Clamping device for printed circuit board (PCB) code spraying

A technology of PCB board and clamping device, which is applied in the field of clamping device for PCB printing, can solve the problems of unadjustable position of printed circuit board, inconvenient acquisition of printing codes of different shapes, inconvenience of printing codes, etc., to improve flexibility Sexuality, easy clamping, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

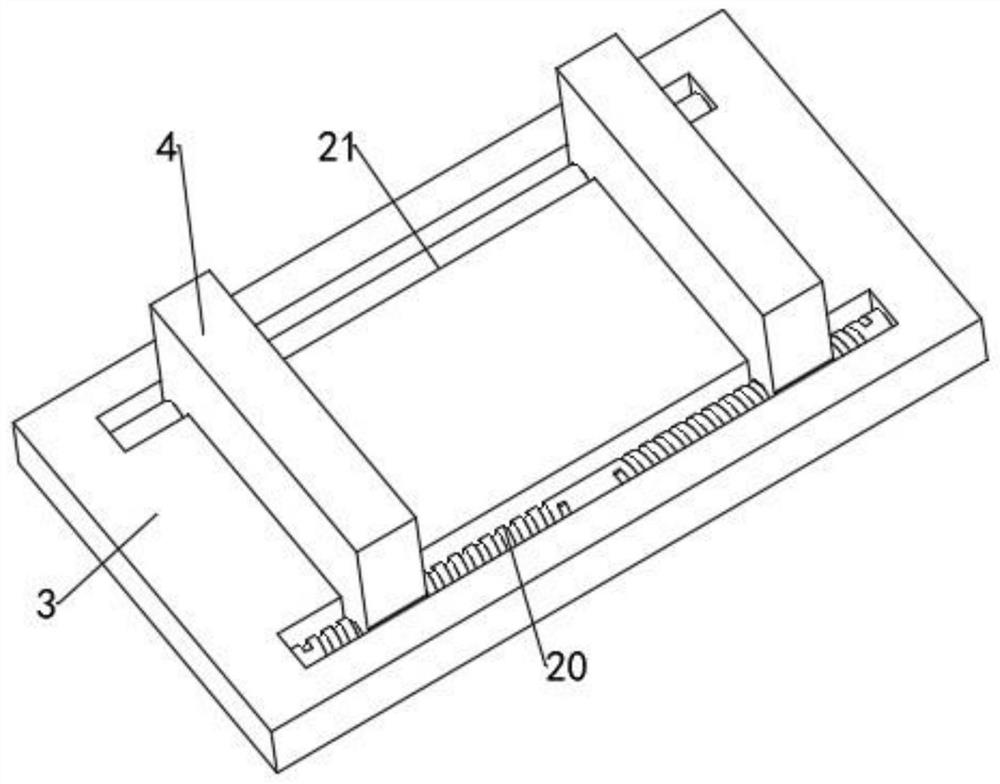

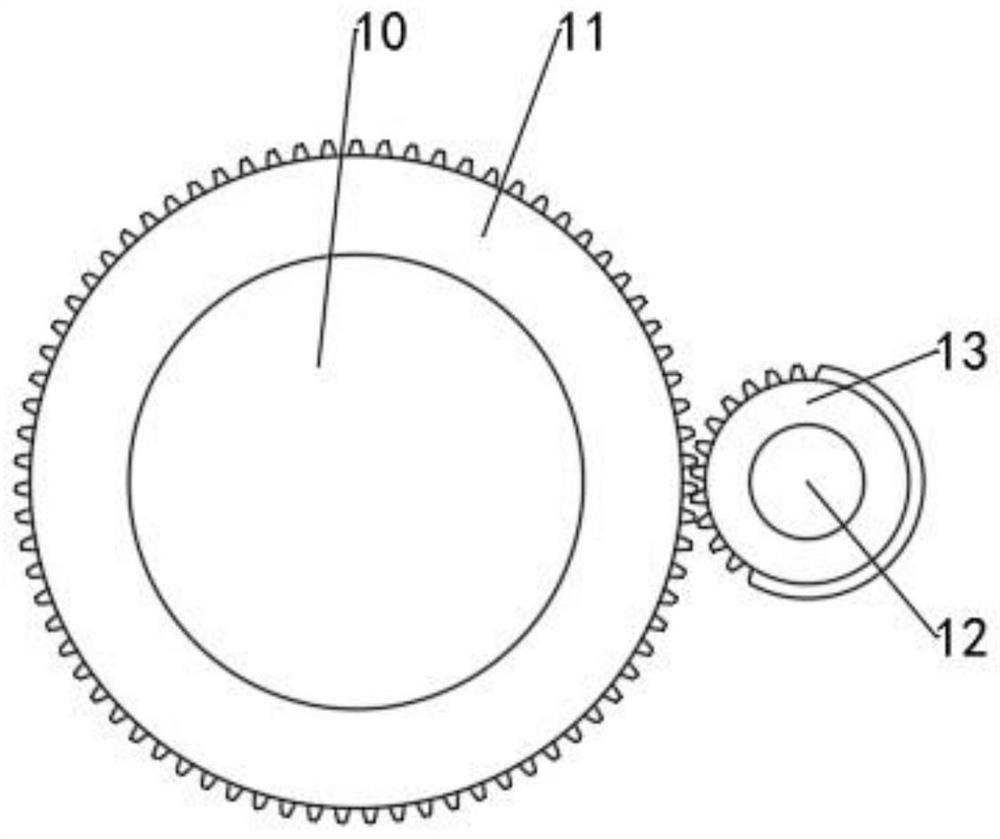

[0020] see Figure 1-4 , a clamping device for PCB board printing, including a base 1, a mounting seat 3 is movably connected to the base 1 via a substrate 2, and two limiting seats 4 are arranged at intervals on the mounting seat 3, and the limiting seat 4 passes through The mounting shaft 16 is connected with a base 17; the inner side of the base 17 is provided with a mounting plate 22 and a fixed seat 24 at intervals, and several horizontal hydraulic telescopic rods 23 are evenly installed between the mounting plate 22 and the base 17, and the mounting plate 22 Two driving rods 27 are connected to the side away from the hydraulic telescopic rod 23 in rotation. The corresponding limit rod 25 is rotationally connected. One end of the limit rod 25 extends to the outside of the base 17 and is equipped with a limit block 26. The hydraulic telescopic rod 23 drives the mounting plate 22 to move straight. Under the transmission action of the drive rod 27 The two limit rods 25 are ...

Embodiment 2

[0029] In order to facilitate the installation and fixation of the clamping device, this embodiment is improved on the basis of Embodiment 1. The improvement is that: the base 1 is evenly arranged with a number of through threaded holes, so that bolts can be used to fix the clamping device. The above-mentioned clamping device is assembled and fixed, and the operation is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com