Method for producing potassium sulfate by utilizing insoluble rocks containing potassium

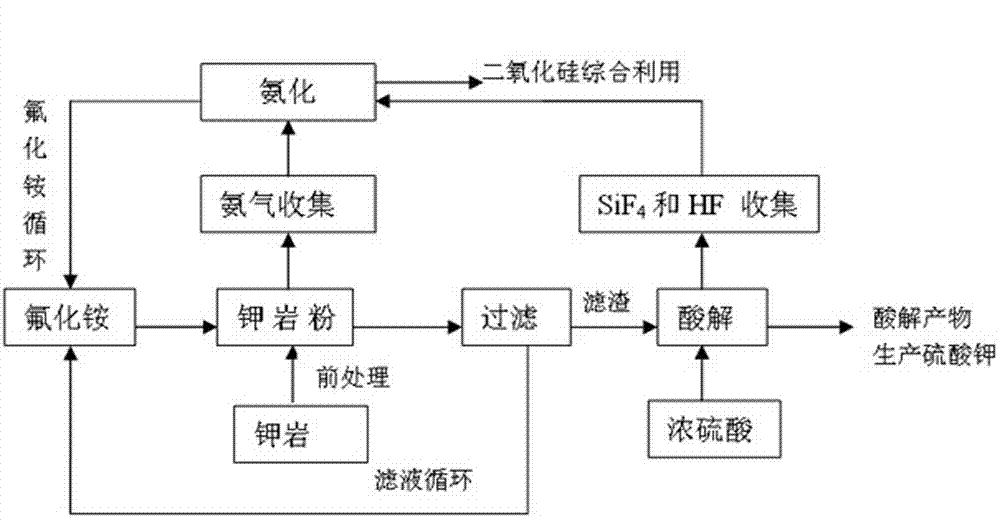

A technology of potassium rock and potassium sulfate, applied in the field of development and utilization of insoluble potassium-containing rock, can solve the problems of high temperature, complicated process, low recovery rate, etc., and achieve the effect of effective utilization, high reaction yield and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Treat 50g of 200-mesh potassium-containing rock powder with 200ml of 1% dilute hydrochloric acid, filter and dehydrate;

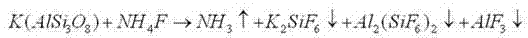

[0034] (2) Add the potassium-containing rock powder in step (1) into 500ml of 20% NH 4 In the reaction kettle of the F solution, stir and heat, react at a temperature of 95°C to 105°C, and collect the evaporated ammonia and water vapor with an absorption bottle;

[0035] (3) After reacting for 2 hours, the reactant is filtered, and the filtrate is returned to step (2) for recycling, and the solid is dried for later use;

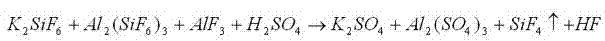

[0036] (4) The solid obtained in step (3) and 40g of 98% concentrated sulfuric acid are subjected to an acid hydrolysis reaction at a temperature of 190°C to 200°C, and the volatilized fluorine-containing gas is defoamed and passed into the ammonia water collected in step (2);

[0037] (5) Dissolve the acidolysis solid product obtained in step (4) with 200g of water, filter and wash;

[0038] (6) The filtrate obtained in step ...

Embodiment 2

[0040] (1) Treat 50g of 200-mesh potassium-containing rock powder with 200ml of 1% dilute hydrochloric acid, filter and dehydrate;

[0041] (2) Add the potassium-containing rock powder in step (1) into 500ml of 20% NH 4 In the reaction kettle of the F solution, stir and heat, react at a temperature of 95°C to 105°C, and collect the evaporated ammonia and water vapor with an absorption bottle;

[0042] (3) After reacting for 1 hour, the reactant is filtered, and the filtrate is returned to step (2) for recycling, and the solid is dried for later use;

[0043] (4) Perform acidolysis reaction on the solid obtained in step (3) and 40g of 98% concentrated sulfuric acid at a temperature of 175°C to 190°C, and pass the volatilized fluorine-containing gas into the ammonia water collected in step (2) after defoaming ;

[0044] (5) Dissolve the acidolysis solid product obtained in step (4) with 200g of water, filter and wash;

[0045] (6) The filtrate obtained in step (5) is adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com