Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Space cloth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Space cloth is a hypothetical infinite plane of conductive material having a resistance of η ohms per square, where η is the Impedance of free space. η ≈ 376.7 ohms. If a transmission line composed of straight parallel perfect conductors in free space is terminated by space cloth that is normal to the transmission line then that transmission line is terminated by its characteristic impedance. The calculation of the characteristic impedance of a transmission line composed of straight, parallel good conductors may be replaced by the calculation of the D.C. resistance between electrodes placed on a two-dimensional resistive surface. This equivalence can be used in reverse to calculate the resistance between two conductors on a resistive sheet if the arrangement of the conductors is the same as the cross section of a transmission line of known impedance. For example, a pad surrounded by a guard ring on a printed circuit board (PCB) is similar to the cross section of a coaxial cable transmission line.

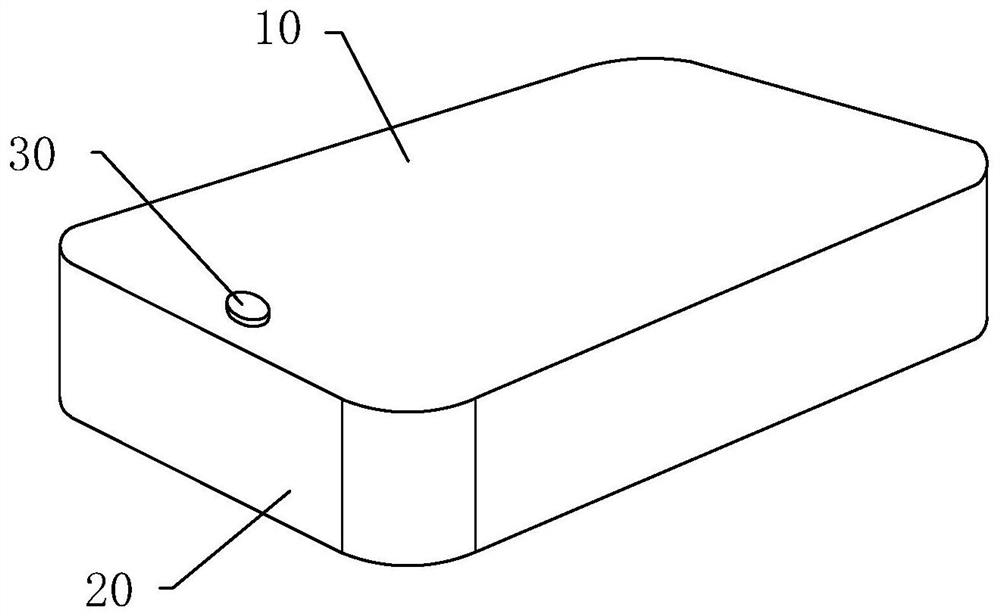

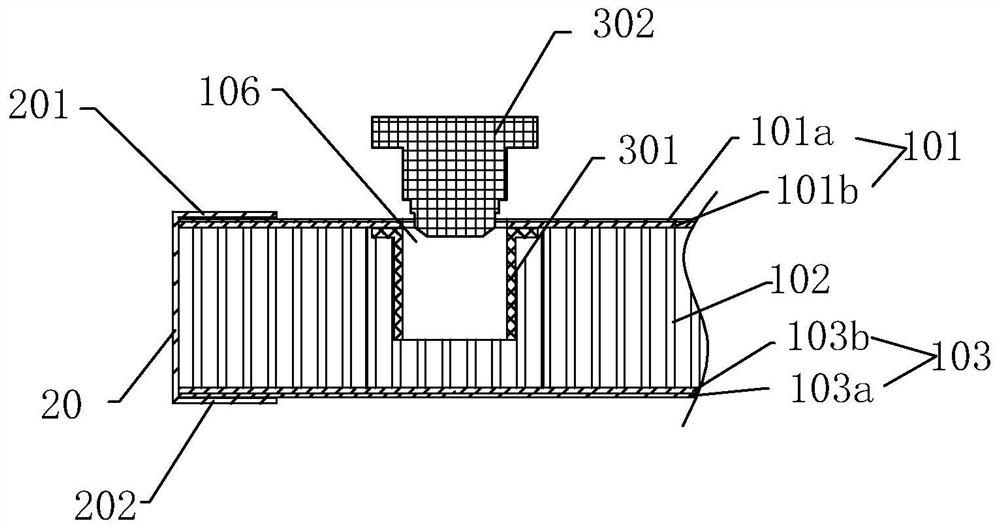

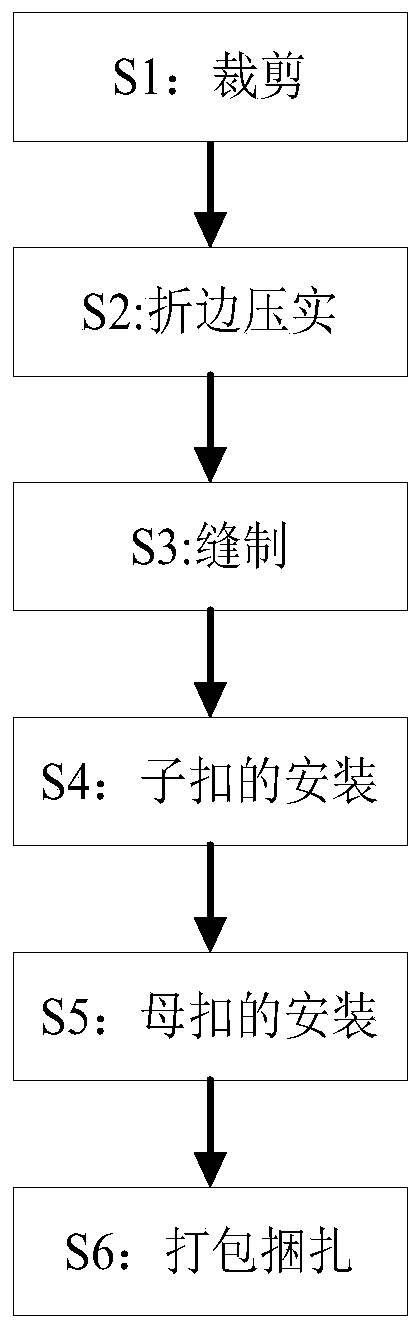

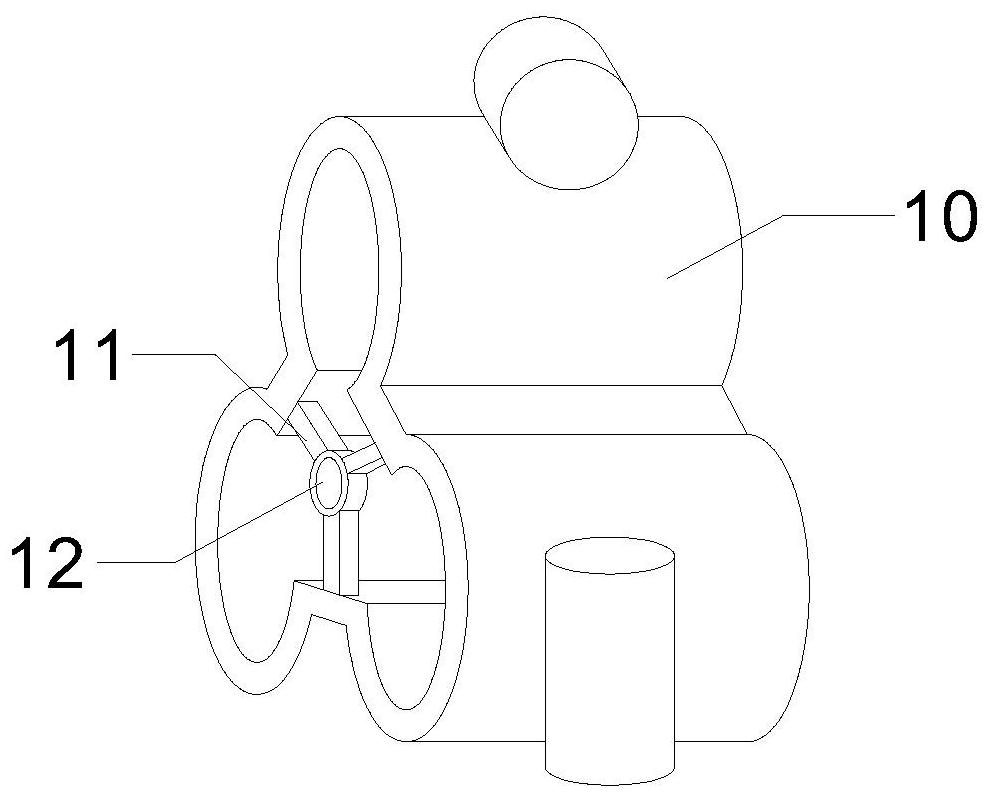

Manufacturing method of spatial cloth inflatable product, and spatial cloth inflatable product

The invention relates to a manufacturing method of a spatial cloth inflatable product, and the spatial cloth inflatable product. The manufacturing method comprises the following steps of S1, preparingspatial cloth with an inflation hole; S2, preparing foxing strips; S3, comprising the following step (a1) of welding the foxing strips with lower-layer base cloth according to a conventional high-frequency welding process; the step (a2) of preparing a straight backing plate, a non-linear backing plate and a non-linear pressing plate matched with the non-linear backing plate, and taking the foxingstrip closest to the inflation hole and upper-layer base cloth as a final welding process; placing the straight backing plate or the non-linear backing plate on the inner surface of the upper-layer base cloth, and covering the upper side edge of the foxing strip on the outer surface of the upper-layer base cloth; welding the foxing strips with the upper-layer base cloth through a high-frequency machine; the step (a3) of arranging an inner shell of an inflation valve between the upper-layer base cloth and the lower-layer base cloth near the inflation hole; the step (a4) of welding the reservedfoxing strips with the upper-layer base cloth into a whole; the step (a5) of taking out the backing plate from the space cloth through the inflation hole; and the step (a6) of moving the inner shellto the inflation hole, and connecting an inflation valve body with the inner shell.

Owner:骆炳华

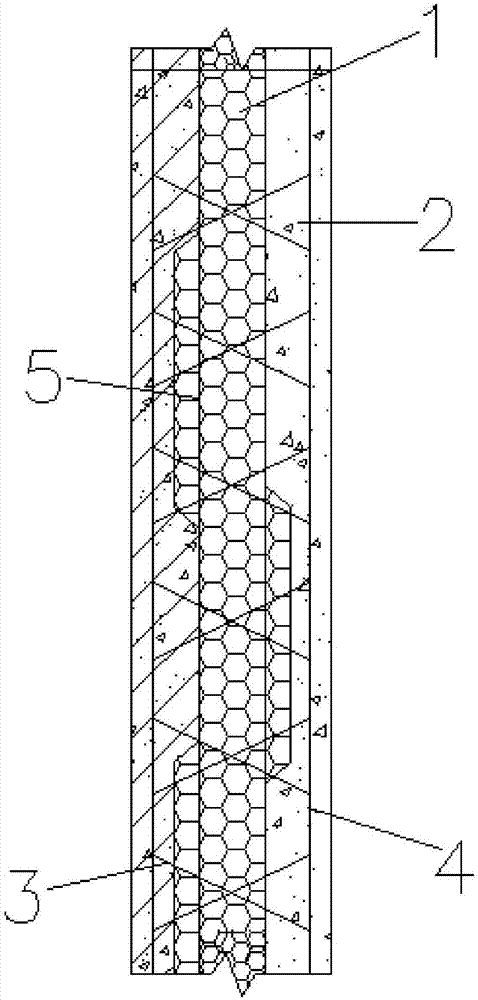

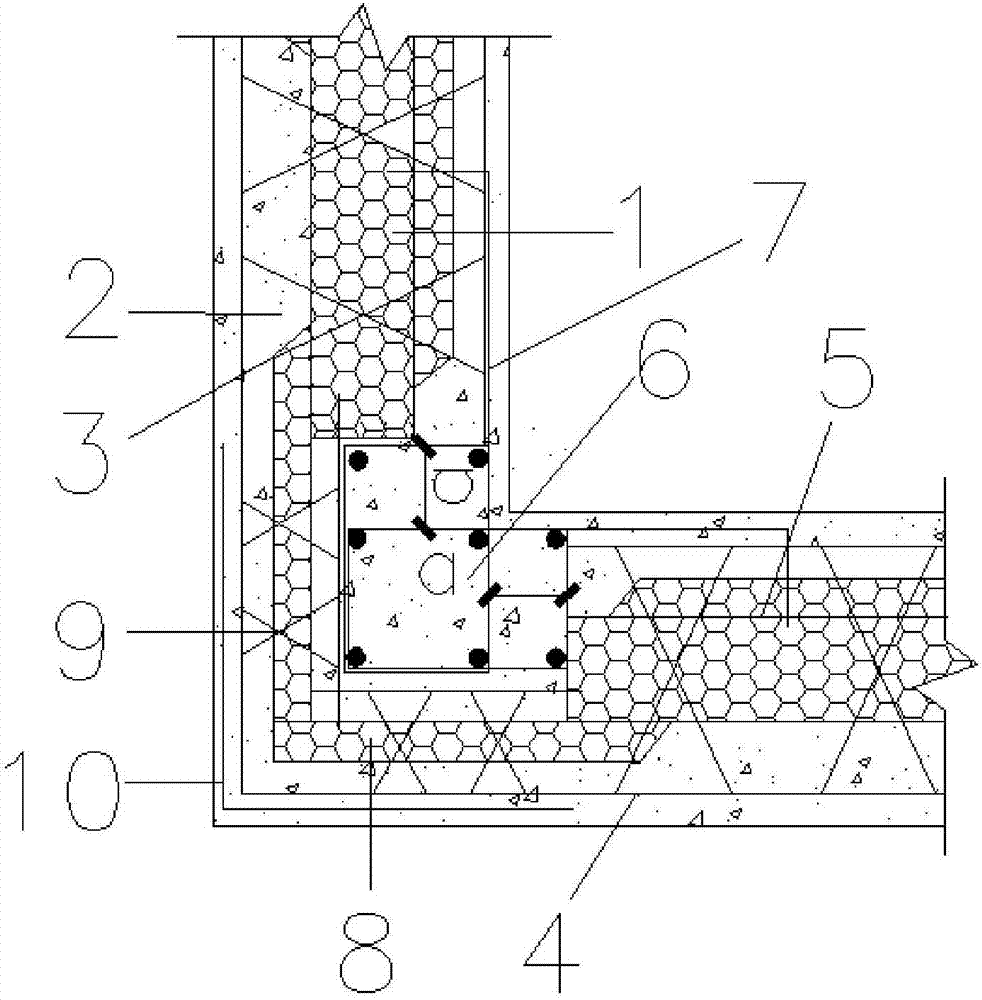

Steel wire net frame composite heat-insulation sandwich wall board node and construction method thereof

ActiveCN106968362AAvoid problemsSolve the real problemWallsClimate change adaptationBuilding energyMechanical engineering

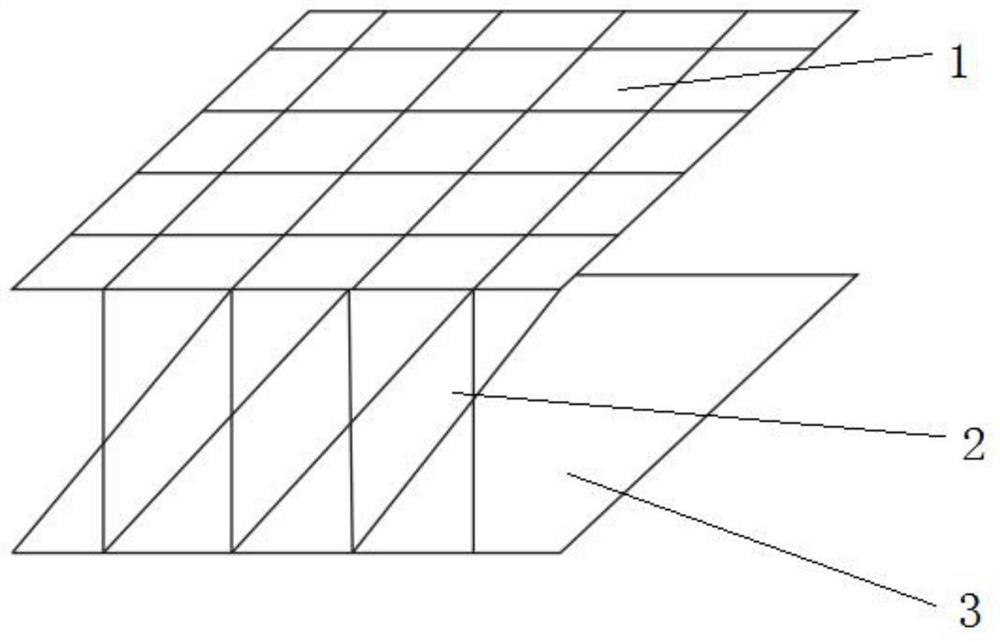

The invention relates to a steel wire net frame composite heat-insulation sandwich wall board node and a construction method thereof and belongs to the technical field of building energy-saving heat insulation. The steel wire net frame composite heat-insulation sandwich wall board node is of a T-shaped, L-shaped or Z-shaped node structure formed by mutually connecting steel wire net frame composite heat-insulation sandwich wall boards. The connecting position of the wall boards is a column body, each steel wire net frame composite heat-insulation sandwich wall board comprises a steel wire net frame formed by two steel wire net pieces which are mutually parallel and a plurality of cold-drawing obliquely-inserting steel wires for being connected with the two corresponding steel wire net pieces, a three-layer heat insulation board sandwiched between the two corresponding steel wire net pieces and concrete layers arranged on the two sides of the corresponding heat insulation board; the steel wire net pieces are formed through longitudinally and transversely intersection of steel wires in a welding mode; and each three-layer heat insulation board comprises a middle-layer thick main heat insulation board body and thin heat insulation board bodies which are arranged on the two sides of the corresponding main heat insulation board body in a spaced mode, every two corresponding heat insulation board bodies on the two sides are distributed in a horse-tooth-stubble shape on the two sides of the corresponding middle main heat insulation board body, and the heat insulation board bodies on any side can cover the abutted seam positions of the middle main heat insulation board bodies.

