Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "P-acetaminophenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

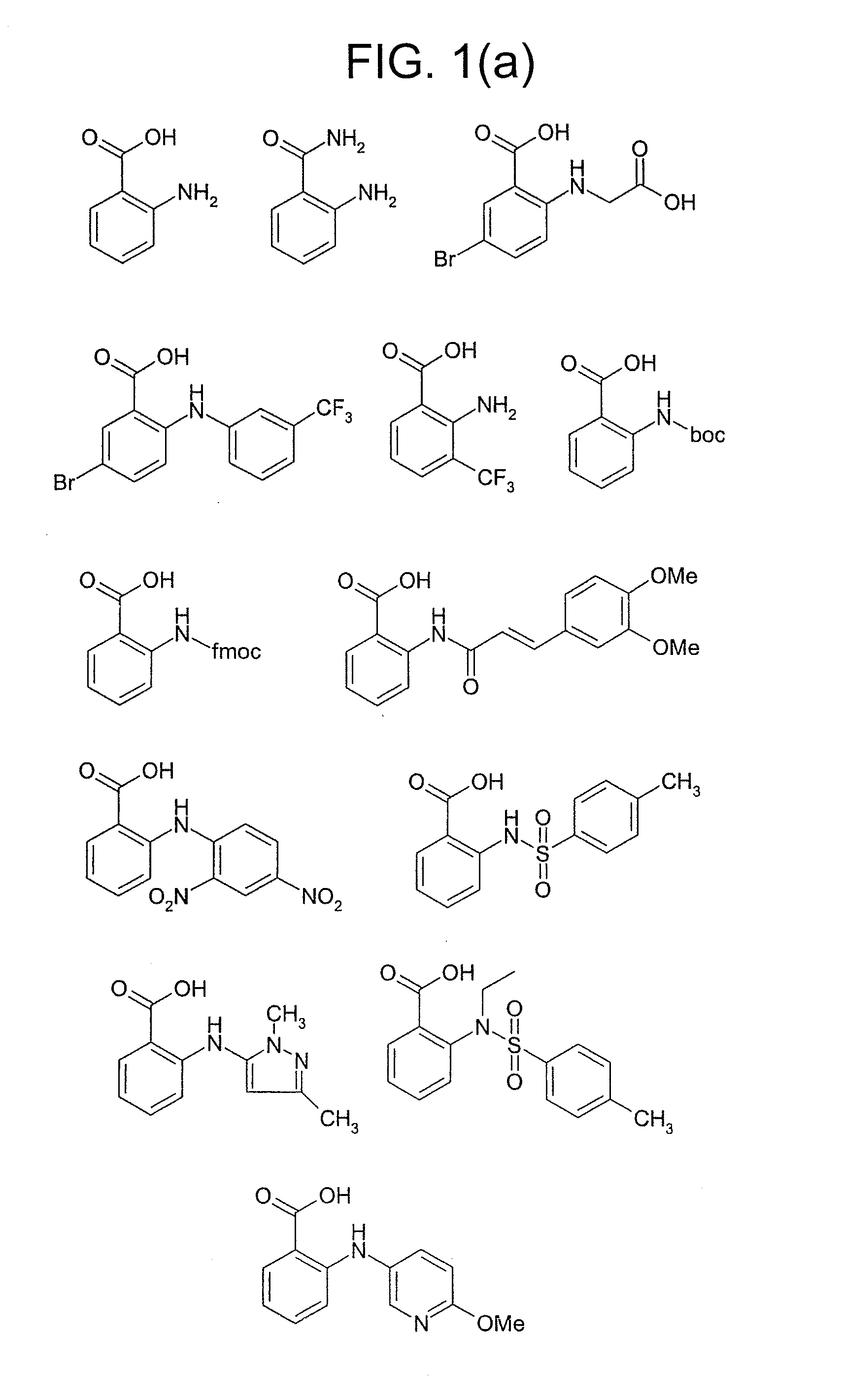

Method of producing organic compounds in presence of oxyethylene ether catalyst and in a solvent minimized environment

InactiveUS6969775B2Little work-upPractical and attractiveOrganic compound preparationCarboxylic acid amides preparationSimple Organic CompoundsPtru catalyst

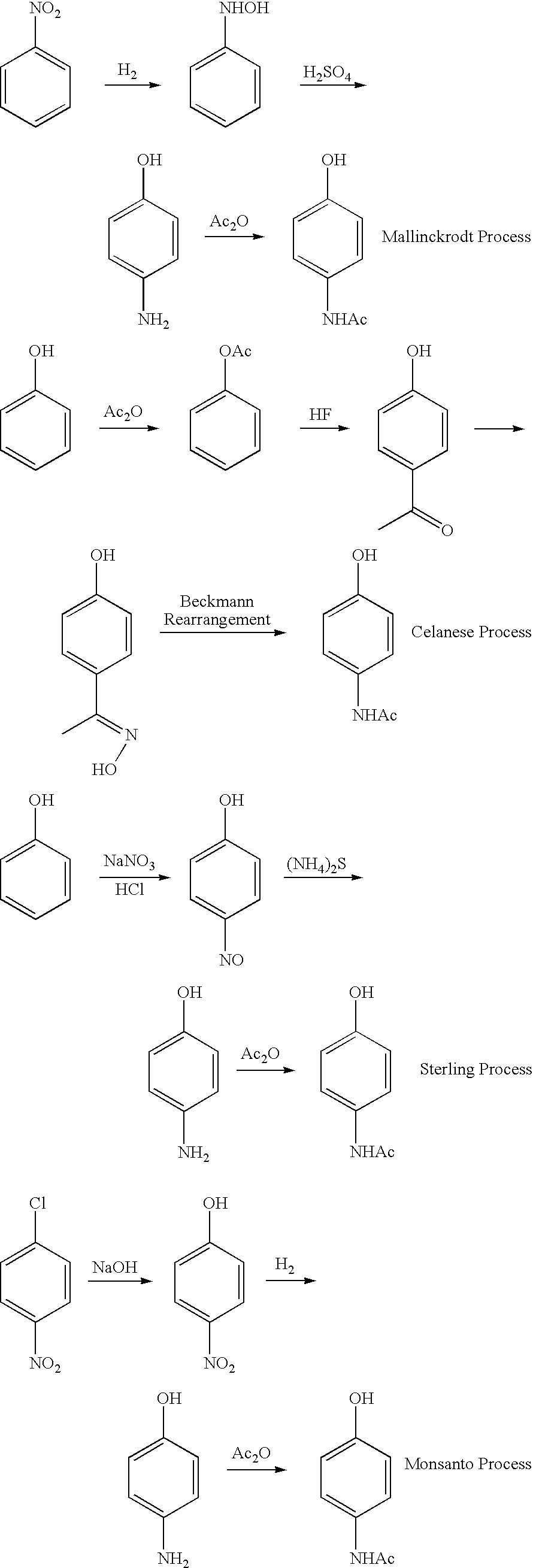

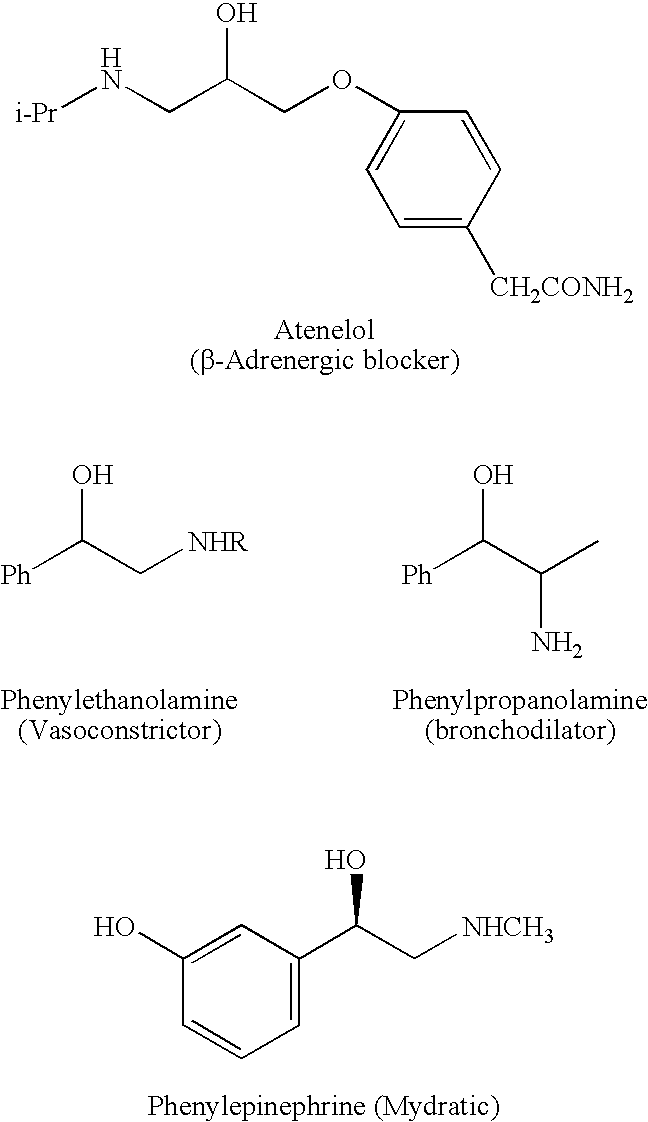

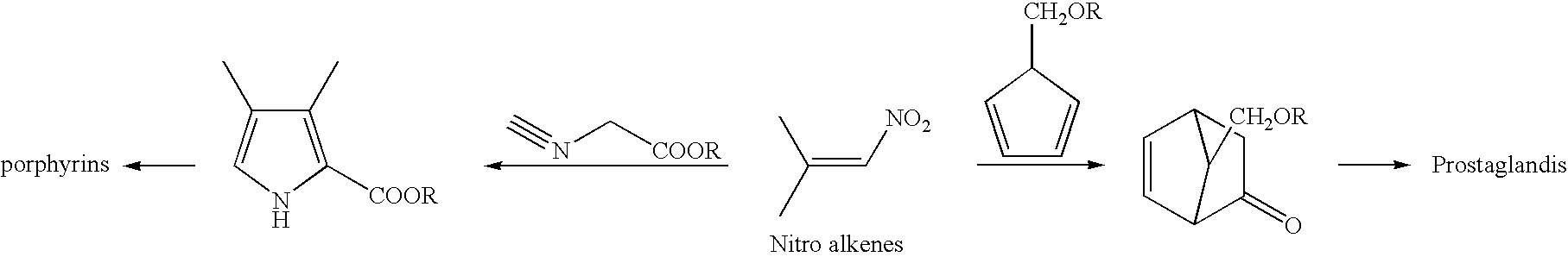

A process of producing organic compounds, such as acetaminophen, nitroalcohols and indoles, employs a catalyst system of an oxyethylene ether and a metal containing inorganic or organic reagent. The oxyethylene ether at least partially complexes the metal of the inorganic or organic reagent. As such, the reactions may be conducted neat. The processes are environmentally friendly and operationally simple.

Owner:TEXAS A&M UNIVERSITY

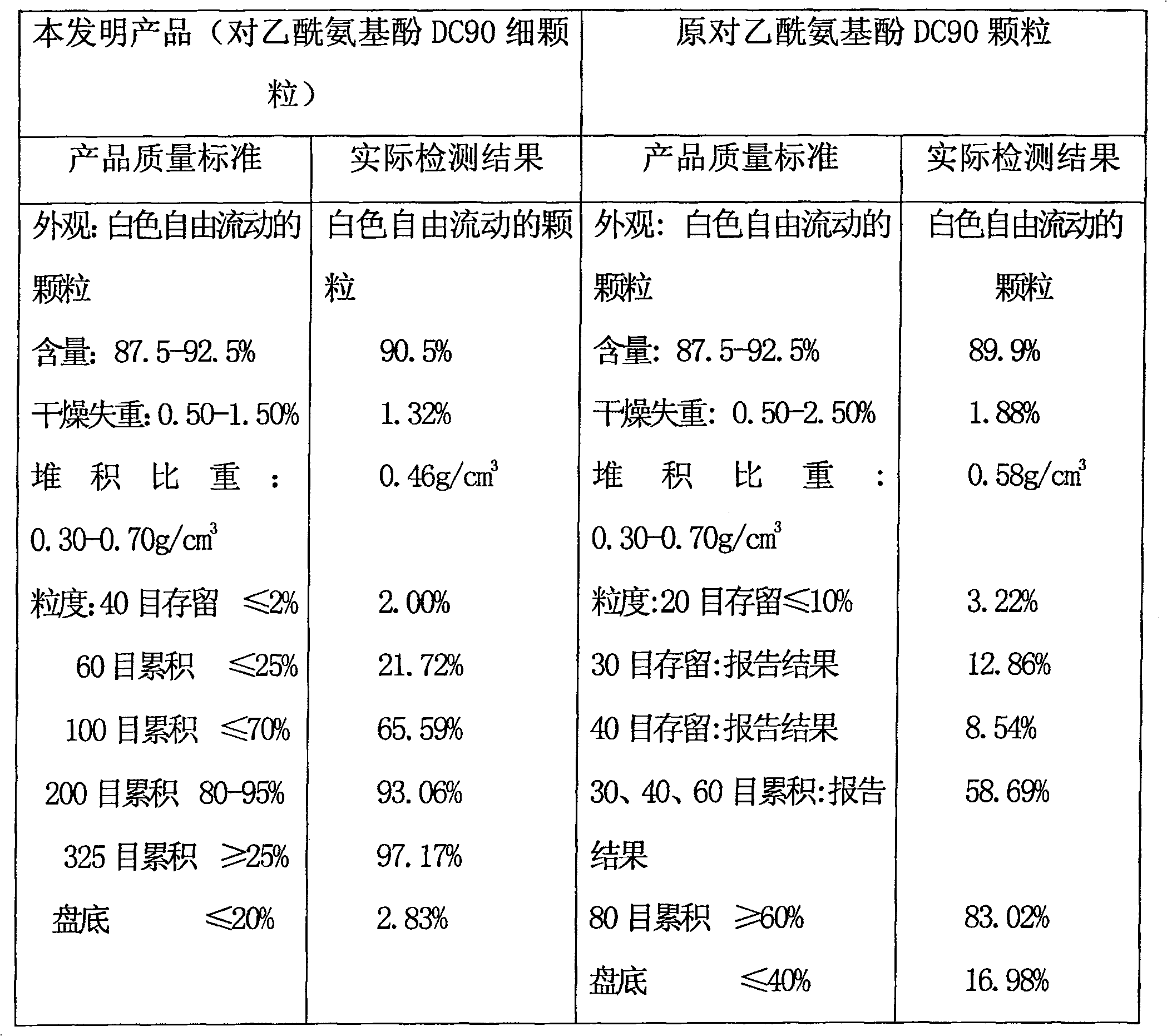

Acetaminopher DC90 fine particle and preparation method thereof

ActiveCN101342144AFine and uniform particlesWell mixedOrganic active ingredientsPowder deliveryCrospovidonesPrill

The invention discloses paracetanol DC90 fine particles and a preparation method thereof. The paracetanol DC90 comprises following materials by weight ratio: 90 percent of paracetanol, 3.50 percent of cornstarch, 3.50 percent of pre gelatinized starch, 2.00 percent of povidone, 0.5 percent of crospovidone and 0.5 percent of stearic acid. Firstly, the paracetanol and the cornstarch are mixed evenly, then the pre gelatinized starch and the povidone are made into starch slurry to be used as bond which is evenly sprayed on the mixture of the fluidied paracetanol and cornstarch, fluidized bed granulation is carried out in the inlet air temperature, the wet particles are dried under the temperature of 80 DEG C and then are cooled at the temperature of 50 DEG C till water conforms to the requirement, the sizes of the particles are adjusted, the stearic acid and the crospovidone are added after the particle sizes are adjusted to be mixed evenly to obtain the paracetanol DC90 fine particles. The invention adopts the above technical proposal to inspect the product, and the particles are fine and uniform and have favorable fluidity, thereby being well and evenly mixed with other small quantities of active components powder.

