Composite material grid component automatic laying head and laying method

A composite material and placement head technology, which is applied in the field of automatic placement head and placement of composite mesh components, can solve problems such as limiting the design space of the grid structure, increasing the volume of the placement head, and clogging of prepregs. To achieve the effect of reducing lateral volume, improving quality and reducing lateral width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

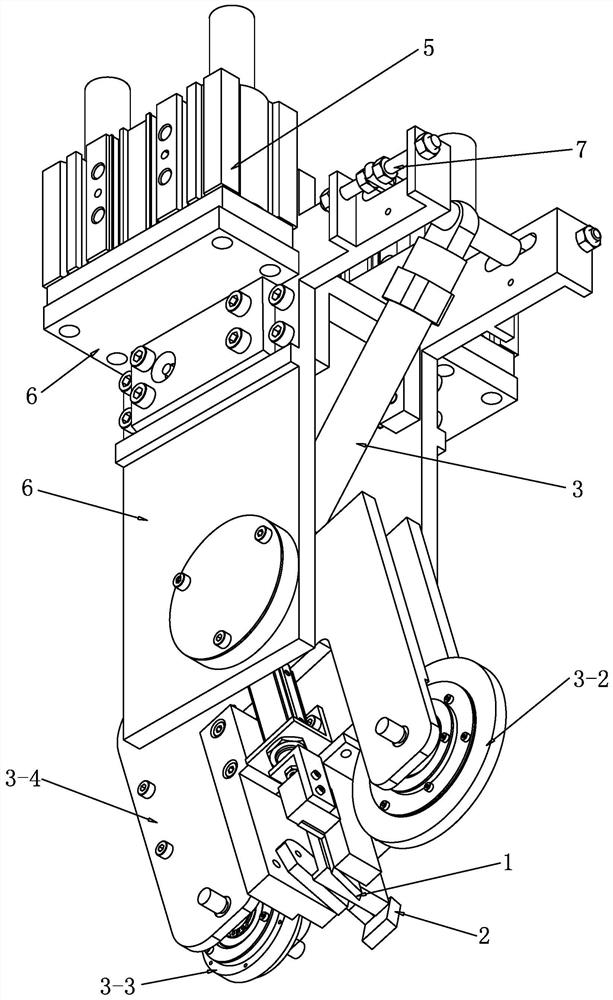

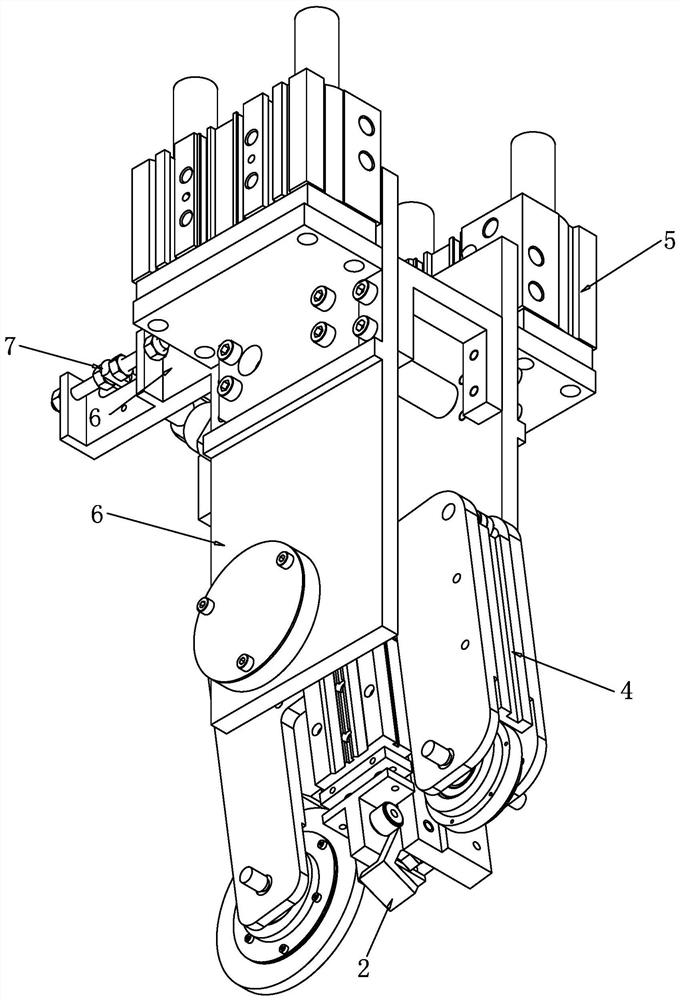

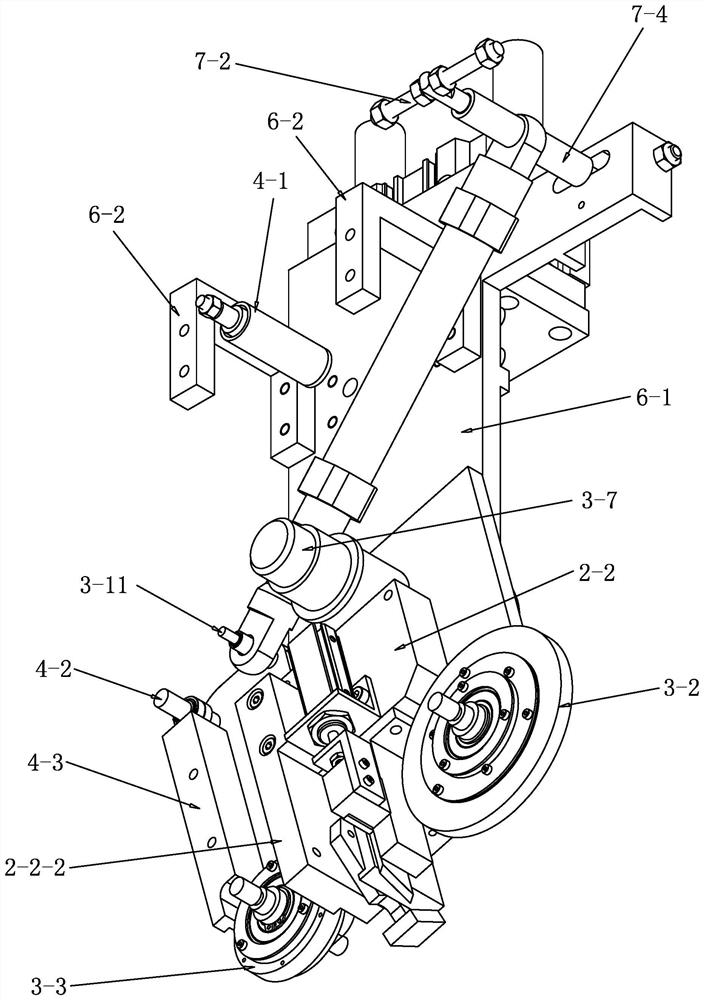

[0024] see Figure 1-Figure 5 As shown, an automatic placement head for a composite material grid member in this embodiment includes a shearing mechanism 1, a clamping mechanism 2, a re-feeding mechanism 3 and a tow guiding assembly 4; it also includes a pressing cylinder 5, a connecting Frame 6 and balance adjustment mechanism 7, described heavy delivery mechanism 3 comprises rotary cylinder 3-1, working pressure roller 3-2, auxiliary pressure roller 3-3 and support frame 3-4; The piston rod end of rotary cylinder 3-1 The part is connected with the support frame 3-4 in rotation, the support frame 3-4 is connected with the connection frame 5 in rotation, the connection frame 6 is connected with the piston rod of the compression cylinder 5, and the cylinder body of the compression cylinder 5 is connected with the existing equipment. The roller 3-2 and the auxiliary pressure roller 3-3 are arranged at intervals and can be rotatably arranged on the support frame 3-4, and the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com