Vacuum arc-extinguishing chamber and arc-extinguishing contact thereof

A technology of arc-extinguishing contacts and contacts, which is applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of small longitudinal magnetic field strength, long contact current path, and poor flow capacity, so as to ensure the longitudinal The effect of increasing the strength of the magnetic field, increasing the flow capacity, and reducing the flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

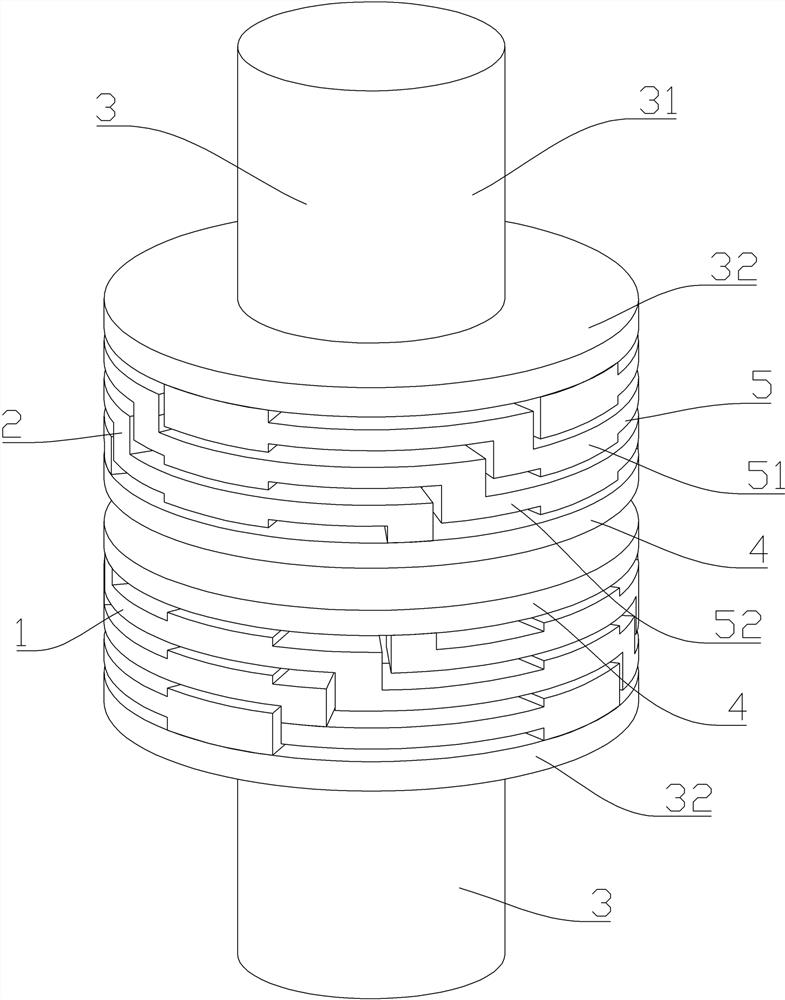

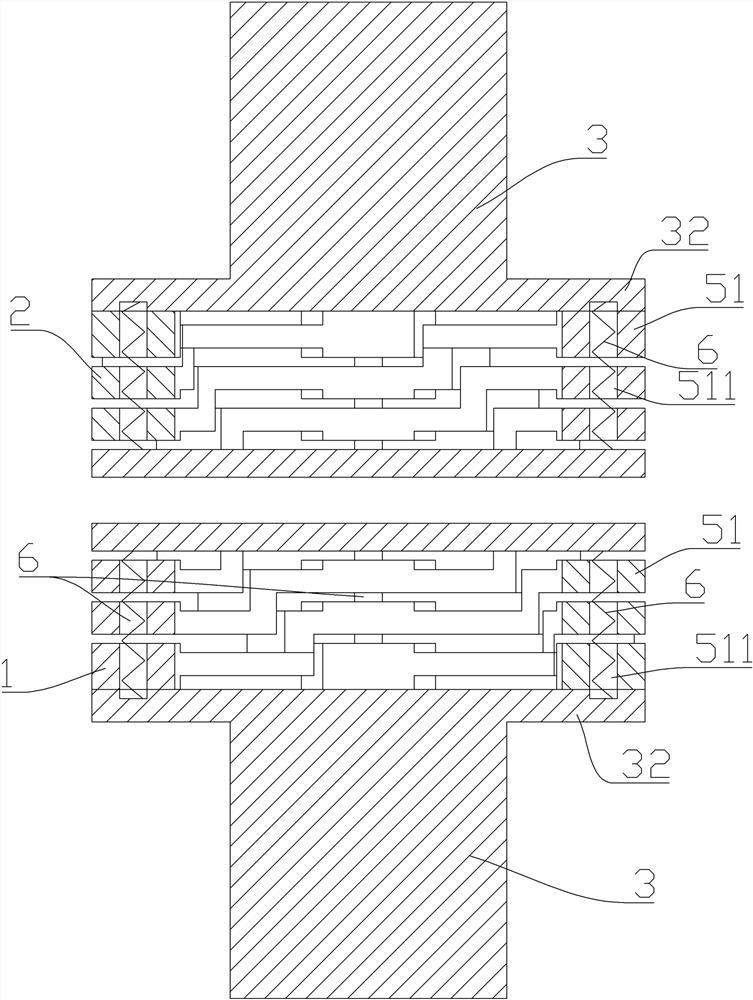

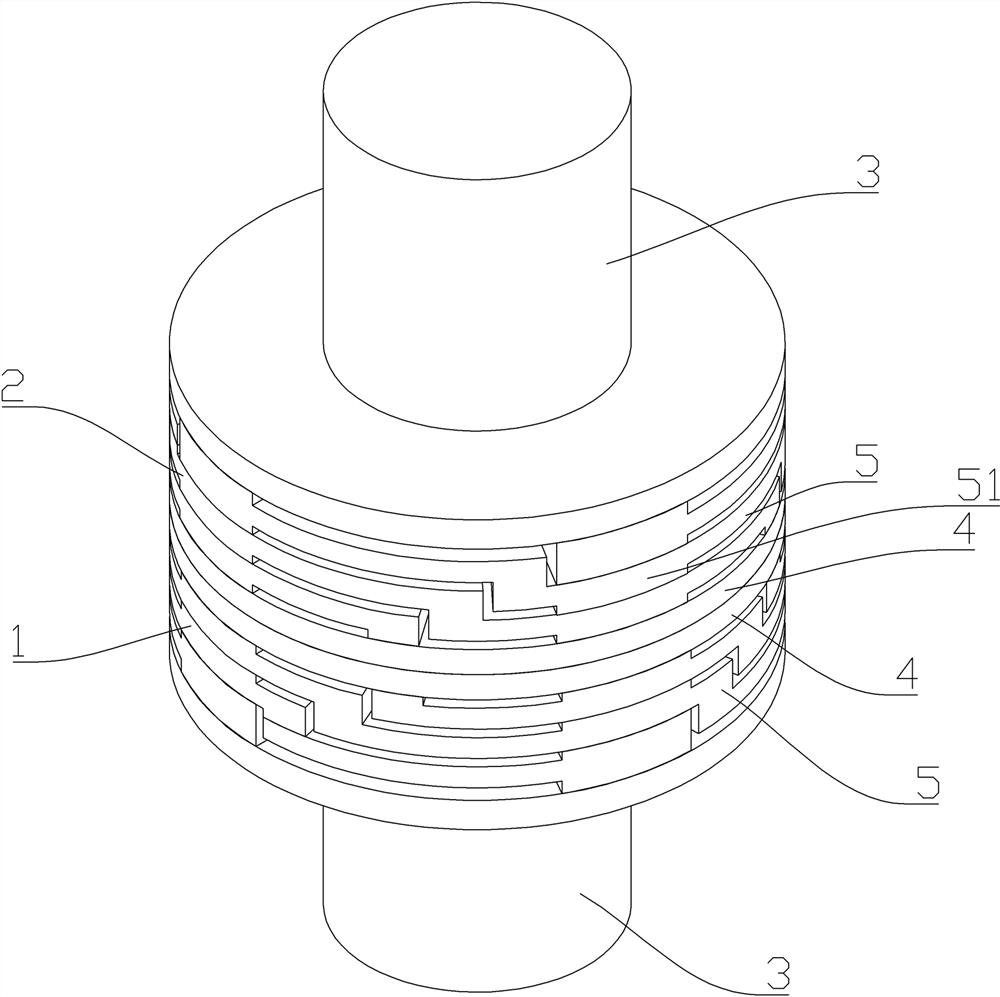

[0050] Such as Figure 1 to Figure 4 As shown, the vacuum interrupter includes a housing, a moving contact 1 and a static contact 2. In this embodiment, both the moving contact 1 and the static contact 2 are arc-extinguishing contacts. The moving contact 1 and the static contact 2 move relative to each other in the casing to realize the connection of the two, and move oppositely in the casing to realize the disconnection of the two. The structure of the arc extinguishing contact involved in the present invention will be introduced below.

[0051] The arc extinguishing contact of the present invention can generate a larger longitudinal magnetic field when the movable contact 1 and the static contact 2 are disconnected, and has a higher flow capacity after the movable contact 1 and the static contact 2 are connected.

[0052] The arc extinguishing contact includes a conductive rod 3 , a contact piece 4 and a longitudinal magnetic conductor 5 . The conductive rod 3 includes a r...

Embodiment 2

[0065] Specific embodiment 2 of the vacuum interrupter of the present invention. The difference between the vacuum interrupter in this embodiment and the vacuum interrupter in the above embodiment is that the longitudinal magnetic conductor itself is an elastic member in this embodiment. For example, the longitudinal magnetic conductor can be It is an elastic conductive sheet. At this time, the longitudinal magnetic conductor relies on its own elastic reset, and no elastic member is required. Of course, in other embodiments, when the conductor itself is an elastic conductor, an elastic member may also be added to ensure the reset effect.

[0066] The specific embodiment 3 of the vacuum interrupter of the present invention, the difference between the vacuum interrupter in this embodiment and the vacuum interrupter in the above embodiment is that all the longitudinal magnetic conductors constitute the conductor contact section.

[0067] The specific embodiment 4 of the vacuum i...

specific Embodiment 5

[0068] Embodiment 5 of the vacuum interrupter of the present invention. The difference between the vacuum interrupter in this embodiment and the vacuum interrupter in the above embodiment is that the longitudinal magnetic conductor is in a spiral shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com