Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Rubidium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

About Rubidium Sulfate. Rubidium Sulfate is a moderately water and acid soluble Rubidium source for uses compatible with sulfates. Sulfate compounds are salts or esters of sulfuric acid formed by replacing one or both of the hydrogens with a metal.

Method for preparing aluminum cesium sulfate and aluminum rubidium sulfate by using tantalum-niobium tailings lepidolite

InactiveCN102173445AImprove utilization efficiencyReduce the impactCell electrodesAluminium sulfatesRubidium sulfateNiobium

The invention provides a method for preparing aluminum cesium sulfate and aluminum rubidium sulfate by using tantalum-niobium tailings lepidolite, which is characterized by comprising the steps of: smashing lepidolite powder into about 100 to 200 meshes; putting the lepidolite powder and a sulfuric acid solution with a concentration of 30 to 70 percent according to a solid-liquid mass ratio of 1:(2-8) into a reaction device; reacting for 3 to 10 hours at 60 to 200 DEG C to remove fluorine and obtain a sulfuric acid solution containing Li<+>, separating and removing a fluorine containing solution; filtering and separating the sulfuric acid solution containing Li<+>, washing filter residue with water fully to remove the filter residue and obtain filtrate which is mother solution 1; and changing the temperature of the mother solution 1 to 10 to 100 DEG C under stirring in order to separate solid aluminum cesium sulfate and solid aluminum rubidium sulfate.

Owner:宜春银锂新能源有限责任公司

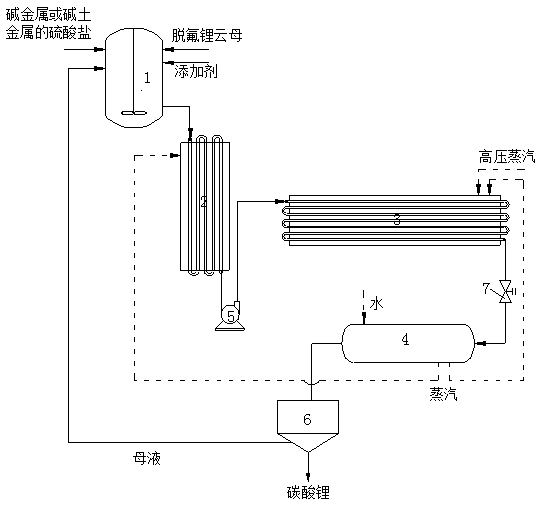

Method for dissolving out to extract lithium from defluorinated lepidolite in pipeline

InactiveCN107739039AFast flowTake advantage ofRubidium/caesium/francium compoundsAlkali metal sulfites/sulfatesAlkaline earth metalSlurry

The invention relates to a method for dissolving out to extract lithium from defluorinated lepidolite in a pipeline. The method comprises the following steps: blending defluorinated lepidolite ore powder, sulfate of alkaline metal or alkaline earth metal, an additive and water according to the ratio to obtain slurry; after pre-heating the paste through a pre-heater, directly conveying the slurry into a pipeline reactor by utilizing a pump and carrying out high-temperature and high-pressure dissolving-out reaction; after reacting, cooling and recycling heat; carrying out solid-liquid separationon the slurry and washing; concentrating filtrate and removing impurities; adding sodium carbonate lithium-settling crystals to obtain a lithium salt product; circulating a lithium-settling mother solution until ingredients are blended to form slurry or sodium separation is carried out; then recycling potassium sulfate, rubidium sulfate and cesium sulfate. The method provided by the invention hasa simple system structure; compared with other lepidolite dissolving-out and lithium extraction technologies, the pipeline reactor is not provided with a mechanical stirring device and high pressureis easy to realize; the method has the advantages of less investment, low cost, small energy consumption and capability of comprehensively utilizing reaction dreg. The method is green and environmentally friendly, has high economic benefits and has an industrial production and application prospect.

Owner:FUZHOU UNIV

Compound boron rubidium sulfate, boron rubidium sulfate crystal and preparation method thereof

ActiveCN103205812APolycrystalline material growthFrom melt solutionsRubidium sulfateTetragonal crystal system

The invention relates to a compound boron rubidium sulfate, a boron rubidium sulfate crystal and a preparation method thereof. The chemical formula of the compound is Rb5BS4O16, the molecular weight is 822.40, the chemical formula of the compound boron rubidium sulfate crystal is Rb5BS4O16, the molecular weight is 822.40, the compound boron rubidium sulfate crystal belongs to a tetragonal system, the space group is P43212, the cell parameters are as follows: a is equal to 10.148(4) A0, c is equal to 16.689(14) A0, Z is equal to 4, V is equal to 1718.8(17) A3, the boron rubidium sulfate compound is prepared by a solid reaction process, the compound is used for growing crystal through a flux growth method to obtain the boron rubidium sulfate crystal, the prepared crystal has a large dimension of at least centimeter level, and the crystal has the advantages of wide transmission waveband, fast preparation speed, simplicity in operation, short growth period, good mechanical property and easiness for processing, and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

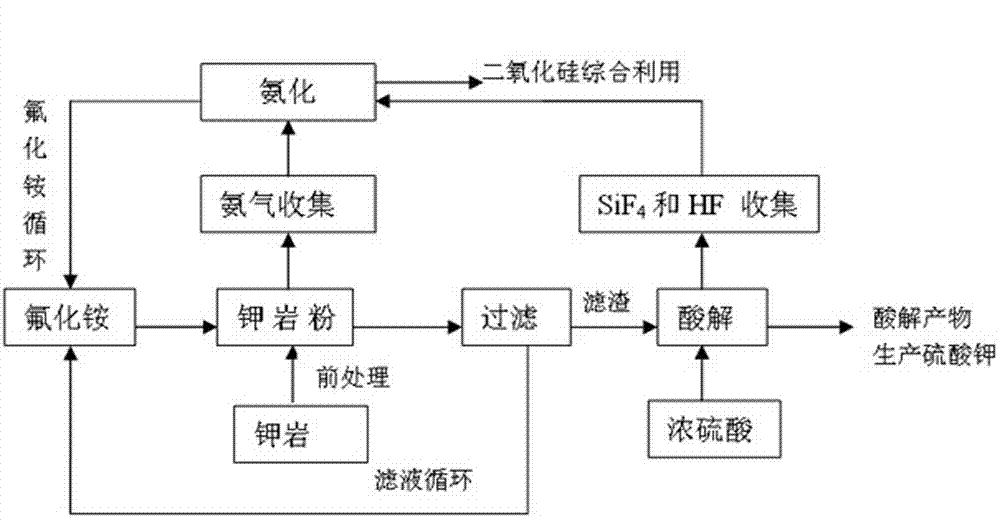

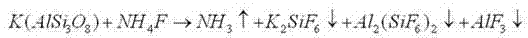

Method for producing potassium sulfate by utilizing insoluble rocks containing potassium

InactiveCN103539165AEfficient use ofReduce the temperatureSulfate/bisulfate preparationPotassium fertilisersNuclear chemistrySoluble solids

The invention relates to a method for producing potassium sulfate by utilizing insoluble rocks containing potassium. The technological process comprises the following steps: (1) pretreating the insoluble rocks containing potassium; (2) treating the insoluble rocks containing potassium by use of ammonium fluoride; (3) filtering a product treated with the ammonium fluoride; (4) performing acidolysis on the product obtained after treatment based on ammonium fluoride; (5) dissolving the product obtained after treatment based on sulfuric acid in water; (6) performing fractional precipitation by regulating the pH (Potential Of Hydrogen) so as to obtain a potassium sulfate solution; (7) regenerating and recycling an ammonium fluoride solution. Potash feldspars K(AlSi3O8) are mainly taken as the rocks containing potassium. Rubidium feldspars and cesium feldspars, which are utilized to replace the potash feldspars, are used for producing rubidium sulfate and cesium sulfate by utilizing the process and the process condition which are provided by the invention. The insoluble rocks containing potassium are converted into acid-soluble solids by use of ammonium fluoride, so that the potassium sulfate is obtained after the acid-soluble solids are acidified by the sulfuric acid; meanwhile, other elements in the rocks are effectively utilized. The ammonium fluoride is recycled in the whole technological process. The technological process is low in temperature, easy to control and high in reaction yield.

Owner:GUIZHOU YUANSHENG POTASSIUM TECH

Method for recovering rubidium, caesium, aluminum and potassium from mixed alum by-produced during extraction of lithium from lithionite

ActiveCN108996532APrevent dehydrationReduce manufacturing costPotassium sulfate preparationRubidium/caesium/francium compoundsRubidium sulfateCesium sulfate

The invention discloses a method for recovering rubidium, cesium, aluminum and potassium from mixed alum by-produced during extraction of lithium from lithionite. According to the invention, the byproduct, i.e., the mixed alum, obtained after the extraction of lithium from lithionite is used as a raw material, and a plurality of products like rubidium sulfate and cesium sulfate are separately extracted. The method comprises the following steps: 1) a hybrid reaction; 2) preparation of aluminum sulfate crystals; and 3) refining of rubidium sulfate and cesium sulfate crystals. The operation of the method is safe and easily practicable. Compared with traditional methods normally using organic solvent extraction for production of rubidium and cesium salts, the method provided by the invention has the following advantages: the comprehensive utilization rate of lithionite is increased, the production cost of lithium salt extraction is lowered, harm to environment during lithium extraction isreduced; and equipment investment is lowered.

Owner:江西海汇龙洲锂业有限公司

Method for extracting aluminum sulfate, aluminum potassium sulfate, rubidium sulfate and cesium sulfate by aid of leaching agents of lithium mica sulfuric acid

ActiveCN107140667AAvoid disadvantages such as not easy to useRubidium/caesium/francium compoundsAluminium sulfatesBall millSolid phases

The invention provides a method for extracting aluminum sulfate, aluminum potassium sulfate, rubidium sulfate and cesium sulfate by aid of leaching agents of lithium mica sulfuric acid. The method includes the steps of mica ball mill activation, solid phase thermal reaction of sulfuric acid, thermal extraction of dilute sulphuric acid, continuous crystallization and preparation of rubidium sulfate and cesium sulfate to obtain aluminum sulfate, aluminum potassium sulfate and cesium sulfate in sequence. The aluminum sulfate, aluminum potassium sulfate and cesium sulfate can be obtained from the preparation method, and the aluminum sulfate and the aluminum potassium sulfate which are extracted can be sold directly in industrial-grade products after disacidifying, washing and drying; in addition, the preparation method is simple in steps, and shortcomings of more waste, difficulty in use of by-product and the like can be overcome.