Owner:保定市冀创建筑工程有限公司 +3

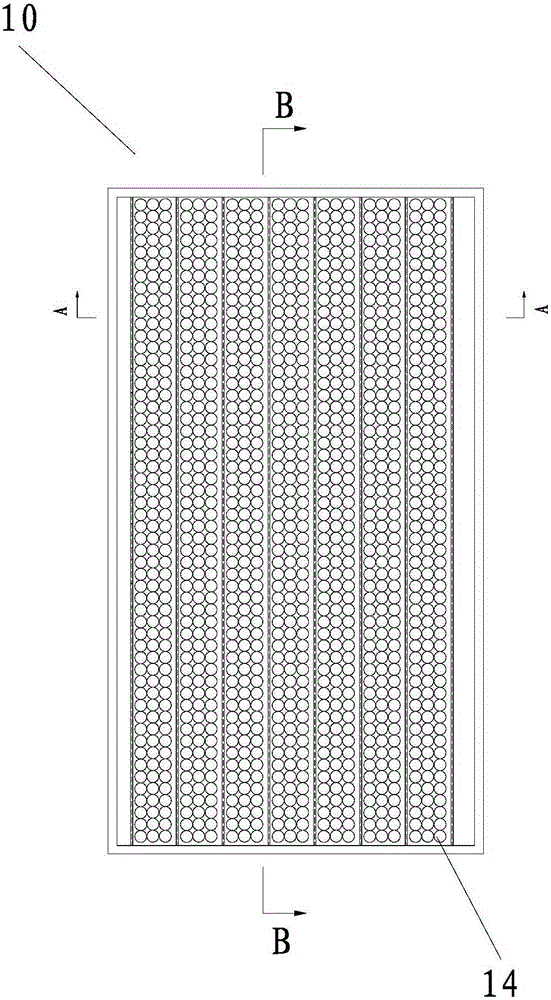

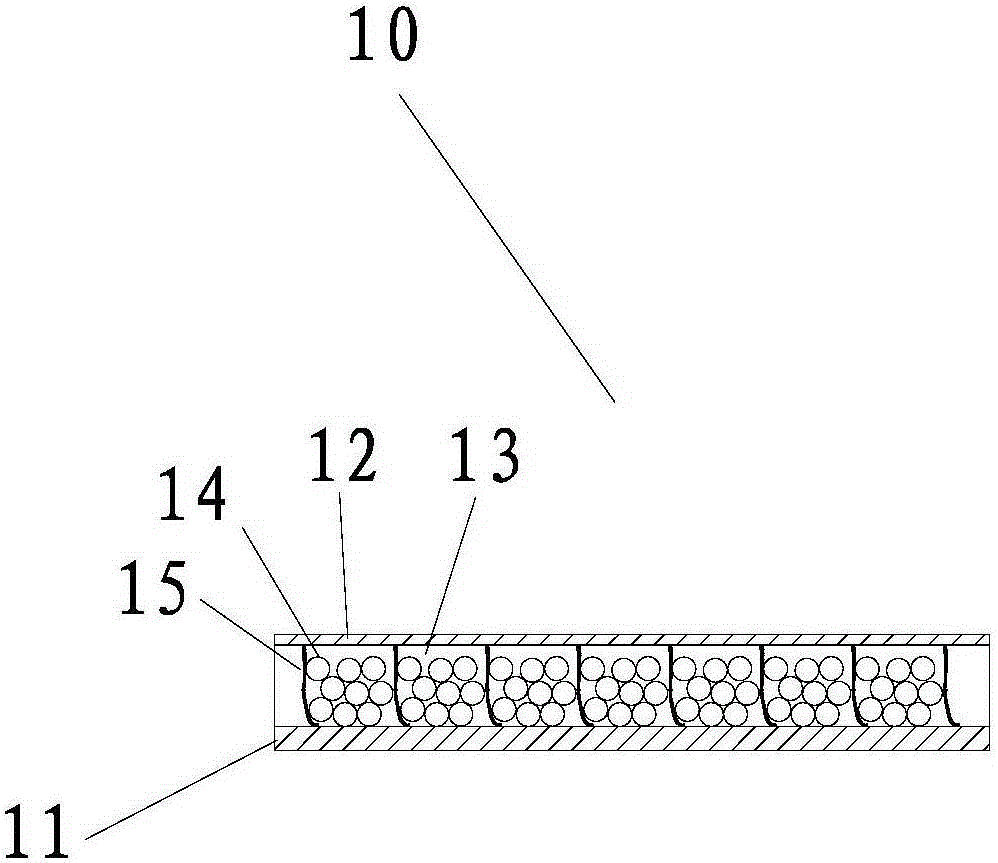

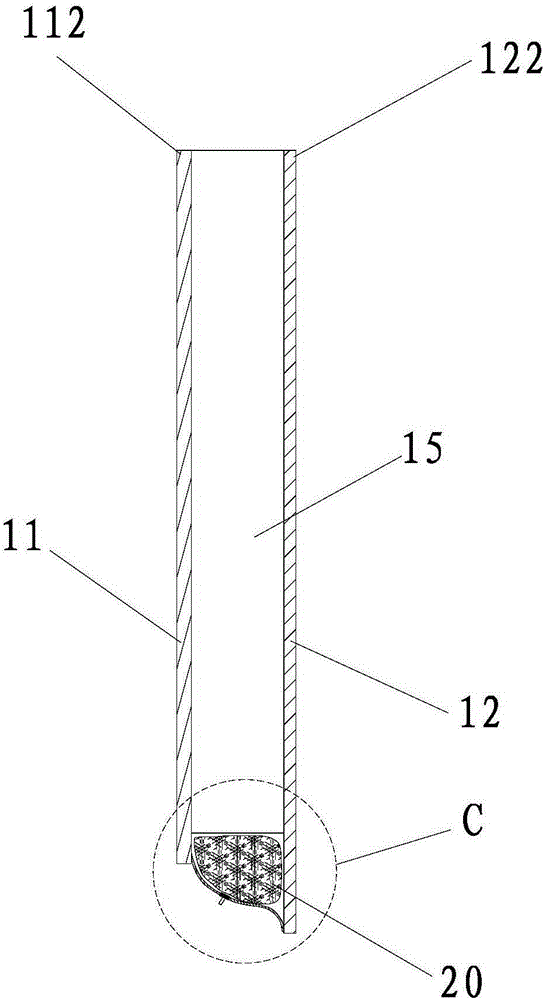

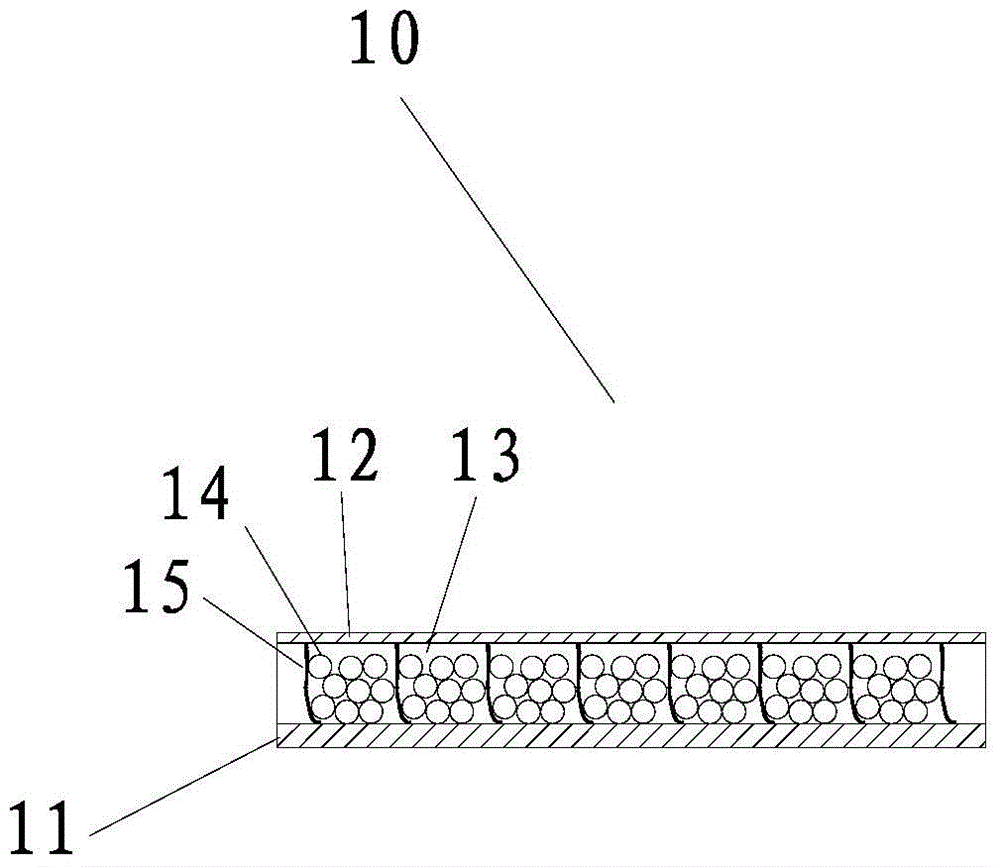

Bead health pad, manufacturing method, and pillowcase and pillow made by bead health pad

InactiveCN105193181AThere will be no shifting phenomenonNot easy to movePillowsRoller massageMechanical engineeringHealth effect

The invention relates to a bead health pad which comprises a piece of basic cloth and a piece of surface cloth arranged above the basic cloth, wherein an accommodating space is formed between the basic cloth and the surface cloth. The bead health pad further comprises a plurality of pieces of spacing cloth, wherein the spacing cloth divides the accommodating space into a plurality of accommodating slots; the accommodating slots are filled with beads; an opening is formed in at least one of the two ends of each accommodating slot along the length direction. The bead health pad further comprises elastic cotton strips for plugging the multiple openings and a zipper assembly. The bead health pad is higher in breathability, has a health effect, and is convenient to manufacture and comfortable in handfeel; the beads are unlikely to stagger and convenient to fill and pour; the cloth is convenient to clean. The invention further provides a pillowcase and a pillow which are made by the bead health pad, and a manufacturing method adopting the bead health pad. The pillowcase is used with a pillow interior, so that the pillow has the effects of high breathability and comfortable handfeel; meanwhile, the pillow has the effects of high breathability, comfortable handfeel and pillowcase stabilization.

Owner:林伟林

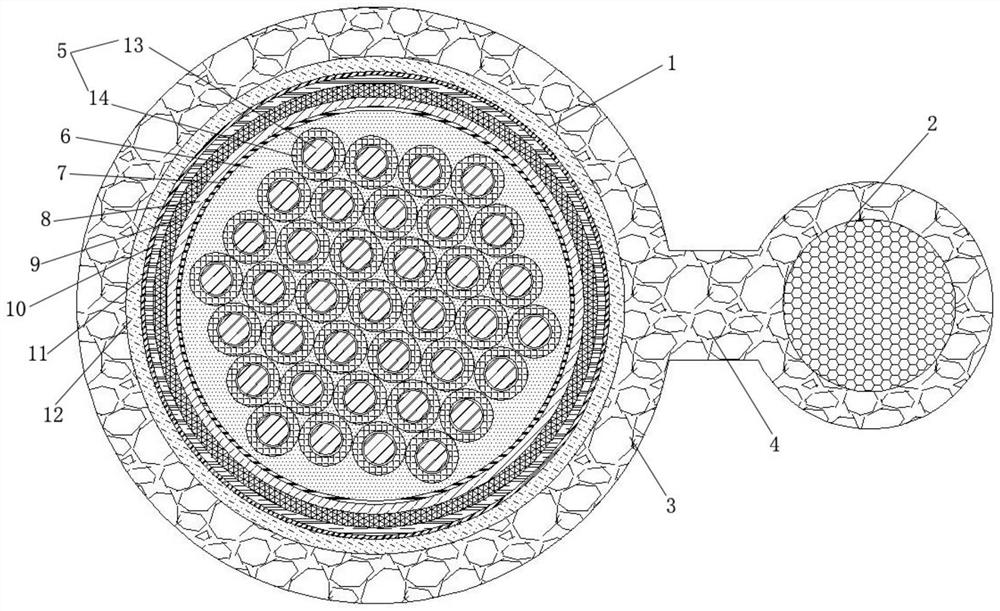

Inflatable surfboard composite material and preparation method thereof

ActiveCN110561865AGood water and oil resistance and weather resistanceHigh strengthNon-macromolecular adhesive additivesWaterborne vesselsWeather resistanceUltimate tensile strength

The invention discloses an inflatable surfboard composite material and a preparation method thereof. The composite material comprises a high-strength space cloth layer, two surfaces of the high-strength space cloth layer are symmetrically and sequentially provided with second pasting layers, first pasting layers and TPU fiber cloth reinforcement layers from the inside out. Each TPU fiber cloth reinforcement layer sequentially comprises a TPU surface film layer, an adhesive layer A, a base cloth layer, an adhesive layer B and a TPU base film layer; the high-strength space cloth layer is formedby one of high-strength polyester fiber space cloth, high-strength nylon fiber space cloth and high-strength aramid fiber space cloth; and the base cloth layer is formed by one of high-strength polyester fiber cloth, high-strength nylon fiber cloth and high-strength aramid fiber cloth. The surfboard made of the composite material provided by the invention has the advantages of large buoyancy, highstrength, good resilience, weather resistance, bacteria resistance, oxidation resistance and ultraviolet resistance, beautiful appearance, portability and the like.

Owner:福建恩迈特新材料有限公司

Space cloth preparation method with three-dimensional pattern effects

InactiveCN108909149ALow costGood weldabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWear resistantEngineering

The invention relates to the field of a space cloth preparation method, in particular to a space cloth preparation method with three-dimensional pattern effects. Two transparent mask layers are attached onto the surface of wire pulling net cloth; a first pattern is sprayed and drawn on the inner side surface of the inner layer mask layer; a second pattern in staggered arrangement with the first pattern is sprayed and drawn on the inner side surface of the mask layer; the inner layer mask has certain thickness, so that the first pattern and the second pattern in staggered arrangement show a three-dimensional effect; through the protection of the outer layer mask layer, the first pattern and the second pattern hide the patterns at the inside; the scratch or abrasion cannot occur, so that thesurface of the prepared space has durable and attractive pattern effects; on the material selection, the inner layer mask layer uses the PVC materials with low cost and good melting connection performance; the outer layer mask layer uses the TPU material with high wear-resistant performance and environmental-friendly performance; the protection effect on inside patterns can be enhanced.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Novel wire-drawing air cushion and production method thereof

PendingCN108660783AEasy to carryIncrease bearing pressureLamination ancillary operationsSynthetic resin layered productsPolyvinyl chlorideEngineering

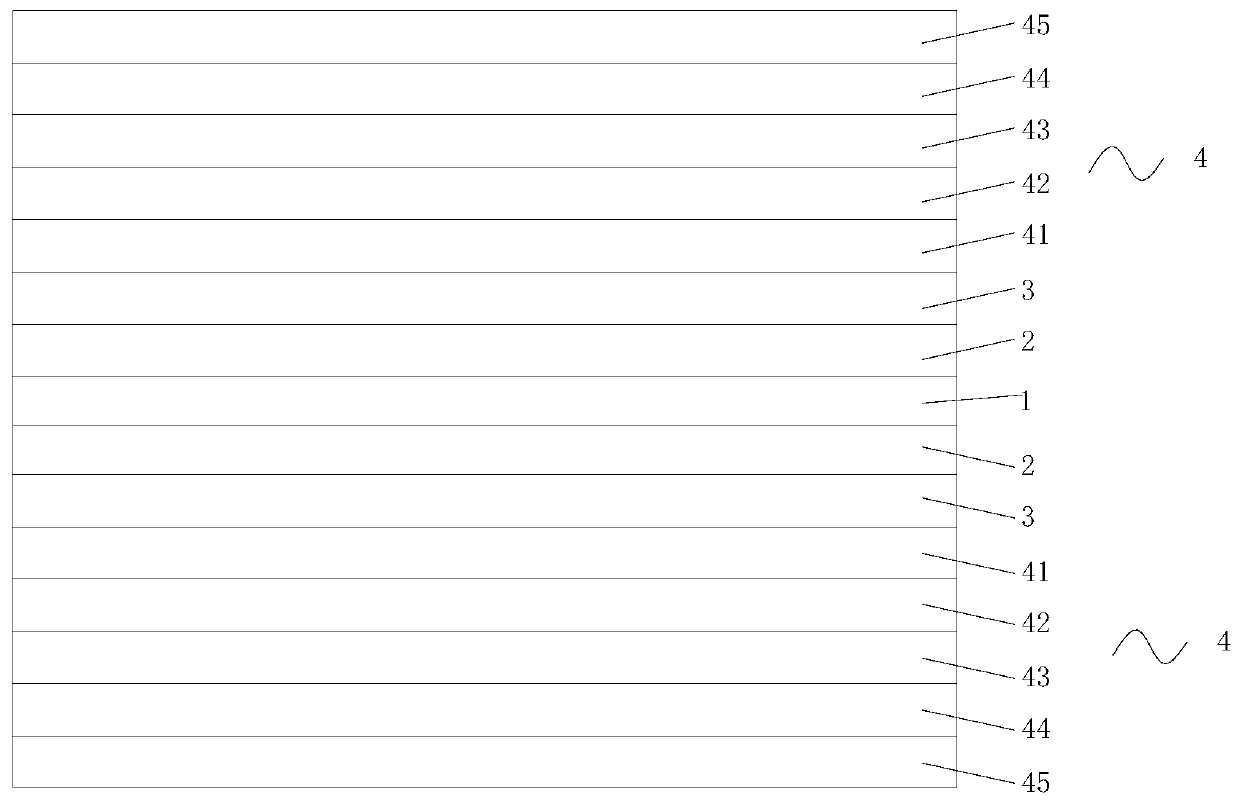

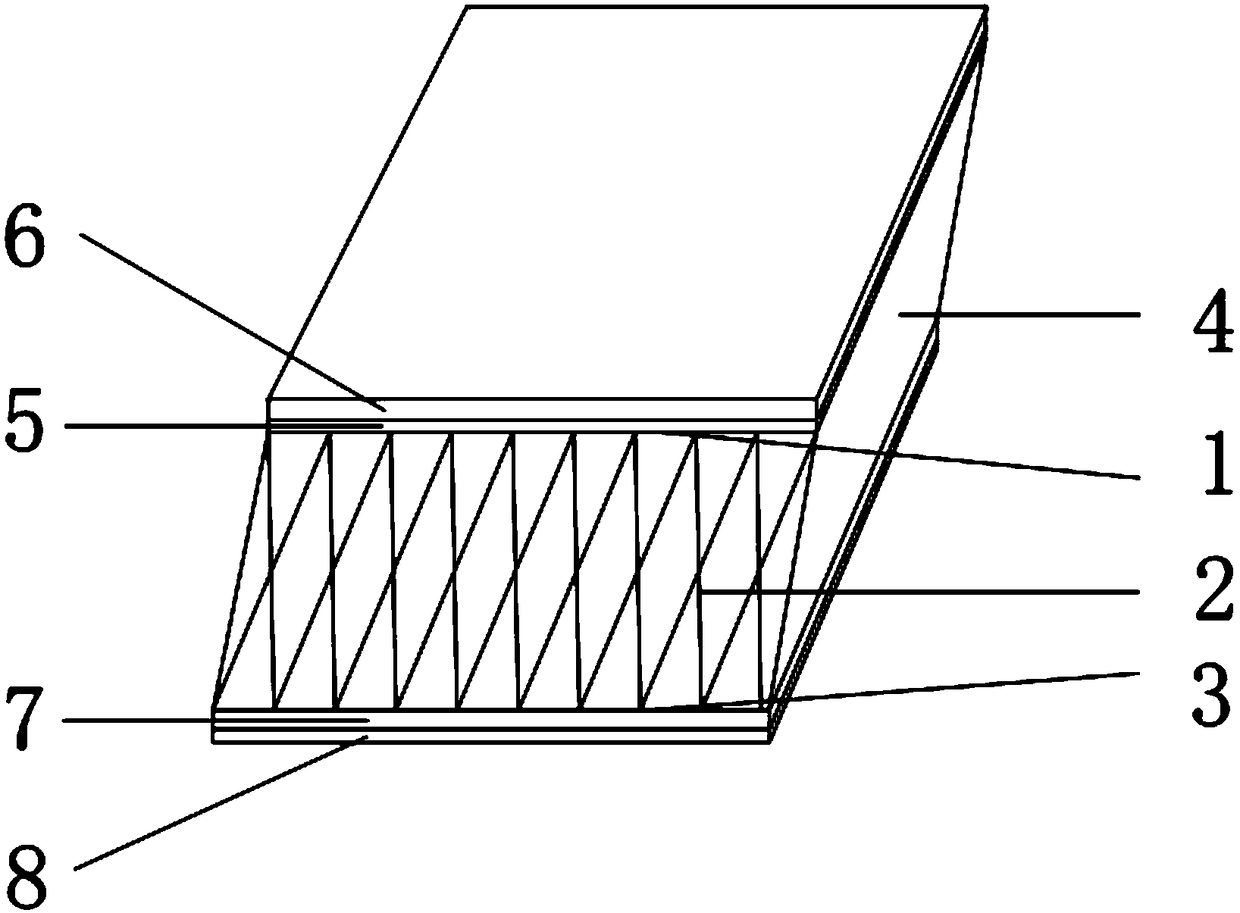

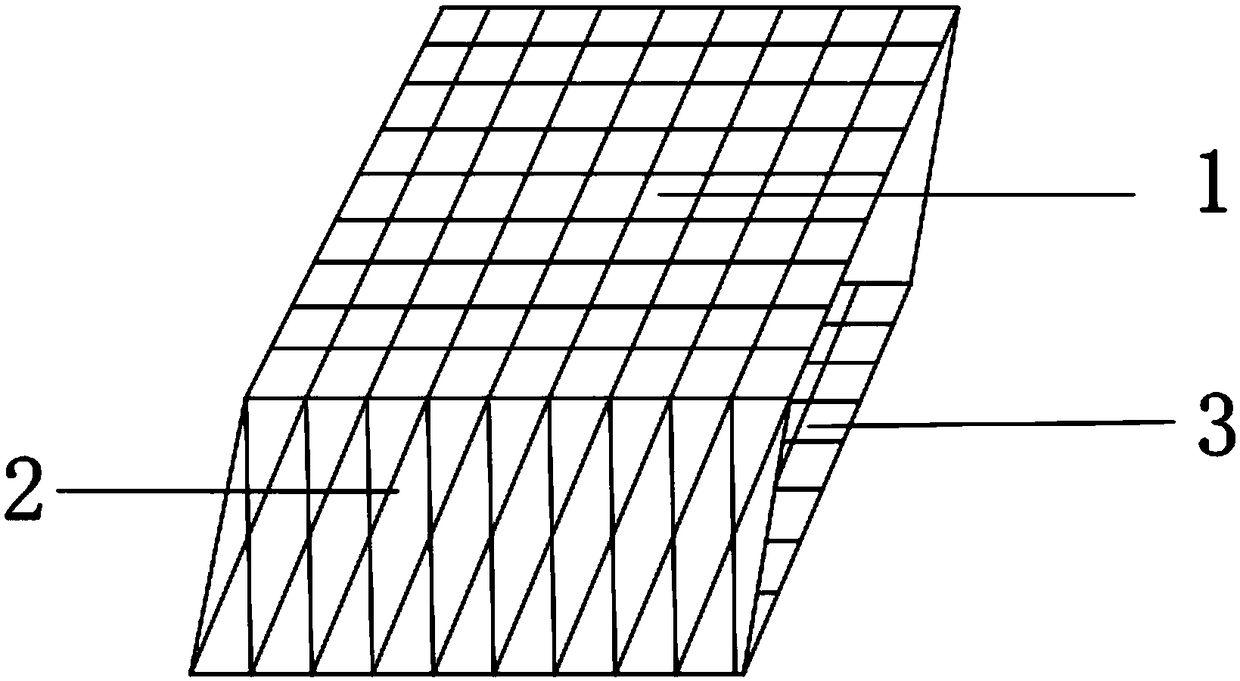

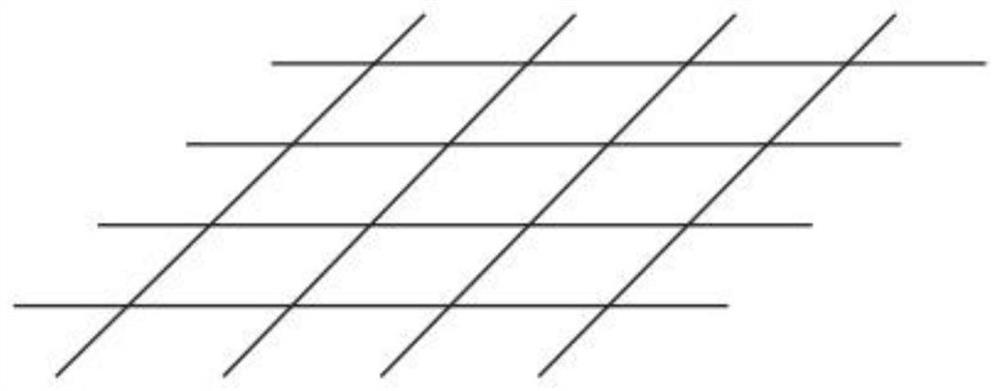

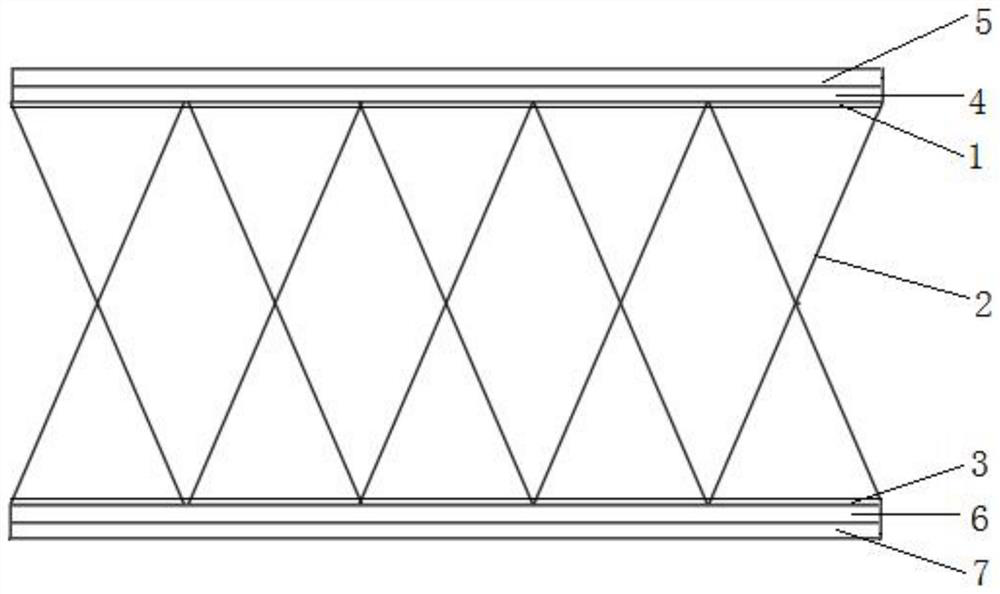

The invention discloses a novel wire-drawing air cushion and a production method thereof. The novel wire-drawing air cushion comprises a piece of space cloth; the space cloth sequentially comprises apiece of first gridding cloth, a piece of wire-drawing cloth and a piece of second gridding cloth which are connected with one another from top to bottom; the upper surface and lower surface of the space cloth are separately coated with a coating; the two ends of the space cloth are separately stuck with a polyvinyl chloride (PVC) connecting strip; the first gridding cloth and the second griddingcloth are separately formed by interweaving warps and wefts, and quadrilateral grids are formed; the wire-drawing cloth comprises a plurality of X-shaped wire-drawing units; the adjacent wire-drawingunits are arranged in a row; all the wire-drawing units are distributed between the first gridding cloth and the second gridding cloth in a criss-crossed way; the upper ends of the wire-drawing unitsare connected with vertexes of grids of the first gridding cloth, and the lower ends of the wire-drawing units are connected with vertexes of grids of the second gridding cloth. The production methodof the novel wire-drawing air cushion comprises the steps of preparing the space cloth; preparing the PVC connecting strips; bonding the PVC connecting strips with the space cloth; scratch coating inner and outer coatings. The product is higher in bearing pressure and firmness and lighter in weight; the production method is higher in production efficiency.

