Central conductor assembly, circulator and isolator

A center conductor and isolator technology, applied in the field of communication accessories, can solve the problems of affecting product performance, poor consistency between the gyromagnetic ferrite and the center junction conductor, low production efficiency, etc., to achieve the effect of ensuring product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

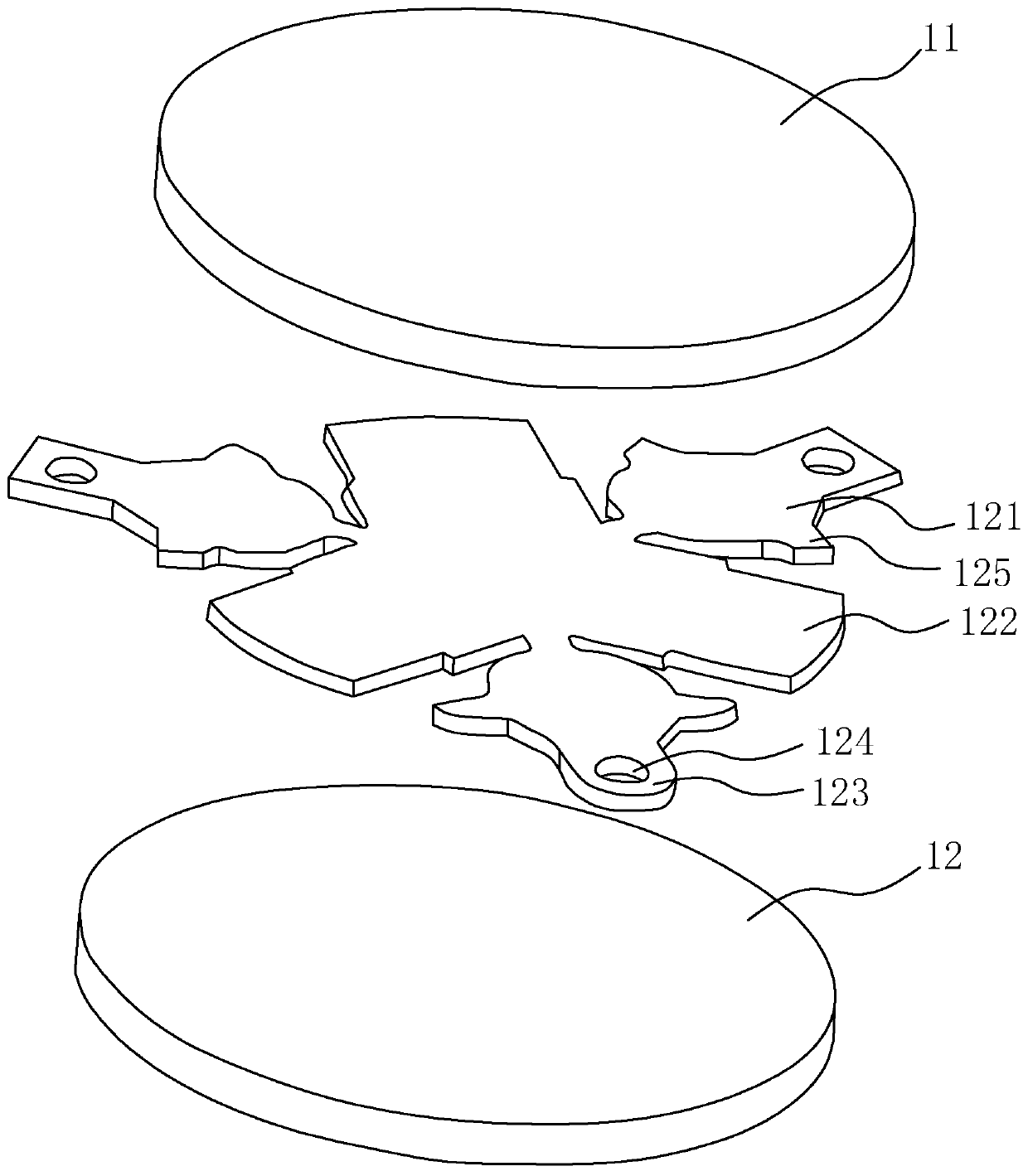

[0032] A center conductor assembly 1, such as figure 1 with figure 2 As shown, it includes: a top-spin ferrite 11, a central junction conductor 12 and a bottom-spin ferrite 13 arranged sequentially from top to bottom and welded and fixed by a high-frequency welding process. The center junction conductor 12 is located on the top-spin ferrite 11 and the central position of the down-rotating ferrite 13, the up-rotating ferrite 11 and the down-rotating ferrite 13 are aligned; the central junction conductor 12 includes a plurality of first resonator 121 and second resonator 122 arranged at intervals, the first A resonator 121 is connected with a connection pin 123 extending from the down-rotating ferrite 13 , and the connection pin 123 is provided with a connection hole 124 .