Owner:江西南氏锂电新材料有限公司

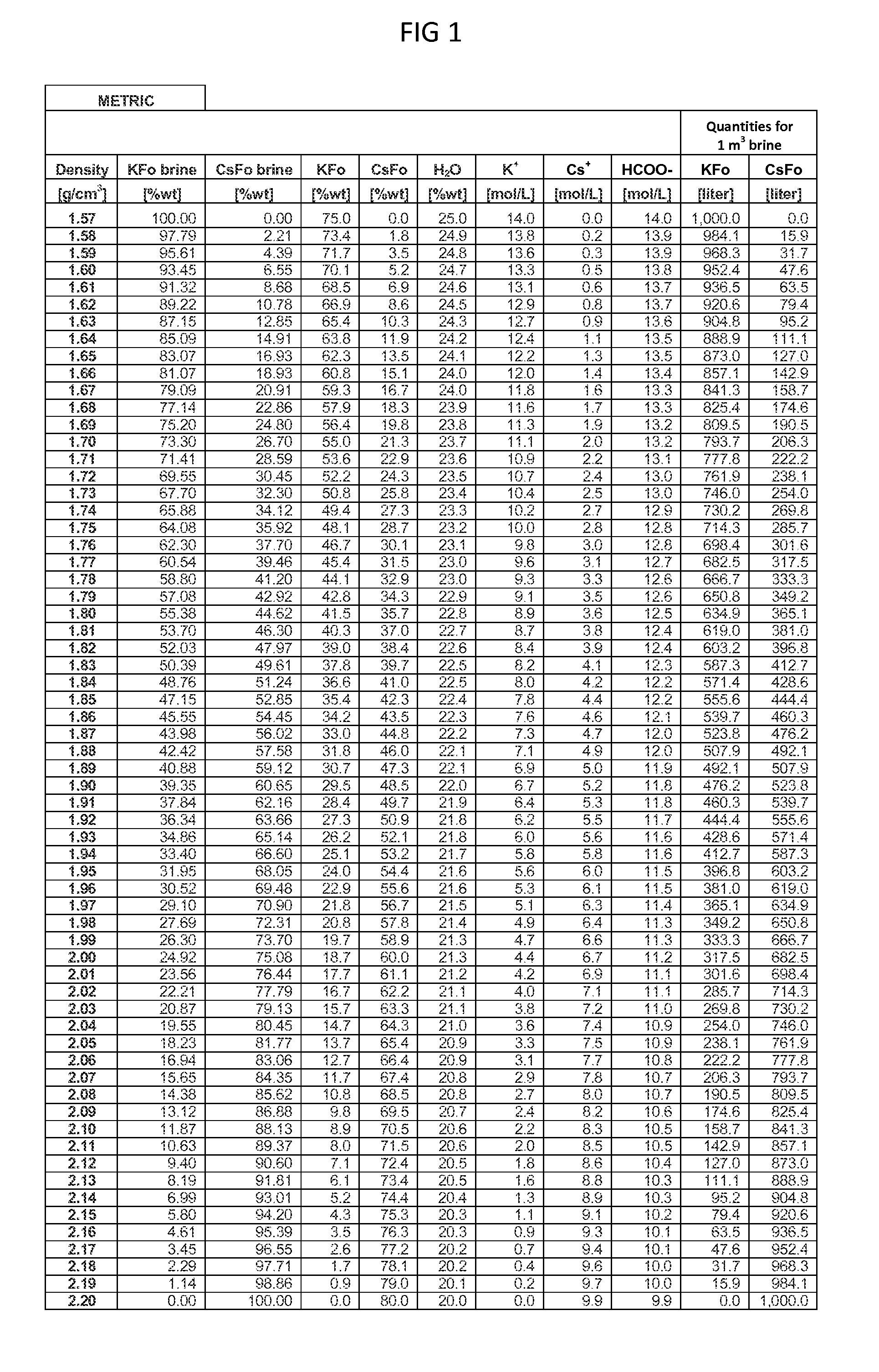

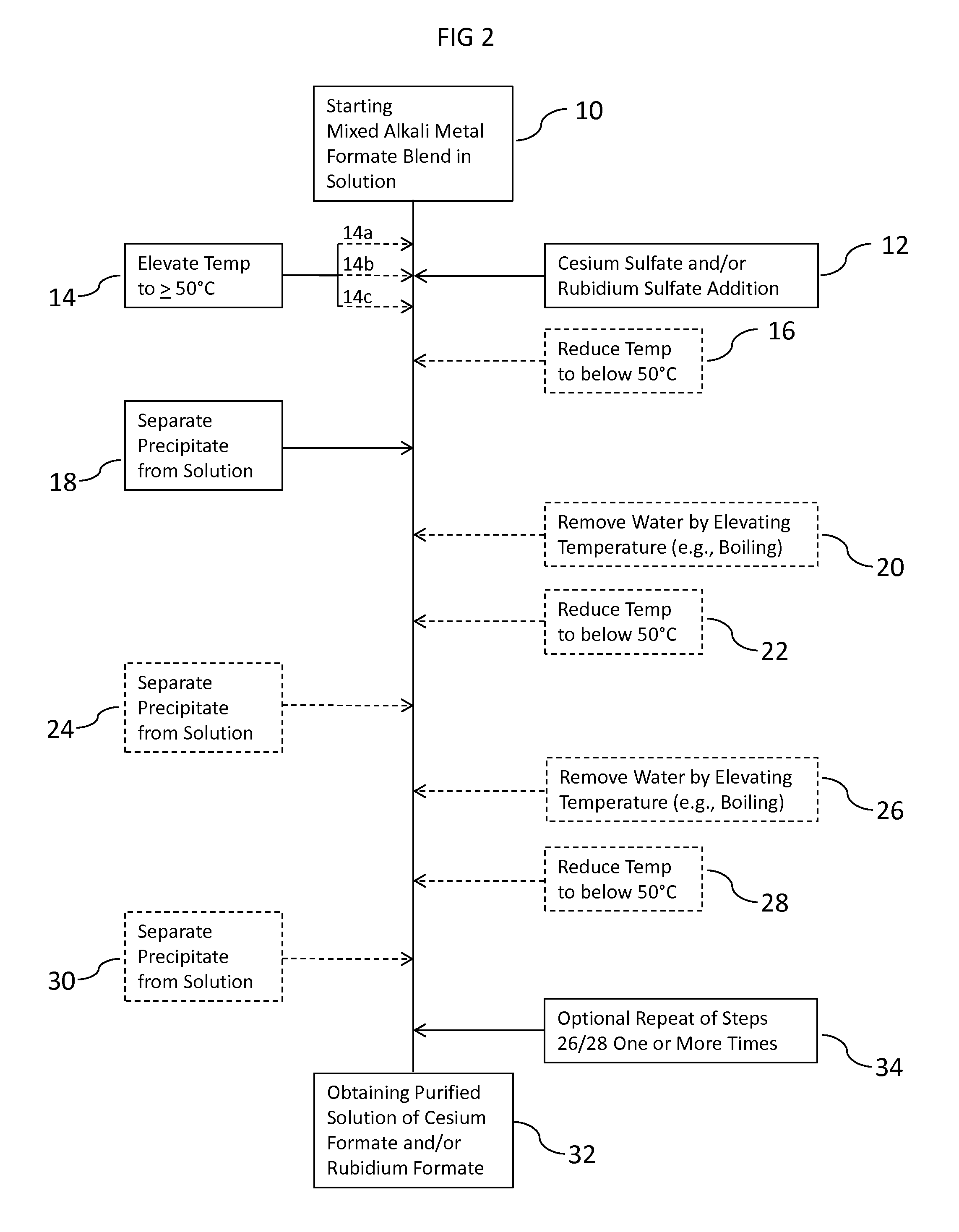

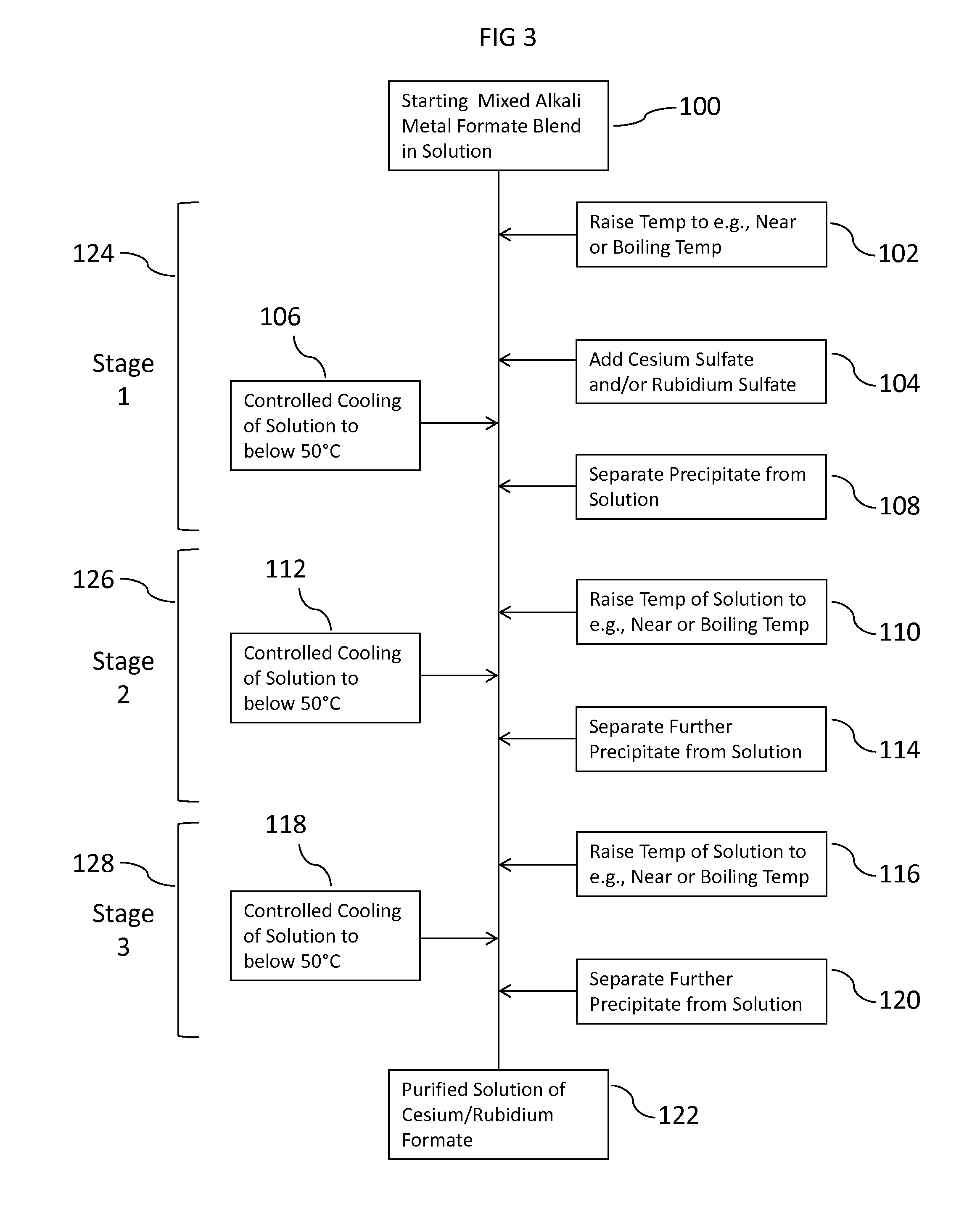

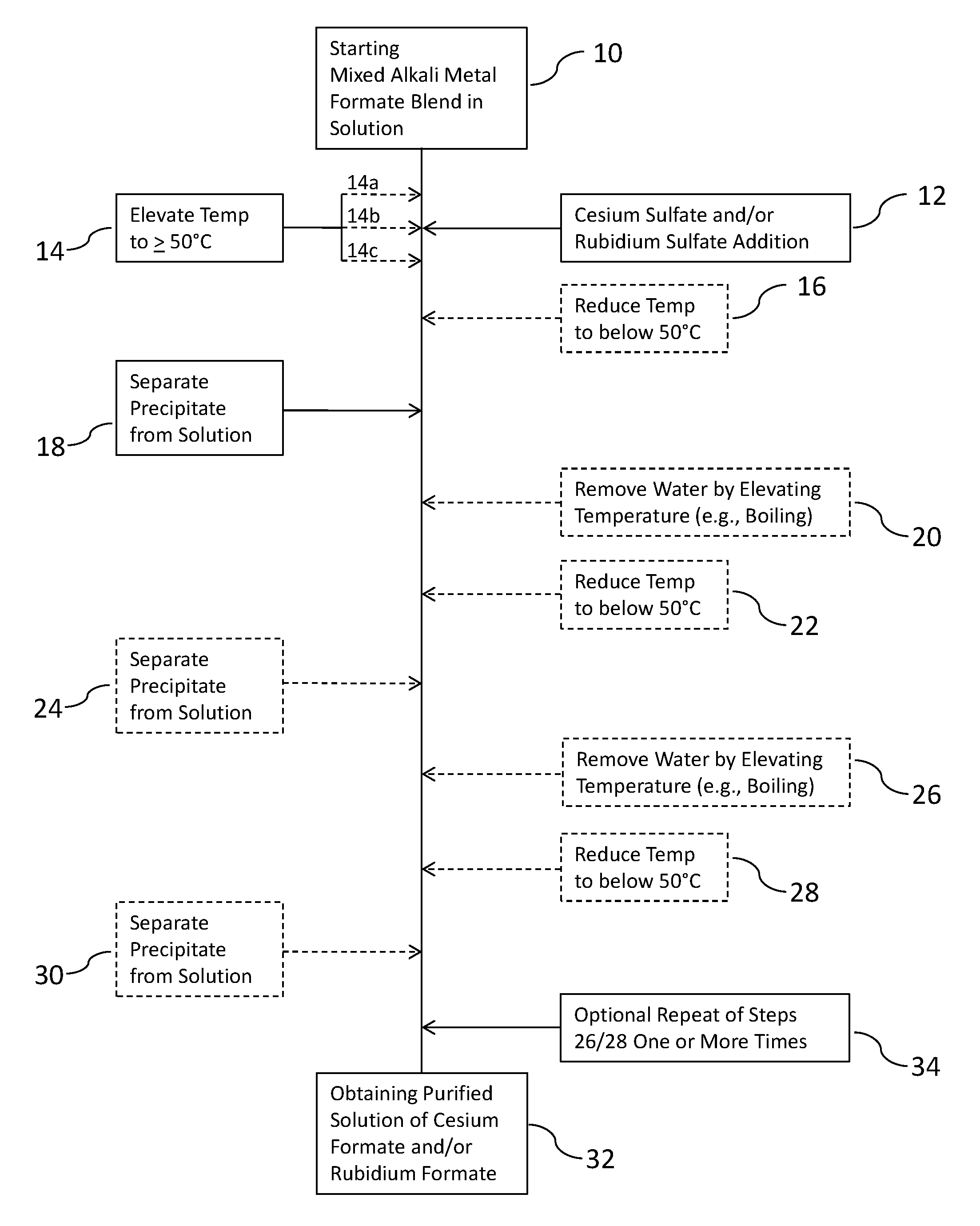

Methods To Recover Cesium Formate From A Mixed Alkali Metal Formate Blend

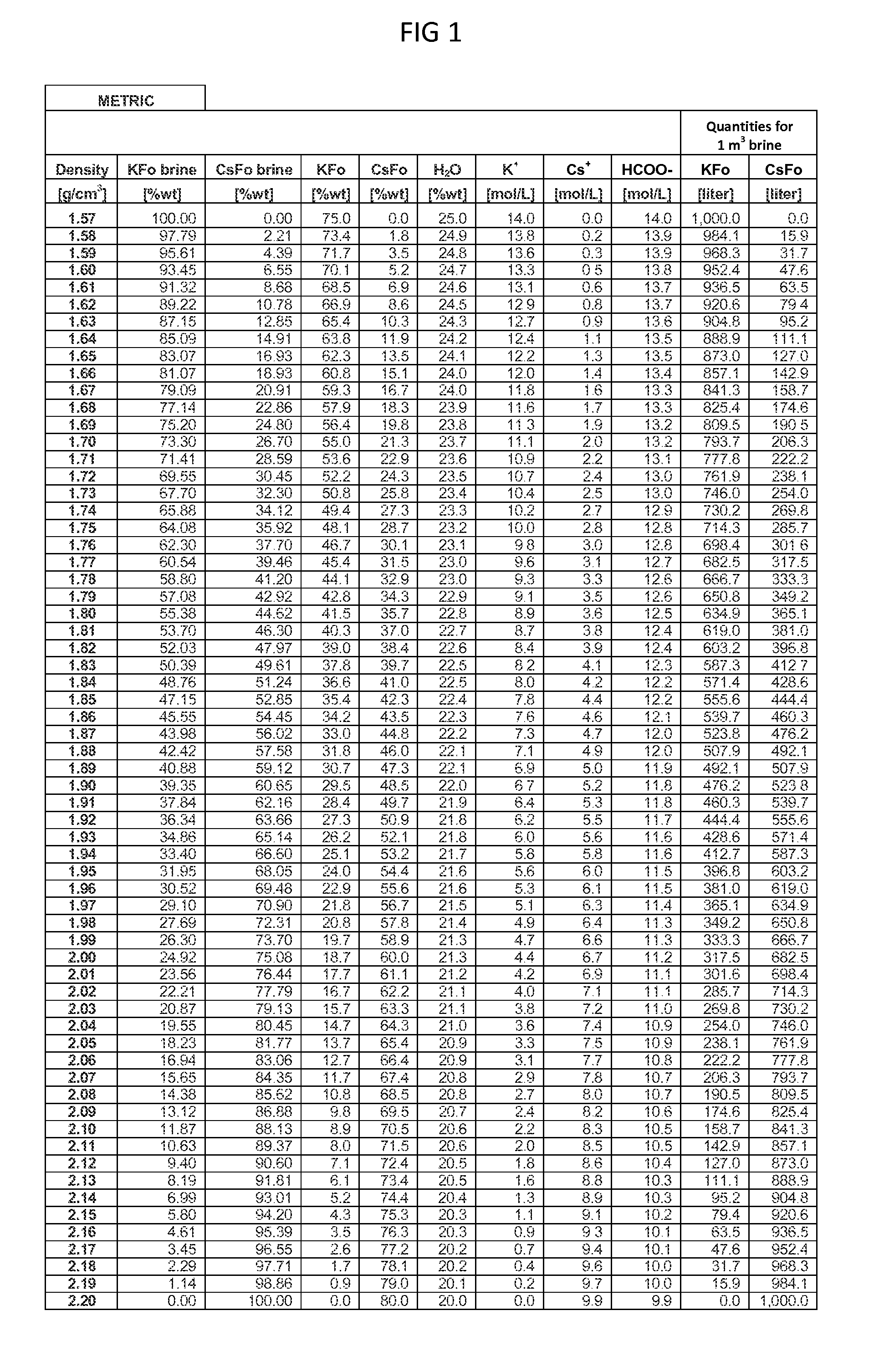

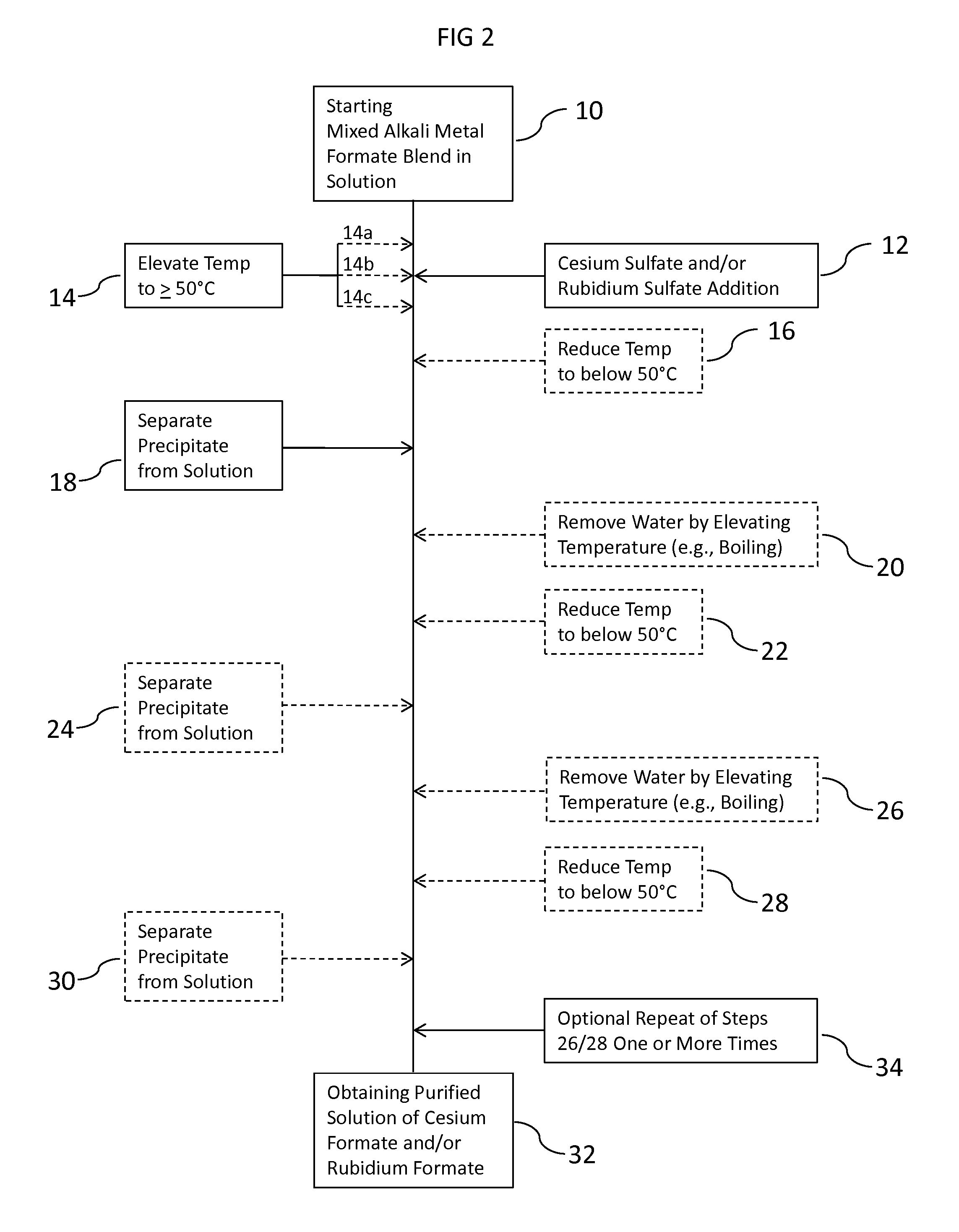

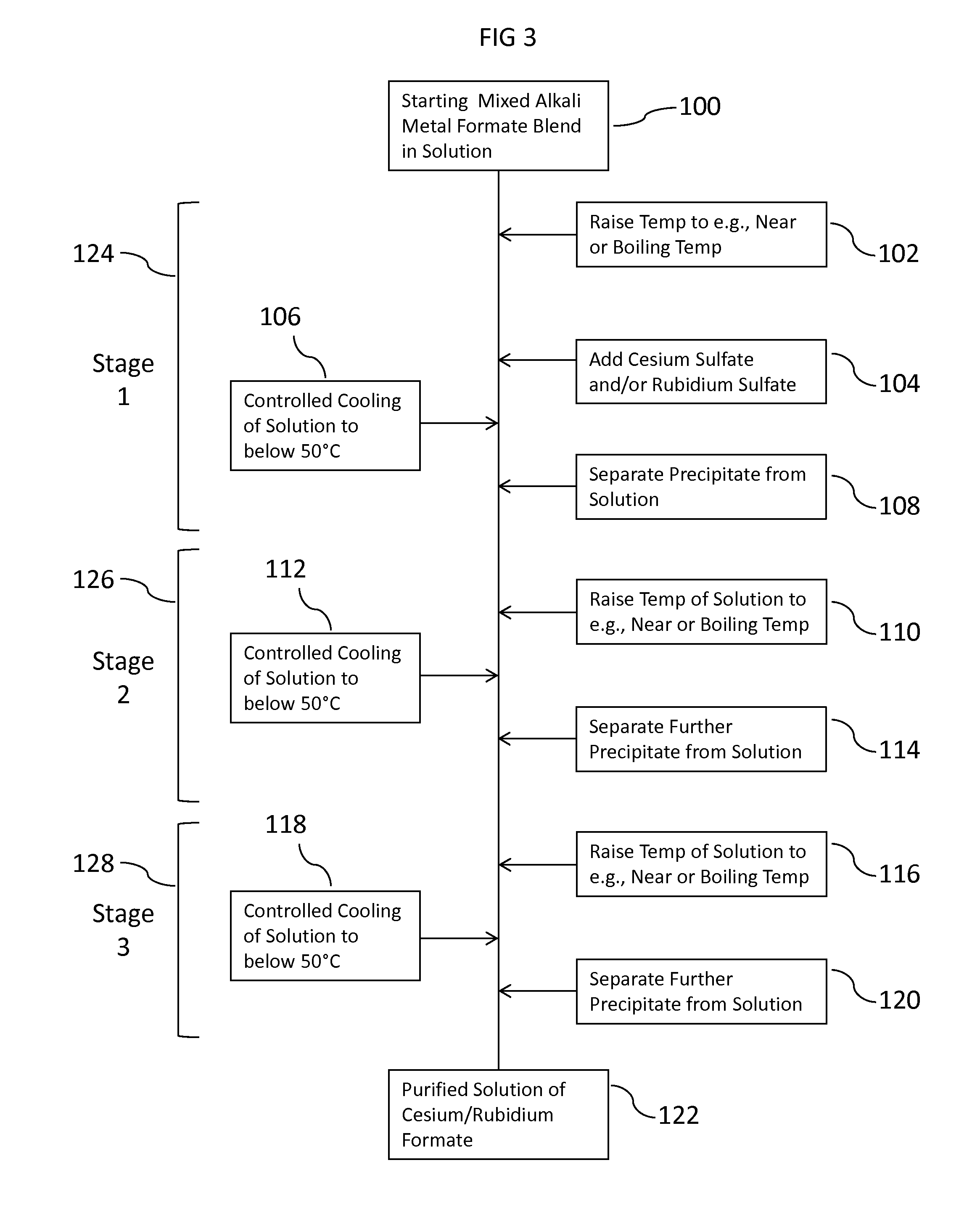

ActiveUS20150152033A1Efficient and inexpensivePreparation from carboxylic acid saltsOrganic compound preparationSodium bicarbonateFormate

Methods to recover or separate cesium formate or rubidium formate or both from a mixed alkali metal formate blend are described. One method involves adding cesium sulfate or rubidium sulfate to the mixed alkali metal formate blend in order to preferentially precipitate potassium sulfate from the mixed alkali metal formate blend. Another method involves adding cesium carbonate or cesium bicarbonate or both to preferentially precipitate potassium carbonate / bicarbonate and / or other non-cesium or non-rubidium metals from the mixed alkali metal blend. Further optional steps are also described. Still one other method involves converting cesium sulfate to cesium hydroxide.

Owner:CABOT SPECIALTY FLUIDS

Preparation method of cesium sulfate and rubidium sulfate

InactiveCN110550646AEasy to handleEasy to recycleRubidium/caesium/francium compoundsRubidium sulfateLithium

The invention relates to the technical field of mineral extraction, in particular to a preparation method of cesium sulfate and rubidium sulfate. A traditional cesium sulfate extraction method is improved, cesium is extracted from lithium-precipitation waste residue firstly by taking t-BAMBP and 260# solvent oil with the specific ratio as extraction solutions and through a multistage extraction technology, a cesium sulfate pure product is obtained, and the product purity reaches up to 99.9% or above; and then rubidium and potassium can be separated from raffinate of cesium extraction by adopting the t-BAMBP and n-hexane with the specific ratio as extraction solutions, the high-purity rubidium sulfate is obtained, and the purity can reach up to 99.9% or above. The preparation process involves a few types of organic solvents, and waste liquid is treated, recycled and reused advantageously.