Owner:威海水知乐户外用品股份有限公司

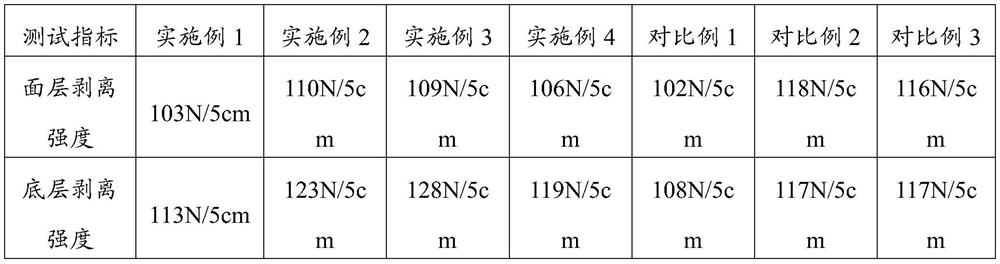

Preparation method of space cloth material

ActiveCN112026191AOvercome the problem of substandard peel strengthConducive to the promotion of industrial productionSynthetic resin layered productsFlat articlesPolymer scienceThin membrane

The invention discloses a preparation method of a space cloth material, and belongs to the technical field of composite materials. The preparation method includes the following steps that the upper surface and the lower surface of PE space cloth are ironed correspondingly, PU (polyurethane) paste is simultaneously applied to the upper surface and the lower surface, drying is conducted, films to bepasted and the pasted PE space cloth are simultaneously preheated, the films are pasted to the upper surface and the lower surface correspondingly, and the space cloth material is obtained. Accordingto the preparation method of the space cloth material, the problems that the films and the PE space cloth are hardly pasted, and the peel strength after pasting does not reach the standard are solved, the peel strength after pasting can reach 150 N / 5 cm or above, a product prepared from the obtained space cloth material can bear higher air pressure, the preparation method can be used for pastingof TPU films and can also be used for pasting of PVC films, and only one time of pasting is conducted, so that the production efficiency is high.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

