Parallel flat crystal optical inhomogeneity absolute measurement method

A parallel flat crystal and non-uniform technology, applied in the field of optical interferometry, can solve the problems of not being widely used, affecting measurement accuracy, and affecting measurement accuracy, and achieves the effects of easy implementation, simple measurement process, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

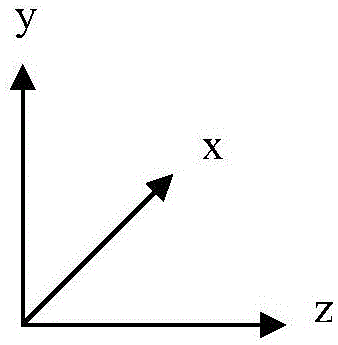

[0022] combine figure 1 , all the measurement processes in the present invention are figure 1 in the reference frame shown. A coordinate system is established, with the emission direction of the optical axis of the Fizeau laser interferometer as the z-axis, the vertical direction of the ground as the y-axis, and the x-axis, y-axis, and z-axis constitute the right-handed coordinate system of the thumb along the optical axis.

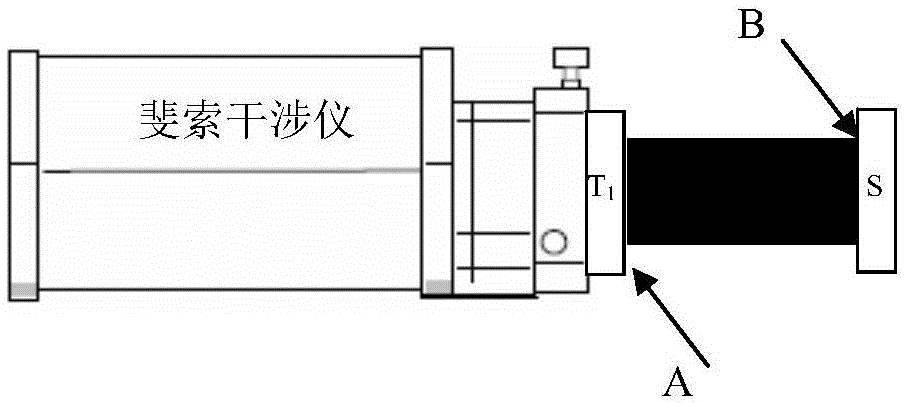

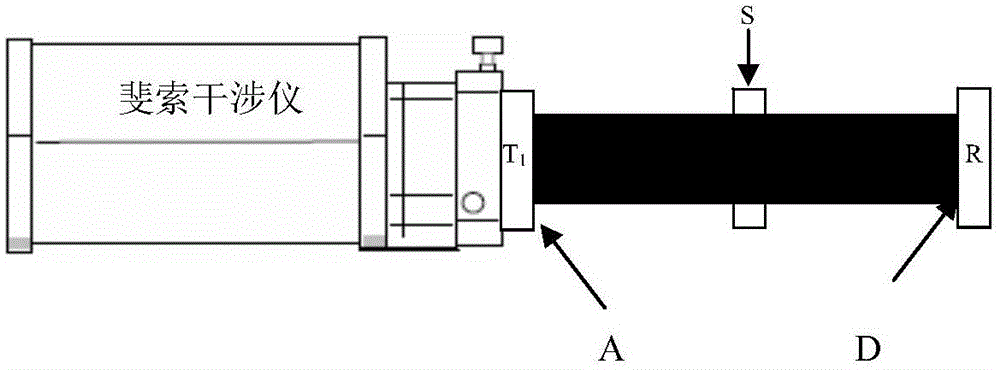

[0023] combine Figure 2 to Figure 7 , the method for absolute measurement of the optical non-uniformity of parallel flat crystals of the present invention comprises the following steps:

[0024] step 1, as figure 2 shown, using a Fizeau-type laser interferometer for the first transmission reference flat crystal T 1 The result M is obtained by performing an interferometric measurement between the working surface A and the front surface B of the parallel flat crystal S to be measured 1 , the formula is as follows:

[0025] M 1 =2B(x,y)-2A(x,y)(1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com