Sapphire fiber-reinforced ceramic-matrix multi-phase composite as well as preparation method and application thereof

A sapphire and fiber technology, applied in the direction of combustion method, metal material coating process, combustion equipment, etc., can solve the problems of low density, limited application, high room temperature brittleness, etc., achieve good interface compatibility and wettability, and promote Diffusion and grain refinement, the effect of reducing interface and crystal plane defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

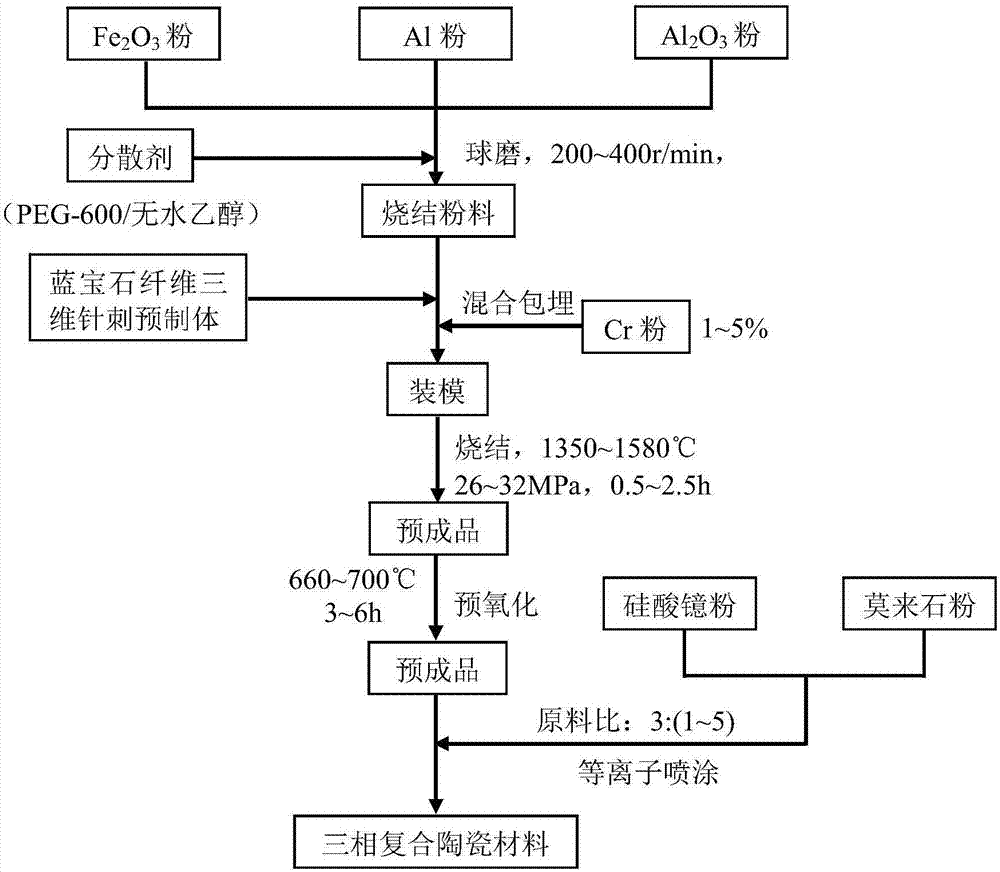

[0024] Such as figure 1 As shown, the invention provides a kind of preparation method of three-phase composite ceramic material, comprises the steps:

[0025] S1: Mix the first component with a dispersant, perform ball milling under the protection of argon, and then dry the ball-milled mixture; wherein, the first component includes iron oxide powder, aluminum powder and aluminum oxide powder.

[0026] Preferably, in the first component: the mass fraction of iron oxide powder is 14% to 27%, the mass fraction of aluminum powder is 7% to 13%, and the mass fraction of aluminum oxide powder is 60% to 79%; the first group The mass ratio of the dispersant and the dispersant is 1: (0.6~1.2); the dispersant is a mixed solution of polyethylene glycol and ethanol or a mixed solution of methyl amyl alcohol and ethanol; in the mixed solution of polyethylene glycol and ethanol, The mass fraction of polyethylene glycol is 3% to 5%; in the mixed solution of methyl amyl alcohol and ethanol, t...