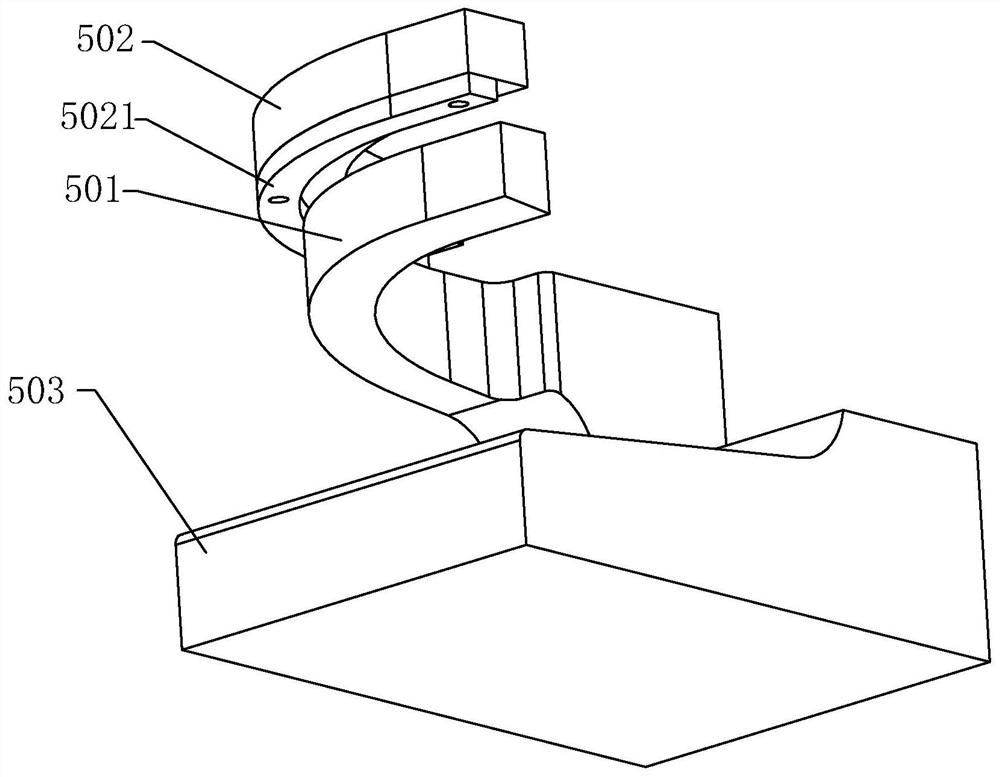

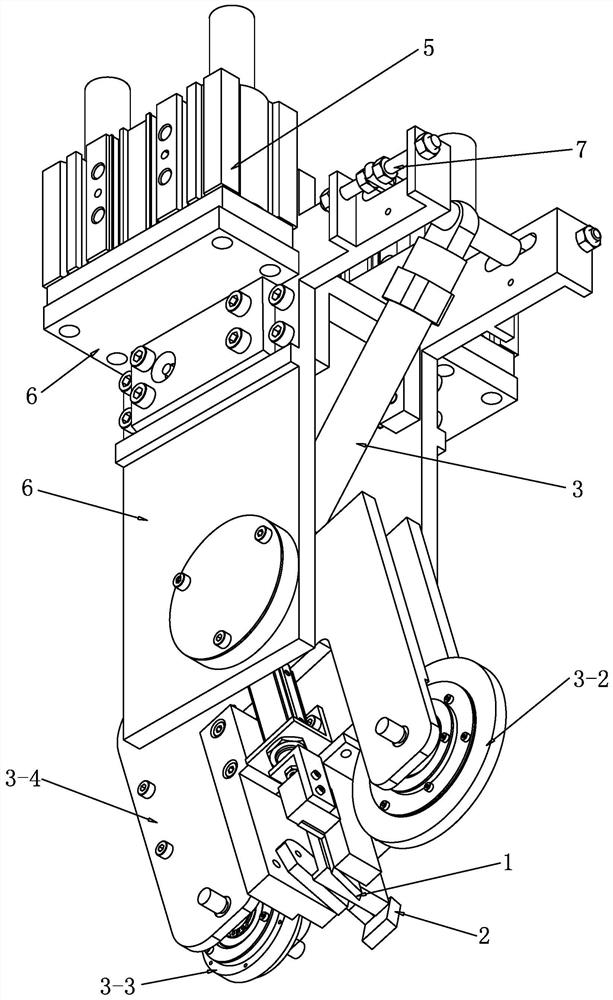

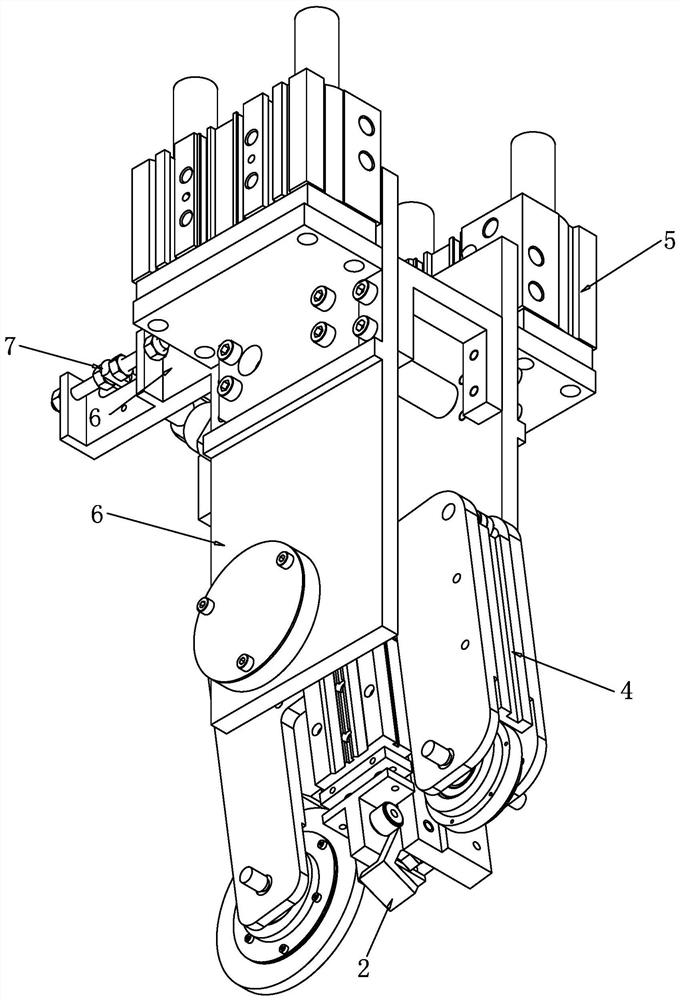

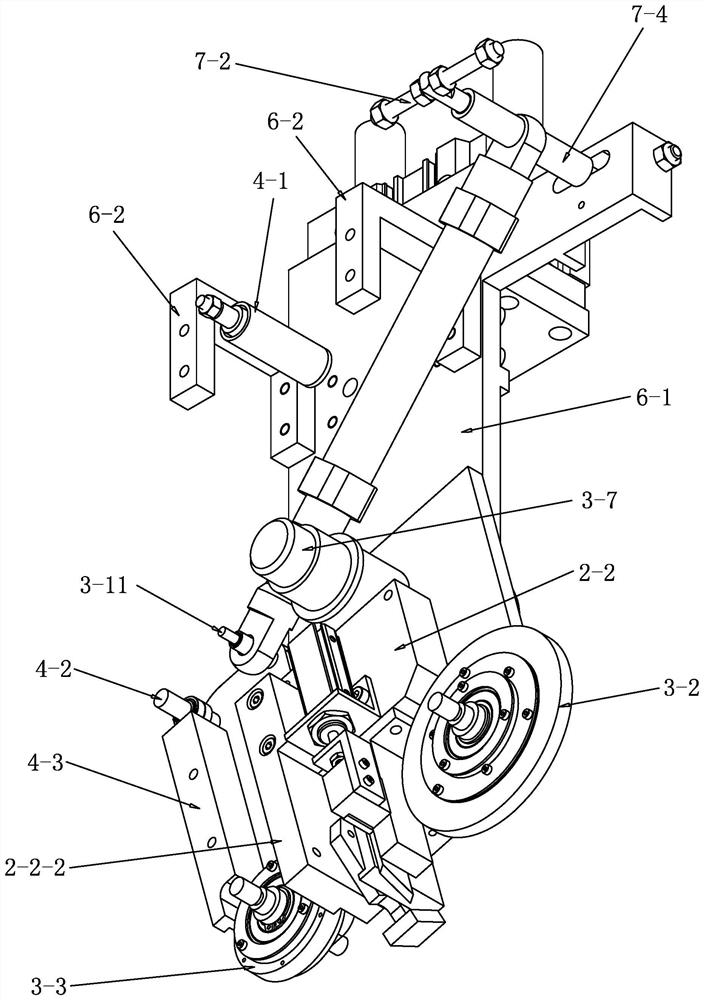

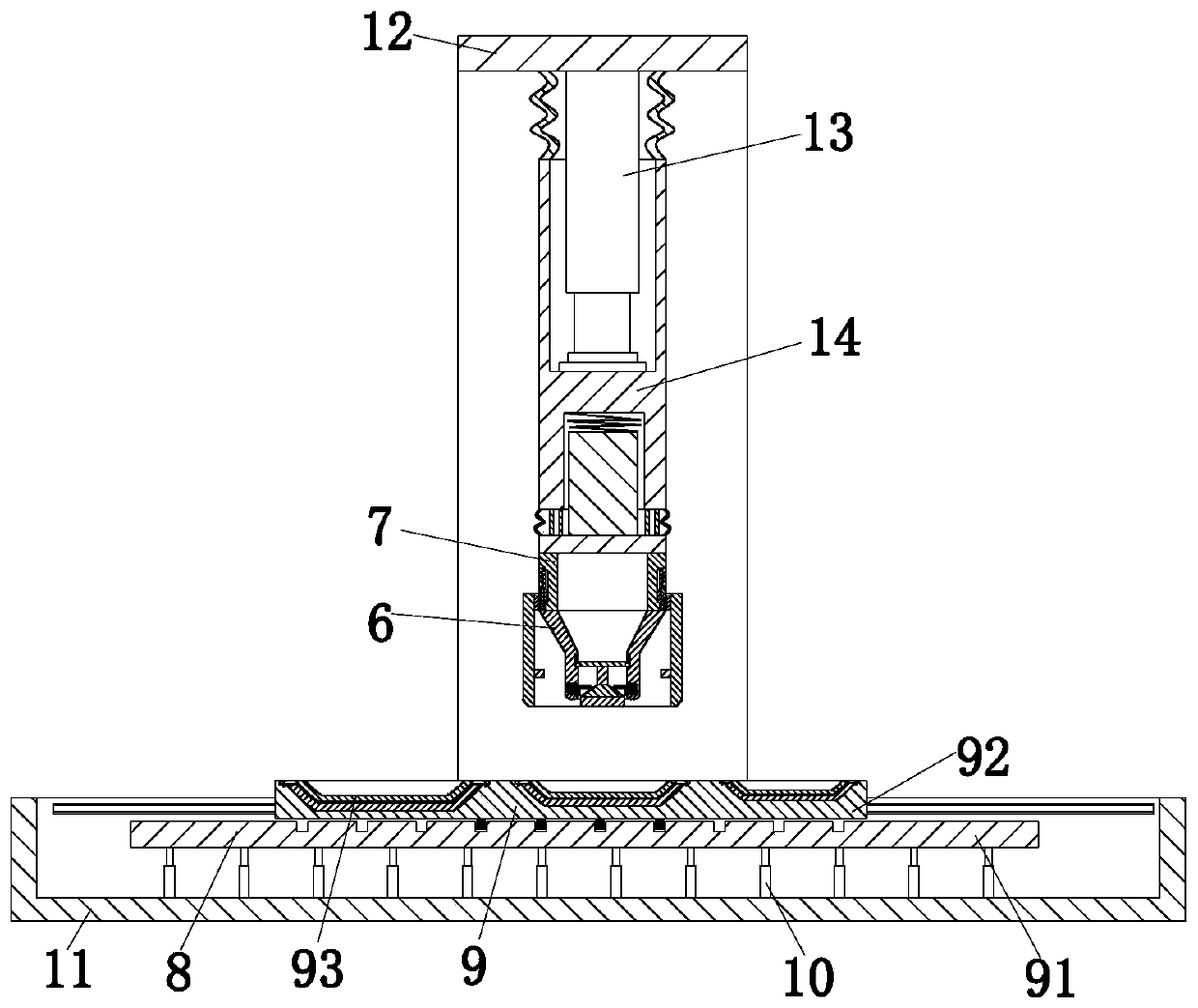

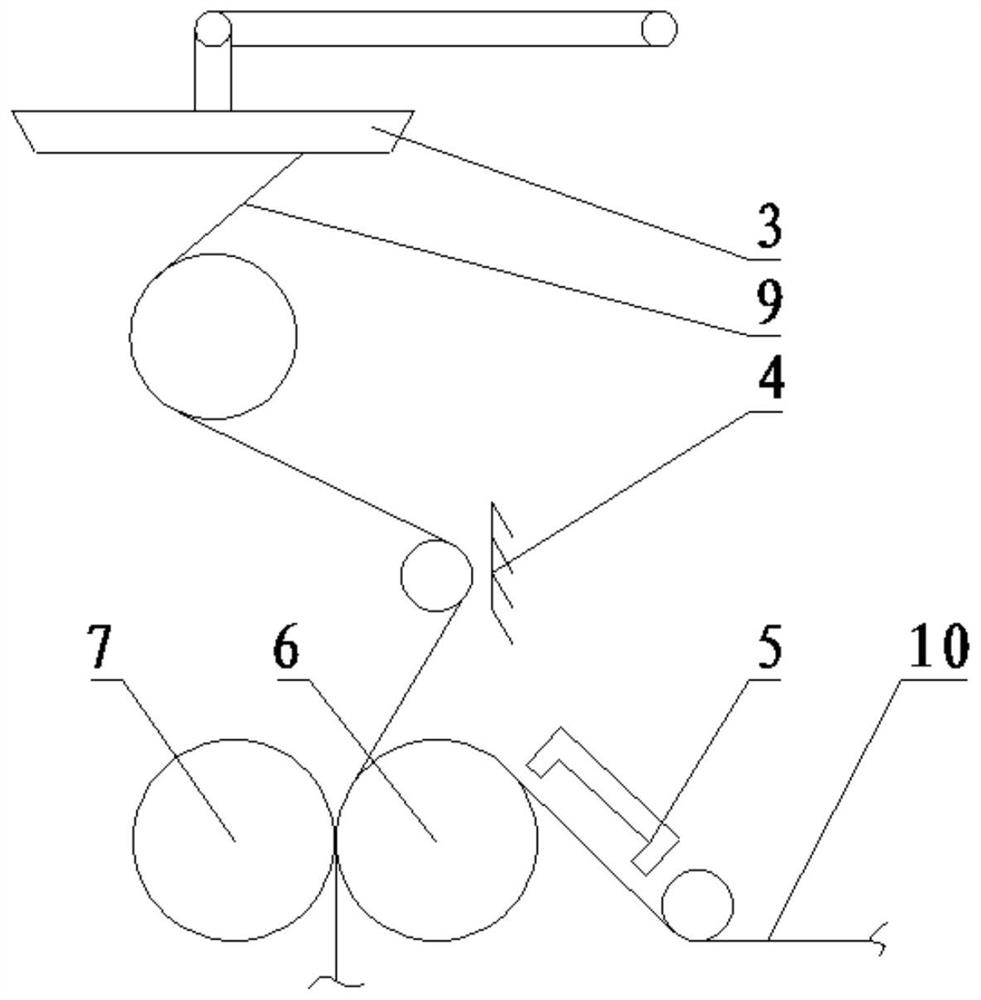

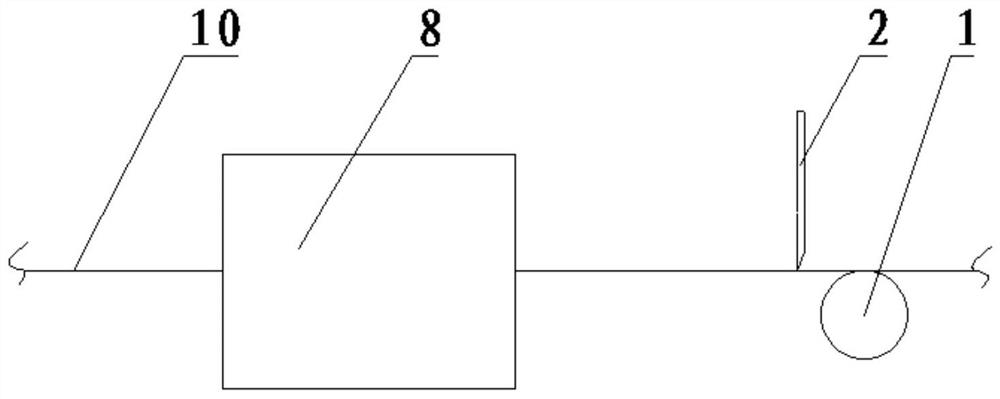

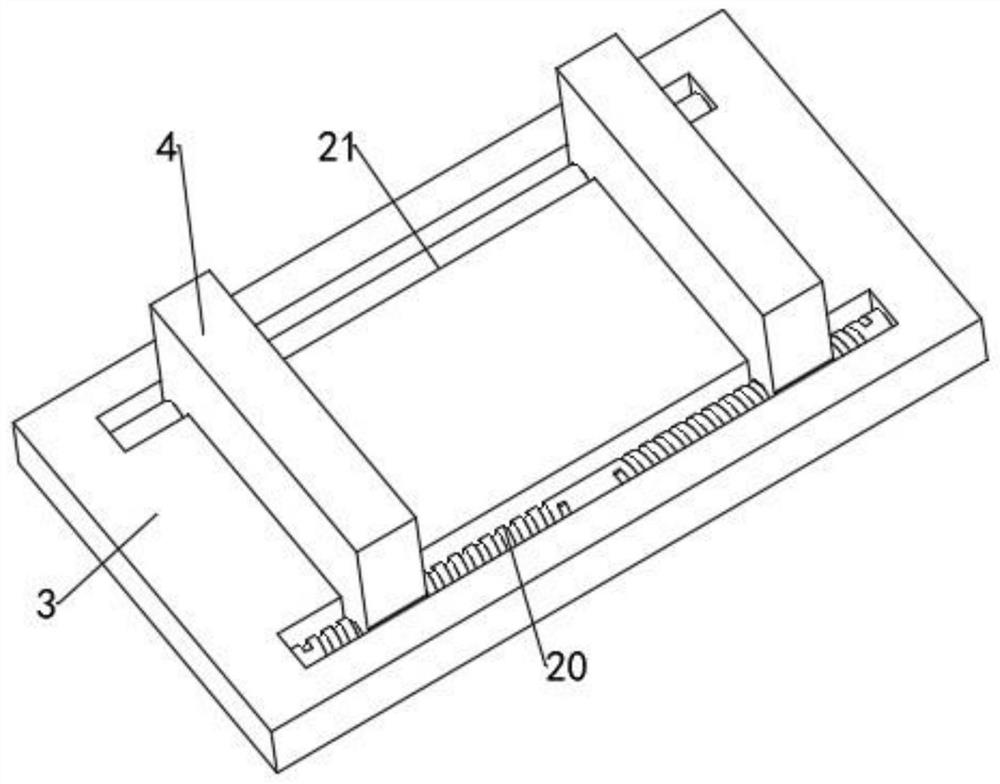

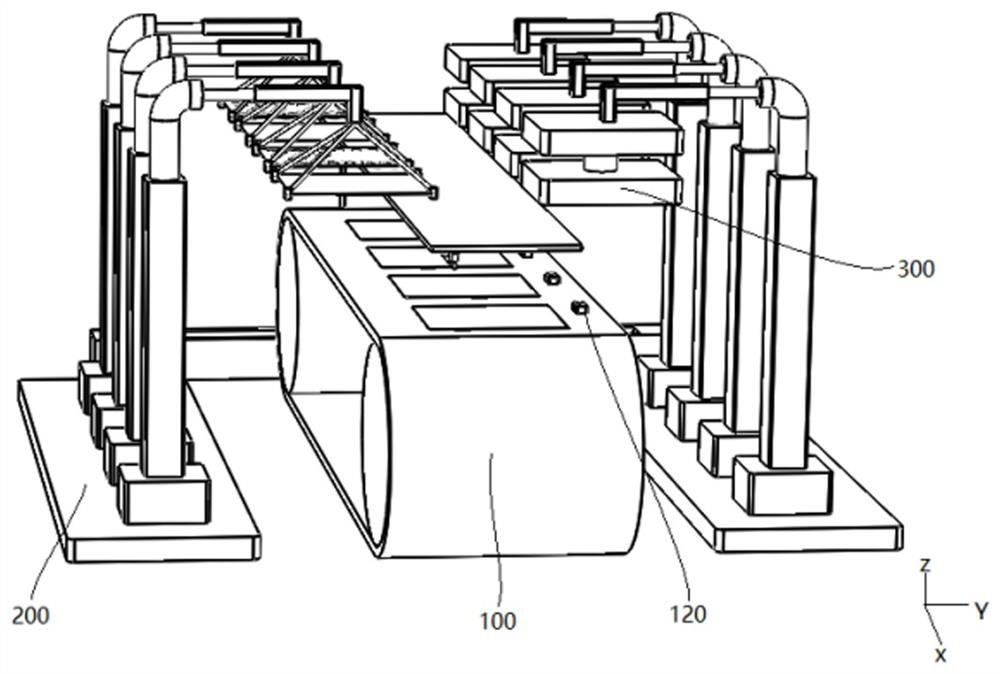

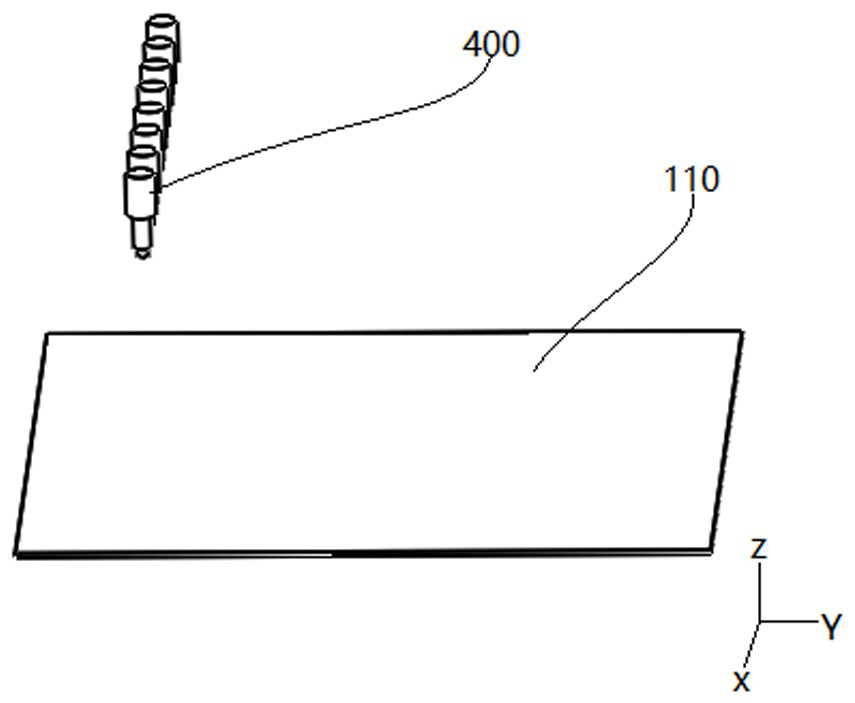

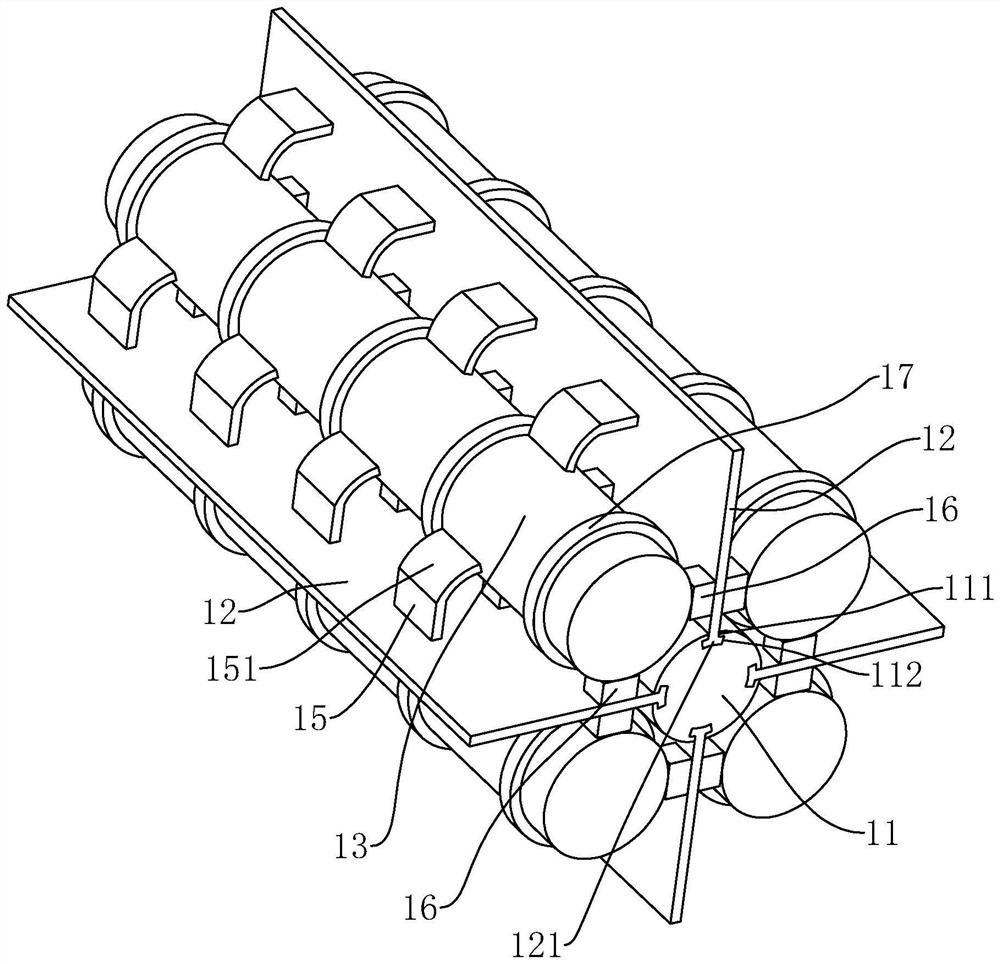

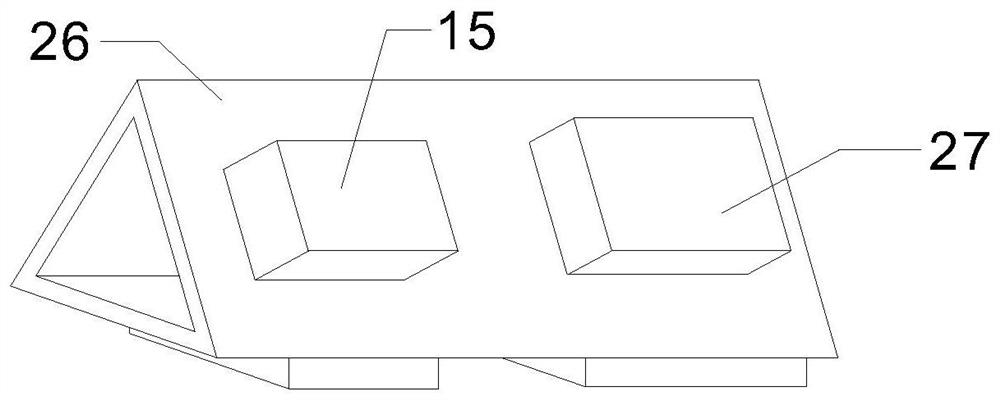

Composite material grid component automatic laying head and laying method

ActiveCN112477196AAffects horizontal widthReduce lateral volumeDomestic netsCylinder blockIndustrial engineering

The invention discloses a composite material grid component automatic laying head and a laying method. The composite material grid component automatic laying head comprises a shearing mechanism, a clamping mechanism, a re-conveying mechanism and a wire bundle guiding assembly. The composite material grid component automatic laying head further comprises a pressing air cylinder, a connecting frameand a balance adjusting mechanism, and the re-conveying mechanism comprises a rotating cylinder, a working compression roller, an auxiliary compression roller and a supporting frame. The supporting frame is rotatably connected with the connecting frame, and the working compression roller and the auxiliary compression roller are arranged in a spaced manner and are rotatably arranged on the supporting frame. The balance adjusting mechanism is arranged above the re-conveying mechanism, the balance adjusting mechanism comprises an adjusting rod, connecting rods and positioning elements, the adjusting rod is slidably arranged on the connecting frame, the two ends of the adjusting rod are arranged on the two connecting rods on the connecting frame in a sleeving manner correspondingly, the position of the adjusting rod is positioned through the positioning elements arranged on the connecting rods, and a cylinder body of the rotating air cylinder is arranged on the adjusting rod in a rotatablemanner. It is guaranteed that the compression rollers can be perpendicular to the laying plane in the laying process, blockage is avoided in the wire bundle re-conveying process, and a wire bundle channel is not occupied by the clamping mechanism and the shearing mechanism.

Owner:HARBIN INST OF TECH

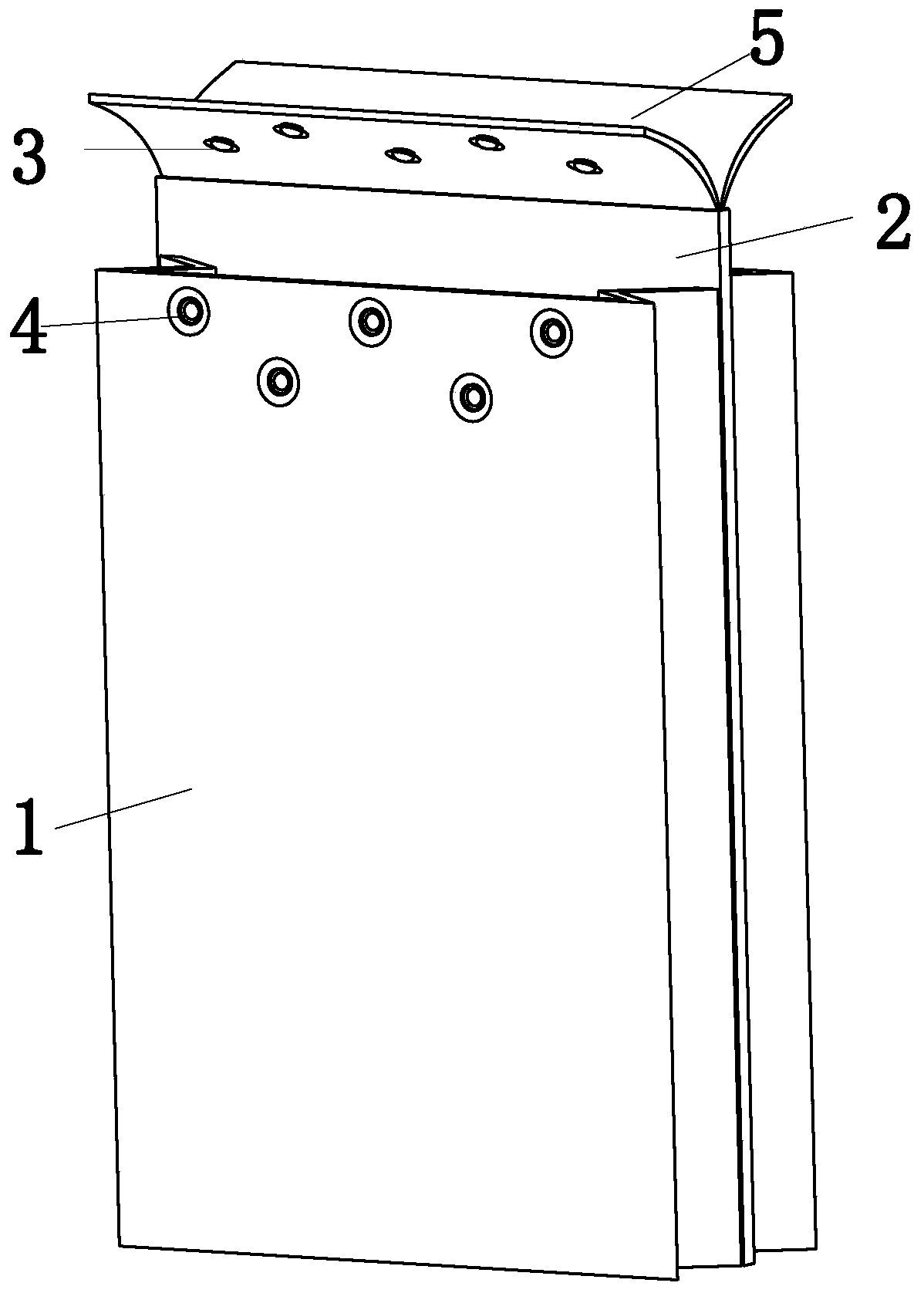

Woven bag, manufacturing device and manufacturing process

ActiveCN110435223AAvoid rollout situationsAvoid breakageBag making operationsPaper-makingComing outEngineering

The invention relates to a woven bag, a manufacturing device and a manufacturing process. The woven bag comprises a woven bag body, spacing cloth, an auxiliary buckles, a main buckle and two sealing edges. A buckling device is further provided by the invention and comprises a buckle pressing head, a tight abutting barrel, a positioning plate, a buckle pipe placement plate, a telescopic rod, a base, a connecting frame, an air cylinder and a buffer barrel. The connecting frame is installed at the rear end of the base; the air cylinder is installed at the upper end of the connecting frame; the push-out end of the air cylinder is installed in the buffer barrel; the lower end of the buffer barrel is connected with the buckle pressing head through the tight abutting barrel; the base is connectedwith the positioning plate through the telescopic rod; and the middle of the base is connected with the buckle pipe placement plate in a sliding fit mode. The woven bag provided by the invention is arranged in a mode of double storage cavities, fragile objects are placed independently, the main and auxiliary buckles are arranged in a bag opening of the woven bag, and the situation that the objects come out of the bag when the woven bag falls over is avoided. By means of the buckling device provided by the invention, the squeezing forces to the inner walls of buckle pipes are the same, and thesituation that the buckling connection gaps between the buckle pipes and buckle sleeves are non-uniform is avoided.

Owner:浙江鑫旭塑业有限公司

Processing method of reinforced three-dimensional pattern space cloth

The invention relates to the field of processing methods of space cloth, in particular to a processing method of reinforced three-dimensional pattern space cloth. By additionally arranging reinforcingsheets on the surface of drawn yarn mesh cloth, the surface of the drawn yarn mesh cloth has higher strength; by spray-painting the inner surface of a first transparent TPU film on the inner side with a background pattern and spray-painting the inner surface of a second transparent TPU film on the outer side with a stripe pattern, the stripe pattern is suspended above the background pattern to present a three-dimensional pattern effect. Under the protection effect of the second transparent TPU film on the outer layer, the stripe pattern is hidden inside and prevented form being scratched or worn, and the surface of the space cloth has a lasting and attractive pattern effect. By adopting the two layers of transparent TPU films as a surface film layer of the space cloth, the space cloth hasmore excellent wear resistance and bending resistance, and the protection effect on the internal pattern can be enhanced.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

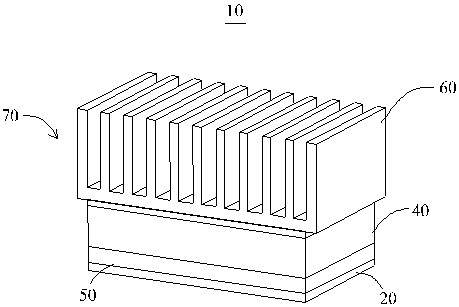

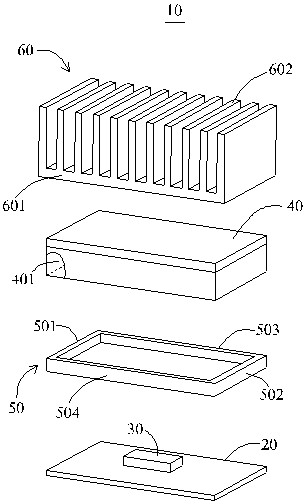

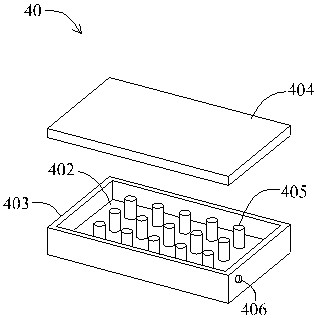

Evaporation structure, radiator, semiconductor device and preparation method

ActiveCN112951728AStrong high temperature resistanceEffective coolingSemiconductor/solid-state device detailsSolid-state devicesDevice materialMechanical engineering

The embodiment of the invention provides an evaporation structure, a radiator, a semiconductor device and a preparation method. The preparation method of the evaporation structure comprises the steps that: a substrate is provided, a bottom plate, a side plate connected with the bottom plate, and a plurality of backflow pieces arranged on the bottom plate at intervals are formed on the substrate, a liquid filling opening is formed in the side plate, the side plate surrounds the bottom plate, so that a cavity with an opening is formed in the substrate; capillary structure layers are formed on the inner surface of the bottom plate, the inner surface of the side plate and the surfaces of the backflow pieces; a base top is provided, a protection piece is arranged in a welding area of the base top, and a capillary structure layer is formed on the side, provided with the protection piece, of the base top to form a top plate; the protection piece is separated from the top plate, so that a welding area can be exposed; the welding area of the top plate corresponds to the side plate and the backflow pieces, the top plate, the side plate and the backflow pieces are welded and fixed through the welding area, and the opening is sealed so that the bottom plate, the top plate and the side plate can be matched to form an evaporation cavity; evaporating liquid is injected through the liquid filling opening, and the liquid filling opening is sealed to form an evaporation structure.

