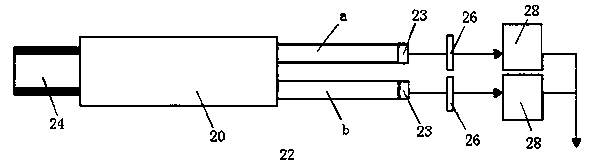

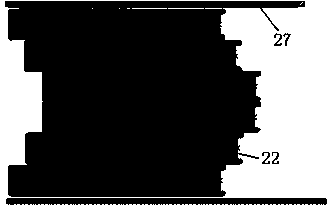

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 2 As shown, an optical fiber sensor for temperature measurement of the present invention includes an optical fiber bundle 20 with a cladding layer 27, and the optical fiber bundle 20 includes a plurality of unit optical fibers 22, and the surface of each unit optical fiber 22 is coated with an anti-oxidation metal Coating, one end of a plurality of unit optical fibers 22 with an anti-oxidation metal coating is gathered to form a probe 24, and the other end forms two branch optical fiber bundles a, b, and the two branch optical fiber bundles a, b are respectively connected to a A filter 26, and a photodetector 28 is respectively connected to the filter 26. Since the probe 24 is formed by gathering one end of a plurality of unit optical fibers 22 with an anti-oxidation metal coating, and at the same time, the other end forms two bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com