Owner:ANQIU LUAN PHARMA

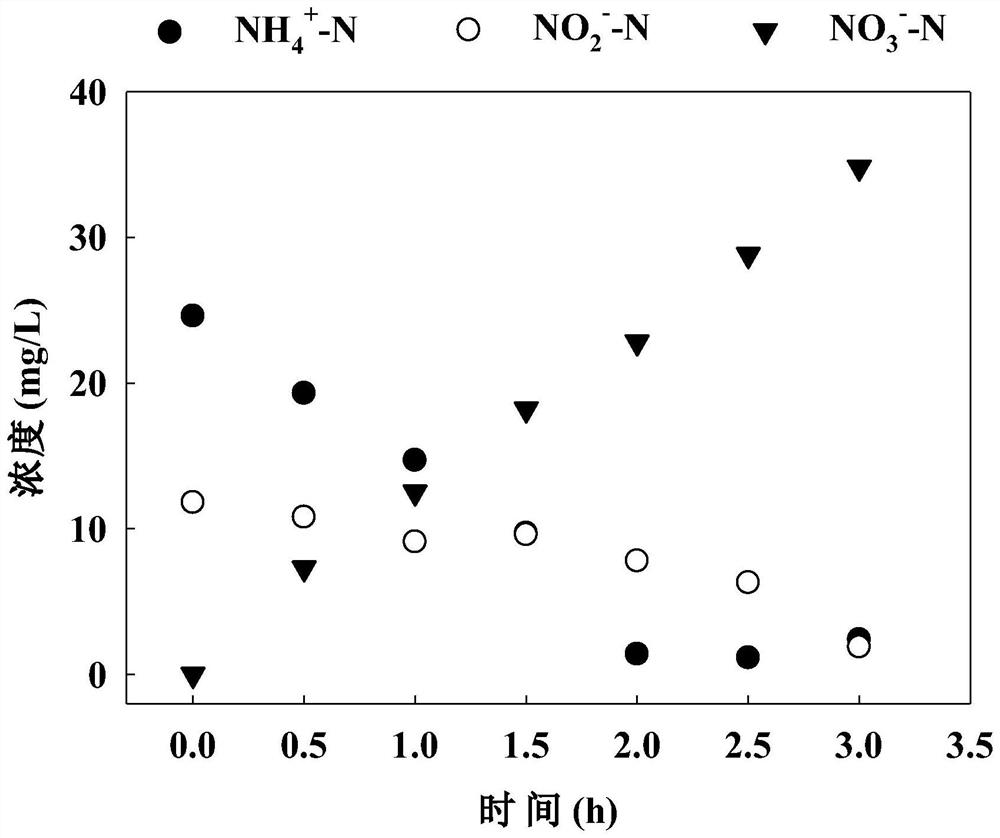

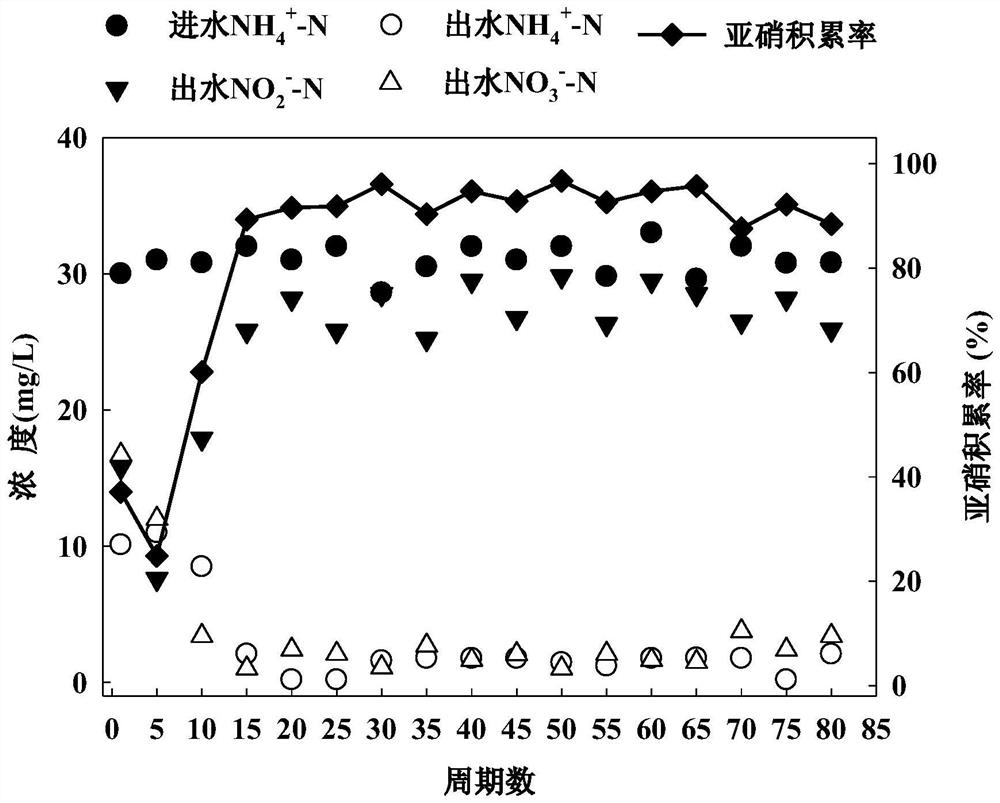

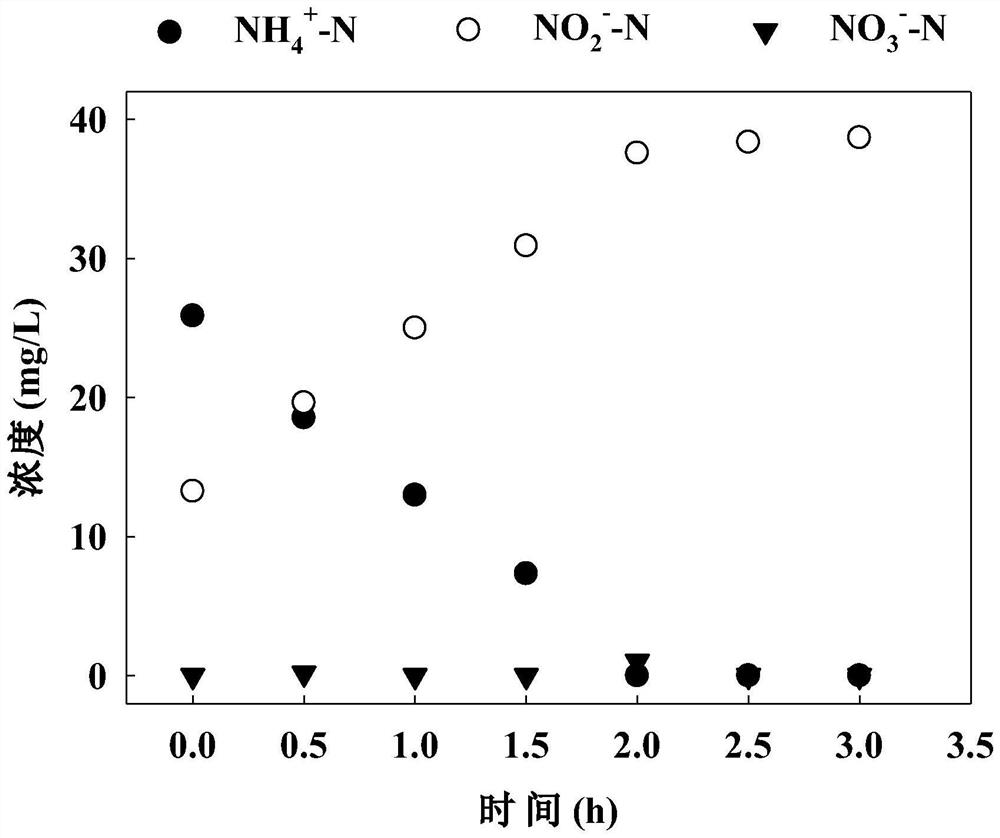

Method for rapidly starting normal-temperature short-cut nitrification of municipal sewage by using acetaminophen

InactiveCN112661258ANo swellingEasy to operateSustainable biological treatmentBiological water/sewage treatmentActivated sludgeP-acetaminophenol

The invention discloses a method for rapidly starting normal-temperature short-cut nitrification of municipal sewage by utilizing acetaminophen, and belongs to the technical field of biological sewage treatment. Two treatment process, namely acetaminophen side flow soaking or direct addition of acetaminophen, are adopted to treat the activated sludge in the method, and then the treated activated sludge finally quickly starts short-cut nitrification by inhibiting the activity of NOB. The inhibitor can quickly start normal-temperature short-cut nitrification of municipal sewage.