[0033] Specifically, in this embodiment, there are three groups of the first resonant body 121 and the second resonant body 122, and the three groups of the first resonant body 121 and the second resonant ...

Embodiment 2

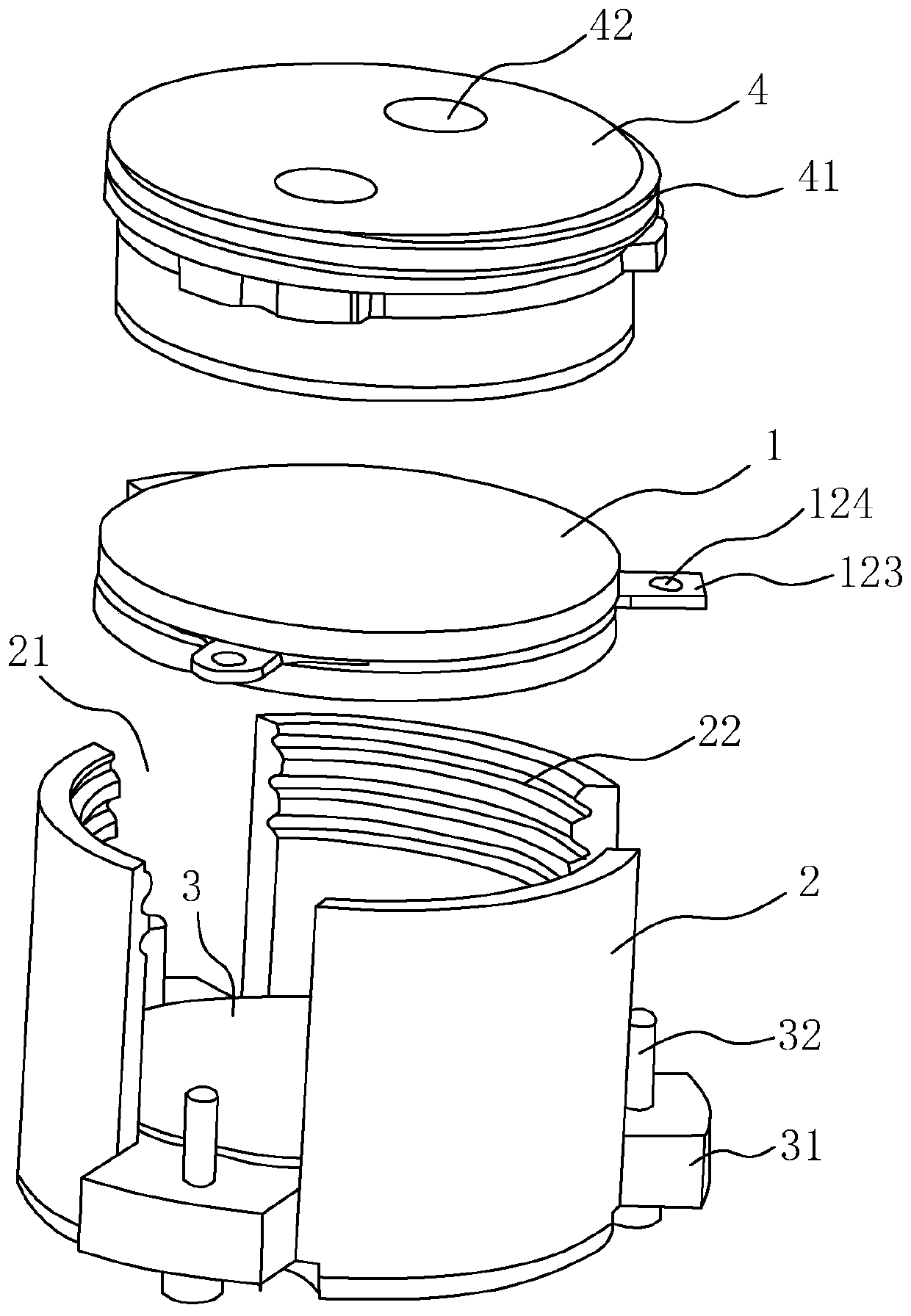

[0037] A circulator and isolator such as image 3 As shown, it includes: a package case 2, which is provided with at least two locking grooves 21 arranged at intervals, and an internal thread 22 is provided at the port of the package case 2; a positioning connector 3 is arranged at the bottom of the package case 2 , the positioning connecting body 3 is provided with a connecting protrusion 31 corresponding to the locking groove 21, the connecting protrusion 31 is embedded in the locking groove 21 and extends to the outside of the package shell 2, and the connecting protrusion 31 is interspersed with a grounding pin 32; In the central conductor assembly 1 described in Embodiment 1, the grounding pin 32 is inserted into the connection hole 124; and, the packaging cover 4 is arranged in the inner cavity of the packaging shell 2, and the outer peripheral wall of the packaging cover 4 is provided with the internal thread 22. The external thread 41, and the package cover 4 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com