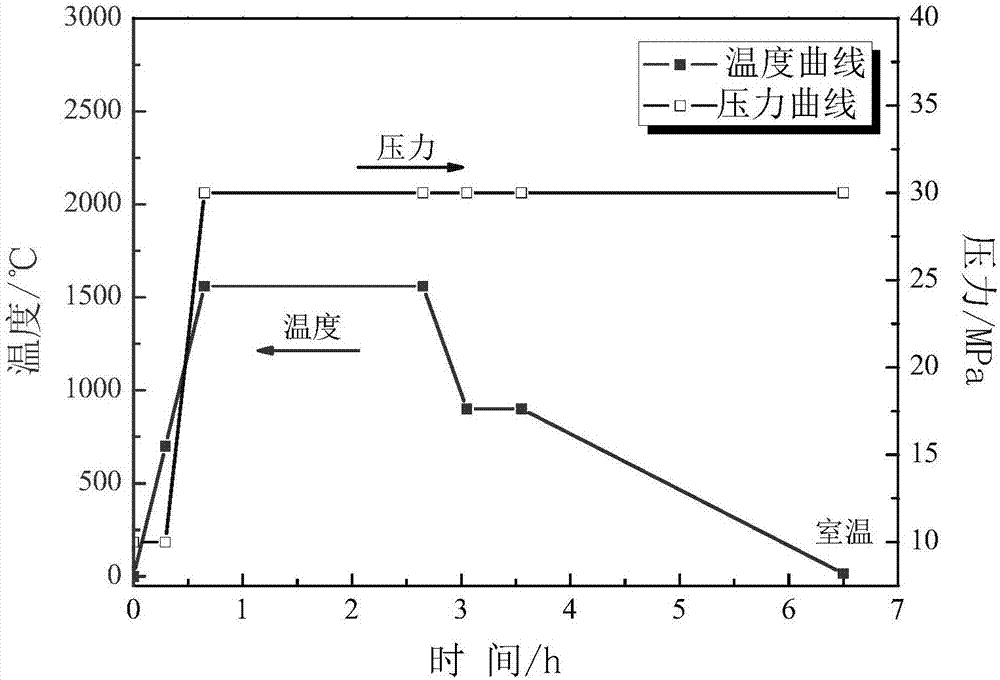

Embodiment 1

[0035] Weigh 56g of Fe with a diameter of 23-140μm 2 o 3 Powder, 29.7g Al powder with a diameter of 8-76μm, 214.2g Al powder with a diameter of 17-126μm 2 o 3 Powder, whose mass fractions are 18.7%, 10.0% and 71.3%, respectively, take the Al with a diameter of 8mm 2 o 3 1.8 kg of grinding balls, take 300 g of a mixed solution of polyethylene glycol (PEG-600) and ethanol, wherein the mass fraction of polyethylene glycol (PEG-600) is 3%. After mixing all the above materials, under the protection of argon, ball mill at a speed of 200r / min for 20h, and the mixture obtained by ball milling was vacuum dried at 45°C for 12h to obtain a dried product.

[0036] The 0° sapphire fiber non-weft fabric treated with steam, the sapphire fiber mesh tire formed by the air-laid machine and the 90° sapphire fiber non-weft fabric are stacked in sequence until the thickness reaches 4mm, and then three-dimensional needle punching is used. forming, the needling density is 36 needles / square cent...

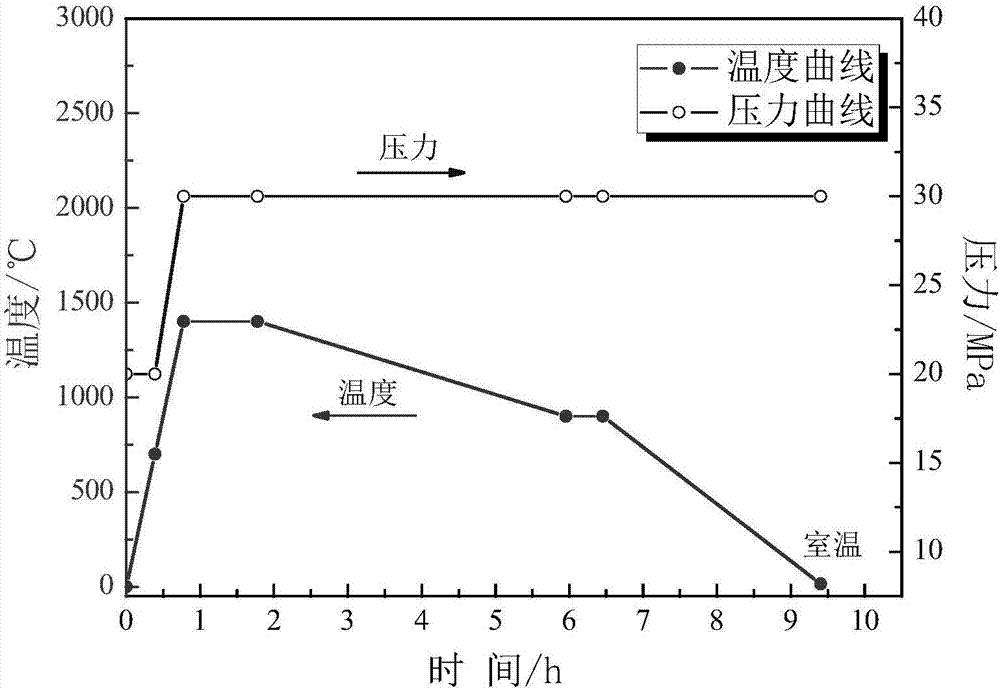

Embodiment 2

[0041] Weigh 72g of Fe with a diameter of 23-140μm 2 o 3 Powder, 35.1g Al powder with a diameter of 8-76μm, 260.0g Al powder with a diameter of 17-126μm 2 o 3 Powder, whose mass fractions are 19.6%, 9.6% and 70.8%, respectively, take the Al with a diameter of 10mm 2 o 3 2.2 kg of grinding balls, take 294 g of a mixed solution of polyethylene glycol (PEG-600) and ethanol, wherein the mass fraction of polyethylene glycol (PEG-600) is 5%. After mixing all the above materials, under the protection of argon, ball milled at a speed of 200r / min for 16h, and the mixture obtained by ball milling was vacuum dried at 45°C for 12h to obtain a dried product.

[0042]The 0° sapphire fiber non-weft fabric treated with steam, the sapphire fiber mesh tire formed by the air-laid machine and the 90° sapphire fiber non-weft fabric are stacked in sequence until the thickness reaches 4mm, and then three-dimensional needle punching method is used to form it. , the needling density is 25 needles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com