Connection structure of cold-insulation superconducting cable shielding layer current lead and assembly method thereof

A shielding layer current and superconducting cable technology, applied in the usage of superconductor elements, superconducting devices, connections, etc., can solve the problems of large assembly space, affecting the structure and size of the terminal thermostat, etc., and achieve small assembly space and overall The effect of small size and optimized overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

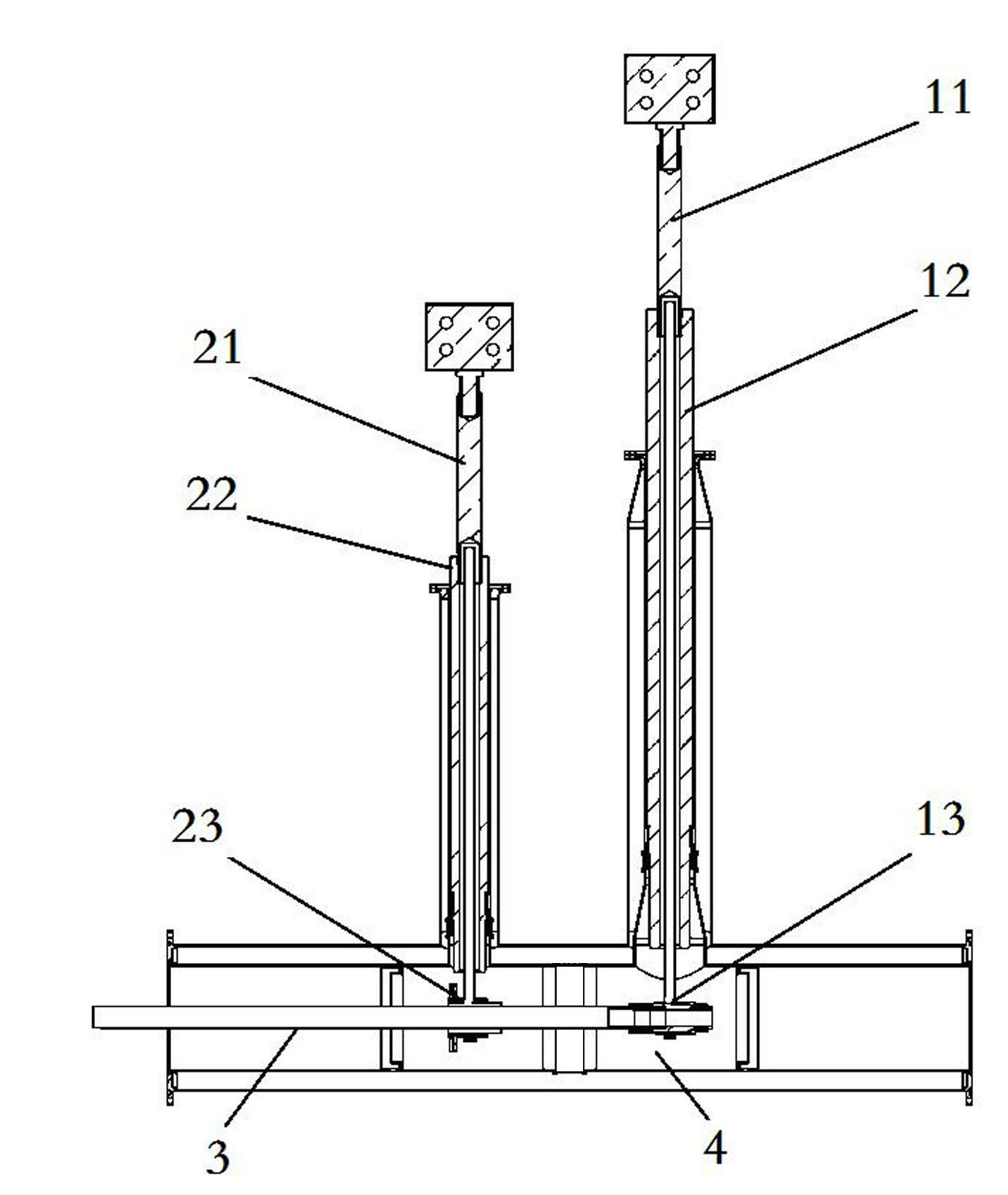

