Manufacturing method of spatial cloth inflatable product, and spatial cloth inflatable product

A cloth inflatable, manufacturing method technology, applied in tents/canopies, building types, buildings, etc., can solve the problems that high-frequency welding technology cannot be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

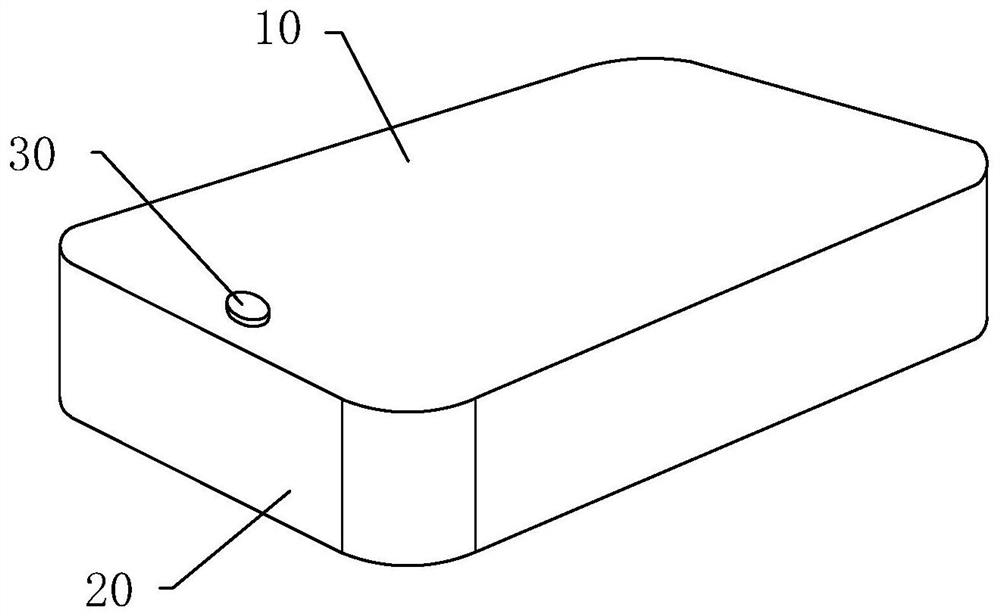

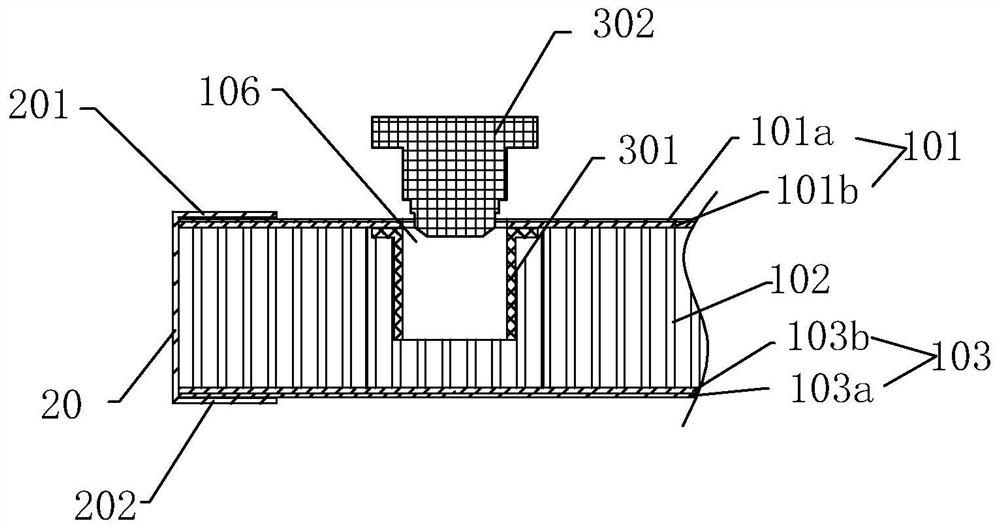

[0062] refer to Figure 1 to Figure 3 , the first embodiment provides a space cloth inflatable product, including a space cloth 10 and a bar 20, the space cloth 10 includes an upper base cloth 101 and a lower base cloth 103, and the upper base cloth 101 is arranged from top to bottom It includes an upper film layer 101a and an upper high-strength fabric layer 101b formed by composite processing, and the lower base fabric 103 includes a lower high-strength fabric layer 103b and a lower film layer 103a formed by composite processing from top to bottom, and the upper film layer 101a and the lower film layer 103a are both TPU film layers, the upper base cloth 101 and the lower base cloth 103 are fixedly connected by a plurality of drawing wires 102, and the surrounding bar 20 has a transverse direction along the length direction and a longitudinal direction along the width direction. Define the side edges of the surrounding bar 20 located on both sides of the longitudinal directio...