Owner:ZTE CORP

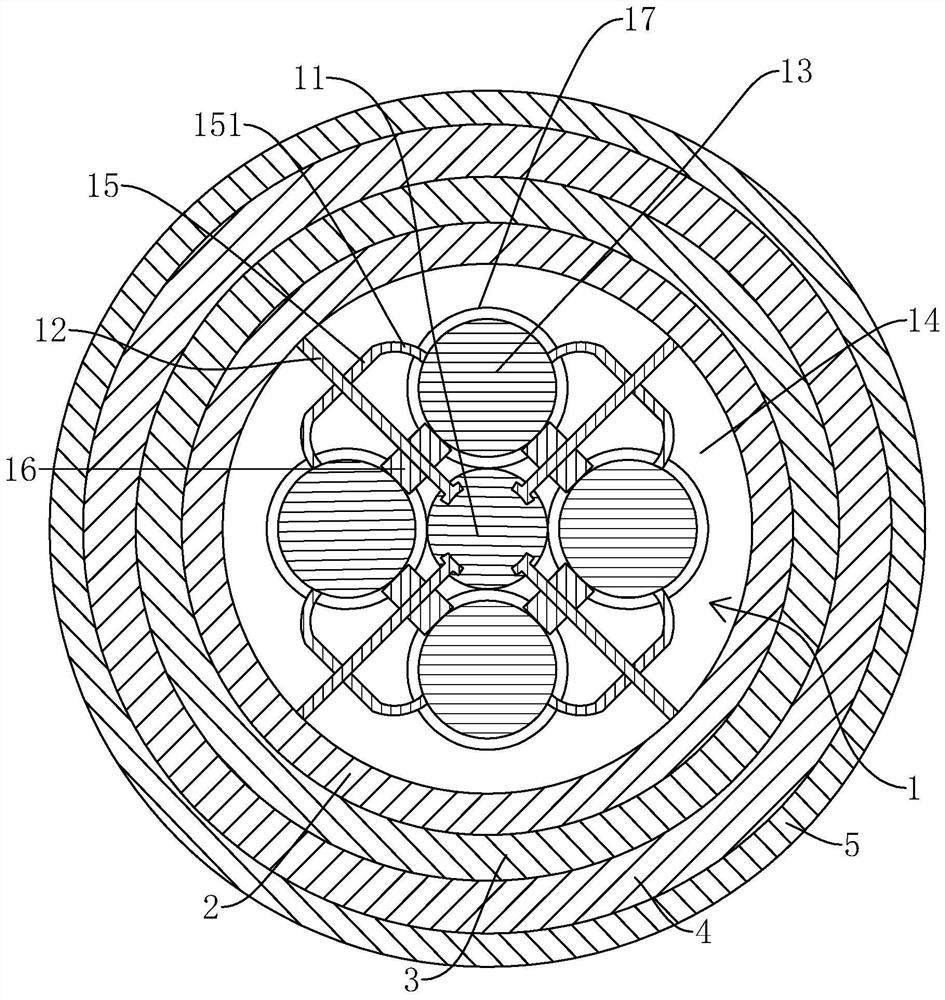

High-strength space cloth material and preparation method thereof

ActiveCN111959070AImprove quality requirementsSynthetic resin layered productsFlat articlesPolymer scienceThin membrane

The invention discloses a high-strength space cloth material and a preparation method thereof. The preparation method belongs to the technical field of composite materials. The preparation method comprises the steps that: applying a PU paste to the upper surface and the lower surface of PE space cloth twice and drying, wherein the amount of the PU paste applied each time is 30-60 gsm, and the viscosity of the PU paste is 40,000-50,000 cps; carrying out corona treatment on one surface of a TPU film; preheating the upper surface and the lower surface of the pasted PE space cloth, and respectively fitting the upper surface and the lower surface of the pasted PE space cloth with the corona-treated surface of the TPU film to obtain the high-strength space cloth material. According to the preparation method, the problems that the TPU film is difficult to fit with the PE space cloth and the peel strength after fitting does not reach the standard are solved, and the peel strength after fittingcan reach 150N / 5cm or above, so that a product prepared from the obtained space cloth material can bear higher air pressure, and the application field of the space cloth material is widened.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Clamping device for printed circuit board (PCB) code spraying

InactiveCN112757787AEasy clampingEasy flipTypewritersOther printing apparatusDrive shaftElectric machinery

The invention discloses a clamping device for printed circuit board (PCB) code spraying. The device comprises a base, wherein the base is movably connected with a mounting seat through a substrate, two limiting seats are arranged on the mounting seat at intervals, and the limiting seats are connected with a base through a mounting shaft; according to the clamping device for PCB code spraying, the two limiting blocks are controlled to be unfolded or folded through a hydraulic telescopic rod, the PCB can be conveniently clamped, it is only needed to occupy a very small clamping area needs, so that it is convenient to spray; by meshing a worm gear with a worm, the PCB can be conveniently driven to be turned over integrally, and a gear motor drives a driving shaft and an assembling shaft to conduct transmission, so that a PVB board operates intermittently, sprayed codes of different shapes can be conveniently obtained, and the machining flexibility is improved; the initial distance between the two limiting seats can be conveniently adjusted through an adjusting lead screw, so that is convenient to clamp the PCB; in addition, a buffer structure is arranged between a base and the base plate, so that the vibration impact of the clamping device during operation is effectively reduced, and the code spraying quality is ensured.

Owner:上海潜利智能科技有限公司

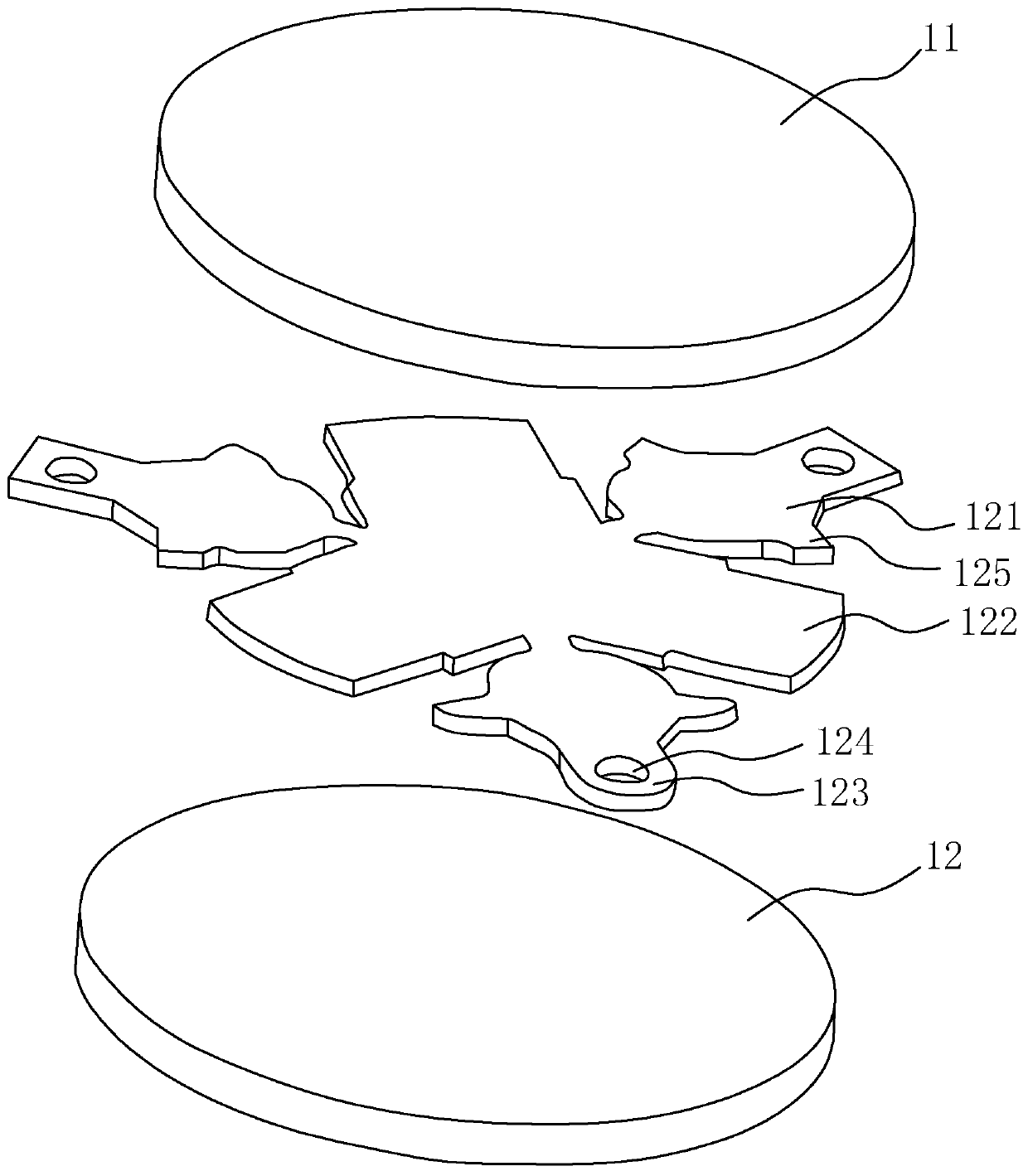

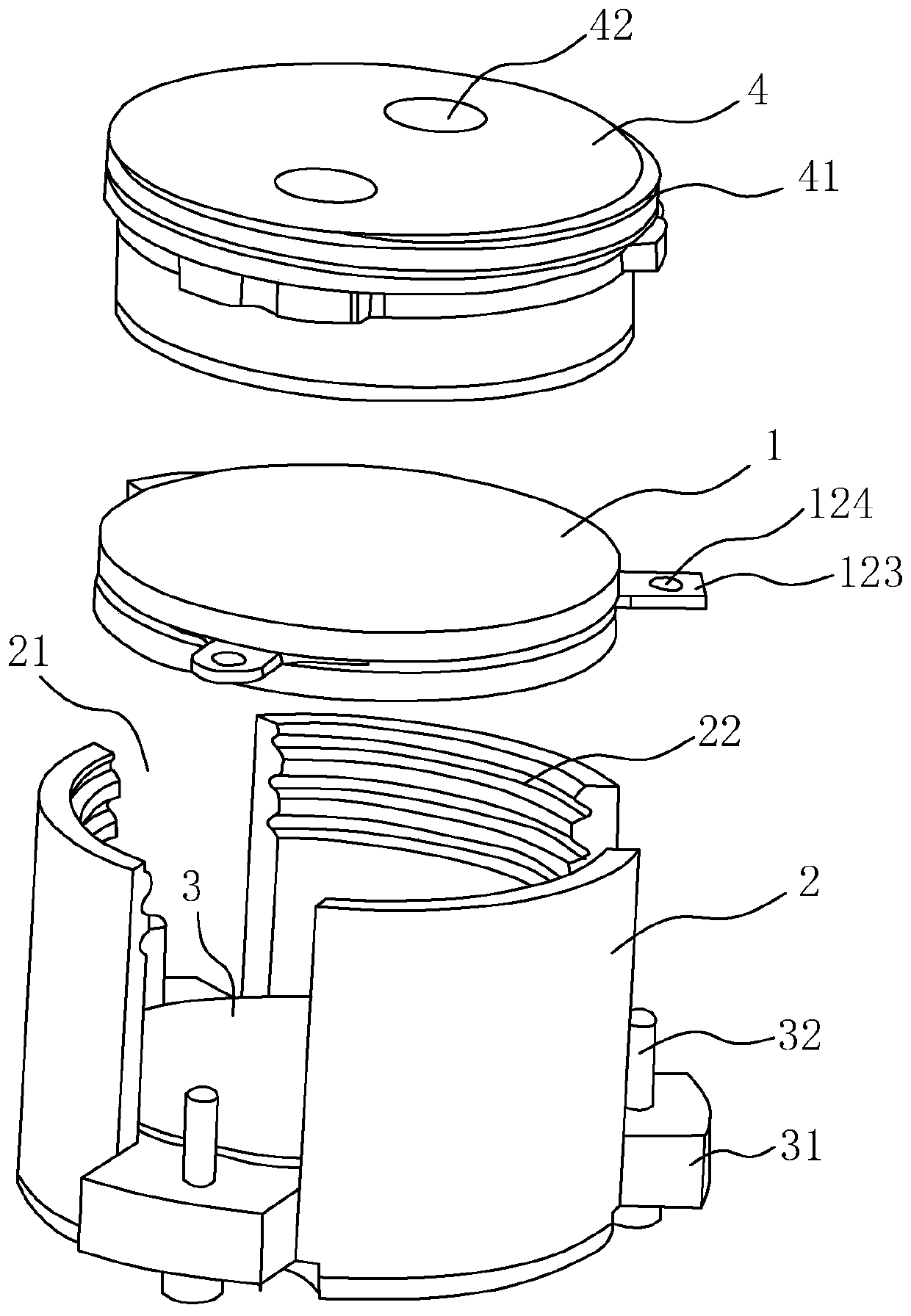

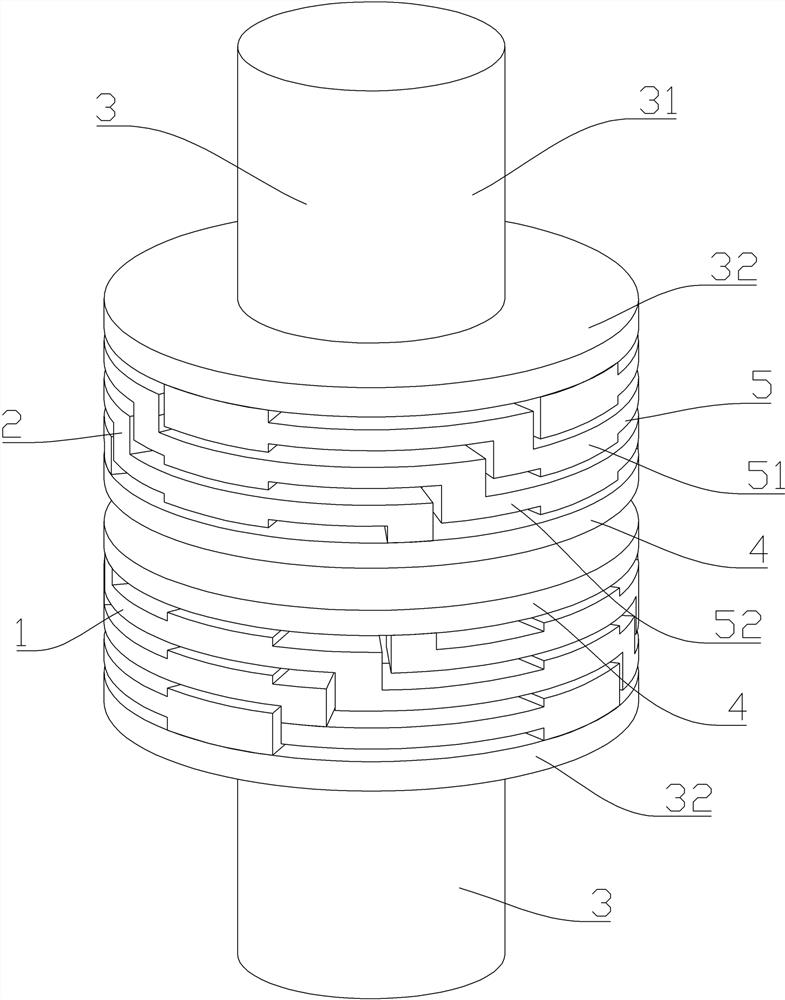

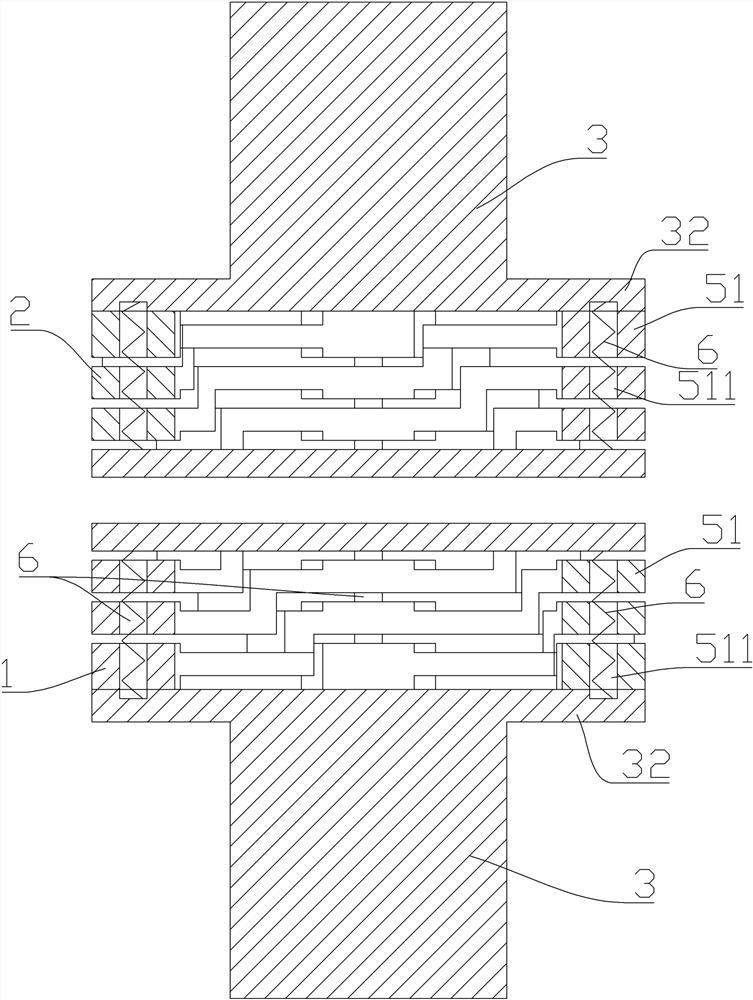

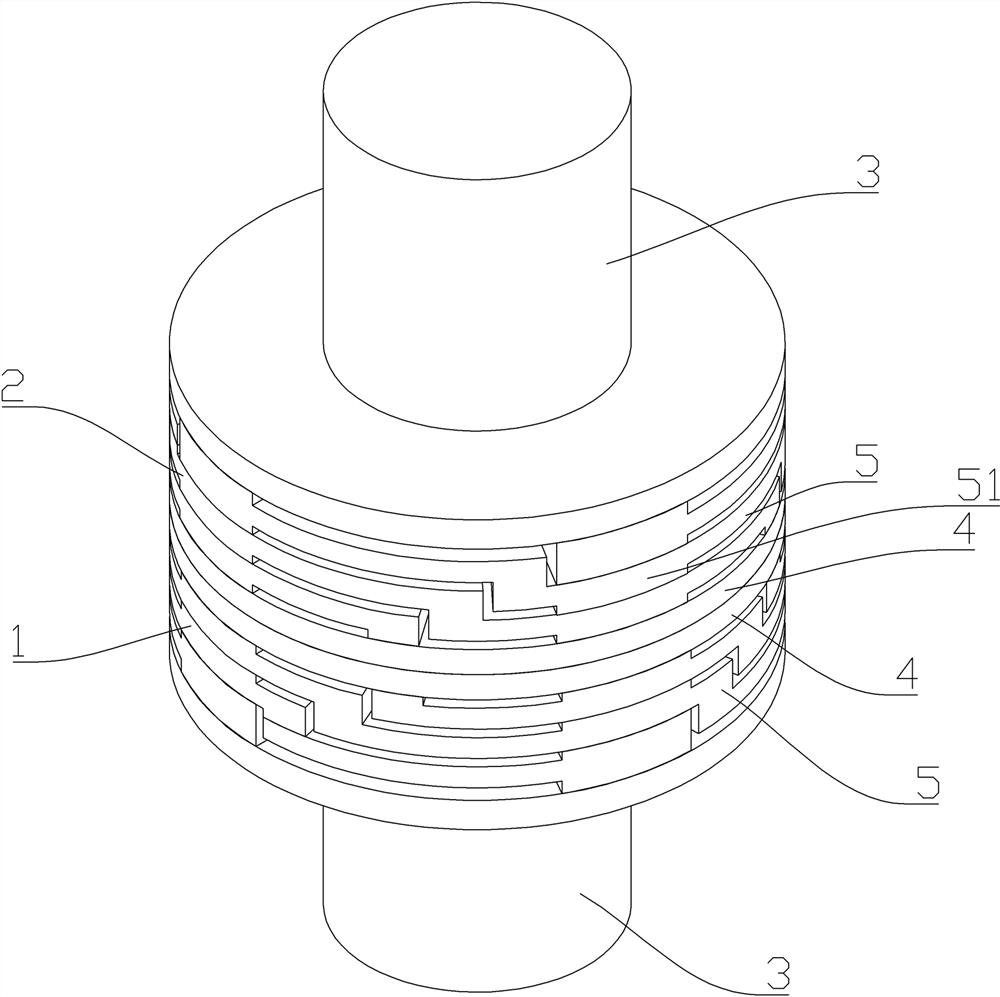

Central conductor assembly, circulator and isolator

PendingCN111403877AGuaranteed performanceImprove consistencyWaveguide type devicesElectrical conductorIsolator

The invention relates to a central conductor assembly, a circulator and an isolator. The central conductor assembly comprises an upper gyromagnetic ferrite, a central junction conductor and a lower gyromagnetic ferrite which are arranged in sequence and are welded and fixed through a high-frequency welding process, the central junction conductor is located at the central position of the upper gyromagnetic ferrite and the lower gyromagnetic ferrite, and the upper gyromagnetic ferrite and the lower gyromagnetic ferrite are aligned. The central junction conductor comprises a plurality of first resonance bodies and second resonance bodies which are arranged at intervals, the first resonance bodies are connected with connecting pins extending out of the lower gyromagnetic ferrite, and the connecting pins are provided with connecting holes. Because the upper gyromagnetic ferrite, the central junction conductor and the lower gyromagnetic ferrite are welded and fixed by a high-frequency welding process, the central junction conductor does not move relative to the upper gyromagnetic ferrite and the lower gyromagnetic ferrite during assembly, the consistency of the upper gyromagnetic ferrite, the central junction conductor and the lower gyromagnetic ferrite is improved, and the product performances of the circulator and the isolator are guaranteed.