Owner:YICHUN KEYUAN CHEM CO LTD

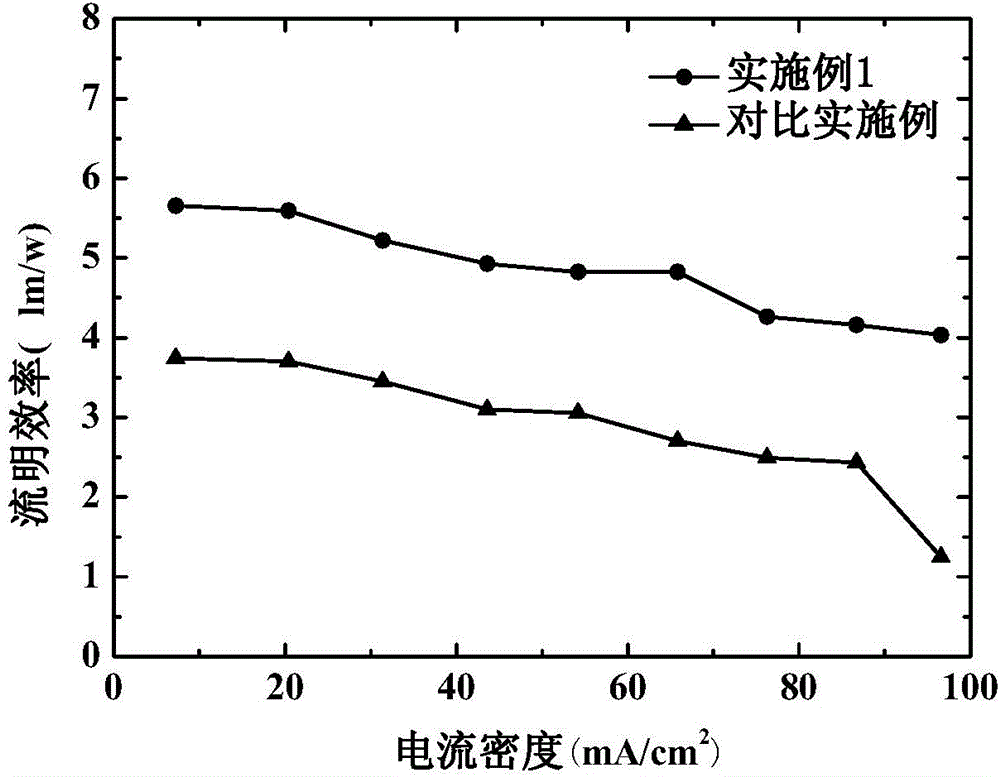

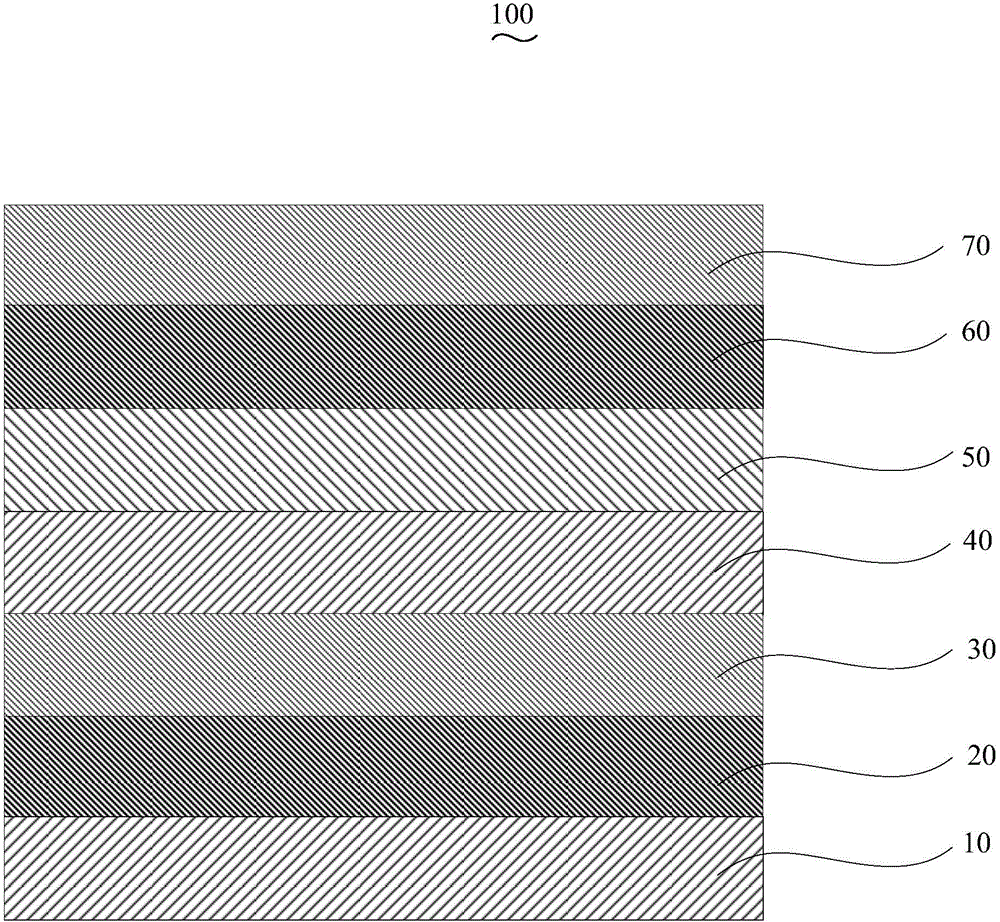

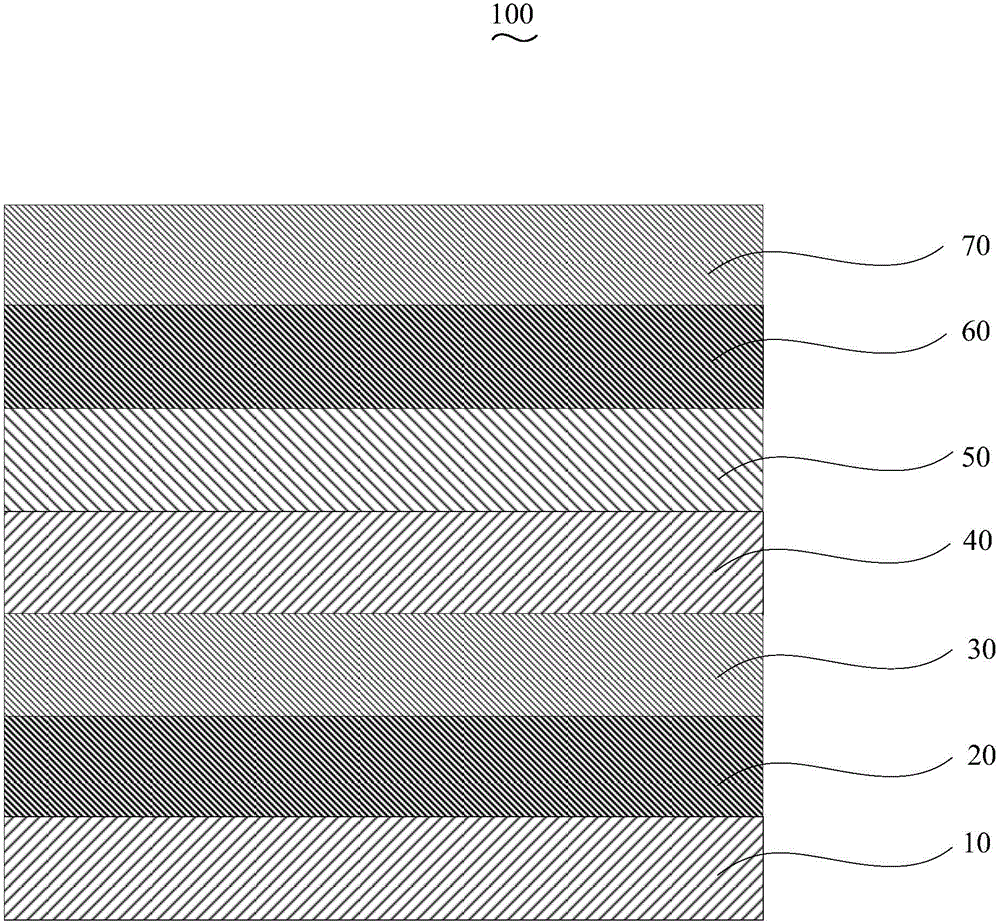

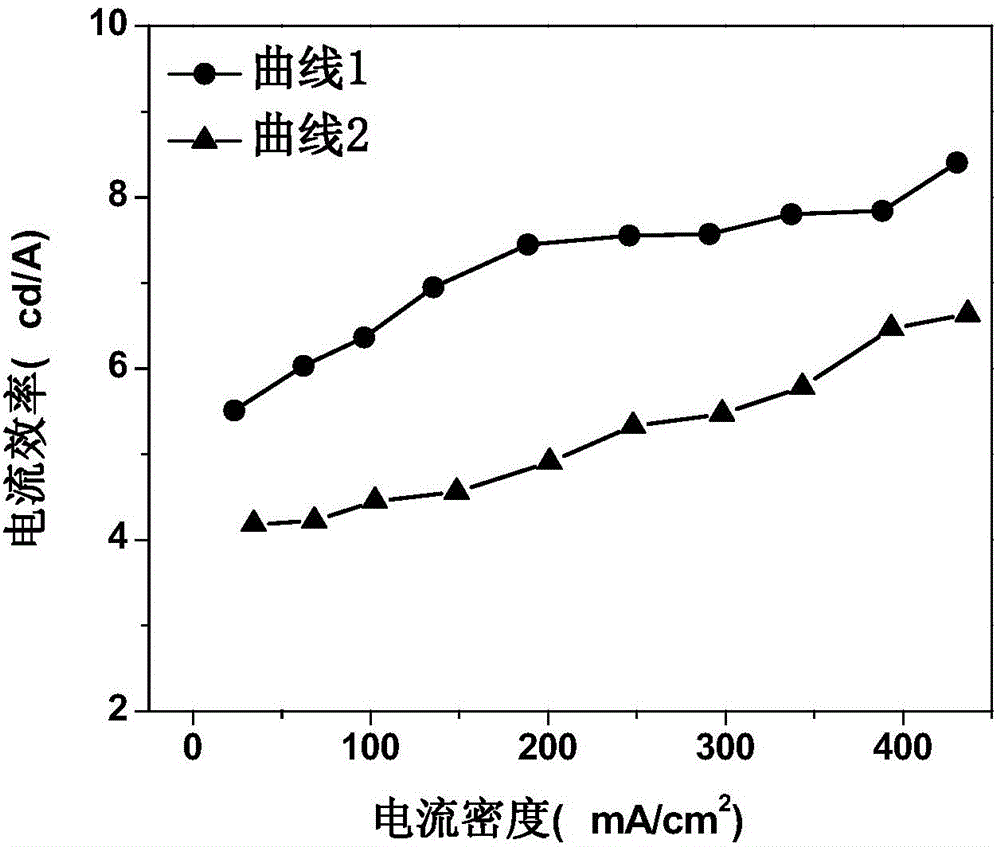

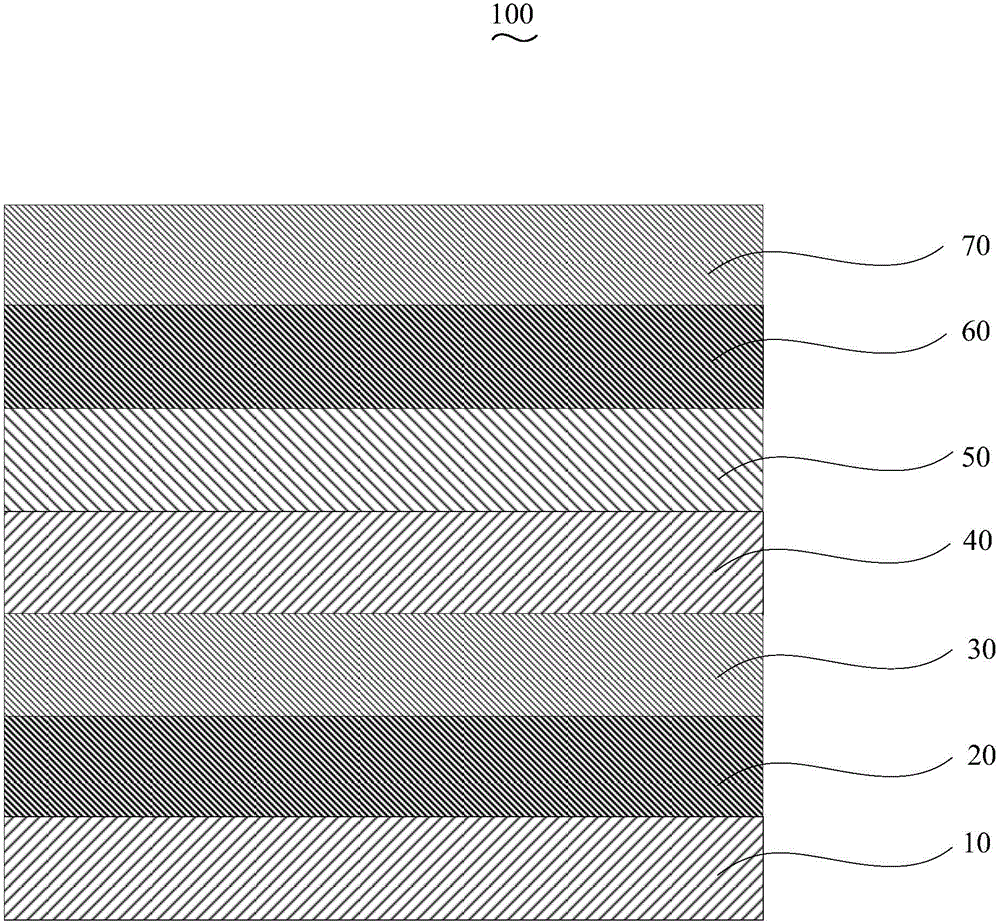

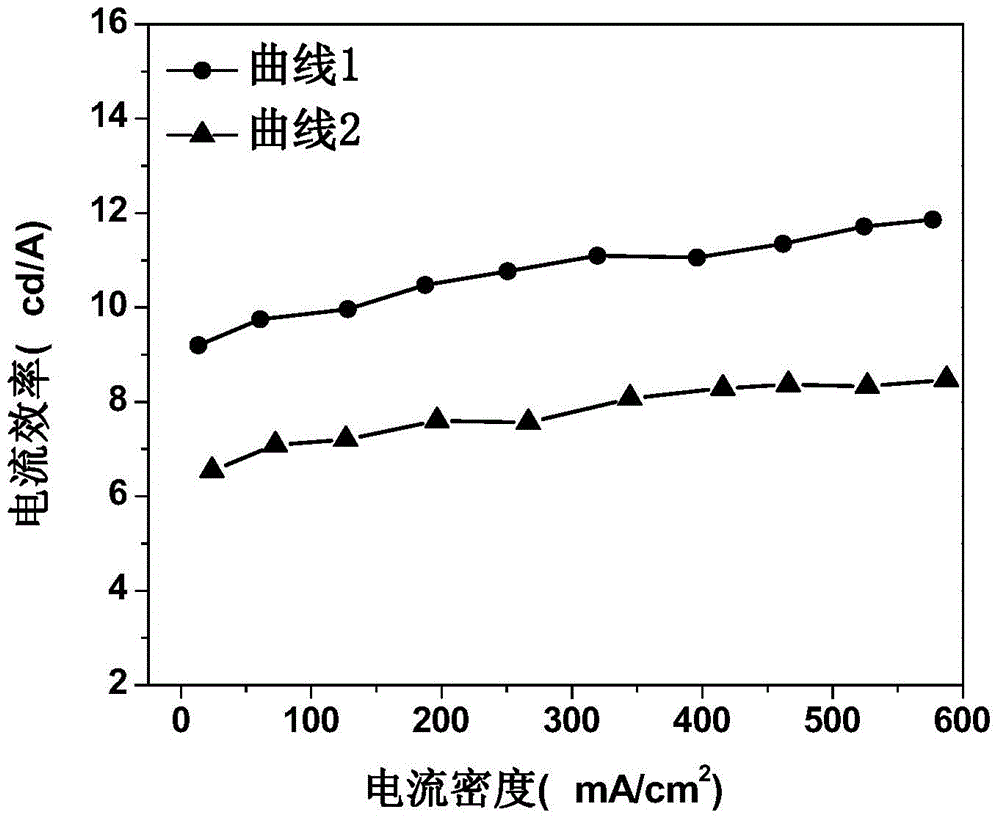

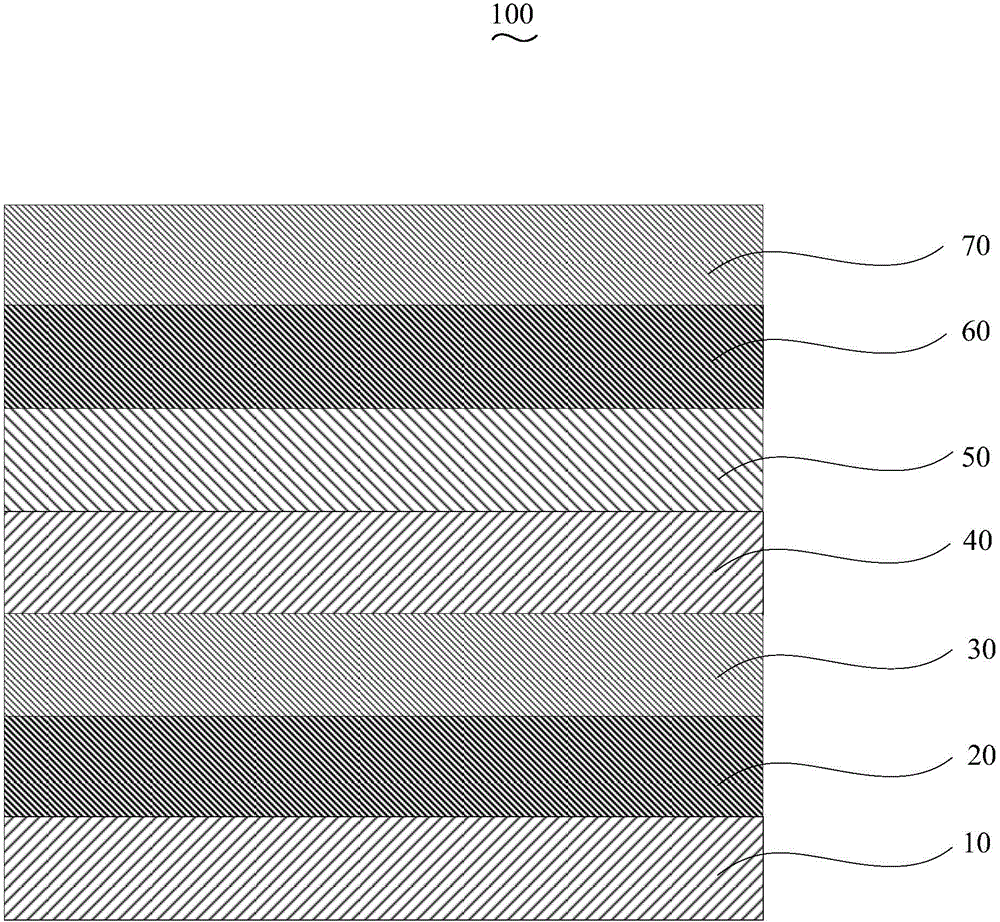

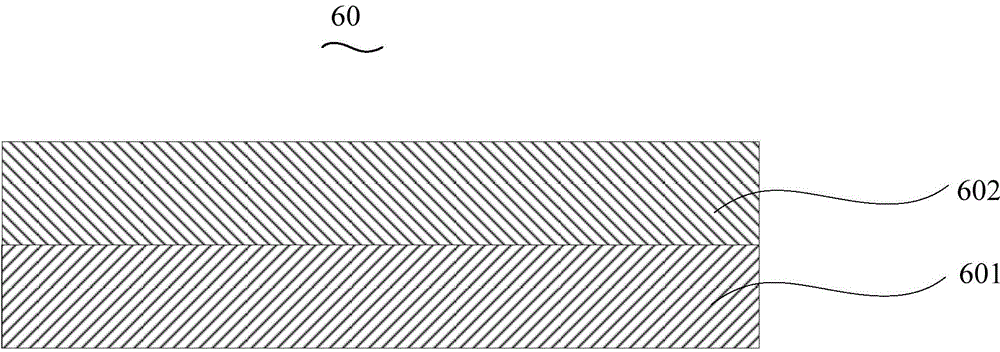

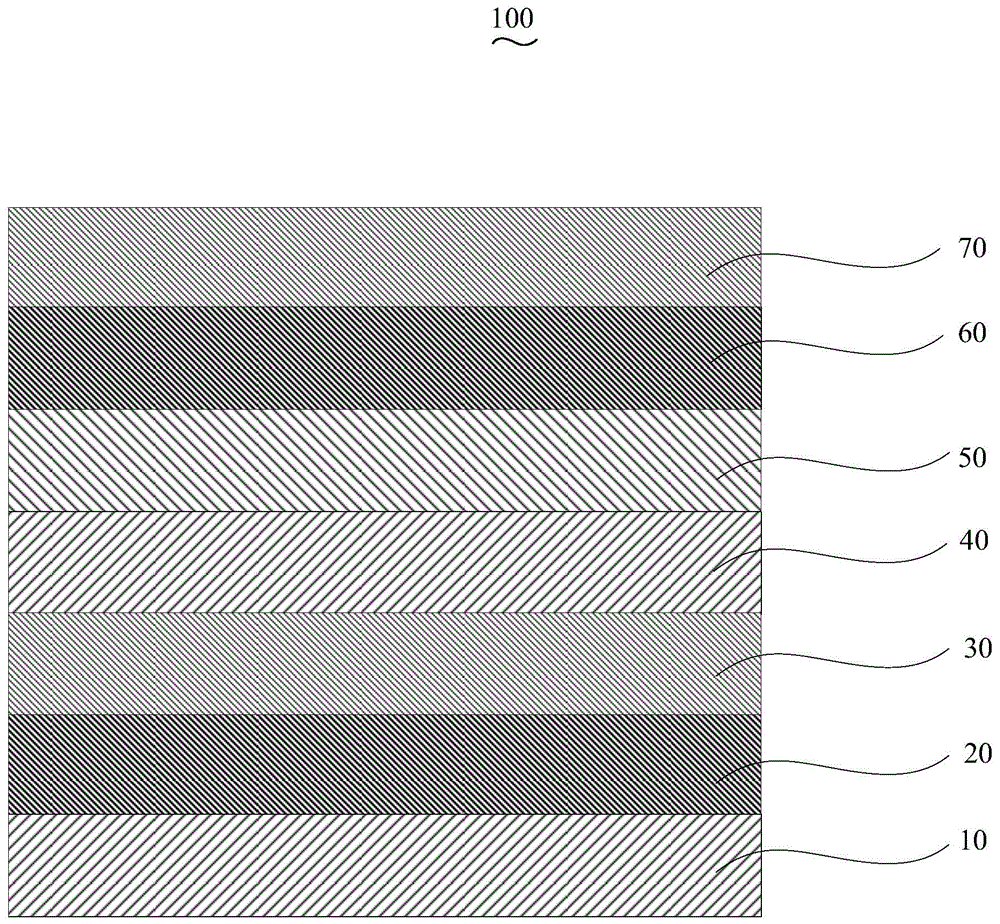

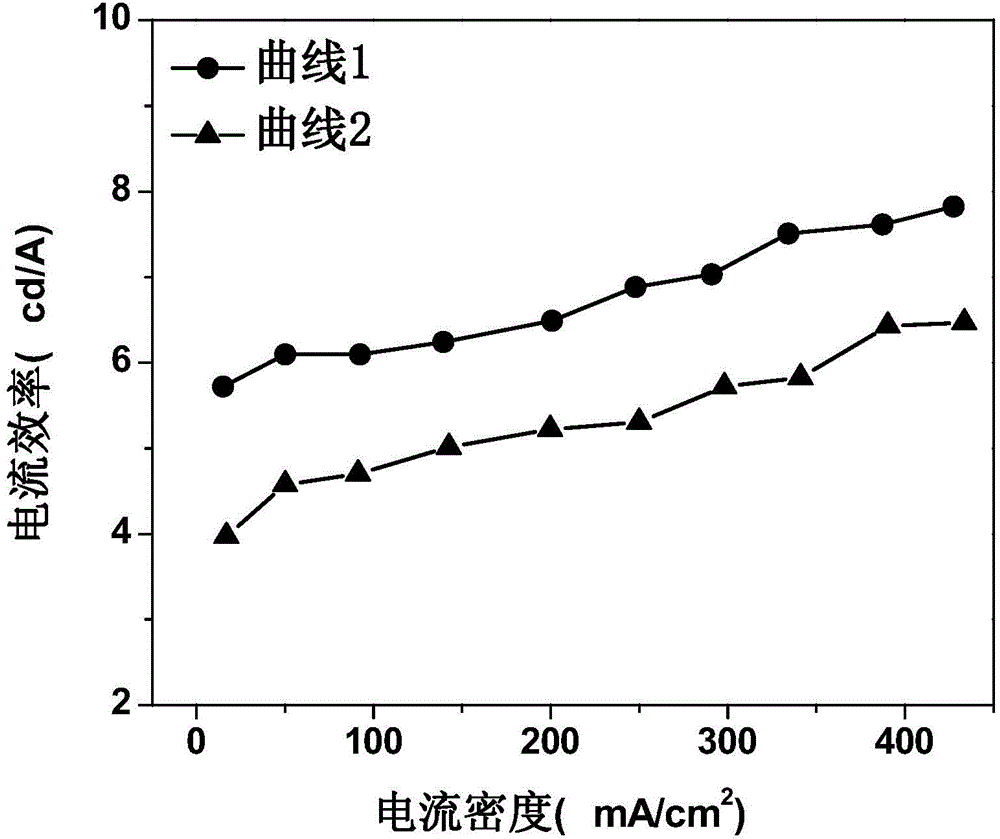

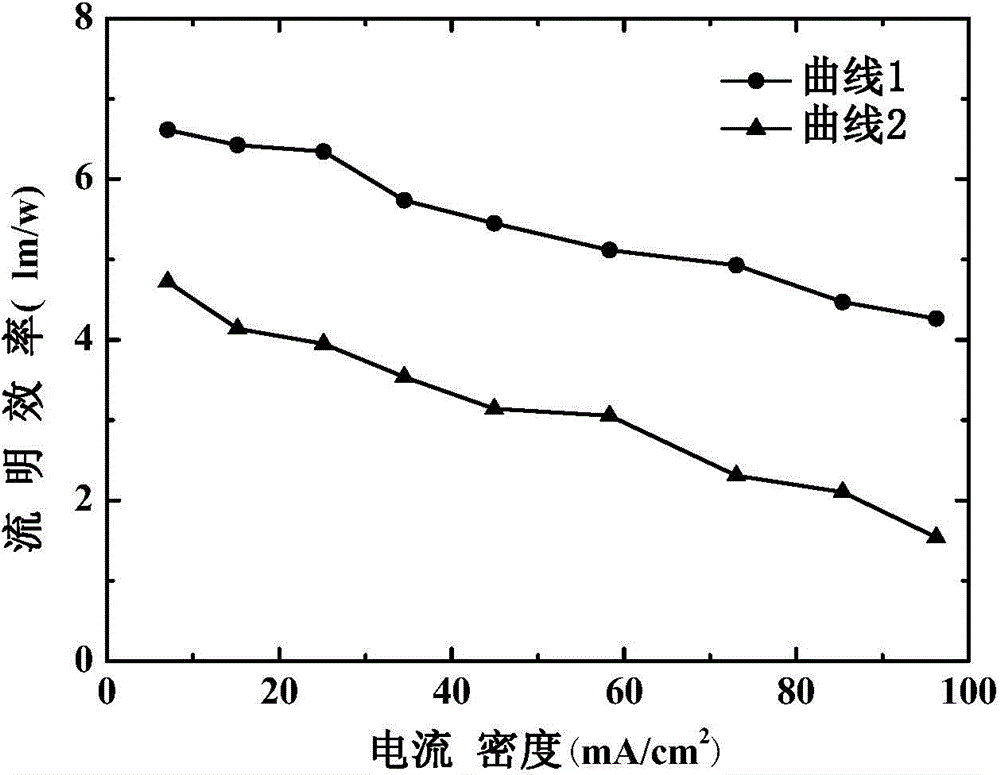

Organic electroluminescent device and manufacturing method thereof

InactiveCN104659227AEasy injectionIncrease transfer rateSolid-state devicesSemiconductor/solid-state device manufacturingRubidium sulfateRubidium carbonate

The invention discloses an organic electroluminescent device and a manufacturing method thereof. The organic electroluminescent device comprises a glass substrate, a conductive anode, a hole injection layer, a hole transmission layer, a luminous layer, an electron transmission layer, an electron injection layer and a cathode which are stacked in sequence, wherein the electron injection layer comprises a rhenium compound doped layer, a rubidium compound layer and a metal layer which are stacked in sequence; the rhenium compound doped layer is arranged on the surface of the electron transmission layer and made from a mixed material formed by mixing a rhenium compound with a bipolar organic material at a mass ratio of (1:1) to (4:1); the rubidium compound layer is made from rubidium carbonate, rubidium chloride, rubidium nitrate or rubidium