Owner:BEIJING UNIV OF TECH

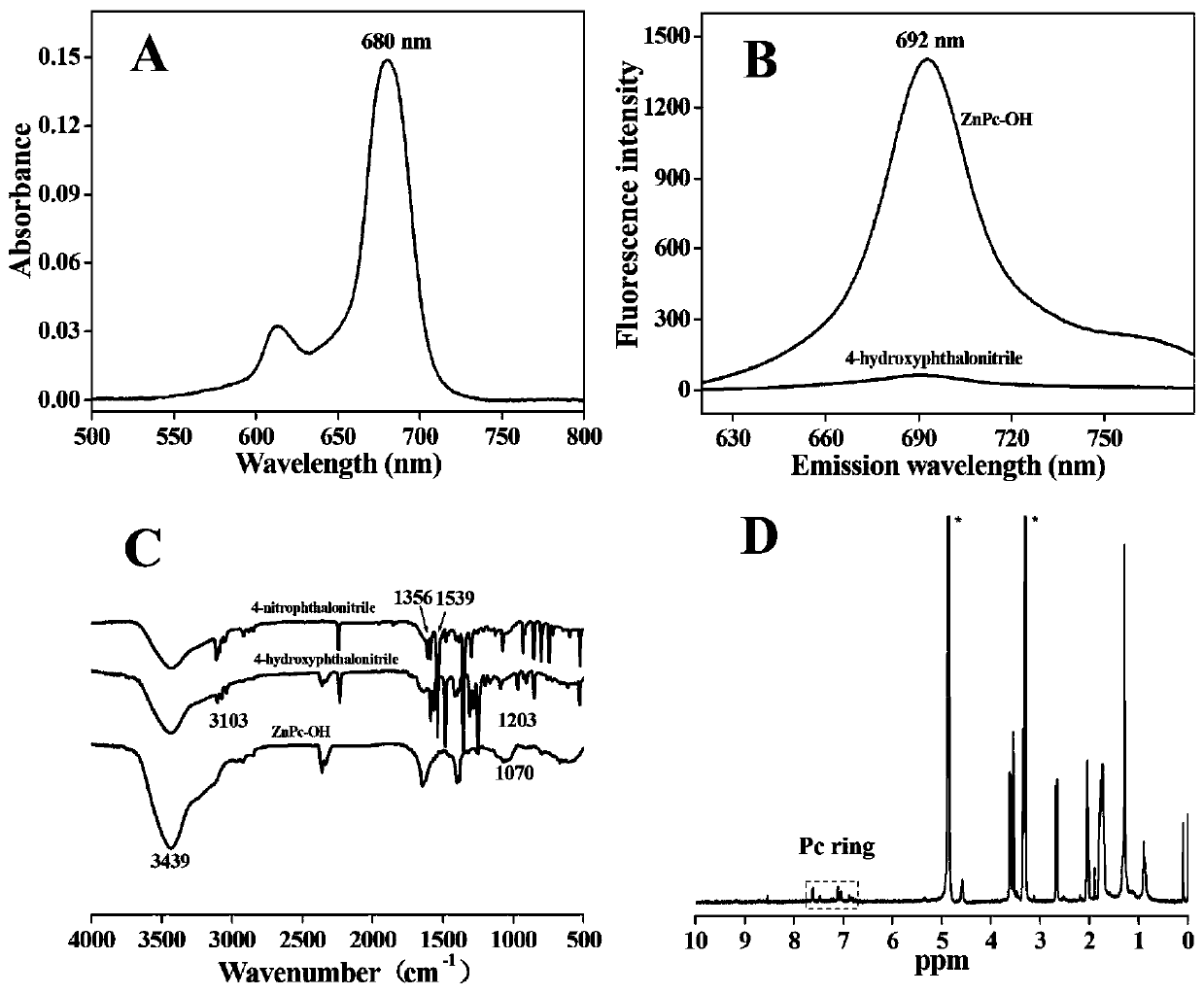

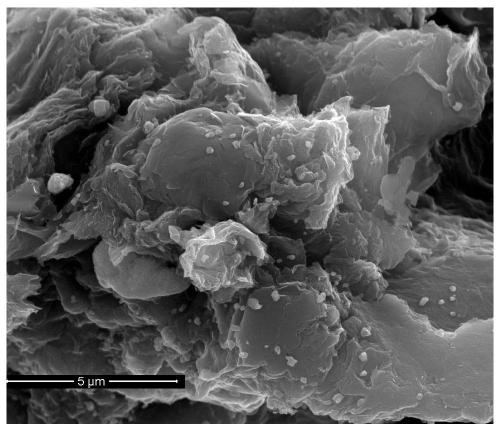

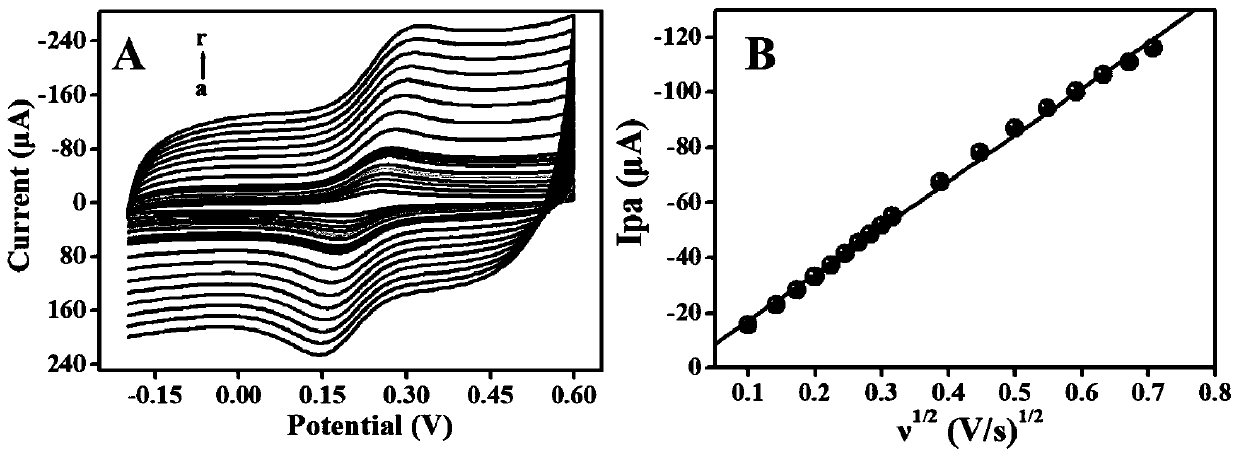

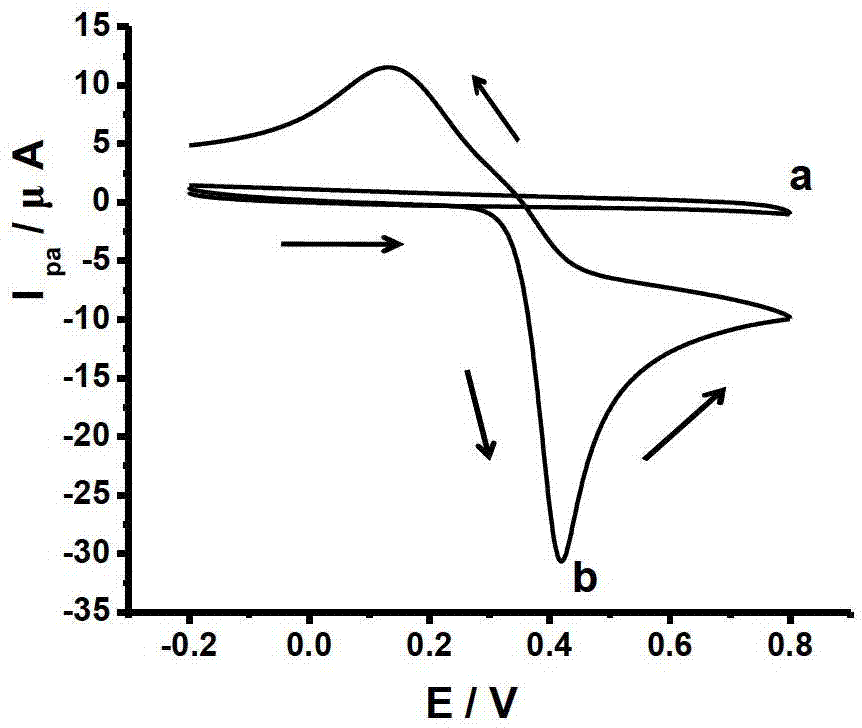

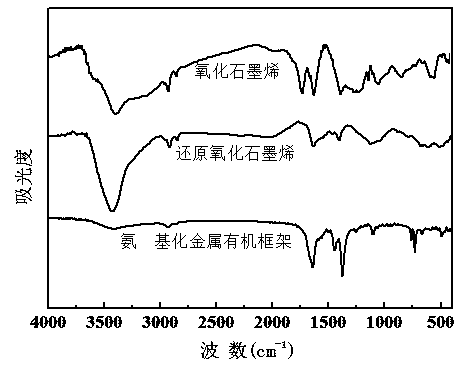

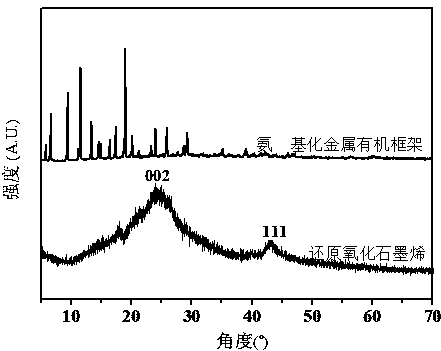

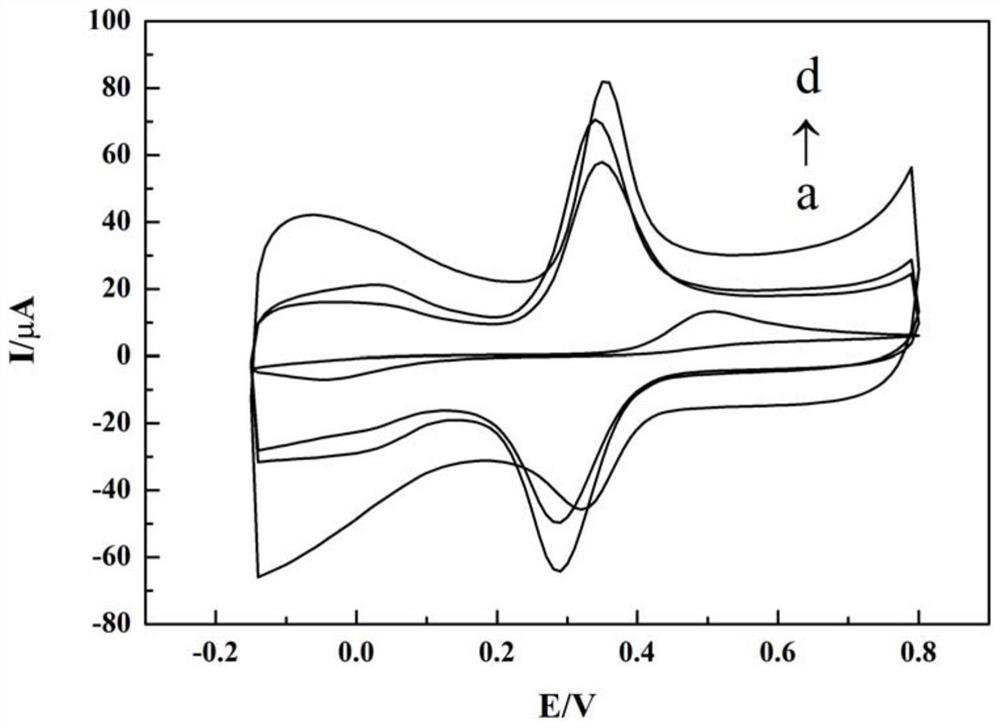

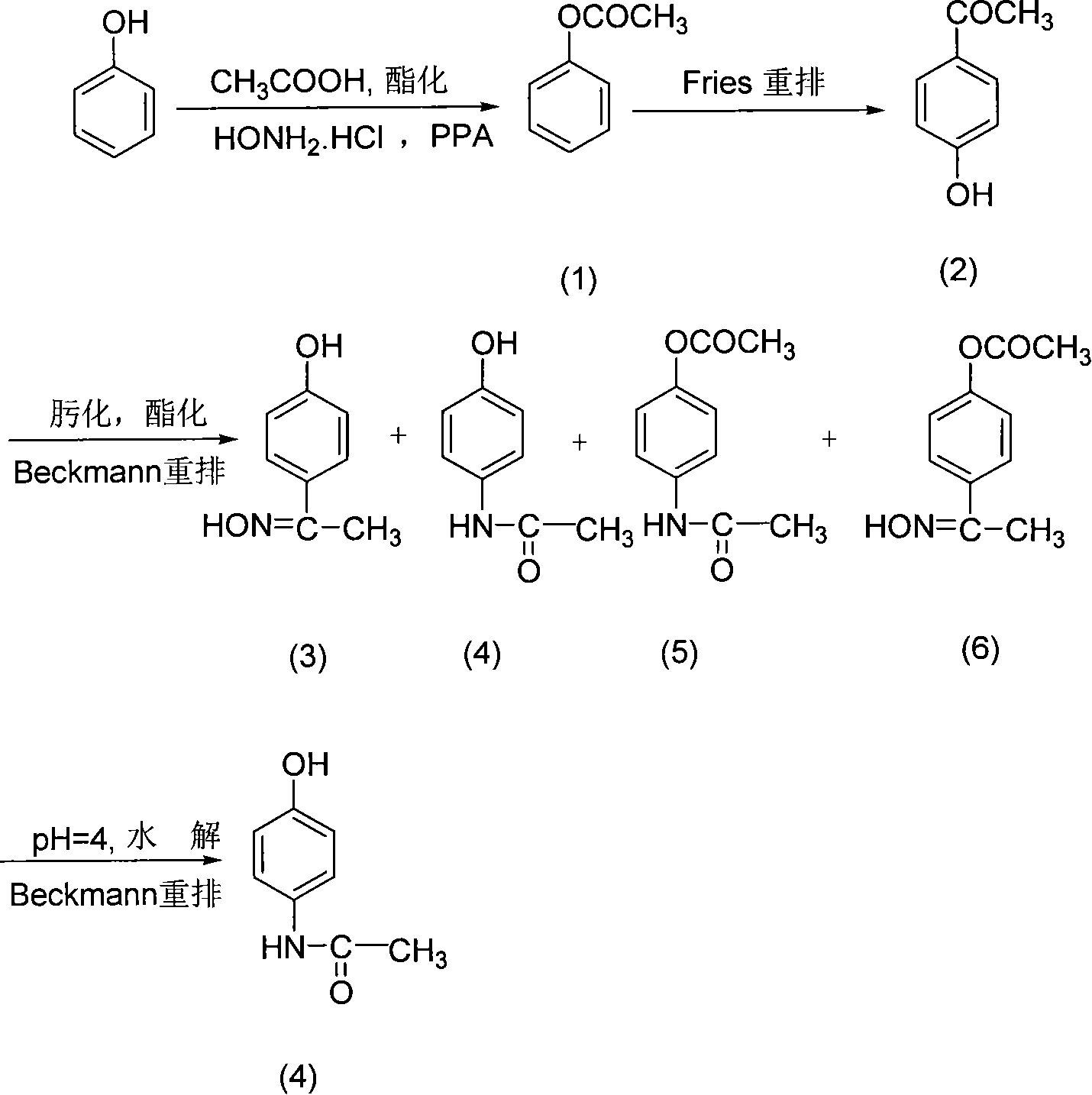

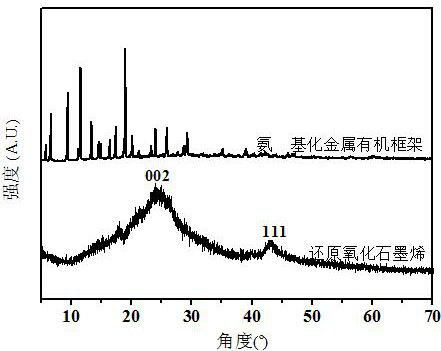

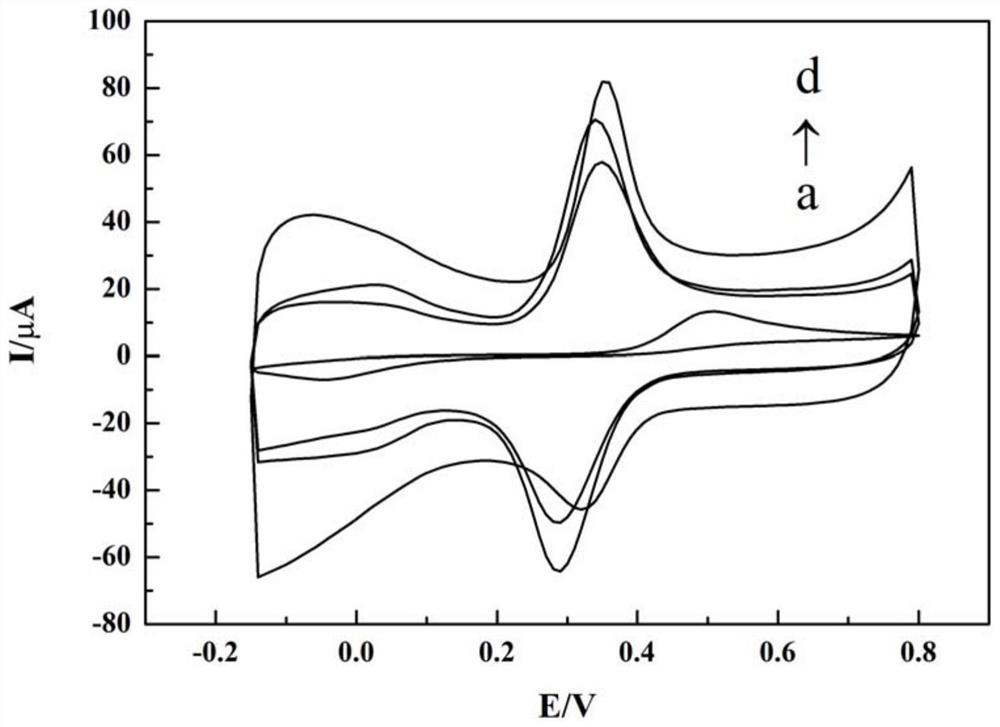

Tetrahydroxy phthalocyanine zinc-reduced graphene oxide nano-composite as well as electrochemical sensor prepared from the same and application thereof

ActiveCN111521653AGood water solubilityGood dispersionMaterial electrochemical variablesP-acetaminophenolNanocomposite

The invention discloses a tetrahydroxy phthalocyanine zinc-reduced graphene oxide nano-composite as well as an electrochemical sensor prepared from the tetrahydroxy phthalocyanine zinc-reduced graphene oxide nano-composite and application of the tetrahydroxy phthalocyanine zinc-reduced graphene oxide nano-composite. The tetrahydroxy zinc phthalocyanine-reduced graphene oxide nano composite is formed by combining water-soluble tetrahydroxy zinc phthalocyanine and reduced graphene oxide large pi bonds through non-covalent bonds. The combination of the two improves the disadvantage of poor dispersibility of the two while giving consideration to the advantages of the two, and has the advantages of large specific surface area, good conductivity, strong stability, easy availability, no toxicityand environmental friendliness. The Nafion tetrahydroxy phthalocyanine zinc-reduced graphene oxide nanocomposite is directly coated on the surface of a glassy carbon electrode through a one-step dispensing method, and the method has the advantages of being rapid and simple to operate, good in reproducibility and the like. The prepared sensor is low in cost, good in stability and selectivity, capable of achieving accurate, rapid and high-sensitivity detection of acetaminophen and wide in detection range, the detection limit is as low as 10 nmol / L, and the sensor has potential application valuein the fields of clinical diagnosis, drug analysis and the like.

Owner:HENAN UNIV OF CHINESE MEDICINE

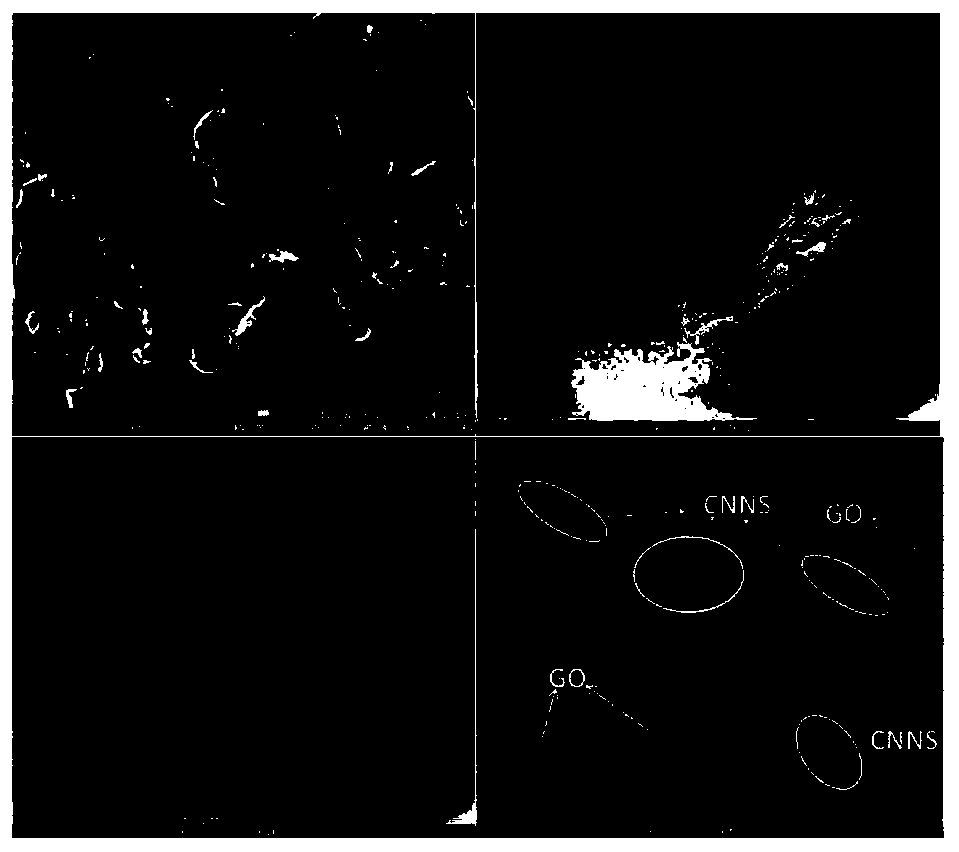

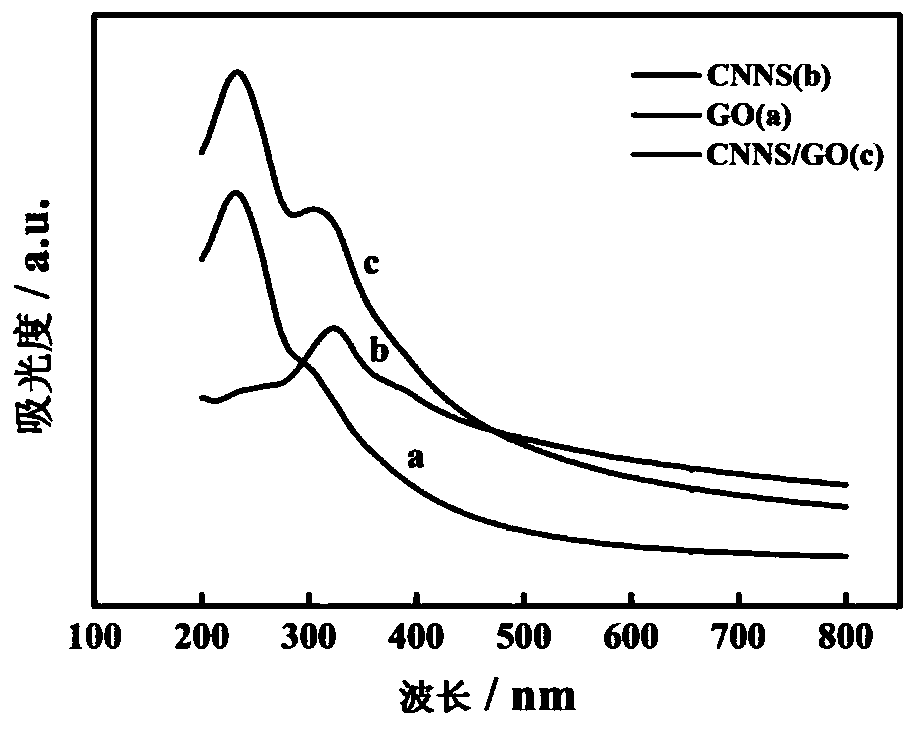

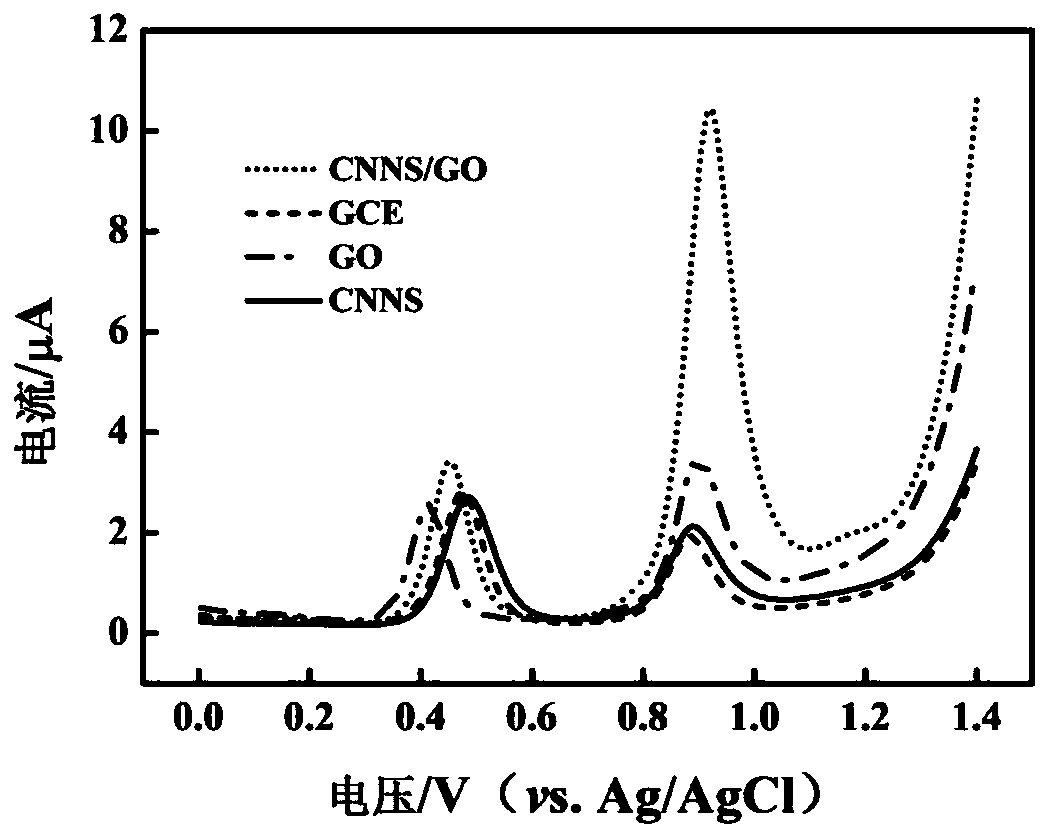

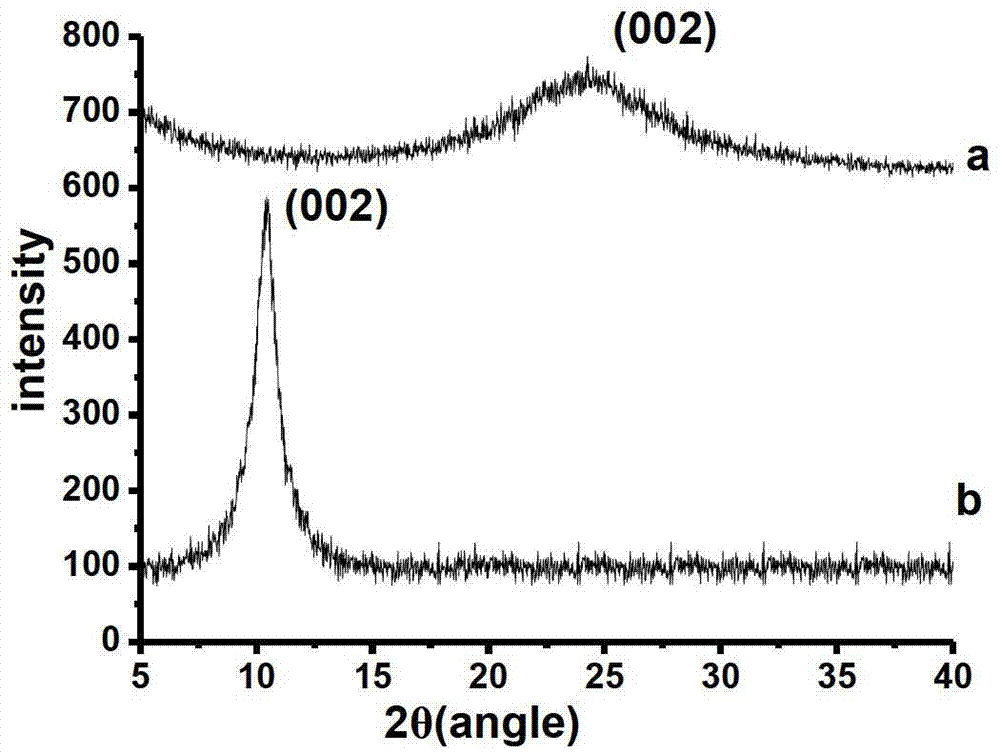

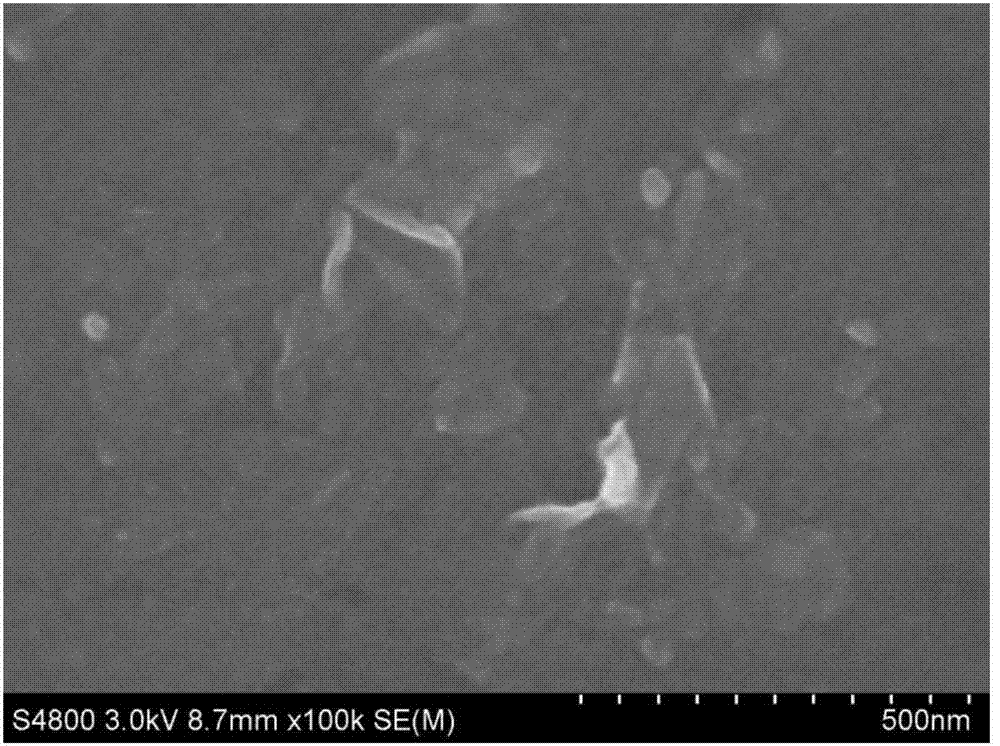

g-C3N4 nanosheet/graphene oxide composite material and preparation method and application thereof

InactiveCN110980666ALarge specific surface areaFacilitates electron transportCarbon compoundsNitrogen and non-metal compoundsP-acetaminophenolOxide composite

The invention relates to a g-C3N4 nanosheet / graphene oxide composite material and a preparation method and application thereof. According to the composite material, Bulk-g-C3N4 is synthesized througha pyrolysis method, then g-C3N4 nanosheets are synthesized through an ultrasonic-assisted method and finally the g-C3N4 nanosheets are fixed on the surface of graphene oxide through an ultrasonic method to obtain the composite material. The composite material is modified on the surface of a glassy carbon electrode to prepare a novel sensor for simultaneous, rapid and real-time detection of acetaminophen and levofloxacin. Results show that the sensor has a wide linear range, a low detection limit and high sensitivity for detection of two substances. High-sensitivity detection and analysis of acetaminophen and levofloxacin can be realized and high selectivity can be obtained in the complex environment medium. Meanwhile, the composite material has the advantages of being simple in instrumentand equipment, low in analysis cost, rapid, simple, convenient and the like, and a new detection method can be provided for evaluating residual pollution of acetaminophen and levofloxacin in the environment.

Owner:SHANXI UNIV

Graphene nano material-modified glassy carbon electrode based on phytic acid dispersion, preparation method and application

InactiveCN103399063BReduce manufacturing costImprove stabilityMaterial electrochemical variablesP-acetaminophenolCatalytic oxidation

The invention belongs to the electrochemistry and nano material technical fields, and especially relates to a graphene nano material-modified glassy carbon electrode based on phytic acid dispersion, a preparation method and an application of the electrode in detection of acetaminophen. The preparation method is as follows: graphene is dispersed in a phytic acid solution, and is subjected to ultrasonic treatment for 4-8 h to obtain a phytic acid dispersion liquid of graphene; a clean glassy carbon electrode is soaked in the phytic acid dispersion liquid of graphene, subjected to self-assembly for 1-4 h, washed and dried; the mass concentration of the phytic acid solution is 30-60%. The glassy carbon has advantages of electrode low preparation cost, simple preparation method and environment protection. The glassy carbon electrode can be applied to detection of acetaminophen, and has good electrocatalytic oxidation activity to detection of acetaminophen. The glassy carbon electrode is advantaged by fast response time, wild linearity range, good reproducibility high stability and freedom from interference of coexisting electroactive substances.

