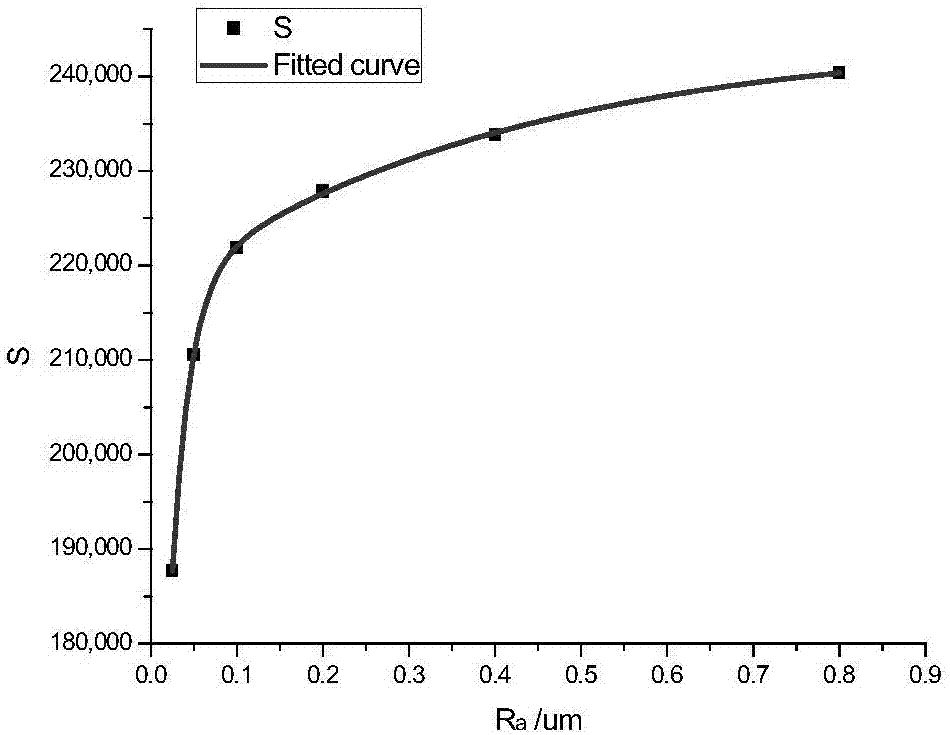

System and method for measuring surface roughness in online manner on basis of laser light scattering processes

A technology of surface roughness and laser scattering method, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of opacity and limited optical methods, and achieve the effects of avoiding secondary damage, good prospects and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] Such as figure 1 As shown, in this embodiment, an online surface roughness measurement system based on the laser scattering method is mainly composed of a laser 1 , an acquisition screen 2 and a data acquisition system 3 .

[0042] The laser 1 emits a collimated laser beam, which is incident on the metal surface to be tested at a set angle (such as 30°). The output of the laser is: wavelength λ=632.8nm, power 5mW.

[0043] The collection screen 2 is a transmissive hard frosted glass, which is placed in the reflection direction to collect the spatial distribution of reflection and scattered light carrying information on the roughness of the metal surface, and the height of the collection screen is consistent with the height of the laser, thereby ensuring that the scattered light band of symmetry.

[0044] The data acquisition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com