Method for measuring pressure in rotating state

A technology of rotation state and measurement method, which is applied in the direction of measuring device, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., can solve problems such as gas leakage, achieve the effect of ensuring accuracy and simplifying the measurement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

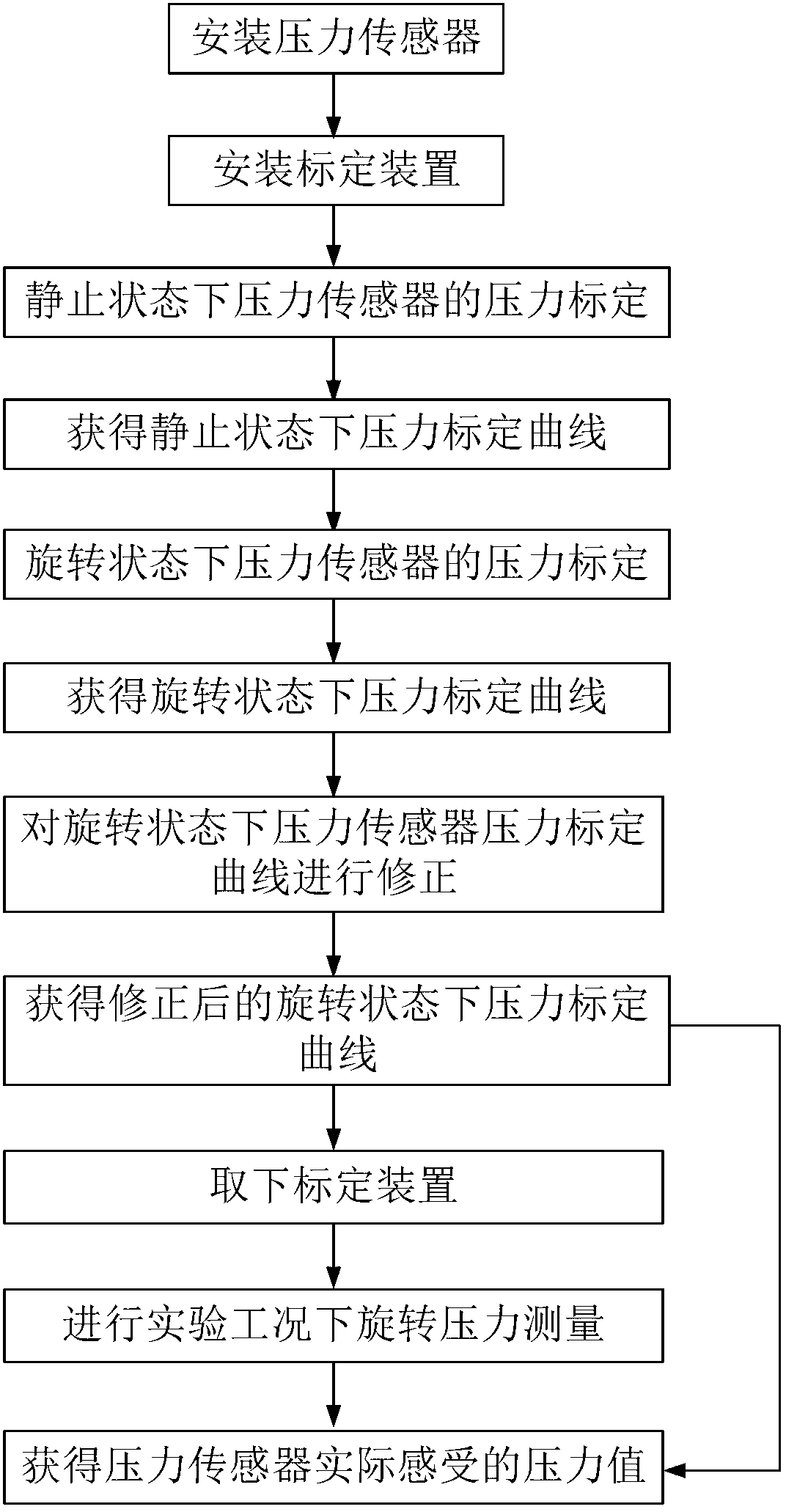

[0035] The present invention is a pressure measurement method in a rotating state, such as figure 1 shown, through the following steps:

[0036] Step 1: installation of pressure sensor 2;

[0037] The pressure sensor 2 is installed in the sensor installation hole opened on the test piece 1 through the two sides to measure the pressure distribution of the tested surface of the test piece 1 . The pressure sensor 2 is a strain gauge pressure sensor 2 with low inertia and high sensitivity. Its working principle is that the pressure-sensitive diaphragm is deformed when subjected to a certain pressure, and the deformation causes the output signal to change. Since the pressure sensor 2 rotates together with the rotating test piece 1 in the actual working condition of the pressure measurement experiment in the rotating state, the deformation of the pressure-sensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com