Novel wire-drawing air cushion and production method thereof

A production method and wire drawing technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as poor pressure bearing capacity and structural stability, increase production costs, and be prone to dislocation, and achieve higher bearing capacity. Effects of pressure and robustness, optimized production process, increased production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

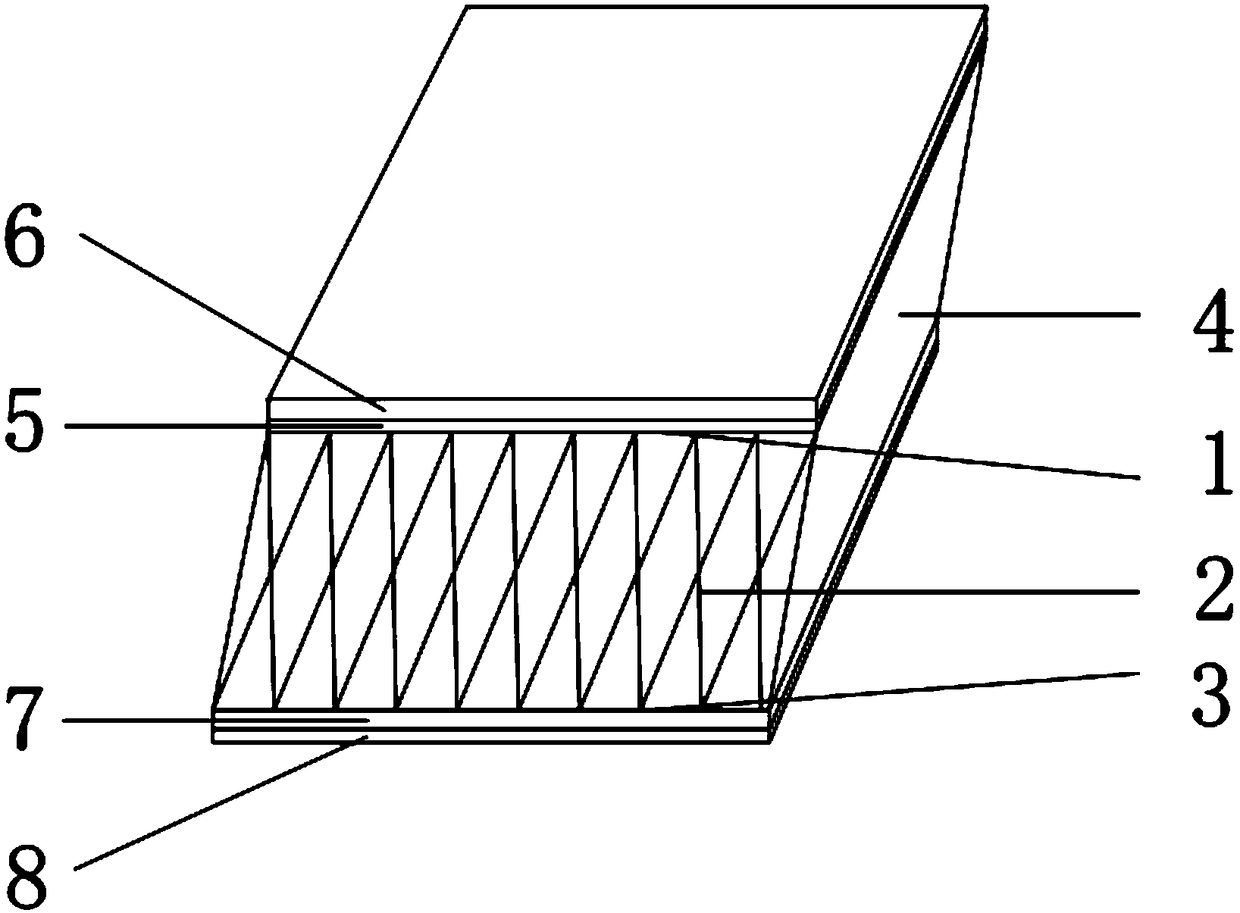

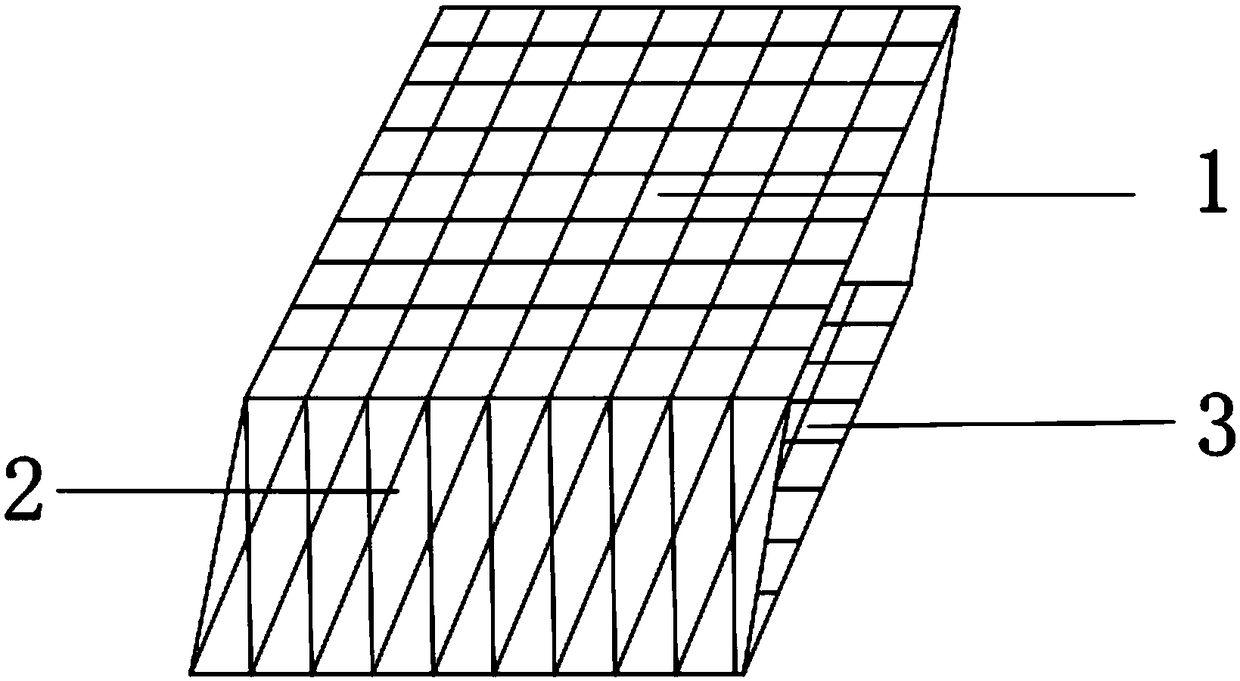

[0019] like figure 1 and 2 A new type of drawing air cushion is shown, the drawing air cushion includes a space cloth; the space cloth includes the first mesh cloth 1, the drawing cloth 2, and the second mesh cloth 3 from top to bottom; the first mesh cloth 1 passes through the drawing cloth 2 is connected with the second grid cloth 3; the upper end of the first grid cloth 1 is coated with No. 1 inner coating 5 and No. 1 outer coating 6 in turn; Coating 7, No. 2 outer coating 8; both ends of the space cloth are pasted with PVC connecting strips 4;

[0020] The first mesh cloth 1 and the second mesh cloth 2 are all formed by interweaving warp threads and weft threads, and the warp threads and weft threads are interwoven to form a quadrilateral grid; the mesh density of the first mesh cloth 1 and the second mesh cloth 3 is uniform. 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com