Owner:SHANGHAI NORMAL UNIVERSITY

Anti-oxidization oxytetracycline hydrochloride injection and preparation method thereof

InactiveCN108635393AStable in natureReduce vitalityAntibacterial agentsAntipyreticVitamin COxytetracycline Hydrochloride

The invention discloses anti-oxidization oxytetracycline hydrochloride injection and a preparation method thereof and relates to the technical field of medicines. The anti-oxidization oxytetracyclinehydrochloride injection is prepared from the following raw materials in parts by weight: 35 to 55 parts of anti-oxidization oxytetracycline hydrochloride, 12 to 15 parts of miloxacin, 10 to 15 parts of enoxacin, 6 to 7 parts of p-acetamidophenol, 22 to 26 parts of herba taraxaci-radix isatidis extracting solution, 6 to 8 parts of glucose, 5 to 8 parts of sodium chloride, 2 to 4 parts of calcium chloride, 3 to 5 parts of zinc sulfate, 80 to 100 parts of ethanol, 16 to 20 parts of triethanolamine, 13 to 16 parts of vitamin C and 180 to 240 parts of purified water; the anti-oxidization oxytetracycline hydrochloride is prepared through a specific method and is matched with other raw materials to use, so that the prepared injection has antibacterial, sterilization and inflammation-diminishing effects; meanwhile, the injection has stable properties and is not easily oxidized and the medicinal effect can be kept for a long period; the injection also can provide necessary nutrients for life bodies, is applicable to disease prevention and bacterium resistance of domestic fowl, domestic animals and large-size animals and has a remarkable curative effect.

Owner:安徽天安生物科技股份有限公司

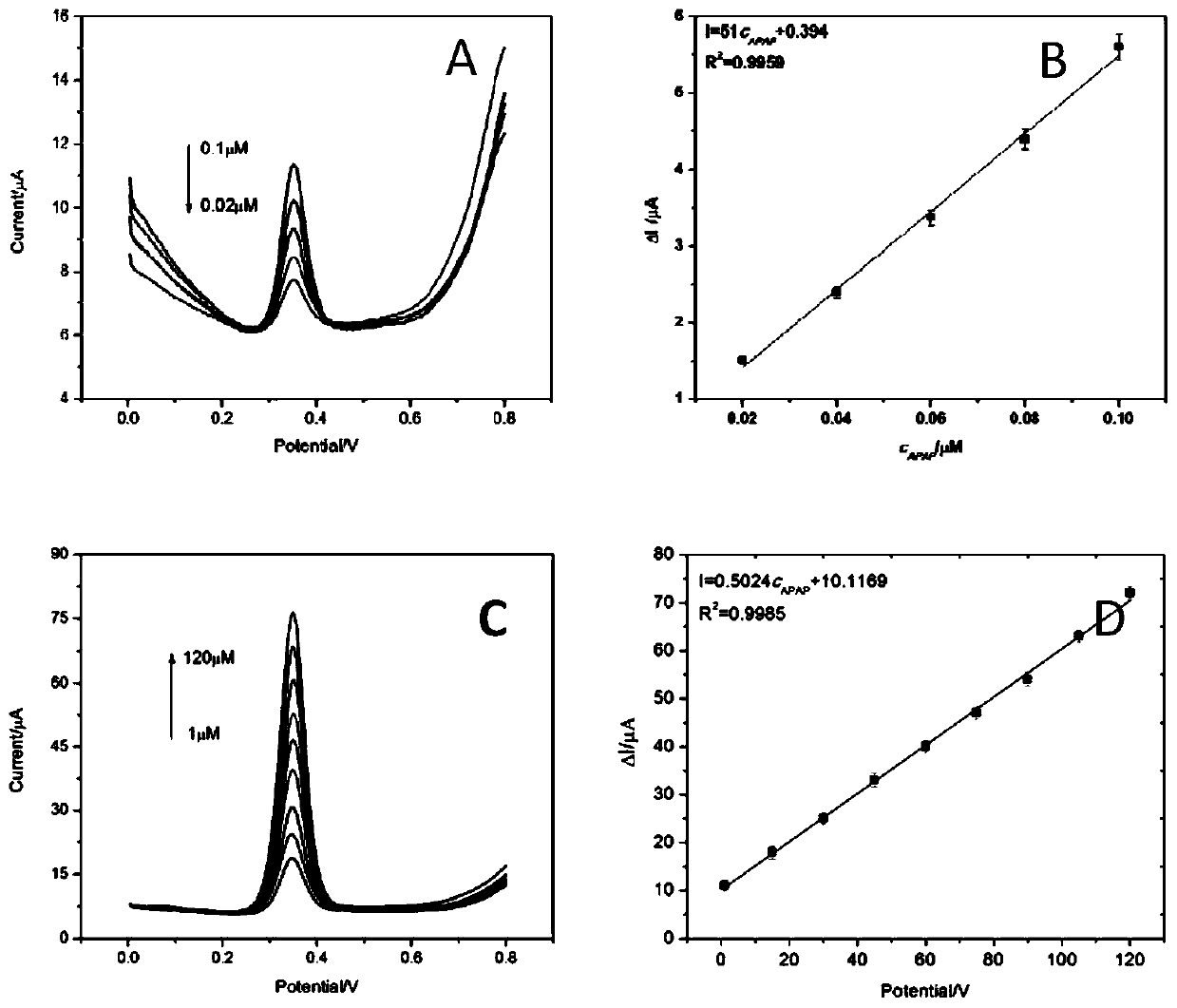

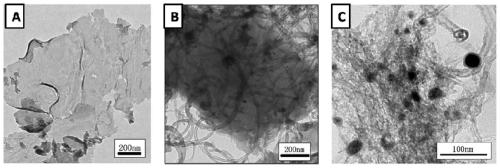

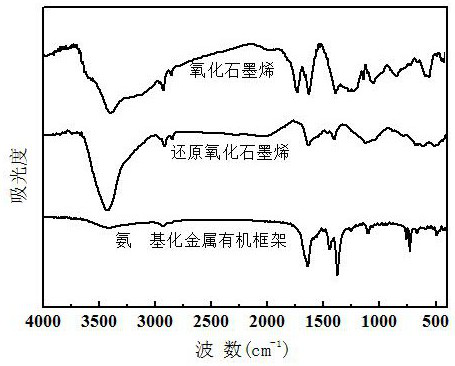

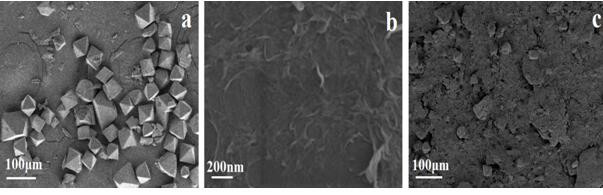

Specific modified electrode based on metal organic framework and preparation and application thereof

ActiveCN110865108AAchieving Simultaneous DetectionWill not interfere with each otherMaterial electrochemical variablesP-acetaminophenolNanoparticle

The invention provides a construction method of a specific modified electrode based on a metal organic framework. The preparation method comprises the steps of ultrasonically dispersing an aminated metal organic framework and reduced graphene oxide into N, N-dimethylformamide, and dropwise coating a dispersion liquid on the surface of a polished glassy carbon electrode to prepare a modified electrode rGO-NH2-Cu3(btc)2 / GCE; forming a three-electrode system by taking the rGO-NH2-Cu3(btc)2 / GCE modified electrode as a working electrode; putting the electrode into an H2SO4 solution containing HAuCl4; and depositing the gold nanoparticles on the surface of the electrode by adopting a potentiostatic deposition method, so as to prepare the specific modified electrode Au / rGO-NH2-Cu3(btc)2 / GCE. Themodified electrode can completely separate oxidation peaks of acetaminophen and p-aminophenol, so that simultaneous detection of acetaminophen and p-aminophenol is realized. The detection method is rapid, simple and convenient, and has good anti-interference performance and stability.

Owner:NORTHWEST NORMAL UNIVERSITY

Abscission and crop storage unit

InactiveUS20120101164A1Delaying abscissionDelaying senescenceBiocideOrganic chemistryMetaboliteToxicology

A composition comprising a compound selected from an auxin, an auxin precursor, an auxin metabolite or a derivative of said auxin, auxin precursor or auxin metabolite or a mixture thereof and optionally acetaminophen or a derivative thereof for improving post-harvest storability of crops.

Owner:TAMINCO NV

Nano composite material, glassy carbon composite electrode, manufacturing methods of nano composite material and glassy carbon composite electrode, and electrochemical sensor

ActiveCN111793393AHigh sensitivityImprove detection efficiencyMaterial nanotechnologyCoatingsP-acetaminophenolP-Aminophenol

The invention discloses a nano composite material, which is prepared from the following components in parts by mass: 2 to 3 parts of MWNTs, 1 to 1.5 parts of CeO2, 184 to 188 parts of a Nafion solution and 1000 parts of ultrapure water. Compared with the prior art, a proper modification material is provided for a working electrode of an electrochemical sensor for simultaneously detecting acetaminophen and p-aminophenol; the high catalytic activity of CeO2 and Nafion and the synergistic effect of CeO2 and Nafion and MWNTs are utilized, the electron transfer capability is further enhanced, and the sensitivity and detection efficiency during detection of acetaminophen and p-aminophenol are improved.

Owner:CHONGQING UNIV OF EDUCATION

Refined yinqiao detoxication dropping pill

This invention relate to a refined chinese medicine Yinqiao Jiedu pills and preparation for cold therapy, characterized in that Dry Ointment Powder of the water extracts of Platcodon Grandiflorum, forsythia fruit, prepared soybean, Glycyrrhiza, Lophatherum gracile Brongn, honeysuckle, arctium fruit, oil of schizonepeta, Menthol, p-acetaminophenol as Active Constituents are made into pills. The objection of the invention is that it overcomes the deficiency of the present Technology, it discloses remarkable characteristics such as high bioavailability, release drugs quickly, significant curative effect, high drugs content, easy administration, lower price, Non-pollution in production. Said drugs have unique formula with the functions of expelling wind, inducing diaphoresis, clearing away heat. Pharmacodynamic study has verified that the performance of pills is superior to conventional oral preparation of refined Chinese medicine Yinqiao Jiedu tablets and it is worth using widely.

