CdTe thin film-based wall surface heat flux density measurement method

A technology of heat flux density and measurement method, which is applied in the directions of material thermal development, fluorescence/phosphorescence, material excitation analysis, etc. It can solve the problems of limited layout density, small temperature field interference, and difficulty in further improving the measurement spatial resolution. The effect of increased sensitivity and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

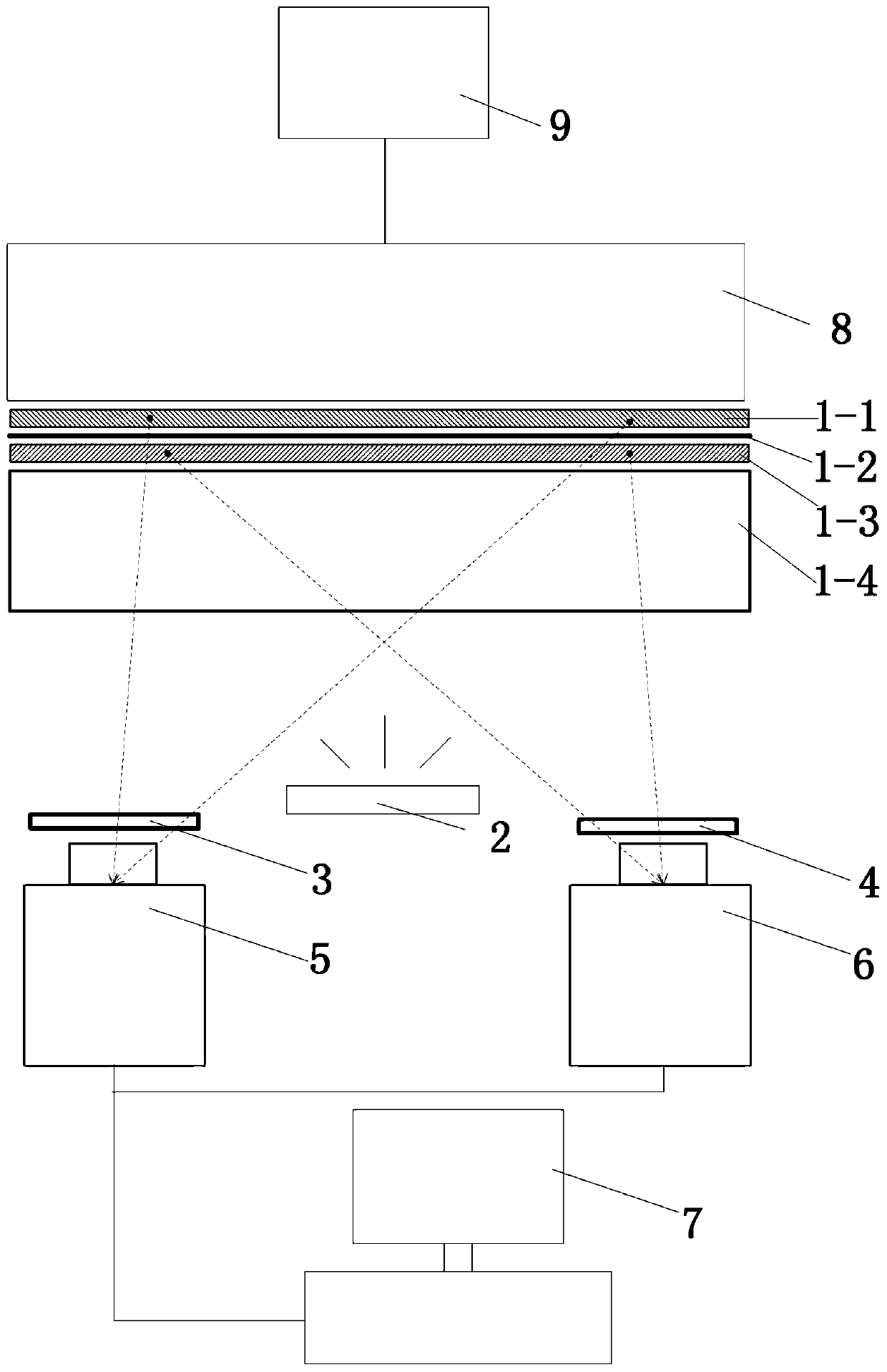

[0026] (1) if figure 1 As shown, the test piece 1 includes a first CdTe film 1-1, a first CdTe film 1-3, a tempered glass film 1-2 and a glass base 1-4. The production steps of test piece 1 are as follows: first, mix 1 g of gelatin with 6 g of water and heat, then drop 0.3 ml of water-soluble CdTe quantum dots into the gelatin solution, shake the mixed solution fully, and heat the mixed solution at 50°C for 15 minutes after shaking. The mixed solution is evenly spin-coated on the surface of the glass substrate 1-4 to prepare the second CdTe thin film 1-3.