Owner:SUZHOU ANJIE TECH

TPU reinforced wiredrawing air cushion and production process thereof

PendingCN112009051AImprove carrying capacityImprove structural stabilitySynthetic resin layered productsCoatingsFiberWear resistance

The invention discloses a TPU reinforced wiredrawing air cushion and a production process thereof. The TPU reinforced wiredrawing air cushion comprises upper gridding cloth, lower gridding cloth and apolyethylene fiber wiredrawing layer. The polyethylene fiber wiredrawing layer is composed of a plurality of X-shaped wire drawing units, the upper end of the upper gridding cloth is sequentially coated with an upper TPU coating and an upper PVC coating, and the lower end of the lower gridding cloth is sequentially coated with a lower TPU coating and a lower PVC coating. The process comprises thefollowing steps: preparing space cloth, preparing a PVC connecting strip, scrape-coating with the TPU coatings, scrape-coating with the PVC coatings, and adhering the PVC connecting strip to the space cloth. The TPU coatings are added, so that the pressure bearing capacity and the structural stability of the wiredrawing air cushion are improved, and the wear resistance and the aging resistance ofthe product are greatly improved; the process is simple to operate, the production efficiency is improved, and the production cost is reduced; and meanwhile, the thickness of the coatings is reduced,the weight of the wiredrawing air cushion is reduced, and a user can carry the wiredrawing air cushion more conveniently.

Owner:威海水知乐户外用品股份有限公司

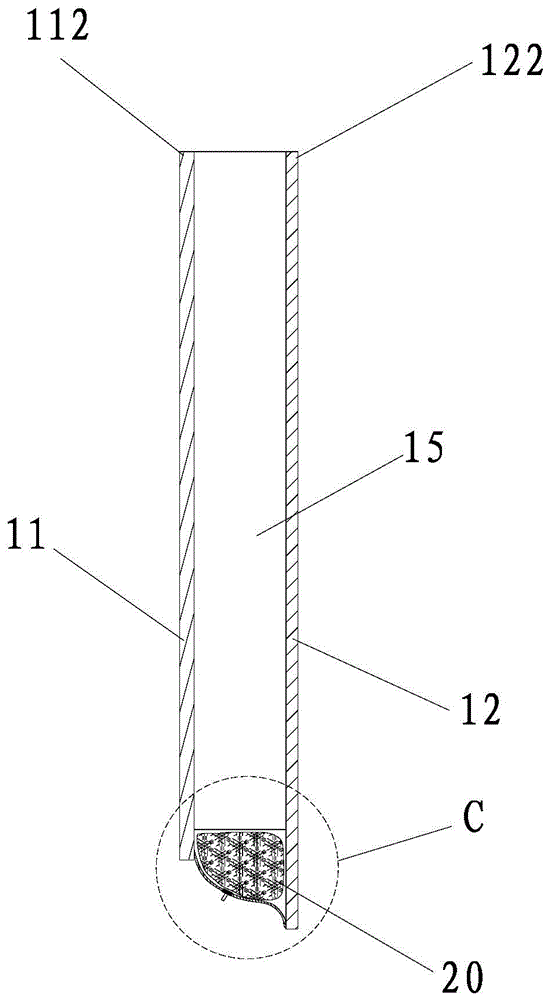

Self-heat-insulation flexible interlayer air duct for tunneling roadway or vertical shaft

ActiveCN109751071AImprove insulation effectReduce heat exchangeMining devicesTunnel/mines ventillationCold airDesign standard

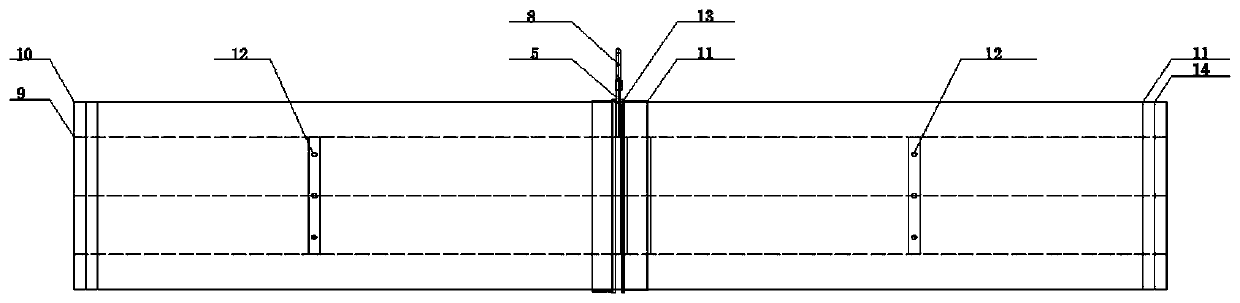

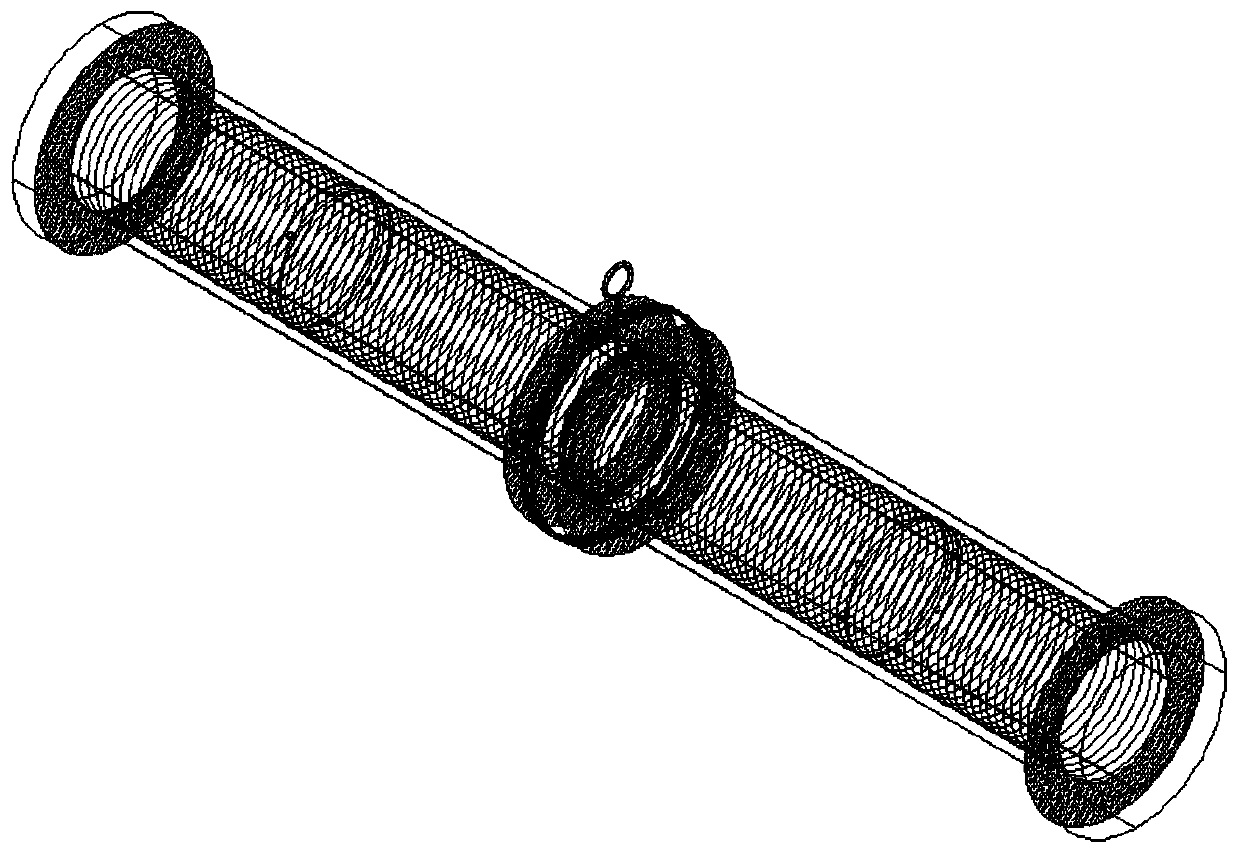

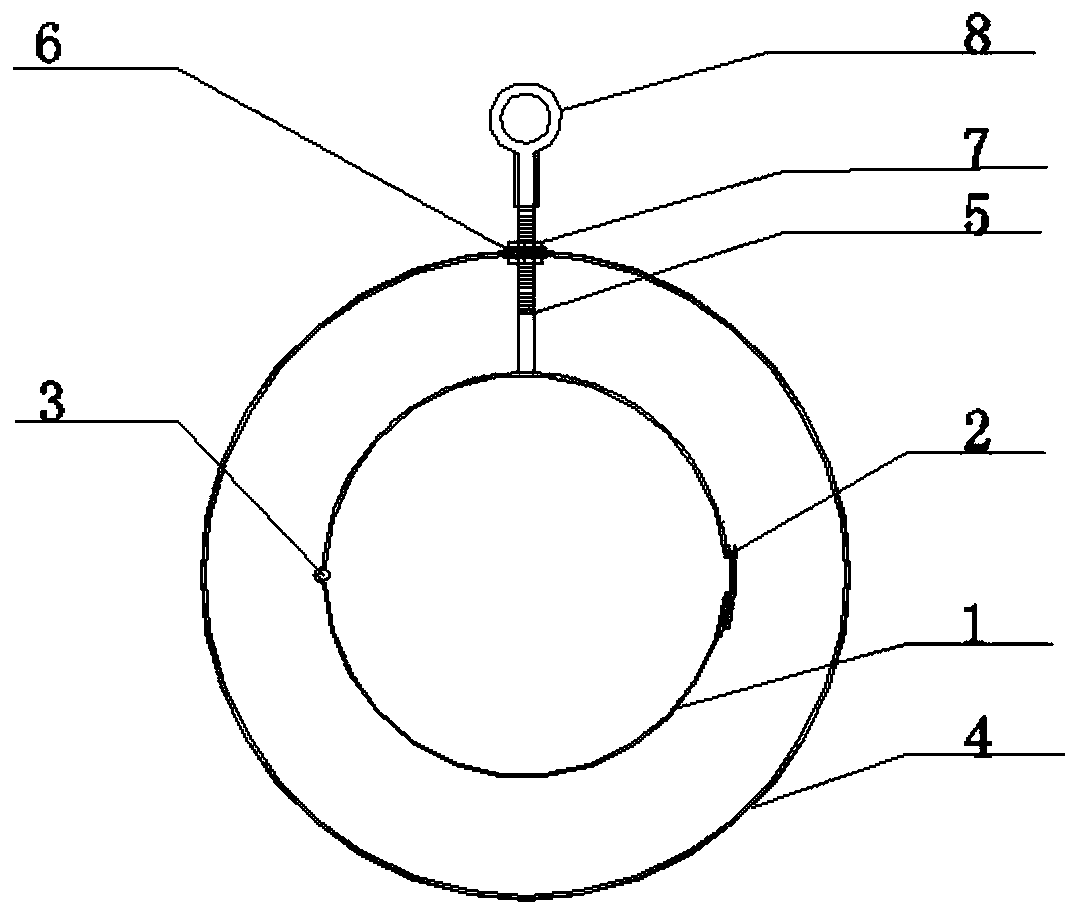

The invention discloses a self-heat-insulation flexible interlayer air duct for tunneling a roadway or vertical shaft. The self-heat-insulation flexible interlayer air duct comprises an air duct mainbody structure and a matched connecting assembly. The air duct main body structure comprises inner-layer air duct cloth, outer-layer air duct cloth and annular space cloth, and the connecting assemblycomprises hoops, a threaded rod and an outer rib ring. The two ends of an inner-layer air duct are fixedly connected through the hoops, outer-layer air ducts are arranged on the two sides of the outer rib ring in a sleeving mode and fixed through the hoops, an annular closed space is formed by the cloth between the head end and the tail end and the cloth of the inner-layer air duct and the outer-layer air duct, the optimal interlayer thickness of the air duct is 30 mm through a numerical calculation method, the thermal resistance value is maximum when the interlayer thickness is obtained, andthe heat preservation effect of the air duct is best. The interlayer air duct reduces heat exchange between cold air in the air duct and the external environment, so that the temperature of the coldair fed into the working surface is close to the design standard; and the design size of the interlayer air duct is standardized, so that the heat preservation effect of the interlayer air duct is optimal under corresponding design conditions. The connecting assembly is simple in structure and flexible to disassemble, installation time can be saved in actual operation, and efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of camouflage space cloth

PendingCN111086314AHigh peel strengthHigh strengthSynthetic resin layered productsLaminationPolymer scienceComposite film

The invention relates to the technical field of textile materials, in particular to a preparation method of camouflage space cloth. The method comprises the following steps: sending a first printed PVC film and a second printed PVC film to be printed into a laminating machine for sufficient preheating, laminating the first printed PVC film and the second printed PVC film together, performing cooling, and spraying patterns on the lower surface to obtain a composite film; and laminating the three layers of films together according to the sequence of the composite film, the space cloth layer andthe lower-layer PVC film to obtain the camouflage space cloth. The preparation method of the camouflage space cloth has the beneficial effects that in the preparation method of the camouflage space cloth, the first printed PVC film and the second printed PVC film to be printed are compounded firstly, and the finished product is compounded and then heated once, so that the two layers are tightly attached together. Because of high peel strength, the obtained camouflage space cloth does not bubble, delaminate and the like after being used for a period of time.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

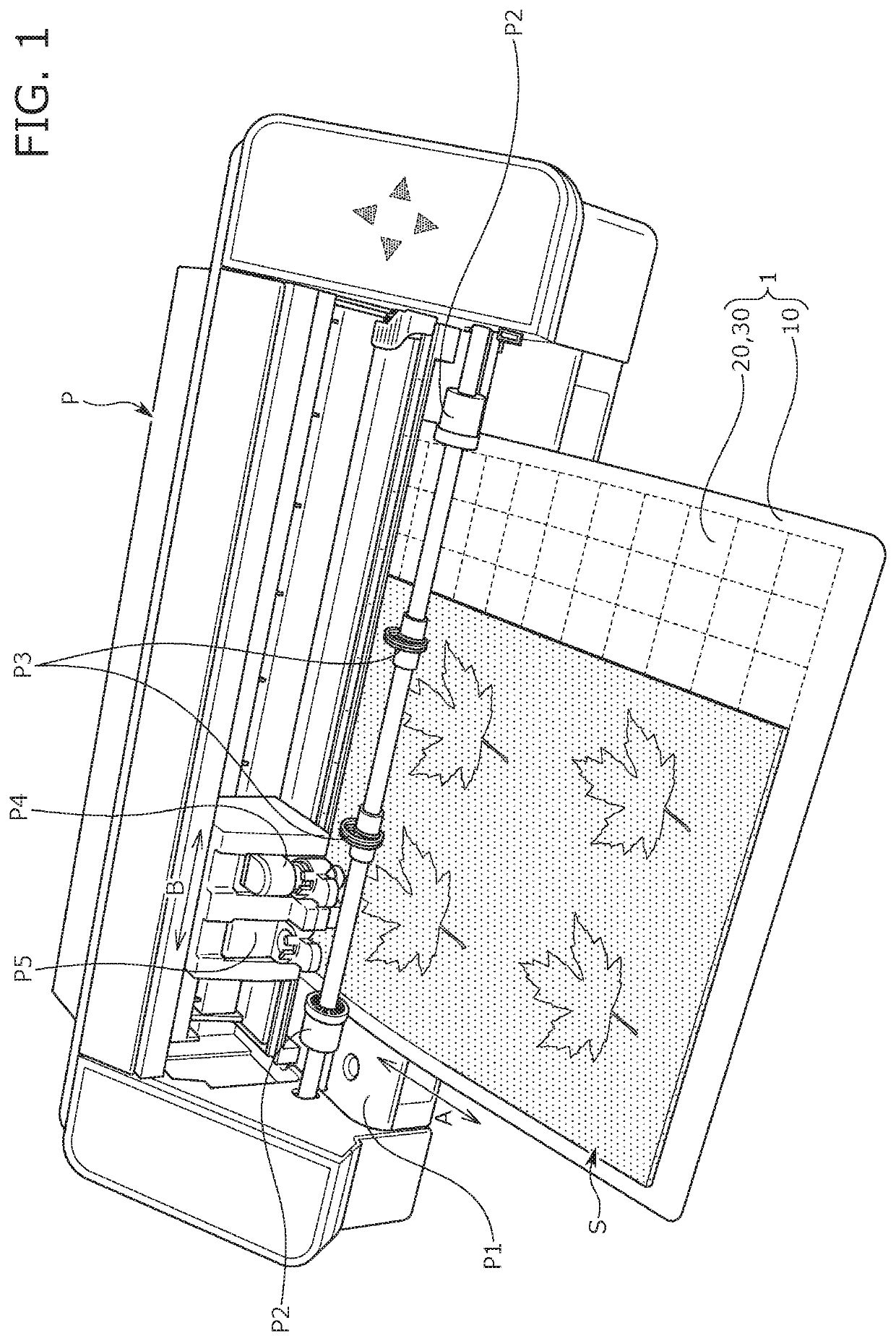

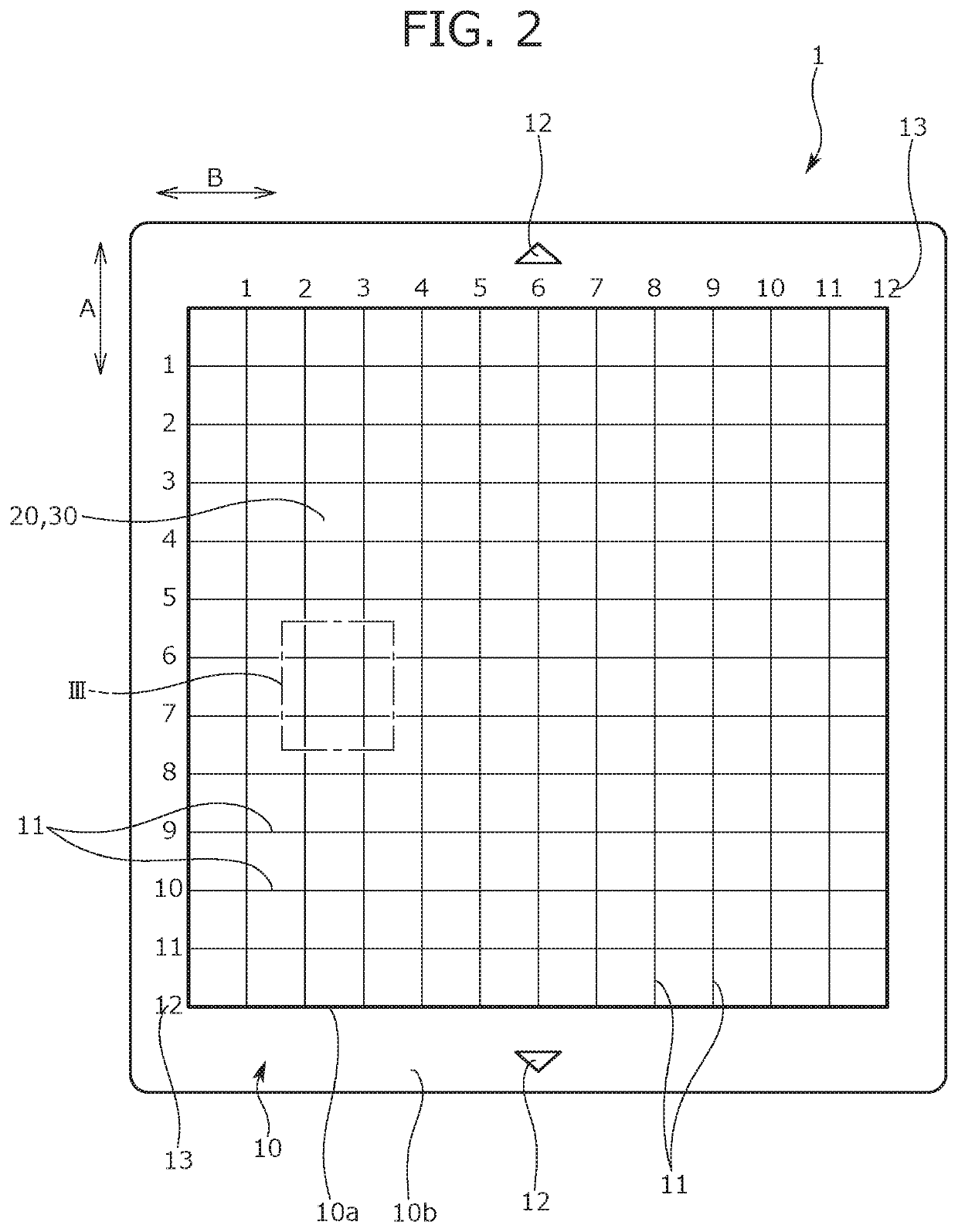

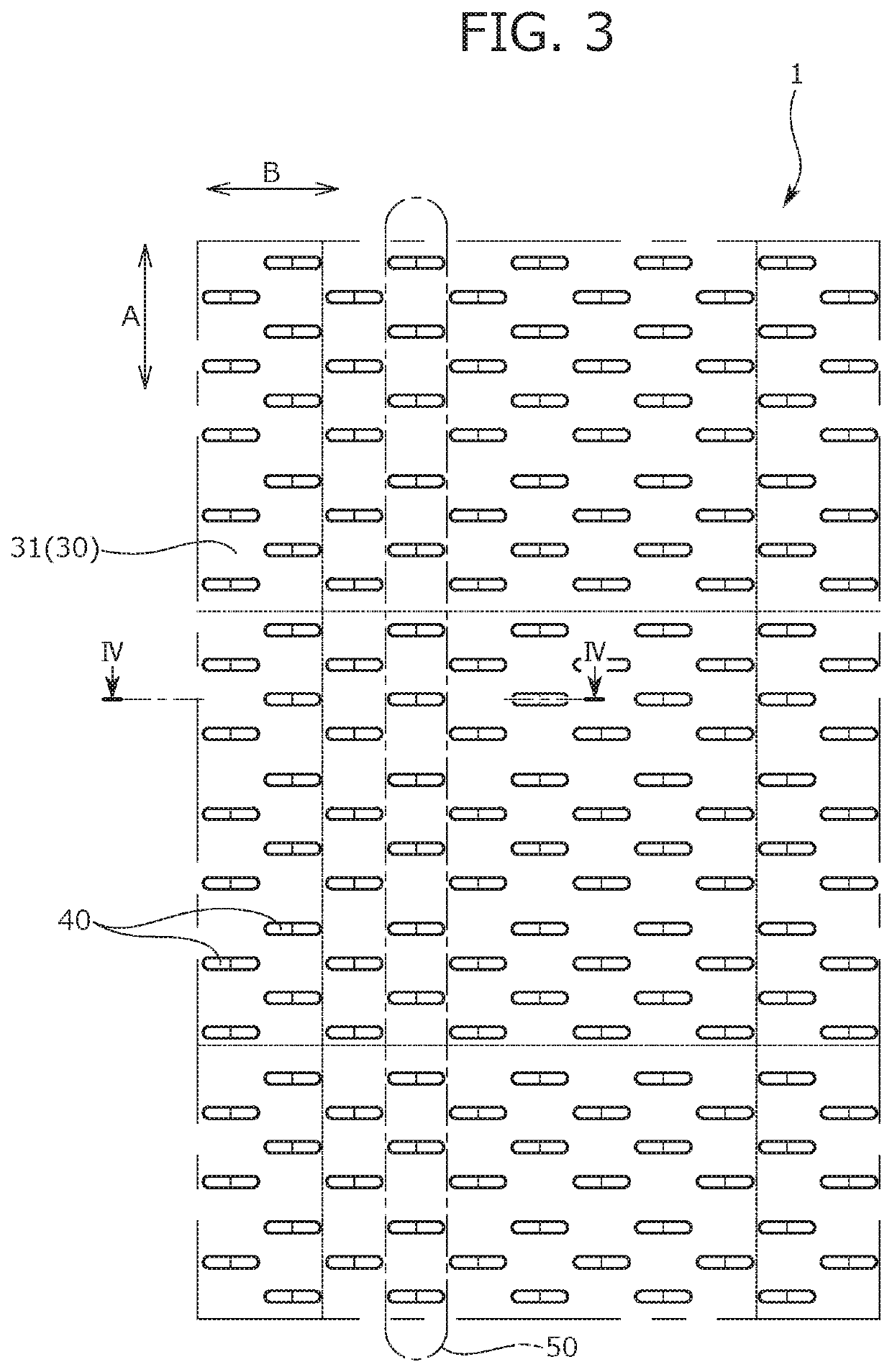

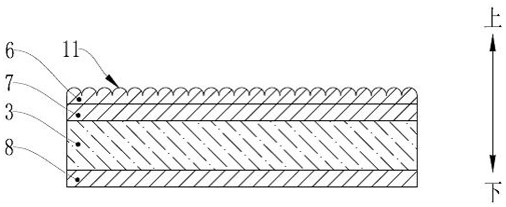

Sheet holder

InactiveUS20210331888A1Narrow widthIncrease engagementOther printing apparatusMetal working apparatusEngineeringPlotter

Provided is a sheet holder capable of suitably holding a cloth sheet medium while a plotter performs processing. The sheet holder is used for a plotter that performs processing on a cloth sheet medium. The sheet holder includes a holder base material on an upper surface of which the sheet medium is mounted, and an engaging sheet attached onto the holder base material and including a plurality of hook-shaped engaging elements to be engaged with the sheet medium. The engaging elements are arranged so as to be arranged in a plane shape at predetermined intervals on the holder base material.