sulfate; the metal layer is made from low-work-function metal with the work function ranging from -2.0 eV to -3.5 eV. The electron injection layer can effectively improve the luminous efficiency of the device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

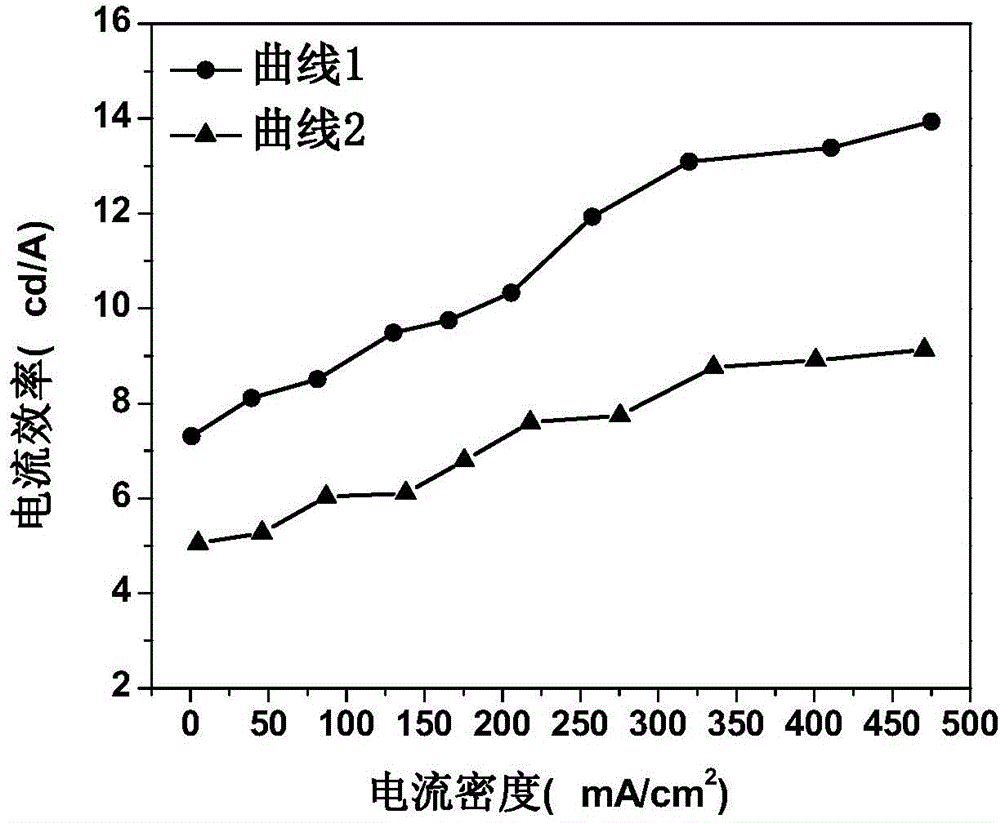

Organic electroluminescence device and preparation method thereof

InactiveCN104659277ALower injection barrierImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundGlass transition

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a luminescent layer, an electron transport layer, an electron injection layer and a cathode which are stacked in sequence, wherein the electron injection layer consists of a ternary doped layer and a cesium salt doped layer; the ternary doped layer comprises a rubidium compound material, a zinc oxide material and an electron transport material I; the rubidium compound material is at least one of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the glass transition temperature of the electron transport material I is 50-100 DEG C; the cesium salt doped layer comprises a cesium salt material and an electron transport material II doped in the cesium salt material; the glass transition temperature of the electron transport material II is 50-100 DEG C; the cesium salt material is at least one of cesium fluoride, cesium carbonate, cesium azide and cesium chloride. The organic electroluminescence device is relatively high in luminescence efficiency. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