Owner:天津同仁堂集团股份有限公司

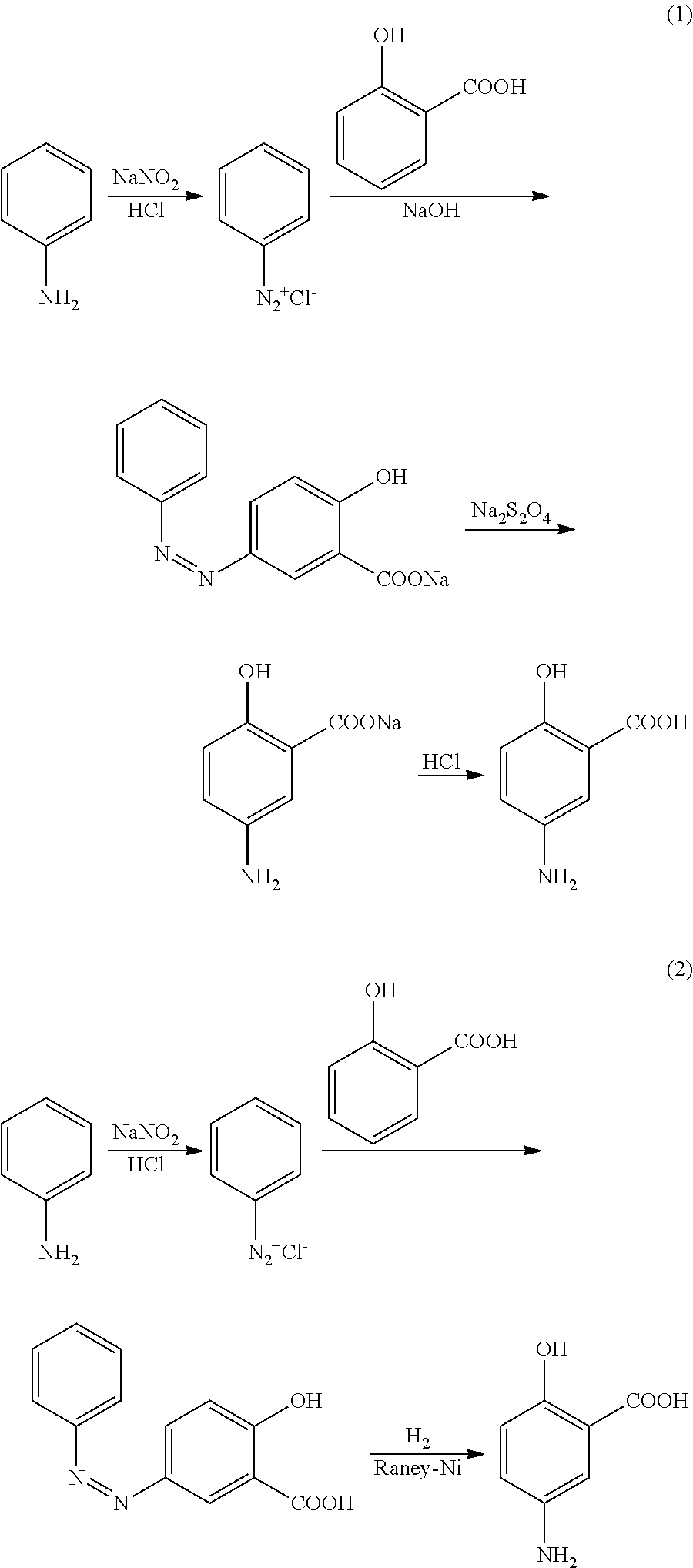

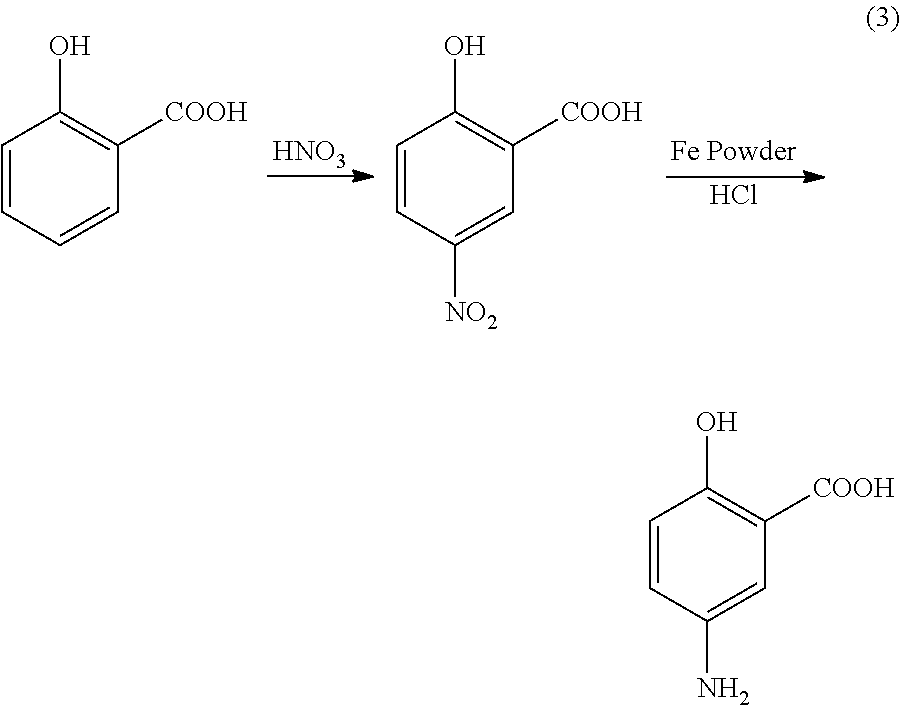

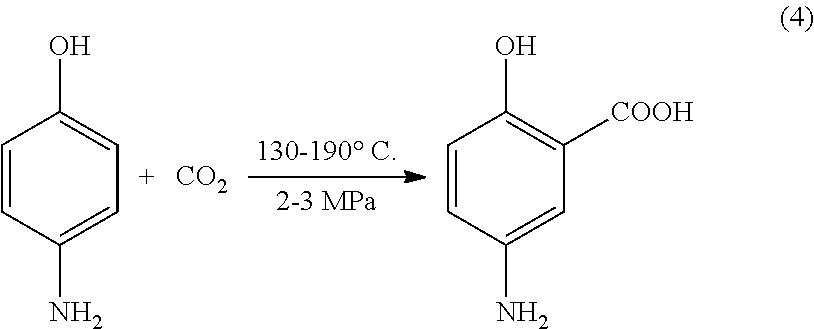

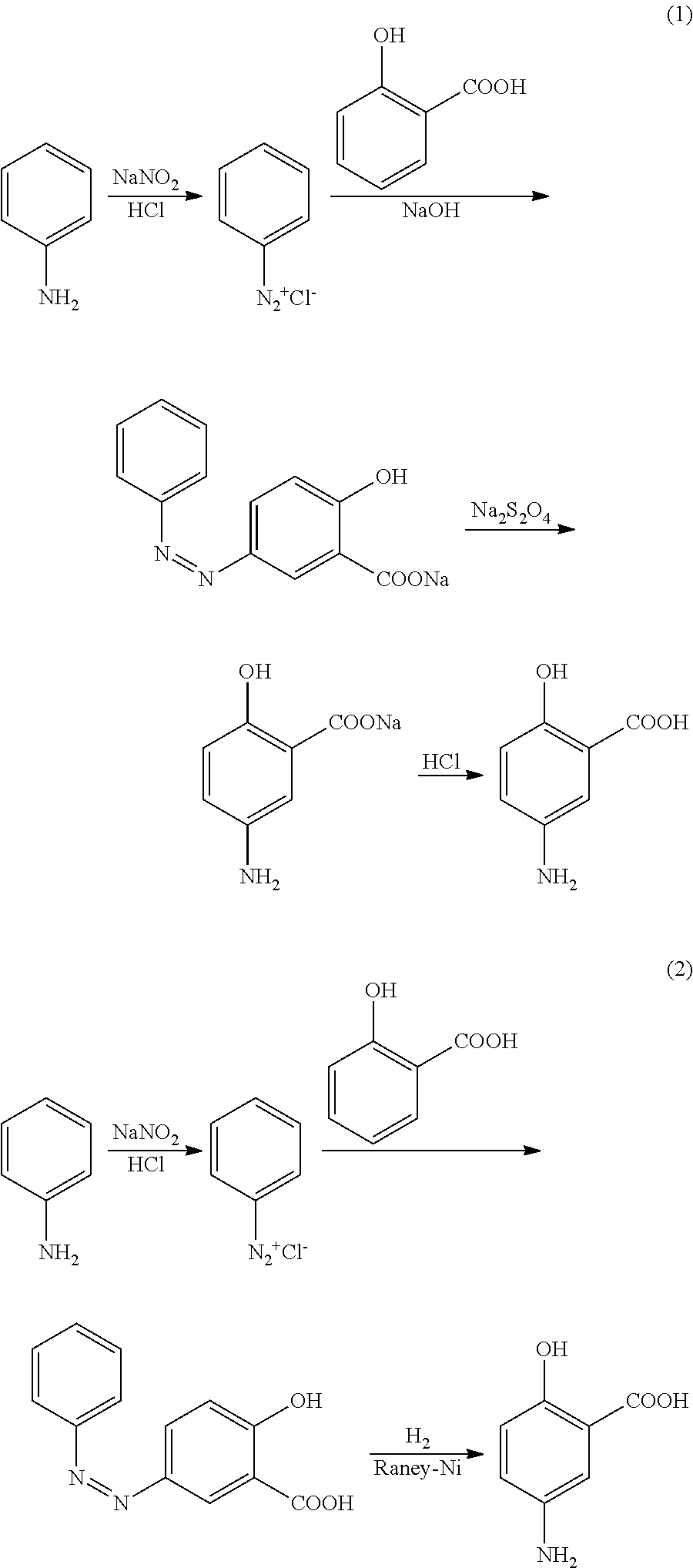

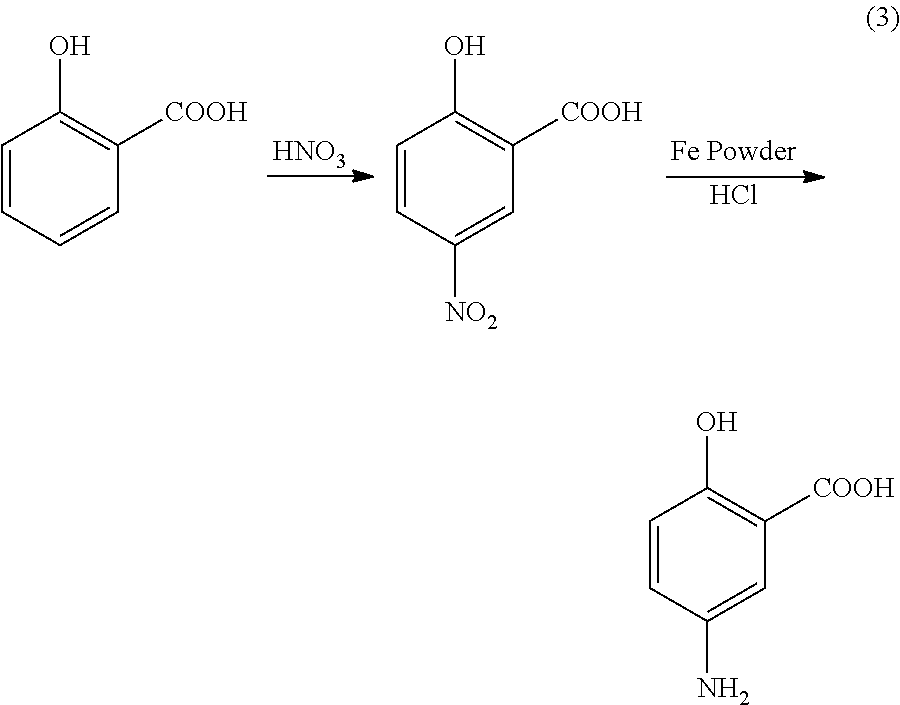

Preparation of 5-aminosalicylic acid by gas phase catalytic carboxylation

ActiveUS20130281730A1Improve catalytic performanceHigh catalytic activityOrganic compound preparationCarboxylic acid amides preparationChemical reactionP-acetaminophenol

Disclosed is a process for preparing 5-aminosalicylic acid by gas phase catalytic carboxylation, characterized in that carbon dioxide is introduced into a system of p-acetaminophenol and a basic compound at a temperature of 150° C.˜220° C. and a pressure of 0.5˜5.0 MPa in the presence of a catalyst, so as to carry out a gas phase catalytic carboxylation reaction to form a 5-aminosalicylate, and the crude product 5-aminosalicylate is separated, and then acidified to prepare 5-aminosalicylic acid (5-ASA). Since the gas phase catalytic reaction replaces a solid phase thermo-chemical reaction, the reaction is significantly improved in terms of the process flow, reaction conditions, product quality and energy consumption. In addition, the reaction has a short reaction time, good selectivity, high yield and no formation of wastes during the reaction, and is suitable for industrial production.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD +1

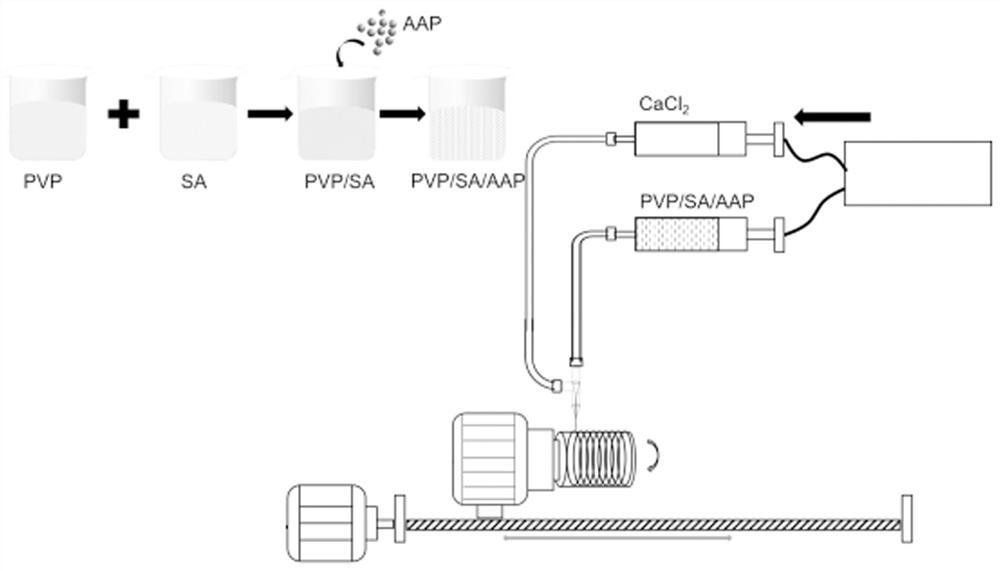

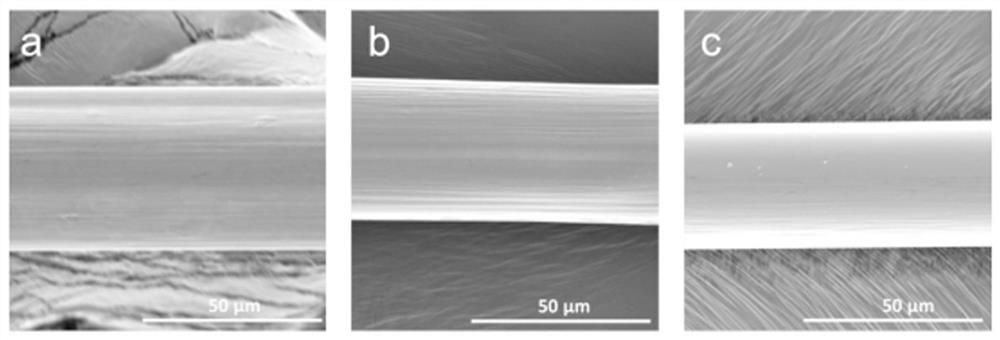

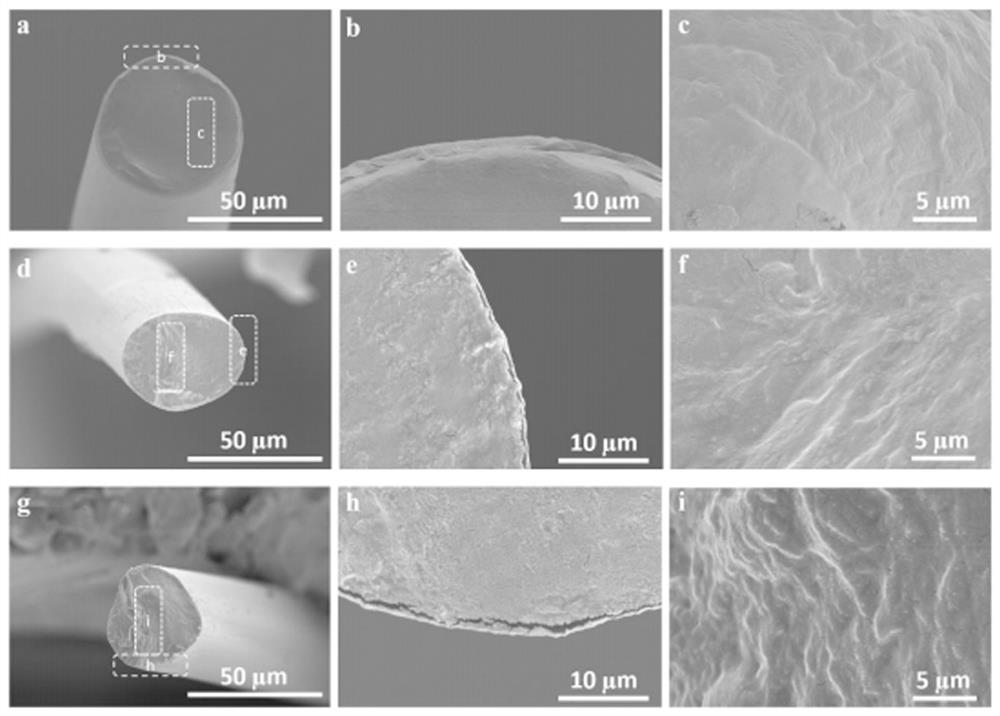

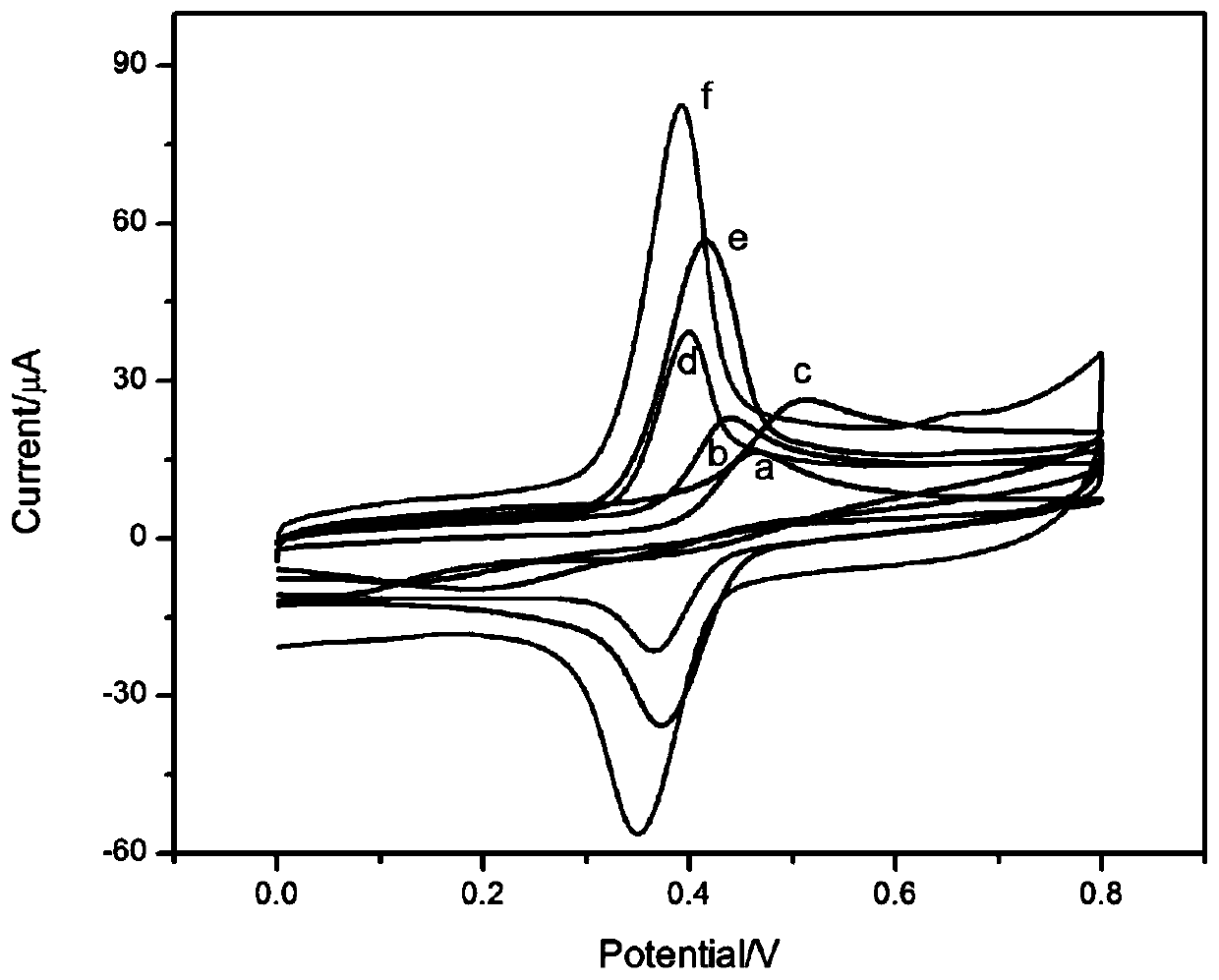

Preparation method of composite drug-loaded fiber based on microfluidics spinning

PendingCN114351287AHigh drug loadingTo achieve drug sustained release effectOrganic active ingredientsFilament/thread formingFiberPolymer science

The invention discloses a preparation method of a composite drug-loaded fiber based on microfluid spinning, which comprises the following steps: A1, taking polyvinylpyrrolidone and sodium alginate, respectively adding water, stirring and heating to obtain a polyvinylpyrrolidone solution and a sodium alginate solution; a2, mixing the polyvinylpyrrolidone solution and the sodium alginate solution, and then adding acetaminophen to form a mixed spinning solution; and A3, taking the mixed spinning solution as a core layer, taking a calcium chloride solution as a sheath flow laminar flow, and preparing the continuous composite drug-loaded fiber in a coaxial microfluid spinning mode. The microfluid spinning technology and the ionic cross-linking curing method are combined to prepare the composite drug-loaded fiber which is neatly arranged and uniform in diameter, the drug loading capacity of the composite drug-loaded fiber is improved, and the drug slow-release effect of the composite drug-loaded fiber is achieved.

Owner:SUZHOU UNIV

Preparation of 5-aminosalicylic acid by gas phase catalytic carboxylation

ActiveUS9067867B2Short reaction timeHigh yieldOrganic compound preparationCarboxylic acid amides preparationChemical reactionP-acetaminophenol

Owner:ZHEJIANG HUAHAI PHARMA CO LTD +1

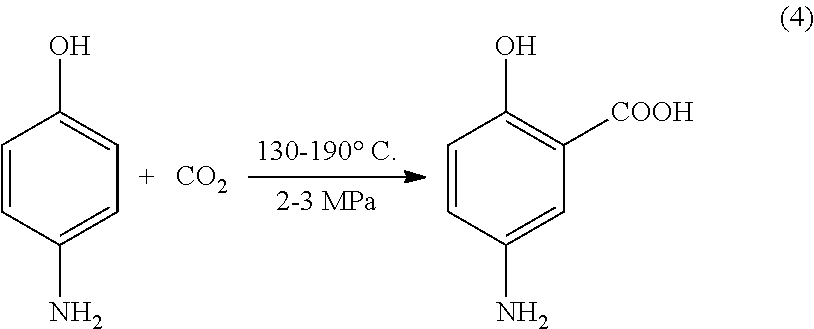

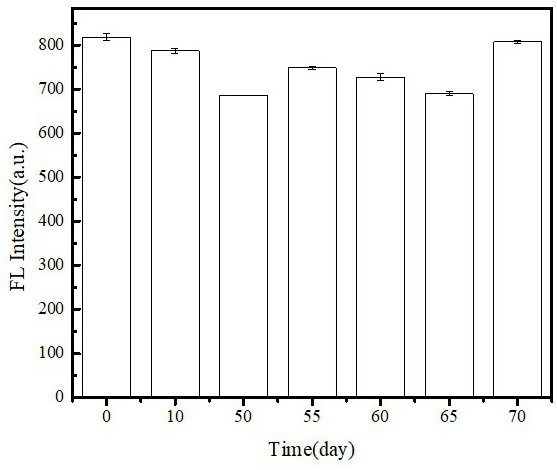

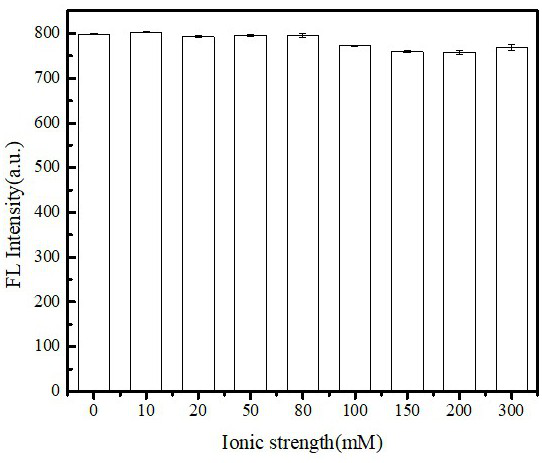

A preparation method of water-soluble fluorescent silicon quantum dots and its application in the selective detection of p-nitrophenol

ActiveCN110511745BThe synthesis method is simpleMild conditionsNanoopticsFluorescence/phosphorescenceQuantum yieldP-acetaminophenol

The invention belongs to the field of fluorescent functional materials, in particular to a water-soluble silicon quantum dot and its preparation method, and its application in the high-sensitivity and high-selectivity detection of p-nitrophenol. The key points of the technical scheme of the present invention are: 3-aminopropyltriethoxysilane is added to ultrapure water at 85°C and vigorously stirred for 10 minutes, then added with acetaminophen solution, and continuously stirred for 5 hours. The silicon quantum dot synthesis method of the invention is simple and convenient, has mild reaction conditions, high quantum yield, good water solubility, long-term storage, and can maintain excellent fluorescence performance even under different pH and different ion strength conditions. The silicon quantum dot emits 495nm fluorescence under excitation of 398nm fluorescence, and p-nitrophenol can specifically quench the fluorescence of the silicon quantum dot. The silicon quantum dot of the present invention shows good application prospects in the aspects of fast, efficient, high selectivity and high sensitivity detection of p-nitrophenol.