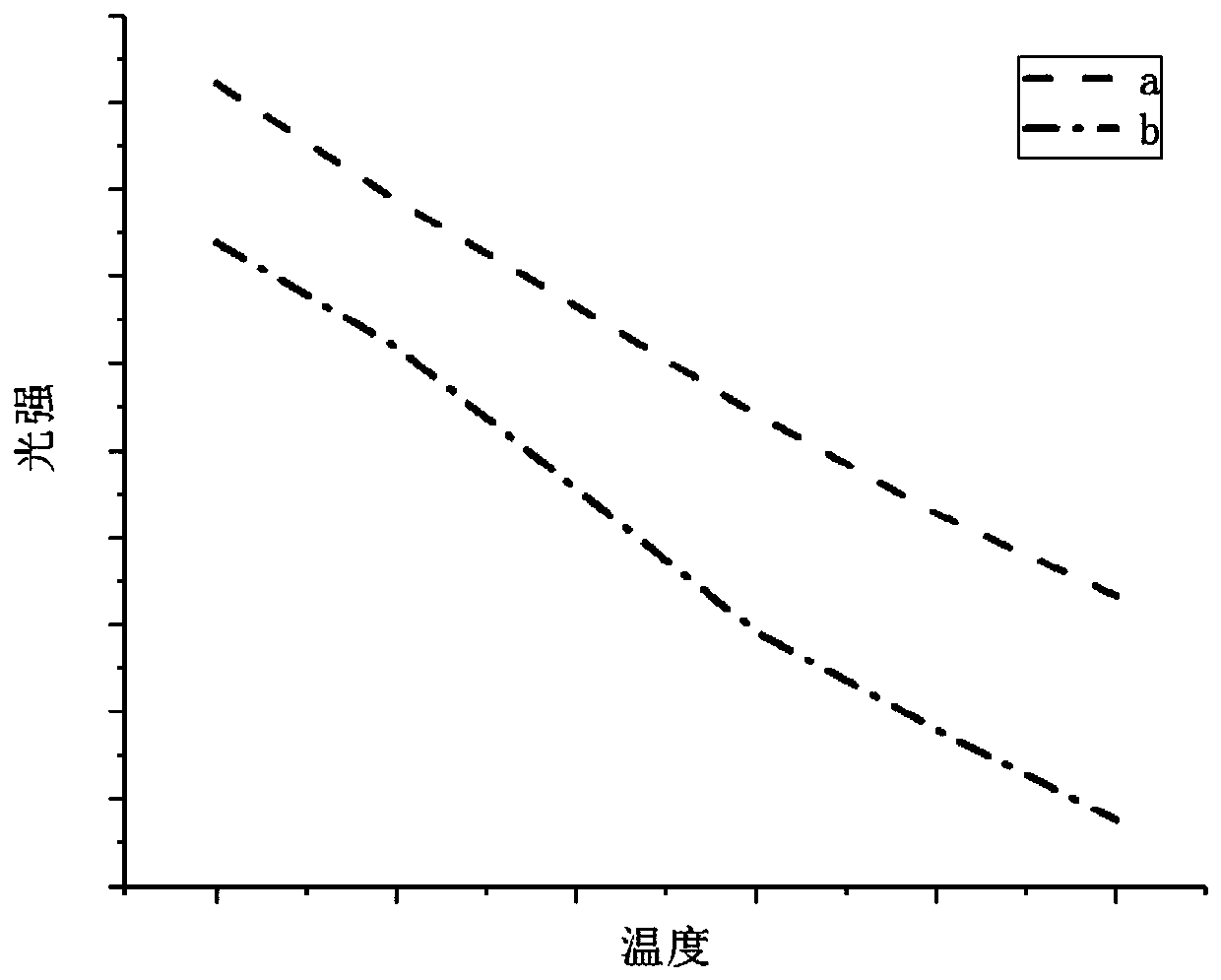

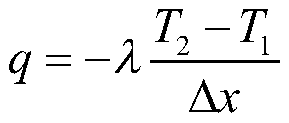

[0027] (2) if figure 1 As shown, temperature calibration: the temperature controller 9 controls the heater 8 to heat the second CdTe film 1-3 to different temperatures, the ultraviolet light source 2 excites the second CdTe film 1-3 to emit fluorescence, and the second filter 4 is used The second high-speed camera 6 collects images of the second CdTe thin film 1-3 at different temperatures, and the luminous intensity of t...

Embodiment 2

[0034] (1) iffigure 1 As shown, the test piece 1 includes a first CdTe film 1-1, a second CdTe film 1-3, a tempered glass film 1-2 and a glass base 1-4. The production steps of test piece 1 are as follows: first, mix 2 g of gelatin with 16 g of water and heat, then drop 0.8 ml of water-soluble CdTe quantum dots into the gelatin solution, fully shake the mixed solution, and then heat the mixed solution at 70°C for 15 minutes at a constant temperature after shaking. The mixed solution is evenly spin-coated on the surface of the glass substrate 1-4 to prepare the second CdTe thin film 1-3.

[0035] (2) if figure 1 As shown, temperature calibration: the temperature controller 9 controls the heater 8 to heat the second CdTe film 1-3 to different temperatures, the ultraviolet light source 2 excites the second CdTe film 1-3 to emit fluorescence, and the second filter 4 is used The second high-speed camera 6 collects images of the second CdTe thin film 1-3 at different temperatures, ...

Embodiment 3

[0042] (1) if figure 1 As shown, the test piece 1 includes a first CdTe film 1-1, a second CdTe film 1-3, a tempered glass film 1-2 and a glass base 1-4. The production steps of test piece 1 are as follows: first, mix 1 g of gelatin with 10 g of water and heat it, then drop 0.5 ml of water-soluble CdTe quantum dots into the gelatin solution, shake the mixed solution fully, and heat the mixed solution at 90°C for 15 minutes after shaking. The mixed solution is evenly spin-coated on the surface of the glass substrate 1-4 to prepare the second CdTe thin film 1-3.

[0043] (2) if figure 1 As shown, temperature calibration: the temperature controller 9 controls the heater 8 to heat the second CdTe film 1-3 to different temperatures, the ultraviolet light source 2 excites the second CdTe film 1-3 to emit fluorescence, and the second filter 4 is used The second high-speed camera 6 collects images of the second CdTe thin film 1-3 at different temperatures, and the luminous intensity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com