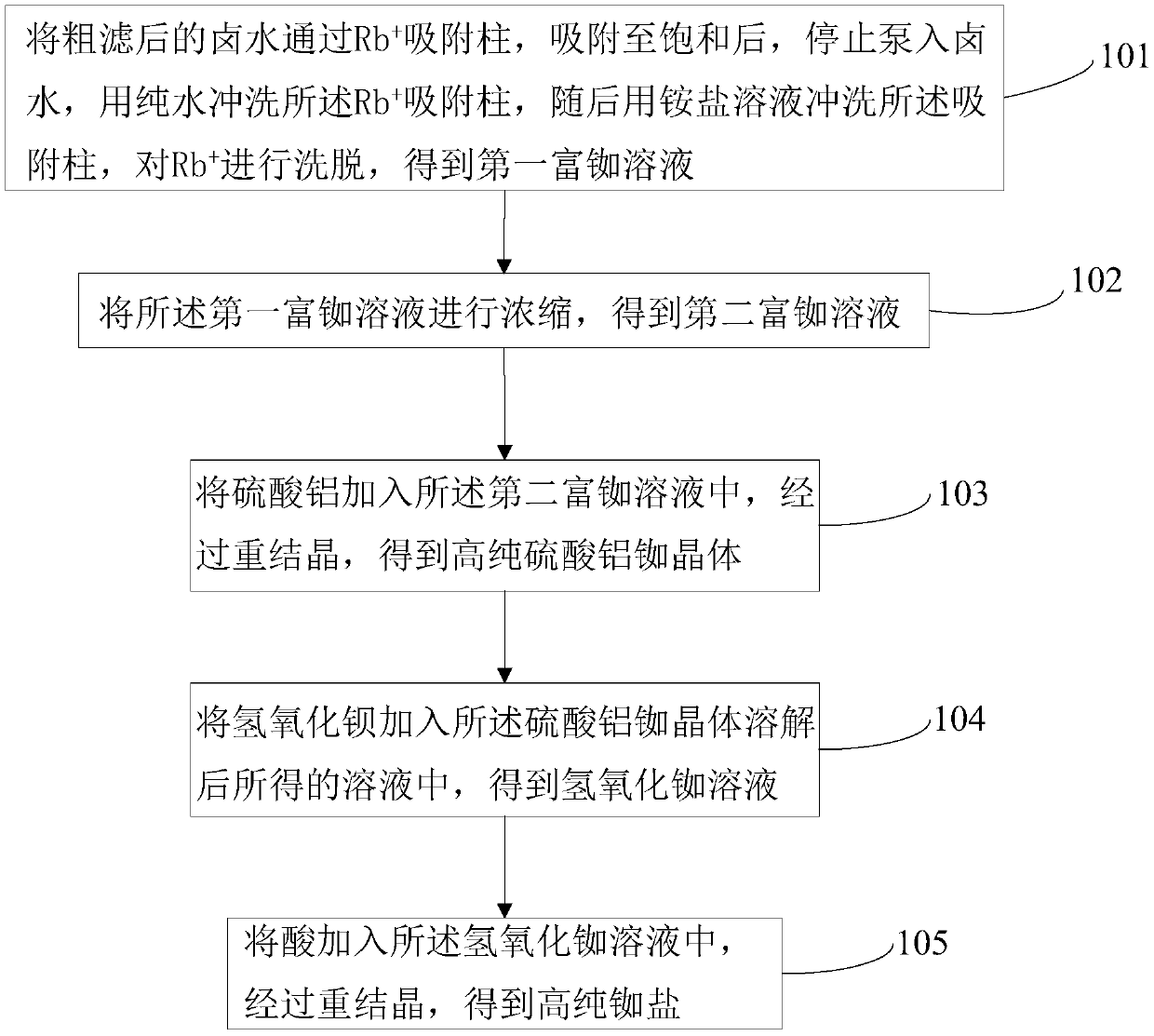

Method for extractingRb+ from low concentration brine and preparing high purity rubidium salt

ActiveCN109824068ASimple preparation processNo pollution in the processOther chemical processesRubidium/caesium/francium compoundsRubidium sulfateAluminium sulfate

The invention belongs to the technical field of hydrometallurgy, in particular to a method for extracting Rb+ from low concentration brine and preparing high purity rubidium salt, which comprises thefollowing steps: saturating crude filtered brine through Rb+ adsorption column; stopping pumping brine and rinsing the Rb+ adsorption column with pure water, then rinsing the adsorption column with anammonium salt solution, eluting the Rb+ to obtain a first rich rubidium solution; concentrating the first rich rubidium solution to obtain a second rich rubidium solution; adding aluminum sulfate tothe second rich rubidium solution and carrying out recrystallization to obtain a highly pure rubidium aluminum sulfate crystal; adding barium hydroxide to the solution obtained after dissolution of the aluminum rubidium sulfate crystal to obtain a rubidium hydroxide solution; and adding acid to the rubidium hydroxide solution and carrying out the recrystallization to prepare the high purity rubidium salt. The method for extracting the Rb+ from the low concentration brine and preparing the high purity rubidium salthas the advantages of being high in efficiency, environmental in process and capable of preparing a variety of rubidium salts with a purity up to 99.99%.