Owner:HENAN NORMAL UNIV

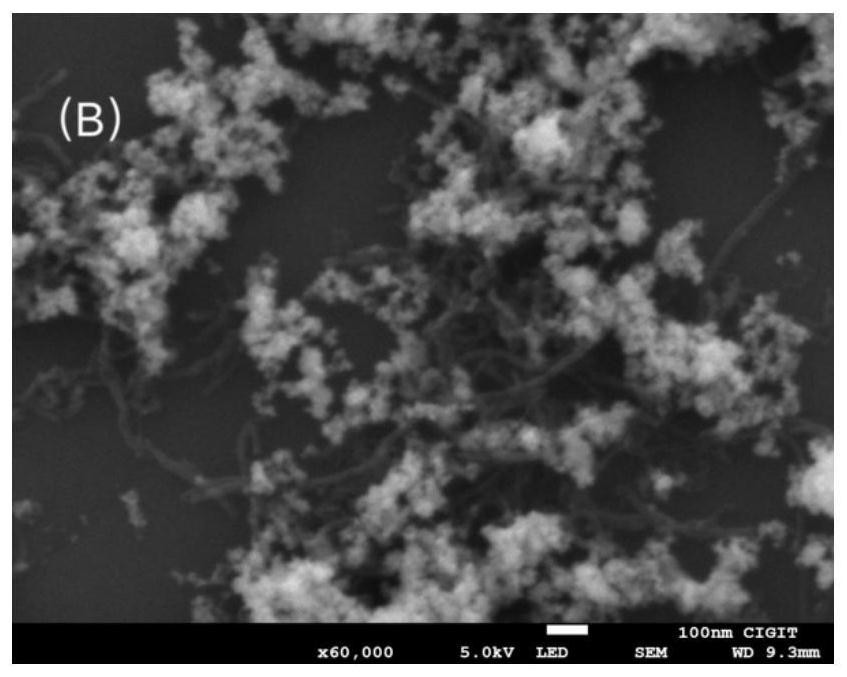

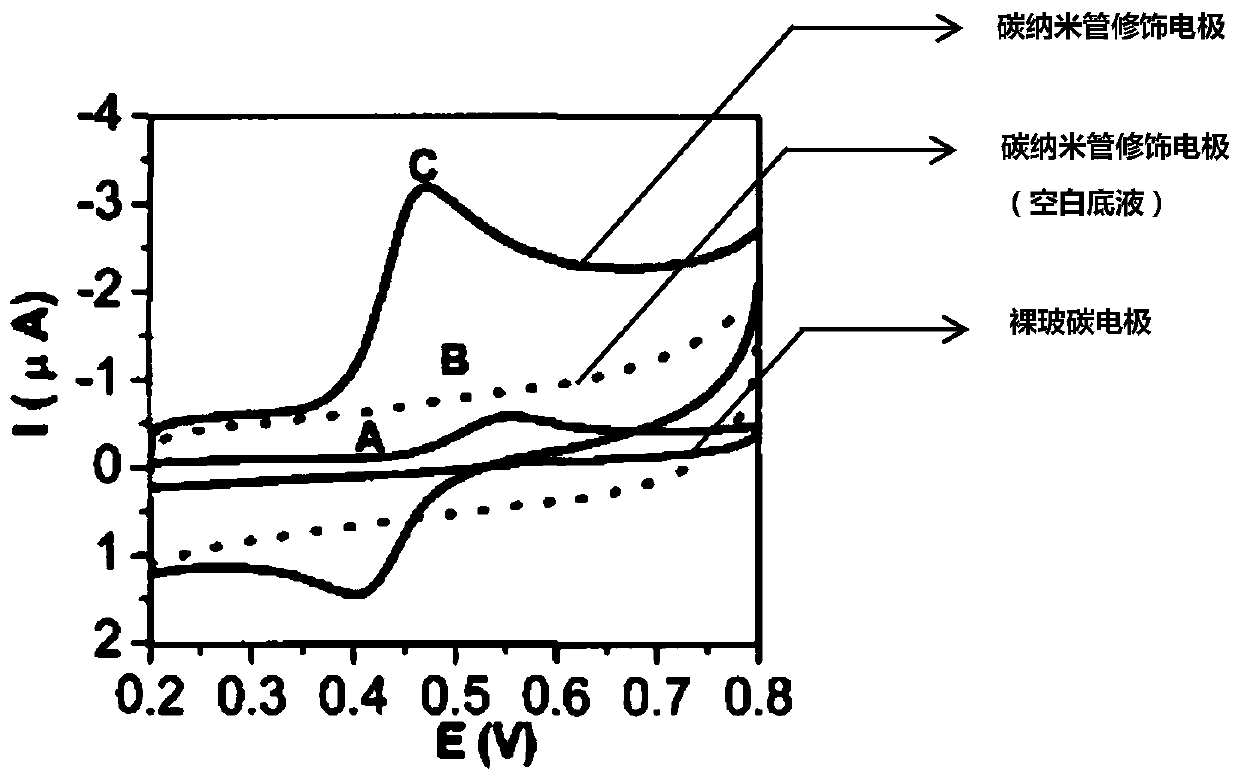

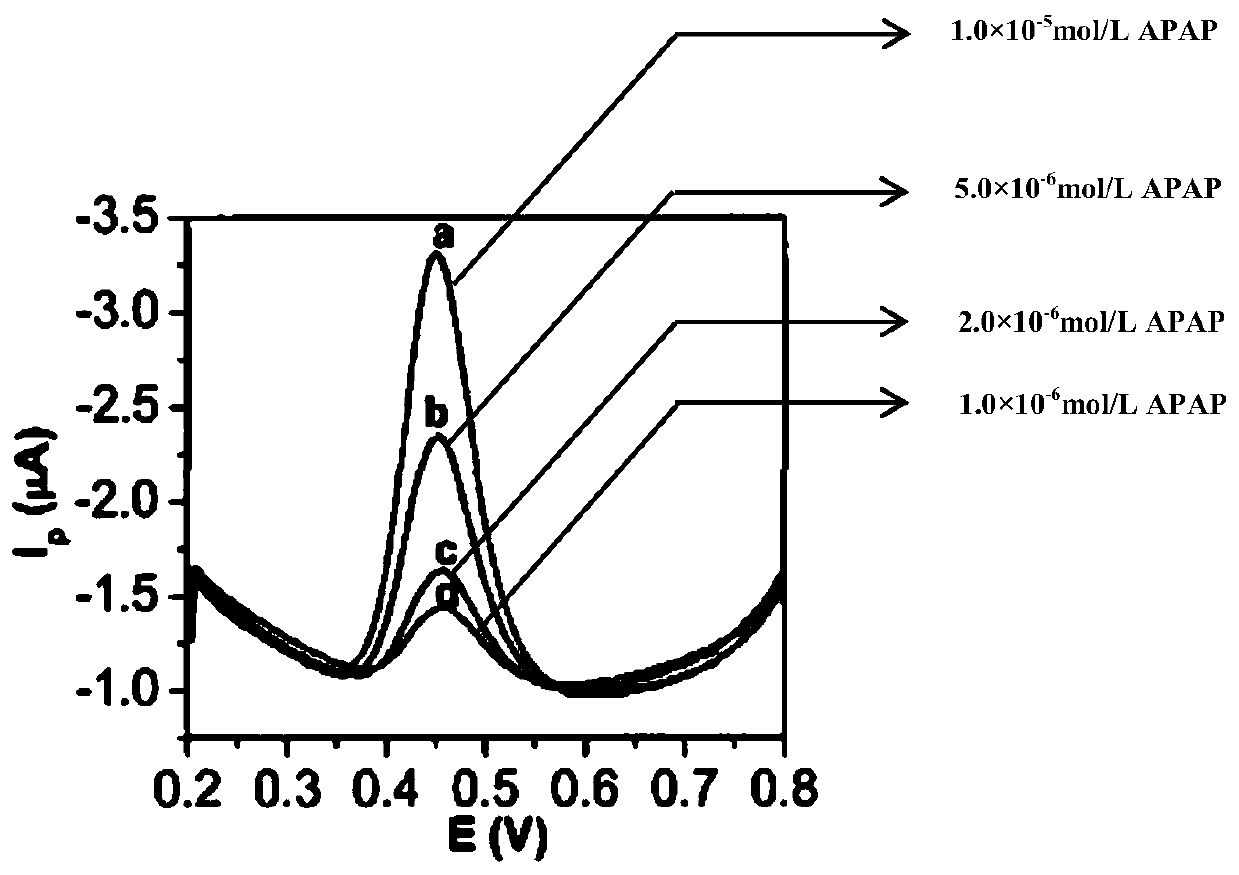

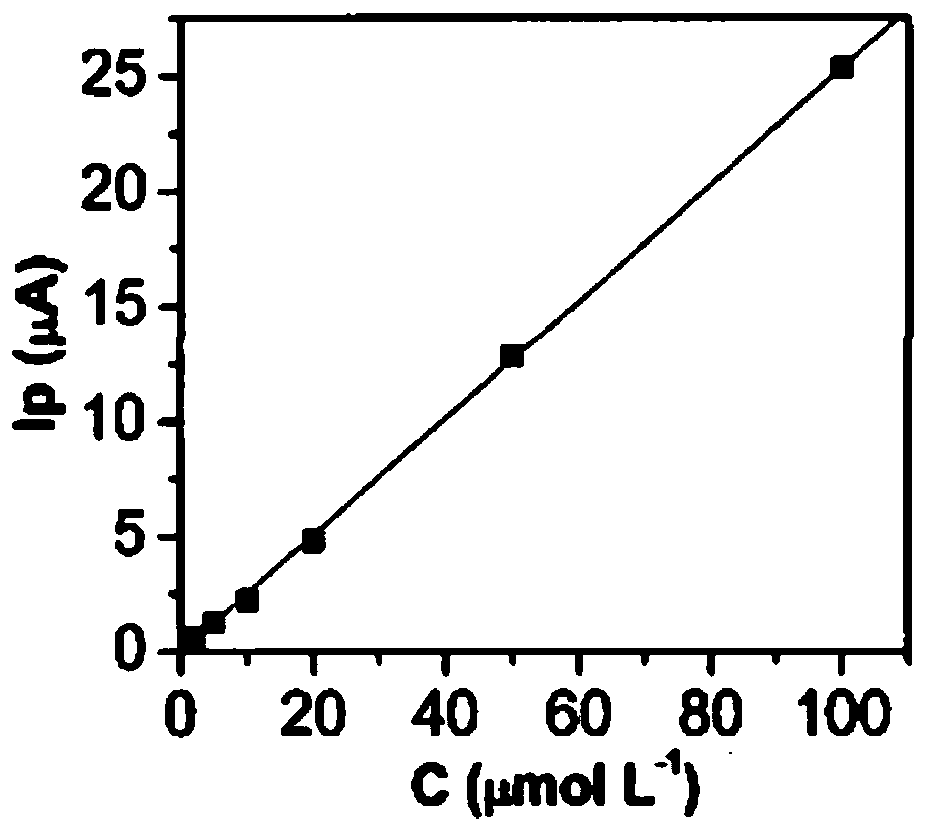

Carbon nanotube modified electrode for acetaminophen detection and preparation method of carbon nanotube modified electrode

PendingCN111505074AHigh sensitivityLow detection limitMaterial electrochemical variablesInterference resistanceP-acetaminophenol

The invention provides a carbon nanotube modified electrode for acetaminophen detection and a preparation method of the carbon nanotube modified electrode. Specifically, the surface of a glassy carbonelectrode is modified with carbon nanotubes, and the glassy carbon electrode is prepared into a detection electrode with three coplanar electrodes, so that accurate determination of acetaminophen isrealized. The carbon nano tube modification layer greatly improves the detection sensitivity and accuracy of the electrode; the electrode has the advantages of high sensitivity, low detection limit, good reproducibility, strong anti-interference capability and the like, the linear range of the electrode for determining acetaminophen is 1.0 * 10 <-4 >-1.0 * 10 <-7 > mol / L, and the detection limit of the electrode is 3.68 * 10 <-8 > mol / L.

Owner:广州钰芯传感科技有限公司

Acetaminopher DC90 fine particle and preparation method thereof

ActiveCN100569227CFine and uniform particlesWell mixedOrganic active ingredientsPowder deliveryCrospovidonesP-acetaminophenol

The invention discloses paracetanol DC90 fine particles and a preparation method thereof. The paracetanol DC90 comprises following materials by weight ratio: 90 percent of paracetanol, 3.50 percent of cornstarch, 3.50 percent of pre gelatinized starch, 2.00 percent of povidone, 0.5 percent of crospovidone and 0.5 percent of stearic acid. Firstly, the paracetanol and the cornstarch are mixed evenly, then the pre gelatinized starch and the povidone are made into starch slurry to be used as bond which is evenly sprayed on the mixture of the fluidied paracetanol and cornstarch, fluidized bed granulation is carried out in the inlet air temperature, the wet particles are dried under the temperature of 80 DEG C and then are cooled at the temperature of 50 DEG C till water conforms to the requirement, the sizes of the particles are adjusted, the stearic acid and the crospovidone are added after the particle sizes are adjusted to be mixed evenly to obtain the paracetanol DC90 fine particles. The invention adopts the above technical proposal to inspect the product, and the particles are fine and uniform and have favorable fluidity, thereby being well and evenly mixed with other small quantities of active components powder.

Owner:ANQIU LUAN PHARMA

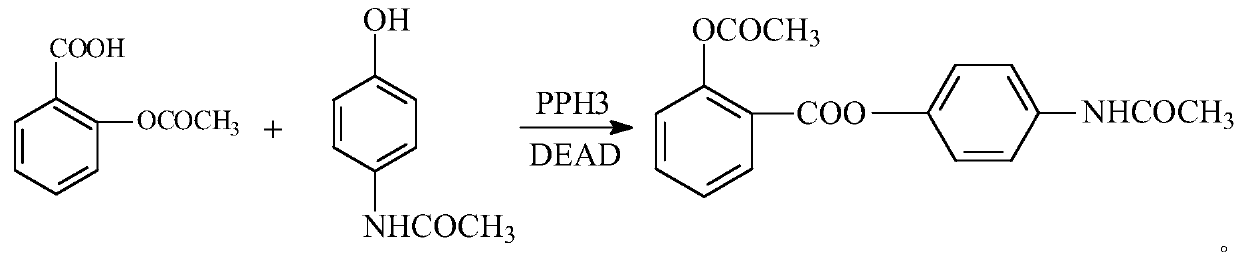

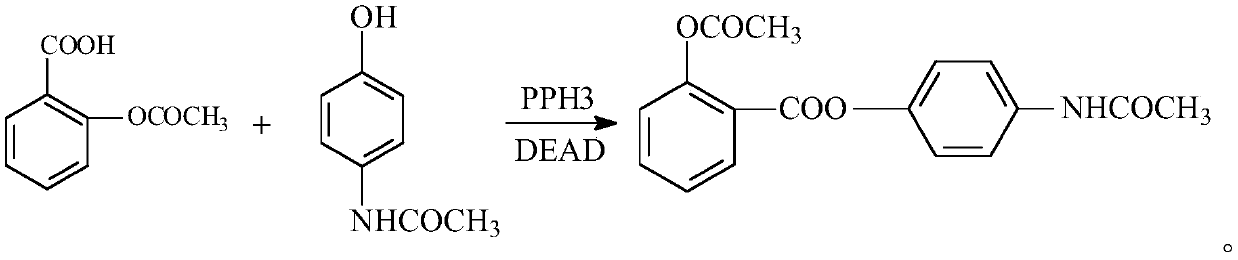

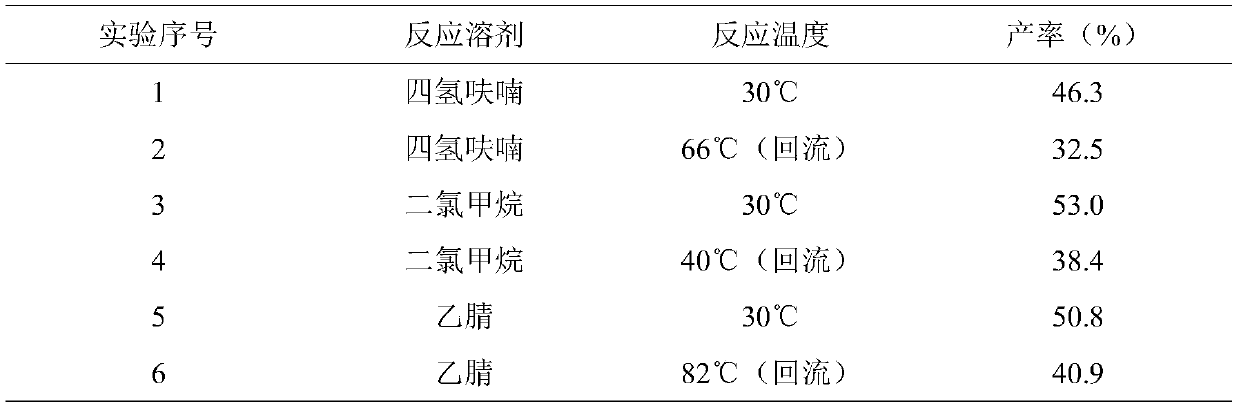

Preparation method of benorilate

ActiveCN111056968ASimple stepsShort process routeOrganic compound preparationCarboxylic acid amides preparationPtru catalystP-acetaminophenol

The invention relates to a preparation method of benorilate, which relates to the technical field of medicine synthesis. According to the invention, acetylsalicylic acid and acetaminophen are used asraw materials to directly synthesize behenolate under the condition of common catalysis of azodicarboxylic acid ester compounds and triphenylphosphine. The preparation method comprises the following steps: adding acetaminophen and a light-delay reaction catalyst I triphenylphosphine into a reaction bottle, adding an organic solvent, adding a light-delay reaction catalyst II, and uniformly mixing;and adding acetylsalicylic acid in batches within 20 minutes, stirring in an ice bath for 20 minutes, heating to normal temperature, magnetically stirring, and reacting for 8.5 hours to obtain the benorilate. According to the present invention, the acetylsalicylic acid and the p-acetamidophenol are catalyzed by using a light delay reaction catalysis system so as to be esterified, such that the steps are simple, the drugs only need to be sequentially added, the process route is short, and the synthesis cost is effectively reduced.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Anti-cold pharmaceutical composition and preparation method thereof

ActiveCN102973856BLong-lasting antipyretic and analgesic effectsNo obvious gastrointestinal irritationAntiviralsRespiratory disorderStemona japonicaClemastine Fumarate

The invention relates to an anti-cold pharmaceutical composition and a preparation method thereof. The pharmaceutical composition comprises the following pharmaceuticals: p-acetamidophenol, clemastine fumarate, folium isatidis, schizonepeta and stemona japonica. The anti-cold pharmaceutical composition is obvious in curative effect, low in cost and capable of providing a selection of treatment pharmaceuticals.

Owner:蚌埠丰原涂山制药有限公司

Preparation method of paracetamol-loaded nanofiber composite material

ActiveCN107550893BAchieve sustainable developmentProtect environmentOrganic active ingredientsAntipyreticP-acetaminophenolCaprolactone

The invention discloses a preparation method of a paracetamol-loaded nano-fiber composite material. The method comprises the following steps: performing grafting reaction on nano-fiber and epsilon-caprolactone to obtain a nano-fiber composite material; dissolving 10 to 35 parts by weight of nano-fiber composite material in 80 parts by weight of acetonitrile under an ultrasonic action to obtain a first mixed solution; dissolving 1 to 3 parts by weight of paracetamol in 80 parts by weight of tetrahydrofuran under an ultrasonic action to obtain a second mixed solution; mixing the first mixed solution with the second mixed solution to obtain a third mixed solution; evaporating and drying the third mixed solution to obtain the paracetamol-loaded nano-fiber composite material. The nano-fiber composite material is prepared from banana stalks as a raw material, and is taken as an introduction carrier of paracetamol, so that sustainable development of resources is realized; moreover, banana fiber is introduced into the nanometer material, so that efficient and cheap medicines can be prepared, and a good economic benefit is achieved.