Owner:SILHOUETTE AMERICA

Antiskid space cloth and preparation process thereof

ActiveCN114834101AIncrease elasticityReduce distortionNon-macromolecular adhesive additivesSynthetic resin layered productsAdhesive glueProcess engineering

The invention relates to the technical field of space cloth, in particular to anti-skid space cloth and a preparation process thereof. The preparation process of the anti-skid space cloth comprises the following steps: step A, unwinding and ironing the space cloth, respectively coating the upper surface and the lower surface of the space cloth with adhesive glue, and drying after coating is completed; b, PVC films are placed on the upper surface and the lower surface of the space cloth respectively, and high-temperature attaching is carried out; and step C, embossing the surface of the PVC film on the upper surface of the space cloth, and cooling to obtain the anti-skid space cloth. According to the preparation process of the anti-skid space cloth, the use of materials can be reduced, the cost is reduced, the process is simplified, the time is saved, the yield is improved, meanwhile, the quality effect is guaranteed, the problems that an existing anti-skid space cloth production process is complex, time-consuming, large in material consumption and high in cost are solved, and the prepared anti-skid space cloth is good in anti-skid effect while the materials can be saved; the mechanical property is good.

Owner:FOSHAN TIANJIN PLASTICS

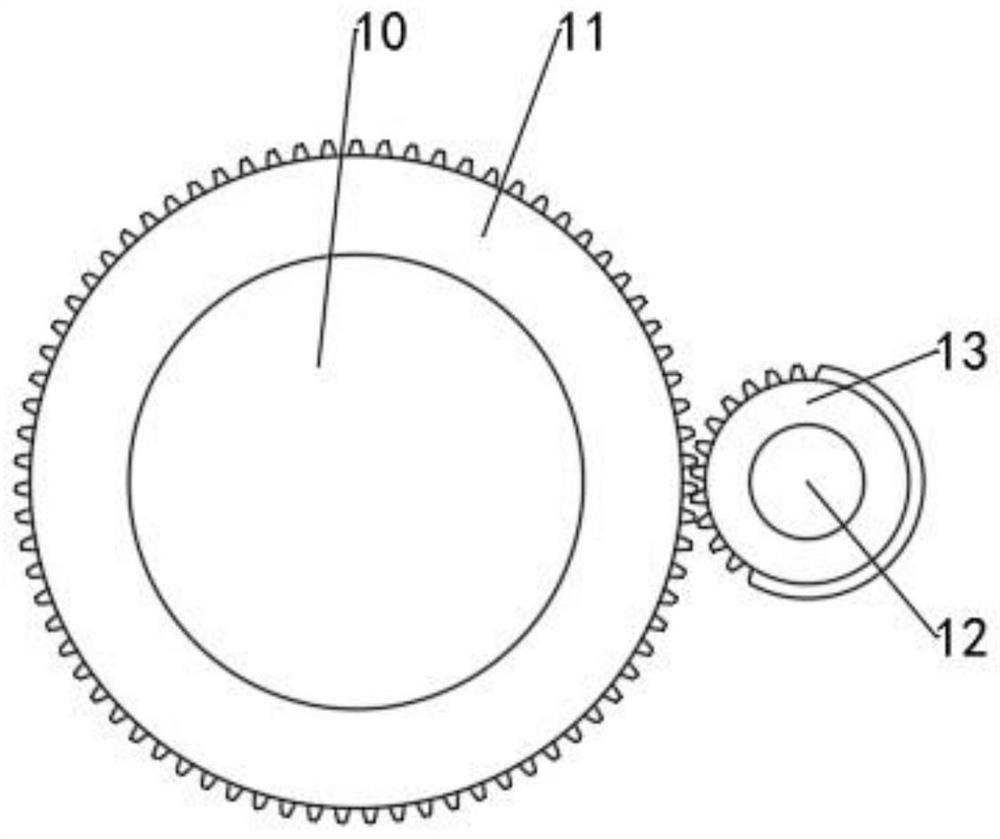

Vacuum arc-extinguishing chamber and arc-extinguishing contact thereof

PendingCN113793775AImprove flow capacityGuaranteed longitudinal magnetic field strengthHigh-tension/heavy-dress switchesAir-break switchesElectrical resistance and conductanceElectrical conductor

The invention relates to a vacuum arc-extinguishing chamber and an arc-extinguishing contact thereof. The arc extinguishing contact comprises a conducting rod, a contact blade and longitudinal magnetic conductors; a plurality of longitudinal magnetic conductors are arranged, the longitudinal magnetic conductors rotate and extend in the axial direction of the conducting rod in the circumferential direction of the contact piece, and the longitudinal magnetic conductors are arranged at intervals in the circumferential direction of the contact piece, and the rotation directions of the longitudinal magnetic conductors are consistent; the longitudinal magnetic conductor is provided with a conductor contact section which is used for being in compression contact with the longitudinal magnetic conductor circumferentially adjacent to the contact blade along the axial direction of the conducting rod; and the adjacent conductor contact sections on the arc extinguishing contact are in contact during flow passage, so that the flow passage path is shortened, the flow passage resistance is reduced, and the flow passage capacity is improved, and during breaking, the longitudinal magnetic conductors are reset, the intervals between the adjacent longitudinal magnetic conductors prevent flow passage, the flow passage path is limited on the extension paths of the longitudinal magnetic conductors, and the longitudinal magnetic conductors rotate and extend, so the arc extinguishing contact can ensure the longitudinal magnetic field intensity. According to the arc extinguishing contact, by changing a current path, the longitudinal magnetic field intensity is ensured, and meanwhile, the through-current capability is improved.

Owner:PINGGAO GRP +1

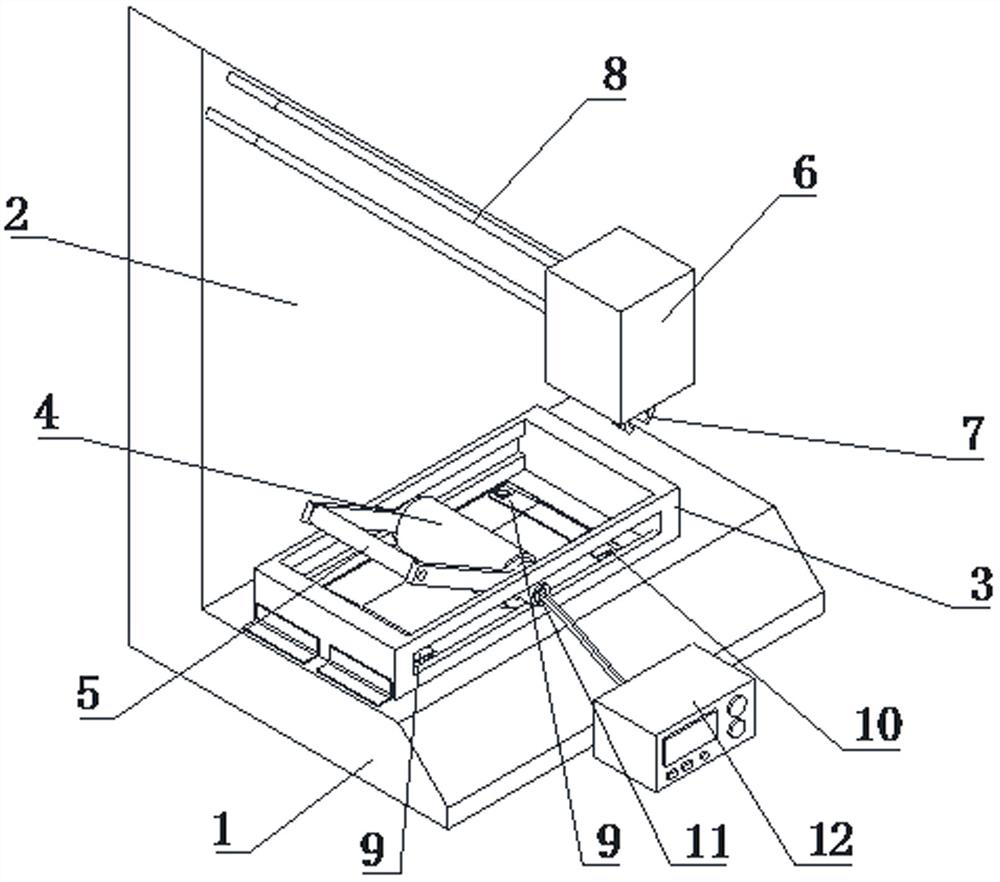

Evaluation device and evaluation method for evaluating the quality consistency of composite material tape winding prepreg

ActiveCN113777024BRealize evaluationReduce distortionUsing mechanical meansMaterial analysisEngineeringMechanical engineering

The present invention relates to the technical field of quality evaluation of composite material tape-wound prepregs, in particular to an evaluation device and evaluation method for evaluating the quality consistency of composite material tape-wound prepregs; Heating mechanism connection; one side of the support seat is provided with an upwardly extending back plate, the gravity roller is fixed on the support seat through the limit frame, the gravity roller can slide back and forth along the length direction of the limit frame, and the limit frame and the support seat are detachably connected , the gravity roller is connected with a hand-held tooling, a tension gauge is provided above the limit frame, a pull hook is provided on the tension gauge, and the side end of the tension gauge is connected to the backboard through an inclined track; At least two pressure plates arranged at intervals in the direction, both ends of each pressure plate are detachably connected to the support seat through detachable connectors, and the evaluation device for the quality of the composite material tape winding prepreg can effectively evaluate the quality of the composite material tape winding prepreg.

Owner:北京玻钢院复合材料有限公司

Bead health care pad and production method, and pillowcase and pillow made of the bead health care pad

InactiveCN105193181BThere will be no shifting phenomenonNot easy to movePillowsRoller massageEngineeringCushion

The invention relates to a bead health pad which comprises a piece of basic cloth and a piece of surface cloth arranged above the basic cloth, wherein an accommodating space is formed between the basic cloth and the surface cloth. The bead health pad further comprises a plurality of pieces of spacing cloth, wherein the spacing cloth divides the accommodating space into a plurality of accommodating slots; the accommodating slots are filled with beads; an opening is formed in at least one of the two ends of each accommodating slot along the length direction. The bead health pad further comprises elastic cotton strips for plugging the multiple openings and a zipper assembly. The bead health pad is higher in breathability, has a health effect, and is convenient to manufacture and comfortable in handfeel; the beads are unlikely to stagger and convenient to fill and pour; the cloth is convenient to clean. The invention further provides a pillowcase and a pillow which are made by the bead health pad, and a manufacturing method adopting the bead health pad. The pillowcase is used with a pillow interior, so that the pillow has the effects of high breathability and comfortable handfeel; meanwhile, the pillow has the effects of high breathability, comfortable handfeel and pillowcase stabilization.

Owner:林伟林

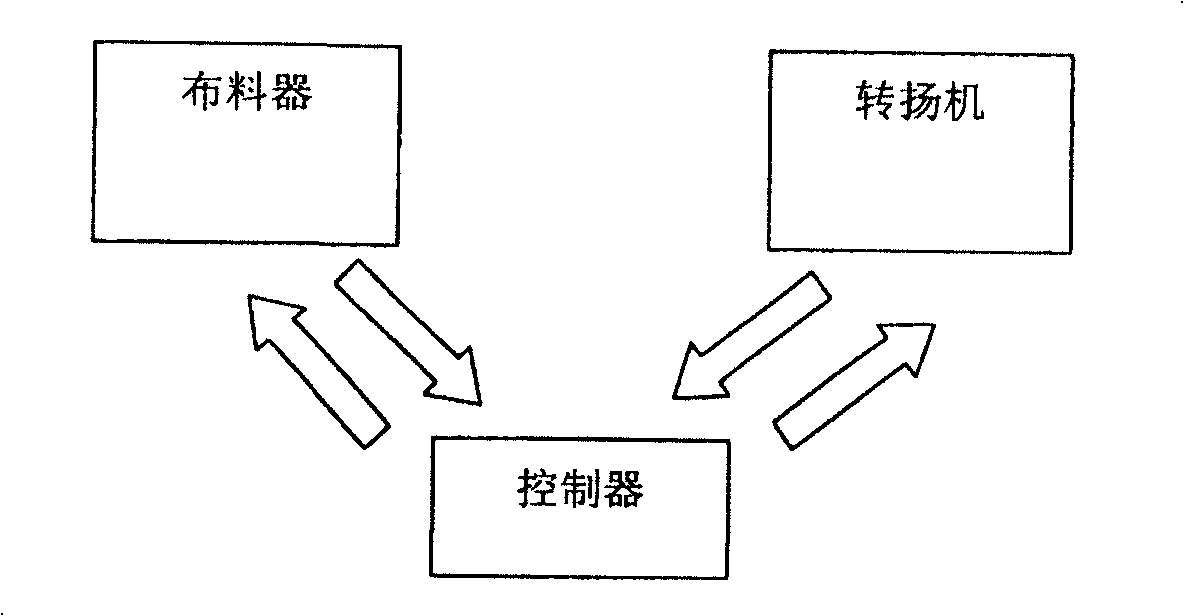

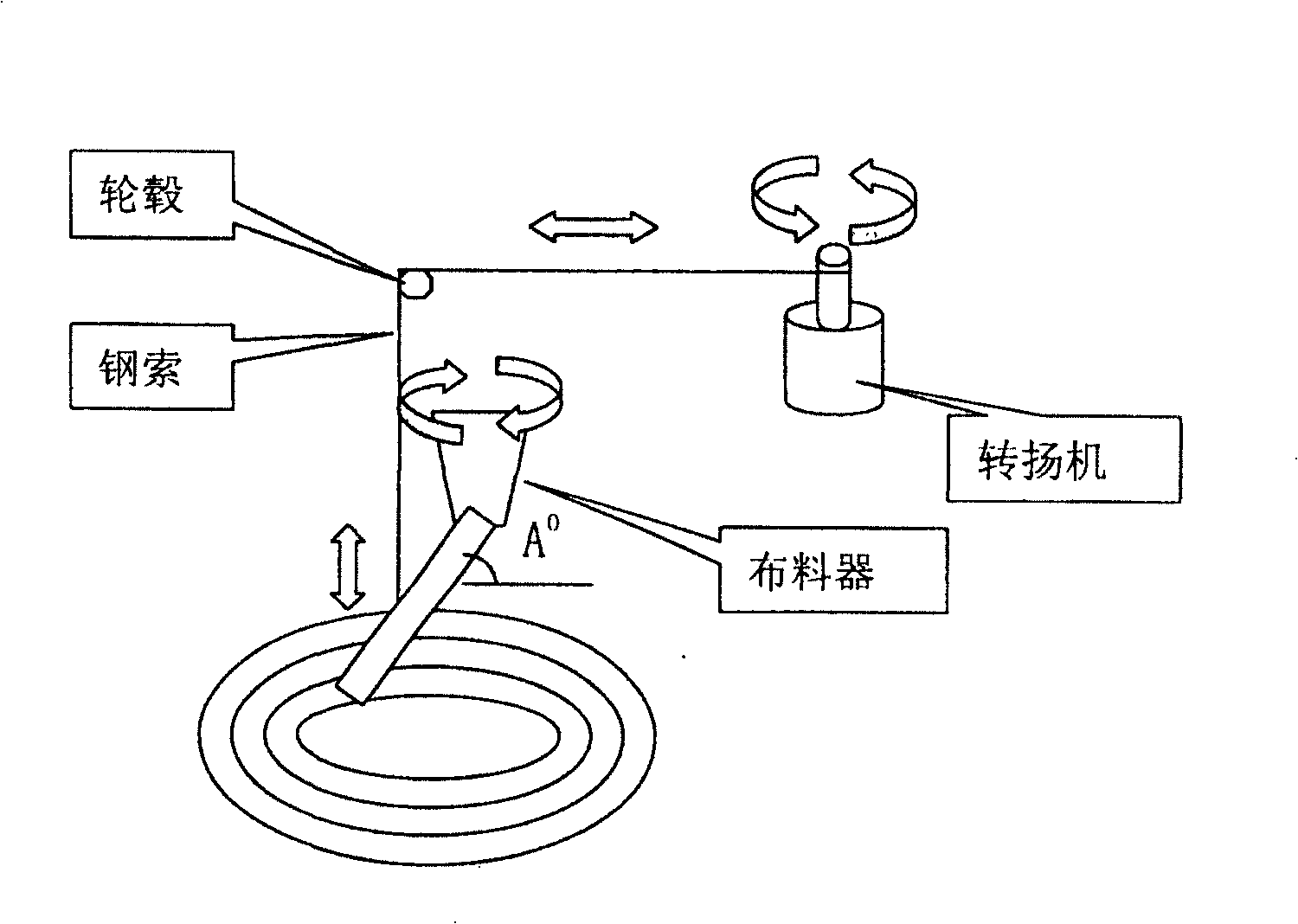

Automated control method for shaft kiln distributing device and the device

InactiveCN100451513CGuaranteed temperatureEasy dischargeVertical furnacesAutomatic controlMechanical engineering

The invention relates to the automatic control method of the shaft cloth implement and its device, the method is joining the signal which controls the cloth implement rotated into the cloth implement by the procedure controller; the cloth implement rotates one lap that is set one lap of the cloth in the cloth region; when the cloth implement rotates N times, set N lap cloth in the cloth region; joining the signal which controls the steel wire rotated of the rotating machine into the rotating machine; the angle of the sprinkler of the cloth and the horizontal changes between 0 and 90 degree; based on the cloth region the circle divided into three or more circle layer with one heart to carry on the bed cloth automatically; the interval distance of the different circle and the circle centre and the cloth lap of the different circle are controlled by the process controller. The merit: optionally select the multiple circumferential surface area or space cloth, control the time of the region cloth, and realize the aim of the shaft shut operation, reduce the discharge of the smoke from the kiln door, keep the kiln temperature, and reduce the energy cost of the ripe cloth burning, save the cost. It reduced the labor intensity, not blocking the kiln.