Owner:陕西省膜分离技术研究院有限公司

Organic electroluminescence device and preparation method thereof

InactiveCN104659251AIncrease transfer rateLower injection barrierSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundIodide

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer is made of one or more rubidium compound materials, one or more copper oxide materials and one or more of metal materials; the rubidium compound material(s) is / are one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the copper oxide material(s) is / are one or more of cuprous iodide, cuprous oxide, copper phthalocyanine and cupric oxide; the work function of the metal materials is -4.0 eV to -5.5 eV. The light efficiency of the organic electroluminescence device is relatively high. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic electroluminescence device and preparation method thereof

InactiveCN104659219ALower injection barrierImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSodium bicarbonateRubidium compound

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a luminescent layer, an electron transport layer, an electron injection layer and a cathode which are stacked in sequence, wherein the electron injection layer consists of a rubidium compound doped layer and a passive material layer; the rubidium compound doped layer comprises a rubidium compound material and a sodium salt material doped in the rubidium compound material; the rubidium compound material is at least one of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the sodium salt material is at least one of sodium carbonate, sodium chloride, sodium bicarbonate and sodium fluoride; the passive material layer is made at least one of silicon dioxide, aluminum oxide, nickel oxide and copper oxide. The organic electroluminescence device is relatively high in luminescence efficiency. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

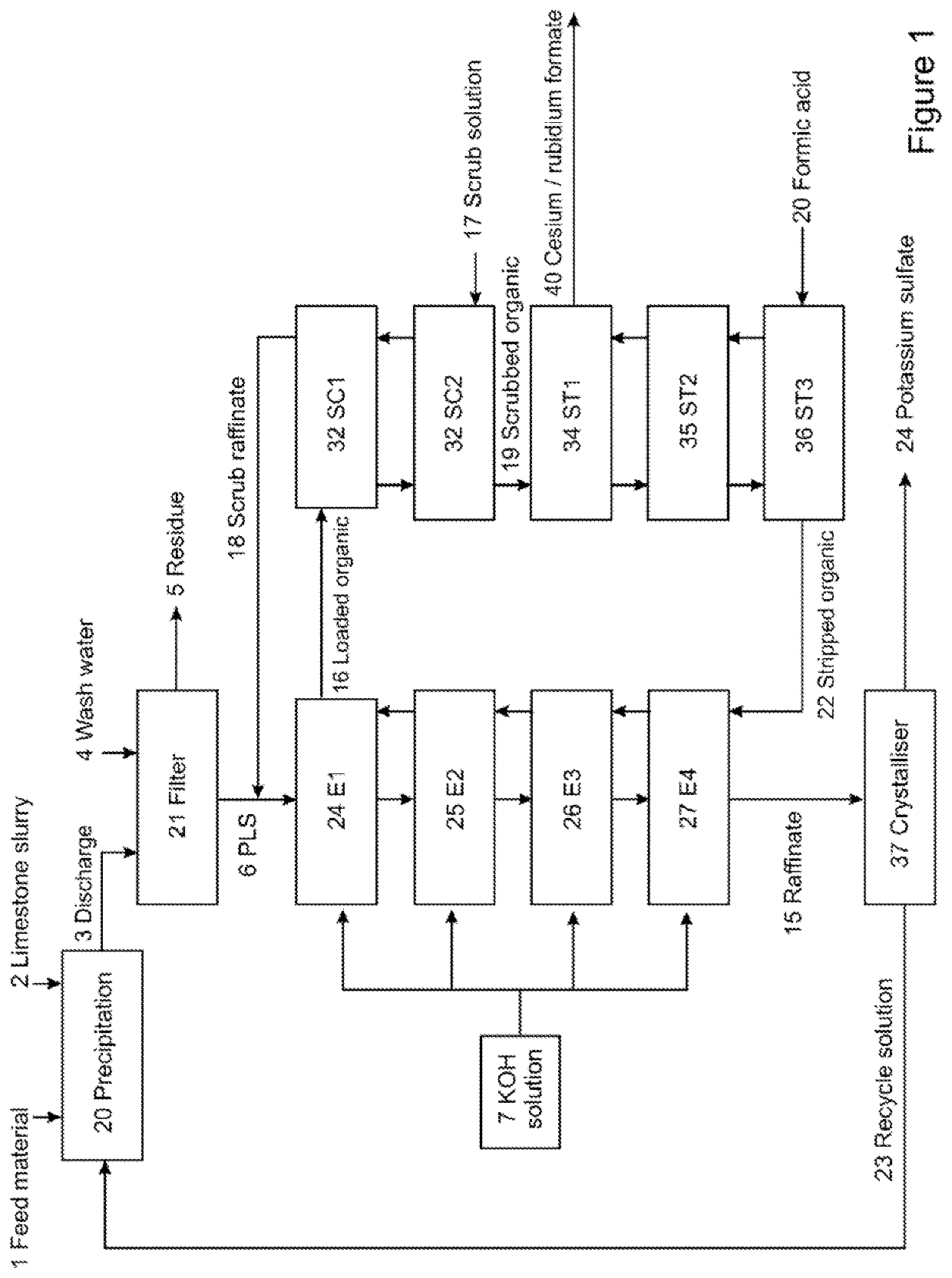

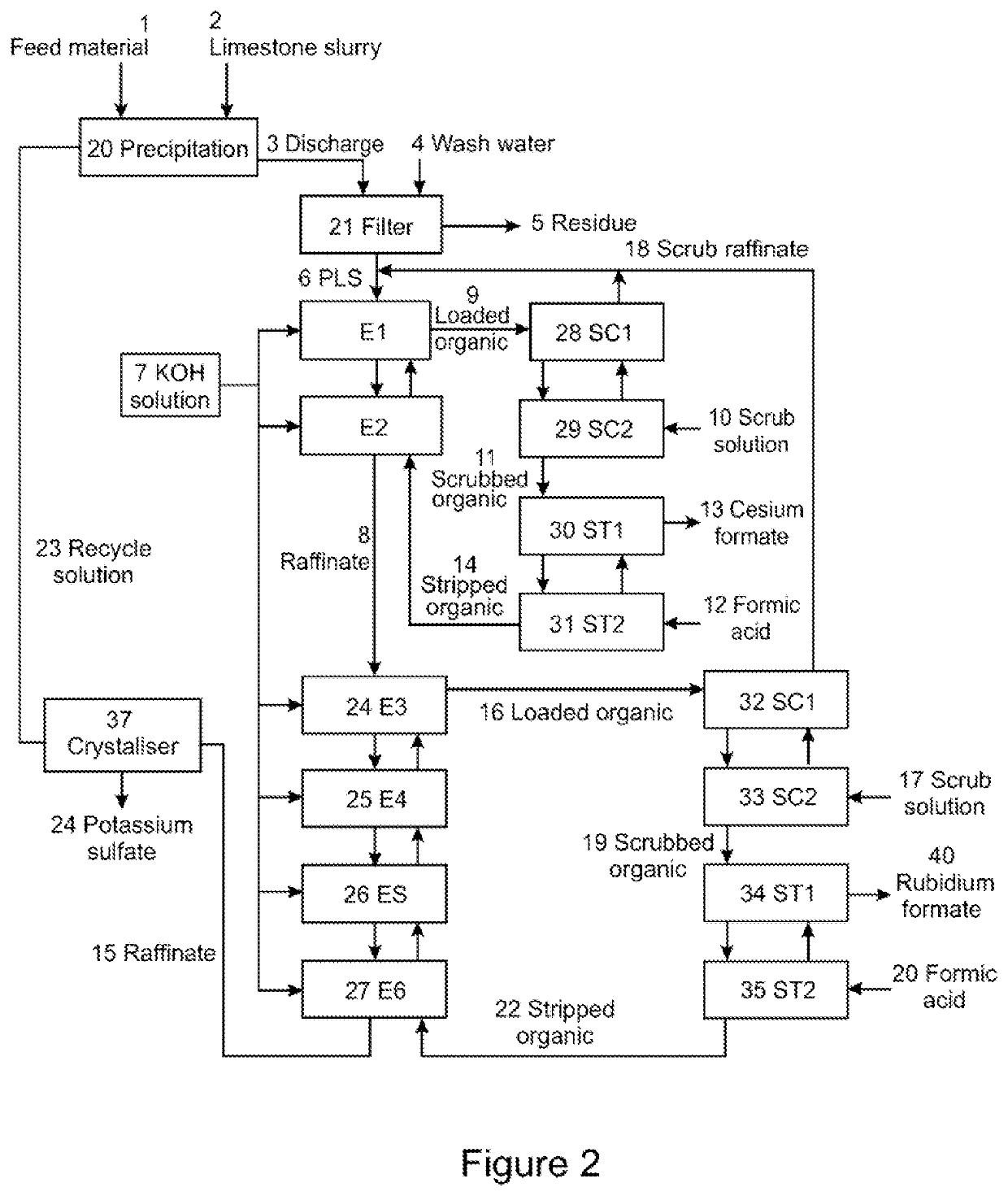

Brine and method for producing same

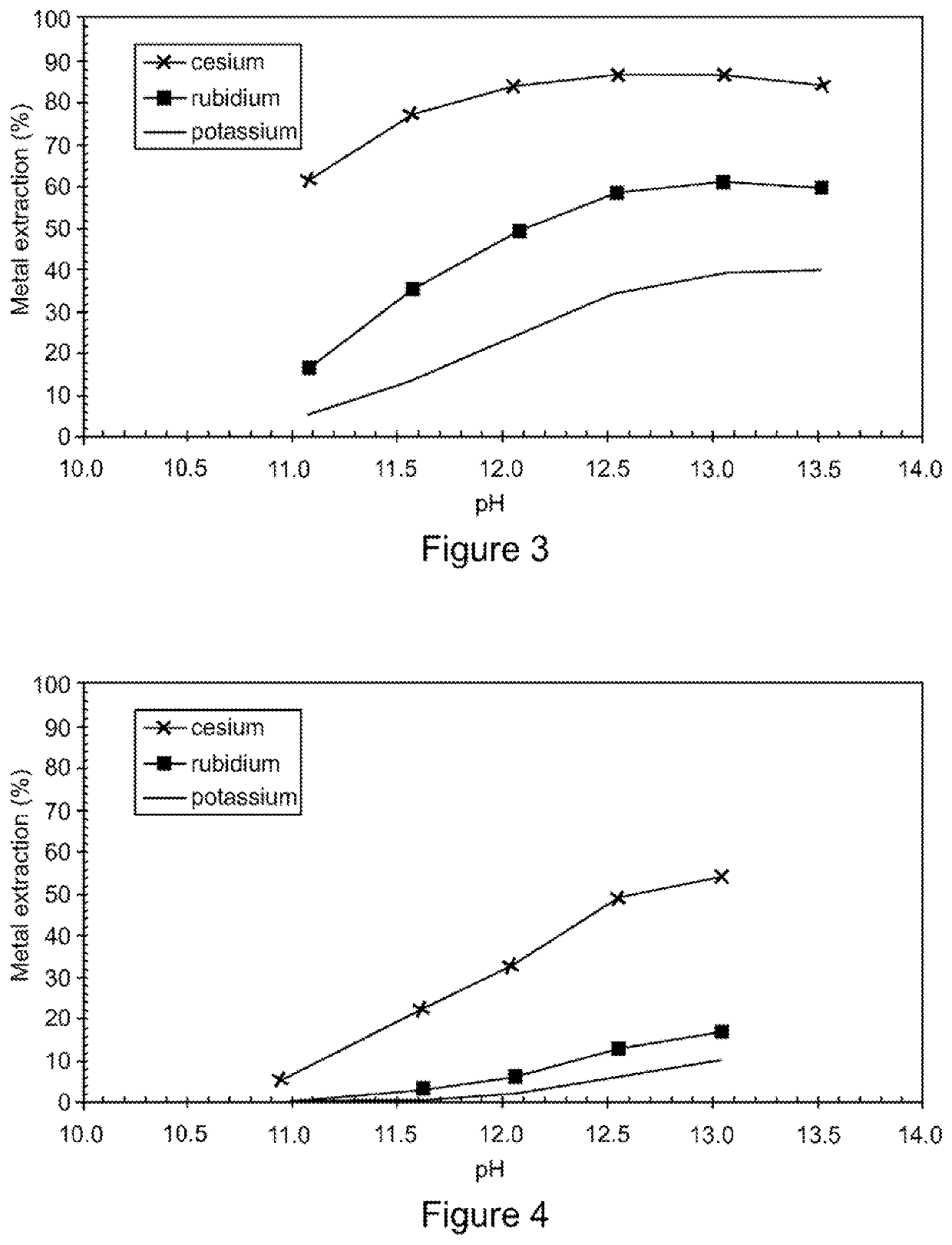

PendingUS20220056556A1Improve extraction efficiencyEfficient scrubbingCounter-current extractionLiquid solutions solvent extractionRubidium sulfateAluminium hydroxide

A method to produce a brine from mixed alum salts, the method comprising the steps of: (i) Dissolving or pulping alum salts (1) containing rubidium alum, cesium alum and / or potassium alum in water or a recycled liquor and adding a neutralising agent to precipitate (20) aluminium as aluminium hydroxide and some sulfate; (ii) Passing the product of step (i) to a solid liquid separation stage (21) to remove precipitated solids (5) from step (i); (iii) A decant or filtrate (6) from step (ii) is passed to a solvent extraction stage (24-27) whereby any contained cesium and rubidium is selectively extracted into the organic phase to form a loaded organic solution (16); (iv) Contacting the loaded organic solution (16) of step (iii) with a scrub solution (17), which is at a pH lower than the extraction pH, to effectively scrub co-loaded potassium from the organic phase; (v) Contacting the scrubbed organic (19) of step (iv) with formic acid (20) to strip cesium and rubidium from the organic, the stripped cesium and rubidium forming a cesium and / or rubidium sulfate brine (21); and (vi) Recycling the stripped organic (22) of step (v) to the extraction stage (24-27).