Owner:GUANGXI TEACHERS EDUCATION UNIV

A kind of regeneration method of deactivated activated carbon in paracetamol refining stage

ActiveCN108554395BReduce recycling costsEasy to operateCarboxylic acid amide separation/purificationCombustible gas purificationActivated carbonP-acetaminophenol

The invention relates to a regeneration method of inactivated activated carbon in a refining stage of acetaminophen. The method comprises an alcohol-alkali desorption stage, a water scrubbing stage, an acid pickling stage and a drying and activating stage. The method has the characteristics of low regeneration cost, simple operation, high regeneration rate, and high economic benefits; almost no carbon is loss in the regeneration process and mechanical property of the activated carbon is not damaged in the regeneration process; the solvent can be recycled for many times and causes no secondarypollution; and the regenerated activated carbon can adsorb 250-285mg / g of methylene blue, and meets the process requirement of the refining and impurity removal stage of acetaminophen on the activatedcarbon.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

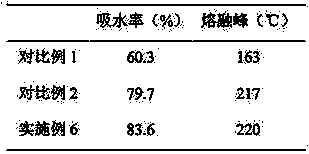

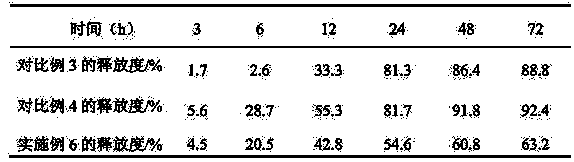

Preparation process of p-acetaminophenol

InactiveCN101298425BSimple processMild reaction conditionsOrganic compound preparationCarboxylic acid amides preparationIce waterP-acetaminophenol

The invention provides a preparation technique of p-acetaminophenoxide; the technique includes the following steps: adding phenol, oxammonium hydrochloride, acetic acid and polyphosphate with mass ratio of 1 : 0.85 : 3.0 : 8.5 to 1 : 0.96 : 4.1 : 9.6 into a reactor and sealing the reactor; carrying out reflux reaction for 3.0 to 5.2h under normal pressure and constant temperature in an oil bath of 75 to 85 DEG C; cooling to the temperature of 20 to 30 DEG C; adding ice water of 10 to 15 times of the volume of the mixed matters into the reactor and adjusting pH to 3.5 to 4.5 by using ammonia; adding nitrogen into the reactor to replace air; adding sodium bisulfite of 1 to 2 times of the weight of phenol and then sealing the reactor, continuously carrying out reaction for 5.0 to 7.2h under the normal pressure and constant temperature in the oil bath of 110 to 132 DEG C, cooling, decompressing and vaporizing the solvent water, then using acetone to wash so as to filter out ammonium phosphate salt, combing the filtrate, vaporizing and recycling the acetone to obtain the crude product, using water to re-crystallize to obtain the white crystal of the p-acetaminophenoxide. The preparation technique of the invention takes the phenol, glacial acetic acid and the oxammonium hydrochloride as the raw materials, takes the polyphosphate as a catalyst, adopts one pot method to prepare the p-acetaminophenoxide and has the advantages of simple technique, mild reaction conditions, low manufacture cost and being environment friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

A copper oxide/carbon nanotube/carbon nitride electrochemical sensor for detecting paracetamol and its preparation method and application

ActiveCN109298049BIncrease surface areaImprove conductivityMaterial electrochemical variablesCarbon compositesP-acetaminophenol

Owner:QINGDAO UNIV

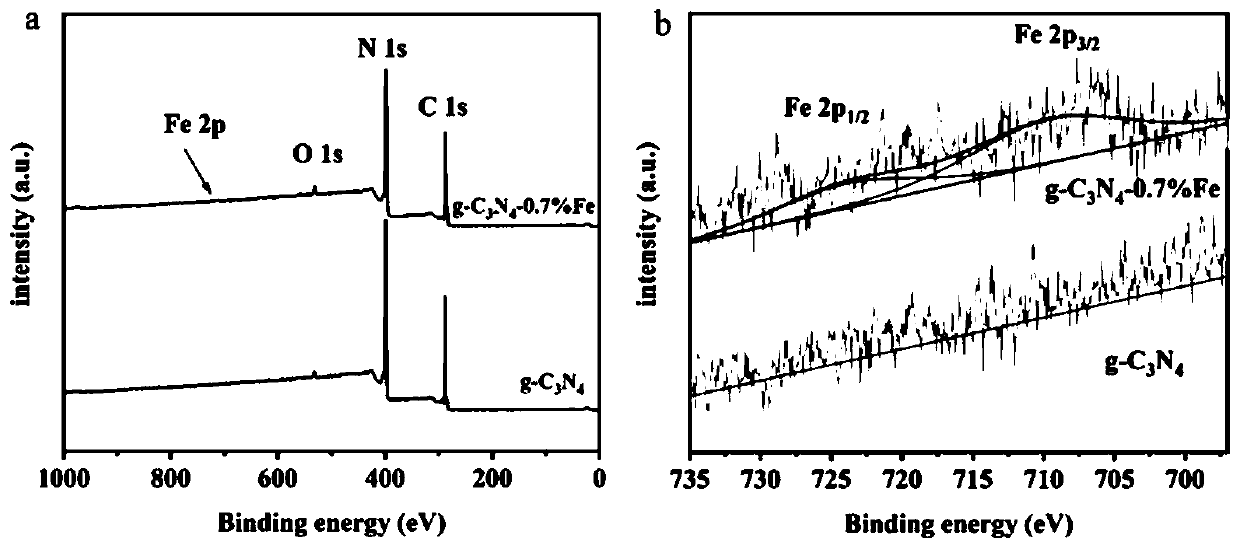

A specific modified electrode based on metal organic framework and its preparation and application

ActiveCN110865108BAchieving Simultaneous DetectionWill not interfere with each otherMaterial electrochemical variablesP-acetaminophenolMetal-organic framework

The invention provides a method for constructing a metal-organic framework-based specific modified electrode, which is to ultrasonically disperse an aminated metal-organic framework and reduced graphene oxide in N,N-dimethylformamide, and make the dispersion The modified electrode rGO‑NH was prepared by drop-coating on the surface of the polished glassy carbon electrode 2 -Cu 3 (btc) 2 / GCE; with rGO‑NH 2 -Cu 3 (btc) 2 / GCE modified electrode is the working electrode to form a three-electrode system; insert HAuCl 4 H 2 SO 4 In the solution, the gold nanoparticles were deposited on the electrode surface by the potentiostatic deposition method, and the specifically modified electrode Au / rGO‑NH 2 -Cu 3 (btc) 2 / GCE. The modified electrode can completely separate the oxidation peaks of acetaminophen and para-aminophenol, and realize the simultaneous detection of the two; moreover, the detection method is fast and simple, and has good anti-interference and stability.

Owner:NORTHWEST NORMAL UNIVERSITY

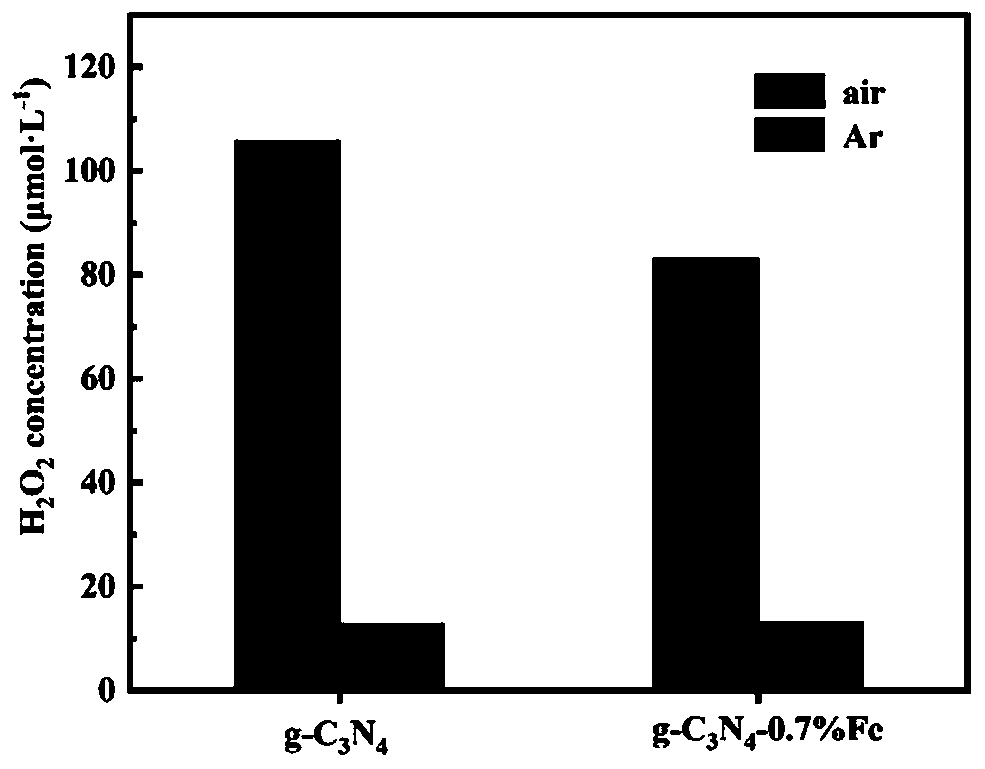

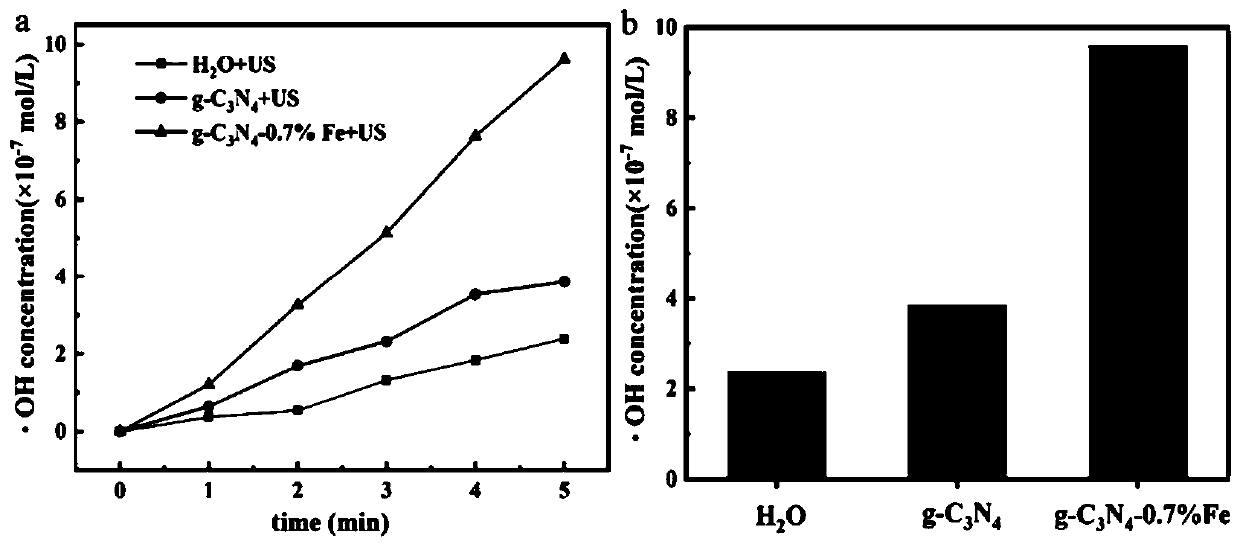

Method for removing acetaminophen in water based on in-situ Fenton reaction

ActiveCN111573817AEfficient removalEliminate damageWater treatment compoundsWater contaminantsP-acetaminophenolUltraviolet lights

The invention discloses a method for removing acetaminophen in water based on an in-situ Fenton reaction, and belongs to the field of treatment of pollutants in water. The method comprises A) a step of synthesis of iron-doped graphite phase carbon nitride, namely a step of calcining a mixture of ferric ions and melamine at high temperature, washing and drying; B) a step of ultrasonically activating to remove acetaminophen, namely a step of adding iron-doped graphite phase carbon nitride into polluted water containing acetaminophen, ultrasonically activating to generate hydrogen peroxide and hydroxyl free radicals, and oxidizing and degrading the acetaminophen. The method is simple to operate, does not need to introduce ultraviolet light or additionally add hydrogen peroxide or other oxidants, and has the advantages of high removal efficiency and wide application conditions.

Owner:湖北省水利水电科学研究院 +1

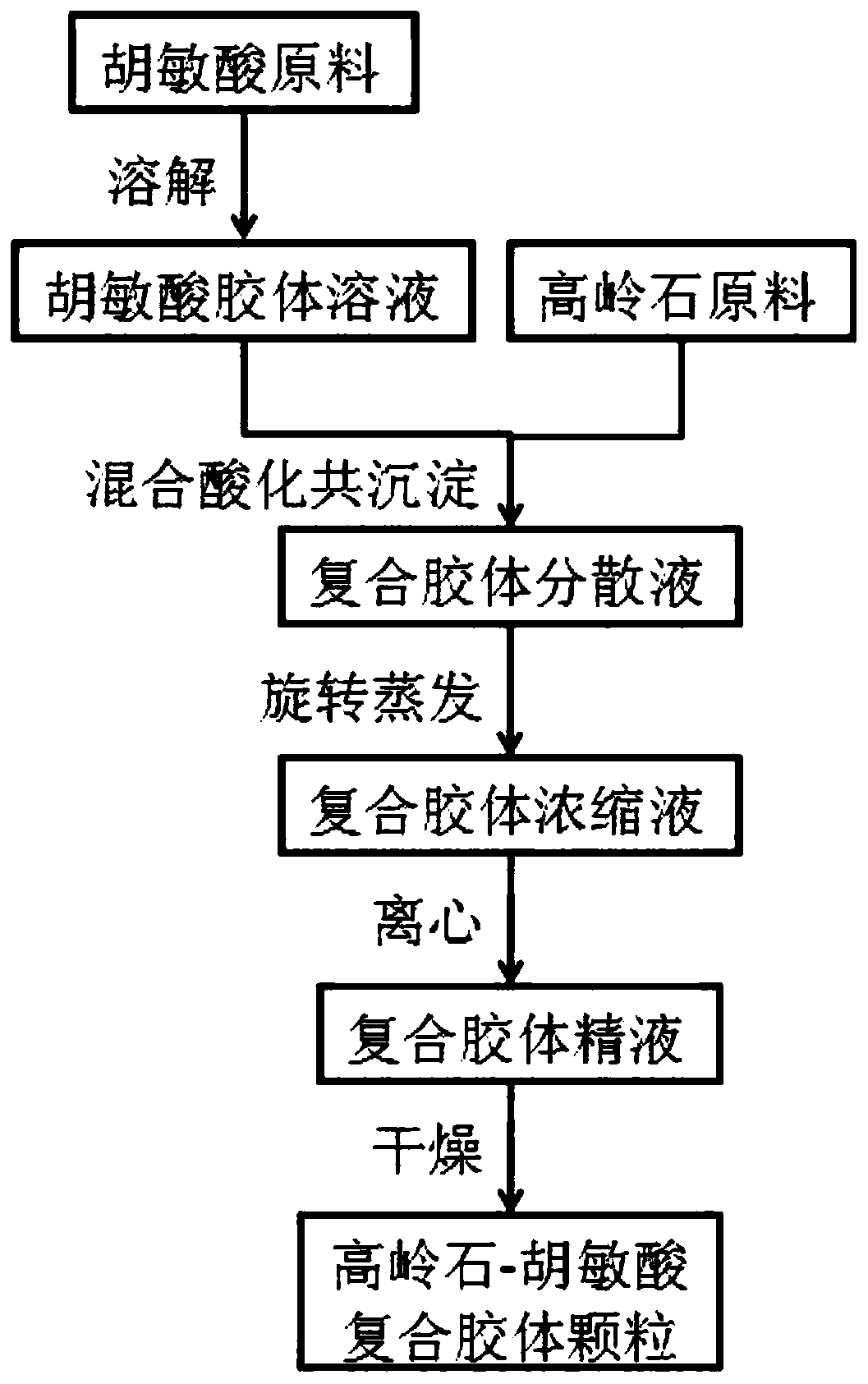

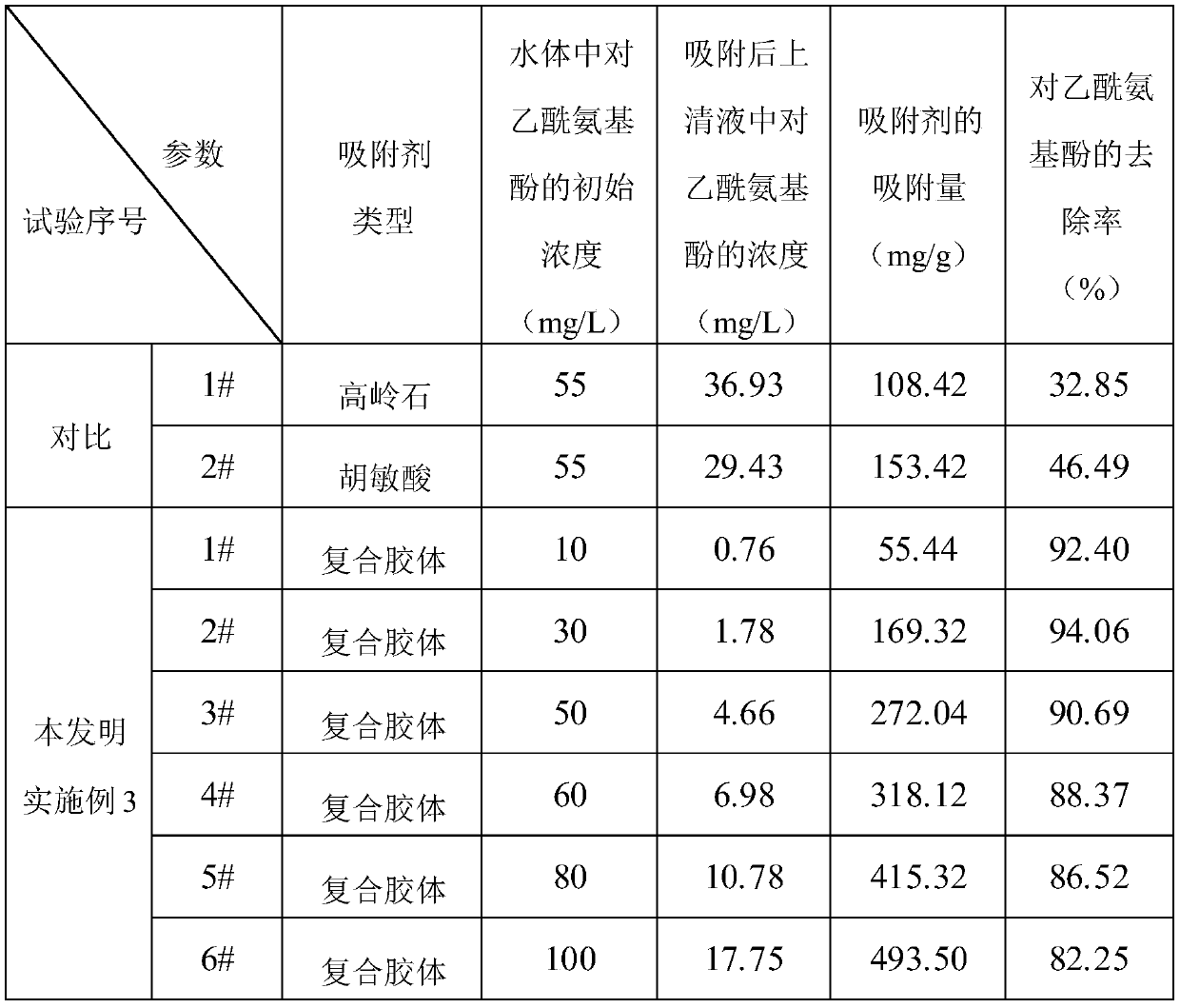

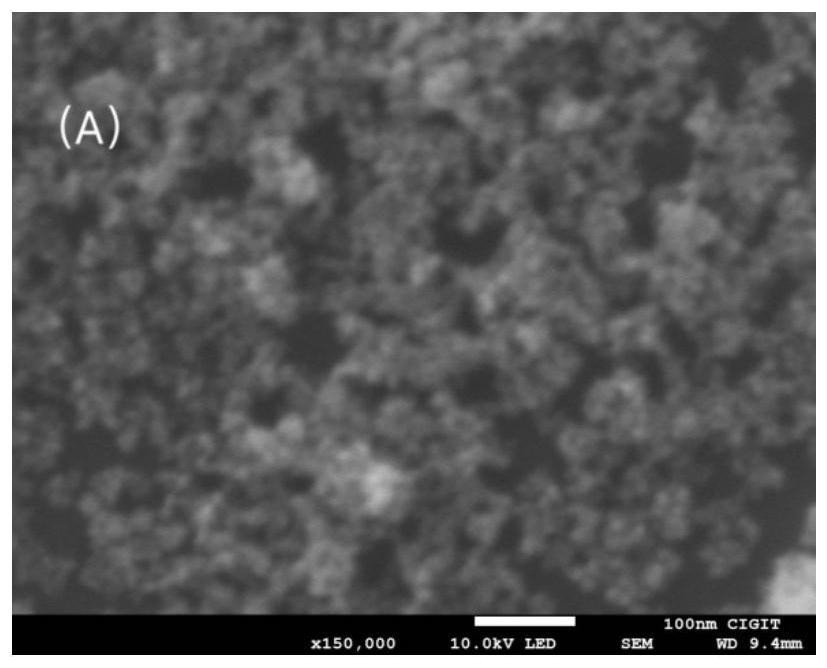

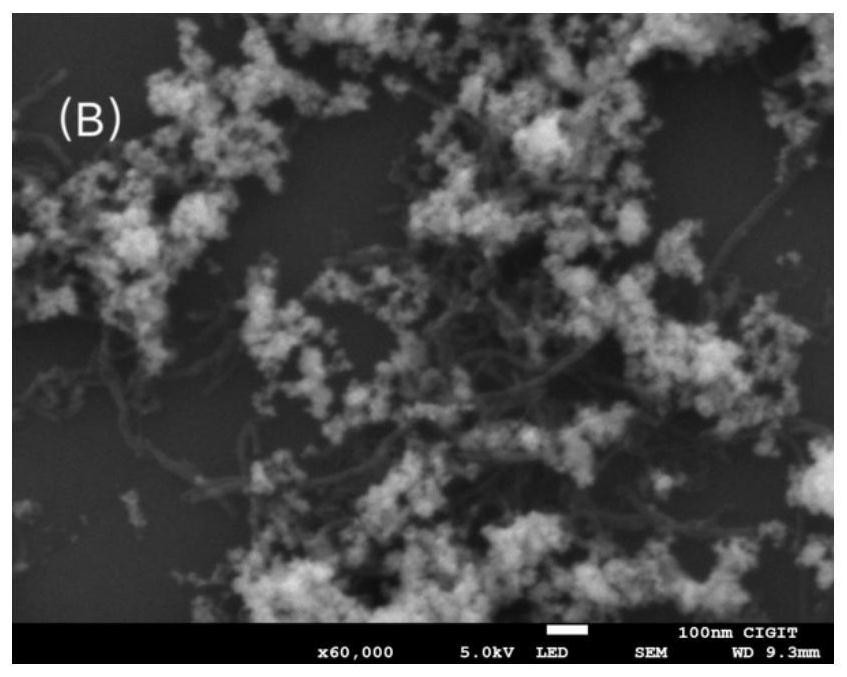

A kind of kaolinite-humic acid composite colloid preparation method for adsorbing acetaminophen