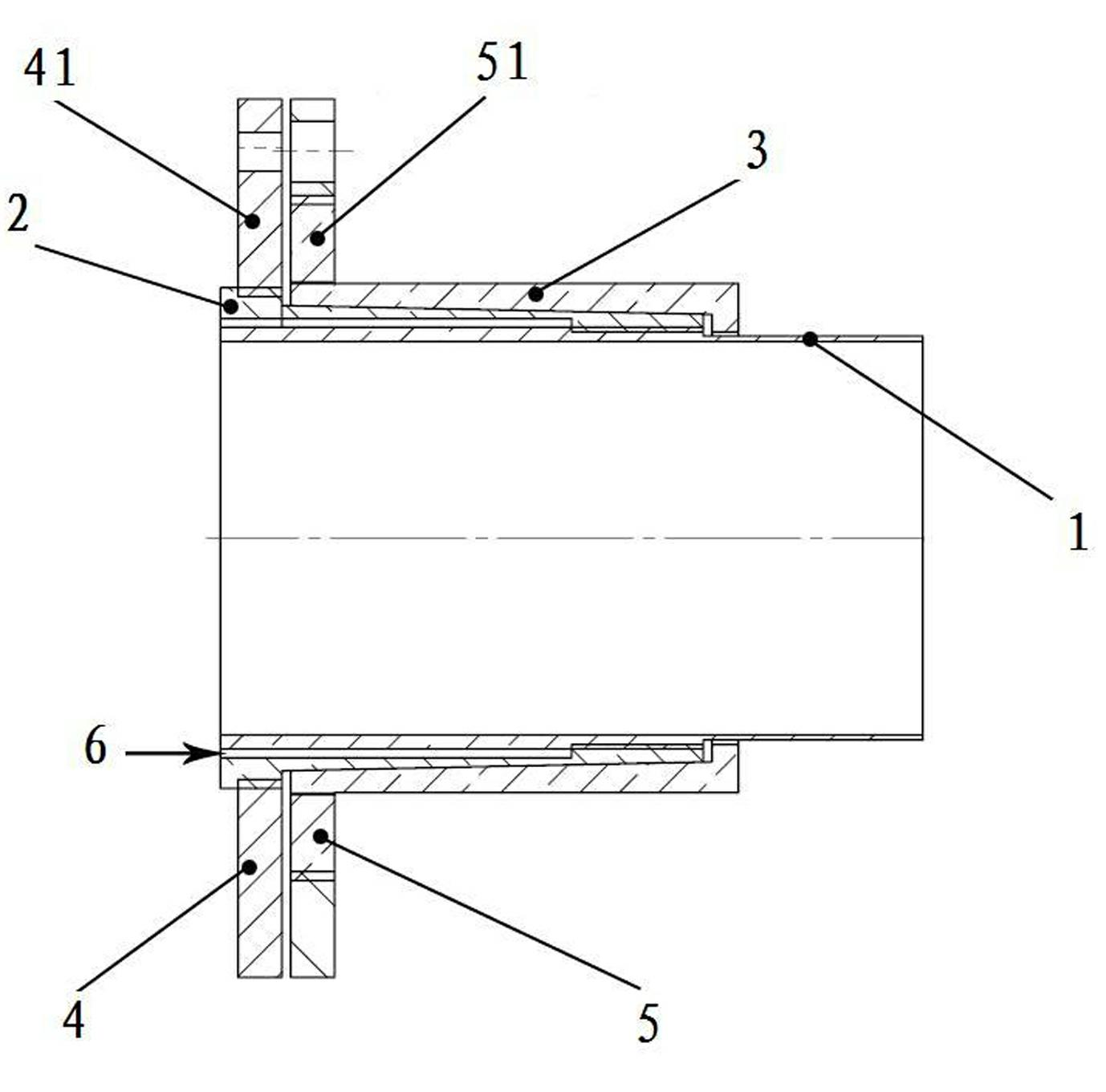

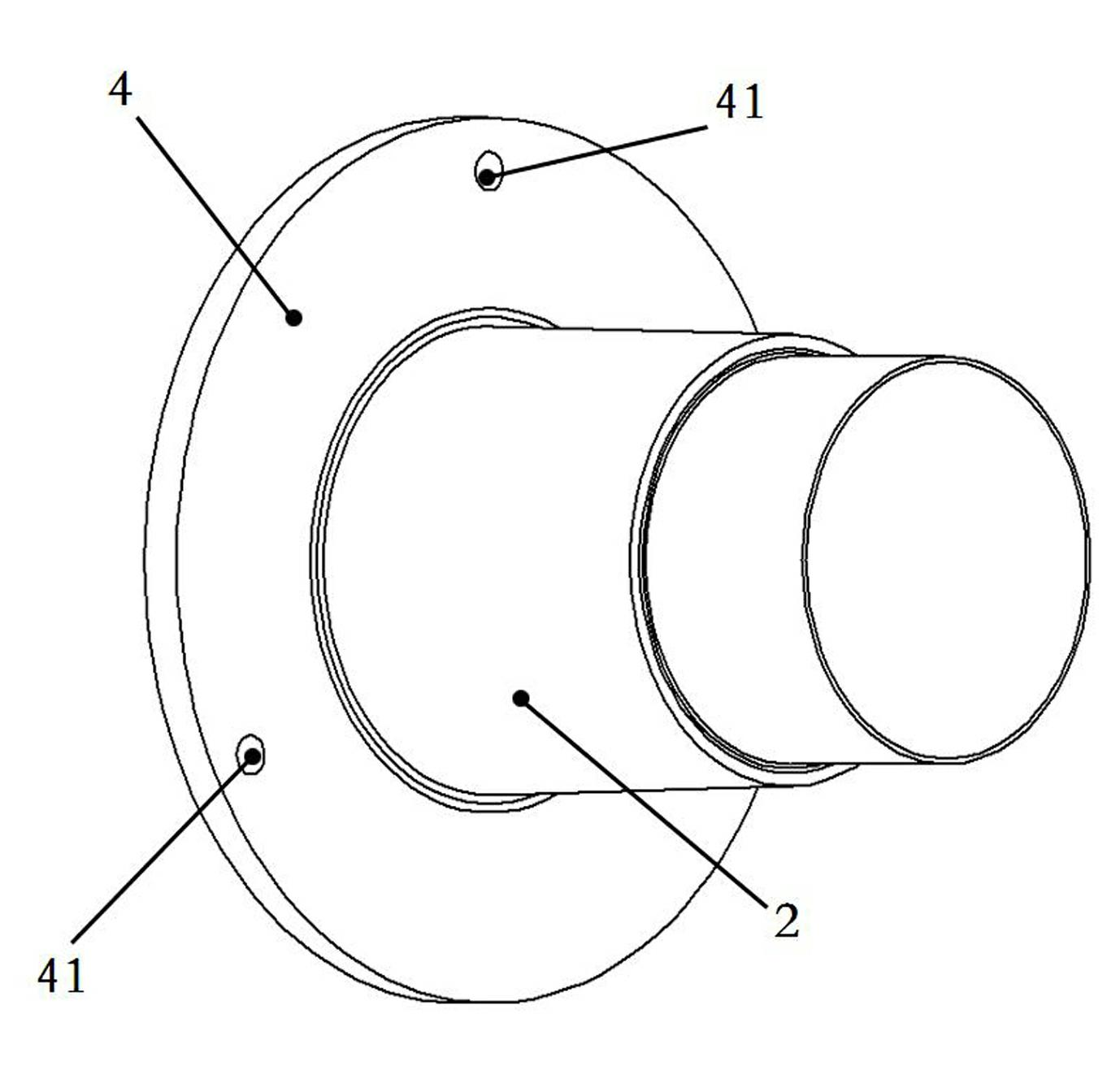

[0031] refer to figure 2 As shown, the connection structure of the current lead of the shielding layer of the cold insulated superconducting cable of the present invention includes an inner sleeve 1, a conductive cone 2, a conductive cone 3 and a set of fastening flanges 4,5.

[0032] The outer wall of the inner sleeve 1 is a three-stage structure of tapered contraction, and the first and second stages ( figure 2 In the shown embodiment, the right direction is defined as the front) and the outer wall is respectively provided with external threads for connecting the conductive cone female 3 and the conductive cone pipe.

[0033] The conductive tapered tube 2 is a tapered tube, and the configuration of its inner side wall matches the outer wall of the inner sleeve 1 at the rear two steps (see figure 2 shown in ), the inner front end of the conductive cone tube 2 has the same internal thread as the inner sleeve 1, and the inner diameter of the conductive cone tube 2 needs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com