Owner:缪建通

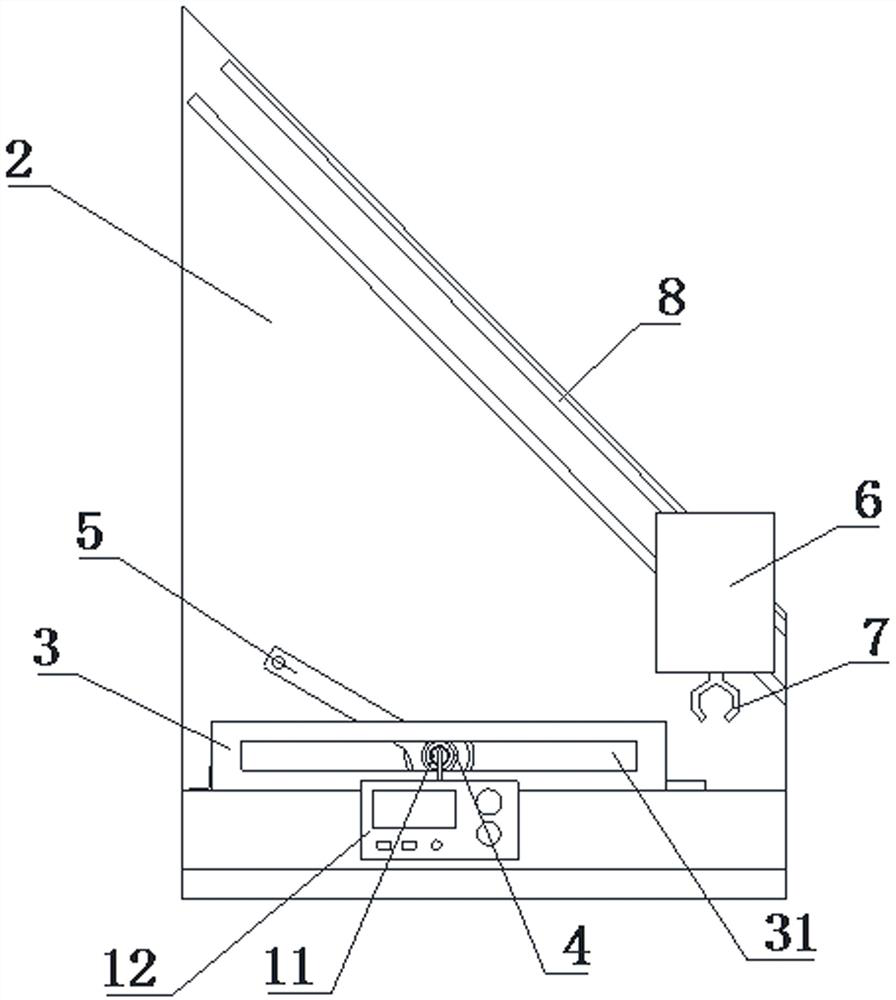

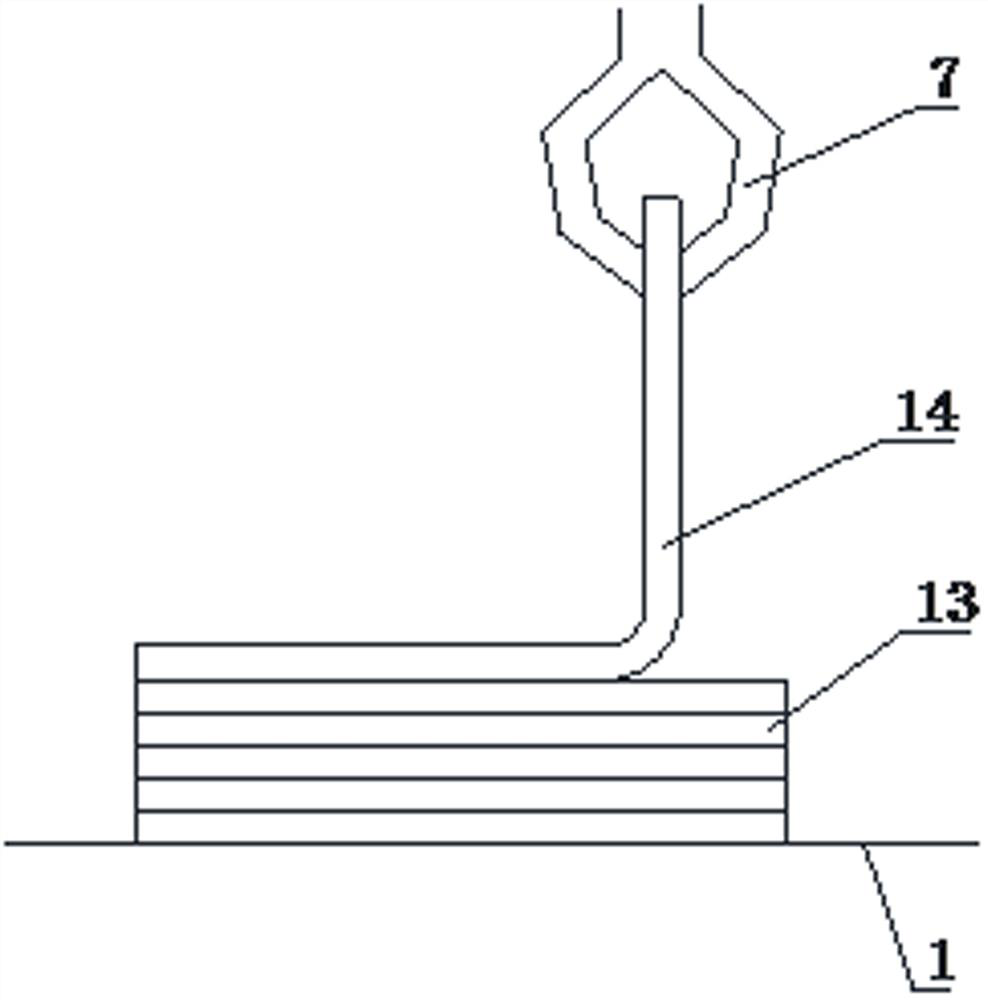

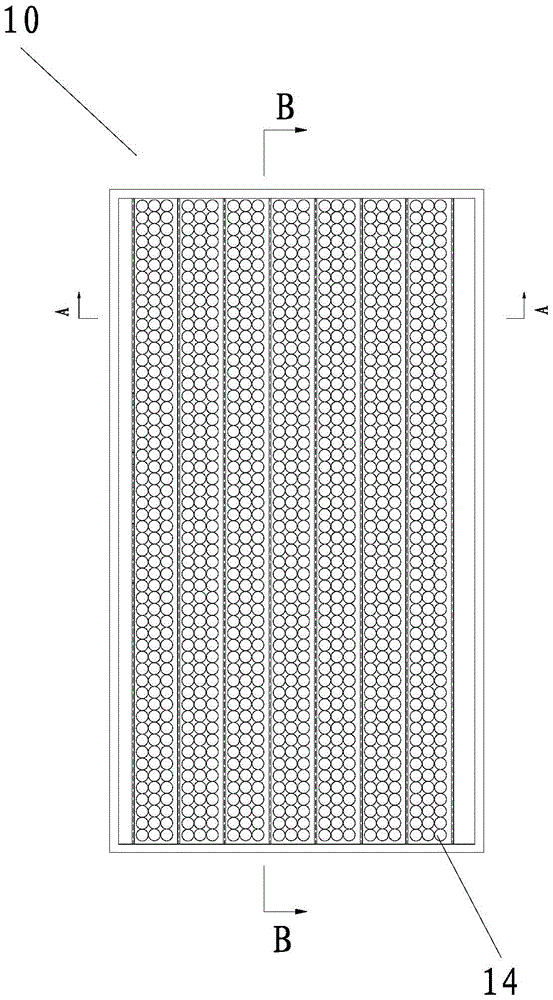

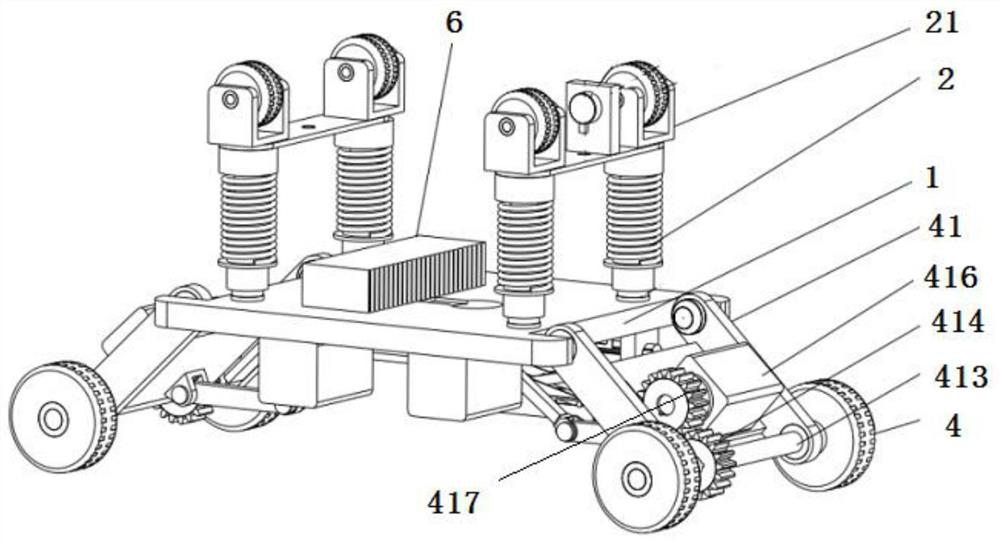

An automatic cloth device with a narrow space in a vertical plane

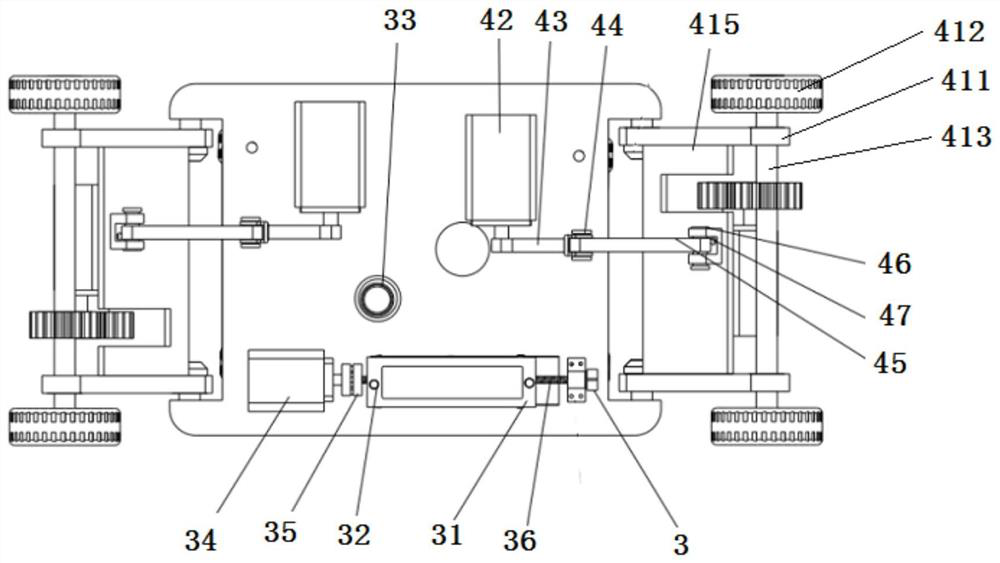

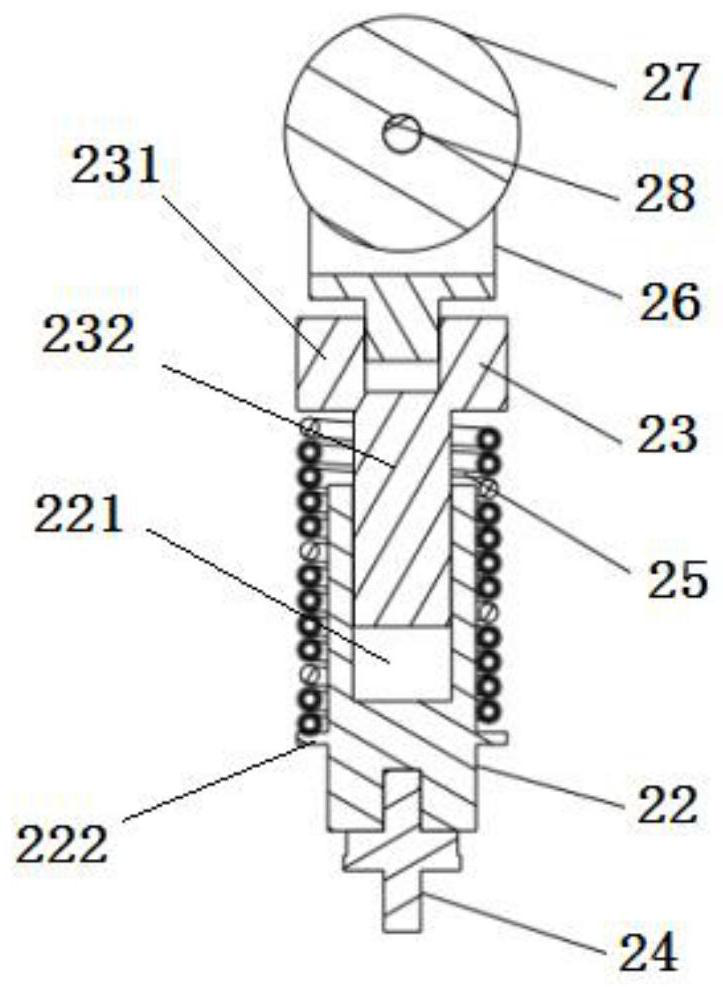

ActiveCN108638020BSolve the problem of limited artificial clothRealize automatic layingManipulatorControl theoryMechanical engineering

The invention discloses an automatic sheet distributing device with variable narrow space on the vertical surface, which comprises a frame. The top surface of the frame is provided with a heavy-duty pressure sensing mechanism, and the bottom surface is provided with a patch mechanism and a crawling mechanism. The patch mechanism includes The patch support plate can be telescopically arranged on the bottom of the frame. There is a light pressure sensor on the patch support plate. The crawling mechanism includes crawling claws hinged at both ends of the frame. The controller with the pressure sensor signal connected, the pressure value transmitted by the patch mechanism through the light pressure sensor uses the controller to drive the patch support plate to complete the patch action, and the pressure value transmitted by the crawling mechanism through the heavy pressure sensor mechanism uses the controller Drive and adjust the crawling range and angle of the crawling claws. The invention can quickly and accurately realize small-space layout, and ensures the effect of radiation detection.

Owner:合肥聚能电物理高技术开发有限公司 +1

Camouflage reinforced space cloth and preparation method thereof

The invention relates to the technical field of textile materials, in particular to camouflage reinforced space cloth and a preparation method thereof. The camouflage reinforced space cloth comprisesPVC camouflage netted sandwich cloth, space cloth and PVC netted sandwich cloth which are sequentially bonded from top to bottom; the PVC camouflage netted sandwich cloth layer comprises a printed transparent PVC film, a first netted sandwich cloth layer and a transparent PVC film which are sequentially laminated from top to bottom; the printed transparent PVC film is a transparent PVC film with apattern printed on the lower surface, and the distribution area of the pattern on the printed transparent PVC film is 10-30% of the area of the printed transparent PVC film; and the first netted sandwich cloth layer is prepared by performing dip coating on polyester fiber mesh cloth by using colored paste. The PVC camouflage sandwich screen cloth has the beneficial effects that the PVC camouflagesandwich screen cloth is additionally arranged on the surface of the space cloth, so the pattern of the space cloth is not prone to abrasion, and strength is higher.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Accurately-positioned fabric bonding device and using method thereof

ActiveCN112140687APrecise bondingImprove breathabilityLamination ancillary operationsLaminationEngineeringStructural engineering

The invention discloses an accurately-positioned fabric bonding device which comprises a conveyor belt, a conveyor, a plurality of pressing devices and a plurality of ultrasonic bonding heads, whereinthe conveyor and the pressing devices are arranged on the two sides of the conveyor belt respectively, the ultrasonic bonding heads are arranged above the conveyor belt, and a plurality of pieces ofbase cloth are arranged on the conveyor belt at intervals; a plurality of sub-conveyors in one-to-one correspondence with the base cloth are arranged on the conveyor; each sub-conveyor comprises a plurality of tensioners and transparent adhesive tapes connected with the tensioners; a plurality of wavy moisture absorption lines are adhered to the transparent adhesive tape in parallel, and the sections of the moisture absorption lines are elliptical; each piece of base cloth and each sub-conveyor correspond to one pressing device; a plurality of distance sensors are regularly arranged on each ultrasonic bonding head, and the ultrasonic bonding heads horizontally move in the X direction and the Y direction on the same plane. According to the device, through tensioning, pressing, pre-positioning and accurate positioning operation, accurate bonding of the base cloth and the moisture absorption lines is achieved, the working procedure is greatly simplified, the cost is saved, and the bondedfabric has high breathability, moisture absorption and certain water retention.

Owner:江苏苏美达轻纺科技产业有限公司

Self-supporting anti-interference multi-core shielding communication cable

InactiveCN114360789AImprove carrying capacityGood flexibilityInsulated cablesInsulated conductorsInterference resistancePolyvinyl chloride

The invention discloses a self-supporting anti-interference multi-core shielding communication cable which comprises multi-core communication wire cores and bearing stranded wires which are arranged at intervals and jointly wrapped in a polyvinyl chloride extruded outer sheath layer, and the polyvinyl chloride extruded outer sheath layer forms thin connecting ribs on interval sections between the multi-core communication wire cores and the bearing stranded wires. The bearing stranded wire is formed by twisting stainless steel wires and aramid stranded wires, the thickness of the thin connecting rib is not smaller than one half of the diameter of the bearing stranded wire, and the multi-core communication wire core comprises a plurality of insulating wire cores and a nylon resin core material which are jointly twisted to form a cable core. The cable core is sequentially coated with an AFRP reinforced wrapping layer, a fluororesin wrapping anti-attrition layer, a shielding net-shaped conductor layer, a copper-plastic composite belt wrapping shielding layer, a nylon wire anti-torsion wrapping layer and a nylon anti-corrosion layer. The cable is better in bearing capacity, excellent in torsion resistance, stable in shielding effect and durable in use.

Owner:浙江中大元通电缆科技有限公司

Mineral Halogen Free Low Smoke Flame Retardant Cable

The invention discloses a mineral-based halogen-free low-smoke flame-retardant cable, which comprises a plurality of wire cores, a flame-retardant layer outside the wire cores, a filling layer between the wire cores and the flame-retardant layer, and a fire-retardant layer outside the flame-retardant layer. The outer sheath, the wire core includes a cylindrical base column, a plurality of separators uniformly distributed along the circumferential direction of the cylindrical base column, copper wires located between two adjacent separators, and filling the gap formed by the separators and copper wires The inner insulation layer; the separator extends axially along the cylindrical base column; elastic sheets are fixed on the adjacent surfaces of two adjacent separators, and the two elastic sheets form an opening for the copper wire to enter, and the opening is smaller than the diameter of the copper wire ; The end of the elastic sheet away from the separator is bent along the radial direction of the cylindrical base column to the central axis of the cylindrical base column to form a guide part; the abutment block is fixed on the separator, and the abutment blocks are arranged at intervals along the axial direction of the cylindrical base column ; After the copper wire is placed between two adjacent separators, the end of the guide part abuts against the outer side of the copper wire, and the inner side of the copper wire is in contact with the abutting block tightly.

Owner:武汉新天地电工科技有限公司

Camouflage space cloth material and preparation method thereof

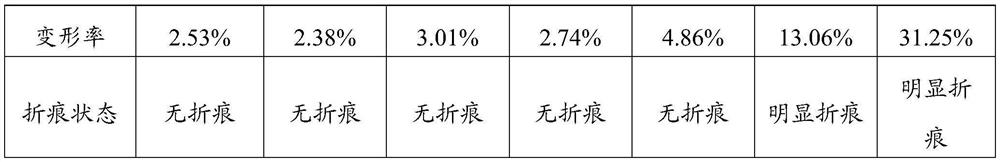

PendingCN113510977AIntegrity guaranteedOvercome the problem of large deformationLamination ancillary operationsSynthetic resin layered productsMechanical engineeringSpace cloth

The invention discloses a preparation method of a camouflage space cloth material, and belongs to the technical field of space cloth materials. The preparation method comprises the following steps that: after space cloth is ironed to be flat, the bottom side of the space cloth is pasted and dried, and pasted space cloth is obtained; one side, not printed with patterns, of a camouflage printing film is pasted to obtain a pasted camouflage printing film; the PVC bottom film is preheated and then attached to the bottom layer of the pasted space cloth; the pasted camouflage printing film is attached to the surface side of the pasted space cloth; and a PVC transparent film is attached to the side, where the patterns are printed, of the pasted camouflage printing film. According to the preparation method of the camouflage space cloth material provided by the invention, the camouflage printing film is directly pasted and cold-drawn to be compounded with space screen cloth without heating treatment, so that the integrity of a camouflage pattern is kept, and the problem of pattern deformation of a finished product is solved; and in the preparation process, the camouflage printing film and the space cloth are pasted on the single side, it is guaranteed that the obtained camouflage space cloth material is low in pattern deformation rate, soft and not prone to generating creases, and the camouflage space cloth material is suitable for preparing inflatable products with large radians.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Crosslinked polyethylene insulated low-smoke halogen-free flame-retardant fireproof power cable

InactiveCN112768126AImprove pressure resistanceImprove the protective effectInsulated cablesPower cablesLow smoke zero halogenPower cable

The invention discloses a crosslinked polyethylene insulated low-smoke halogen-free flame-retardant fire-resistant power cable core which comprises a cable core. The cable core comprises an insulating layer, a reinforcing rib and three conductors. The three conductors abut against each other and are arranged at equal intervals, and the reinforcing rib is connected in a cavity enclosed by the outer walls of the three conductors in a penetrating manner; the outer wall of the cable core is coated with the insulating layer, the outer wall of the insulating layer is provided with a plurality of evenly-distributed limiting grooves, the inner walls of the limiting grooves are slidably connected with one side of a limiting batten, the two ends of the limiting batten abut against the inner wall of an inner sheath, and the outer wall of the inner sheath is coated with an armor layer; and the outer wall of armor layer is coated with a mica tape fireproof layer, and the outer wall of the mica tape fireproof layer is coated with an outer sheath. The cross-linked polyethylene insulated low-smoke halogen-free flame-retardant fire-resistant power cable provided by the invention is good in voltage resistance and protection capability, relatively weak in heat conduction efficiency, and high in heat resistance and fire resistance. And meanwhile, the cable has higher pulling resistance and bending resistance.

Owner:江西新吉电缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com