ActiveCN107282017BWide variety of sourcesLow costOther chemical processesAlkali metal oxides/hydroxidesP-acetaminophenolKaolinite

The invention discloses a preparation method of kaolinite-humic acid composite colloid for absorbing acetaminophen. The kaolinite-humic acid composite colloid is prepared by taking kaolinite and humic acid as a main raw material, mixing the humic acid colloid solution with quantified montmorillonite, and performing a series of post treatment steps with specific parameters. Through specific technical parameters, the kaolinite is organically compounded with humic acid together to obtain the absorbent material taking kaolinite as a wall material and the humic acid as the core material. The kaolinite-humic acid composite colloid has very high specific area and special charge property, and can provide enough absorbing site, thereby increasing the absorption capacity of the acetaminophen.

Owner:BAOJI UNIV OF ARTS & SCI

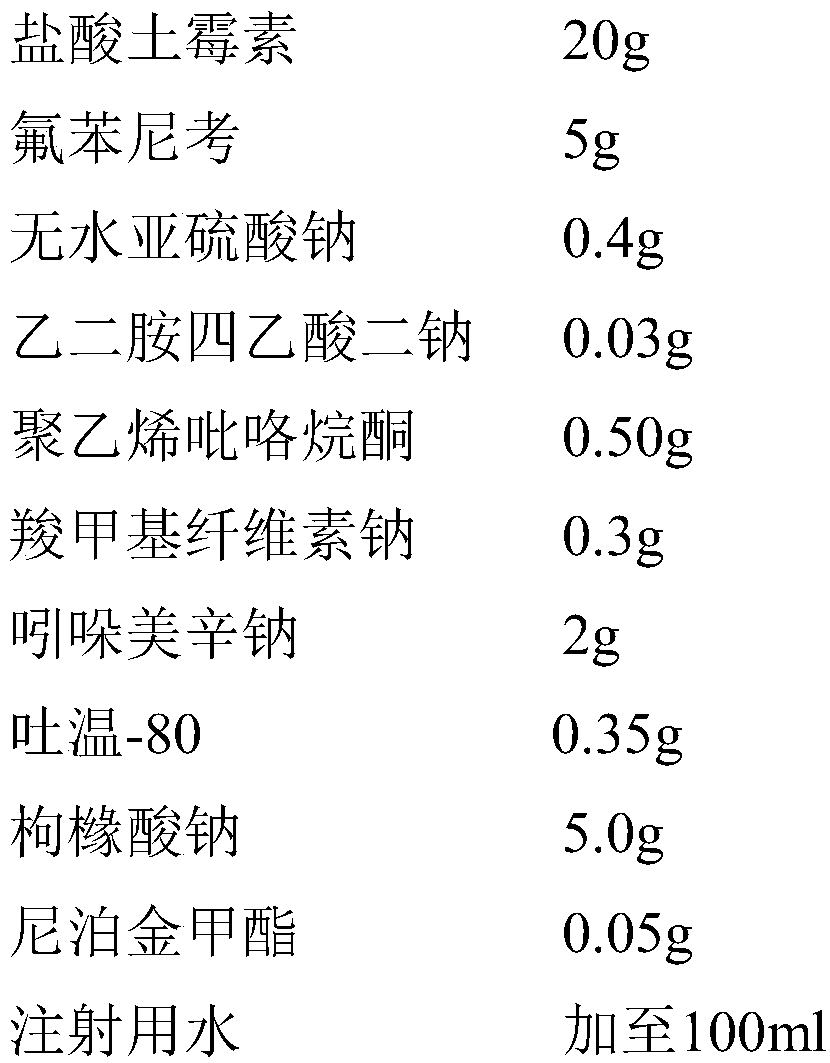

P-ethyl phenol aminophenol anal injection for children and its prepn

InactiveCN1506045ALow toxicityAvoid painOrganic active ingredientsAntipyreticDiseaseP-acetaminophenol

The present invention is p-acetaminophenol anal injection as antipyretic analgesic for children and its preparation process. P-acetaminophenol anal injection consists of p-acetaminophenol as main material, supplementary material including propylene glycol, polyglycol-400, sodium bisulfite, Nipagin M and complexone III, and water. The medicine is injected into rectum directly and this can avoid pain and direct influence on liver, resulting in lowered toxicity and raised safety.

Owner:湖南康尔佳药业管理集团有限公司

Nanocomposite material, glassy carbon composite electrode and method for manufacturing both, electrochemical sensor

ActiveCN111793393BHigh sensitivityImprove detection efficiencyMaterial nanotechnologyCoatingsCarbon compositesP-acetaminophenol

The invention discloses a nanocomposite material, which comprises the following components in terms of mass parts: (2-3) parts of MWNTs, (1-1.5) parts of CeO 2 , (184‑188) parts of Nafion solution and 1000 parts of ultrapure water; compared with the prior art, the present invention provides a suitable modification material for the working electrode of the electrochemical sensor for simultaneously detecting acetaminophen and p-aminophenol, Utilizes CeO 2 The high catalytic activity of Nafion and Nafion, as well as the synergistic effect between the two and MWNTs, further enhanced the electron transfer ability, and improved the sensitivity and detection efficiency of acetaminophen and p-aminophenol detection.

Owner:CHONGQING UNIV OF EDUCATION

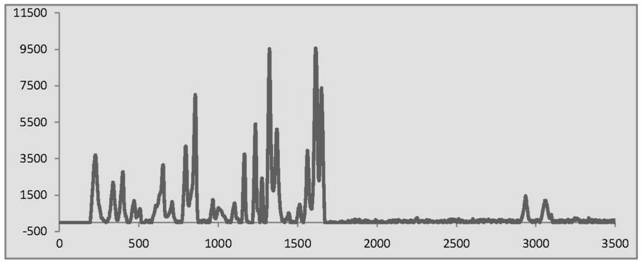

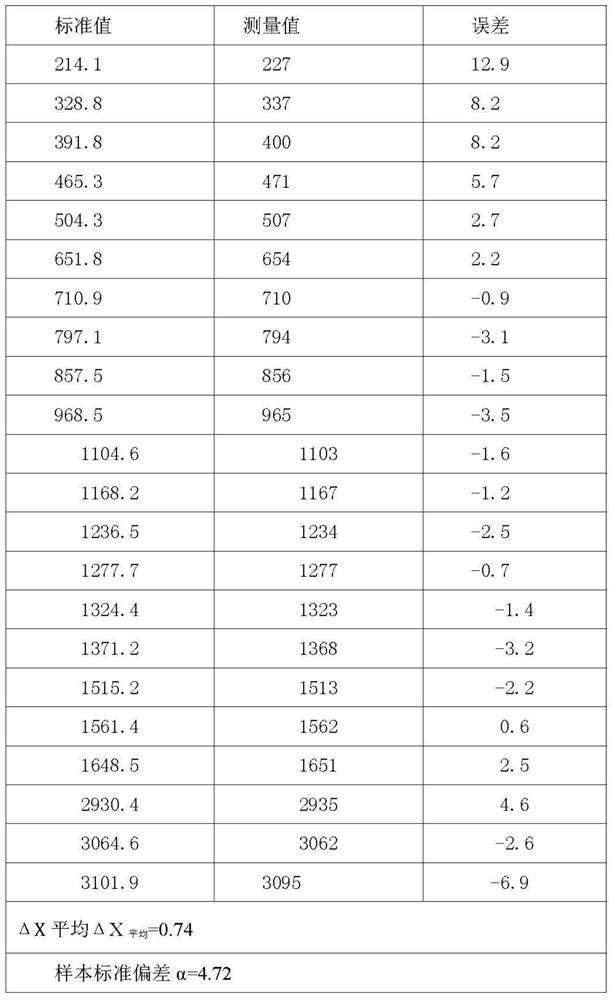

Method for rapid calibration of Raman spectrometer using acetaminophen

ActiveCN110865067BReal-time calibrationValid calibrationRaman scatteringOptical spectrometerP-acetaminophenol

The method of the present invention using acetaminophen to quickly calibrate the Raman spectrometer comprises: using a Raman spectrometer to collect the spectrum of the acetaminophen standard substance, collecting and obtaining n characteristic peak spectral peak positions; obtaining each characteristic peak spectral peak position difference ΔX n =X n -Y n , to calculate the average error ΔX 平均 =(ΔX 1 +ΔX 2 +ΔX 3 +...,ΔX n ) / n; Calculate the difference between each two consecutive measurement characteristic peak spectral peak positions L (n‑1)n =X n -X n‑1 , get the interval between two characteristic peak spectral peak positions; do difference calculation S for every two consecutive standard spectral peak positions (n‑1)n =Y n -Y n‑1 Get the interval between two standard spectral peaks; calculate the average shift coefficient A 平均 , when ΔX 平均 ≠0, modify the Raman spectrum measurement results, Z n修正后 =A 平均 *Z n +ΔX 平均 .

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE +1

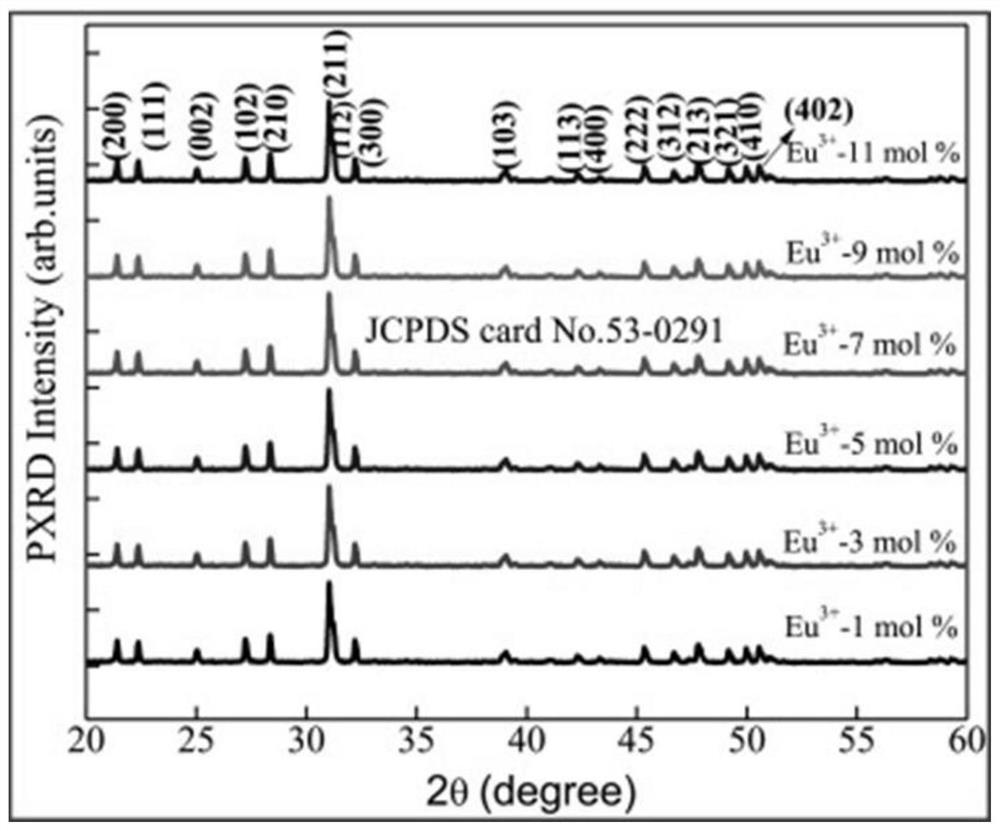

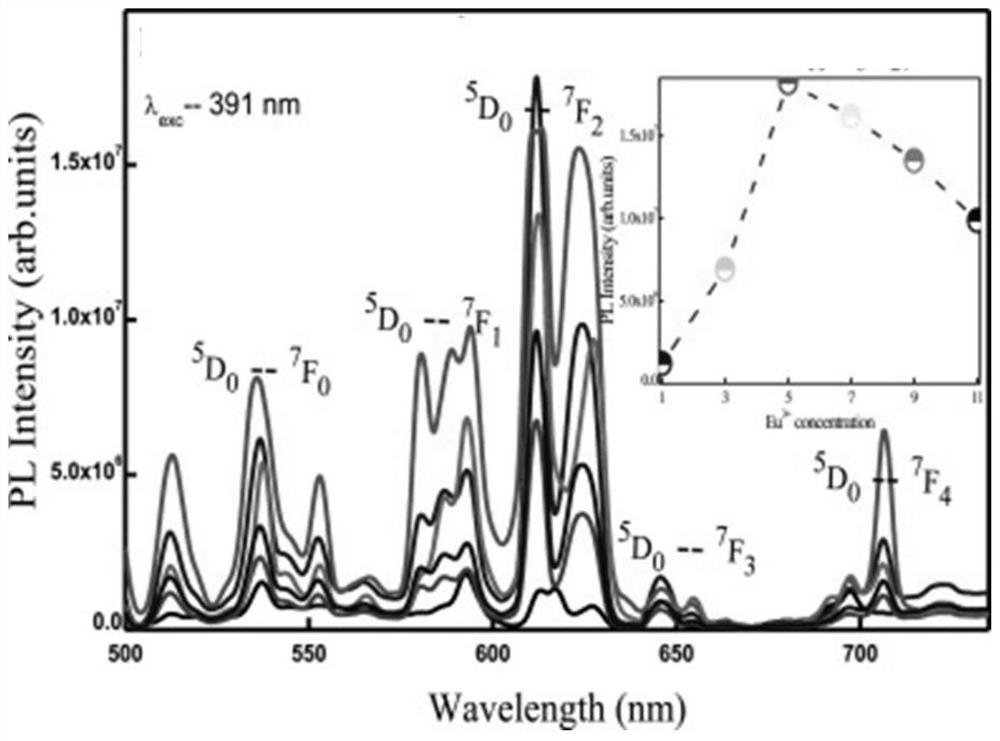

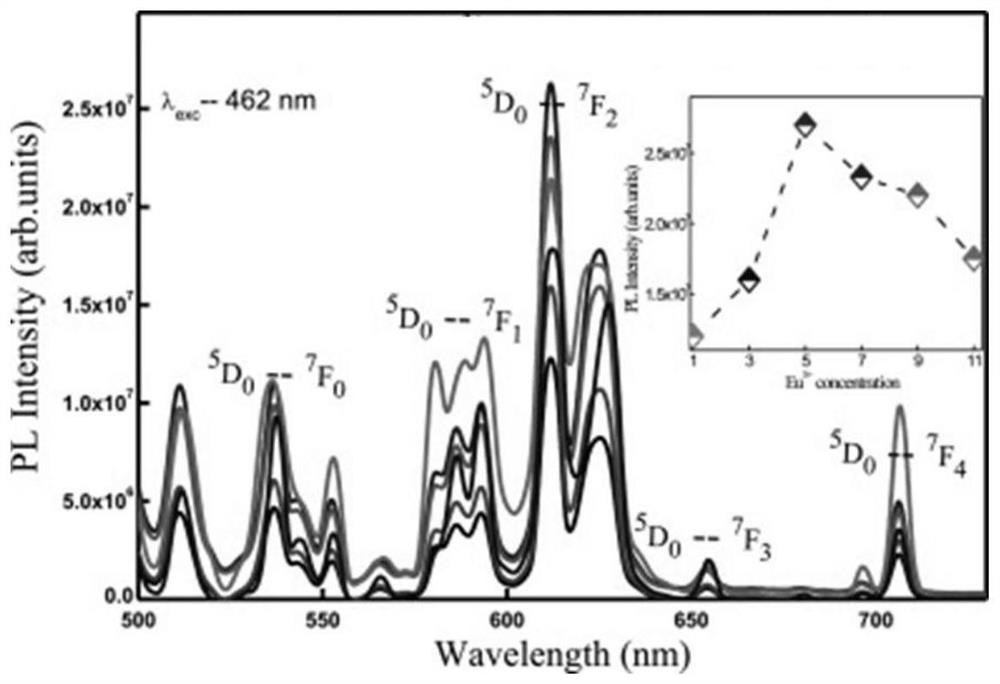

Fluorescent powder applied to electrochemical detection as well as preparation and application methods thereof

PendingCN112538349APreparation fitIncrease productionLuminescent compositionsMaterial electrochemical variablesModified carbonP-acetaminophenol

The invention discloses fluorescent powder applied to electrochemical detection as well as preparation and application methods thereof, belonging to the technical field of preparation and applicationof luminescent materials. The chemical formula of the fluorescent powder is Lu10Si6O27: x% Eu<3+>, wherein x is larger than or equal to 5 and smaller than or equal to 9. According to the invention, pure fluorescent powder is prepared through a solution combustion method, and the prepared fluorescent powder shows red light emission under excitation of light with a wavelength of 391 nm and shows yellow-green light emission under excitation of light with a wavelength of 462 nm. A modified carbon paste electrode prepared from the fluorescent powder can be used for detecting acetaminophen. The preparation method provided by the invention is simple in process, stable in product performance and suitable for industrial production.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com