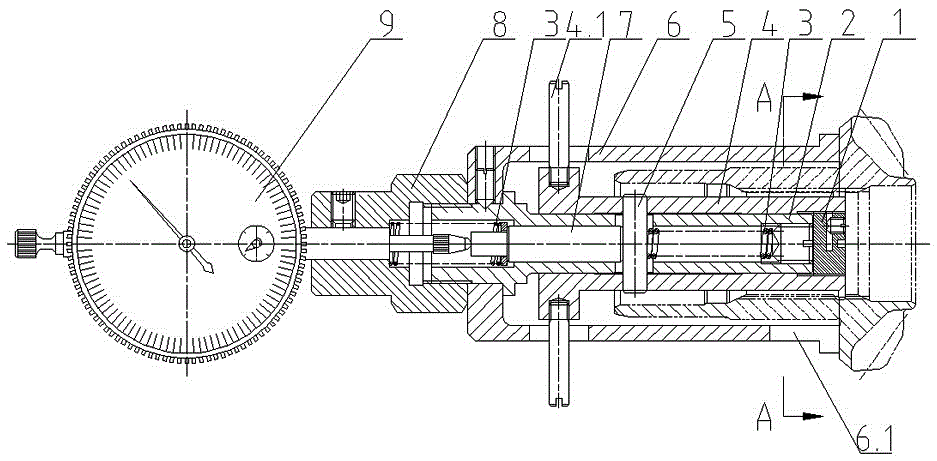

Tool for detecting linear distance between inner hole annular groove and outer end face of gear

A technology of straight-line distance and outer end surface, which is applied in the direction of mechanical clearance measurement, etc., can solve the problems that indirect dimensions cannot be directly measured, and achieve the effects of good detection timeliness, simple measurement structure and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

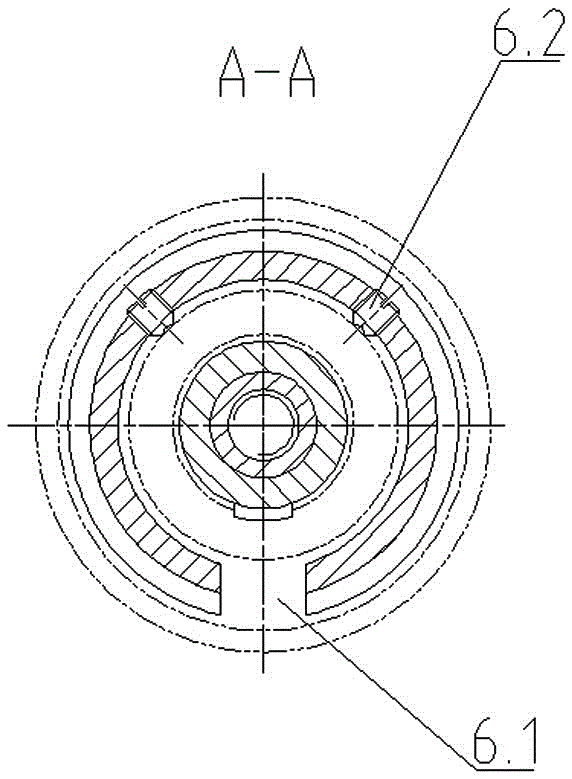

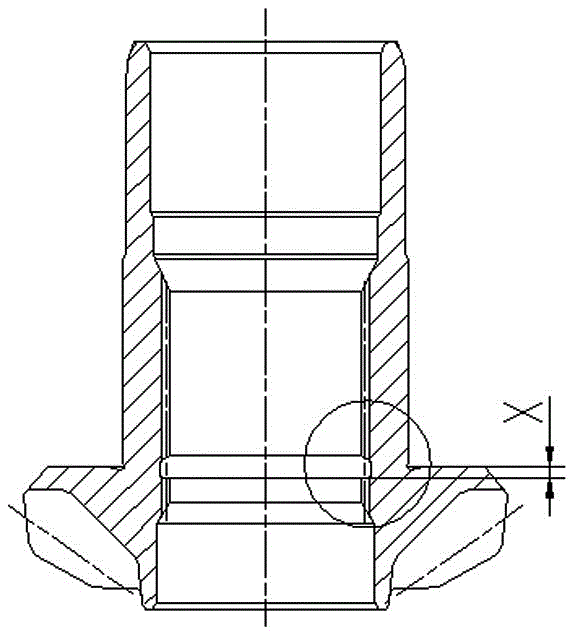

[0016] figure 1 and figure 2 The straight-line distance between the groove of the inner ring ring of the gear and the outer end surface is shown, which includes a plug 1, an inner shaft sleeve 2, a spring 3, a measuring sleeve 4, a cylindrical pin 5, an outer sleeve 6, a push rod 7, a table base 8 and Percentage table9. The inner shaft sleeve 2 is a hollow tube shaft, and one end with an external thread is coaxially positioned and installed with the small-diameter end of the outer sleeve 6, and then axially connected to the watch base 8, and the dial indicator 9 stem is inserted into the watch base 8 Hole for positioning installation. The measuring sleeve 4 is also a hollow tube shaft, the inner hole is in clearance fit with the inner shaft sleeve 2, and the outer walls of both ends of the measuring sleeve 4 are respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com