Owner:LI TECH PTY LTD

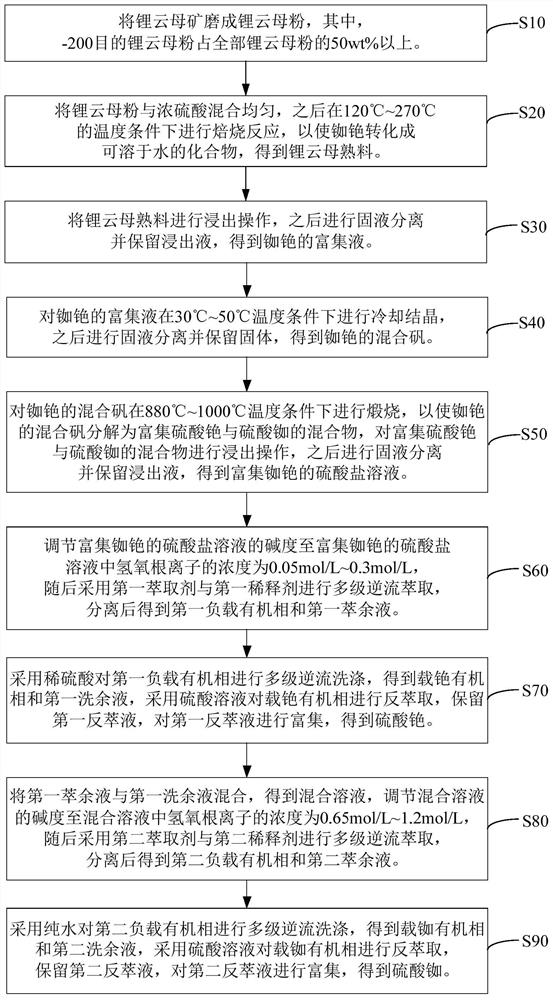

Method for extracting cesium and rubidium from lepidolite

The invention relates to a method for extracting cesium and rubidium from lepidolite. According to the method for extracting cesium and rubidium from lepidolite, separation, enrichment, purification and recovery of rubidium and cesium are effectively achieved, and the resource utilization rate is high. As verified by tests, through treatment of lepidolite ore with the Rb2O content being about 1.0%and the Cs2O content being about 0.2% by the method, sulfate solutions with the Rb content being 12 g / L and the Cs content being 2 g / L respectively can be obtained through extraction, then cesium sulfate and rubidium sulfate with the purity being 98% or above are obtained through recovery, and the total recovery rate of cesium and rubidium is 80% or above.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Organic electroluminescence device and preparation method thereof

InactiveCN104659246AImprove conductivityImprove light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingIron(III) sulfideRubidium compound

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer comprises a rubidium compound doped layer and a metal doped layer; the rubidium compound doped layer is made of a rubidium compound material and a molysite material doped in the rubidium compound material; the rubidium compound material is one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the molysite material is one or more of ferric chloride, ferric bromide and ferric sulfide; the metal doped layer is made of a first metal material and a second metal material doped in the first metal material; the work function of the first metal material is -2.0 eV to -3.5 eV; the work function of the second metal material is -4.0 eV to -5.5 eV. The light efficiency of the organic electroluminescence device is relatively high. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic light-emitting device and manufacturing method thereof

InactiveCN104659215AEasy injectionIncrease transfer rateSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundPhenanthroline

The invention discloses an organic light-emitting device, which comprises an anode, a hole injection layer, a hole transmission layer, a light emitting layer, an electron transport layer, an electron injection layer and a cathode laminated in sequence, wherein the electron injection layer is composed of a two-element doping layer and a rubidium compound layer; the two-element doping layer rubidium compound material and electron transport material; the rubidium compound material selects at least one from rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the electron transport material selects at least one from 4, 7-Diphenyl-1, 10-phenanthroline, 2-(4-tert-Butylphenyl)-5-(4-biphenyl)-1,3,4-oxadiazole, 8-Hydroxyquinoline aluminum salt and N-aryl benzimidazole; and the rubidium compound layer material is also the rubidium compound material. The above organic light-emitting device is high in light emitting efficiency. The invention also provides an organic light-emitting device manufacturing method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic electroluminescence device and preparation method thereof

InactiveCN104659253AIncrease transfer rateLow melting pointSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundAzide

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer is made of one or more rubidium compound materials, one or more cesium salt materials and titanium dioxide; the rubidium compound material(s) is / are one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the cesium salt material(s) is / are one or more of cesium fluoride, cesium carbonate, cesium azide and cesium chloride. The light efficiency of the organic electroluminescence device is relatively high. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic electroluminescence device and preparation method thereof

InactiveCN104659224AIncrease transfer rateImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLithium oxideLithium chloride

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a luminescent layer, an electron transport layer, an electron injection layer and a cathode which are stacked in sequence, wherein the electron injection layer consists of a rubidium compound doped layer and a metal doped layer; the rubidium compound doped layer comprises a rubidium compound material and a metal material I doped in the rubidium compound material; the rubidium compound material is at least one of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the work function of the metal material I is -2.0 eV to -3.5 eV; the metal doped layer comprises a metal material II and a lithium salt material doped in the metal material II; the work function of the metal material II is -2.0 eV to -3.5 eV; the lithium salt material is at least one of lithium oxide, lithium fluoride, lithium chloride and lithium bromide. The organic electroluminescence device is relatively high in luminescence efficiency. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic electroluminescence device and preparation method thereof

InactiveCN104659222AEasy injectionIncrease transfer rateSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundPhenanthroline

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer comprises a two-element-doped layer and a metal doped layer; the two-element-doped layer is made of one or more rubidium compound materials and an organosilicon small molecular material; the rubidium compound material(s) is / are one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the energy gap of the organosilicon small molecular material is -3.5 eV to -5.5 eV; the metal doped layer is made of one or more of metal materials and one or more electron transporting materials; the work function of the metal materials is -2.0 eV to -3.5 eV; the electron transporting material(s) is / are one or more of 4,7-diphenyl-1,10-phenanthroline, 2-(4'-tert-butylphenyl)-5-(4'-biphenyl)-1,3,4-oxadiazole, 8-hydroxyquinoline aluminum, and N-aryl benzimidazole.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic light-emitting device and manufacturing method thereof

InactiveCN104659216AEasy to injectEasy injectionSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundMetallic materials

The invention discloses an organic light-emitting device, which comprises an anode, a hole injection layer, a hole transmission layer, a light emitting layer, an electron transport layer, an electron injection layer and a cathode laminated in sequence, wherein the electron injection layer is composed of a three-element doping layer and a titanium dioxide layer; the three-element doping layer comprises rubidium compound material, electron transport material and metal material; the rubidium compound material selects at least one from rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; and the electron transport material selects at least one from 4, 7-Diphenyl-1, 10-phenanthroline, 2-(4-tert-Butylphenyl)-5-(4-biphenyl)-1,3,4-oxadiazole, 2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline, and 2,2'-(1,3-Phenylene)-bis [5-(4-tert-butylphenyl)-1,3,4-oxadiazole]. The above organic light-emitting device is high in light emitting efficiency. The invention also provides an organic light-emitting device manufacturing method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Methods to recover cesium formate from a mixed alkali metal formate blend

ActiveUS9452966B2Efficient and inexpensivePreparation from carboxylic acid saltsOrganic compound preparationSodium bicarbonateFormate

Methods to recover or separate cesium formate or rubidium formate or both from a mixed alkali metal formate blend are described. One method involves adding cesium sulfate or rubidium sulfate to the mixed alkali metal formate blend in order to preferentially precipitate potassium sulfate from the mixed alkali metal formate blend. Another method involves adding cesium carbonate or cesium bicarbonate or both to preferentially precipitate potassium carbonate / bicarbonate and / or other non-cesium or non-rubidium metals from the mixed alkali metal blend. Further optional steps are also described. Still one other method involves converting cesium sulfate to cesium hydroxide.

Owner:CABOT SPECIALTY FLUIDS

Organic electroluminescence device and preparation method thereof

InactiveCN104659221ALower injection barrierImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundGlass transition

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a luminescent layer, an electron transport layer, an electron injection layer and a cathode which are stacked in sequence, wherein the electron injection layer consists of a rubidium compound doped layer and an electron transport material doped layer; the rubidium compound doped layer comprises a rubidium compound material and a metallic oxide material doped in the rubidium compound material; the rubidium compound material is at least one of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the metallic oxide material is at least one of molybdenum trioxide, tungsten trioxide and vanadium pentoxide; the electron transport material doped layer comprises an electron transport material and an organosilicon small molecule material doped in the electron transport material; the glass transition temperature of the electron transport material is 50 DEG C to 100 DEG C. The organic electroluminescence device is relatively high in luminescence efficiency. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic light-emitting device and production method thereof

InactiveCN104638144AEasy injectionEasy transferSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionRubidium compound

The invention relates to an organic light-emitting device and a production method thereof. The organic light-emitting device is of a layered structure and comprises an anode conducting substrate, a hole injection layer, a hole transmission layer, a light-emitting layer, an electron transmission layer, an electron injection layer and a cathode layer which are stacked in sequence; the electron injection layer comprises a rubidium compound layer, a ternary doping layer and a rhenium compound layer; the rubidium compound layer is made of rubidium carbonate, rubidium chloride and rubidium nitrate or rubidium sulfate, the ternary doping layer is made of materials of low-work function metal, high-work function metal and metal sulfide. The rubidium compound layer in the electron injection layer is low in melting point and easy to evaporate and plate; work function is low due to existing of metal ions, electron injection barrier between the electron transmission layer and the injection layer can be lowered, and injection of electrons is benefited.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic electroluminescent device and preparation method thereof

InactiveCN104659243ALower injection barrierImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingIron(III) sulfideRubidium compound

An organic electroluminescent device comprises an anode, a hole injection layer, a hole transport layer, a light emitting layer, an electron transport layer, an electron injection layer, and a cathode, which are stacked in sequence. The electron injection layer is composed of a rubidium compound doped layer and a ferric salt doped layer. The rubidium compound doped layer includes a rubidium compound material group and an electron transport material doped in the rubidium compound material. The rubidium compound material includes at least one selected from rubidium carbonate, rubidium chloride, rubidium nitrate, and rubidium sulfate. The electron transport material includes at least one selected from 4,7-diphenyl-1,10-phenanthroline, 2-(4'-tert-butylphenyl)-5-(4'-biphenyl)-1,3,4-oxadiazole, 8-hydroxyquinoline aluminum, and N-arylbenzimidazole. The ferric salt doped layer includes a ferric salt material and a bipolar organic transport material doped in the ferric salt material. The ferric salt material includes at least one selected from ferric chloride, ferric bromide and ferric sulfide.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

A method for extracting aluminum sulfate, aluminum potassium sulfate, rubidium sulfate and cesium sulfate using lepidolite sulfuric acid leaching solution

ActiveCN107140667BAvoid disadvantages such as not easy to useRubidium/caesium/francium compoundsAluminium sulfatesPotassiumBall mill

Owner:江西南氏锂电新材料有限公司

Organic electroluminescence device and preparation method thereof

InactiveCN104659276AImprove the scattering effectIncrease transfer rateSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundElectron

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer is made of one or more rubidium compound materials, one or more metal oxide materials and zinc powder; the rubidium compound material(s) is / are one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the metal oxide material(s) is / are one or more of molybdenum trioxide, tungsten trioxide and vanadic oxide. The light efficiency of the organic electroluminescence device is relatively high. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Methods To Recover Cesium Formate From A Mixed Alkali Metal Formate Blend

ActiveUS20160355406A1Efficient and inexpensivePreparation from carboxylic acid saltsOrganic compound preparationFormatePrecipitated sulphur

Methods to recover or separate cesium formate or rubidium formate or both from a mixed alkali metal formate blend are described. One method involves adding cesium sulfate or rubidium sulfate to the mixed alkali metal formate blend in order to preferentially precipitate potassium sulfate from the mixed alkali metal formate blend. Another method involves adding cesium carbonate or cesium bicarbonate or both to preferentially precipitate potassium carbonate / bicarbonate and / or other non-cesium or non-rubidium metals from the mixed alkali metal blend. Further optional steps are also described. Still one other method involves converting cesium sulfate to cesium hydroxide.

Owner:CABOT SPECIALTY FLUIDS

Organic light-emitting device and production method thereof

InactiveCN104638140AGuaranteed performanceStable in natureSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundElectron transmission

The invention relates to an organic light-emitting device and a production method thereof. The organic light-emitting device comprises an anode conducting substrate, a hole injection layer, a hole transmission layer, a light-emitting layer, an electron transmission layer, an electron injection layer and a cathode layer which are stacked in sequence; the electron injection layer comprises a rubidium compound doping layer and an iron salt layer; the rubidium compound doping layer is made of materials of a rubidium compound, low-work function metal and high-work function metal; the rubidium compound is made of materials of rubidium carbonate, rubidium chloride, rubidium nitrate or rubidium sulfate. The rubidium compound of the organic light-emitting device is low in melting point and easy to evaporate and plate; due to existing of metal ions, work function is low, an electronic injection barrier between the electron transmission layer and the injection layer can be reduced, and injection of the electron is benefited.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic electroluminescence device and preparation method thereof

InactiveCN104659223AIncrease transfer rateLower injection barrierSolid-state devicesSemiconductor/solid-state device manufacturingLithium oxideLithium chloride

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer is made of one or more rubidium compound materials, one or more electron transporting materials and one or more lithium salt materials; the rubidium compound material(s) is / are one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the electron transporting material(s) is / are one or more of 4,7-diphenyl-1,10-phenanthroline, 2-(4'-tert-butylphenyl)-5-(4'-biphenyl)-1,3,4-oxadiazole, 8-hydroxyquinoline aluminum, and N-aryl benzimidazole; the lithium salt material(s) is / are one or more of lithium oxide, lithium fluoride, lithium chloride and lithium bromide. The light efficiency of the organic electroluminescence device is relatively high. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com