Embodiment 2

[0085] refer to Figure 3 to Figure 5 , the second embodiment provides a space cloth inflatable product, including a space cloth 10 and a bar 20, the space cloth 10 includes an upper base cloth 101 and a lower base cloth 103, and the space cloth 10 includes an upper base cloth 101 and the lower base cloth 103, the upper base cloth 101 includes an upper film layer 101a and an upper high-strength fabric layer 101b formed by composite processing from top to bottom, and the lower base cloth 103 includes a lower layer processed by composite processing from top to bottom. The high-strength fabric layer 103b and the lower film layer 103a, the upper film layer 101a and the lower film layer 103a are both PVC film layers, and the upper base cloth 101 and the lower base cloth 103 are fixedly connected by a plurality of drawing wires 102, so The surrounding bar 20 has a transverse direction along the length direction and a longitudinal direction along the width direction, and defines that...

Embodiment 3

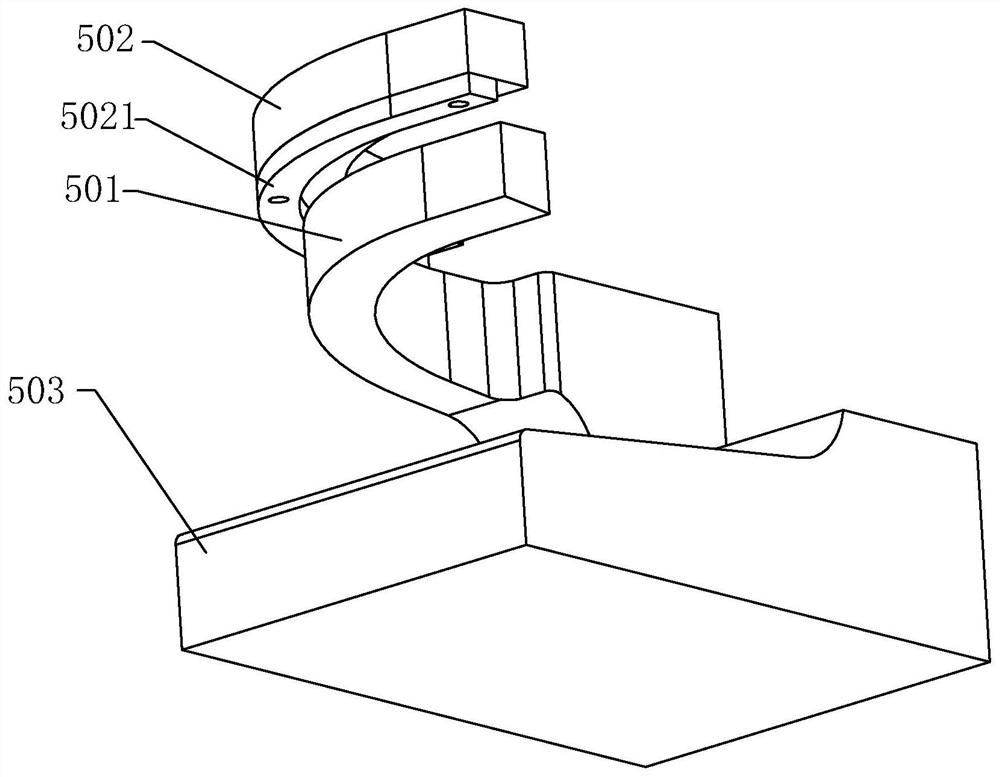

[0104] refer to figure 2 , Figure 6 , Figure 7 , the third embodiment provides a space cloth inflatable product, including a space cloth 10 and a bar 20, the space cloth 10 includes an upper base cloth 101 and a lower base cloth 103, and the upper base cloth 101 is arranged from top to bottom It includes an upper film layer 101a and an upper high-strength fabric layer 101b formed by composite processing, and the lower base fabric 103 includes a lower high-strength fabric layer 103b and a lower film layer 103a formed by composite processing from top to bottom, and the upper film layer 101a and the lower film layer 103a are both TPU film layers, the upper base cloth 101 and the lower base cloth 103 are fixedly connected by a plurality of drawing wires 102, and the surrounding bar 20 has a transverse direction along the length direction and a longitudinal direction along the width direction. Define the side edges of the surrounding bar 20 located on both sides of the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com